1. Introduction

The execution of daily production plans in underground metal mines is facilitated by a coordinated approach that includes mining, equipment installation, transportation, and strategic deployment of crushing machinery. The rational allocation of equipment and vehicles within the mine has a significant impact on overall production capacity and efficiency, which in turn has a significant impact on the economic profitability of mining operations. According to the research, taking the statistics of iron ore mines as an example, the production time of haul trucks accounts for only 70% of the total time [

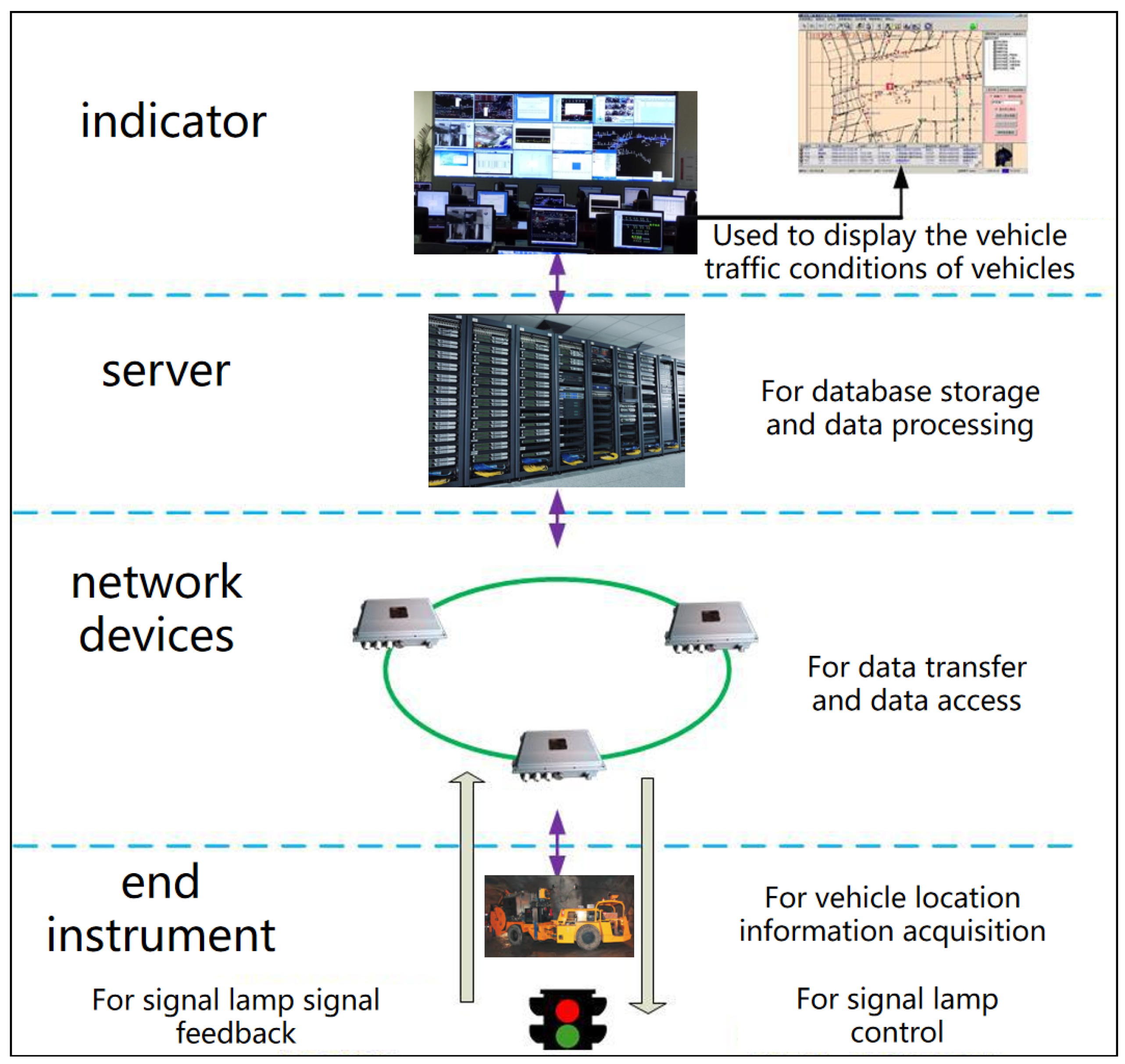

1]. This is due to the complex driving route, the complex types of running vehicles, and the narrow driving channel, which makes it difficult to optimize the transportation system. In addition, due to the blindness of traditional scheduling, the driving routes of trackless equipment are often conflicting and blocked, resulting in the stagnation of the transportation system. With the popularization of 5G mobile signal transmission technology in underground mines, the trackless transportation dispatching system of underground mines will usher in a new reform. Through real-time signal transmission, the dispatching center can determine the position and operation situation of the trackless equipment in real-time, so intelligent scheduling can be realized.

