Research on the Influence of Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood

Abstract

1. Introduction

2. Materials and Methods

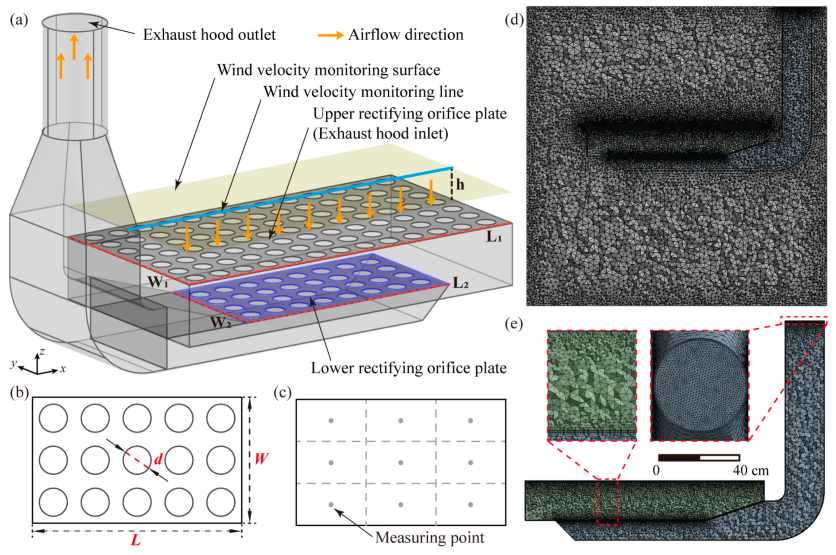

2.1. Model Establishment, Evaluation Method, and Mesh

2.2. Control Equations and Boundary Conditions

3. Results

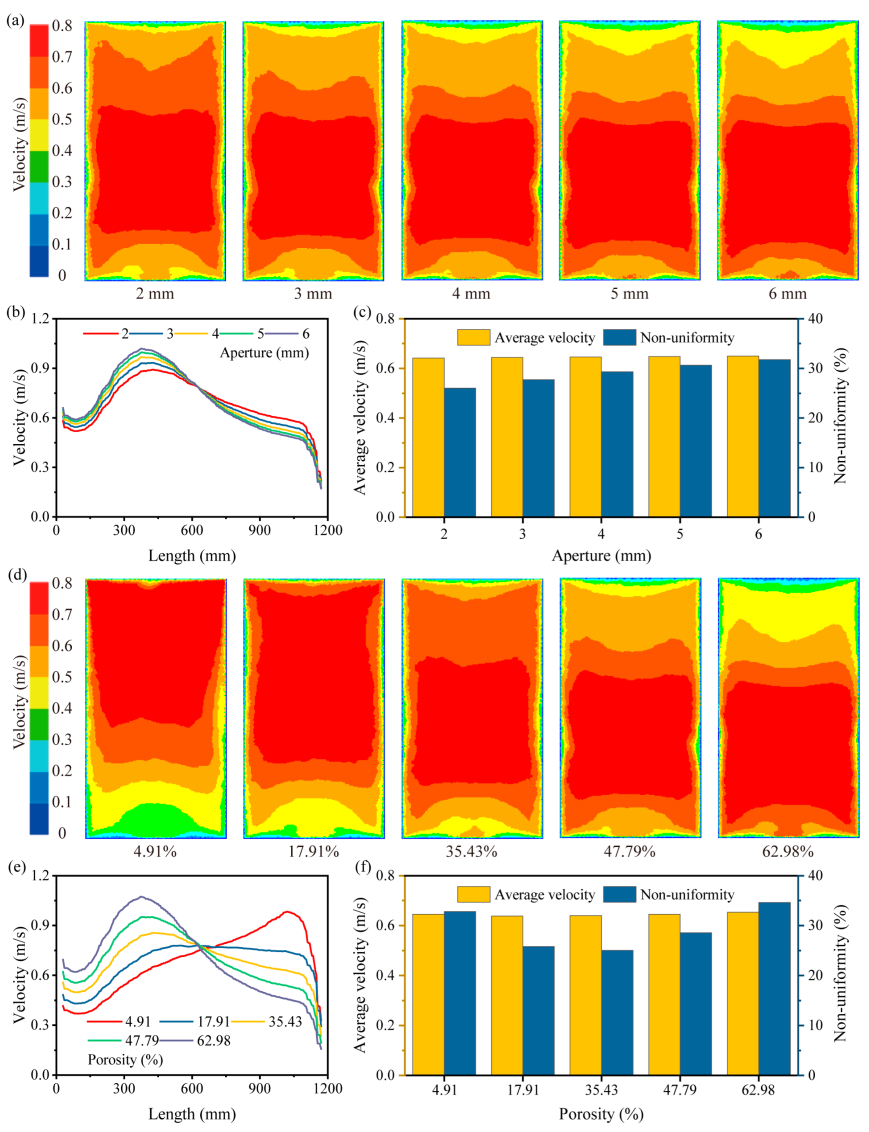

3.1. Influence of Single-Layer Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood

