Featured Application

A paper-based triboelectric nanogenerator using carbon nanotube composite papers, as developed in this study, has the potential to be used as an energy harvester in fields such as the Internet of Things (IoT).

Abstract

A unique triboelectric nanogenerator (TENG) using carbon nanotube (CNT) composite papers is proposed in this work. CNT composite papers can be fabricated easily using a method based on the production of Japanese washi paper. To obtain and evaluate the proposed TENGs, several types of CNT composite papers and aluminum plates were prepared. As the CNT composite paper contained many paper fibers, it was expected to be negatively charged, and the aluminum plate was expected to be positively charged across the triboelectric series. Through various experiments, it was confirmed that CNT composite papers could be used as TENGs. In addition, it was found that when a CNT composite paper was used, it contributed to triboelectricity generation, and the contained CNTs efficiently transferred the generated charge to the electrodes. Furthermore, output voltages approaching a maximum RMS value of 300 mV could be obtained. The results of this study will aid in the practical application of paper-based TENGs in the near future.

1. Introduction

Renewable energy, such as solar, wind, and geothermal energy, is gaining considerable attention as a solution to the energy and environmental problems that have arisen in recent years. These types of renewable energy are continuously regenerated in nature and can be used indefinitely. This is especially promising for devices used in IoT and other applications because there are cases in which batteries are difficult to replace. Moreover, there are increasing demands for energy harvesters that can acquire energy from nature. Among these energy harvesters, triboelectric nanogenerator (TENG) devices, which are extremely simple in structure and use frictional charging, have been the most actively studied in recent years [1,2,3,4,5,6]. In this study, carbon nanotubes (CNTs) are considered to develop new types of TENGs.

A TENG is a generator that can effectively convert low-frequency mechanical energy that is wasted in the outside world into electrical energy. For example, TENGs are being developed that use wave energy from the ocean as their energy source. This can be achieved independently or in combination with a conventional generator. In the last few years, the operating principle of TENGs has been developed, enabling them to harness power from dynamic blue energy (ocean and river waves) [7,8,9,10,11]. The operating principle of TENGs involves the repetition of contact and separation between two materials (sheets) with opposite frictional charges, resulting in a periodic change in the potential difference, which is extracted to generate electricity. Generally, a material that tends to carry a positive frictional charge and a material that tends to carry a negative frictional charge are prepared for TENGs [1,2].

CNTs, which were discovered in 1991 [12], are known for their high chemical stability, mechanical strength, high electrical and thermal conductivity, and metallic and semiconducting nature [13,14,15,16,17,18]. Due to the various beneficial characteristics described above, there are great expectations for the practical application of various devices using CNTs [19]. However, because CNTs are generally nanoscale materials with a diameter of only a few nm and a length of only a few μm, and because most commercial products on the market are in powder form or in water dispersions, they are difficult to handle. This makes it challenging to develop applications for them. Therefore, research is being conducted not only on methods that use CNTs alone but also on their application to devices in the form of composite materials in combination with other materials. Such solutions are referred to as “CNT composite materials”. By creating a composite material, their handling becomes easier, and the functions of CNTs can be exploited in this form [20,21,22,23].

CNT composite papers [24], which can be easily handled as they are “familiar materials” with the various features of CNTs, are currently being developed. These composite papers have attracted much attention as new, unique materials because they have the same processability and deformability as paper while maintaining the various functions of CNTs. Various applications based on the CNT composite papers have already been investigated, including paper dye-sensitized solar cells [25], paper actuators [26], and thermoelectric power-generating papers [27].

Recently, to improve their flexibility and power-generating efficiency, a new type of TENG based on the combination of CNTs and polymers has been proposed [4,5]. Such TENGs have certain usefulness as energy harvesters, but it has been found that issues remain regarding their durability and the complexity of their fabrication. In this context, the CNT composite paper is expected to represent a candidate for new TENG devices. Therefore, the development of a unique TENG device using CNT composite papers is considered in this study. A CNT composite paper can be produced easily using a method derived from the traditional Japanese method of washi paper production [24]. In addition, unlike other typical plain materials, this paper has a unique structure in which the CNT network is embedded in a network of paper fibers. Moreover, because it is paper, it is expected to have higher mechanical strength compared to gel- or polymer-based TENGs. The most widely used materials for TENGs are cellulose gels [28], ion gels [28], and polydimethylsiloxane (PDMS) [5]. According to reports, cellulose gels have a tensile strength of 13.8 MPa [29], ionic gels have a tensile strength of approximately 1.5 MPa [30], depending on the ions used, and PDMS has a tensile strength of 10.8 MPa [31]. In contrast, the strength of the paper (cellulose material) is reported to be in the order of GPa [32]. In addition to this, it has been reported that papers containing CNTs (CNT composite papers) become even stiffer than regular papers as the amount of CNTs increases [33]. Therefore, even if CNTs are not included, there would be a strength advantage when using such papers. Thus, CNT composite papers could represent a strong candidate for the next generation of TENGs containing CNTs and could be used, for example, in the IoT field as energy harvesters in the near future.