Worldwide, some scholars have studied the intelligent scheduling algorithm of trackless equipment in underground mine transportation systems. A heuristic approach based on linear programming is used to minimize the waiting time at loading points for multiple trucks with different capacities [

2]. This method, used to determine mass flow along the path, has been run in real-time applications in more than 10 mines and improves productivity by 10 to 20%. Beaulieu and Gamache proposed an enumeration algorithm based on dynamic programming for optimizing fleet management in underground mines [

3]. The method arranges vehicles to move in a transport network consisting of single-lane bidirectional roads, aiming to find the route and schedule of each vehicle to minimize the movement time without conflict. Jie Hou et al. use transport network modeling and optimize the network model, providing information about transport distance and driving time. The transport distance is calculated from the length of the route center line based on the tunnel layout [

4]. The model has a significant effect on reducing the operation cost of mines. Yu et al. investigated how fast local search and parallel computation with the genetic algorithm can be used to solve the trackless transport vehicle path problem to minimize the number of vehicles and total transport distance or time [

5]. This method not only improves the optimization capability in the global scope, but also ensures operational efficiency. Some people have also proposed an enumeration algorithm based on dynamic planning [

6,

7]. The algorithm applies a multi-objective heuristic based on a two-stage Pareto local search and VNS (2 PPLS-VNS), multi-objective variable neighborhood search (MOVNS), and non-(NSGA-II) to job planning problems with dynamic truck assignments [

8,

9]. The experiment demonstrates good convergence [

10]. The aforementioned studies offer insights into potential avenues for intelligent scheduling algorithms in underground trackless transport equipment in mines. However, the majority of these studies focus on a single objective, with the primary aim being the reduction in route conflicts. The issue of bidirectional transport on the ramps of underground metal mines is distinct from that of scheduling mine trucks in open-pit mines. Inevitably, there will be instances of route conflicts involving trackless equipment. Furthermore, in the context of underground mine transport scheduling, focusing exclusively on route conflict issues while neglecting the necessity to adhere to passage priority in vehicle production will inevitably result in logistical inconsistencies. It is therefore imperative to investigate the optimal design of transport routes in order to maximize production transport efficiency, while allowing for potential route conflicts and ensuring compliance with the relevant engineering transport laws.

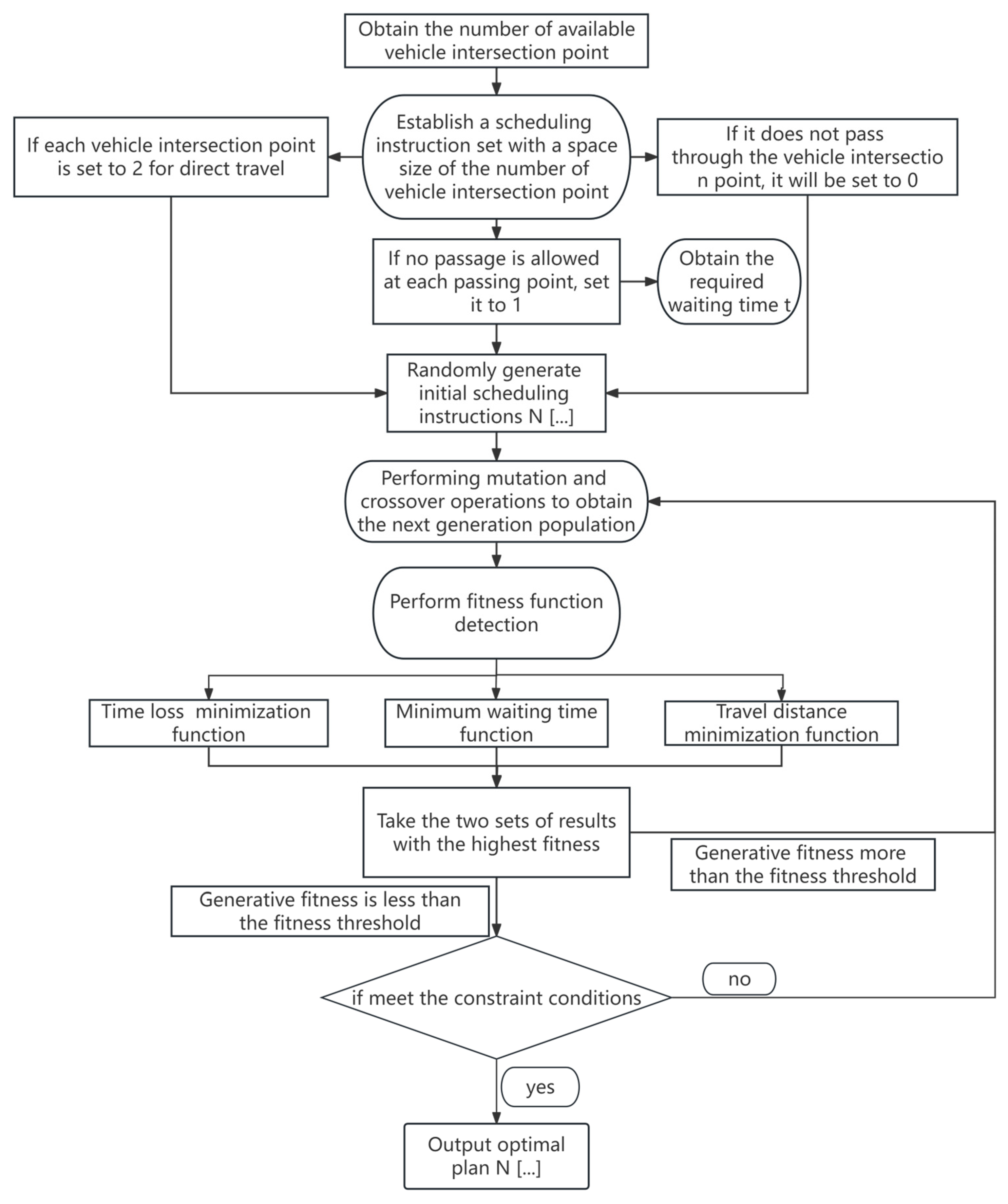

This paper discusses the problems of an intelligent scheduling system for trackless transport on slope roads, with a view to addressing the issues of the low utilization of trackless transport passes in underground mines, the conflict and blockage of transport routes due to the unscientific planning of transport routes, low transport efficiency, and so on. The principal findings of the research are as follows: 1. An improved genetic algorithm is proposed, which introduces the constraints of the law of vehicle transport in underground mines in the calculation of adaptability in a novel manner. 2. In the proposed improved genetic algorithm, a coding method is proposed which is more applicable to trackless transport in underground mines. 3. The principle of fuzzy logic is applied, and the interval positioning method is used to divide the road sections and locate the vehicles. This approach reduces the spatial complexity of the algorithm and improves its response speed. 4. The proposed improved genetic algorithm is used to carry out simulation experiments on the trackless transport of underground mines. The results of the experiments demonstrate that the algorithm is effective in improving the efficiency of the trackless transport of underground mines and in enhancing economic benefits.

