Abstract

The utilization of reclaimed asphalt pavement (RAP) in asphalt mixtures not only reduces production costs and resource consumption but also provides significant environmental benefits. Consequently, technology and methodologies used for asphalt pavement recycling, aimed at enhancing the utilization rate of RAPs, have emerged as prominent topics in both academic research and engineering practice. Given the complex thermal history and poor low-temperature performance (LTP) of RAP, investigating the effects of varying thermal histories of RAPs on the LTP of a mixture holds substantial practical significance for increasing the utilization rate of RAP in seasonally frozen regions. In this study, scanning electron microscopy (SEM), the thermal stress restrained specimen test (TSRST), the trabecular bending test, and the bending beam creep test (BBCT) are utilized to examine the effects of the indoor simulation methods that produce RAPs with varying thermal histories and contents on a recycled asphalt mixture (RAM) from both microscopic and phenomenological perspectives. Additionally, this research investigates the accuracy of predicting the LTP of RAMs using the Burgers model. The test results indicate that the LTP of an RAM is influenced not only by the RAP content and its thermal history but also by the ambient temperature. Regardless of the thermal history of the RAP, the LTP of an RAM tends to decrease as the RAP content increases. Different thermal histories of RAPs exert varying effects on the low-temperature viscoelastic behavior of an RAM. The UVRAP reduces the viscoelastic temperature range of an RAM by an average of 10.79%, whereas the THRAP increases it by an average of 2.16%. These effects can be attributed to the distinct micromorphology of the asphalt on the surfaces of RAPs with a varying thermal history. Specifically, a greater number of micropores and microcracks on the asphalt surface leads to a poorer LTP of RAMs. Additionally, the residuals of the Burgers model for predicting the LTP of an RAM with THRAP exceeded −2. However, the Burgers model demonstrates predictive capabilities for evaluating the LTP of an RAM filled with RAP from the same source or with a similar thermal history.

1. Introduction

In recent years, the widespread use of reclaimed asphalt pavement (RAP) in road engineering construction has become increasingly popular due to the depletion of non-renewable raw materials and rising petroleum costs [1]. Many countries and regions have adopted RAP to produce a hot-mix recycled asphalt mixture and a warm-mix recycled asphalt mixture, and the blending ratio steadily increases [2]. The Research indicates that incorporating 50% RAP into the mixture can lead to a cost reduction of approximately 24–35% in asphalt mixture production, a figure that may be further increased by the rapid escalation of asphalt prices [3]. Utilizing RAP not only effectively lowers construction expenses and reduces natural resource consumption but also addresses waste material disposal concerns, ultimately yielding significant economic and environmental benefits [4]. However, the RAP content in recycled asphalt mixtures (RAMs) is still low due to various factors, such as the mixing process, rejuvenating agent, manufacturing process grading type, production temperature, mixing time, application environment, expected performance, RAP source, and properties. Consequently, the full benefits of RAP may not be fully realized [5].

Most of Northern China is in a seasonally frozen area, with cold temperatures in winter. Low-temperature cracking has become one of the most common conditions of asphalt pavement. When the thermal stress generated by the thermal shrinkage of the asphalt mixture at low temperatures exceeds its tensile strength, low-temperature cracking will occur. The quality of the mixture mainly depends on the quality of its constituent materials. As one of the main components of RAM, RAP includes asphalt concrete milled from the existing infrastructure and asphalt mixture discarded during the production process. These asphalt mixtures, which are exposed to complex environments for a long time during the production, mixing, rolling, and service processes, will age. As a result, the physical and chemical properties of asphalt mixtures change after aging. The variations in the production processes of asphalt mixtures; the geographical and natural environments of milled pavement locations; and differences in RAP production, storage, transportation cycles, and exposure environments all contribute to variations in RAP’s’ thermal history and subsequent aging differences [6]. Adding RAPs with different thermal histories to an asphalt mixture will have varying impacts on the road performance of the mixture, especially the low-temperature crack resistance [7,8]. Therefore, studying the impact of different thermal history RAPs on the LTP of RAMs is necessary and can provide a reference basis for the use of RAPs from different sources in the northern region.

In order to evaluate the low-temperature performance of RAMs, a lot of research is used. Moon et al. conducted flexural creep tests using a bending beam rheometer and found that the addition of RAP reduced the creep stiffness of RAMs at low temperatures [9]. Hasan Ozer used the fracture energy method to conduct a semicircular cross-section fracture test study on asphalt mixtures with different RAPs and recycled asphalt shingle (RAS) content. The results indicated a consistent drop in the fracture energy as the RAP and RAS increased [10]. Tao Yang examined the low-temperature cracking resistance of different RAMs with varying RAP content through 3PBB and TSRST tests, revealing that as the RAP content increased, the fracture temperature and transition temperature rose while the failure strain and fracture energy decreased, indicating a decrease in low-temperature performance [11]. Babagoli et al. observed that, as the short-term aged RAP and the long-term aged RAP content increased, the fracture energy decreased, and the low-temperature crack resistance weakened under different traffic load levels [12]. Xiang Shu et al. utilized the semicircle bending test (SCB) to assess the impact of RAP on the crack resistance of asphalt mixtures. Their findings indicated that the inclusion of RAP generally decreases the J integral value, leading to a reduction in crack resistance, particularly in a mixture subjected to short-term aging. Interestingly, long-term aging did not significantly influence the J integral of the HMA mixture [13]. Jinrong Wu conducted a semi-circular bending (SCB) test to analyze the effects of the reclaimed asphalt. The experimental results show that the fracture energy of the RAM decreases with the increases in the RAP content and the salt concentration but increases with an increase in the loading rate [14]. Similar to the above research results, some studies have also shown that the LTP of RAMs shows a monotonic decreasing trend with an increase in the RAP content [2,15,16].

Some studies have found different trends between LTP and RAP content. Yuheng Chen et al. used a semi-circular bending test to evaluate the LTP of RAMs through failure load and fracture energy. They observed that, with an increase in the RAP content, both the maximum load and fracture energy initially rise before declining, with the optimal LTP achieved at 30% RAP content [17]. Falchetto conducted a bending beam rheometer (BBR) test on RAMs, comparing three calculation methods and noting that at a 15% RAP content, the performance is comparable to that of the original asphalt mixture. However, the performance deteriorates significantly when the RAP content exceeds 25% [18]. Xiang Ma et al. used the critical value of bending strain energy density as the primary evaluation index of LTP. Compared with the new material, only the LTP of the mixture with 20% RAP doping is improved, whereas continuing to increase the RAP doping will instead worsen its anti-cracking performance [19]. Collectively, these studies suggest that the LTP of RAMs peaks at a specific RAP dosage.

