Thermal Stress Analysis of Maxillary Dentures with Different Reinforcement Materials Under Occlusal Load Using Finite Element Method

Abstract

1. Introduction

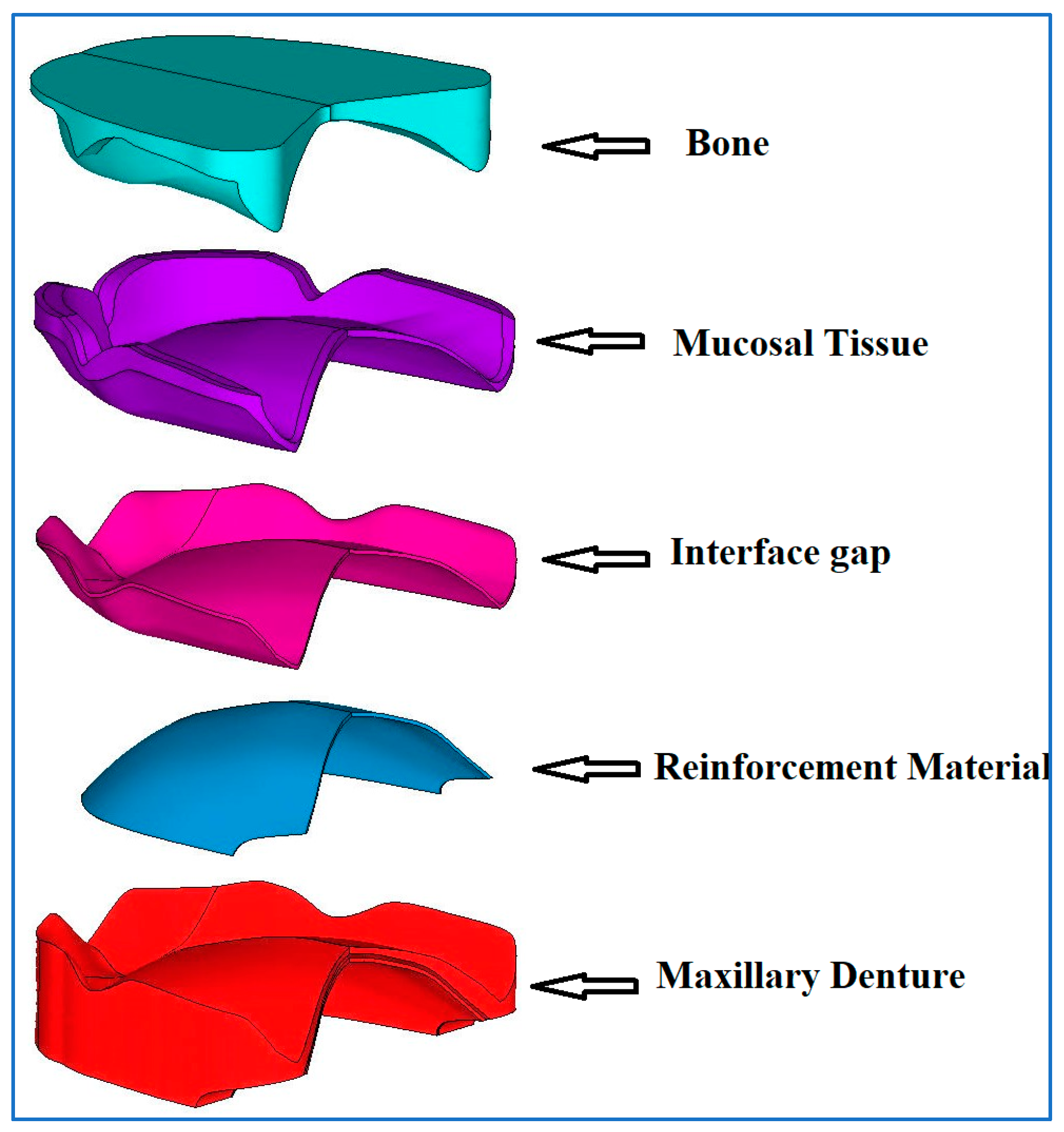

2. Materials and Methods

3. Results

3.1. Stress Analysis of Maxillary Denture Under Only Temperature Change

3.2. Stress Distributions Under Only 230 N Load

3.3. Stress Distributions Under Both Temperature Change and Occlusal Force of 230 N