Section 2 provides a comprehensive description of the initial scheduling model for underground metal mine trackless transport. This includes an in-depth analysis of the technical characteristics of the model, interval fuzzy positioning, the generation of transport task sequences, the construction of mathematical models, cost calculation, and the constraints of the scheduling model.

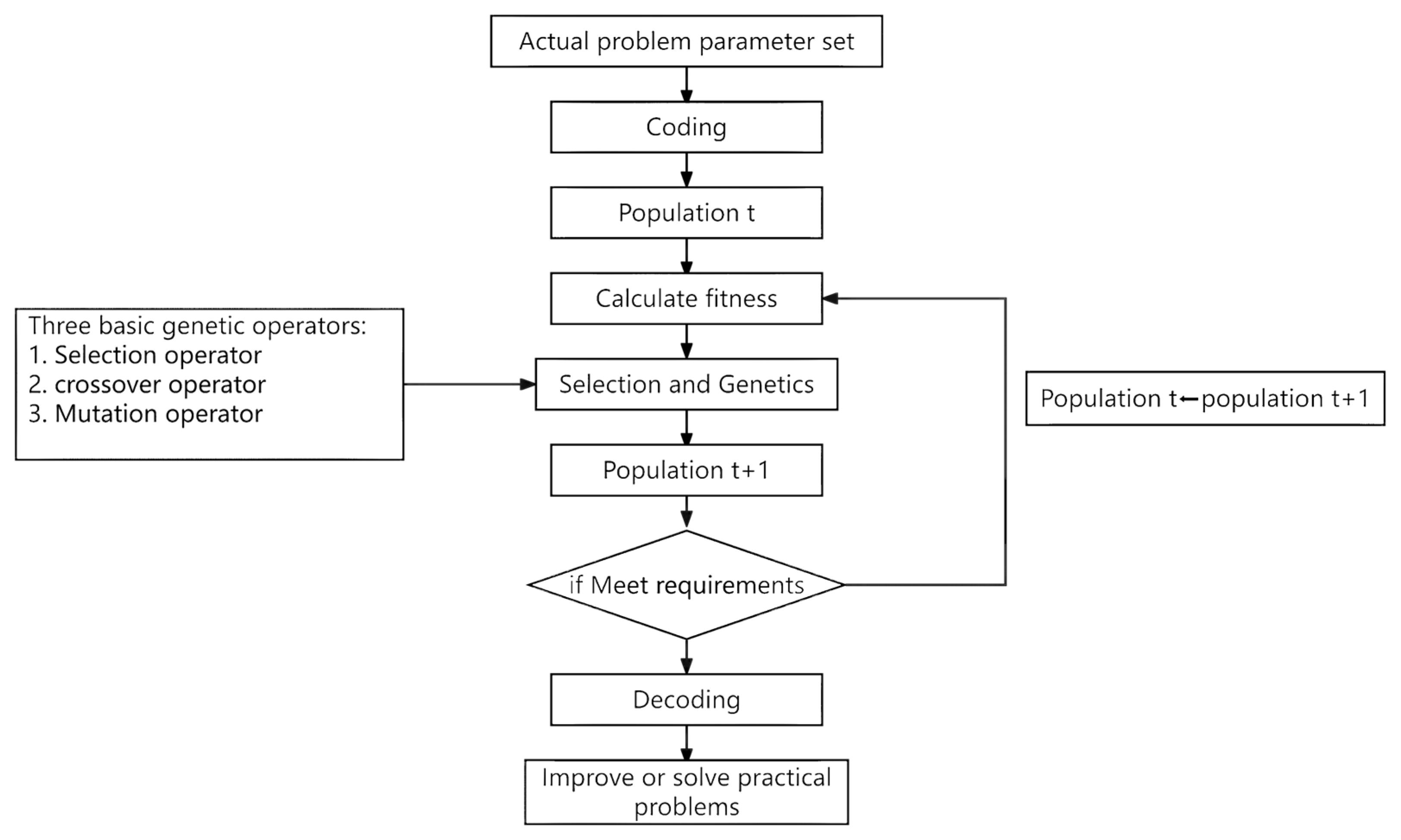

Section 3 proposes an optimization method based on an improved genetic algorithm, which enhances the coding method and innovates the adaptation calculation to align with the transport scheduling requirements of underground mines.

Section 4 validates the efficacy of the proposed algorithm in enhancing transport efficiency, reducing costs and congestion through computer simulation experiments, demonstrating a notable improvement before and after the optimization.

5. A Genetic Algorithm-Based Approach to Scheduling Effect Analysis

5.1. Transportation Conditions on Site

The main development conditions of a mining area are as follows: −60 ~ −240 m adopts the lower-plate central shaft, auxiliary slope road joint development, and underground ore transportation by rail transportation. Waste rock is transported by truck to the −280 m level and by 35 t electric truck transportation. A ramp is set from the surface to −250 m for auxiliary transportation of personnel and air intake, as well as materials. The section size of the ramp is 4.8 m × 3.5 m (width × high).