Subsequently, researchers incorporated RAPs and other materials concurrently into the asphalt mixture to investigate the LTP of mixtures. The interaction of multiple mineral materials led to varying trends in the LTP of mixtures. Tapsoba N. et al. examined the LTP of RAMs containing RAPs and manufacturing waste roofing asphalt shingles (RAS). They observed that the RAP content below 15% did not significantly affect LTP. However, as the RAP content increased, the LTP deteriorated significantly [20]. Ziari utilized the semi-circular bending (SCB) test to investigate the cracking behavior of asphalt mixtures containing varying percentages of RAP and glass fibers. The results indicated that the incorporation of up to 0.12% glass fiber significantly enhanced the resistance of all mixtures to crack initiation and propagation [21]. Ki Hoon Moon used the indirect tensile (IDT) test and the semi-circular bending (SCB) test to assess the influence of RAPs and taconite minerals on the low-temperature properties of an asphalt mixture. The findings indicated that the addition of RAP resulted in poor low-temperature properties, but when the RAP content was below 20%, the incorporation of taconite minerals could improve LTP. Nevertheless, with a further increase in RAP content, even with higher taconite ore content, the LTP could not be restored [9]. The above research indicates that when the RAP content is low, the LTP of RAPs remains similar to that of the original mixture in the presence of multiple other materials, and a continuous increase in the RAP content leads to a significant deterioration in LTP.

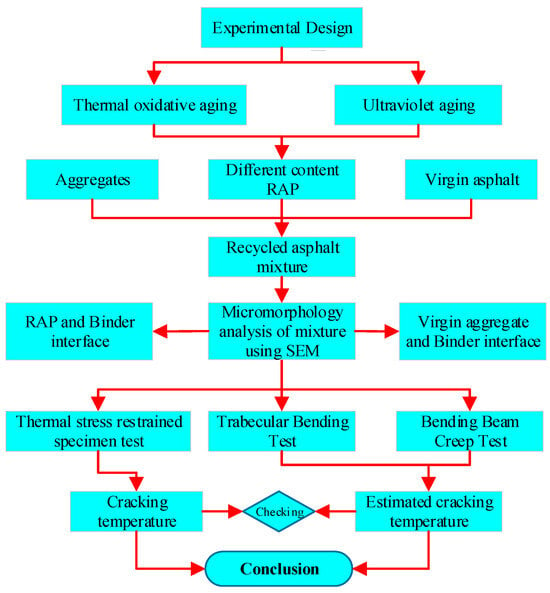

Previous research has investigated the impact of RAPs on their LTP. However, these studies have primarily focused on the effects of thermal-oxidative-aged RAP on the low-temperature properties of the RAMs. The researchers did not categorize RAP according to its different thermal histories, resulting in inconsistencies in the reported maximum dosage of RAP and the observed impacts on the LTP of RAMs. This inconsistency hinders the effective disposal of the RAP and the enhancement of its blending rate. According to whether chemical reactions occur during the aging process, asphalt mixture aging can be divided into the two types of: thermally reversible aging and irreversible chemical aging [22]. Numerous studies have shown that solvent recovery or heating during the regeneration process will destroy the reversible structural molecules in asphalt, so the impact of reversible aging on the low-temperature properties of the asphalt mixture can be ignored [23]. However, irreversible aging cannot be eliminated and can be divided into thermal- oxidative aging, ultraviolet aging, exudation, and biodegradation. Among these, high-temperature oxidation and ultraviolet light are the primary reasons for the aging of pavement materials. The varying degrees of RAP undergoing the aforementioned aging processes will result in varying thermal histories, potentially affecting the LTP of RAMs. Consequently, in this project, the indoor production of thermal- oxygen aging reclaimed asphalt pavement (THRAP) and ultraviolet aging reclaimed asphalt pavement (UVRAP) is employed to simulate the different thermal histories of the RAPs. In this study, the thermal stress restrained specimen test (TSRST), the trabecular bending test, and the bending beam creep test (BBCT) are utilized to evaluate RAM of the same grade with varying contents of RAPs with different thermal histories. Scanning electron microscopy (SEM) was employed to investigate the micromorphology of the interface between RAP and asphalt, as well as new aggregates and asphalt in the RAM. The analysis focused on the impact of the RAP content and thermal histories on the LTP of RAMs from both phenomenological and microscopic perspectives. The findings of this research contribute to the understanding of the feasibility of using RAM with RAPs from different sources in the northern region, ultimately leading to a reduction in the demand for new materials, a decrease in environmental pollution, and positive social, environmental, and economic outcomes. The steps of the research process are illustrated in Figure 1.

Figure 1.

Flow chart of the analytical approach followed in this study.

2. Materials and Methods

2.1. Asphalt and Aggregates

The selected asphalt was 90 # matrix asphalt. The technical performance indicators are listed in Table 1. The aggregate used in this study was basalt, produced in Inner Mongolia, China. The performance characteristics of the aggregate and mineral powders are summarized in Table 2 and Table 3.

Table 1.

Properties of AC 90 binder used in this study.

Table 2.

Properties of aggregates used in this study.

Table 3.

Properties of mineral powder used in this study.

2.2. Rejuvenator

The rejuvenator used in this study was XT-1, which was obtained from Changzhou Xintuo Pavement Modification Materials Co., Ltd., Changzhou, China. The performance of the rejuvenator is summarized in Table 4.

Table 4.

Properties of rejuvenator used in this study.

2.3. Synthetic Aggregate Gradation

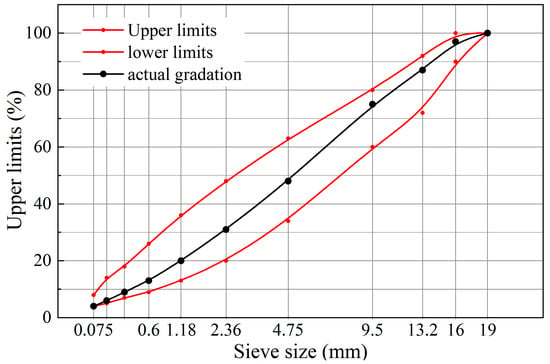

In this study, dense-graded hot-mix asphalt concrete with a nominal maximum particle size of 16 mm (referred to as AC-16) was used as the research object. The gradation and upper and lower limits of AC-16 are presented in Table 5 and Figure 2, respectively. Marshall mix design was utilized to find the optimum binder content as 5.0% by weight of the total mixture.

Table 5.

Gradation and the upper and lower limits of the range of AC-16.

Figure 2.

Gradation of the designed mixture.

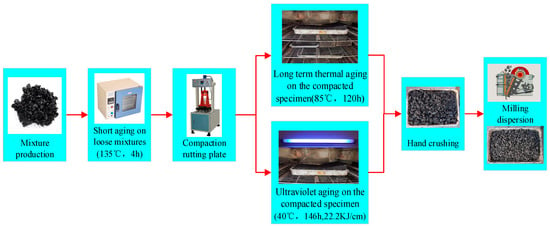

2.4. RAP Preparation

To simulate the aging of the asphalt mixture from the construction process to the service stage, the AC-16 asphalt mixture with the objective gradation of the aggregate and 5.0% binder content was first mixed and then subjected to the short-term aging process at 135 °C for 4 h. The loose mixture was then compacted into rutting panel specimens. The specimens were allowed to cool for at least 16 h and were then de-molded. Two aging methods were used to produce RAP in this study, as follows:

- THOA: Based on the short-term aging process, the rutting plates were subjected to the SHRP long-term aging process at 85 °C for 120 h.

- UVOA: Based on the short-term aging process, the other parts of the rutting plates were subjected to the ultraviolet aging process at 40 °C. The average irradiation intensity on the surface of the actual test sample was 570 w/m2 for 146 h.

