Experimental Study on Mechanical Properties of Rock in Water-Sensitive Oil and Gas Reservoirs Under High Confining Pressure

Abstract

1. Introduction

2. Experimental Device and Sample Preparation

2.1. Experimental Equipment and Methods

2.2. Sample Preparation and Experimental Scheme

- Experimental scheme: In order to test the mechanical properties of shale rock, the effects of water sensitivity characteristics under different confining pressures and different water contents on its mechanical properties were analyzed. The samples of shale rock with water contents of 0%, 2%, 4%, 6%, and 8% were subjected to triaxial compression tests under confining pressures of 60 MPa, 70 MPa, and 80 MPa.

- Experimental procedure: After the shale rock sample had been wrapped with rubber film, it was fixed on the pressurized platform, and the anisotropic strain gauge was installed. We then started the system to set the control parameters, installed the pressure chamber cover, and filled the oil to discharge the gas. After the oil had been filled, the confining pressure was applied, and the setting confining pressure was loaded at the rate of 2 MPa/min, after which the axial strain rate was set as 10−6/s for the loading experiment. After the sample had been damaged, the system automatically generated the test data. The physical parameters of the tested shale rock samples are shown in Table 1.

3. Experimental Results and Analysis

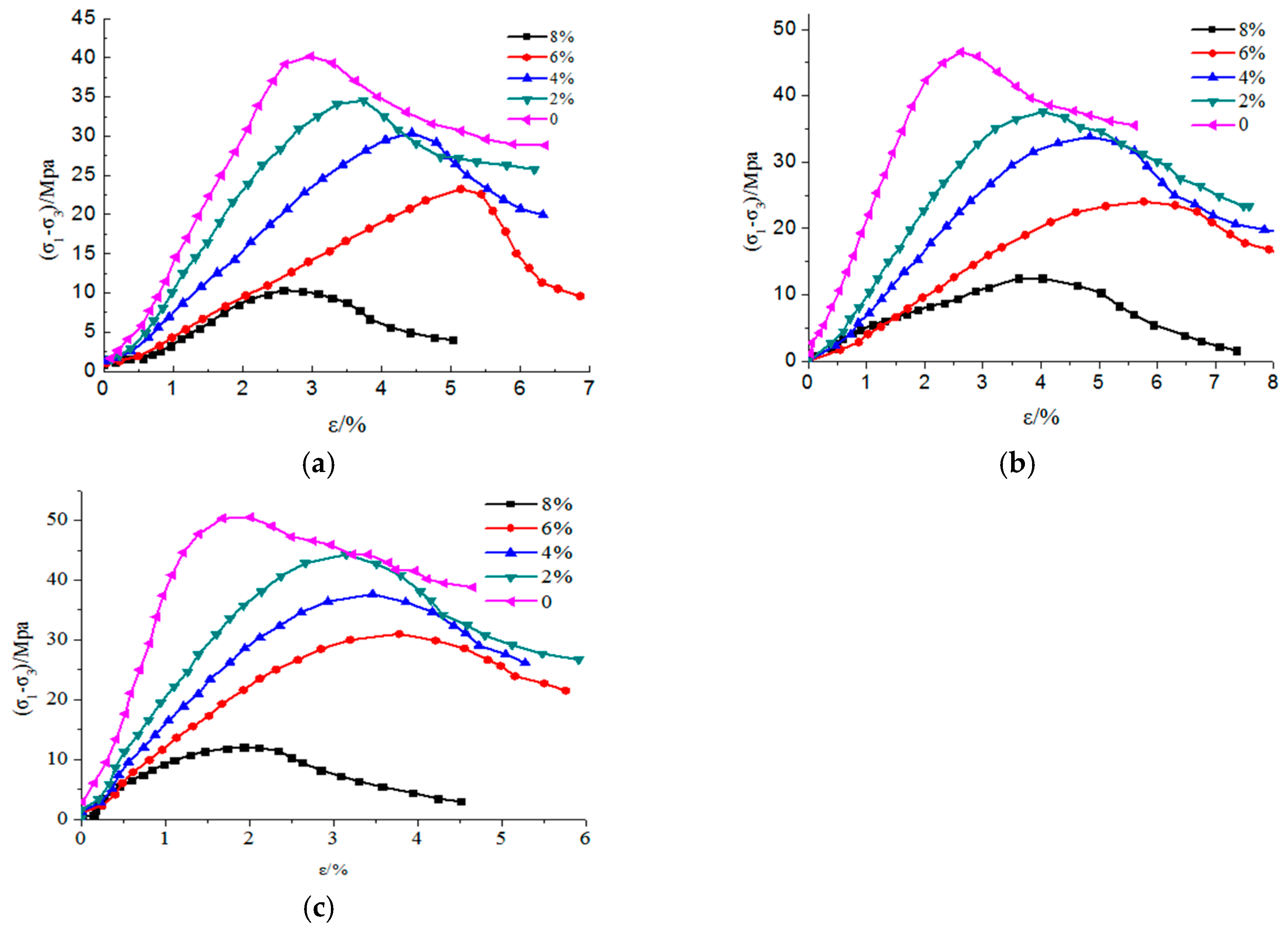

3.1. Stress–Strain Curves of Shale Rock Samples

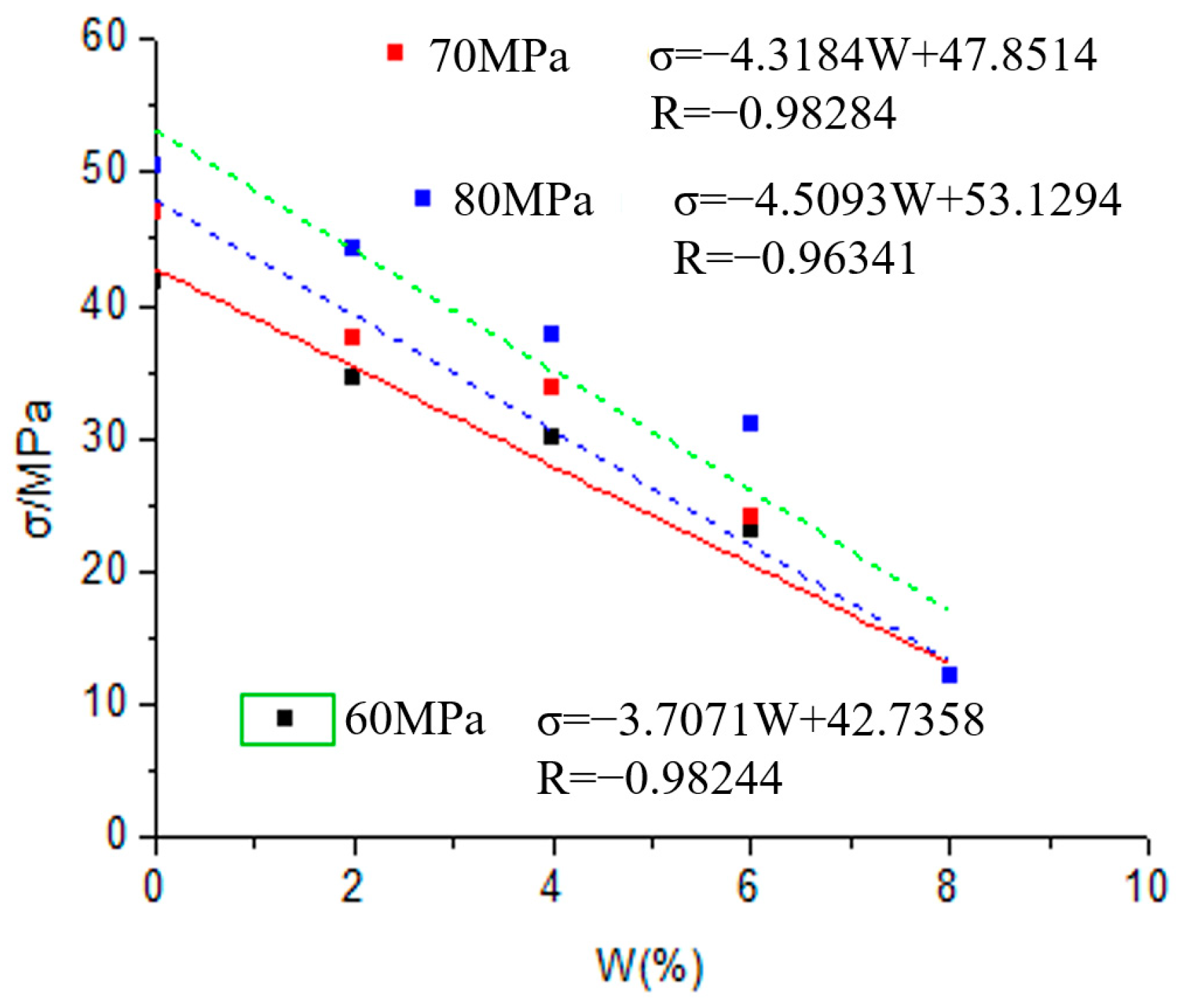

3.2. Strength Characteristic Analysis

- When the dry shale rock sample increases from 60 MPa to 80 MPa, the strength increases from 41.659 MPa to 50.491 MPa, an increase of 21.2%. When the saturated shale rock sample increases from 60 MPa to 80 MPa, the strength increases from 9.872 MPa to 11.746 MPa, an increase of 18.98%. It can be seen that the strength of the shale rock clearly increases under the action of high confining pressure;

- When the confining pressure is 60 MPa, the compressive strength of shale with a water content from 0 to 8% decreases from 41.659 MPa to 10.347 MPa, a decrease of 75.16%. When the confining pressure is 70 MPa, the compressive strength of shale with a water content from 0 to 8% decreases from 46.932 MPa to 10.512 MPa, a decrease of 77.60%. When the confining pressure is 80 MPa, the compressive strength of the shale rock decreases from 50.491 MPa to 12.038 MPa, a decrease of 76.16%. It can be seen that hydration significantly degrades the compressive strength of shale.