Next, −240 ~ −420 m is jointly developed by the ramp and the two-wing air shaft, and transported by a 35 t electric truck. The section of the ramp is 5.1 m × 4.1 m, with an average slope of 10%. The ore is transported to the main shaft of the −243 m level. The waste rock is transported by truck from the 12 t diesel pit to the −280 m level waste rock shaft.

Then, −420 ~ –600 m adopts the ramp of −600 m, and the ramp extends from −435 m to −600 m. The ramp section is 5.1 m × 4.1 m, and the electric truck service reaches the −600 m level. The ore of the phase III project is transported by electric truck to the −243 m level and discharged into the main shaft of the phase I project.

The ore (waste) rock developed in the Xishan mining area is transported by truck to −243 m for unloading, with an average transportation distance of 3500 m and transportation cost of 45.50 yuan/t. The deep development project of the Xishan mining area was originally transported to the surface by truck, with an average transportation distance of 7150 m and a transportation cost of 30.60 yuan/t.

5.2. Experimental Design of Computer Simulation

Each test cycle is 24 h, and seven cycles are conducted to simulate the traffic of the ramp for one week. The test simulation production task comes from the actual production task of Sanshan Island mining area in a certain week in March 2023. There were four indicators: (1) the number of vehicles passing the ramp per 24 h; (2) the average distance of vehicles; (3) the transportation cost of vehicles; and (4) the length of the ramp.

According to the above field transportation conditions, the ramp from the surface to −1200 m is selected as the simulated experimental environment. The average slope of this section of the road is 10%, the total length is 12 km, and the whole two-way single lane is passed. Vehicle passing is only possible at the passing bays, which is in line with the actual situation of the project. There is a middle section entrance every 60 m from the downward vertical direction of the surface, and a passing bay is set every 100 m from the downward vertical direction of the surface, with a total of 32 passing bays. When two cars have been parked at the passing bay, the passing bay will be regarded as the passing bay. According to the daily production situation of Sanshan Island mining area, there are 20 electric trucks carrying 35 t of heavy loads, 40 diesel trucks carrying 12 t, 20 manned pickup trucks, and 20 operating vehicles, totaling 100 test vehicles. The design running speed of the trackless transport vehicle shall not exceed 35 km/h, and the maximum acceleration shall not be more than 1.26 m/s2 according to the national standard of “Chinese Automobile Driving Conditions”.

Figure 6 shows the main underground operating vehicles applied at the project site.

Figure 7 shows the algorithm logic of this system.