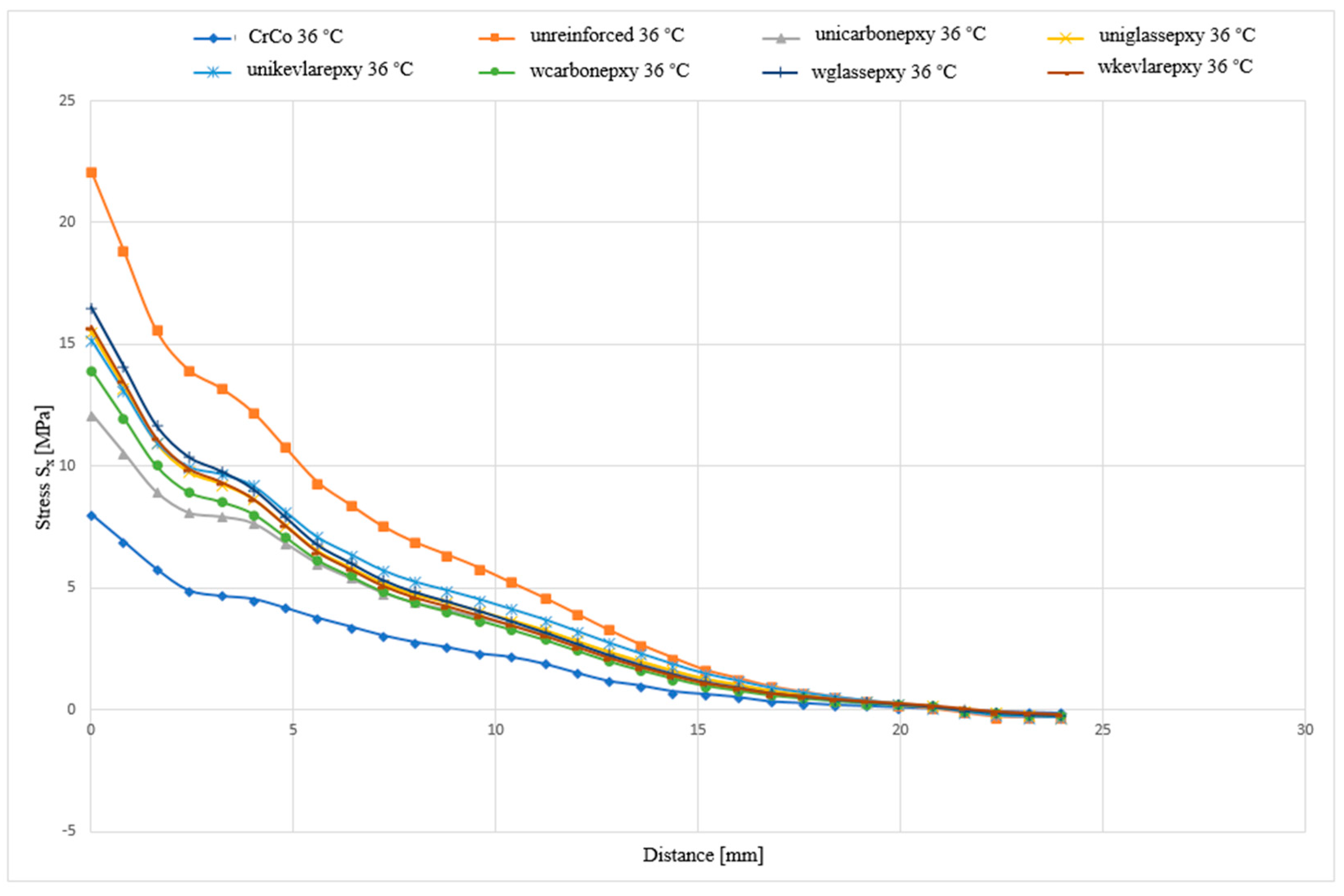

3.4. Stress Analysis in Critical Notchs of the Dentures Under 230 N and Thermal Loading

3.5. Failure Analysis of Reinforcement Materials

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khindria, S.K.; Mittal, S.; Sukhija, U. Evolution of denture base materials. J. Indian Prosthodont. Soc. 2009, 9, 64–69. [Google Scholar]