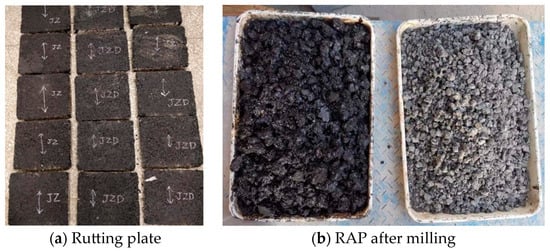

Two types of aged rut plates are illustrated in Figure 3a. Subsequently, the rut plates were heated to 85 °C, manually crushed, and placed into the jaw crusher to simulate milling and crushing before being dispersed for use, as illustrated in Figure 3b. The detailed experimental plan can be seen in Figure 4.

Figure 3.

Rutting plate and RAP after milling.

Figure 4.

Laboratory production of RAP.

2.5. Asphalt Content and Rejuvenator Dosage

The determination of the asphalt content of RAP was conducted using both the extraction method and the combustion furnace method. The combustion furnace method was preferred over the extraction method to eliminate the interference of trichloroethylene and mineral powder on the measurement results. The asphalt content of two RAP samples was determined by measuring the asphalt mass loss coefficient before the experiment, followed by calculation and correction using Formula (1). Additionally, asphalt in the RAP was extracted and recovered through centrifugation. The XT-1 rejuvenator with asphalt mass fractions of 4%, 8%, 12%, and 16% was added to the two aged asphalts. The designations TH, UV, TH 4%, TH 8%, TH 12%, TH 16%, UV 4%, UV 8%, UV 12%, and UV 16% were used to represent the thermal oxygen aging asphalt, the ultraviolet aging asphalt, and the aging asphalt with the corresponding proportions of rejuvenator. The changes in the three major indicators were analyzed to determine the optimal amount of rejuvenator.

where Cfi is the mass loss coefficient (%); mB1 is the mass of each aggregate mixture (g); mB2 is the mass of asphalt (g); mB5 is the total mass of the initial sample (g); mB6 is the mass loss of sample combustion (g); P is the asphalt content (%); m3 is the total mass of the initial sample; and the m4 sample loses mass (g).

2.6. Mix Design and Specimen Preparation

In this study, seven types of asphalt mixtures were explored, which include RAM with 20%, 40%, and 60% THRAP and UVRAP, in addition to a conventional hot-mix asphalt mixture serving as the control group, denoted as TH 0.2, TH 0.4, TH 0.6, UV 0.2, UV 0.4, UV 0.6, and OR. The gradation of the mixture design is presented in Table 5, with an asphalt dosage of 5% and the gradation curve is illustrated in Figure 2. The quality of the new asphalt is determined by subtracting the mass of asphalt contained in the RAP from the total amount of asphalt in each RAM. This specific calculation is illustrated in Formula (3). Subsequently, the mixture is compacted into a rut specimen measuring 300 mm × 300 mm × 50 mm, which is then cut into dimensions of 250 ± 2.0 mm in length, 30 ± 2.0 mm in width, and 35 ± 2.0 mm in height for further use.

where ma is the mass of new asphalt required for the mixture; M is the total mass of the mixtures; Pa is the asphalt content set for the mixture; PRAP is the amount of RAP in the mixtures; Pold is the old asphalt content in RAP; and Pr is the amount of rejuvenator.

ma = M × [Pa − PRAP × Pold × (1 + Pr)]

2.7. Micromorphology Analysis of Mixture Using SEM

The principle of the scanning electron microscope (SEM) is based on the interaction between electrons and matter, enabling non-destructive microscopic observation of sample surfaces. SEM was employed to investigate the microstructure of indoor RAMs, with a focus on the micromorphological characteristics of asphalt mixtures subjected to varying thermal histories [24]. In the experiment, thin slices of the asphalt mixture specimens were cut to a thickness of 1.5 to 2.0 mm, followed by the selection of a suitable observation area. Each thin slice was then further cut into a 5 mm cube, ensuring that the observation area remained intact. After the cutting process, the sample’s surface was cleaned and coated with gold/palladium powder to enhance conductivity. Subsequently, the sample was examined to compare the micromorphology of the interface between new aggregate and asphalt in the mixture, as well as between RAP with different thermal histories.

2.8. Low-Temperature Performance Test

Commonly used LTP tests for asphalt mixtures include the direct tensile tests, the thermal stress restrained specimen test, the trabecular bending test, the bending beam creep test, and the shrinkage coefficient test. In this study, the thermal stress restrained specimen test, the trabecular bending test, and the bending beam creep test were conducted to assess the impact of thermal history and RAP content on the LTP of asphalt mixtures. Additionally, in this study, the aim was to evaluate the feasibility of utilizing the Burgers model, grounded in rheological theory, to determine the cracking temperature of RAMs and predict its LTP.

2.8.1. Thermal Stress Restrained Specimen Test (TSRST)

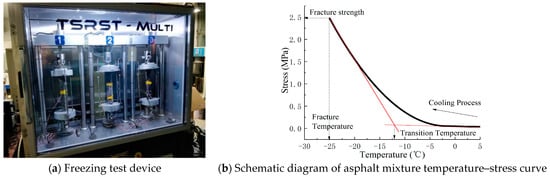

Based on experiments, the American SHRP program suggests that the TSRST is effective in assessing the LTP of asphalt mixtures due to its on-site simulation capabilities, data applicability, and ease of operation [25]. The TSRST provides the following four evaluation indices: fracture temperature, fracture strength, transition temperature, and slope of the temperature–stress curve. Figure 5 shows the experimental equipment and schematic diagram of the asphalt mixture temperature–stress curve. In this project, seven types of asphalt mixtures were evaluated following AASHTO TP-10-93 standards. The initial test temperature was set at 5 °C with a cooling rate of 10 °C/h.

Figure 5.

Freezing test device and schematic diagram of asphalt mixture temperature–stress curve.

2.8.2. Trabecular Bending Test

The trabecular bending test is straightforward to conduct and provides clear stress results. This method was utilized to assess the LTP of seven types of asphalt mixtures. The testing procedure followed the T0715-2011 method outlined in the JTG E 20-2011 specification. To replicate harsh winter conditions in seasonally frozen regions, tests were conducted at −20 °C, −10 °C, and 0 °C. The midpoint loading method was employed with a loading rate of 50 mm/min. Each asphalt mixture was tested with a minimum of 3 parallel specimens, and the maximum bending and tensile strain εB upon specimen failure were calculated using Equation (4). Additionally, the stress–strain curve was used to determine the strain energy density of the RAM, as follows:

where εB is the maximum bending and tensile strain when the specimen fails (µε); L is the span of the specimen (mm); h is the height of the specimen (mm); and d is the mid-span deflection of the specimen when it fails (mm).

2.8.3. Bending Beam Creep Test (BBCT)

The bending beam creep test was conducted based on the trabecular bending test following the T 0728-2000 method specified in JTG E 20-2011. The test temperatures were −20 °C, −10 °C, and 0 °C. At least 5 specimens were tested at each temperature, and the average value was calculated. Before the experiment, specimens were conditioned at the test temperature for over 12 h. The loading stress was set at 10% of the failure load, with a loading time of 5400 s. The bending creep for each asphalt mixture was determined using the calculation formulas presented in Equations (5)–(7).

