Heat Transfer Efficiency While Cooling with a Water Spray, Air-Assisted Water Spray and Water Jet Under Boiling and Single-Phase Forced Convection Conditions †

Abstract

1. Introduction

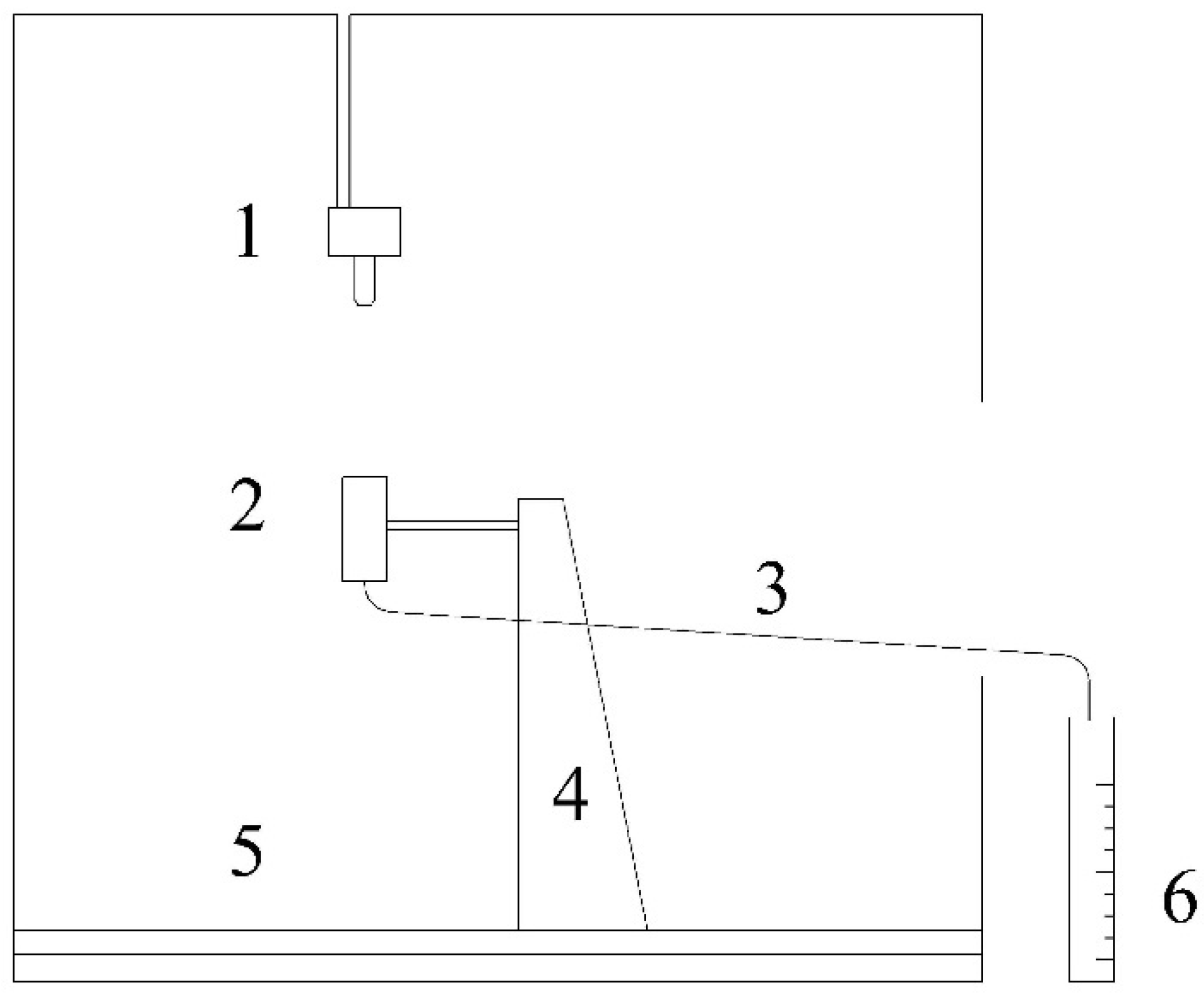

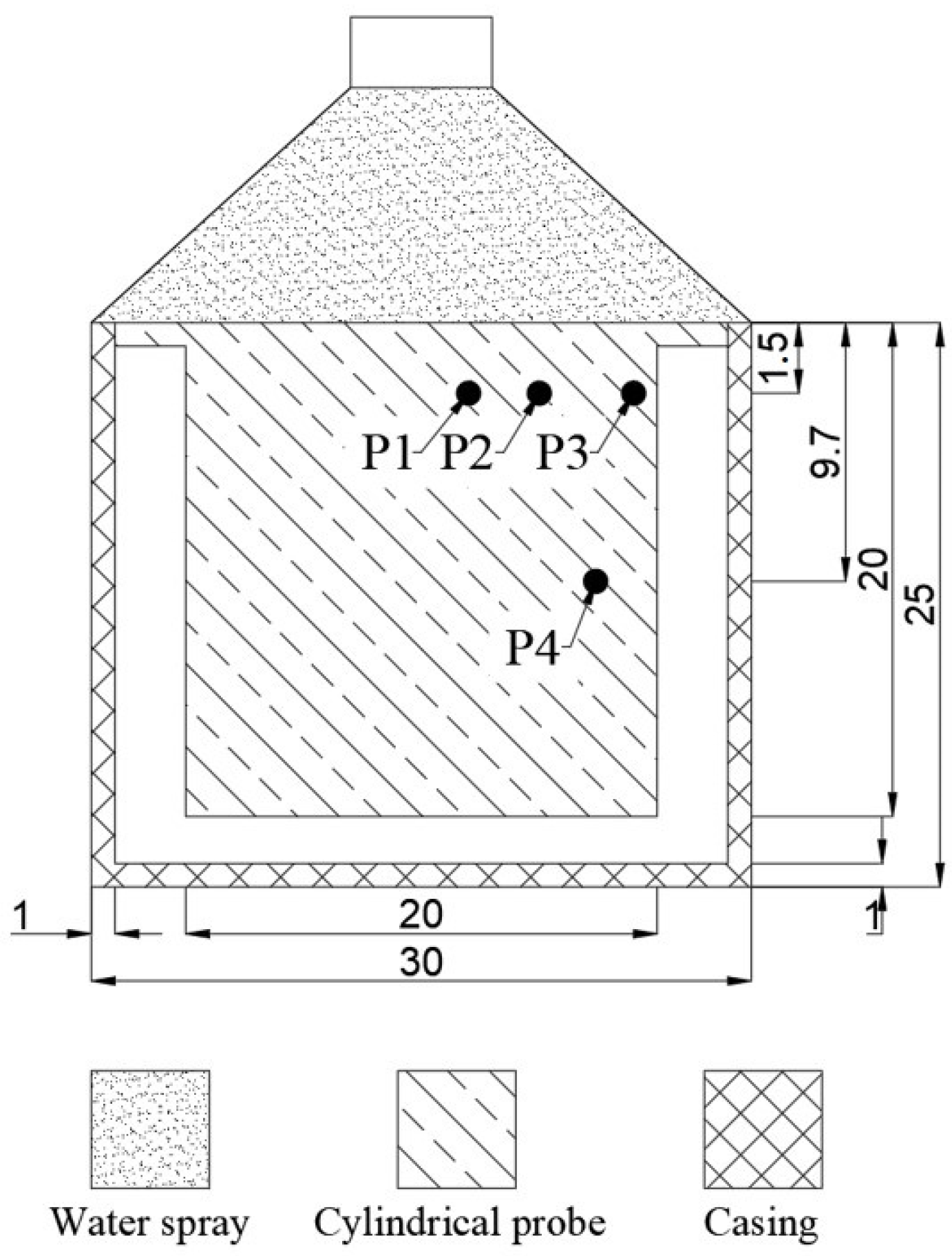

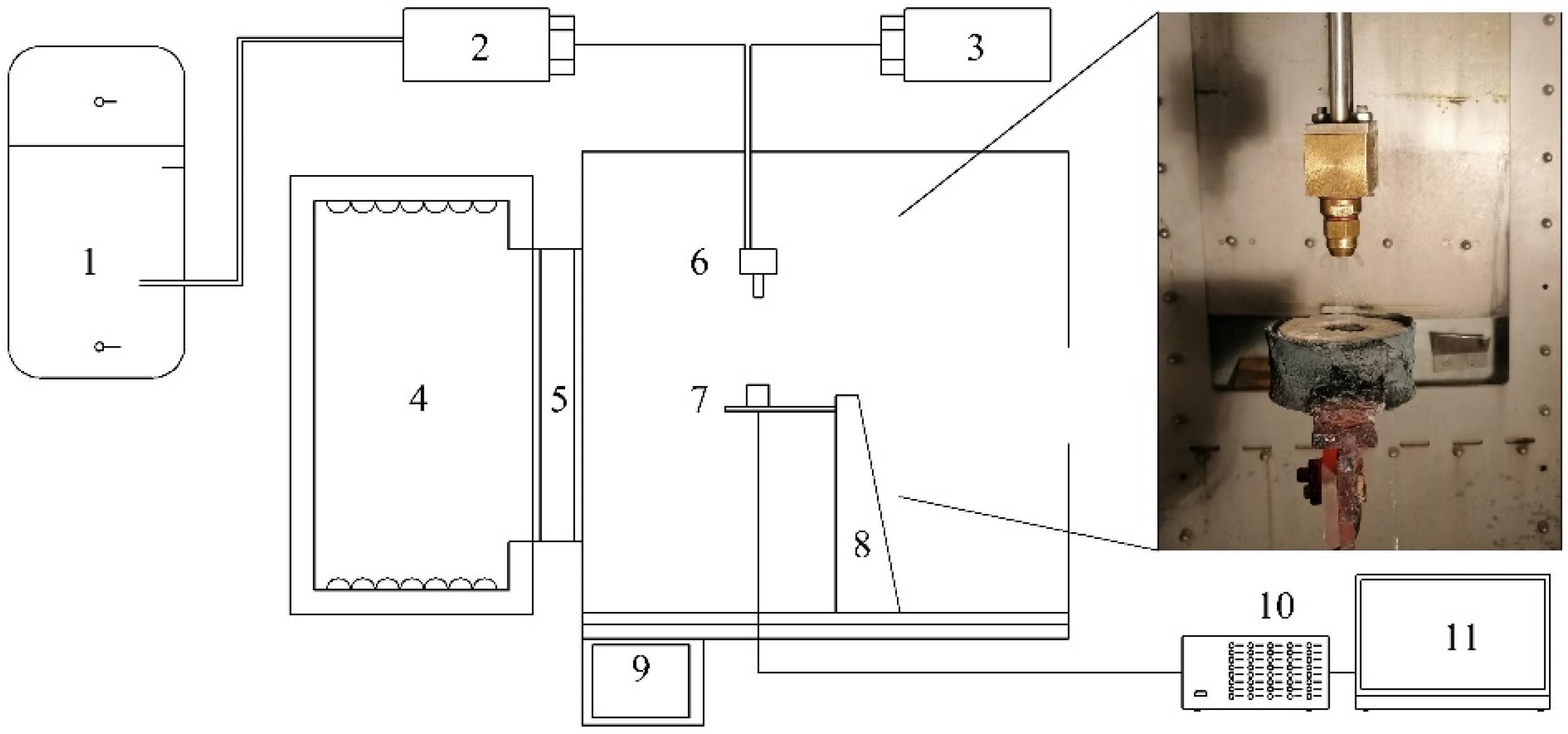

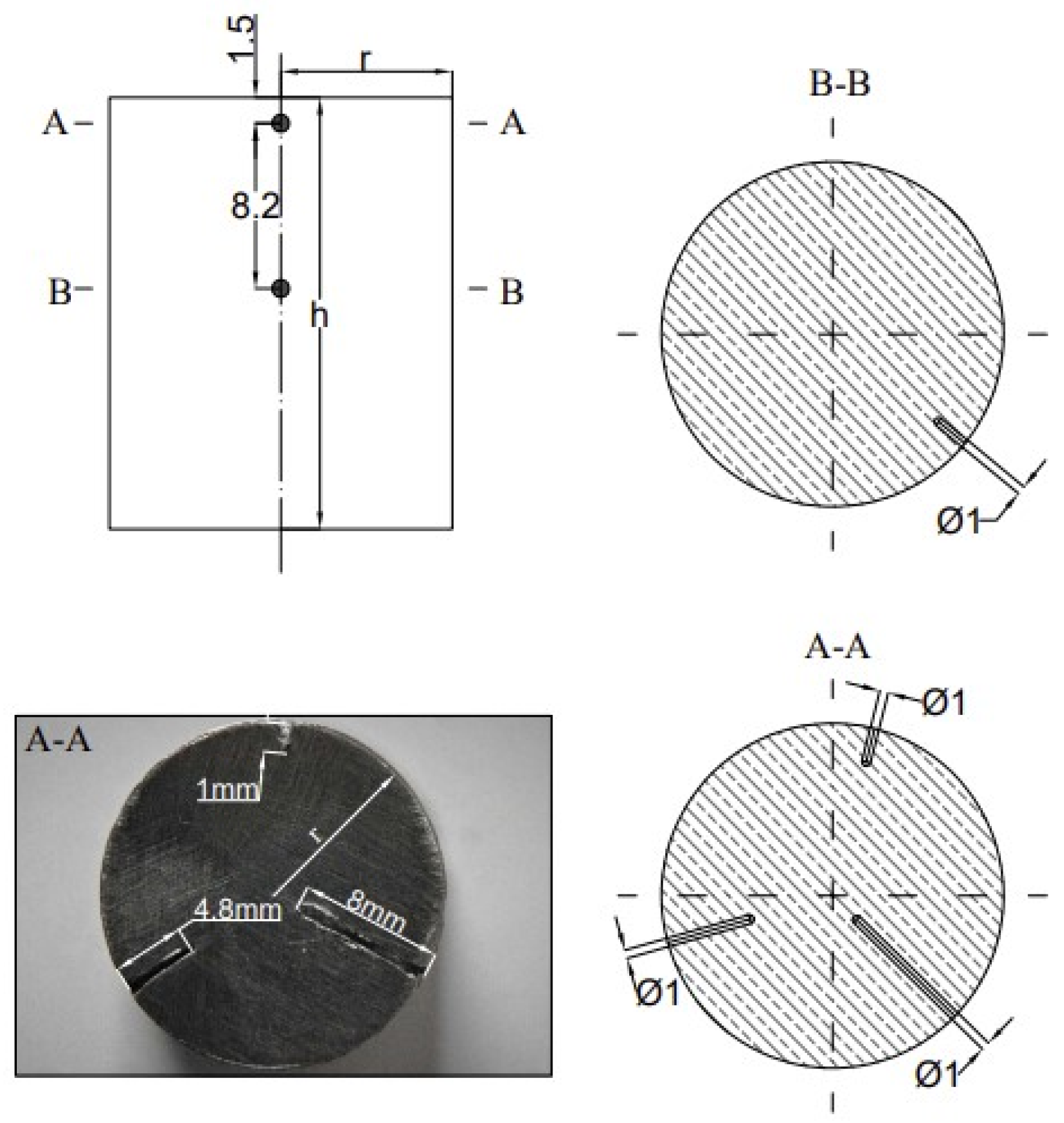

2. Materials and Methods

2.1. Experimental Tests

- R—cylinder radius, m;

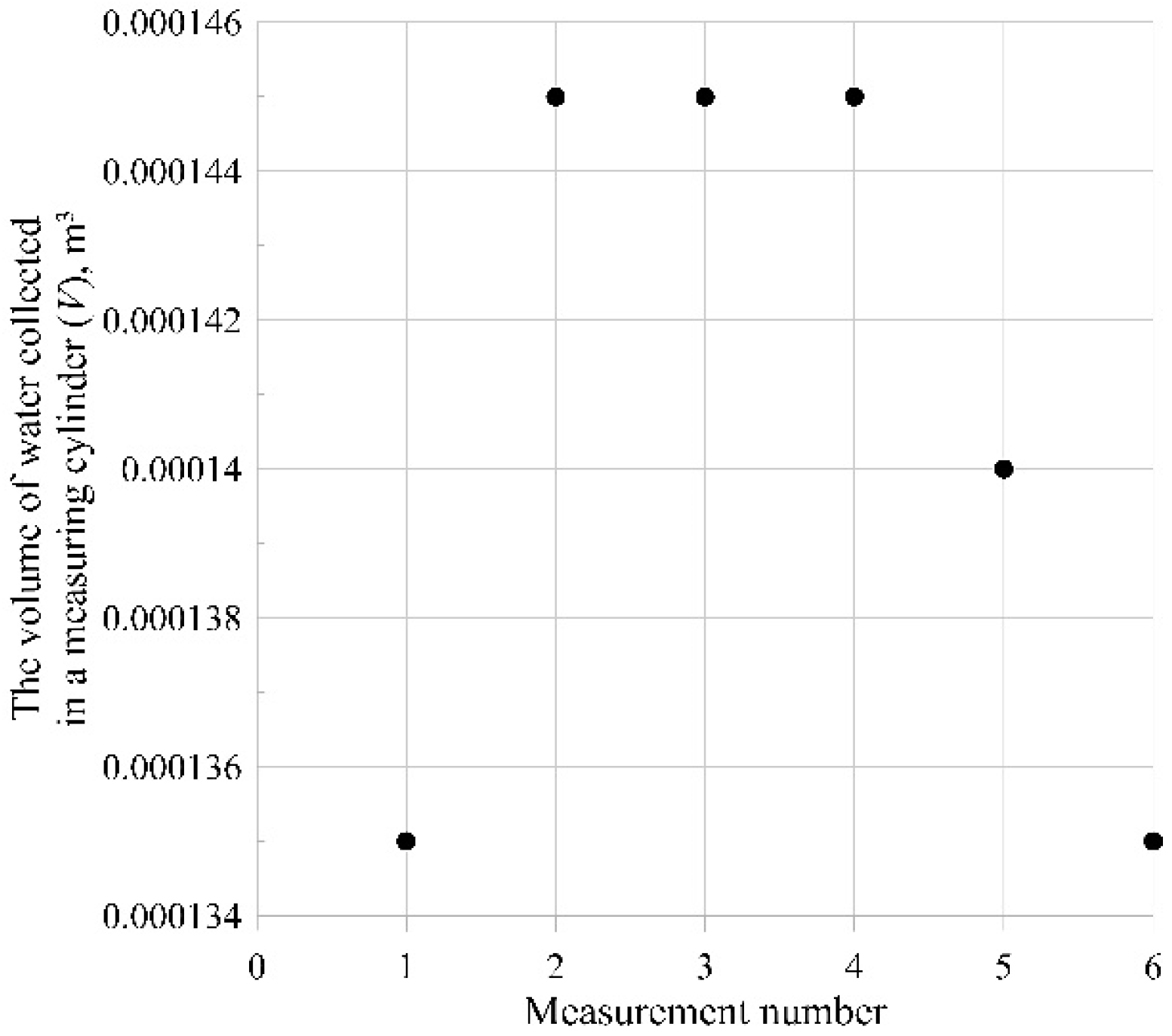

- V—volume of the water collected in the measuring cylinder, m3;

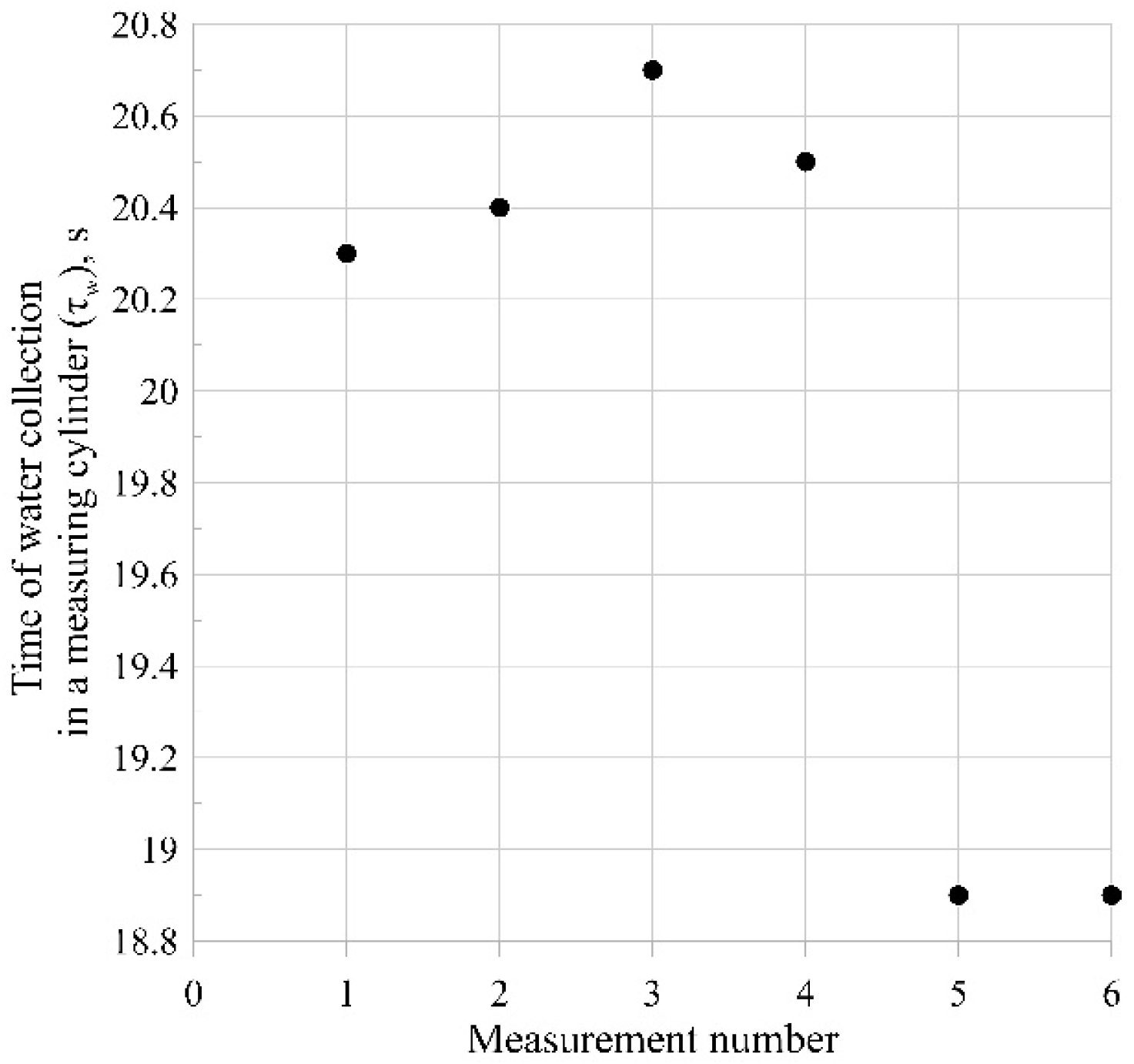

- τw—time of collection of the water in the measuring cylinder, s.

- —the accuracy of water flux density measurement, m3/(m2·s);