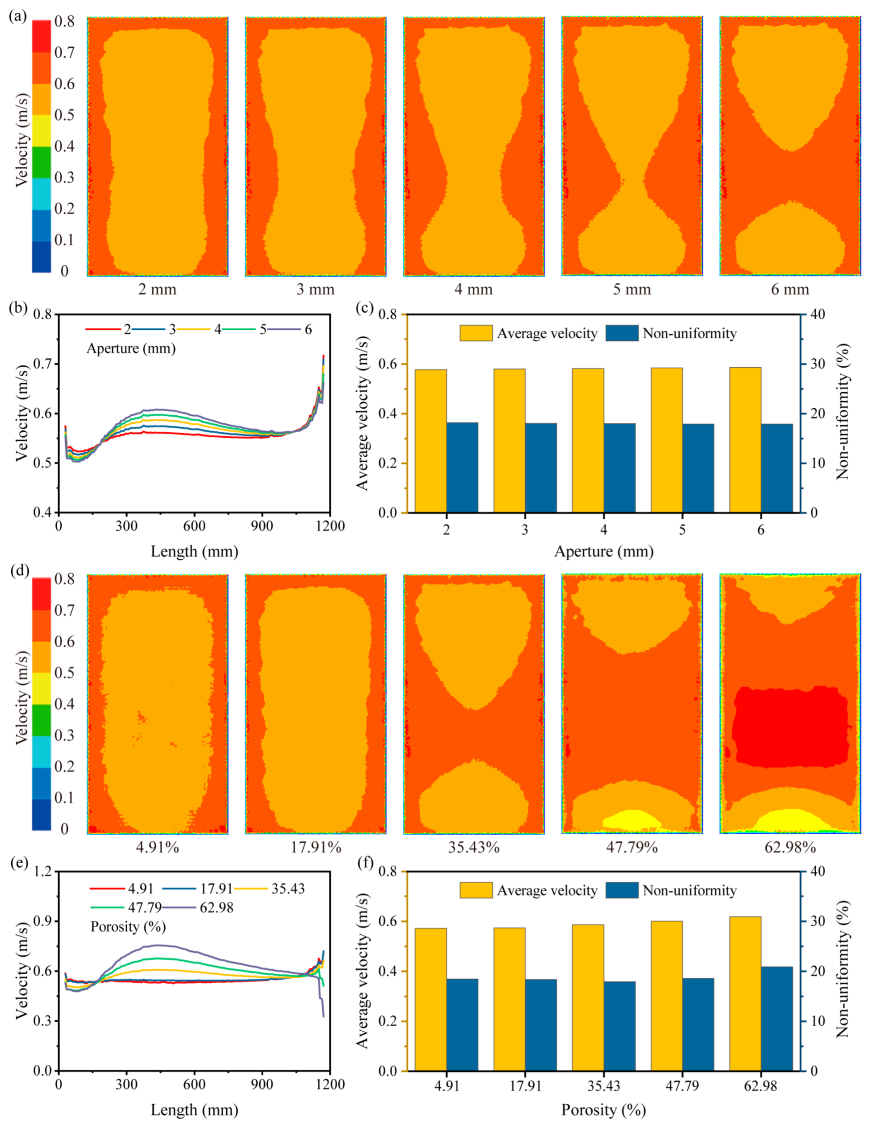

3.2. Influence of Double-Layer Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood

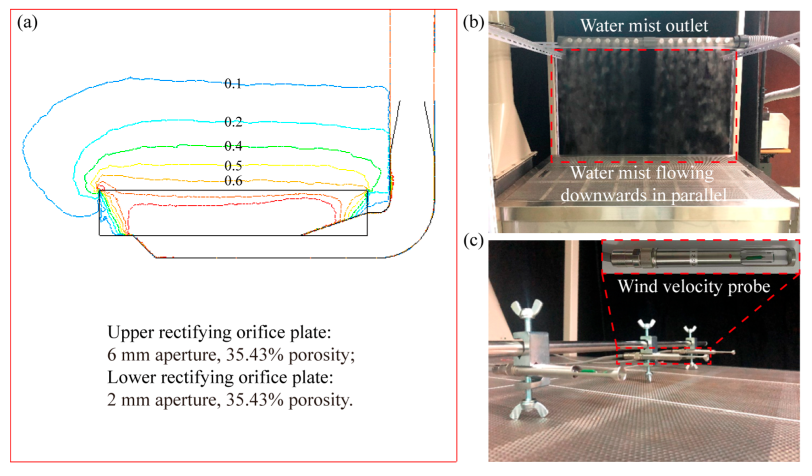

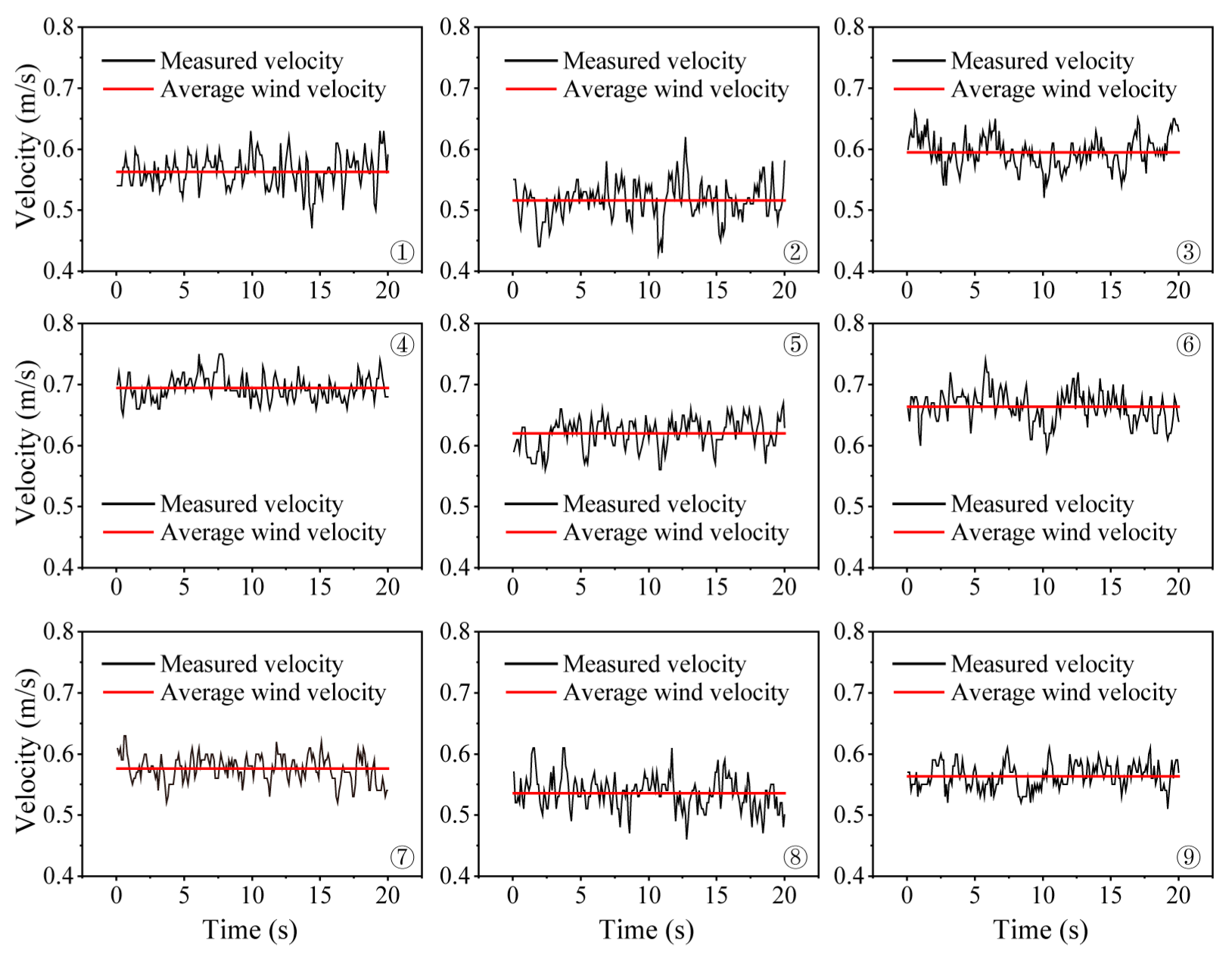

4. Experiment and Discussion

5. Conclusions

- (1)

- The average wind velocity of the exhaust hood generally increases with the increase in aperture and porosity of the rectifying orifice plate. The impact of the aperture on the airflow uniformity of the exhaust hood depends on the position of the plate. Near the exhaust hood outlet, the airflow uniformity is negatively correlated with the aperture; near the exhaust hood inlet, the airflow uniformity is positively correlated with the aperture. A rectifying orifice plate with a porosity of 35.43% can effectively improve the airflow uniformity of the exhaust hood.