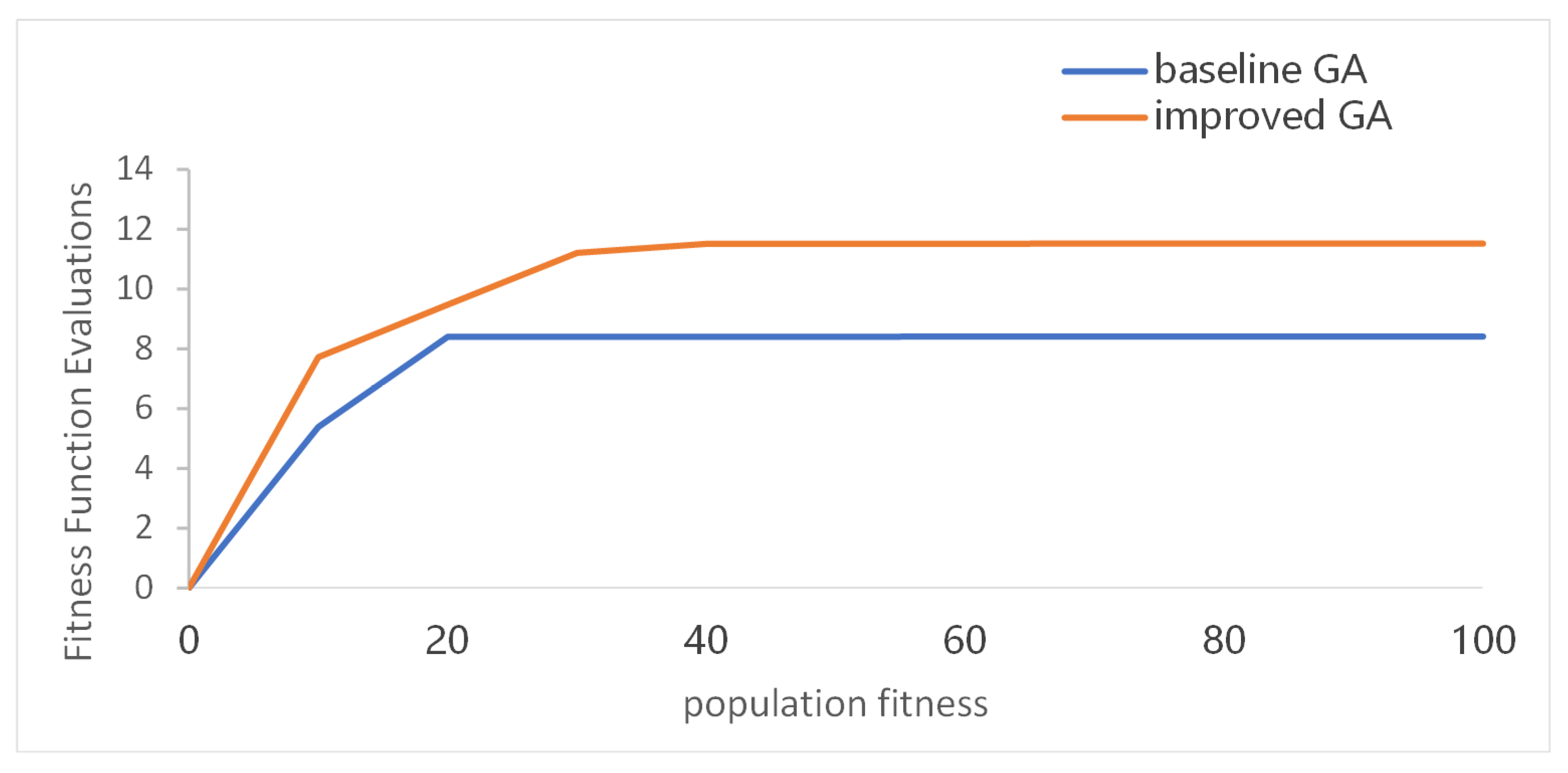

The dataset employed in this study was gathered from an underground gold mine and pertains to the navigation of vehicles through a mine devoid of tracks. The dataset comprises 100 test vehicles and three data items: vehicle trajectories, time spent on vehicle transport, and a list of vehicle transport tasks. The GA and a modified version of the GA were employed for 100 iterations each, with a population size of 31, and were executed independently 50 times to obtain the population fitness average.

5.2.1. Convergence and Stability of Improved GA

We tested how complex our algorithm is in terms of FFEs (Fitness Function Evaluations). The improved algorithm is a little more complex than the baseline GA, which does not include the vehicle traveling state in the DNA encoding. This means the vehicle has only two states: passing and not passing the node. You can see how the two algorithms compare in

Figure 8 below.

The consequence of a baseline GA, driven by the imperative to circumvent route conflicts, is that vehicles will queue to depart and await the next vehicle to depart until the previous one has completed its task. Consequently, the average time between tasks is increased by 28.7 min, while the average waiting time in passing bays is reduced from 8.3 min to zero. This results in a significant increase in the overall time cost, which in turn leads to a reduction in the total adaptation. However, the speed of convergence of the algorithm is greatly increased due to the decrease in the conditionality of the optimized data.

Figure 9 illustrates that the data stability of the enhanced GA across 50 independent trials exhibits minimal variation in comparison to the baseline GA. Nevertheless, the overall adaptation data exhibit a marked improvement in comparison to the baseline GA. The mean value of the baseline GA statistics is as follows: The mean value is 8.18, while the median value is. The mean value is 8.15, with a minimum value of. The maximum value is 13.41, the standard deviation is 2.12, and the variance is 4.50. Improved GA statistics: The mean value is 11.93, while the median is. The minimum value is 12.26. The mean value is 8.44, with a maximum value of 14.89 and a standard deviation of 1.71. The variance is 2.92.

5.2.2. Reducing the Number of Iterations of the Improved GA

The scheduling of trackless transport on the ramp is a dynamic process, and the response speed of the intelligent dispatching system is greater than the actual running speed of trackless transport vehicles. And because of the time required by the signal and the driver, the response speed needs to be much greater than the running speed of the trackless transport vehicle. The underground ramp road of Sanshan Island Gold Mine is divided into 46 sections according to the meeting points in

Section 3.1.1 of this paper, and traffic lights are installed at each meeting point. Excluding the personal factors of the driver of the trackless transport vehicle, it is assumed that the driver needs 2 s from seeing the traffic signal to the execution, and the greatest short-circuit section distance is 228 m. If the speed limit of the trackless transport vehicle on the ramp is 25 km/h, 32.8 s is required from the beginning to the end of the shortest circuit section in the limit case, so the response time of the system shall not be greater than the difference between the two. Since the total number of operating vehicles in the underground ramp of Sanshan Island Gold Mine is about 100, the response time should be less than 0.308 s.

The termination condition of the end cycle of the genetic optimization algorithm is the total fitness for one round of cycles greater than the total fitness of the basic solution obtained in the next cycle:

In this case, because the data accuracy of the floating-point float format data is six decimal places, the response time of the simulation operation is more than 0.308 s, so the accuracy threshold of the algorithm’s fitness needs to be set. In this case, six sets of comparison experiments are carried out: the fitness accuracy threshold of the algorithm is set to maintain the float accuracy—that is, 6 decimal places—and the decimal places of 5 bits, 4 bits, 3 bits, 2 bits, 1 bit, and an integer that reduce the accuracy. The response time data are obtained as shown in

Figure 10: (output accuracy of time function in bits for 0.001 ms).

According to the data, the response time when the fitness accuracy threshold of the algorithm is set to maintain the response time of the system is less than the running time of the trackless transport vehicle, so it can be considered that the algorithm has good convergence and the response sensitivity meets the actual needs of the project.

5.3. Data Analysis of the Experimental Results

5.3.1. Number of Vehicles Passing through the Ramp Per 24 H

The number of vehicles passing through the ramp every 24 h can simply and directly reflect the road traffic efficiency of the ramp. The trackless transport vehicle passes the ramp per unit time, which refers to the process of entering the ramp from the fork at the surface or the middle to leaving the ramp from the surface or the middle. For each completion into the ramp and leaving the ramp, the count will be added on the statistical table. The more different types of vehicles pass every 24 h, the higher the traffic efficiency of the ramp, and the more efficient the trackless transport vehicles are in completing the transportation task.