2. Materials and Methods

2.1. Fabrication of CNT Composite Paper

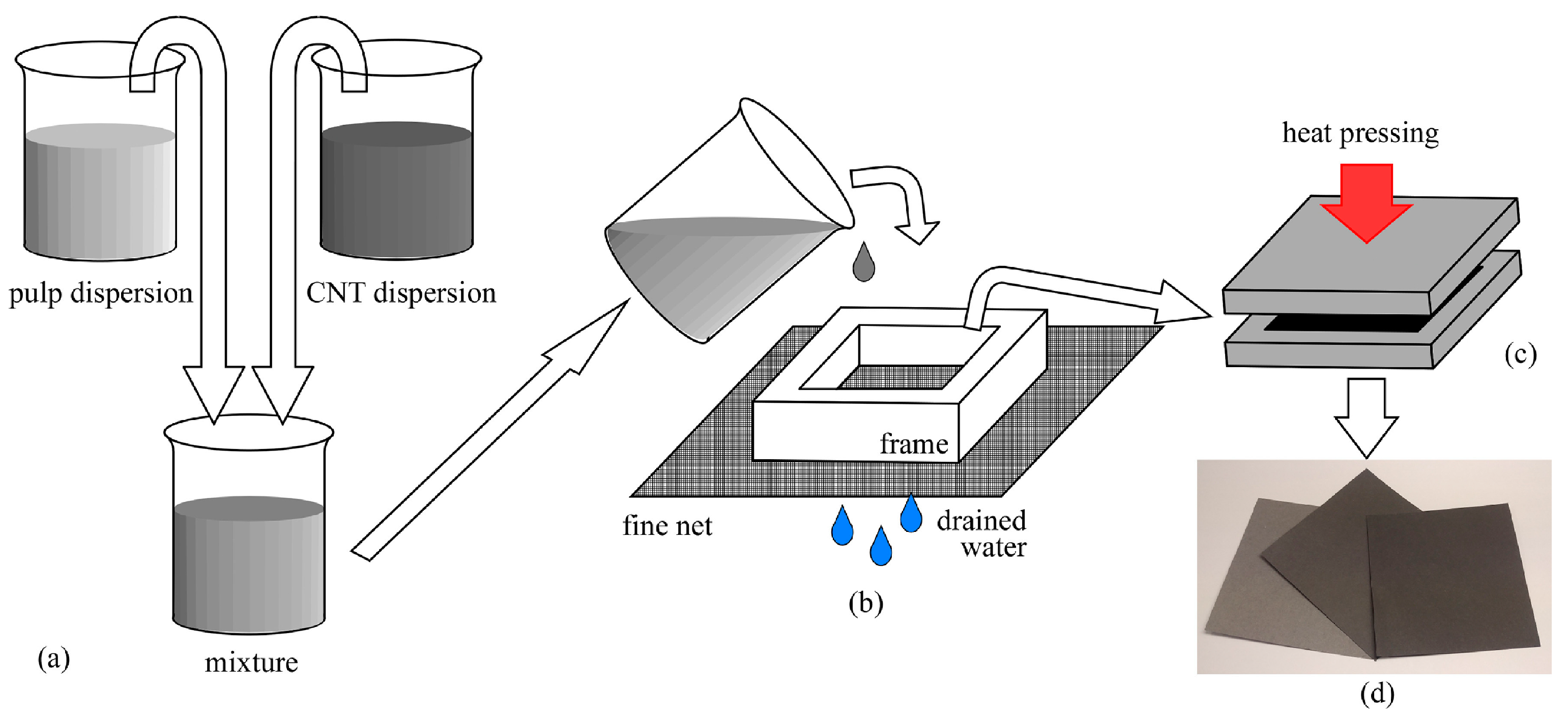

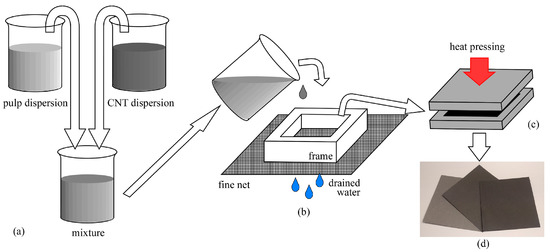

The purpose of this work is to explore the conditions for the use of CNT composite papers as TENGs and to evaluate the performance of these papers in TENGs, rather than to develop a fabrication method. The procedure for the fabrication of the CNT composite paper is based on the traditional Japanese method of washi paper making [24,27]. The method of preparing CNT composite papers adopted in this study, based on the method reported in Ref. [27], is described below.

- (1)

- Mix the CNTs and dispersant in pure water.

- (2)

- Prepare the CNT dispersion by dispersing the mixture obtained in (1) with an ultrasonic homogenizer for 1 h.

- (3)

- Mix pulp material in pure water.

- (4)

- Prepare a pulp (raw material of paper, derived from eucalyptus) dispersion by stirring the mixture obtained in (3) with an agitator for 1 h.

- (5)

- Mix and stir the CNT dispersion prepared in (2) with the pulp dispersion prepared in (4) to prepare a mixture.

- (6)

- Pour the mixture prepared in (5) into the paper-making apparatus to dehydrate it.

- (7)

- Remove the dehydrated raw ingredients prepared in (6) from the apparatus and subject them to heat pressing to enable drying and forming, resulting in the CNT composite paper.

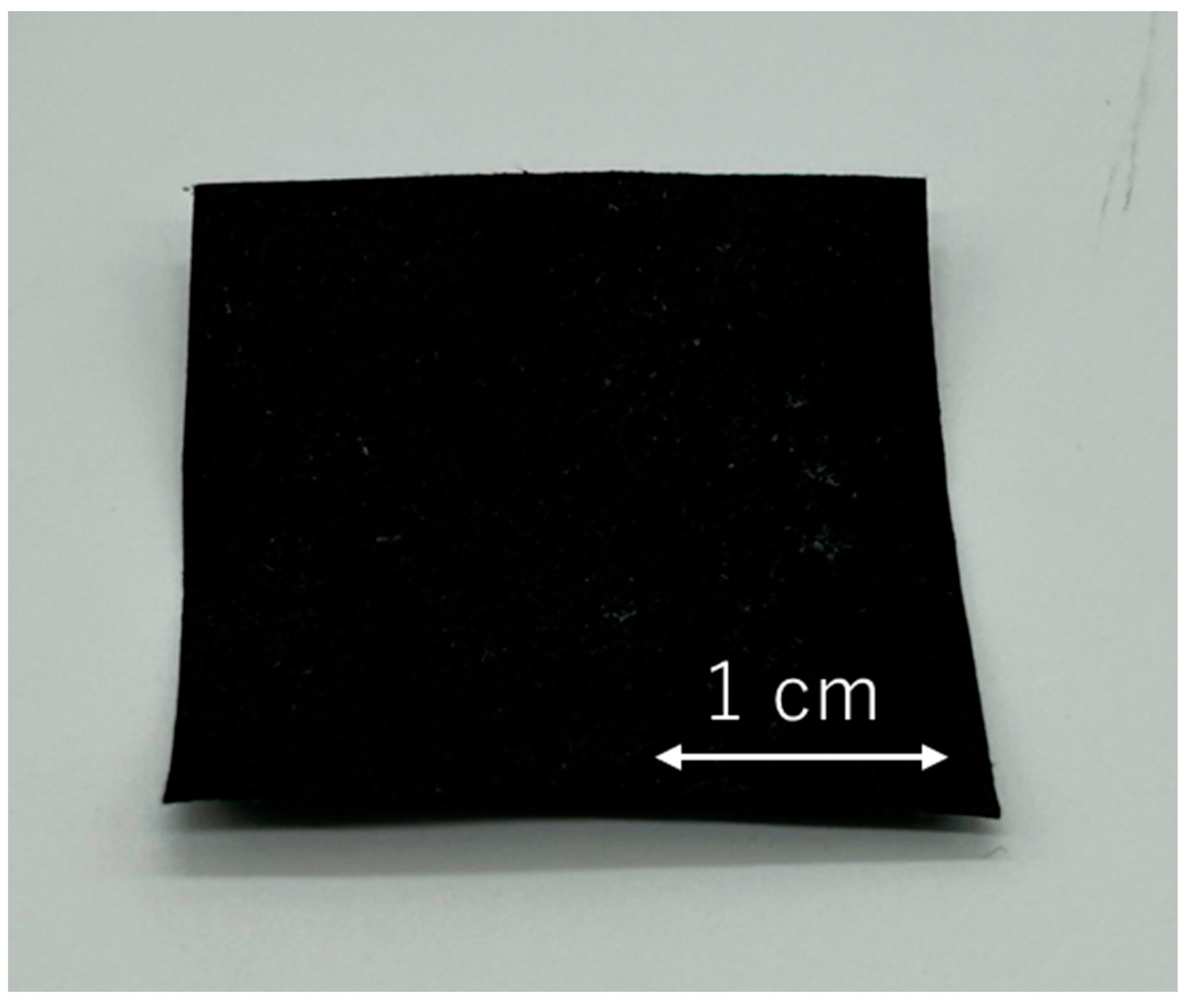

A schematic of the fabrication method is shown in Figure 1. Figure 2 shows the fabricated CNT composite paper obtained in this study. The evaluation of CNT composite papers through SEM, Raman scattering measurements, etc. has been performed in previous studies [24,26,27]. As the fabrication method is the same in this study, it is assumed that the physical properties are similar.

Figure 1.

Schematic of the CNT composite paper-making method: (a) preparation of mixture, (b) dehydration, and (c) heat pressing. (d) Completed samples (color differences were caused by the number of CNTs that they contained) (from Ref. [27] under License CC BY 4.0).