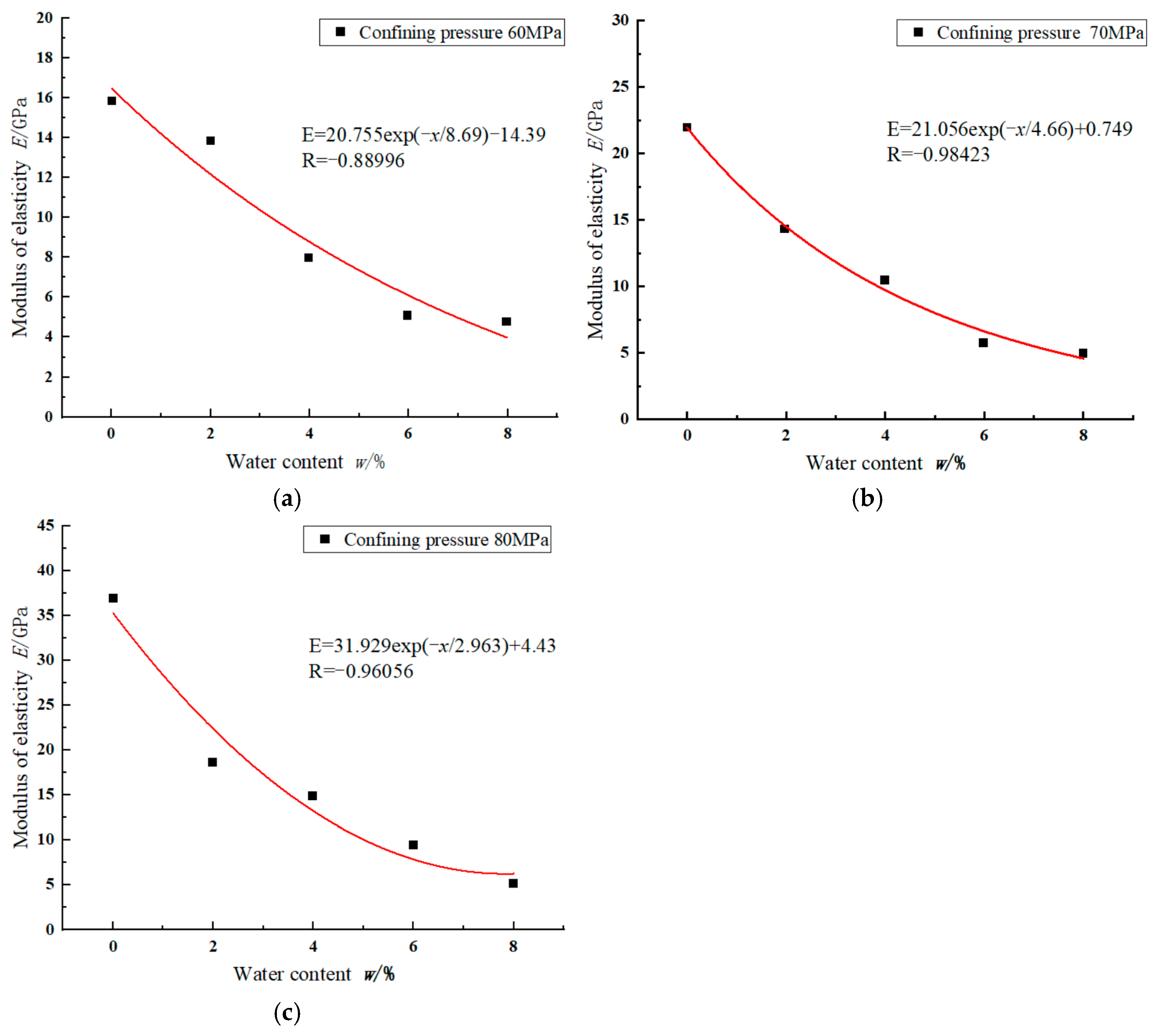

3.3. Deformation Characteristic Analysis

4. Macro and Micro Damage Analysis

4.1. Macro and Micro Analysis of the Influence of Water–Shale–Rock Interaction on the Strength of Shale

4.2. Effect of Water on Macroscopic Failure Mode of Shale

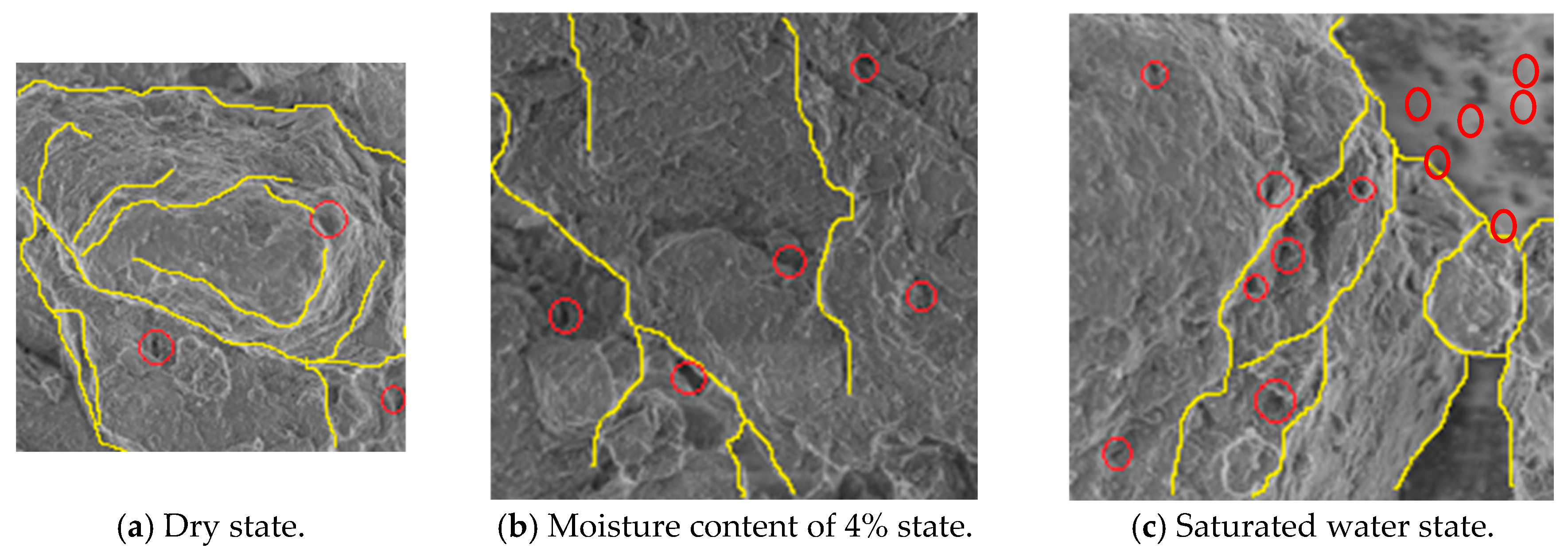

4.3. Effect of Water on the Microstructure of Shale

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X.; Zhou, L.; Pu, X.; Jin, F.; Han, W.; Xiao, D.; Chen, S.; Shi, Z.; Zhang, W.; Yang, F. Geological characteristics of shale rock system and shale oil exploration breakthrough in a lacustrine basin: A case study from the Paleogene 1st sub-member of Kong 2 Member in Cangdong sag, Bohai Bay Basin, China. Pet. Explor. Dev. 2018, 45, 377–388. [Google Scholar] [CrossRef]

- She, H.; Hu, Z.; Qu, Z.; Zhang, Y.; Guo, H. Determination of the hydration damage instability period in a shale borehole wall and its application to a Fuling shale gas reservoir in China. Geofluids 2019, 2019, 3016563. [Google Scholar] [CrossRef]

- Zhu, K.; Chen, J.; Lu, S. Analysis and practice of Nanpu No. 3 tectonic deep brittle shale stability mechanism. Drill. Prod. Technol. 2016, 39, 1–4. [Google Scholar]