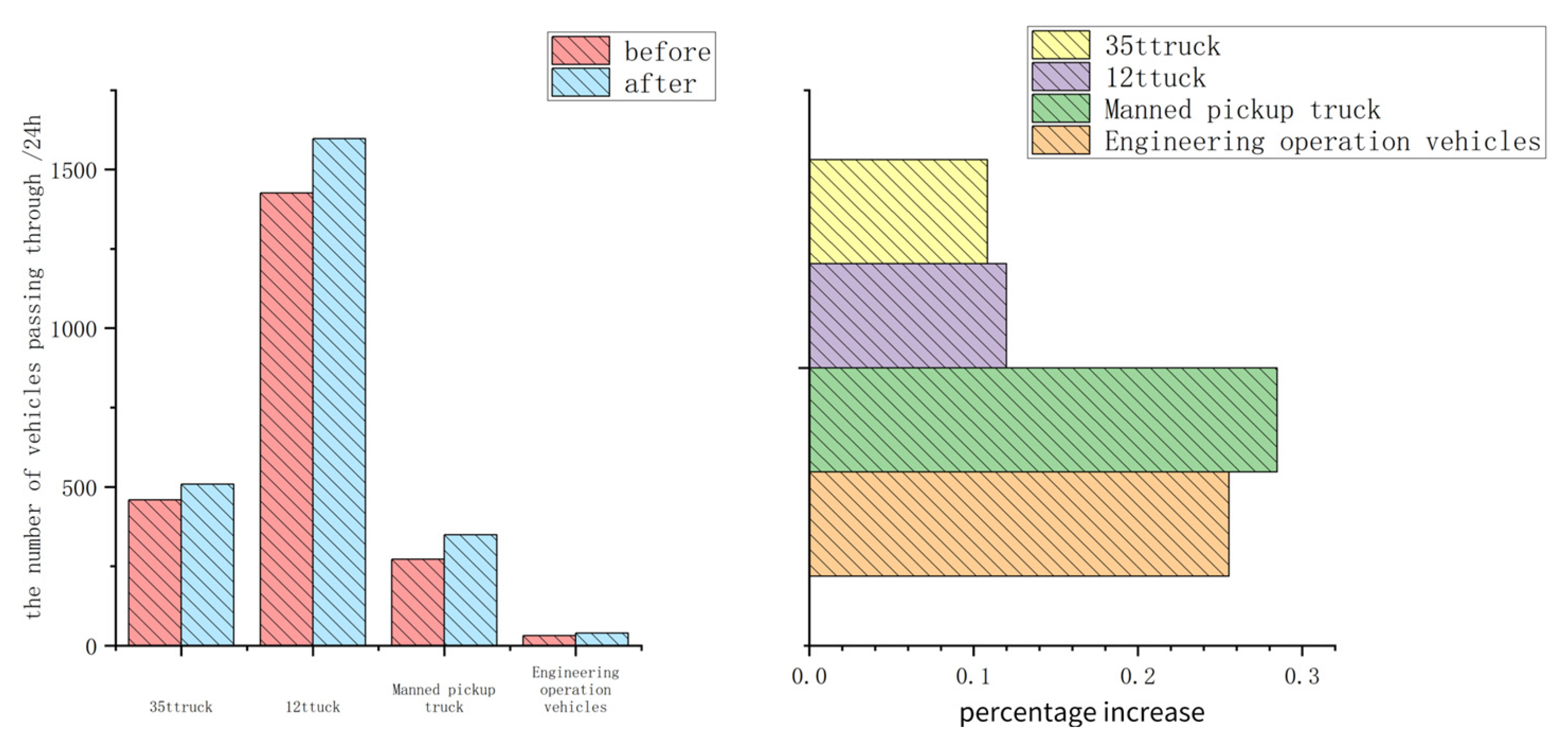

According to the simulation experiment data as shown in

Figure 11, the number of electric trucks carrying 35 t and diesel trucks carrying 12 t increased by 10.84% and 12.01% per 24 h, respectively, while the number of manned pickup trucks and engineering vehicles such as shovel machines increased by 28.47% and 25.54%, respectively. Among them, the increase in the number of transport trucks is significantly reduced compared with the increase in the latter two vehicles, which is because the priority of transport trucks is higher than the latter two in actual production. In the process of the trackless transport vehicle passing, the trackless transport vehicle with lower priority reverses to the nearest passing bays, so the optimization algorithm improves the traffic efficiency of the trackless transport vehicle with lower priority.

5.3.2. Average Travel Distance of the Trackless Transport Vehicles

This means each time the trackless transport vehicle completes the transport mission and arrives at the beginning of the next mission. The improvement in the average transport distance by the optimization algorithm is mainly reflected in the fact that when the optimized scheduling is not used, the two vehicles need to reverse to the nearest passing bays. After the completion of the trackless transport vehicle passing, the reversing section and the repassing section of the trackless transport vehicle passing are completely wasted. Therefore, when performing optimized scheduling, it can avoid invalid trips being caused, thus reducing the average transport distance of vehicles.