Figure 2.

Fabricated CNT composite paper (3 cm × 3 cm).

2.2. Construction of and Experiments on TENG Based on CNT Composite Papers

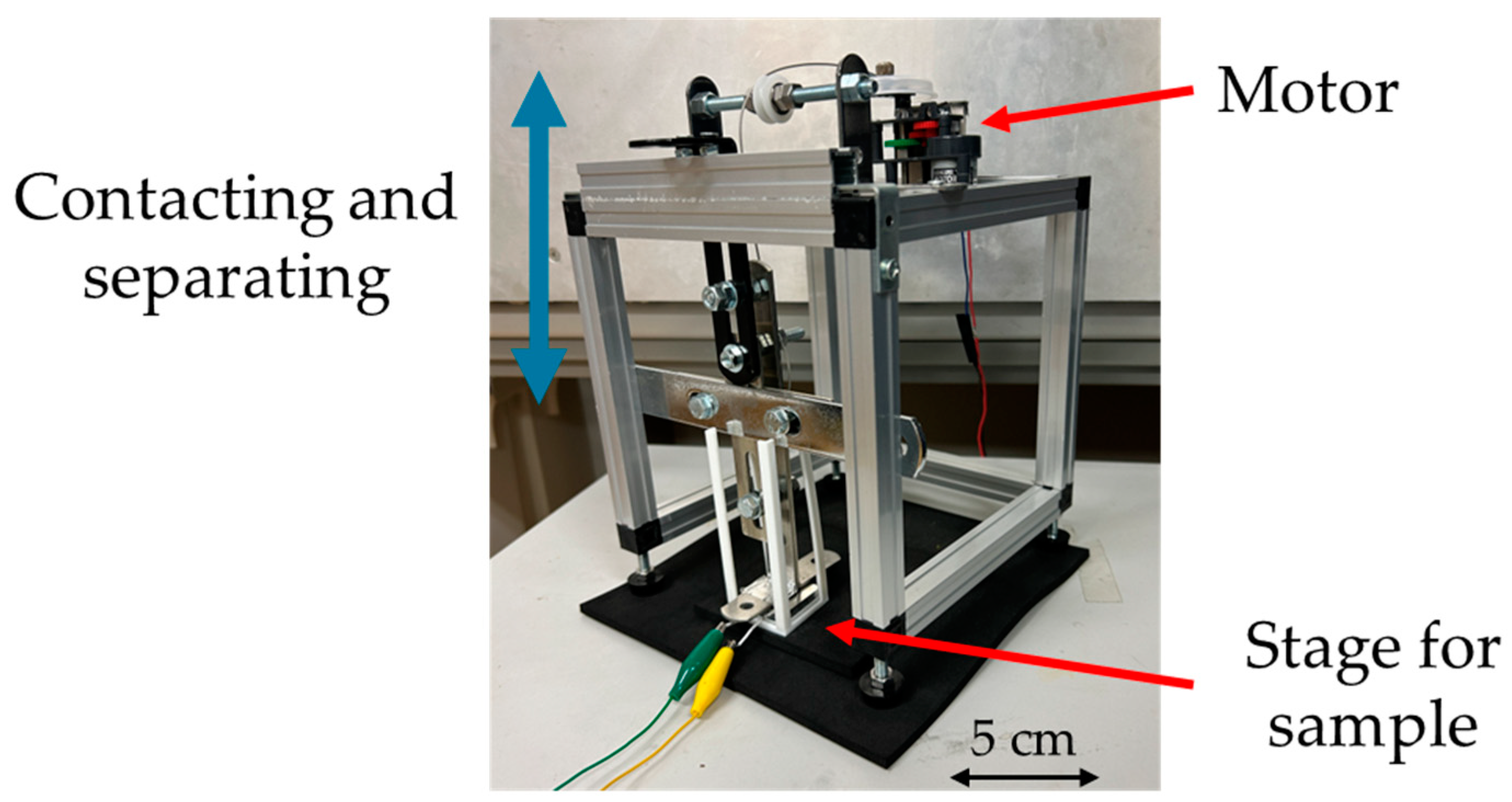

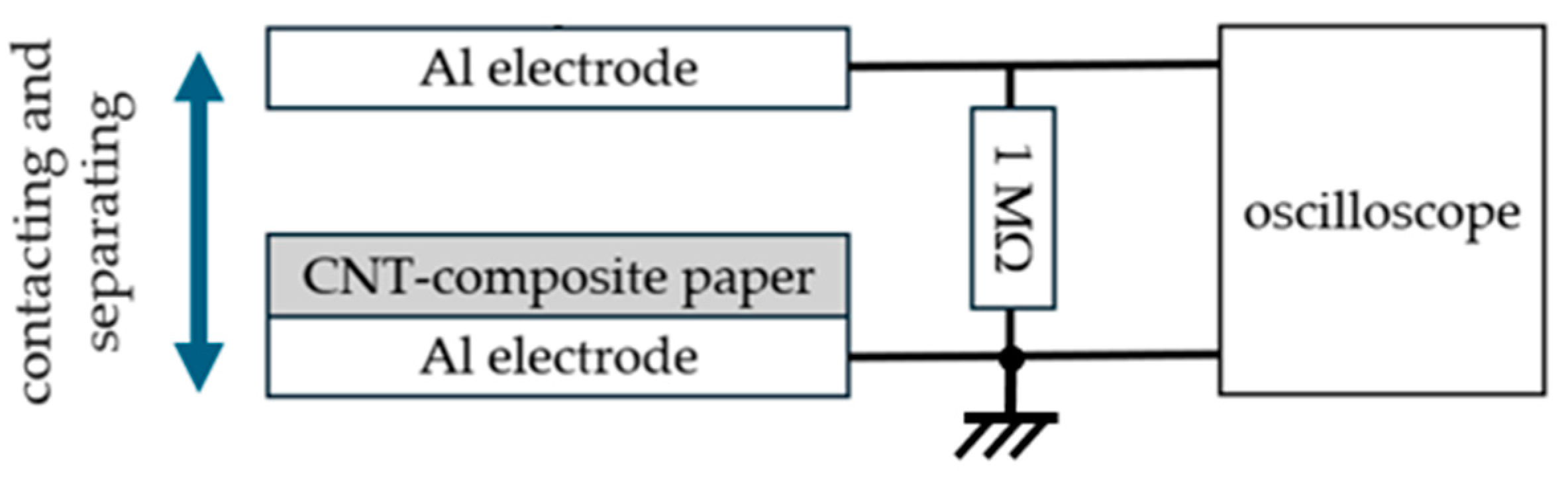

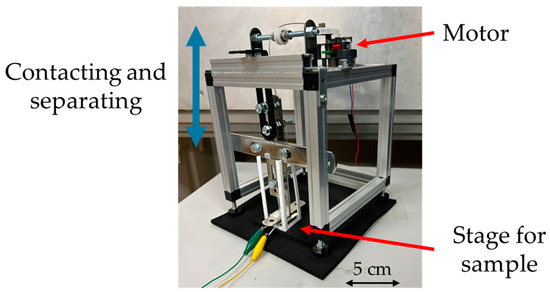

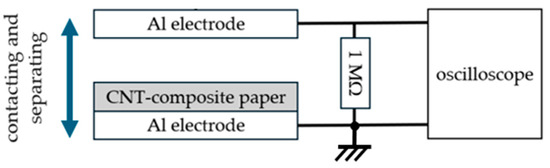

In this section, the fabrication of and experimental methods using the proposed TENG are described. As explained in the Introduction, a TENG requires two materials. In this study, the TENG is constructed using the CNT composite paper, as described in Section 2.1, as well as aluminum plates. The proposed TENG generates electricity by periodically creating contact and separation between the aluminum electrode and the CNT composite paper. In order to quantitatively evaluate the output voltage, an apparatus (Figure 3) that can create such contact and separation at a constant speed is used in this study. A schematic of the experimental setup used is shown in Figure 4. In the apparatus, the rotation of a motor placed at the top is converted into linear (up-and-down) motion by a crank. One end of the crank is connected to an aluminum electrode plate, which periodically establishes contact with and separates from the CNT composite paper. By controlling the voltage applied to the motor, the rotational speed of the motor can be controlled, resulting in a change in the speed of contact and separation. To supply a DC voltage to the motor, we use a DC stabilized power supply (Agilent, E3630A, Agilent Technologies, Inc., Santa Clara, CA, USA).

Figure 3.

Apparatus for demonstration of the proposed TENG.

Figure 4.

Schematic of the experimental system.

In the experiment, resistance of 1 MΩ is applied as a load, and the voltage at both ends of the load resistance is measured with a digital oscilloscope (IWATSU, DS-5105B, IWATSU Electric Co., Ltd., Tokyo, Japan). As the CNT composite paper contains many paper fibers, the top surface of the paper is expected to be negatively charged, and the aluminum plate is expected to be positively charged across the triboelectric series of paper and aluminum [2]. On the other hand, one side of the CNT composite paper is fixed to the other aluminum electrode, as shown in Figure 4. In the contact process, the contact interface of aluminum will be biased positively, and the oscilloscope probe side will be biased negatively. Also, the contact interface of the CNT composite paper will be biased negatively, and the probe side will be biased positively. Therefore, a negative peak will be seen in the contact process because the negative current will flow to the oscilloscope. In the separation process, the reverse of the contact process will occur, and the positive current will flow to the oscilloscope. As a result, a positive peak will be seen in the separation process. In this experiment, the aluminum electrode on the bottom side is used as a reference, as shown in Figure 4.

In the experiment, the output data often contain a large amount of noise. To remove the noise from the obtained output data, a Fourier transform is used. Then, the RMS of the waveform without the noise is calculated to obtain the output, and it is evaluated.

For the evaluation, the proposed TENG device was constructed. Firstly, four types of CNT composite paper were prepared using the method described in Section 2.1 to clarify the role of CNTs in the proposed TENG. Here, the CNTs SG101-CNT (ZEON CORPORATION, Tokyo, Japan), (6,5)-chirality CNT (CHASM, SG65i), and (7,6)-chirality CNT (CHASM, SG76, CHASM Advanced Materials, Canton, MA, USA), which are single-walled and have semiconducting properties, were prepared. In addition, NC7000 (Nanocyl SA, Sambreville, Belgium), which is multi-walled and has metallic properties, was also used. To prepare the CNT dispersions as described in step 2 of the method presented in Section 2.1, 15 mg each of the chosen CNTs, 100 mg of sodium dodecyl sulfate (SDS, Nacalai Tesque, Inc., Kyoto, Japan) as