- Cheng, Y.Y.; Li, J.Y.; Fok, S.L.; Cheung, W.L.; Chow, T.W. 3D FEA of High-Performance Polyethylene Fiber Reinforced Maxillary Dentures. Dent. Mater. 2010, 26, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Watts, D.C. The effect of reinforcement with woven E-glass fibers on the impact strength of complete dentures fabricated with high-impact acrylic resin. J. Prosthet. Dent. 2003, 91, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Lee, Y.; Oh, S.; Cho, H.; Oda, Y.; Bae, J. Reinforcing effects of different fibers on denture base resin based on the fiber type, concentration and combination. Dent. Mater. J. 2012, 31, 1039–1046. [Google Scholar] [CrossRef] [PubMed]

- Uzun, G.; Hersek, N.; Tinçer, T. Effect of five woven fiber reinforcements on the impact and transverse strength of a denture base resin. J. Prosthet. Dent. 1999, 81, 616–620. [Google Scholar] [CrossRef]

- Seo, S.R.; Murata, H.; Hong, G.; Vergani, C.E.; Hamada, T. Influence of thermal and mechanical stresses on the strength of intact and relined denture bases. J. Prosthet. Dent. 2006, 96, 60–67. [Google Scholar] [CrossRef]

- John, J.; Gangadhar, S.A.; Shah, I. Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J. Prosthet. Dent. 2001, 86, 424–427. [Google Scholar] [CrossRef]

- Cheng, Y.Y.; Cheung, W.L.; Chow, T.W. Strain Analysis of Maxillary Complete Denture with Three-Dimensional Finite Element Method. J. Prosthet. Dent. 2010, 103, 309–318. [Google Scholar] [CrossRef]

- Jagger, D.C.; Harisson, A.; Jandt, K.D. The Reinforcement of Denture. J. Oral Rehabil. 1999, 26, 185–194. [Google Scholar] [CrossRef]

- Hirajima, Y.; Takahashi, H.; Minakuchi, S. Influence of a denture strengthener on the deformation of a maxillary complete denture. Dent. Mater. J. 2009, 28, 507–512. [Google Scholar] [CrossRef][Green Version]

- Akan, E.; Gungor, M.A.; Yilmaz, G.; Artunc, C.; Benli, S. Stress Analysis of Fiber-reinforced Maxillary Dentures under Different Loadings. J. Reinf. Plast. Compos. 2010, 29, 2961–2974. [Google Scholar] [CrossRef]

- Deboer, J.; Vermilyea, S.G.; Brady, R.E. The effect of carbon fiber orientation on the fatigue resistance and bending properties of two denture resins. J. Prosthet. Dent. 1984, 51, 119–121. [Google Scholar] [CrossRef]

- Yazdanie, N.; Mahood, M. Carbon fiber acrylic resin composite: An investigation of transverse strength. J. Prosthectic Dent. 1985, 54, 543–547. [Google Scholar] [CrossRef]

- Alla, R.K.; Sajjan, S.; Alluri, V.R.; Ginjupalli, K.; Upadhya, N. Influence of Fiber Reinforcement on the Properties of Denture Base Resins. J. Biomater. Nanobiotechnol. 2013, 4, 91–97. [Google Scholar] [CrossRef]

- Grave, A.M.H.; Chandler, H.D.; Woolfaardt, J.F. Denture base acrylic reinforced with high modulus fibre. Dent. Mater. 1985, 1, 185–187. [Google Scholar] [CrossRef]