- gw—average water flux density, m3/(m2·s);

- A—area of the inlet to the sleeve, m2;

- ΔA—the accuracy of the measurement of the sleeve inlet surface area, m2;

- ΔV—the accuracy of the measuring cylinder, m3;

- Δτw—time measurement error, s.

- where

- d—diameter of the sleeve inlet, m;

- Δd—accuracy of the calliper, m.

- where

- τr—human reaction time, s;

- —accuracy of the stopwatch, s.

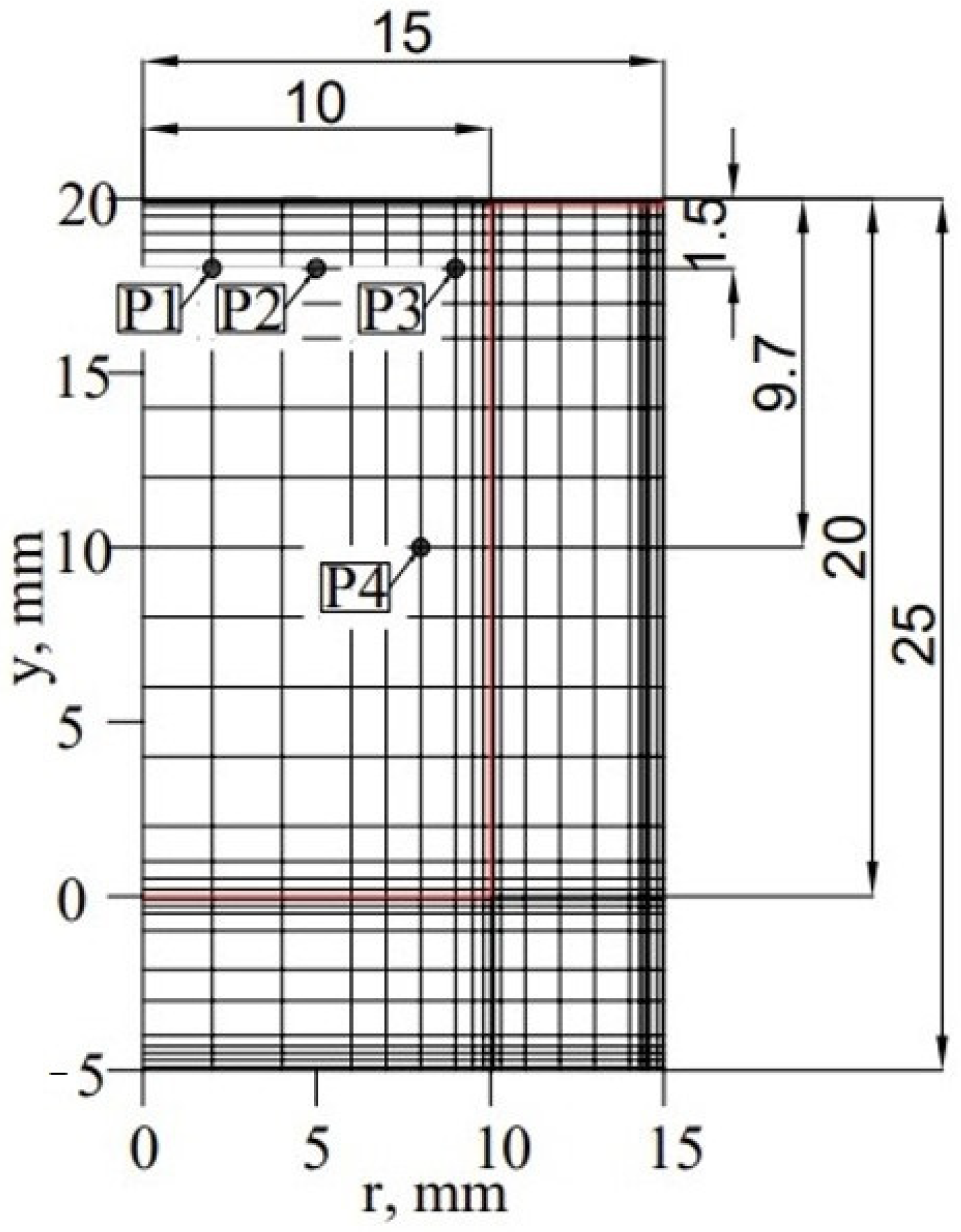

2.2. Heat Conduction Model Used to Identify the Boundary Conditions of the Heat Transfer

- —density of the sensor material, kg/m3;

- —specific heat, J/(kg·K);

- t—sensor temperature, °C;

- r, y—cylindrical coordinates;

- τ—time, s;

- λ—thermal conductivity, W/(m·K);

- h—sensor height, m.