a dispersant, and 20 mL of pure water were used. In addition, to prepare the pulp dispersion for step 4 of the method given in Section 2.1, 100 mg of pulp material and 100 mL of pure water were used. The pulp material used for the fabrication of the CNT composite paper in this study was derived from eucalyptus and was provided by Mitsubishi Paper Mills, Ltd., Tokyo, Japan. The CNT composite papers were prepared following the method described in Section 2.1. Finally, they were cut into squares with a length of 3 cm on each side. The resistance was then measured with a four-terminal resistance meter (HIOKI, RM3544-01, Hioki E.E. Corporation, Nagano, Japan) to evaluate the electrical properties. The sheet resistance was calculated from the measured values and used as an index of the performance of the CNT composite paper. Then, using conductive tape, the CNT composite papers, cut into 3 cm squares, were fixed to aluminum plates cut into 5 cm squares. These were placed at the bottom of the device, as shown in Figure 3, for each measurement, with the CNT composite paper on the upper side. The CNT composite paper was applied as a TENG by establishing contact with and separating these samples from the aluminum electrode, which was connected to the clamp of the apparatus. The stabilized power supply for the motor drive of the apparatus was 2 V.

2.3. Investigation of Performance Changes Due to Changes in CNT Composite Paper-Making Conditions

2.3.1. Effect of Changing Amount of CNTs

As explained in Section 3.1 below, the results were not dependent on the type of CNTs, so only SG101-CNTs were used for the investigation and the following experiments. Here, the effect of changing the amount of CNTs on the output was investigated. For this, four types of CNT composite paper were prepared with 0, 5, 15, and 30 mg of CNTs. To prepare the CNT dispersion, 50 mg of SDS and 20 mL of pure water were used. For the pulp dispersion, 200 mg of pulp material and 100 mL of pure water were used. The above amounts were used to investigate the effect of reducing the amount of CNTs contained in relation to the amount of pulp. The original amounts of CNTs and pulp were 15 mg and 100 mg, respectively. As the pulp content was set to 200 mg for convenience during production, the ratio of CNTs with 30 mg was the same as the original ratio.

2.3.2. Effect of Changes in Pulp Amount in CNT Composite Paper

The effect of changing the amount of pulp material included in the CNT composite paper on the output was also investigated. The CNTs used were as follows: SG101, (6,5)-chirality, and (7,6)-chirality CNTs. For comparison, a pulp-only paper without CNTs was also prepared. Table 1 shows the conditions during the sample preparation. The amount of each CNT used was fixed at 15 mg. Regarding the amount of pulp, 100 mg and 200 mg were used for each CNT. As a result, a total of 8 types were prepared.

Table 1.

Conditions for sample preparation.

3. Results

3.1. Performance Evaluation of TENG Using CNT Composite Paper

After the CNT composite papers were prepared by following the methods described in Section 2.1 and Section 2.2, they were configured as TENGs. Table 2 shows the typical properties of the fabricated CNT composite papers. In the table, a variation in the thickness of the resulting CNT composite paper can be seen. However, the thickness was not deliberately changed. Sample preparation is a manual process, which inevitably results in variations. Due to the use of paper, there were also many surface irregularities. The amount of pulp used in the sample preparation was set at a fixed value, as described in Section 2, so the ratio of CNTs to pulp was also set at a fixed value. Therefore, this variation was considered to be generally acceptable. If the process of CNT composite paper production is mechanized in the future, it is expected that the thickness variation will be resolved.

Table 2.

Measured properties of fabricated CNT composite papers.