- (2)

- Exhaust hoods with a double-layer rectifying orifice plate structure can improve airflow uniformity by approximately 40% compared to those with a single-layer structure. When designing exhaust hoods with more stringent requirements for airflow uniformity, a multi-layer rectifying orifice plate structure can be used to further enhance airflow uniformity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Property | Units |

| L1 | Length of the upper rectifying orifice plate | mm |

| W1 | Width of the upper rectifying orifice plate | mm |

| L2 | Length of the lower rectifying orifice plate | mm |

| W2 | Width of the lower rectifying orifice plate | mm |

| d | Aperture of the rectifying orifice plate | mm |

| α | Opening ratio of the rectifying orifice plate | % |

| L | Length of the rectifying orifice plate | mm |

| W | Width of the rectifying orifice plate | mm |

| m | Number of holes on the rectifying orifice plate | / |

| h | Height from the upper rectifying orifice plate to the monitoring surface and line | mm |

| n | Number of measuring points | / |

| Wind velocity non-uniformity | % | |

| Measured wind velocity at the measuring point | m/s | |

| Average wind velocity | m/s |

References

- Hughes, R.T. An Overview of Push—Pull Ventilation Characteristics. Appl. Occup. Environ. Hyg. 1990, 5, 156–161. [Google Scholar] [CrossRef]

- Ye, W.-B. Design Method and Modeling Verification for the Uniform Air Flow Distribution in the Duct Ventilation. Appl. Therm. Eng. 2017, 110, 573–583. [Google Scholar] [CrossRef]

- Huebener, D.J.; Hughes, R.T. Development of Push-Pull Ventilation. Am. Ind. Hyg. Assoc. J. 1985, 46, 262–267. [Google Scholar] [CrossRef]

- Wang, Y.; Quan, M.; Zhou, Y.; Cao, Y.; Xie, C.; Li, L. Experimental Study on the Flow Field and Economic Characteristics of Parallel Push-Pull Ventilation System. Energy Built Environ. 2020, 1, 393–403. [Google Scholar] [CrossRef]

- Chen, J.; Jin, L.; Yang, B.; Chen, Z.; Zhang, G. Influence of the Internal Structure Type of a Large-Area Lower Exhaust Workbench on Its Surface Air Distribution. Int. J. Environ. Res. Public Health 2022, 19, 11395. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.F.; Lin, S.Y.; Jan, S.-Y.; Hsieh, R.H.; Chen, Y.-K.; Chen, C.-W.; Yeh, W.-Y.; Chang, C.-P.; Shih, T.-S.; Chen, C.-C. Aerodynamic Characteristics and Design Guidelines of Push–Pull Ventilation Systems. Ann. Occup. Hyg. 2005, 49, 1–15. [Google Scholar] [CrossRef]

- Liu, K.; Yang, S.; Zeng, L.; Gao, J.; Hou, Y.; Cao, C.; Shi, B.; Mo, X.; Zhang, Q.; Hou, C. Combining Push-Pull Airflow and Top Draft Hood for Local Exhaust of Tyre Vulcanization Process. Energy Built Environ. 2020, 1, 296–306. [Google Scholar] [CrossRef]

- Chern, M.-J.; Ma, C.-H. Numerical Investigation and Recommendations for Push-Pull Ventilation Systems. J. Occup. Environ. Hyg. 2007, 4, 184–197. [Google Scholar] [CrossRef]

- Chen, J.; Jin, L.; Chen, Z.; Yang, B.; Sun, Y.; Zhou, S. Center-Line Velocity Change Regime in a Parallel-Flow Square Exhaust Hood. Int. J. Environ. Res. Public Health 2020, 17, 4485. [Google Scholar] [CrossRef]

- Chen, J. Research on the Axial Velocity Change Rule of Desktop Slot Exhaust Hood. Ind. Health 2018, 56, 278–284. [Google Scholar] [CrossRef]