3. Results and Discussion

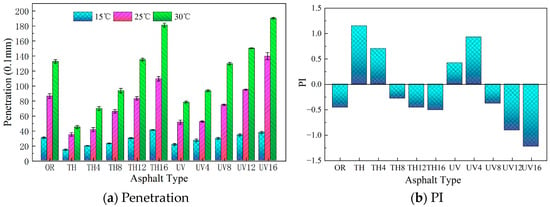

3.1. Asphalt Content and Rejuvenator Content

The calculated asphalt content results are presented in Table 6 and the recovery performance of aging asphalt is summarized in Table 7 and Figure 6. The analysis of Table 7 and Figure 6 reveals that the THRAP obtained through indoor simulation exhibits more severe aging compared to the UVRAP. This difference is attributed to the penetration depth of the asphalt film on the RAP surface due to UV aging, leading to the formation of a UV aging gradient in the RAP. The inner layer of RAP shows relatively lighter aging [26]. The addition of a rejuvenator gradually improves the properties of both aged asphalts. The PI value indicates that the rejuvenator addition reduces the temperature-sensing performance of aged asphalt. Following aging, there is an increase in the content of gum and asphaltene in the asphalt. The rejuvenator, which is rich in saturated and aromatic phenols, increases the proportion of light components in the asphalt, thereby partially restoring its performance. Analysis of the three major indicators and changes in the PI value suggests that 12% rejuvenator content by asphalt mass is needed to restore the original performance of THRAP, while UVRAP requires 8% rejuvenator content.

Table 6.

Asphalt content of RAP.

Table 7.

Recovery performance of aging asphalt.

Figure 6.

Laboratory production of RAP.

3.2. Scanning Electron Microscope (SEM)

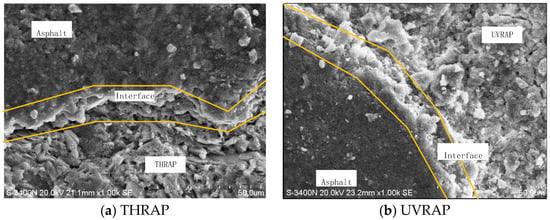

3.2.1. RAP and Binder Interface

In Figure 7, the dark area represents asphalt, while the bright area represents indoor-simulated RAP aggregate. It can be observed that the surface morphology of RAP-coated asphalt varies in asphalt mixtures with different thermal histories. Compared to UVRAP-coated asphalt, THRAP-coated asphalt exhibits a rougher surface with a more pronounced flocculent structure and an increased presence of angular fragments resulting from higher stiffness due to aging [27]. Microscopic analysis reveals that the THRAP surface asphalt in the mixture shows more advanced aging compared to the UVRAP surface asphalt. Additionally, no distinct ‘sandwich’ structure is observed in the RAP surface asphalt, indicating a lack of strict boundaries between the old and new asphalt. Studies suggest that this phenomenon is linked to the inclusion of a rejuvenator in the mixture [28]. However, some demarcation between asphalt and RAP is still noticeable, albeit with a relatively smooth transition at the asphalt–aggregate interface. It can be seen that the combination of asphalt and RAP is relatively effective under the action of the rejuvenator, which helps enhance the crack resistance of the asphalt mixture.

Figure 7.

SEM images of RAP and binder interface (×1000).

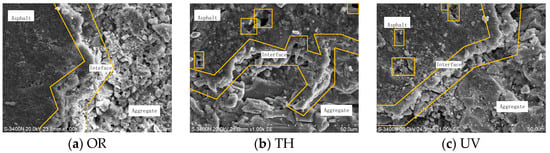

3.2.2. Virgin Aggregate and Binder Interface

The surface morphology of the interface between the new aggregate and asphalt in an asphalt mixture with different thermal histories is illustrated in Figure 8. The dark area represents asphalt, while the bright area represents new aggregate. The yellow lines in the figure roughly define the range of asphalt, aggregates and contact interfaces, and the yellow boxes mark the micropores on the microstructure of aged asphalt. A comparative analysis of the asphalt on the surface of the new aggregate reveals that the original asphalt in the mixture has not undergone the aging process, resulting in a relatively smooth surface. As the asphalt penetrates the aggregate, some boundaries become less distinct, indicating a close bond between the asphalt and aggregate [29]. Further comparative observations reveal that the surface of the asphalt in the THRAP mixture is relatively rougher and exhibits a more pronounced floc structure. Additionally, due to insufficient miscibility and aging, both asphalts contain a certain number of micropores and microcracks. And the THRAP mixture has a higher number of micropores and microcracks compared to the UVRAP mixture. Surface micromorphology observation at the interface between the new aggregate and asphalt indicates that the original asphalt mixture exhibits superior structural stability, whereas the thermally oxygen-aged asphalt presents the roughest surface, characterized by an increased number of micropores and microcracks. The UV-aged asphalt falls between these two extremes. The presence of micropores and microcracks on the surface of these asphalt may facilitate the cracking of the asphalt interface at low temperatures, consequently reducing the LTP of RAMs.

Figure 8.

SEM images of virgin aggregate and binder interface (×1000).

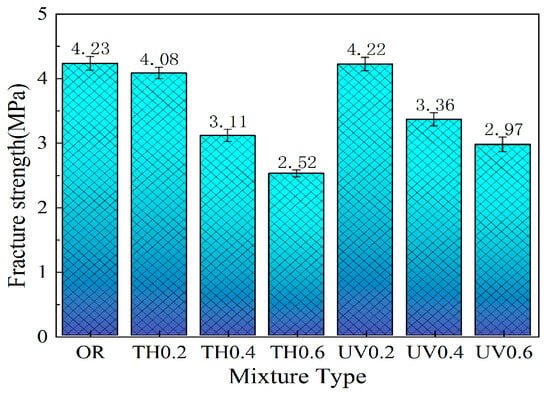

3.3. Fracture Strength, Fracture Temperature, and Transition Temperature

The fracture strength and fracture temperature results of the mixture obtained through the TSRST are illustrated in Figure 9 and Figure 10. In this study, it is revealed that as the RAP content increases, both the fracture strength and fracture temperature of RAMs gradually decrease. The observed order was OR > UV 0.6 > TH 0.6 > UV 0.4 > TH 0.4 > UV 0.2 > TH 0.2, indicating that the addition of RAP diminishes the low-temperature crack resistance of RAMs, consistent with previous research findings [30,31]. This decrease is attributed to the harder and more brittle nature of the aged asphalt present in RAP, in contrast to the original asphalt. Furthermore, a higher RAP content leads to poorer asphalt miscibility within the mixtures, resulting in an increased number of microcracks and micropores. These defects render the RAM more susceptible to fracture at lower temperatures due to thermal stress during the cooling process.

Figure 9.

Fracture strength of asphalt mixture.

Figure 10.

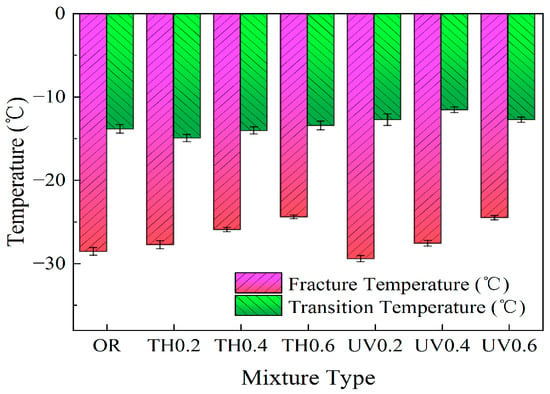

Fracture temperature and transition temperature of asphalt mixture.