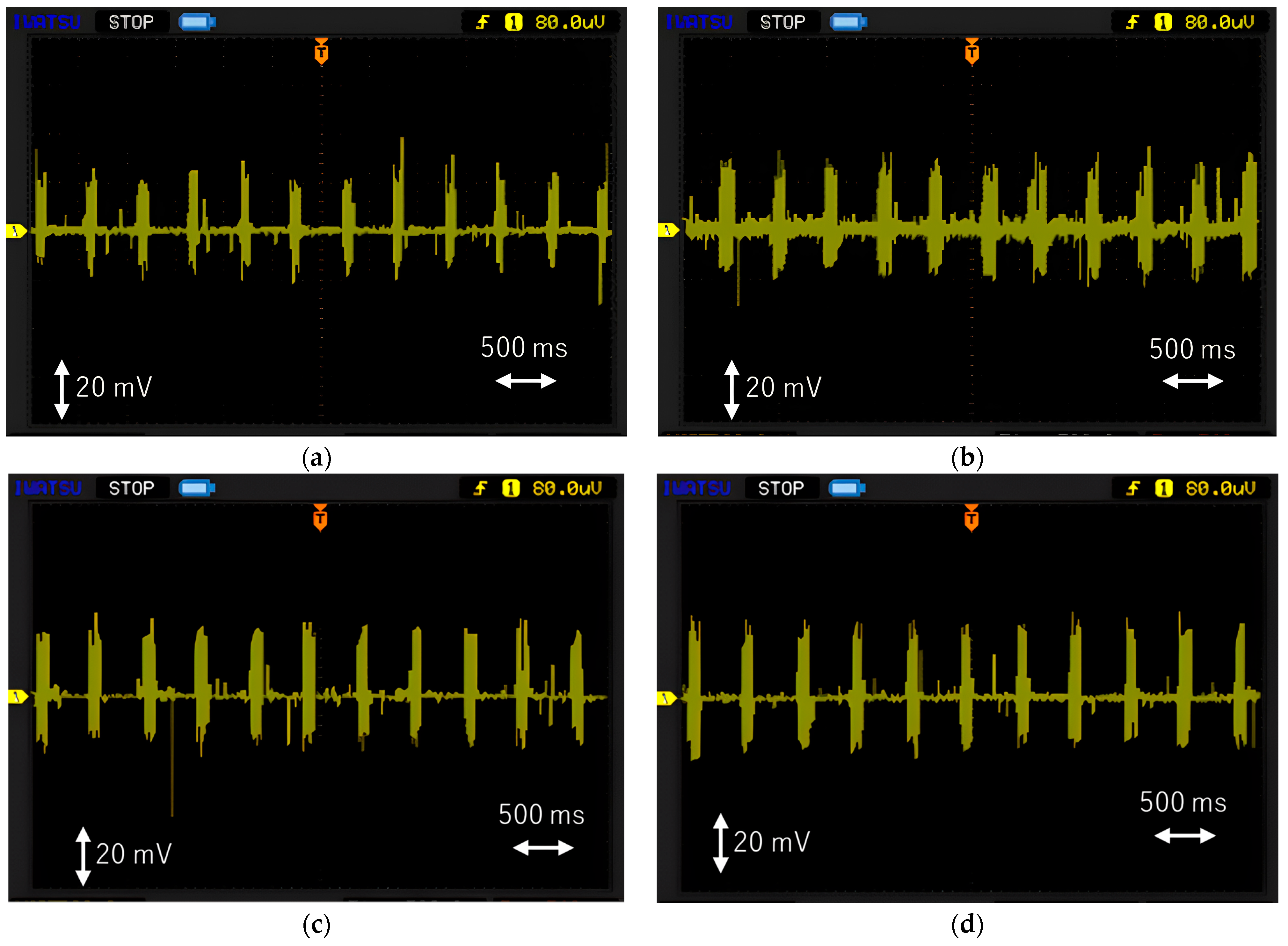

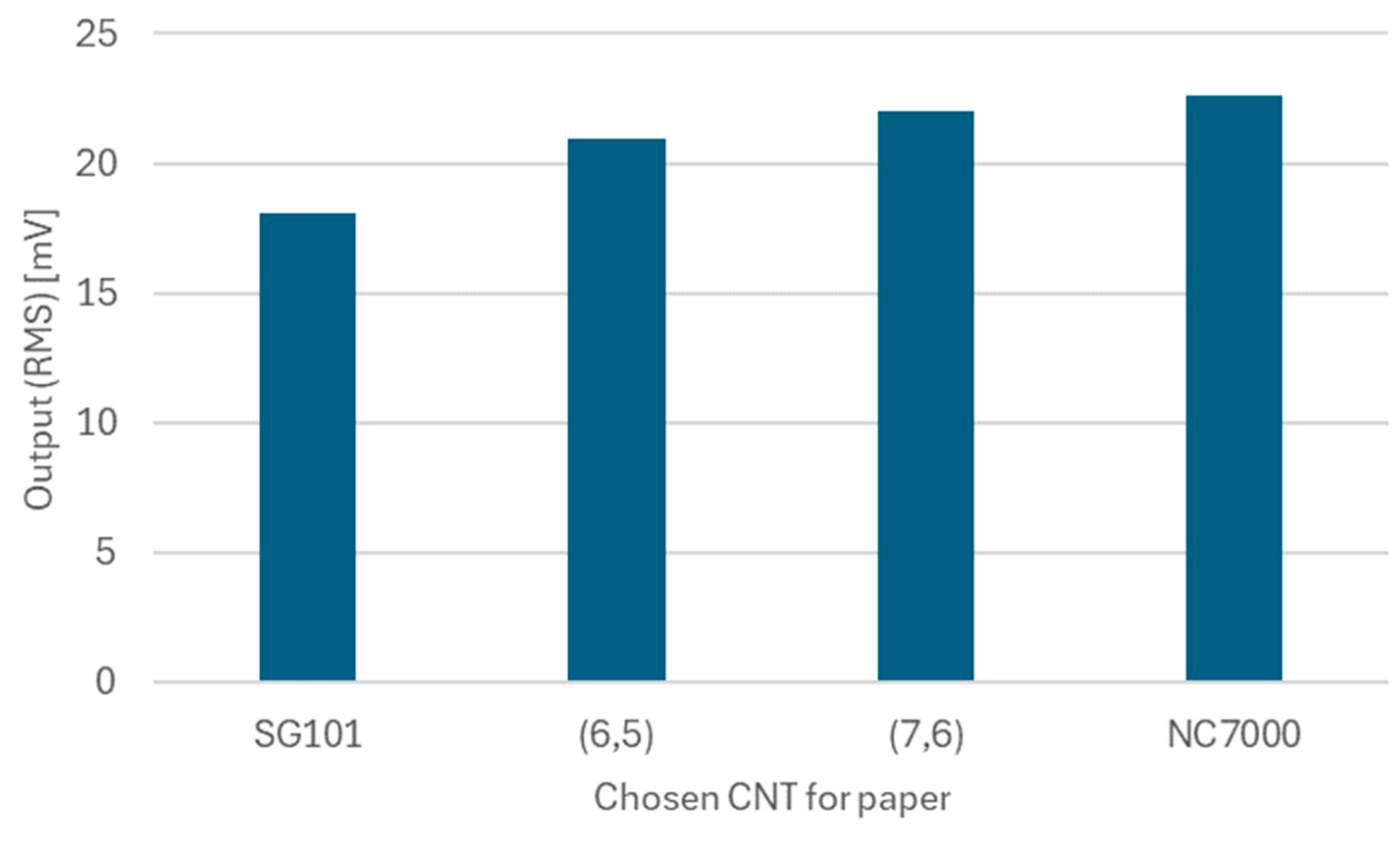

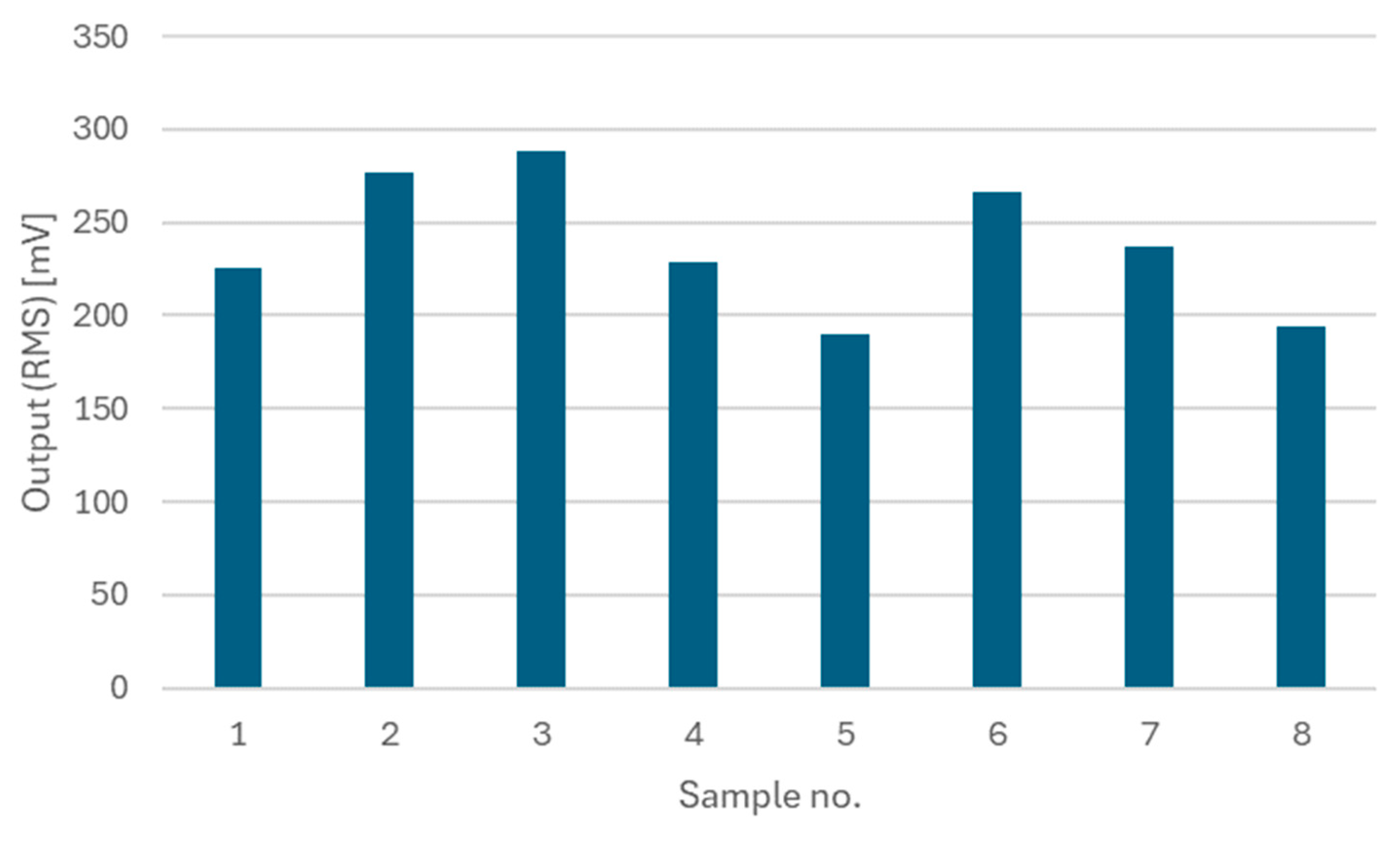

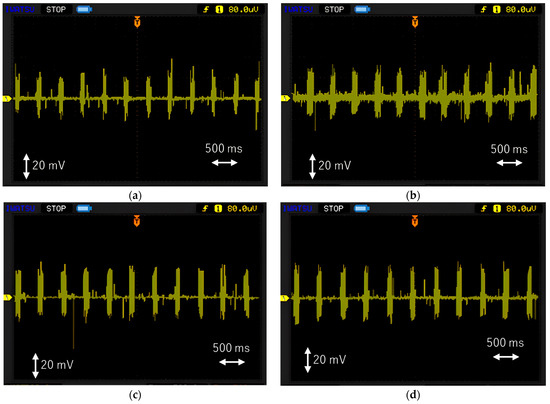

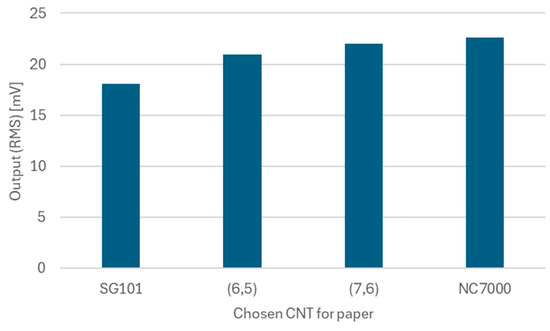

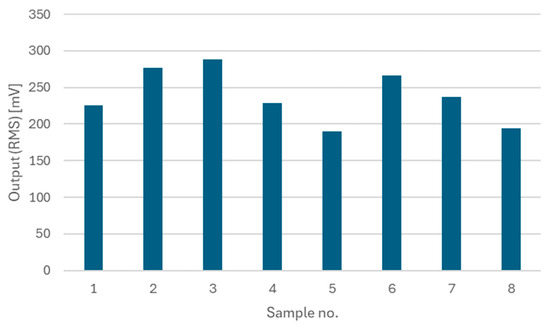

Figure 5 shows the results regarding power generation with the TENGs placed in the apparatus, as shown in Figure 3. Here, the potential change in the load resistance was observed with an oscilloscope. From the output results, positive and negative peak voltages appeared alternately in a constant rhythm for all CNT composite papers. These represent distinctive waveforms in triboelectric power generation. In other words, it was confirmed that CNT composite papers can be used as TENGs. Figure 6 shows the RMS values calculated based on the oscilloscope measurements. Triboelectricity generation was observed for the SG101, (6,5)-chirality, and (7,6)-chirality CNTs with semiconducting properties and NC7000 CNTs with metallic properties. There was no significant difference in the magnitude of the output. These results suggest that, in triboelectricity generation using CNT composite papers, the CNTs may not serve to increase the output but rather assist in charge transfer within the composite paper. As described in the Introduction, unlike other typical plain materials, the CNT composite paper has a unique structure in which the CNT network is embedded in a network of paper fibers. According to Table 1, each CNT composite paper showed low resistivity. Generally, low-resistance materials are not preferred as TENG materials. However, it is considered that the low resistivity is not necessarily a disadvantage when using CNT composite papers because they have a mixture of surfaces that are advantageous for triboelectricity generation (pulp area) and surfaces that can easily collect the generated charge (CNT network area) if viewed locally.

Figure 5.

Triboelectricity generation results for four types of CNT composite paper. (a) SG101, (b) (6,5)-chirality, (c) (7,6)-chirality, and (d) NC7000.

Figure 6.

RMS values of output derived from Figure 5.