- Kij—heat conduction matrix;

- Cij—heat capacity matrix;

- Bi—boundary condition vector.

- α—heat transfer coefficient, W/(m2·K);

- Ta—water temperature, °C.

- —temperature of the cooled surface, °C;

- —coolant temperature, °C.

- pi—vector of unknown parameters;

- m—number of temperature measurements performed by one sensor;

- n—number of temperature sensors;

- —sample temperature measured by sensor j at time τi;

- —computed sample temperature at the location of sensor j at time τi.

- ϑ—dimensionless sensor radius;

- Rmax—maximum sensor radius, m.

- η—dimensionless time.

- σ—Stefan–Boltzmann radiation constant, W/(m2·K4);

- T1—temperature of the inner surface of the casing, K;

- T2—temperature of the sensor side, K;

- ε1—emissivity of the sensor surface;

- ε2—emissivity of the casing surface;

- λp—thermal conductivity of air, W/(m·K);

- Lco—distance between sensor and casing, m;

- Pr—Prandtl number;

- Ra—Rayleigh number.

- Tot—ambient temperature, K;

- Lo—diameter of the outer casing, m.

- αb—heat transfer coefficient on the side surface of the casing, W/(m2·K);

- tb—temperature of the outer surface of the side casing, °C.

2.3. Numerical Calculations

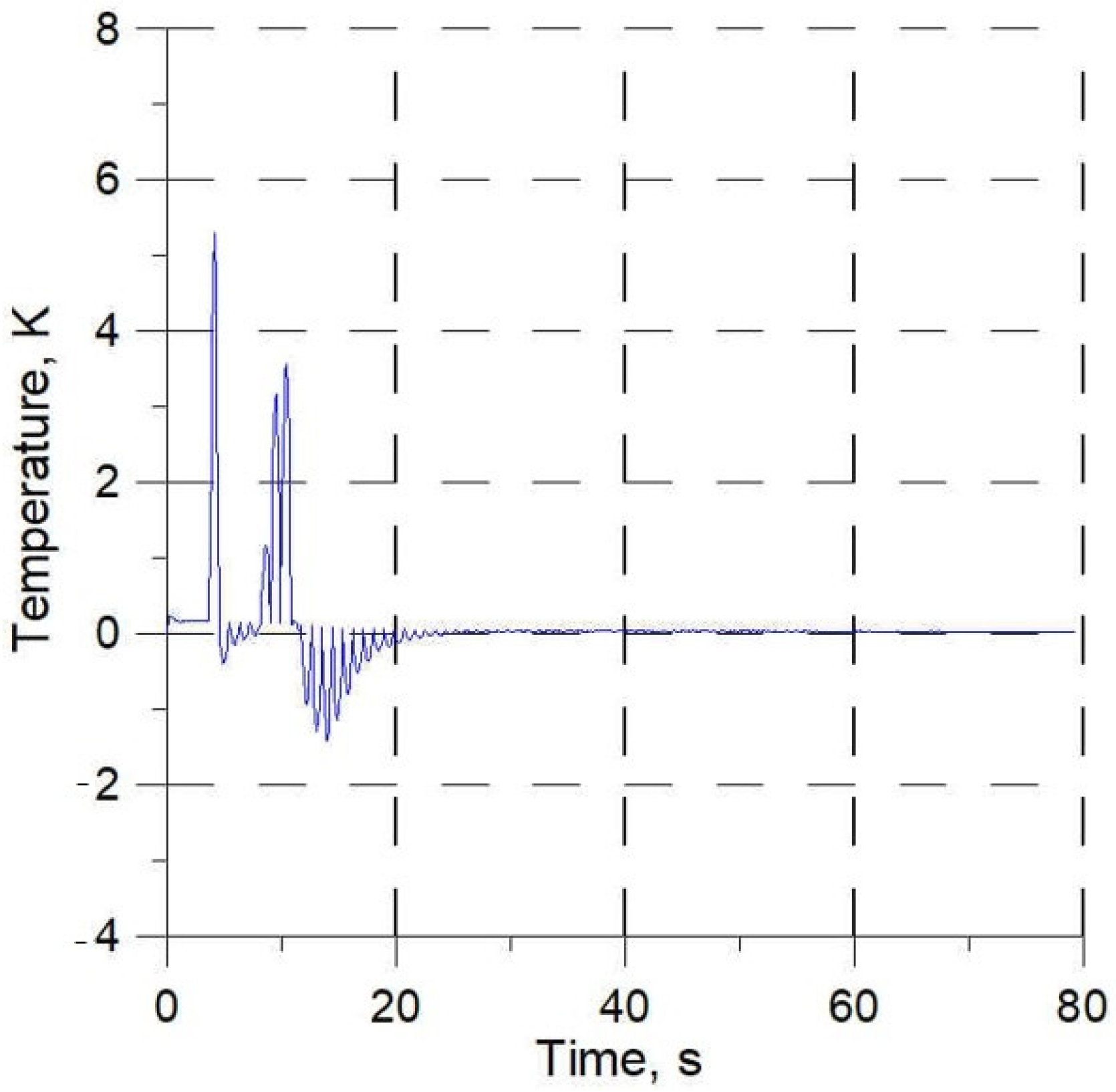

Uncertainty of the Inverse Solution

- F1—scaling factor for the heat transfer coefficient in the sensor axis (r = 0);

- F2—scaling factor for the heat transfer coefficient in the sensor edge.