The transition temperature is a crucial indicator of the rheological properties of an asphalt mixture at low temperatures. It separates the temperature–stress curve into two distinct segments; the first segment reflects the stress relaxation performance of the mixture, while the latter segment’s stress relaxation properties disappear. As the temperature decreases, the asphalt mixture shifts from viscoelastic behavior to elastic behavior. The transition temperature signifies the point at which the viscoelastic behavior of the mixture changes [32]. The transition temperature is determined graphically, using a specific method that involves marking the tangent lines of the viscoelastic and elastic stage curves on the temperature–stress curve of the asphalt mixture. The temperature corresponding to the intersection of these two tangent lines is the transition temperature. Analysis of Figure 10 reveals that the transition temperature of the RAM with UVRAP is higher than that of the original asphalt mixture. Conversely, the transition temperature of the RAM with THRAP is lower than that of the original asphalt mixture. The viscoelastic temperature range of the RAM with UVRAP is narrowed by 10.79%, while the elastic temperature range is extended by 1.30%. On the contrary, the elastic temperature range of the RAM with THRAP is extended by 2.16%, while the elastic temperature range is narrowed by 18.75%. This suggests that UVRAP accelerates the shift from viscoelasticity to elasticity within a narrow temperature range and extends the temperature range for elastic stage failure of RAMs. In contrast, THRAP accelerates the destruction of the asphalt mixture during the elastic stage. RAPs with varying thermal histories have different effects on the stress relaxation capacity of RAMs.

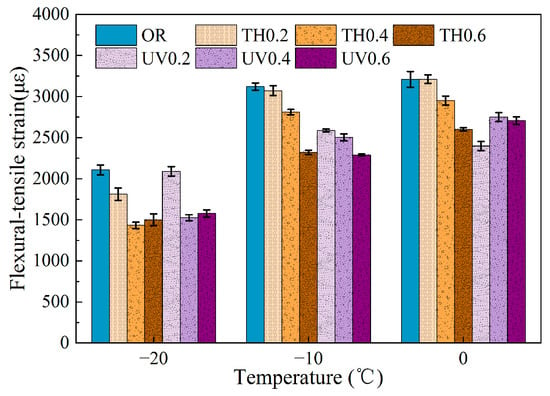

3.4. Flexural–Tensile Strain and Strain Energy Density

Studies have indicated a direct correlation between asphalt pavement cracks and the flexural–tensile strain of an asphalt mixture [13,33]. Exceeding the threshold of this strain can lead to low-temperature cracking. Therefore, the flexural–tensile strain serves as an evaluation metric. As shown in Figure 11, the trabecular bending test demonstrates that the flexural–tensile strain of RAMs gradually decreases as the temperature drops. The strain reduction between −10 °C and −20 °C is notably greater than that between 0 °C and −10 °C. This trend is attributed to reduced Brownian motion in asphalt molecules and a decrease in free volume between them as the temperature declines. Consequently, the viscous flow of asphalt mortar increases, causing a decline in flexural–tensile strains [34]. When considering the impact of RAP content on the LTP of RAMs, it is observed that an increase in RAP content at −10 °C leads to a progressive decrease in the flexural–tensile strain of RAMs. This decrease is due to the diminished capacity of RAMs to absorb energy before failure when RAP is incorporated [35]. Although this reduction weakens the LTP of RAMs, the trend is less pronounced at 0 °C and −20 °C. Furthermore, when comparing the influence of different thermal histories of the RAP content on the LTP of mixtures, it is noted that at 0 °C and −10 °C, when the RAP content is 40%, the flexural–tensile strain of RAMs with THRAP exceeds that of those with UVRAP, indicating superior low-temperature deformation ability at these temperatures. However, as the RAP content increases or the temperature drops to −20 °C, the LTP of RAMs with UVRAP is relatively better than that of those with THRAP.

Figure 11.

The flexural–tensile strain of asphalt mixture.

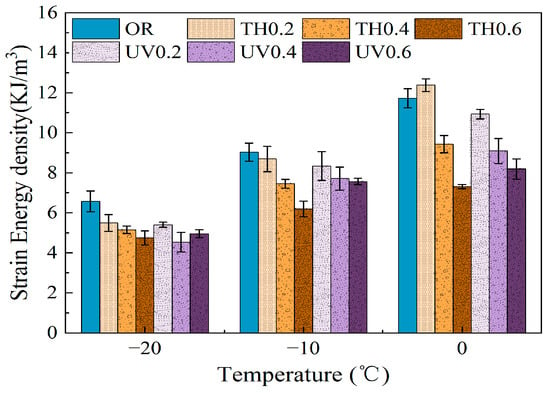

Strain energy density is a measure of the amount of strain energy consumed per unit volume at the center bottom of a trabecular specimen during fracture. It accounts for both strength and strain, providing a more accurate assessment of the LTP of RAMs compared to relying solely on failure strength or failure strain [26]. Research has shown that strain energy density closely reflects the actual behavior of asphalt mixtures under low-temperature tensile failure [36]. When an asphalt mixture is damaged, the higher the bending strain energy density is, the better is the LTP of an asphalt mixture. The strain energy density function can be represented by Equation (8), as follows:

where ωf is the strain energy density function, that is, the envelope area under the σ-ε curve when the stress reaches its peak; σ(ε) is the function of stress concerning strain; and εc is the strain corresponding to the maximum stress.

By using a cubic polynomial to fit the rising section of the stress–strain curve before the peak, Formula (9) can be utilized to calculate the strain energy density of seven types of asphalt mixtures.

The strain energy density results in Figure 12 show that with an increase in RAP content, the asphalt mixture becomes less flexible and deformable. The destruction occurs at a lower energy. A comparison of the effects of different thermal histories of RAPs on the LTP of asphalt mixtures reveals that the RAM with 20% THRAP exhibits better low-temperature crack resistance than that with 20% UVRAP. However, as the RAP content further increases, the LTP shows the opposite trend. Analyzing the strain energy density at various temperatures indicates that with a 20% increase in UVRAP or THRAP content at 0 °C, the strain energy density decreases by an average of 15.6% and 30.1%, respectively. Moreover, at −20 °C, the strain energy density decreases by an average of 4.5% and 7.6%. This indicates that the impact of increasing RAP content on the LTP of asphalt mixtures is more pronounced at medium and low temperatures (0 °C) compared to lower temperatures (−20 °C).

Figure 12.

The strain energy density of asphalt mixture.