3.2. Investigation of Performance Changes Due to Changes in CNT Composite Paper-Making Conditions

3.2.1. Effect of Changing Amount of CNTs

In this subsection, it is considered how the triboelectricity generation performance changes with the changing amount of CNTs in the samples prepared via the methods described in Section 2.3.1. Table 3 shows the typical properties of the fabricated CNT composite papers. In the table, a variation in the thickness of the resulting samples can be seen. The reason for this is the same as that described in Section 3.1.

Table 3.

Measured properties of fabricated CNT composite papers. For the sample without CNTs (0 mg of CNT), the resistance value cannot be measured because it exceeded the measurement limit of the resistance meter.

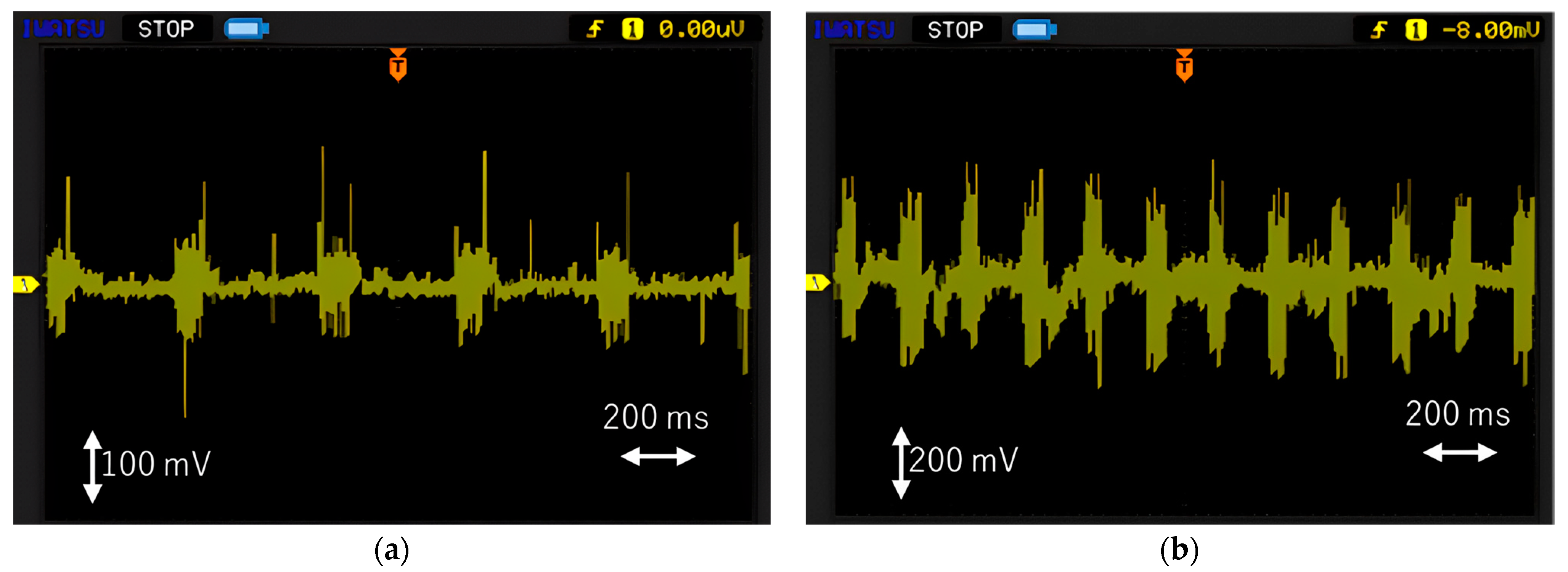

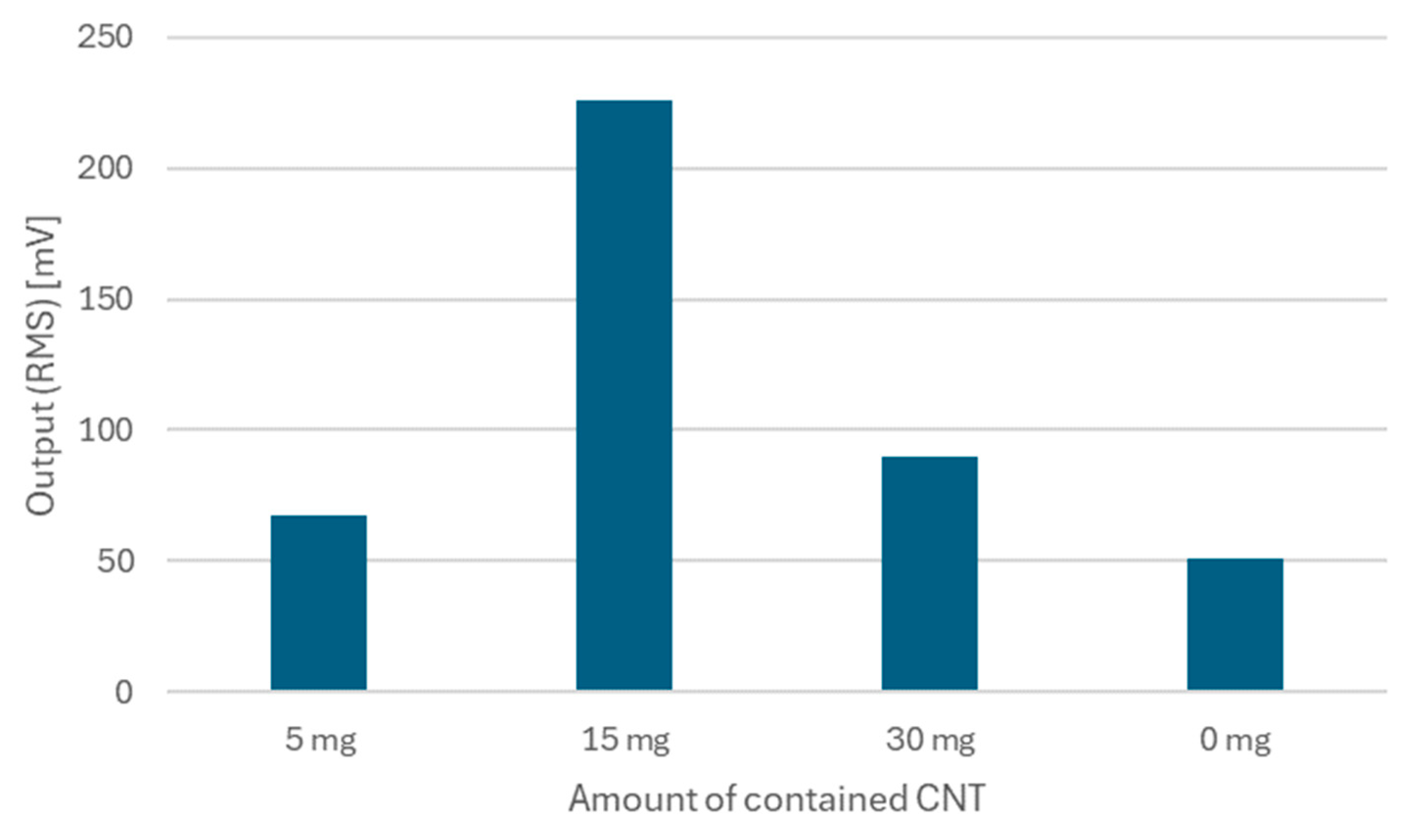

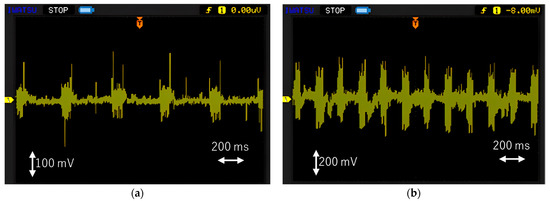

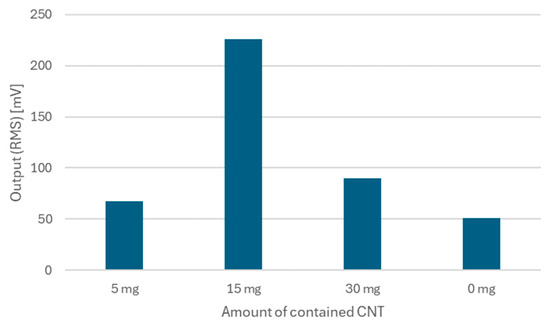

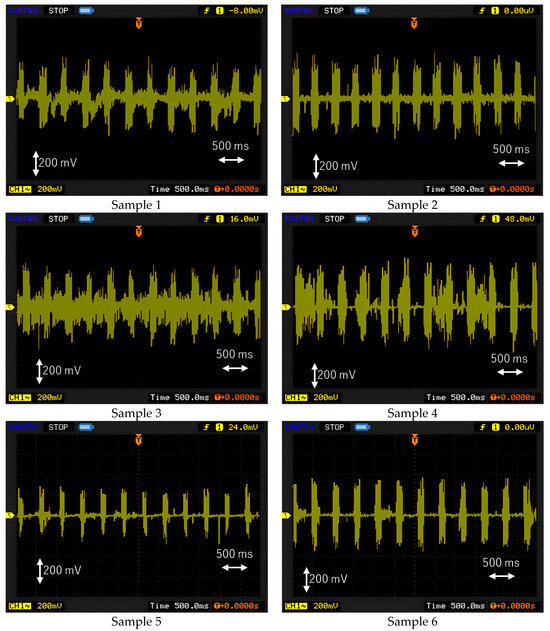

Figure 7 shows the results in terms of power generation for our TENGs with changes in the CNT amount. Figure 7a–c show the output from samples containing CNTs, confirming the presence of a waveform that is characteristic of triboelectricity, similar to the results in Figure 5. Figure 7d is the output from a pulp-only sample without CNTs, which did not show the characteristics of triboelectricity, in comparison with Figure 7a–c. In addition, this waveform showed many signals that appeared to be noise. This may have been due to the fact that this sample did not contain CNTs, so the generated charge could not be collected properly, resulting in more noise. In addition, in the measurements, some results showed asymmetric peaks instead of the clearly alternating output peaks that appear in general TENGs. According to other reports [34,35], depending on the surface shape of the device, there may not