3. Results and Discussion

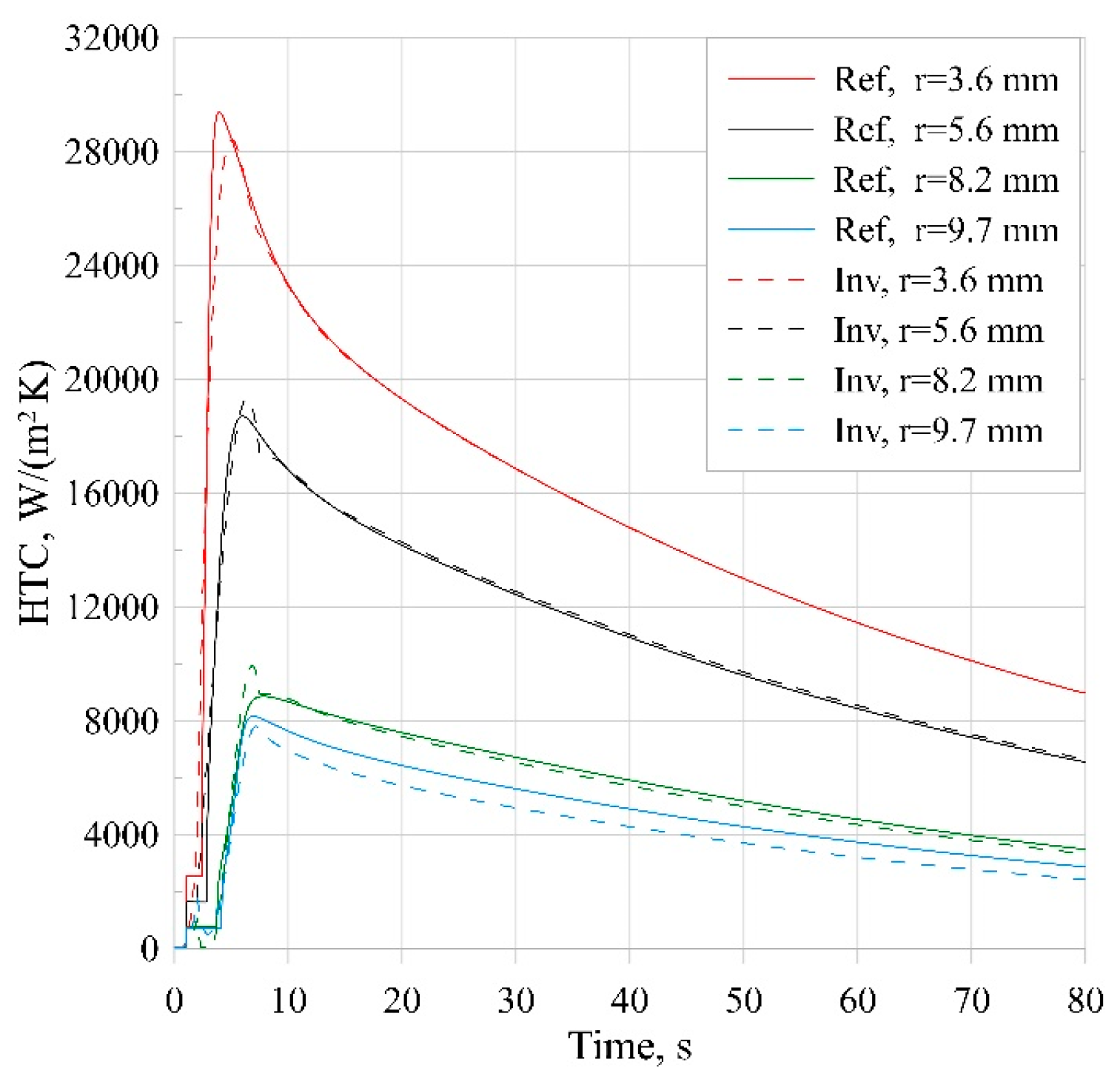

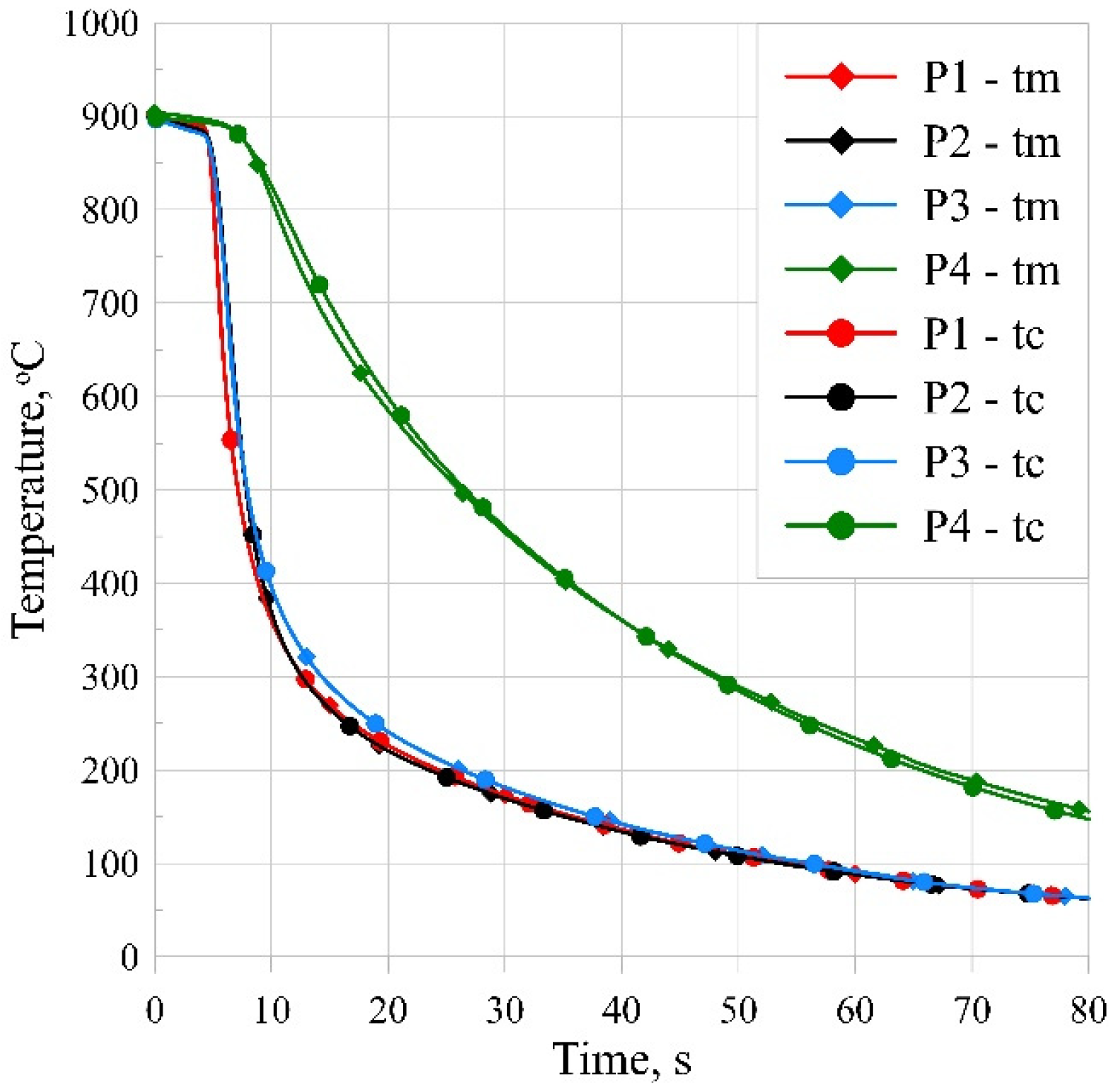

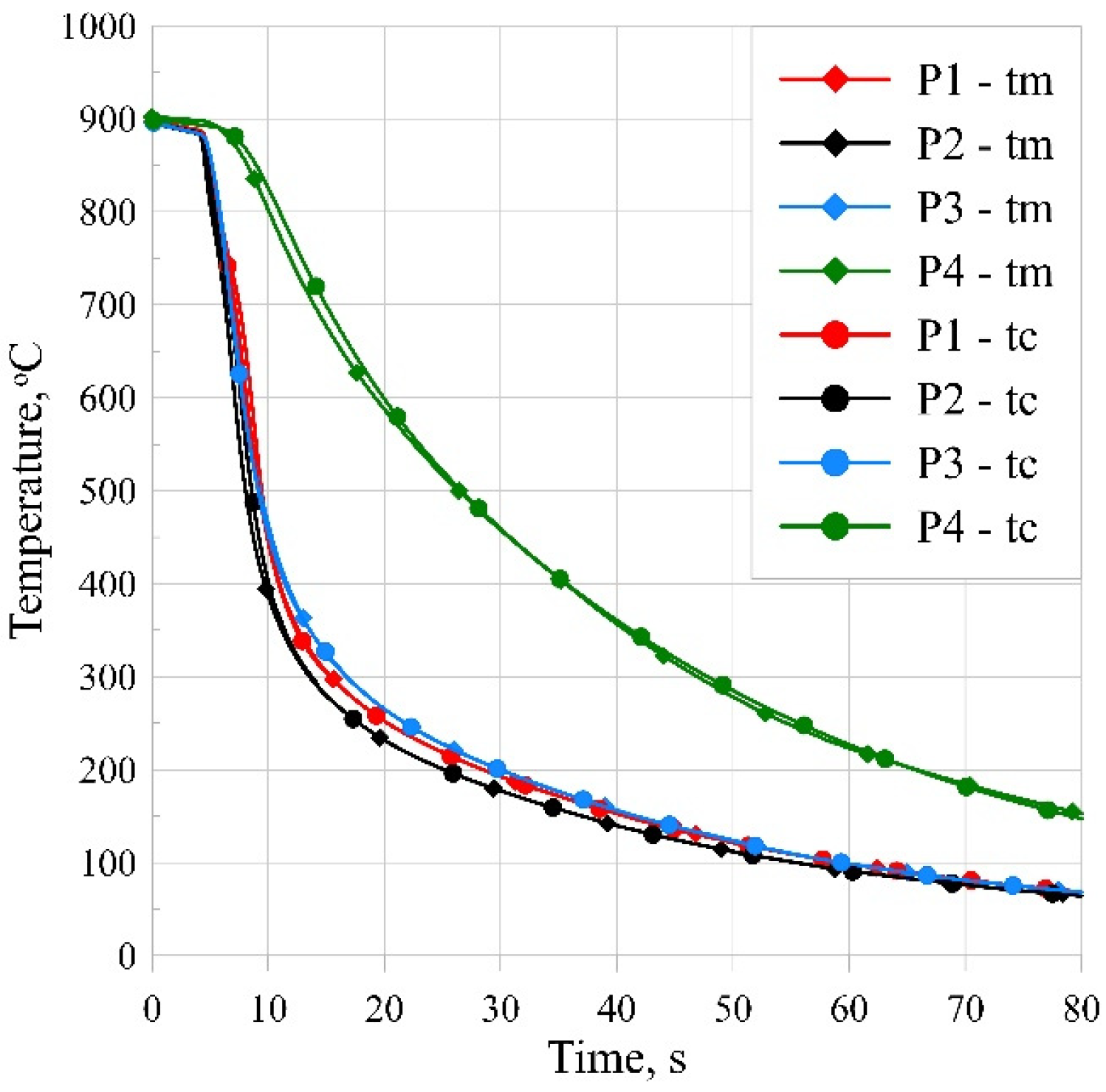

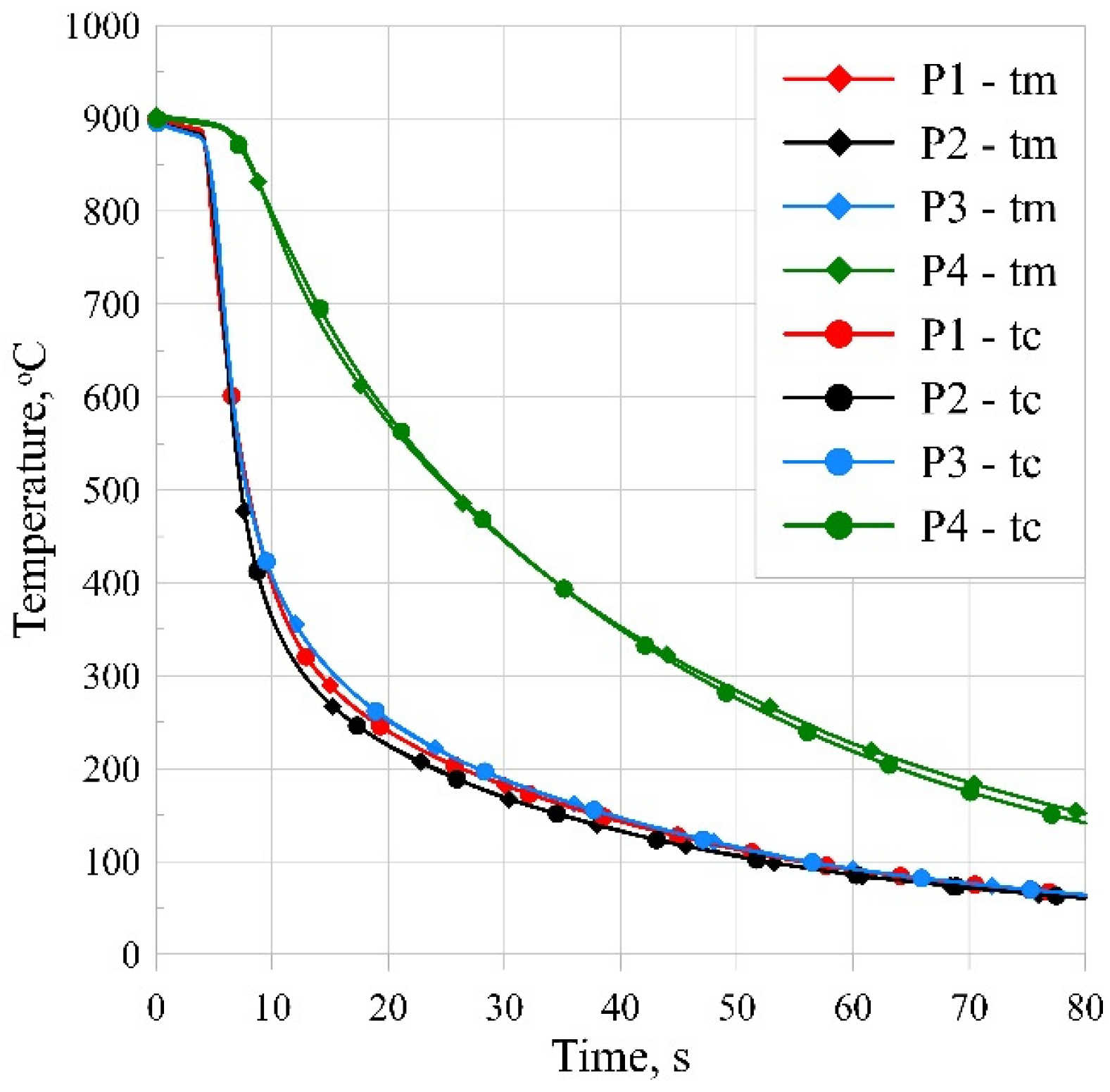

3.1. The Accuracy of the Inverse Calculations

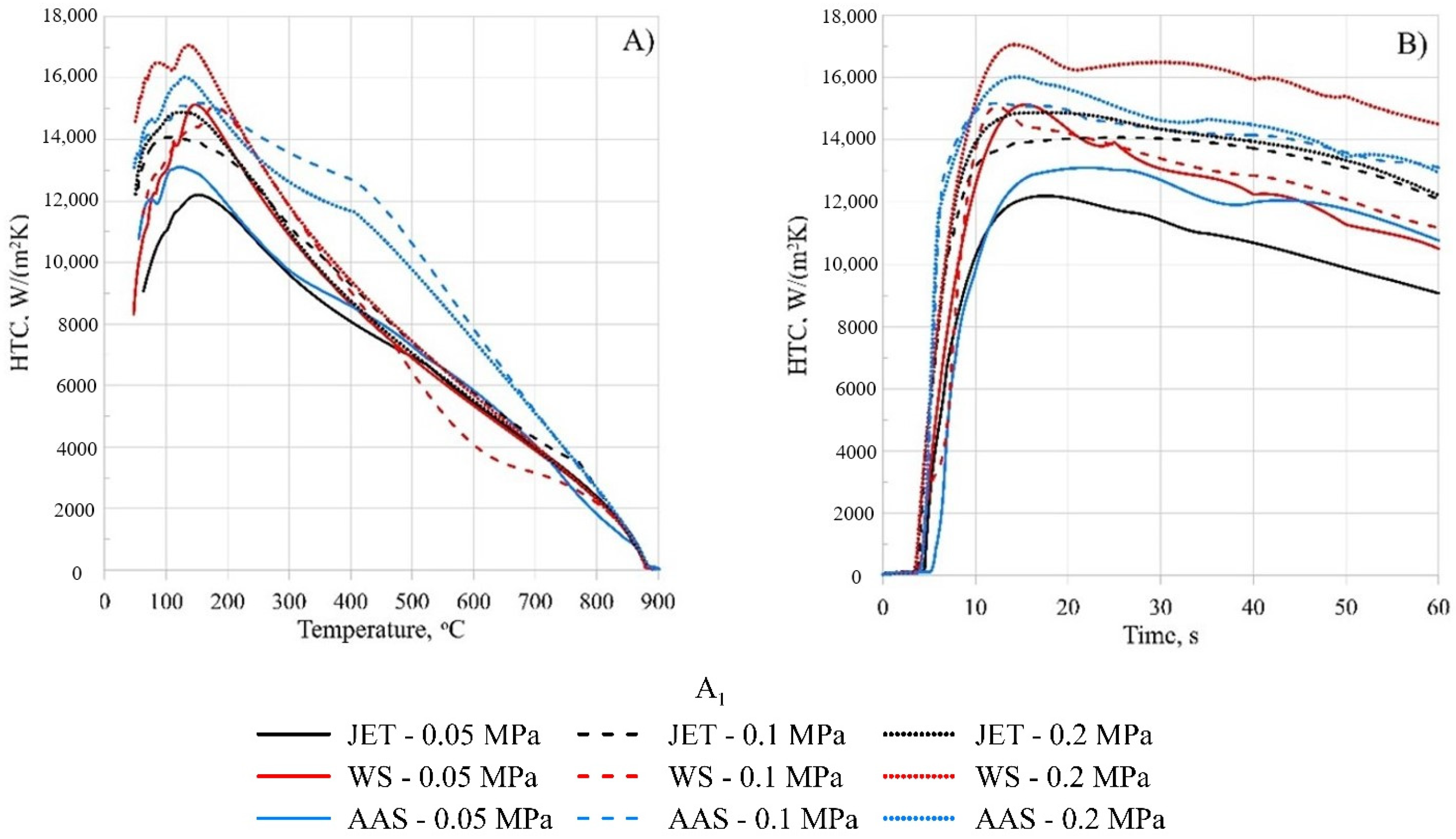

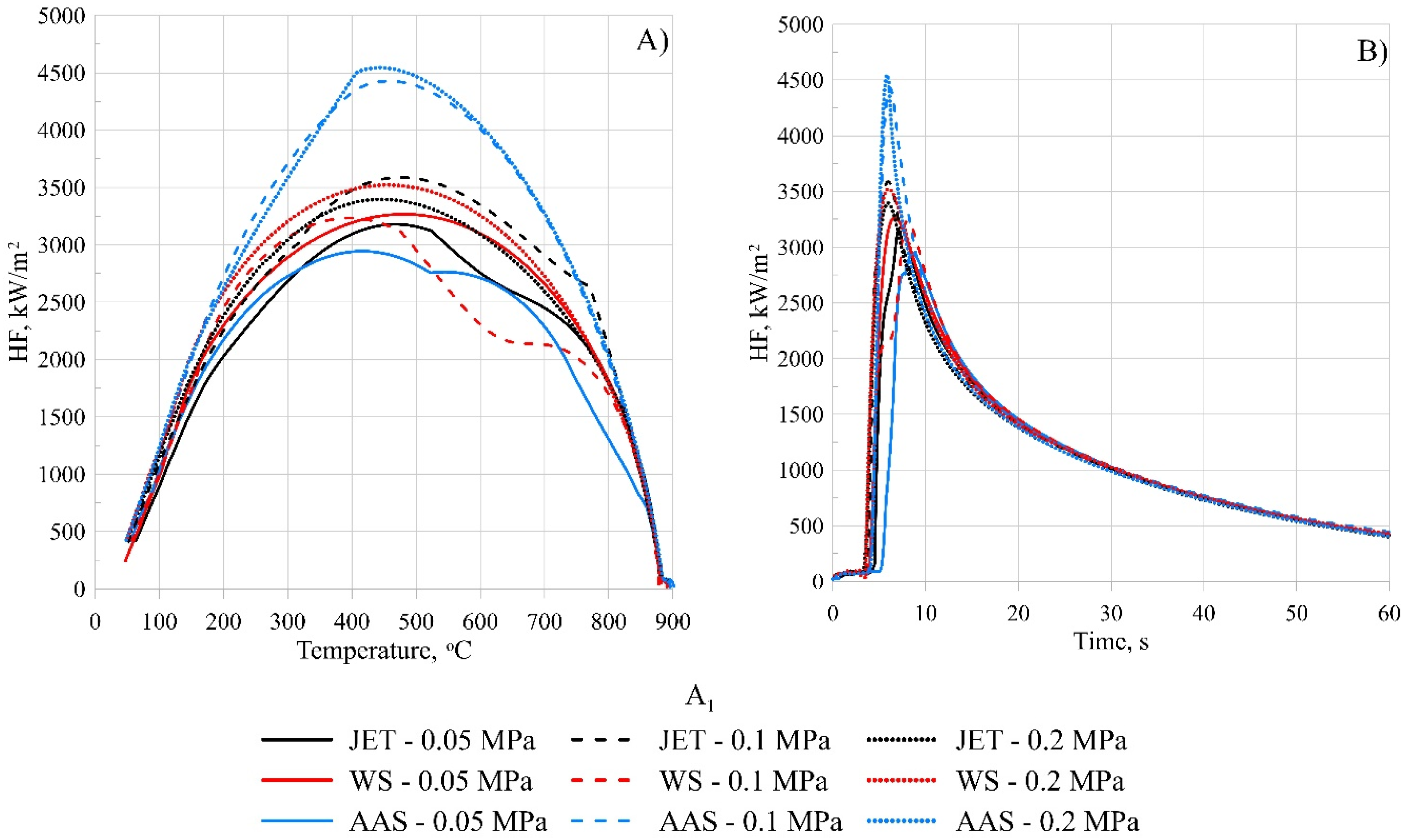

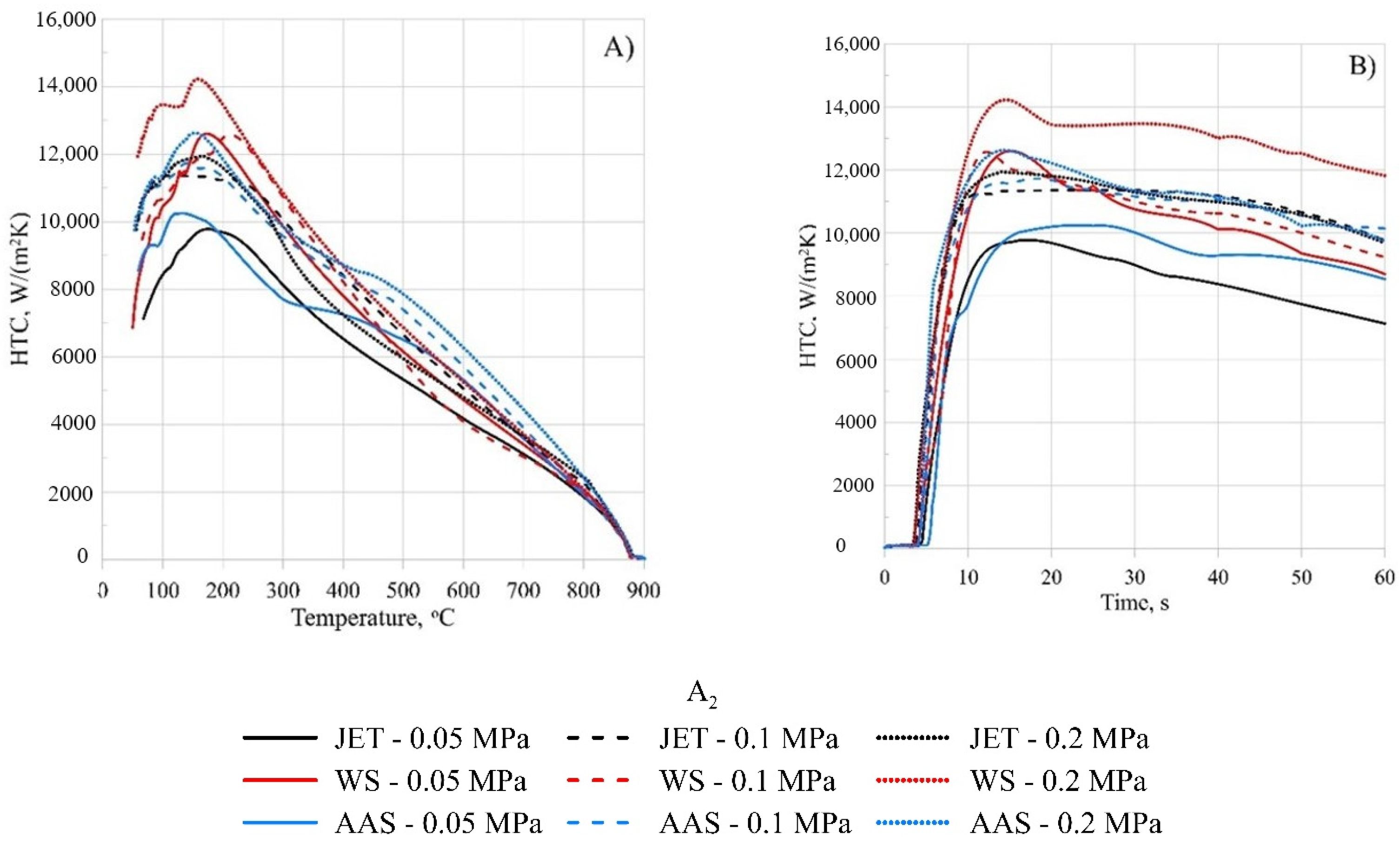

3.2. Comparison of Average Values of HTC and HF on the Cooled Surface

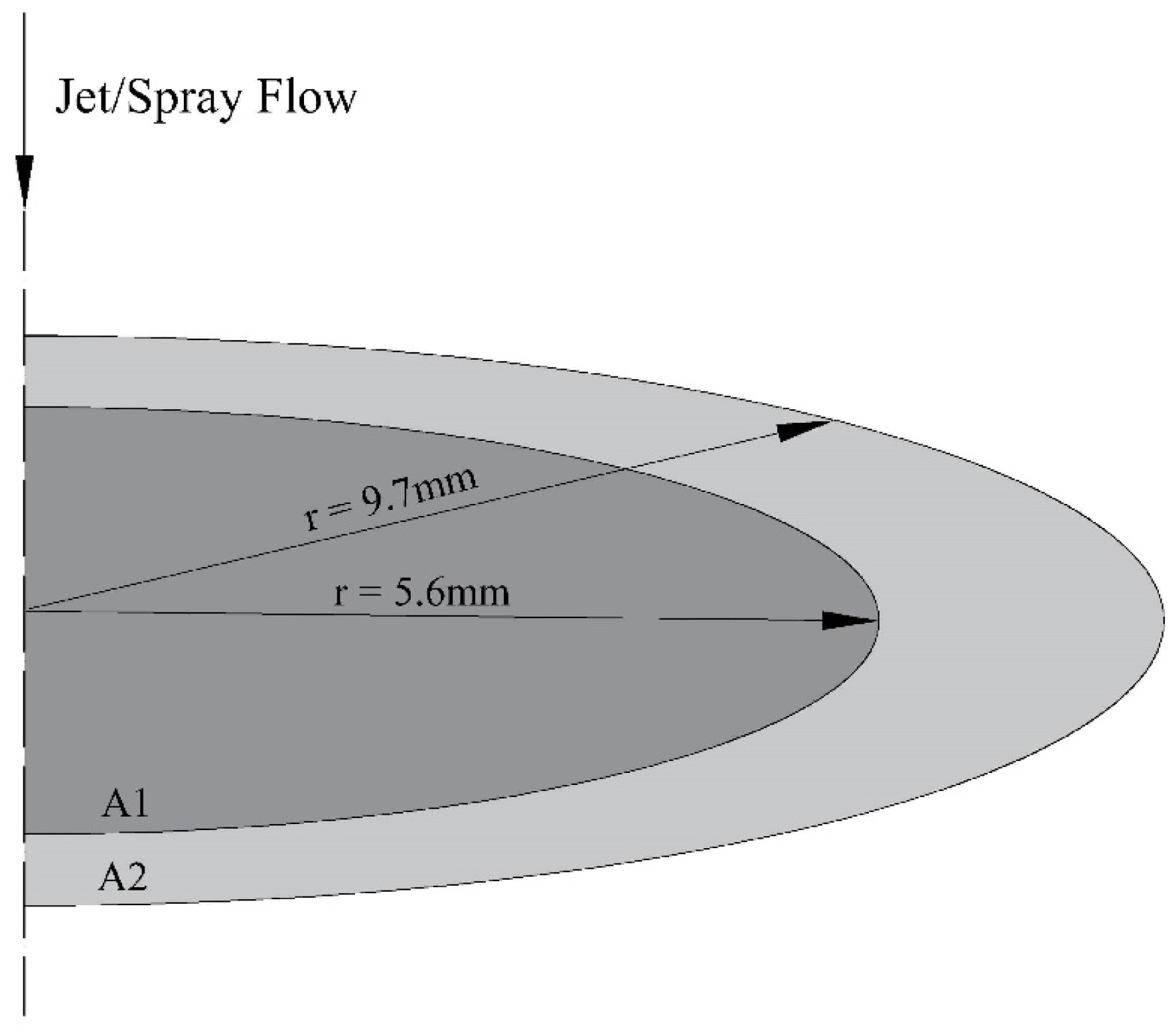

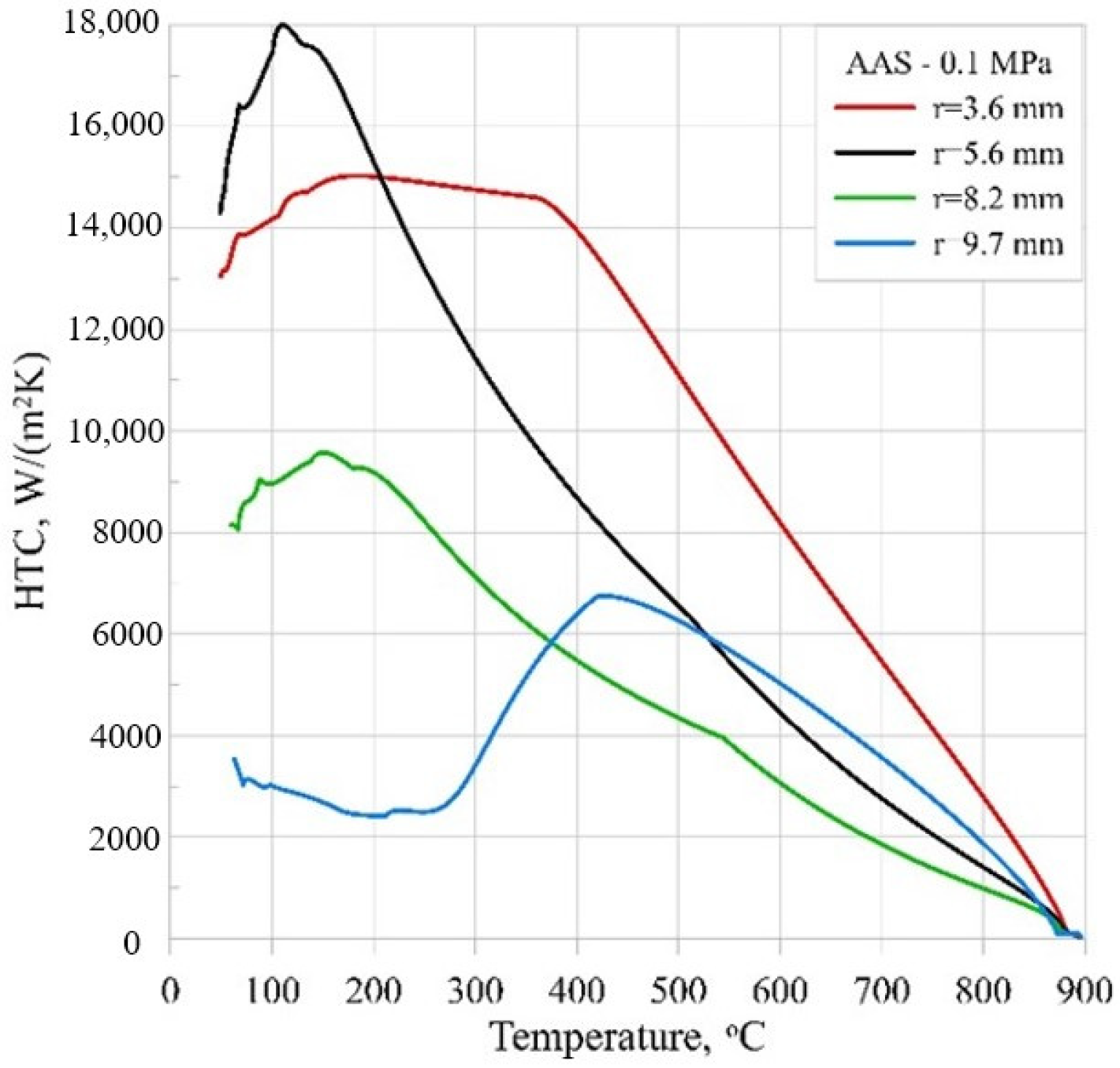

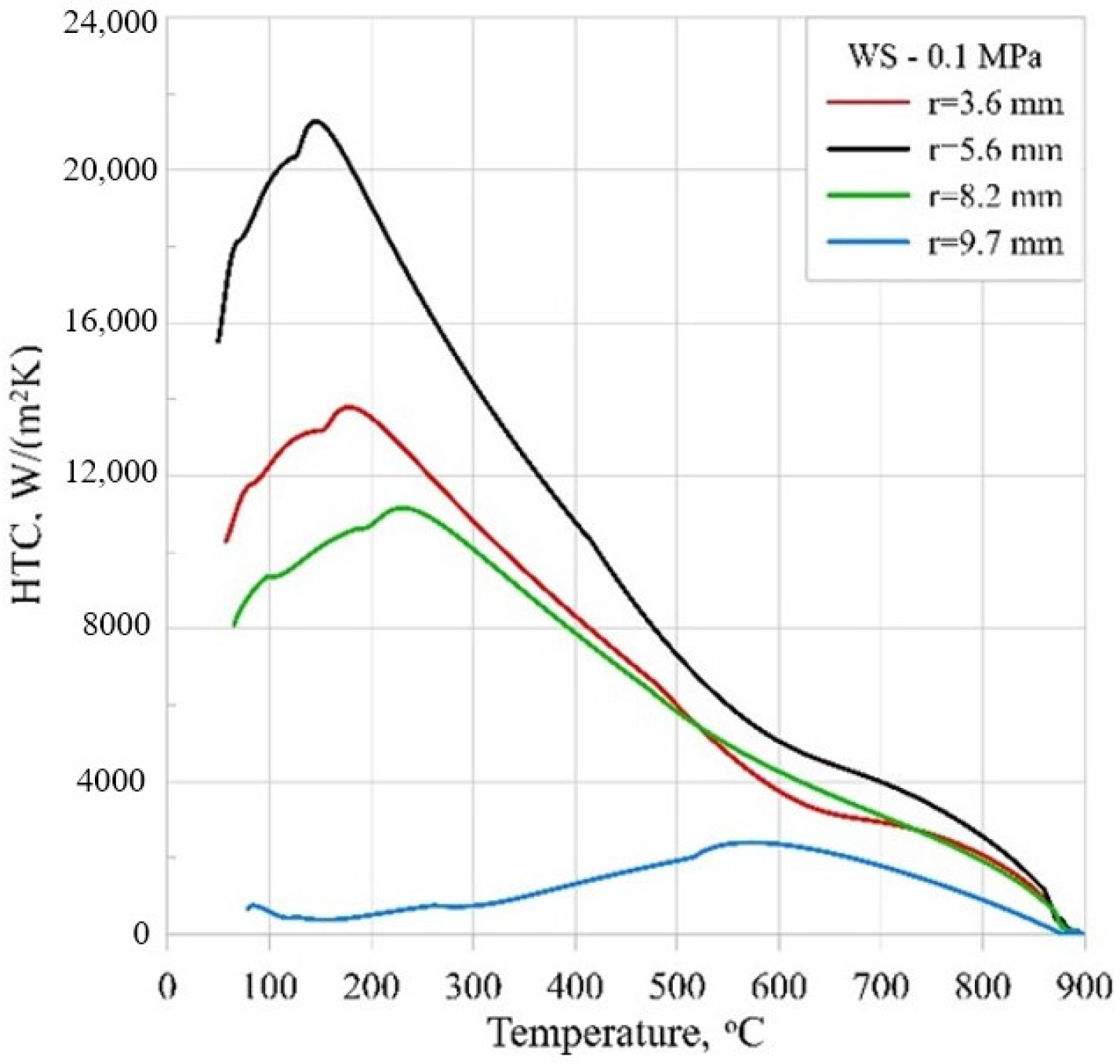

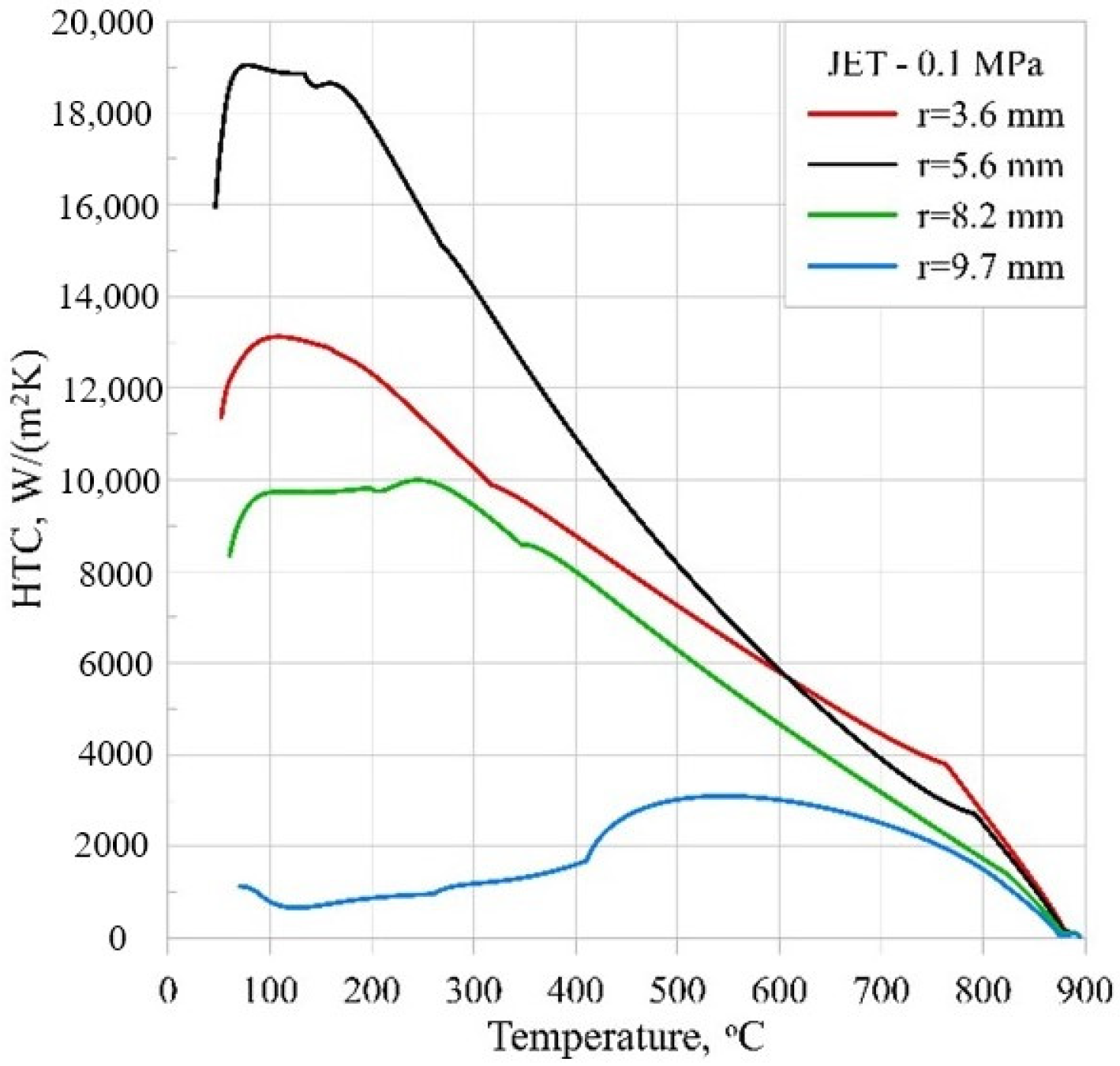

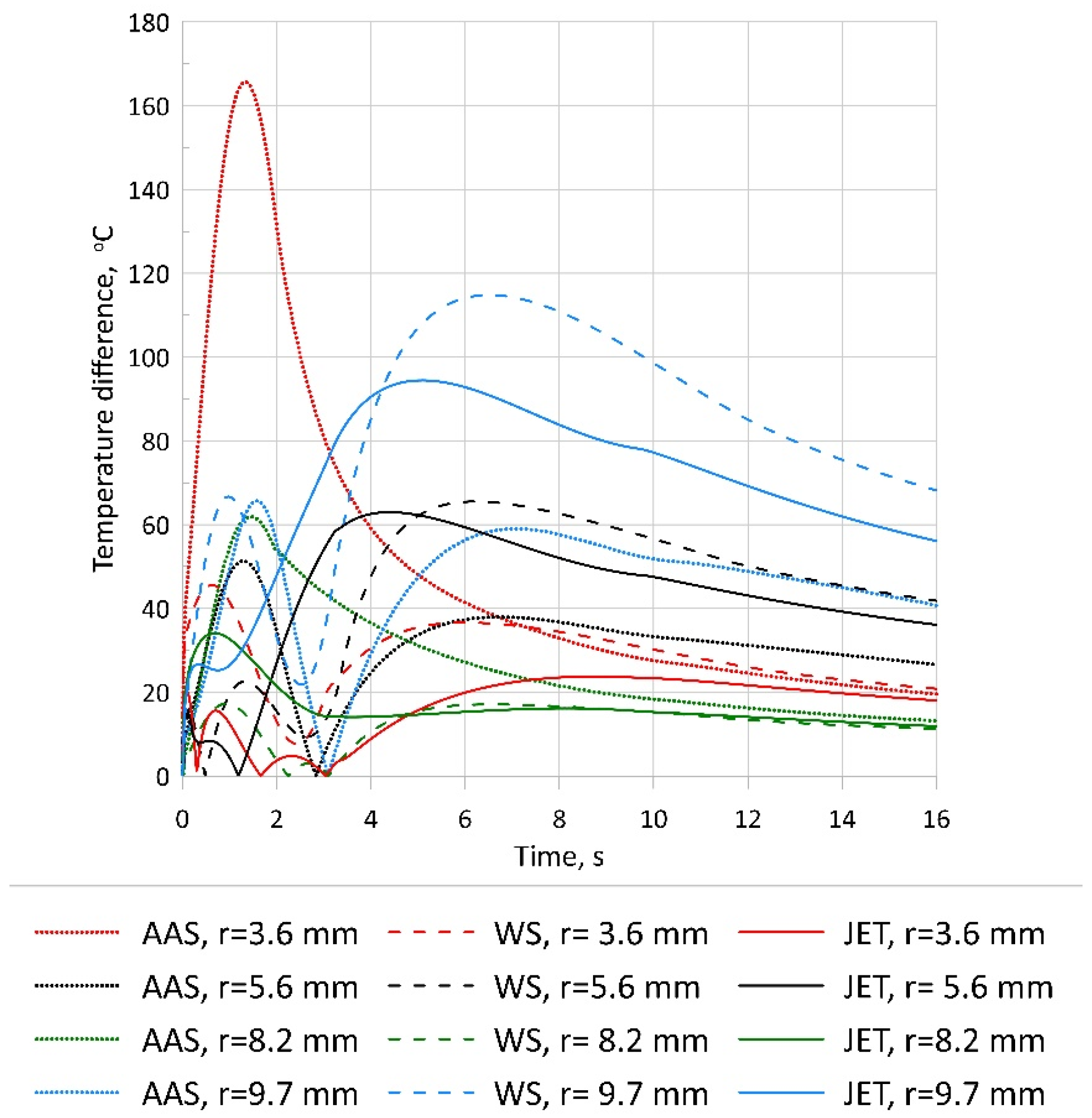

3.3. Cooling Uniformity

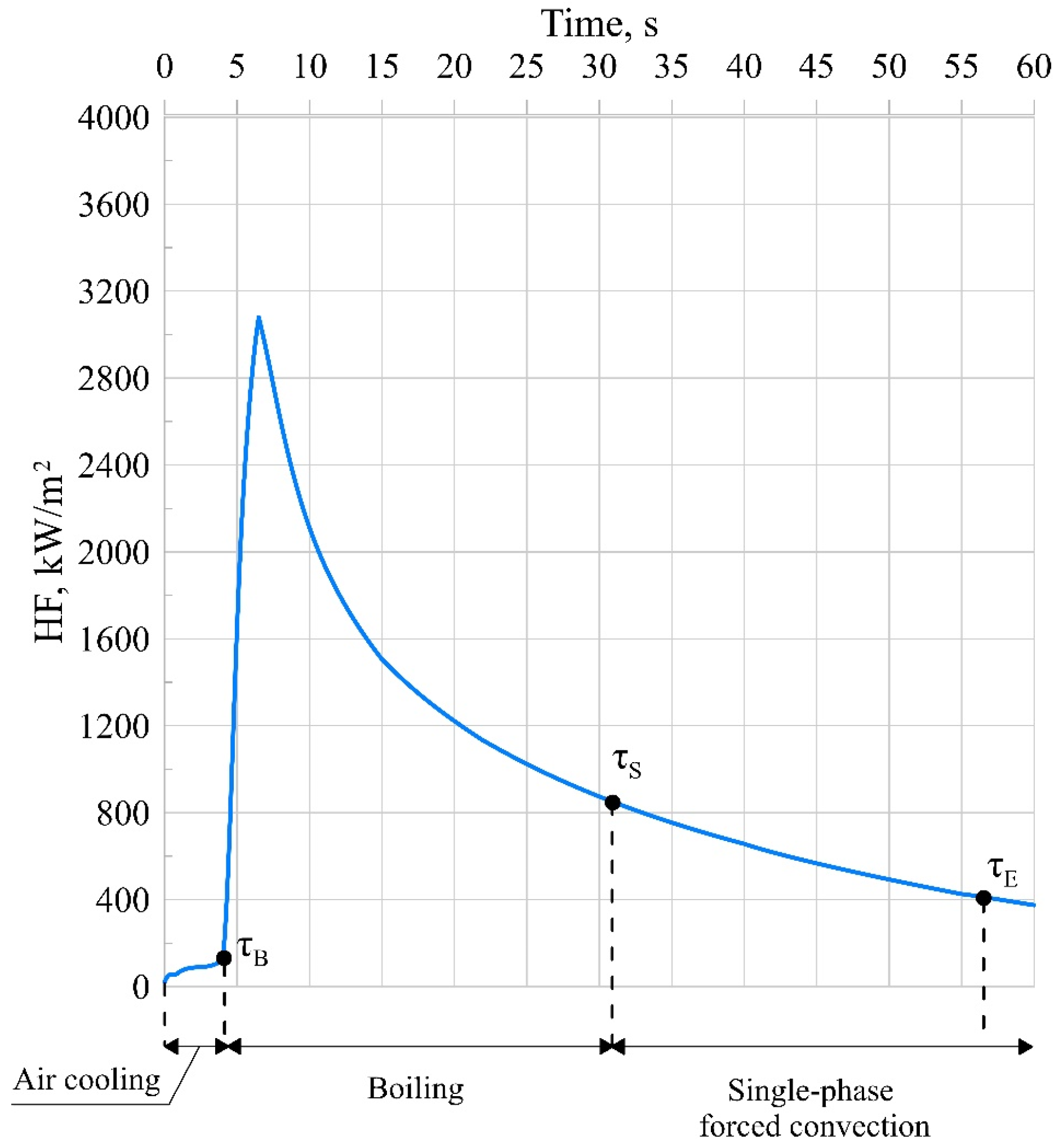

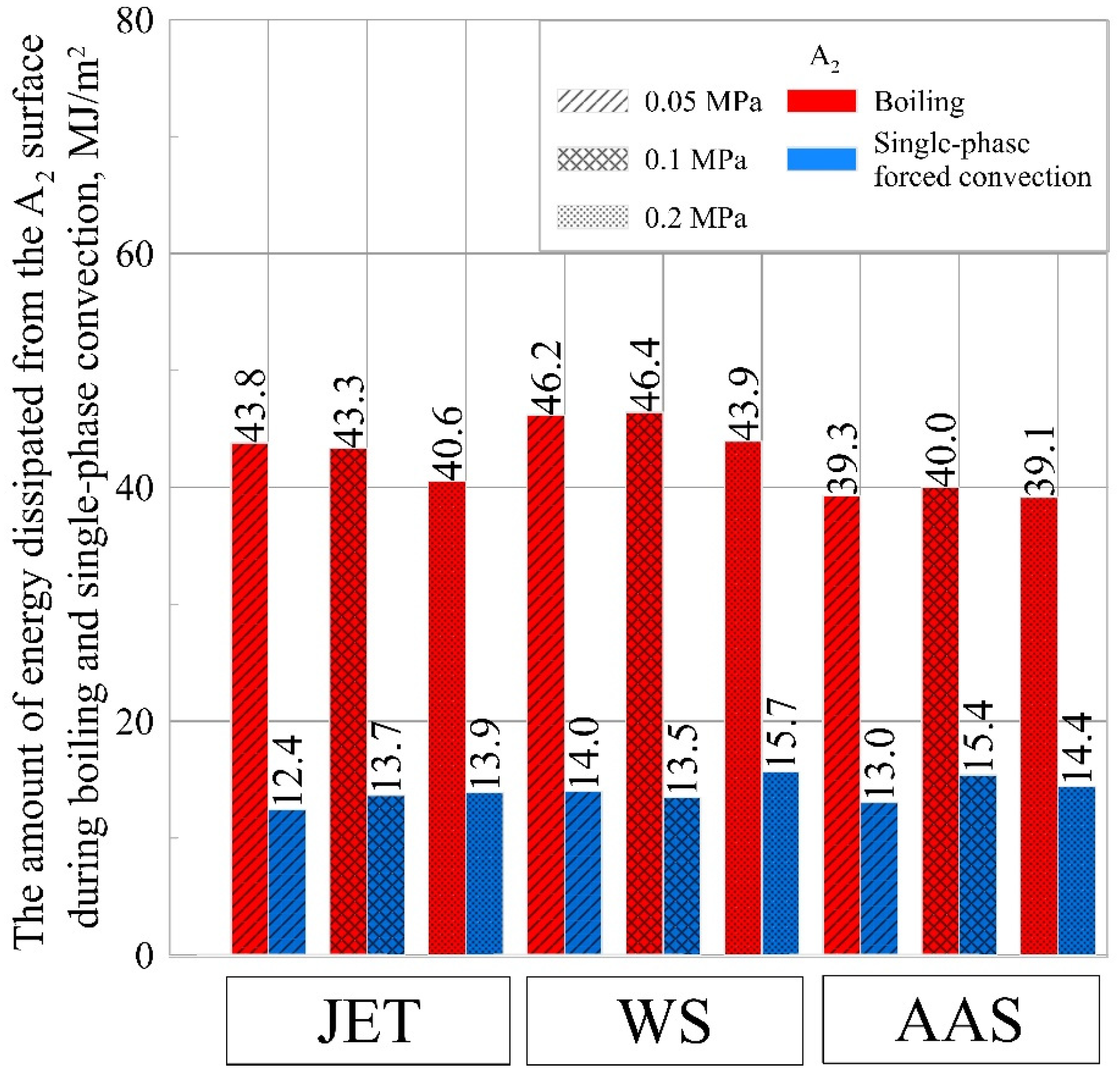

3.4. Comparison of the Amount of Energy Dissipating from the Surface During Boiling and Forced Single-Phase Convection

- τB—time to start boiling, s;

- τS—time in which the cooled surface to reach the temperature of 100 °C, s.

- The amount of energy dissipating from a cooled surface caused by single-phase cooling was calculated using Formula (36):

- τE—time of single-phase cooling ending, s.

4. Conclusions

- The analyzed systems did not allow for obtaining a homogeneous distribution of the HTC on the surface. The smallest maximum differences in HTC distribution were obtained for the AAS system (11,200 W/m2K).