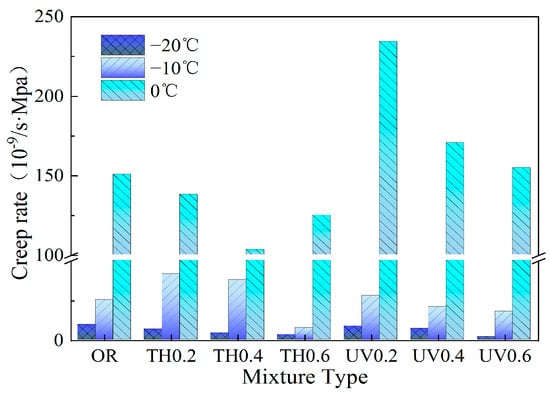

3.5. Creep Rate

Asphalt mixtures exhibit typical viscoelastic behavior within their operational temperature range, with mechanical properties being closely related to loading time and ambient temperature. The results from the BBCT are illustrated in Figure 13, indicating that lower temperatures result in a decreased creep rate and stress relaxation of the asphalt mixture, thereby compromising its resistance to deformation. Analyzing the influence of RAP content on the LTP of RAMs, it was observed that an increase in RAP content leads to a gradual reduction in the creep rate of RAMs. This suggests that the addition of RAP diminishes the LTP of RAMs, aligning with findings from TSRST and the trabecular bending test. Furthermore, analysis of the influence of different thermal histories of RAP on the LTP of RAMs shows that the stress relaxation capacity of a mixture displays varying trends at different temperatures. When the ambient temperature exceeds the transition temperature, the UVRAP results in a more rapid decay in the stress relaxation capacity of RAMs as the temperature decreases. Conversely, when the ambient temperature falls below the transition temperature, the decay of the stress relaxation capacity of RAMs slows down. However, this trend is reversed for RAMs with THRAP. By the time the temperature drops to −20 °C, the RAMs become more susceptible to cracking than the original asphalt mixture in a low-temperature environment. This observation aligns with the fracture strength results obtained from the TSRST. RAPs with varying thermal histories alter the low-temperature viscoelastic behavior of RAMs. Furthermore, the LTP of an RAM is correlated with the ambient temperature.

Figure 13.

Creep rate of asphalt mixture.

3.6. Comprehensive Analysis of Low-Temperature Performance

Through three kinds of LTP tests, various indicators such as fracture strength, fracture temperature, transition temperature, and flexural–tensile strain at three different temperatures, along with strain energy density and creep rate, were obtained. A comprehensive analysis of these low-temperature indicators reveals that at temperatures of 0 °C, −10 °C, and −20 °C, asphalt mixtures with different thermal histories of RAP exhibit distinct low-temperature behaviors. Specifically, the varying thermal histories of RAPs alter the viscoelastic properties of the asphalt mixture. At an ambient temperature of −20 °C, which is below the mixture transition temperature, the asphalt mixture enters the elastic deformation stage. Within this temperature range, the LTP of the original asphalt mixture surpasses that of the mixtures with UVRAP or THRAP, aligning with the results obtained from the TSRST. Conversely, at temperatures of −10 °C or 0 °C, where the ambient temperature exceeds the mixture transition temperature, the asphalt mixture is in the viscoelastic deformation stage. In this range, when RAP content is less than 60%, the original asphalt mixture demonstrates superior LTP compared to those with THRAP, and better performance than those with UVRAP. This indicates that the LTP of RAMs is influenced not only by the thermal history of RAPs but also significantly by the ambient temperature.

3.7. Prediction of Low-Temperature Cracking Temperature

In this study, it is demonstrated that the Burgers model is capable of accurately characterizing the rheological properties of asphalt mixtures at low temperatures, within a specific temperature range [37,38]. Comprising two spring units and two damper units, the Burgers model is a four-parameter rheological model. The experimental analysis is conducted using the bending beam creep tests on RAMs at temperatures of −20 °C, −10 °C, and 0 °C. The software 1stOpt curve fitting is utilized to determine the parameters required for the Burgers model creep Equation (10).

where E1 is the instantaneous elastic modulus; η1 is the steady flow viscosity coefficient; E2 is the delayed elastic modulus; and η2 is the delayed flow viscosity coefficient.

In conjunction with the temperature shrinkage strain test findings, consider that the temperature shrinkage strain rate in seasonally frozen regions is 4 × 10−4/s. Assuming a local cooling rate of 10 °C/h and a starting temperature of 10 °C during winter, then, 0, . We can substitute these values into the constitutive equation (Formula (10)) to calculate the temperature stress of the asphalt mixture during the cooling process, as shown in Expression (11).

where .

The viscoelastic parameters in the formula above are derived from bending creep experiments conducted at specific temperatures. For viscoelastic materials, the time–temperature equivalence principle can be applied to address variations in material parameters during continuous cooling [39]. The Arrhenius displacement factor is utilized in the calculation process, as shown in Formula (12).

where α(T) is the shift factor; ΔEa is the surface activation energy; R is the universal gas constant, taken as 8.314 J/K/mol; and T0 is the reference temperature, taken as 273 K.

Then, the temperature stress calculation formula of the asphalt mixture during the cooling process can be expressed as follows:

Putting Formula (13) into the asphalt mixture temperature strain energy formula, the specific expression of the temperature strain energy can be obtained as follows:

To simplify the calculation, Formula (14) is discretized with a time step of 2 s. The integral is then discretized to derive the temperature strain energy calculation presented in Formula (15), as follows:

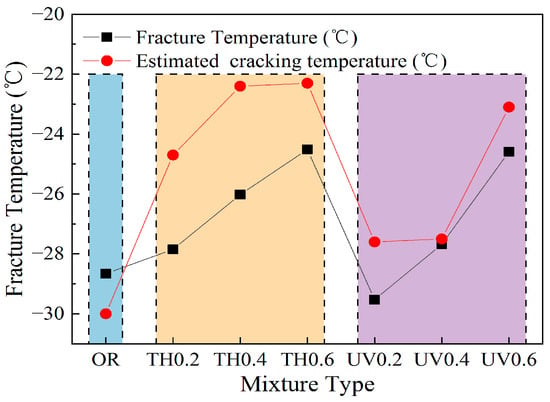

The temperature strain energy of an asphalt mixture refers to the internal energy generated due to the accumulation of temperature shrinkage stress within a unit volume of the mixture as the temperature decreases. This energy gradually increases as the temperature declines. In contrast, the bending strain energy density of the mixtures, derived from the trabecular bending test, decreases progressively as the temperature declines. The opposing trends observed in these two strain energy densities indicate the existence of a critical temperature. When the ambient temperature drops below this critical threshold, resulting in the temperature strain energy density surpassing the bending strain energy density, low-temperature cracking occurs in the asphalt mixture. This critical temperature serves as an estimate of the cracking temperature of the mixtures. However, the accuracy of the bending strain energy test results at −30 °C is limited due to equipment constraints and other factors. The test was conducted at only −20 °C, −10 °C, and 0 °C, with data at −30 °C obtained through calculations. By applying the time–temperature equivalence principle, viscoelastic parameters at −30 °C are calculated to ascertain the temperature strain energy density value at that temperature. The comparison between the estimated temperature at the final intersection and the fracture temperature from the TSRST is depicted in Figure 14.

Figure 14.

Comparison of fracture temperature and estimated cracking temperature.

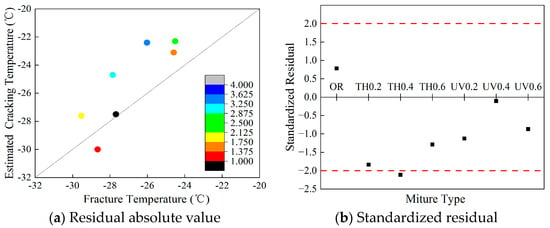

Upon analysis of the data, it is evident that there is a variation between the estimated temperature and the actual fracture temperature obtained from TSRST experiments. The temperature deviations for the original mixture, the RAM with UVRAP, and the RAM with THRAP were found to be −4.68%, 4.40%, and 11.46%, respectively. Notably, the deviation in prediction for the first two mixtures is relatively small, while the accuracy of the prediction for the RAM with THRAP is lower. To evaluate the accuracy of predicting the LTP of RAMs using the Burgers model, in this paper, residual analysis is employed to assess the prediction model. The residual, defined as the difference between the experimental value and the model’s estimated value, is calculated using the formula presented in Equation (16). The standardized residual is determined by dividing each residual by its standard deviation, as calculated using Equation (17).