- Hao, Y.; Song, G.; Zhou, G.; Li, Z.; Wang, W.; Li, B.; Zhang, C. Petrological characteristics of Paleogene shale in Jiyangdepression. Pet. Exp. Geol. 2016, 38, 489–495. [Google Scholar]

- Zhao, K.; Fan, Y.; Yu, B.; Han, J.; Xu, Y.; Gao, S. Progress on shale stability of hard brittle. Oil Drill. Prod. Technol. 2016, 38, 277–285. [Google Scholar] [CrossRef]

- You, M. Comparison of the accuracy of some conventional triaxial strength criteria for intact rock. Int. J. Rock Mech. Min. Sci. 2011, 48, 852–863. [Google Scholar] [CrossRef]

- Li, R.; Han, L.; Meng, Y.; Liu, J.; He, S. Three axis test of shale and study of borehole stability. J. Pet. Nat. Gas 2015, S5, 768–769. [Google Scholar]

- Guang, X.; Chen, Z.; Liu, X.; Wang, Y.; Si, N. Study on borehole wall stability of rational shale formation in three directions stress state. Sci. Technol. Eng. 2015, 15, 54–57. [Google Scholar]

- Yin, S.; Ding, W.; Sun, Y.; Wang, X.; Zhang, M.; Zhang, N. Uniaxial compressive fracture characteristics of shale and UCS influencing factors. Earth Sci. Front. 2016, 23, 75–95. [Google Scholar] [CrossRef]