- The ability of the fluid to dissipate heat from the surface was the highest for the AAS system and it increased with increasing water pressure (the increase in pressure from 0.1 MPa to 0.2 MPa caused an over 47% increase in the ability of water to dissipate heat). For the other considered systems, the relationship was reversed.

- The highest amount of heat dissipating from the surface in the boiling range was obtained for the WS cooling system. A 17.55% increase in the amount of heat dissipating from the surface at a pressure of 0.05 MPa, a 16% increase at a pressure of 0.1 MPa and a 12.28% increase at a pressure of 0.2 MPa were achieved compared to the amount of heat dissipating during AAS-cooling. The obtained result was influenced by the low thermal conductivity of the tested material and material thickness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nukiyama, S. The maximum and minimum values of the heat Q transmitted from metal to boiling water under atmospheric pressure. Int. J. Heat Mass Transf. 1966, 9, 1419–1433. [Google Scholar] [CrossRef]

- Karwa, N.; Gambaryan-Roisman, T.; Stephan, P.; Tropea, C. Experimental investigation of circular free-surface jet impingement quenching: Transient hydrodynamics and heat transfer. Exp. Therm. Fluid Sci. 2011, 35, 1435–1443. [Google Scholar] [CrossRef]

- Karwa, N.; Schmidt, L.; Stephan, P. Hydrodynamics of quenching with impinging free surface jet. Int. J. Heat Mass Transf. 2012, 55, 3677–3685. [Google Scholar] [CrossRef]