Figure 15 presents the residual absolute value color gradient and standard residual values for seven pairs of data. The figure indicates that the standard residual values for the original asphalt mixture and an RAM with UVRAP added are relatively small, with differences ranging from −2 to +2, suggesting that the model predictions are fairly accurate. In contrast, the standard residuals for the RAM with THRAP are generally excessive. Notably, when the addition amount reaches 40%, the standard residuals exceed acceptable limits, indicating the presence of outlier data. This analysis reveals that the Burgers model is more suitable for predicting the performance of the original asphalt mixtures and an RAM with UVRAP, while it exhibits reduced accuracy in forecasting the LTP of an RAM with THRAP. This discrepancy can be attributed to two main factors. Firstly, the calculation of the bending strain energy density at −30 °C relies on a three-point temperature fitting curve, leading to a relatively constant value due to the elastic properties of asphalt mixtures at low temperatures. Secondly, the assumption of a local cooling rate of 10 °C/h when calculating the temperature strain energy density does not align with the actual cooling rate experienced by those mixtures at low temperatures. Studies [23] have shown that the greater the cooling rate, the greater the temperature strain energy density. Resulting in a lower actual temperature strain energy density than the calculated value. These factors contribute to a more conservative estimate of the cracking temperature, particularly manifest in the case of the RAM with THRAP. Notably, for RAM with the same thermal history RAP, the predicted temperature and fracture temperature exhibit a similar trend, indicating a gradual decrease in LTP as the RAP content increases. It can be seen that the above model is not suitable for the comparative evaluation of the LTP of an RAM with RAPs from different sources, but it demonstrates predictive capabilities for evaluating the LTP of an RAM with RAPs from the same source or with a similar thermal history.

Figure 15.

Residual absolute value and standardized residual.

4. Conclusions and Recommendations

In this project, thermal oxidative aged RAP (THRAP) and ultraviolet aged RAP (UVRAP) were prepared in a laboratory to simulate RAPs with varying thermal histories. The asphalt content in the RAPs was determined using the combustion furnace method, and aged asphalt was extracted through an extraction experiment. By analyzing three major indicators and the changes in the PI value, the content of the rejuvenator was determined. Subsequently, one original asphalt mixture and six types of RAMs with varying contents and thermal histories of RAP were prepared. The objective was to evaluate the suitability of RAPs from various sources under cold winter conditions in seasonally frozen regions.

- (1)

- The RAP-wrapped asphalt lacks a distinct ‘sandwich’ structure, indicating that there are no clear boundaries between the old and new asphalt. Additionally, the microscopic morphology of the asphalt on the surface of the new aggregate in RAMs appears rougher than that of the original asphalt mixture, displaying a significant number of micropores and microcracks. This rougher surface morphology may potentially lead to a decrease in the LTP of mixtures.

- (2)

- Regardless of the thermal history of the RAP, the LTP of an RAM tends to decrease as the RAP content increases. For RAMs with differing thermal histories but identical RAP content, when the ambient temperature is above the transition temperature, the LTP of an RAM with UVRAP is superior to that of mixtures with THRAP. Conversely, the opposite trend is observed when the ambient temperature falls below the transition temperature.

- (3)

- Different thermal histories of RAPs exert varying effects on the low-temperature viscoelastic behavior of an RAM. The UVRAP accelerates the transition of the mixture from viscoelasticity to elasticity within a narrow temperature drop range and extends the temperature range during which the mixture remains in the elastic stage before failure. Conversely, the addition of the THRAP produces the opposite effect.

- (4)

- The prediction of cracking temperature using the Burgers model, along with an analysis of the model’s accuracy through residuals indicated that the model exhibited low accuracy in predicting the LTP of an RAM with THRAP. However, it effectively predicts the LTP for an RAM mixed with RAPs from the same source or with similar thermal histories.

In summary, the results of this study indicate that RAPs with varying thermal histories exert different effects on the LTP of RAMs. This finding offers valuable guidance for the application of such mixtures in the regions of seasonal freezing. However, this research has certain limitations. The use of RAPs generated indoors can’t simulate the complex thermal history conditions encountered during actual road surface usage. Addressing this complexity should be a focus of future research. We recommend that subsequent studies utilize the RAPs sourced from different projects for thermal histories comparisons, or conduct indoor simulations that encompass a broader range of aging conditions. This approach will facilitate a more comprehensive evaluation of the impacts of various thermal histories RAPs on the performance of RAMs at low temperatures.

Author Contributions

Data curation, C.J. and Q.A.; formal analysis, C.J. and Q.A.; funding acquisition, Y.C.; methodology, C.J. and Y.C.; supervision, Y.C.; validation, C.J., Y.C. and Q.A.; writing—original draft, C.J. and Q.A.; writing—review and editing, C.J. and Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation Project of China (Grant No. 52168063); the Basic Scientific Research Expenses Program of Universities directly under Inner Mongolia Autonomous Region (JY20220297); and the Natural Science Foundation of Inner Mongolia in China (2022MS05022, 2023MS05027).

Data Availability Statement

The data presented in this study are available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Keymanesh, M.R.; Amani, S.; Omran, A.T.; Karimi, M.M. Evaluation of the impact of long-term aging on fracture properties of warm mix asphalt (WMA) with high RAP contents. Constr. Build. Mater. 2023, 10, 132671. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The Challenges of Using Reclaimed Asphalt Pavement for New Asphalt Mixtures: A Review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef] [PubMed]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavements: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Mantalovas, K.; Mino, G.D. The Sustainability of Reclaimed Asphalt as a Resource for Road Pavement Management through a Circular Economic Model. Sustainability 2019, 11, 2234. [Google Scholar] [CrossRef]

- Sabahfar, N.; Nossain, M. Effect of Asphalt Rejuvenating Agent on Aged Reclaimed Asphalt Pavement and Binder Properties: Technical Summary; Kansas State University Transportation Center: Manhattan, KS, USA, 2016. [Google Scholar]

- Gaspar, M.; Vasconcelos, K.; Lopes, M.; Bernucci, L. Evaluation of Binder Blending on Warm Mix Recycling. In Proceedings of the 2018 ISAP Conference, Fortaleza, Brazil, 19–21 June 2018; Volume 6, p. 20. [Google Scholar]

- Singh, D.; Girimath, S. Influence of RAP sources and proportions on fracture and low temperature cracking performance of polymer modified binder. Constr. Build. Mater. 2016, 120, 10–18. [Google Scholar] [CrossRef]

- Tran, N.H.; Taylor, A.; Willis, R. Effect of Rejuvenator on Performance Properties of HMA Mixtures with High RAP and RAS Contents; Rep. No. 12–05; National Center for Asphalt Technology (NCAT), Auburn University: Auburn, AL, USA, 2012. [Google Scholar]