- Shimizu, H.; İkeda, T.; Wakabayashi, N.; Ohyama, T. Effect of metal strengthener length on stress distribution in acrylic denture bases: A finite element study. J. Oral Rehabil. 2004, 31, 879–883. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Yoshida, K.; Shimizu, H. Effect of location of glass fiber-reinforced composite reinforcement on the flexural properties of a maxillary complete denture in vitro. Inf. Healthc. 2011, 69, 215–221. [Google Scholar]

- Takahashi, T.; Gonda, T.; Maeda, Y. Influence of reinforcing materials on strain of maxillary complete denture. Inf. Healthc. 2013, 71, 307–311. [Google Scholar] [CrossRef]

- Naik, A.V. Complete Denture Fractures: A clinical study. J. Indian Prosthodont. Soc. 2009, 9, 148–150. [Google Scholar] [CrossRef]

- Keyf, F.; Uzun, G. The effect of glass fibre reinforcement on the transverse strength, deflection and modulus of elasticity of repaired acrylic resins. Int. Dent. J. 2000, 50, 93–97. [Google Scholar] [CrossRef]

- Darbar, U.R.; Huggett, R.; Harrison, A. Denture fracture—A survey. Br. Dent. J. 1994, 176, 342–345. [Google Scholar] [CrossRef] [PubMed]

- Prombonas, A.; Vlissidis, D. Effects of the position of artificial teeth and load levels on stress in the complete maxillary denture. J. Prosthet. Dent. 2002, 88, 415–422. [Google Scholar] [CrossRef] [PubMed]

- Van Straten, R.J.; Hitge, M.L.; Kalk, W.; Schenk, J. A study of acrylic resin denture base material distortion using computer-aided holographic interferometry. Int. J. Prosthodont. 1991, 4, 577–585. [Google Scholar]

- Fernandes, C.P.; Glantz, P.O.J.; Svensson, S.A.; Bergmark, A. Reflection photoelasticity: A new method for studies of clinical mechanics in prosthetic dentistry. Dent. Mater. 2003, 19, 106–117. [Google Scholar] [CrossRef]

- Baixuan, Y.; Ainara, I.; Peter, H.; Heidi-Lynn, P. Analytical Model for Dental Implant Insertion Torque. SSRN Electron. J. 2022, 131, 105223. [Google Scholar]

- Pelekhan, B.; Dutkiewicz, M.; Shatskyi, I.; Velychkovych, A.; Rozhko, M.; Pelekhan, L. Analytical Modeling of the Interaction of a Four Implant-Supported Overdenture with Bone Tissue. Materials 2022, 15, 2398. [Google Scholar] [CrossRef]

- Rees, J.S.; Huggett, R.; Harrison, A. Finite element analysis of the stress-concentrating effect of fraenal notches in complete dentures. Int. J. Prosthodont. 1990, 3, 238–240. [Google Scholar]

- McCabe, F.J.; Walls, G.W.A. Applied Dental Materials; Ninth Edition Blackwell Publishing Ltd.: London, UK, 2008. [Google Scholar]

- Ansys Help Page. Available online: https://ansyshelp.ansys.com/public/account/secured?returnurl=/Views/Secured/corp/v242/en/ans_elem/Hlp_E_SOLID186.html?q=solid186 (accessed on 23 October 2024).

- Gibbs, C.H.; Mahan, P.H.; Mauderli, A.; Lundeen, H.C.; Walsh, E.K. Limits of human bite strength. J. Prosthet. Dent. 1986, 56, 226–229. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 2nd ed.; Marcel Dekkel: New York, NY, USA, 1993. [Google Scholar]

- Goguta, L.M.; Bratu, D.; Jivanescu, A.; Erimescu, R.; Marcauteanu, C. Glass fibre reinforced acrylic resin complete dentures: A 5-year clinical study. Gerodontology 2012, 29, 64–69. [Google Scholar] [CrossRef]