- Kim, T.; Oh, D.W.; Do, K.H.; Park, J.M.; Lee, J. Effect of initial temperature of a cylindrical steel block on heat transfer characteristics of staggered array jets during water jet quenching. Heat Transf. Eng. 2015, 36, 1037–1045. [Google Scholar] [CrossRef]

- Cebo-Rudnicka, A.; Malinowski, Z.; Buczek, A. The influence of selected parameters of spray cooling and thermal conductivity on heat transfer coefficient. Int. J. Therm. Sci. 2016, 110, 52–64. [Google Scholar] [CrossRef]

- Ali, K.; Amna, R.; Usman, M.; Malik, M.I.; Kim, K. An investigation of the influence of surface roughness, water quality and nozzle on spray cooling of Aluminum alloy 6082. Therm. Sci. Eng. Prog. 2019, 10, 280–286. [Google Scholar] [CrossRef]

- Xu, R.; Li, L.; Zhang, L.; Zhu, B.; Liu, X.; Bu, X. Influence of pressure and surface roughness on the heat transfer efficiency during water spray quenching of 6082 aluminum alloy. J. Mater. Process. Technol. 2014, 214, 2877–2883. [Google Scholar] [CrossRef]

- Cebo-Rudnicka, A.; Hadała, B.; Szajding, A.; Jasiewicz, E. Investigation of the impact of the spray cooling process using various spray nozzles on the unevenness of energy transfer from the metal surface. Int. Commun. Heat Mass Transf. 2024, 155, 107501. [Google Scholar] [CrossRef]

- Jasiewicz, E.; Hadała, B.; Kubaszek, T.; Kościelniak, B.; Cebo-Rudnicka, A.; Dychtoń, K.; Pędrak, P. The influence of MCrAlY coating application and its thickness on the heat transfer during water spray cooling. Int. J. Heat Mass Transf. 2024, 220, 124985. [Google Scholar] [CrossRef]