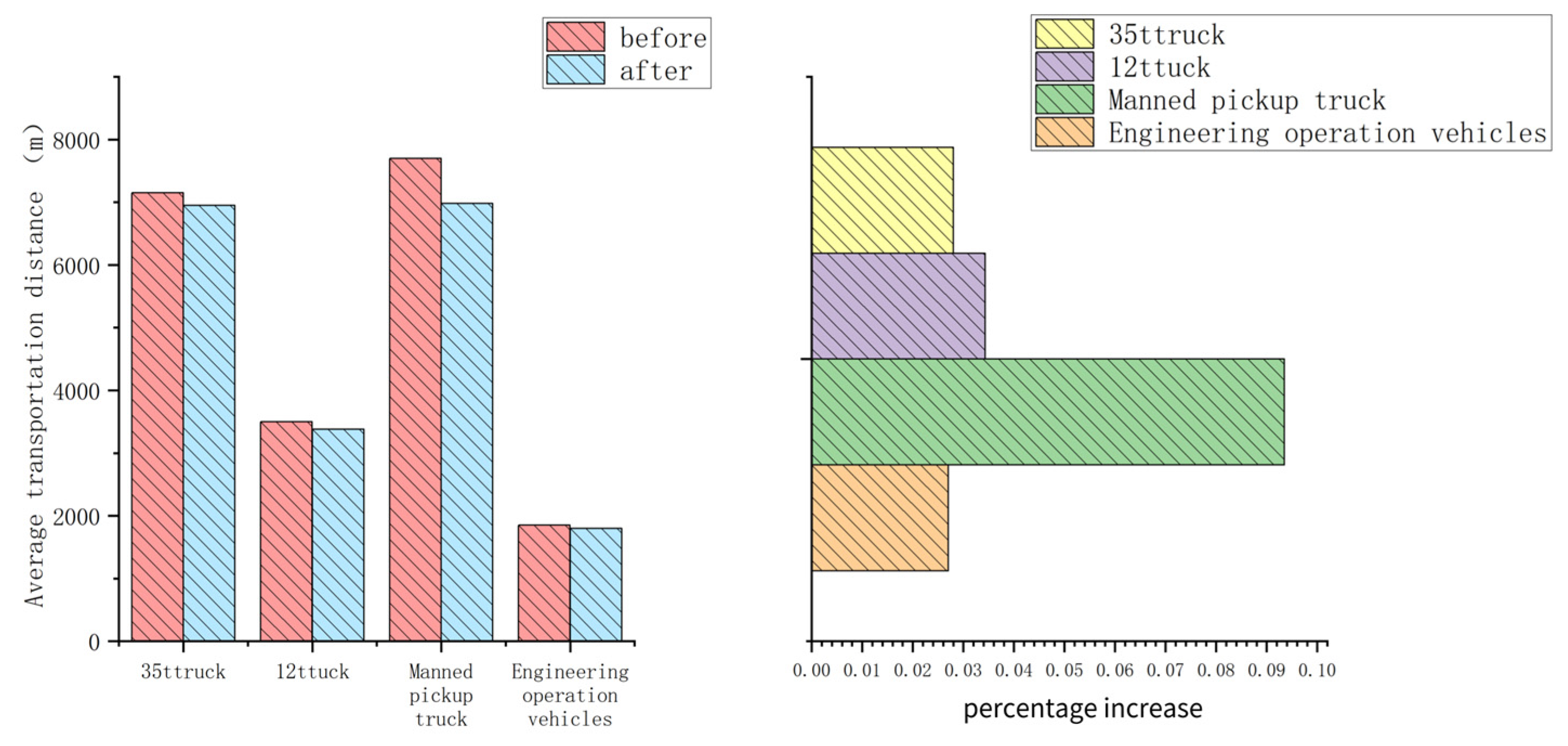

The simulated experimental data show that the average travel of the four different models is reduced after the optimization algorithm. As shown in

Figure 12, while the average travel of the 35 t electric truck decreased from 7150 m to 6950 m, down by 2.8%, the average travel of the 12 t diesel truck decreased from 3500 m to 3380 m by 3.43%. The average travel of the manned pickup truck was significantly reduced from 7700 m to 6980 m, or 9.35%, and the average travel decreased from 1850 m to 1800 m, a decrease of 2.70%. It can be seen from the change in the average trip data before and after optimization that the optimization algorithm improves the most for the average stroke of cars with low priority and long average stroke.

5.3.3. Transportation Costs of Vehicles

The transportation cost of the trackless transport vehicle is mainly reflected in the fuel consumption and the loss of the tires. It is known that the fuel consumption cost of the diesel mine dump truck is 0.4 ~ 0.5 yuan/t × km, and the average annual consumption of mine truck tires is 79 pieces. Using the optimization algorithm can effectively reduce the reverse operation of trackless transport vehicles because of vehicle passing, greatly reducing the number of vehicle braking and acceleration, and, at the same time, also reducing the invalid travel of trackless transport vehicles, thus greatly extending the service life of the tire and engine, reducing the trackless transport vehicle fuel consumption, and reducing the use of the trackless transport vehicle loss rate, significantly reducing the transportation cost of mine production. The experimental data are shown in

Figure 13.

The results of the simulated experimental data indicate that the optimization algorithm has the greatest impact on reducing the transportation cost of the manned pickup truck. The transportation cost was reduced from 11.2 yuan/t to 8.1 yuan/t, representing a 27.68% saving. Similarly, the transportation cost of the 12 t diesel truck was reduced from 14.3 yuan/t to 12.4 yuan/t, resulting in a 13.29% saving. Finally, the transportation cost of the 35 t electric truck was reduced from 45.5 yuan/t to 42.7 yuan/t, representing a 6.15% saving. The transportation cost is shown in

Figure 14.