- Vallittu, P.K. A Review of Fiber-Reinforced Denture Base Resins. J. Prosthet. 1996, 5, 270–276. [Google Scholar] [CrossRef]

- Stipho, H.D. Repair of Acrylic Resin Denture Base Reinforced with Glass Fiber. J. Prosthet. Dent. 1998, 80, 546–550. [Google Scholar] [CrossRef] [PubMed]

- Beyli, M.S.; von Fraunhofer, J. An analysis of causes of fracture of acrylic resin dentures. J. Prosthet. Dent. 1981, 46, 238–241. [Google Scholar] [CrossRef] [PubMed]

| Elements | Young’s Modulus (MPa) | Poisson’s Ratio | Thermal Expansion Coefficient (Strain/K) |

|---|---|---|---|

| Bone | 13.700 | 0.3 | - |

| Mucosal Tissue | 2.8 | 0.4 | - |

| Interface Gap | 0.07 | 0.3 | - |

| Maxillary Denture | 3200 | 0.36 | 70 |

| Elements | E1 (GPa) | E2 (GPa) | Thermal Expansion Coefficient α1 (Strain/K) | Thermal Expansion Coefficient α2 (Strain/K) |

|---|---|---|---|---|

| CrCo | 210 | 210 | 14.4 | 14.4 |

| UD Carbon/Epoxy | 135 | 10 | −0.3 | 28 |

| UD Glass/Epoxy | 40 | 8 | 6 | 35 |

| UD Kevlar/Epoxy | 75 | 6 | 4 | 40 |

| Woven Carbon/Epoxy | 70 | 70 | 2.1 | 2.1 |

| Woven Glass/Epoxy | 25 | 25 | 11.6 | 11.6 |

| Woven Kevlar/Epoxy | 30 | 30 | 7.4 | 7.4 |

| Reinforcement Material of PMMA Denture and Value of Temperature | The Tensile Stresses at the Tip of the Incisal Notch, Maximum Stress (MPa) | The Compressive Stresses at Labial Frenal Notch, Minimum Stress (MPa) | Percentage Change in Maximum Stress According to the Unreinforced Denture (%) | Percentage Change in Minimum Stress According to the Unreinforced Denture (%) |