- Yu, H.; Li, Y. Research on conventional triaxial compression test and constitutive model of silty mudstone. Yangtze River 2011, 42, 56–106. [Google Scholar] [CrossRef]

- Tian, H.; Chen, W.; Zhao, W.; Tian, T.; Yuan, K. Analysis of triaxial stress relaxation properties of red silty mudstone of Yichang-Badong highway. Rock Soil Mech. 2013, 34, 981–986. [Google Scholar] [CrossRef]

- Diao, H. Rock mechanical properties and brittleness evaluation of shale reservoir. J. Rock 2013, 29, 3300–3306. [Google Scholar]

- You, M. Strength and strength criteria for intact rock. J. Fudan Univ. Nat. Sci. Ed. 2013, 52, 569–582. [Google Scholar]

- Zhou, S.; Yin, S.; Wang, F.; Li, D.; Yi, W. Test analysis and application of stress on the fragility of shale reservoir. Pet. Drill. Technol. 2017, 45, 113–120. [Google Scholar]

- Zhao, J.; Xu, W.; Li, Y.; Hu, J.; Li, J. A new method for evaluating shale gas reservoir pressure. Nat. Gas Geosci. 2015, 26, 1165–1172. [Google Scholar]

- Yuan, H.; Cheng, Y.; Wang, W.; Guo, H.; Han, Z.; Zhang, Y. Analysis of sloughing period of mudstone shaft in long horizontal drilling. Sci. Technol. Eng. 2017, 17, 183–189. [Google Scholar]

- Duan, T.; Ren, Y. Mechanical properties and wave velocity damage of sandstone under uniaxial compression with different water content. Coal Geol. Explor. 2019, 47, 153–158. [Google Scholar]

- Zhang, W.; Zhang, D.; Zhao, J. Experimental investigation of water sensitivity effects on microscale mechanical behavior of shale. Int. J. Rock Mech. Min. Sci. 2021, 145, 104837. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, J.; Zhang, D. Construction and validation of the upscaling model of organic-rich shale by considering water-sensitivity effects. J. Pet. Sci. Eng. 2022, 216, 110718. [Google Scholar] [CrossRef]

- Alouhali, R.; Al-Arfaj, M.; Al-Rashead, M.; Hayton, S. Shale-Fluid Sensitivity for an Unconventional Shale Formation. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018. [Google Scholar] [CrossRef]

| ID | Altitude (cm) | Diameter (cm) | ID | Altitude (cm) | Diameter (cm) | ID | Altitude (cm) | Diameter (cm) |