- Wu, X.; Liu, L.; Luo, X.; Chen, J.; Dai, J. Study on Flow Field Characteristics of the 90° Rectangular Elbow in the Exhaust Hood of a Uniform Push–Pull Ventilation Device. Int. J. Environ. Res. Public Health 2018, 15, 2884. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Quan, M.; Zhou, Y. Effect of Velocity Non-Uniformity of Supply Air on the Mixing Characteristics of Push-Pull Ventilation Systems. Energy 2019, 187, 115962. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Zhou, Y.; Shu, Y.; Liu, J. Experimental Study on One-Side Confined Jets from a Parallel-Flow Outlet in a Push–Pull Ventilation System. Indoor Built Environ. 2015, 24, 73–86. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.; Li, C.; Ding, J.; Yang, Y.; Ren, X. A Field Measurement Study of a Parallel-Flow Push–Pull System for Industrial Ventilation Applications. Int. J. Vent. 2016, 15, 167–181. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Gao, J.; Cao, C.; Lv, L.; Xie, M.; Zeng, L. Critical Velocity of Active Air Jet Required to Enhance Free Opening Rectangular Exhaust Hood. Energy Build. 2020, 225, 110316. [Google Scholar] [CrossRef]

- Yan, H.; Li, X.; Fu, Z.; Bai, Z.; Zhang, H. Uniform Exhaust Characteristics of New-Type Airbox Components of Continuous Miner. Trans. Can. Soc. Mech. Eng. 2023, 47, 388–397. [Google Scholar] [CrossRef]

- Jiang, W.; Xu, X.; Wen, Z.; Wei, L. Applying the Similarity Theory to Model Dust Dispersion during Coal-Mine Tunneling. Process Saf. Environ. Prot. 2021, 148, 415–427. [Google Scholar] [CrossRef]

- Muta, R.; Chung, J.; Li, C.; Yoo, S.-J.; Ito, K. Pollutant Capture Efficiencies in and around the Opening Surface of a Fume Hood under Realistic Conditions. Indoor Built Environ. 2022, 31, 1636–1653. [Google Scholar] [CrossRef]

- Cao, Z.; Zhou, Y.; Cao, S.; Wang, Y. Chapter 2—Local Ventilation. In Industrial Ventilation Design Guidebook, 2nd ed.; Goodfellow, H.D., Wang, Y., Eds.; Academic Press: Cambridge, MA, USA, 2021; pp. 7–108. ISBN 978-0-12-816673-4. [Google Scholar]

- Deng, Q.; Liu, H.; He, Y.; Huang, T.; Zhou, H.; Bao, Y. Uniformity and Energy Evaluation of Equal Cross-Section Ventilation System(ECVS) for Long Tunnel in Underground Buildings. Energy Built Environ. 2022, 3, 86–94. [Google Scholar] [CrossRef]

- Zaïdi, H.; Fohanno, S.; Taïar, R.; Polidori, G. Turbulence Model Choice for the Calculation of Drag Forces When Using the CFD Method. J. Biomech. 2010, 43, 405–411. [Google Scholar] [CrossRef]

- Muta, R.; Ito, K. Impact of Heat Generation and Use of Experimental Instruments in a Fume Hood on Pollutant Capture Efficiency. Jpn. Archit. Rev. 2022, 5, 702–713. [Google Scholar] [CrossRef]

| Parameters | Settings |

|---|---|

| Viscous Model | k ε |

| Energy | Off |

| Convergence Standard | 10−6 |

| Exhaust Hood Outlet Boundary Type | Velocity - Inlet |

| Inlet Velocity Magnitude (m/s) | 13 |

| Hydraulic Diameter (m) | 0.2 |

| Turbulence Intensity (%) | 3.53 |

| Boundary Type of the Computational Domain | Outflow (Surrounding) Wall (Top and Bottom) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Du, C.; Wang, Y.; Yang, B. Research on the Influence of Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood. Appl. Sci. 2024, 14, 9917. https://doi.org/10.3390/app14219917

Liu L, Du C, Wang Y, Yang B. Research on the Influence of Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood. Applied Sciences. 2024; 14(21):9917. https://doi.org/10.3390/app14219917

Chicago/Turabian StyleLiu, Lindong, Cuifeng Du, Yuan Wang, and Bin Yang. 2024. "Research on the Influence of Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood" Applied Sciences 14, no. 21: 9917. https://doi.org/10.3390/app14219917

APA StyleLiu, L., Du, C., Wang, Y., & Yang, B. (2024). Research on the Influence of Rectifying Orifice Plate on the Airflow Uniformity of Exhaust Hood. Applied Sciences, 14(21), 9917. https://doi.org/10.3390/app14219917