- Cebo-Rudnicka, A.; Hadała, B. Investigation of the influence of including or omitting the oxide layer on the result of identifying the local boundary condition during water spray cooling. Coatings 2024, 14, 884. [Google Scholar] [CrossRef]

- Panda, A.; Pati, A.R.; Pradhan, S.; Saha, B.; Kumar, A.; Mohapatra, S.S. High mass flux air atomized spray with subcooled water: A novel methodology to enhance the heat transfer rate in film boiling regime. Int. J. Heat Mass Transf. 2018, 120, 1287–1304. [Google Scholar] [CrossRef]

- Puschmann, F.; Specht, E. Transient measurement of heat transfer in metal quenching with atomized sprays. Exp. Therm. Fluid Sci. 2004, 28, 607–615. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, Z.; Dou, R.; Zhou, G.; Zhang, F. Experimental study of the air-atomized spray cooling of high-temperature metal. Appl. Therm. Eng. 2014, 71, 43–55. [Google Scholar] [CrossRef]

- Hauksson, A.T.; Fraser, D.; Prodanovic, V.; Samarasekera, I. Experimental study of boiling heat transfer during subcooled water jet impingement on flat steel surface. Ironmak. Steelmak. 2004, 31, 51–56. [Google Scholar] [CrossRef]

- Sikdar, S.; Mukhopadhyay, A. Numerical determination of heat transfer coefficient for boiling phenomenon at runout table of hot strip mill. Ironmak. Steelmak. 2004, 31, 495–502. [Google Scholar] [CrossRef]