|---|---|---|---|---|---|---|---|---|

| A-1 | 10.23 | 4.85 | B-1 | 9.86 | 4.85 | C-1 | 9.85 | 4.85 |

| A-1 | 10.12 | 4.92 | B-1 | 10.03 | 4.92 | C-1 | 9.64 | 5.08 |

| A-1 | 10.32 | 5.05 | B-1 | 9.85 | 4.88 | C-1 | 10.12 | 4.85 |

| A-2 | 10.10 | 5.12 | B-2 | 10.12 | 5.01 | C-2 | 10.03 | 5.04 |

| A-2 | 10.30 | 4.87 | B-2 | 10.06 | 5.10 | C-2 | 10.25 | 5.13 |

| A-2 | 10.11 | 4.85 | B-2 | 10.21 | 5.07 | C-2 | 10.08 | 5.09 |

| A-3 | 9.88 | 4.87 | B-3 | 9.88 | 4.89 | C-3 | 10.10 | 4.98 |

| A-3 | 10.30 | 5.01 | B-3 | 9.96 | 4.92 | C-3 | 10.05 | 5.12 |

| A-3 | 10.10 | 5.06 | B-3 | 10.22 | 4.83 | C-3 | 10.18 | 4.98 |

| A-4 | 9.85 | 4.90 | B-4 | 10.14 | 4.88 | C-4 | 9.96 | 5.06 |

| A-4 | 10.28 | 5.14 | B-4 | 10.30 | 4.85 | C-4 | 10.05 | 5.08 |

| A-4 | 10.13 | 5.02 | B-4 | 10.11 | 4.85 | C-4 | 9.85 | 5.11 |

| A-5 | 10.06 | 4.85 | B-5 | 9.88 | 4.90 | C-5 | 10.12 | 5.01 |

| A-5 | 10.03 | 4.98 | B-5 | 9.85 | 4.89 | C-5 | 10.28 | 5.12 |

| A-5 | 10.16 | 4.85 | B-5 | 9.75 | 5.01 | C-5 | 10.13 | 5.06 |

| ID | Intensity (MPa) | Average Compressive Strength (MPa) | ID | Intensity (MPa) | Average Compressive Strength (MPa) | ID | Intensity (MPa) | Average Compressive Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| A-1 | 35.092 | 41.659 | B-1 | 49.527 | 46.932 | C-1 | 57.839 | 50.491 |

| A-1 | 43.317 | B-1 | 49.223 | C-1 | 59.245 | |||

| A-1 | 46.568 | B-1 | 42.046 | C-1 | 34.389 | |||

| A-2 | 37.853 | 34.552 | B-2 | 39.417 | 37.577 | C-2 | 48.196 | 44.273 |

| A-2 | 33.891 | B-2 | 37.481 | C-2 | 38.362 | |||

| A-2 | 31.912 | B-2 | 35.833 | C-2 | 46.261 | |||

| A-3 | 35.124 | 29.945 | B-3 | 27.573 | 33.819 | C-3 | 30.253 | 37.666 |

| A-3 | 29.348 | B-3 | 37.118 | C-3 | 39.368 | |||

| A-3 | 25.363 | B-3 | 36.766 | C-3 | 43.377 | |||

| A-4 | 26.367 | 23.034 | B-4 | 27.851 | 24.049 | C-4 | 30.687 | 30.991 |

| A-4 | 25.142 | B-4 | 26.416 | C-4 | 28.421 | |||

| A-4 | 17.593 | B-4 | 17.88 | C-4 | 33.865 | |||

| A-5 | 12.463 | 10.347 | B-5 | 11.646 | 10.512 | C-5 | 14.147 | 12.038 |

| A-5 | 9.857 | B-5 | 13.422 | C-5 | 11.736 | |||

| A-5 | 8.721 | B-5 | 6.468 | C-5 | 10.231 |

| Confining Pressure/MPa | The Ratio of Residual Strength to Peak Strength Under Different Water Contents % | Softening Coefficient η | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | ||

| 60 | 65.12 | 55.57 | 52.45 | 49.71 | 41.66 | 24.89 |

| 70 | 66.85 | 59.74 | 59.23 | 58.54 | 58.31 | 26.84 |

| 80 | 67.48 | 65.89 | 64.58 | 63.89 | 62.76 | 27.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Liang, J.; Dou, Y. Experimental Study on Mechanical Properties of Rock in Water-Sensitive Oil and Gas Reservoirs Under High Confining Pressure. Appl. Sci. 2024, 14, 11478. https://doi.org/10.3390/app142411478

Li M, Liang J, Dou Y. Experimental Study on Mechanical Properties of Rock in Water-Sensitive Oil and Gas Reservoirs Under High Confining Pressure. Applied Sciences. 2024; 14(24):11478. https://doi.org/10.3390/app142411478

Chicago/Turabian StyleLi, Mingfei, Jingwei Liang, and Yihua Dou. 2024. "Experimental Study on Mechanical Properties of Rock in Water-Sensitive Oil and Gas Reservoirs Under High Confining Pressure" Applied Sciences 14, no. 24: 11478. https://doi.org/10.3390/app142411478

APA StyleLi, M., Liang, J., & Dou, Y. (2024). Experimental Study on Mechanical Properties of Rock in Water-Sensitive Oil and Gas Reservoirs Under High Confining Pressure. Applied Sciences, 14(24), 11478. https://doi.org/10.3390/app142411478