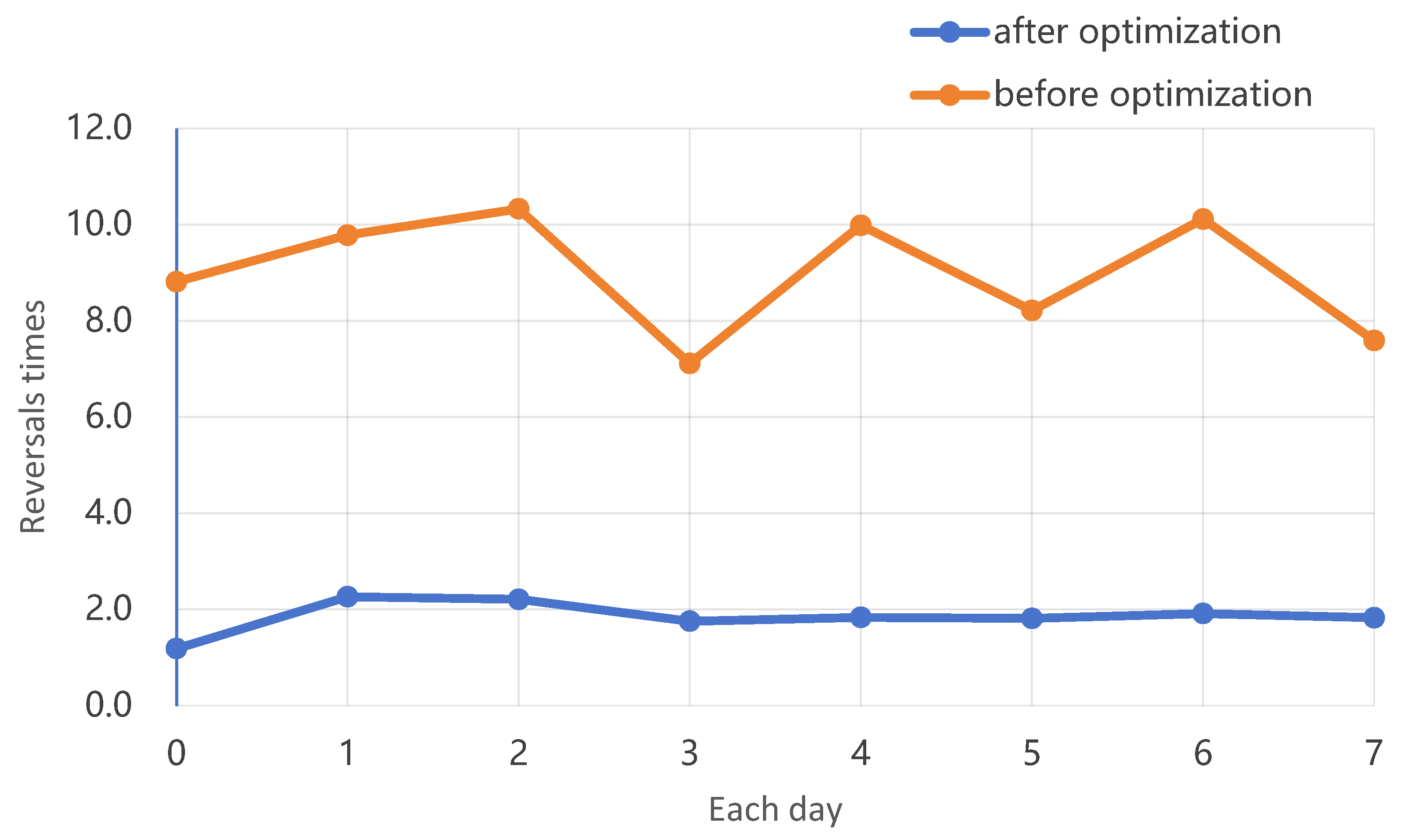

5.3.4. Passage Duration of the Ramp

The passage time of the ramp is defined as the time required for the simulated vehicle to traverse the ramp from the surface to the underground end. This measurement can be used to assess the patency degree of the ramp. Following the implementation of the optimization algorithm, the trackless transport vehicle is required to reverse for an extended period due to the trackless transport vehicle passing, resulting in a significant loss of time and the formation of traffic jams on the ramp. The experimental data from the simulation indicate that the walk from the surface to the slope underground takes 4.7 h before the implementation of the optimization algorithm. In contrast, the passage time of the optimization algorithm is reduced to 3.3 h, representing a significant reduction of 29.79%.

6. Conclusions

This paper examines the blockage of underground two-way one-way ramps. Given that the ramp is unable to reverse at the non-passing bay and that the interval fuzzy positioning method is employed, the ramp is divided and the real-time position section number of each vehicle is stored in the queue array. This method avoids the real-time reading of the position of trackless transport vehicles, reduces the spatial complexity of the algorithm, and can significantly improve the response speed of the algorithm and the requirements of the chip.

At the same time, the daily production and transportation tasks are optimized by an improved genetic algorithm. The fitness function is established from three aspects: traffic priority, transportation time cost, and distance cost. This is in accordance with the actual production requirements of the mine. The algorithm is more suitable for ramp path planning by improving the coding method. Finally, this study designs a simulation experiment according to the actual production and transportation situation of the project site. This experiment evaluates the comprehensive optimization effect of the proposed algorithm for different kinds of vehicles running on the ramp. The data indicate that the optimization algorithm is more effective when the priority is lower and the travel time is longer. In particular, for manned pickup trucks and other low-priority vehicles, the comprehensive indicators can be optimized and improved by more than 28%. However, for trackless transport vehicles such as mining trucks with the highest traffic priority and a close relationship to production efficiency, the optimization effect of the average travel and transportation cost is less than 10%, and the improvement is not significant. Nevertheless, the substantial reduction in blockage on the slope road has led to a notable enhancement in the driving speed and transportation efficiency of all vehicle types.

The research presented in this thesis is not without limitations and offers scope for further exploration in the future. 1. The simulation experiments are based on specific mine conditions. It remains to be seen whether they are applicable to other underground metal mines of the same type or even non-metal underground mines in the trackless transport. In the future, it would be beneficial to conduct experiments in a greater variety of mining conditions in order to assess the adaptability of the algorithm to differing mining conditions. 2. The transport scheduling only considers the route planning on the ramp. For underground mines, the route planning of vehicles in roadways has yet to be incorporated into the algorithmic optimization calculation. This is a crucial area for future research.