- Moon, K.H.; Falchetto, A.C.; Marasteanu, M.; Turos, M. Using Recycled Asphalt Materials as an Alternative Material Source in Asphalt Pavements. J. Civ. Eng. 2014, 18, 149–159. [Google Scholar] [CrossRef]

- Ozer, H.; Al-Qadi, I.L.; Singhvi, P.; Khan, T.; Rivera-Perez, J.; El-Khatib, A. Fracture characterization of asphalt mixtures with high recycled content using Illinois semicircular bending test method and flexibility index. Transp. Res. Board 2016, 2575, 130–137. [Google Scholar] [CrossRef]

- Yang, T.; Jia, Y.; Pan, Y.; Zhao, Y. Evaluation of the Low-Temperature Cracking Performance of Recycled Asphalt Mixture: A Development of Equivalent Fracture Temperature. Buildings 2022, 12, 1366. [Google Scholar] [CrossRef]

- Babagoli, R.; Norouzi, N.; Ameli, A. Laboratory investigation of the influence of aging and compaction effort on low temperature performance of asphalt mixture containing different percentage of RAP. Constr. Build. Mater. 2021, 298, 123899. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.; Vukosavljevic, D. Evaluation of Cracking Resistance of Recycled Asphalt Mixture Using Semi-Circular Bending Test. Mater. Pavement Anal. Geotech. Spec. Publ. 2010, 203, 58–65. [Google Scholar]

- Wu, J.; Ren, H.; Jin, A. Low-temperature fracture resistance of plant-mixed heat recycled asphalt mixture based on SCB. Mater. Res. Express 2023, 10, 115101. [Google Scholar] [CrossRef]

- Lin, H.; Zhuang, Y.; Hu, G. Influence of RAP Content on Pavement Performance of Hot Plant Recycling Asphalt Mixture. Mech. Mater. 2014, 2, 830–833. [Google Scholar] [CrossRef]

- Jiang, T.; Fan, Q.; Hou, M.; Mi, S.; Yan, X. Effects of Rejuvenator Dosage, Temperature, RAP Content and ejuvenation Process on the Road Performance of Recycled Asphalt Mixture. Sustainability 2023, 15, 3539. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Xiang, Q.; Qin, W.; Yi, J. Research on the influence of RAP and aged asphalt on the performance of plant-mixed hot recycled asphalt mixture and blended asphalt. Case Stud. Constr. Mater. 2021, 12, e00722. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H.; Kim, D.H. Evaluation of recycled asphalt mixture at low temperature using different analytical solutions. Can. J. Civ. Eng. 2019, 47, 801–811. [Google Scholar] [CrossRef]

- Ma, X.; Wang, J.; Xu, Y. Investigation on the Effects of RAP Proportions on the Pavement Performance of Recycled Asphalt Mixtures. Front. Mater. 2022, 8, 842809. [Google Scholar] [CrossRef]

- Tapsoba, N.; Baaj, H.; Sauzéat, C.; Benedetto, H.D.; Ech, M. 3D analysis and modelling of Thermal Stress Restrained Specimen Test (TSRST) on asphalt mixes with RAP and roofing shingles. Constr. Build. Mater. 2016, 120, 393–402. [Google Scholar] [CrossRef]

- Ziari, H.; Aliha, M.R.M.; Moniri, A.; Saghafi, Y. Crack Resistance of Hot Mix Asphalt Containing Different Percentages of Reclaimed Asphalt Pavement and Glass Fiber. Constr. Build. Mater. 2020, 230, 117015. [Google Scholar] [CrossRef]

- Xu, J.; Fan, Z.; Lin, J.; Liu, P.; Wang, D.; Oeser, M. Study on the effects of reversible aging on the low temperature performance of asphalt binders. Constr. Build. Mater. 2021, 295, 123604. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Zheng, P. Toward a better understanding of the low-temperature reversible aging phenomenon in asphalt binder. Int. J. Pavement Eng. 2020, 23, 240–249. [Google Scholar] [CrossRef]

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, L.; Ji, L. Analysis of the evaluation indices from TSRST. J. Mater. Civ. Eng. 2012, 10, 1310–1316. [Google Scholar]

- Chen, Z.; Zhang, H.; Duan, H. Investigation of ultraviolet radiation aging gradient in asphalt binder. Constr. Build. Mater. 2020, 246, 118501. [Google Scholar] [CrossRef]

- Mokhtari, A.; Lee, H.D.; Williams, R.C.; Guymon, C.A.; Scholte, J.P.; Schram, S. A novel approach to evaluate fracture surfaces of aged and rejuvenator-restored asphalt using cryo-SEM and image analysis techniques. Constr. Build. Mater. 2017, 133, 301–313. [Google Scholar] [CrossRef]

- Jiang, Y.; Gu, X.; Zhou, Z.; Ni, F.; Dong, Q. Laboratory Observation and Evaluation of Asphalt Blends of Reclaimed Asphalt Pavement Binder with Virgin Binder using SEM/EDS. Transp. Res. Rec. 2018, 2672, 69–78. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, T.; Fan, J.; Fang, Z.; Chen, T.; Zhou, Y. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement. J. Clean. Prodn. 2020, 263, 121447. [Google Scholar] [CrossRef]

- Mensching, D.J.; Daniel, J.S.; Bennert, T.; Medeiros, M.S.; Elwardany, M.D.; Mogawer, W.; Hajj, E.Y.; Alavi, M. Low-temperature Properties of Plant-produced RAP Mixtures in the Northeast. Road Mater. Pavement Des. 2014, 15, 1–27. [Google Scholar] [CrossRef]

- Cooper, S.B.; Mohammad, L.N.; Elseifi, M.A. Laboratory Performance of Asphalt Mixtures Containing Recycled Asphalt Shingles, Reclaimed Asphalt Pavement, and Recycling Agents. J. Mater. Civ. Eng. 2017, 29, D4016001. [Google Scholar] [CrossRef]

- Isacsson, U.; Zeng, H. Low-temperature Cracking of Polymer-Modified Asphalt. Mater. Stuct. 1998, 31, 58–63. [Google Scholar] [CrossRef]

- Song, W. Study on the high and low temperature performance of nano alumina modified asphalt mixture. Int. J. Microstruct. Mater. Prop. 2023, 4, 229–238. [Google Scholar] [CrossRef]

- Yu, C.; Yang, Q.; Chen, Y. Multi-scale observation of oxidative aging on the enhancement of high–temperature property of SBS-modified asphalt. Constr. Build. Mater. 2021, 313, 125478. [Google Scholar] [CrossRef]

- Wang, J.; Ng, P.L.; Gong, Y.; Su, H.; Du, J. Experimental Study of Low Temperature Performance of Porous Asphalt Mixture. Appl. Sci. 2021, 11, 4029. [Google Scholar] [CrossRef]

- Krepl, O.; Klusák, J. Multi-parameter average strain energy density factor criterion applied on the sharp material inclusion problem. Procedia Struct. Integr. 2018, 13, 1279–1284. [Google Scholar] [CrossRef]

- Jaczewski, M.; Judycki, J.; Jaskuła, P. Modelling of asphalt mixes under long time creep at low temperatures. Transp. Res. Procedia 2016, 14, 3527–3535. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. [Google Scholar] [CrossRef]

- Shaw, M.T.; MacKnight, W.J. Introduction to Polymer Viscoelasticity; East China University of Science and Technology: Shanghai, China, 2012. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).