|---|---|---|---|---|

| Unreinforced 0 °C | 30.76 | −52.85 | - | - |

| Unreinforced 36 °C | 31.15 | −53.32 | - | - |

| Unreinforced 70 °C | 31.52 | −53.76 | - | - |

| CrCo 0° | 15.16 | −43.94 | 50.72 | 16.86 |

| CrCo 36 °C | 7.43 | −39.80 | 76.15 | 25.36 |

| CrCo 70 °C | 4.77 | −35.88 | 84.87 | 33.26 |

| UniCarbon/Epoxy 0 °C | 19.11 | −51.01 | 37.88 | 3.48 |

| UniCarbon/Epoxy 36 °C | 9.94 | −42.20 | 68.09 | 20.86 |

| UniCarbon/Epoxy 70 °C | 10.69 | −34.26 | 66.09 | 36.27 |

| UniGlass/Epoxy 0 °C | 23.14 | −52.31 | 24.78 | 1.02 |

| UniGlass/Epoxy 36 °C | 16.01 | −45.85 | 48.61 | 14.01 |

| UniGlass/Epoxy 70 °C | 11.07 | −40.02 | 64.88 | 25.56 |

| UniKevlar/Epoxy 0 °C | 21.10 | −51.03 | 31.5 | 3.44 |

| UniKevlar/Epoxy 36 °C | 12.47 | −44.17 | 59.97 | 17.16 |

| UniKevlar/Epoxy 70 °C | 11.60 | −37.89 | 63.2 | 29.52 |

| WovenCarbon/Epoxy 0 °C | 20.70 | −49.91 | 32.71 | 5.56 |

| WovenCarbon/Epoxy 36 °C | 11.93 | −44.14 | 61.7 | 17.22 |

| WovenCarbon/Epoxy 70 °C | 9.22 | −38.75 | 70.75 | 27.92 |

| WovenGlass/Epoxy 0 °C | 24.70 | -51.89 | 19.7 | 1.82 |

| WovenGlass/Epoxy 36 °C | 19.34 | −47.74 | 37.91 | 10.47 |

| WovenGlass/Epoxy 70 °C | 14.27 | −43.83 | 54.73 | 18.47 |

| WovenKevlar/Epoxy 0 °C | 24.15 | −51.92 | 23.38 | 1.76 |

| WovenKevlar/Epoxy 36 °C | 17.78 | −47.09 | 42.93 | 11.68 |

| WovenKevlar/Epoxy 70 °C | 12.04 | −42.53 | 61.8 | 20.89 |

| Reinforcement Material of PMMA Denture and Value of Temperature | Maximum Stress | Minimum Stress | The Tsai-Wu Strength Ratio Index |

|---|---|---|---|

| CrCo 0° | 371.98 | −267.34 | 0.4895 |

| CrCo 36 °C | 281.06 | −232.11 | 0.2852 |

| CrCo 70 °C | 276.64 | −198.84 | 0.3409 |

| UniCarbon/Epoxy 0 °C | 267.51 | −152.17 | 0.1599 |

| UniCarbon/Epoxy 36 °C | 321.75 | −170.44 | 0.2359 |

| UniCarbon/Epoxy 70 °C | 372.97 | −187.71 | 0.4693 |

| UniGlass/Epoxy 0 °C | 140.53 | −63.77 | 0.5008 |

| UniGlass/Epoxy 36 °C | 183.57 | -65.91 | 0.8991 |

| UniGlass/Epoxy 70 °C | 224.21 | −67.92 | 1.4656 |

| UniKevlar/Epoxy 0 °C | 119.14 | −99.67 | 0.1183 |

| UniKevlar/Epoxy 36 °C | 271.21 | −106.86 | 0.2090 |

| UniKevlar/Epoxy 70 °C | 339.26 | 113.65 | 0.3249 |

| WovenCarbon/Epoxy 0 °C | 202.5 | −92.37 | 0.1071 |

| WovenCarbon/Epoxy 36 °C | 238.75 | −103.65 | 0.1852 |

| WovenCarbon/Epoxy 70 °C | 272.98 | −114.30 | 0.2902 |

| WovenGlass/Epoxy 0 °C | 113.04 | −39.27 | 0.3437 |

| WovenGlass/Epoxy 36 °C | 139.1 | −40.50 | 0.6937 |

| WovenGlass/Epoxy 70 °C | 163.70 | −45.06 | 1.1504 |

| WovenKevlar/Epoxy 0 °C | 125.98 | −45.14 | 0.4692 |

| WovenKevlar/Epoxy 36 °C | 153.48 | −48.27 | 0.4260 |

| WovenKevlar/Epoxy 70 °C | 179.44 | −59.42 | 0.7665 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benli, S.; Baş, G. Thermal Stress Analysis of Maxillary Dentures with Different Reinforcement Materials Under Occlusal Load Using Finite Element Method. Appl. Sci. 2024, 14, 10271. https://doi.org/10.3390/app142210271

Benli S, Baş G. Thermal Stress Analysis of Maxillary Dentures with Different Reinforcement Materials Under Occlusal Load Using Finite Element Method. Applied Sciences. 2024; 14(22):10271. https://doi.org/10.3390/app142210271

Chicago/Turabian StyleBenli, Semih, and Gökhan Baş. 2024. "Thermal Stress Analysis of Maxillary Dentures with Different Reinforcement Materials Under Occlusal Load Using Finite Element Method" Applied Sciences 14, no. 22: 10271. https://doi.org/10.3390/app142210271

APA StyleBenli, S., & Baş, G. (2024). Thermal Stress Analysis of Maxillary Dentures with Different Reinforcement Materials Under Occlusal Load Using Finite Element Method. Applied Sciences, 14(22), 10271. https://doi.org/10.3390/app142210271