- Yang, L.; Ren, J.; Jiang, H.; Ligrani, P. Experimental and numerical investigation of unsteady impingement cooling within a blade leading edge passage. Int. J. Heat Mass Transf. 2014, 71, 57–68. [Google Scholar] [CrossRef]

- Telejko, T. Chłodzenie Powierzchni Metali za Pomocą Cieczy w Warunkach Wysokich Temperature; Wydawnictwa AGH: Kraków, Poland, 2016. [Google Scholar]

- Chen, H.; Cheng, W.-l.; Zhang, W.-w.; Peng, Y.-h.; Jiang, L.-j. Energy saving evaluation of a novel energy system based on spray cooling for supercomputer centre. Energy 2017, 141, 304–315. [Google Scholar] [CrossRef]

- Li, B.Q.; Cader, T.; Schwarzkopf, J.; Okamoto, K.; Ramaprian, B. Spray angle effect during spray cooling of microelectronics: Experimental measurements and comparison with inverse calculations. Appl. Therm. Eng. 2006, 26, 1788–1795. [Google Scholar] [CrossRef]

- Panão, M.R.O.; Guerreiro, J.P.P.V.; Moreira, A.L.N. Microprocessor cooling based on an intermittent multijet spray system. Int. J. Heat Mass Transf. 2012, 55, 2854–2863. [Google Scholar] [CrossRef]

- Feng, S.; Hu, W.; Li, D. The Experimental Study on the Spray Cooling Device of Domestic Air Conditioning in Beijing Area. Procedia Eng. 2017, 205, 1034–1041. [Google Scholar] [CrossRef]

- Bandaru, S.V.R.; Villanueva, W.; Thakre, S.; Bechta, S. Multi-nozzle spray cooling of a reactor pressure vessel steel plate for the application of ex-vessel cooling. Nucl. Eng. Des. 2021, 375, 111101. [Google Scholar] [CrossRef]

- Anglart, H.; Alavyoon, F.; Novarini, R. Study of spray cooling of a pressure vessel head of a boiling water reactor. Nucl. Eng. Des. 2010, 240, 252–257. [Google Scholar] [CrossRef]

- Abdolzadeh, M.; Ameri, M. Improving the effectiveness of a photovoltaic water pumping system by spraying water over the front of photovoltaic cells. Renew. Energy 2009, 34, 91–96. [Google Scholar] [CrossRef]

- Hadipour, A.; Zargarabadi, M.R.; Rashidi, S. An efficient pulsed- spray water cooling system for photovoltaic panels: Experimental study and cost analysis. Renew. Energy 2021, 164, 867–875. [Google Scholar] [CrossRef]

- Sun, Y.; Guan, Z.; Gurgenci, H.; Hooman, K.; Li, X. Investigations on the influence of nozzle arrangement on the pre-cooling effect for the natural draft dry cooling tower. Appl. Therm. Eng. 2018, 130, 979–996. [Google Scholar] [CrossRef]

- Sun, Y.; Guan, Z.; Gurgenci, H.; Hooman, K.; Li, X.; Xia, L. Investigation on the influence of injection direction on the spray cooling performance in natural draft dry cooling tower. Int. J. Heat Mass Transf. 2017, 110, 113–131. [Google Scholar] [CrossRef]

- de Oliveira, M.; Ward, J.; Garwood, D.R.; Wallis, R.A. Quenching of Aerospace Forgings from High Temperatures Using Air-Assisted, Atomized Water Sprays. J. Mater. Eng. Perform. 2002, 11, 80–85. [Google Scholar] [CrossRef]

- Alam, M.S.U.; Karachi, I.; Specht, I.E.; Schmidt, I.J.; Müller, R. Experimental Study of Local Heat Transfer During Quenching of Metals by Spray and Multiple Jets. Ph.D. Thesis, Otto-von-Guericke-Universität Magdeburg, Magdeburg, Germany, 1978. [Google Scholar]

- Labergue, A.; Gradeck, M.; Lemoine, F. Comparative study of the cooling of a hot temperature surface using sprays and liquid jets, Int. J. Heat Mass Transf. 2015, 81, 889–900. [Google Scholar] [CrossRef]

- Jasiewicz, E.; Hadała, B.; Cebo-Rudnicka, A.; Malinowski, Z.; Jasiewicz, K. Comparison of the Heat Transfer Efficiency of Selected Water Cooling Systems. In Proceedings of the 15th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics (HEFAT 2021), Online, 26–28 July 2021. [Google Scholar]

- Promat, Product Data Sheet PROMAFORM-1260. Available online: https://image.propec.cz/promat/technicke-listy/TL-AJ_PROMAFORM-1260.pdf (accessed on 1 November 2024).

- Polish norm PN-EN 60584-2: 1997; Thermocouples. Tolerances. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Hottinger Baldwin Messtechnik, Datasheet of MGCplus Device. Available online: https://image.makewebeasy.net/makeweb/0/j0C8v2QY1/Document/MGCplus_Data_Sheet.pdf?v=202012190947 (accessed on 1 November 2024).

- Szydłowski, H. Teoria Pomiarów; book; PWN: Warszawa, Poland, 1978. [Google Scholar]

- Bąk, J.; Bąk-Gajda, D. Wybrane czynniki psychologiczne wpływające na czas reakcji kierowcy. Zesz. Nauk. Inst. Pojazdów/Politech. Warsz. 2013, 5, 21–29. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method, Fifth., 1: The Basis; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Telejko, T.; Malinowski, Z. Application of an inverse solution to the thermal conductivity identification using the finite element method. J. Mater. Process. Technol. 2004, 146, 145–155. [Google Scholar] [CrossRef]

- Malinowski, Z.; Hadała, B.; Cebo-Rudnicka, A. Inverse solutions to a vertical plate cooling in air—A comparative study. Int. J. Heat Mass Transf. 2022, 188, 122636. [Google Scholar] [CrossRef]

- Kręglewski, T.; Rogowski, T.; Ruszczyński, A.; Szymanowski, J. Metody Optymalizacji w Języku FORTRAN; Wydawnictwo Naukowe PWN: Warszawa, Poland, 1984. [Google Scholar]

- Goldfarb, D. A family of variable-metric methods derived by variational means. Math. Comput. 1970, 24, 23–26. [Google Scholar] [CrossRef]

- Flether, R. A new approach to variable metric algorithms. Comput. J. 1970, 13, 317–322. [Google Scholar] [CrossRef]

- Shanno, D.F. Conditioning of Quasi-Newton Methods for Function Minimization. Math. Comput. 1970, 24, 647–656. [Google Scholar] [CrossRef]

- Broyden, C.G. The convergence of a class of double-rank minimization algorithms: 2. The new algorithm. J. Inst. Math. Its Appl. 1970, 6, 222–231. [Google Scholar] [CrossRef]

- Malinowski, Z. Numeryczne Modele w Przeróbce Plastycznej i Wymianie Ciepła; AGH Uczelniane Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2005. [Google Scholar]

- Bibus Metals, Data Sheet for Inconel 600. Available online: https://www.bibusmetals.pl/fileadmin/editors/countries/bmpl/Data_sheets/Inconel_600_karta_katalogowa.pdf (accessed on 1 November 2024).

- Schwerdtfeger, K. The Making, Shaping and Treating of Steel, 11th ed.; AISE Steel Foundation: Pittsburgh, PA, USA, 2003. [Google Scholar]

- Choi, J.W.; Choi, J.W. Convective Heat Transfer Coefficient for High Pressure Water Jet. ISIJ Int. 2002, 42, 283–289. [Google Scholar] [CrossRef]

- Schmidt, J.; Boye, H. Influence of velocity and size of the droplets on the heat transfer in spray cooling. Chem. Eng. Technol. 2001, 24, 255–260. [Google Scholar] [CrossRef]

- Panda, A.; Kumar, A.; Mohapatra, S.S. Water soluble polymer added high mass flux spray: A novel approach for the attainment of enhanced heat transfer rate in transition boiling regime. Int. J. Heat Mass Transf. 2020, 157, 119838. [Google Scholar] [CrossRef]

- Malinowski, Z.; Telejko, T.; Hadała, B.; Cebo-Rudnicka, A.; Szajding, A. Dedicated three dimensional numerical models for the inverse determination of the heat flux and heat transfer coefficient distributions over the metal plate surface cooled by water. Int. J. Heat Mass Transf. 2014, 75, 347–361. [Google Scholar] [CrossRef]

| Type of Cooling | Pressure, MPa | Total Cooling Time, s | Initial Temperature of the Sensor, °C |

|---|---|---|---|

| JET | 0.05 | 70 | 895 |

| 0.1 | 80 | 895 | |

| 0.2 | 80 | 895 | |

| WS | 0.05 | 80 | 893 |

| 0.1 | 80 | 896 | |

| 0.2 | 65 | 891 | |

| AAS | 0.05 | 80 | 903 |

| 0.1 | 80 | 898 | |

| 0.2 | 80 | 900 |

| Type of Cooling | Pressure, MPa | Average Water Flux Density, m3/(m2∙s) | Accuracy of the Water Flux Density Measurement, m3/(m2∙s) | Relative Error of the Water Flux Density Measurement δ, % |

|---|---|---|---|---|

| JET | 0.05 | 62.27∙10−3 | 5.43∙10−3 | 7.95 |

| 0.1 | 95.86∙10−3 | 8.67∙10−3 | 9.04 | |

| 0.2 | 143.31∙10−3 | 17.05∙10−3 | 11.90 | |

| WS | 0.05 | 35.26∙10−3 | 1.89∙10−3 | 5.36 |

| 0.1 | 43.72∙10−3 | 2.43∙10−3 | 5.56 | |

| 0.2 | 44.38∙10−3 | 2.83∙10−3 | 6.38 | |

| AAS | 0.05 | 21.38∙10−3 | 1.30∙10−3 | 6.08 |

| 0.1 | 28.24∙10−3 | 1.63∙10−3 | 5.77 | |

| 0.2 | 22.47∙10−3 | 1.36∙10−3 | 6.05 |

| No. | Type of Cooling | Pressure, MPa | Average Error of Temperature Calculations, K |

|---|---|---|---|

| 1 | JET | 0.05 | 0.1 |

| 2 | 0.1 | 0.5 | |

| 3 | 0.2 | 0.9 | |

| 4 | WS | 0.05 | 0.3 |

| 5 | 0.1 | 0.6 | |

| 6 | 0.2 | 0.4 | |

| 7 | 0.05 | 0.9 | |

| 8 | AAS | 0.1 | 0.5 |

| 9 | 0.2 | 0.4 |

| Type of Cooling | Pressure, MPa | τS, s | Temperature at Point P4 Obtained at Time τS, °C | τE, s | Temperature at Point P4 Obtained at Time τE, °C |

|---|---|---|---|---|---|

| AAS | 0.05 | 34 | 422.3 | 59 | 237.6 |

| 0.1 | 30 | 447.8 | 56 | 254.5 | |

| 0.2 | 29 | 423.0 | 53 | 253.9 | |

| WS | 0.05 | 36 | 390.3 | 65 | 214.2 |

| 0.1 | 36 | 391.9 | 62 | 213.8 | |

| 0.2 | 30 | 430.7 | 56 | 242.1 | |

| JET | 0.05 | 39 | 372.4 | 68 | 197.9 |

| 0.1 | 32 | 417.9 | 57 | 245.2 | |

| 0.2 | 30 | 433.4 | 54 | 252.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasiewicz, E.; Hadała, B.; Cebo-Rudnicka, A.; Malinowski, Z.; Jasiewicz, K.; Svyetlichnyy, D. Heat Transfer Efficiency While Cooling with a Water Spray, Air-Assisted Water Spray and Water Jet Under Boiling and Single-Phase Forced Convection Conditions. Appl. Sci. 2024, 14, 10428. https://doi.org/10.3390/app142210428

Jasiewicz E, Hadała B, Cebo-Rudnicka A, Malinowski Z, Jasiewicz K, Svyetlichnyy D. Heat Transfer Efficiency While Cooling with a Water Spray, Air-Assisted Water Spray and Water Jet Under Boiling and Single-Phase Forced Convection Conditions. Applied Sciences. 2024; 14(22):10428. https://doi.org/10.3390/app142210428

Chicago/Turabian StyleJasiewicz, Elżbieta, Beata Hadała, Agnieszka Cebo-Rudnicka, Zbigniew Malinowski, Kamil Jasiewicz, and Dmytro Svyetlichnyy. 2024. "Heat Transfer Efficiency While Cooling with a Water Spray, Air-Assisted Water Spray and Water Jet Under Boiling and Single-Phase Forced Convection Conditions" Applied Sciences 14, no. 22: 10428. https://doi.org/10.3390/app142210428

APA StyleJasiewicz, E., Hadała, B., Cebo-Rudnicka, A., Malinowski, Z., Jasiewicz, K., & Svyetlichnyy, D. (2024). Heat Transfer Efficiency While Cooling with a Water Spray, Air-Assisted Water Spray and Water Jet Under Boiling and Single-Phase Forced Convection Conditions. Applied Sciences, 14(22), 10428. https://doi.org/10.3390/app142210428