be clearly alternating output peaks. The surface of the CNT composite paper used in this study was not smooth and had non-uniform flatness. Therefore, no clearly alternating output peaks could be seen in the output waveform in this study. Figure 8 shows the RMS values calculated based on the oscilloscope measurements. While there was no significant difference in the output between the samples containing 5 mg and 30 mg of CNTs, the output of the 15 mg sample was approximately 3.7 times higher than that of the aforementioned samples. This suggests that there is an optimal amount of CNTs required to increase the output and that the inclusion of more CNTs will decrease the output. It is also thought that CNTs do not increase the output; rather, they efficiently transfer the electric charge generated during triboelectric power generation to the electrodes, as initially assumed.

Figure 7.

Triboelectricity output results for each CNT amount. (a) 5 mg, (b) 15 mg, (c) 30 mg, and (d) 0 mg.

Figure 8.

RMS values of output derived from Figure 7.

3.2.2. Effect of Changes in Pulp Amount in CNT Composite Paper

In this subsection, we consider how the triboelectricity generation performance changes with changing amounts of pulp in the samples obtained via the methods described in Section 2.3.2. Table 4 shows the typical properties of the fabricated CNT composite papers. The preparation conditions for each sample are described in Table 1. In the table below, a variation in the thickness of the resulting samples is again observed. The reason for this is the same as that described in Section 3.1 and Section 3.2.

Table 4.

Measured properties of fabricated CNT composite papers. For samples 4 and 8, without CNTs (0 mg of CNT), the resistance values cannot be measured because they exceeded the measurement limit of the resistance meter.

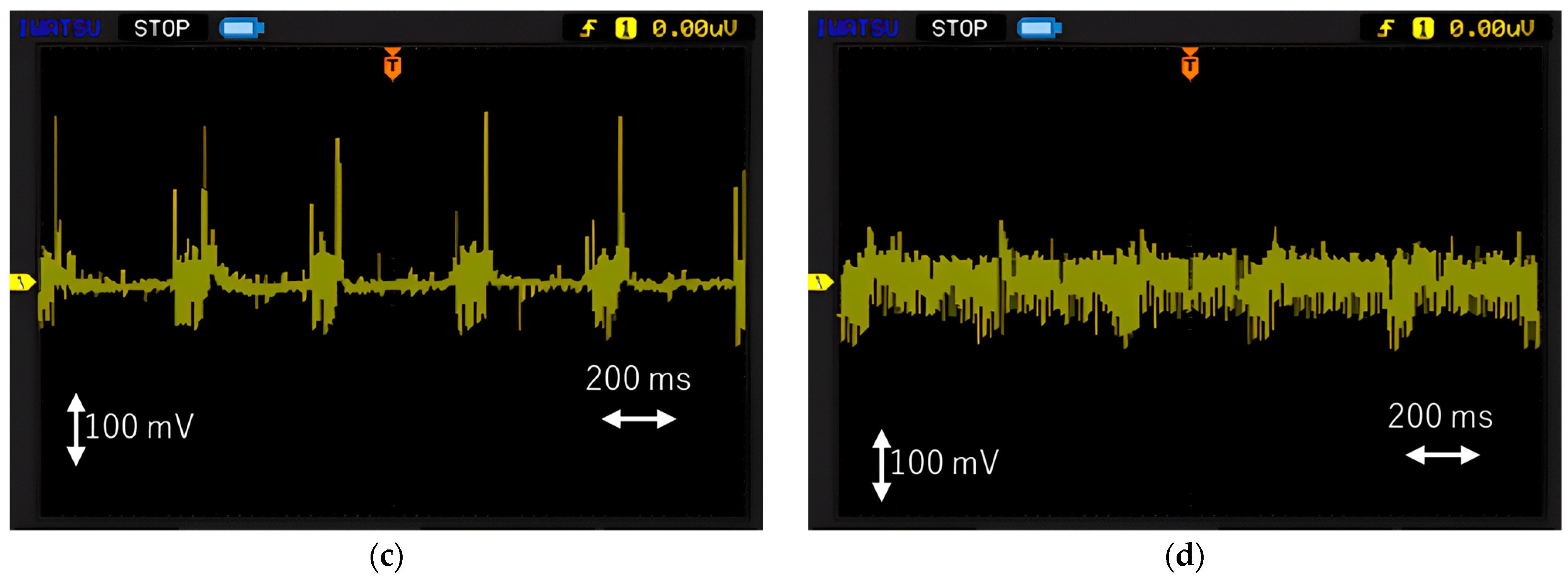

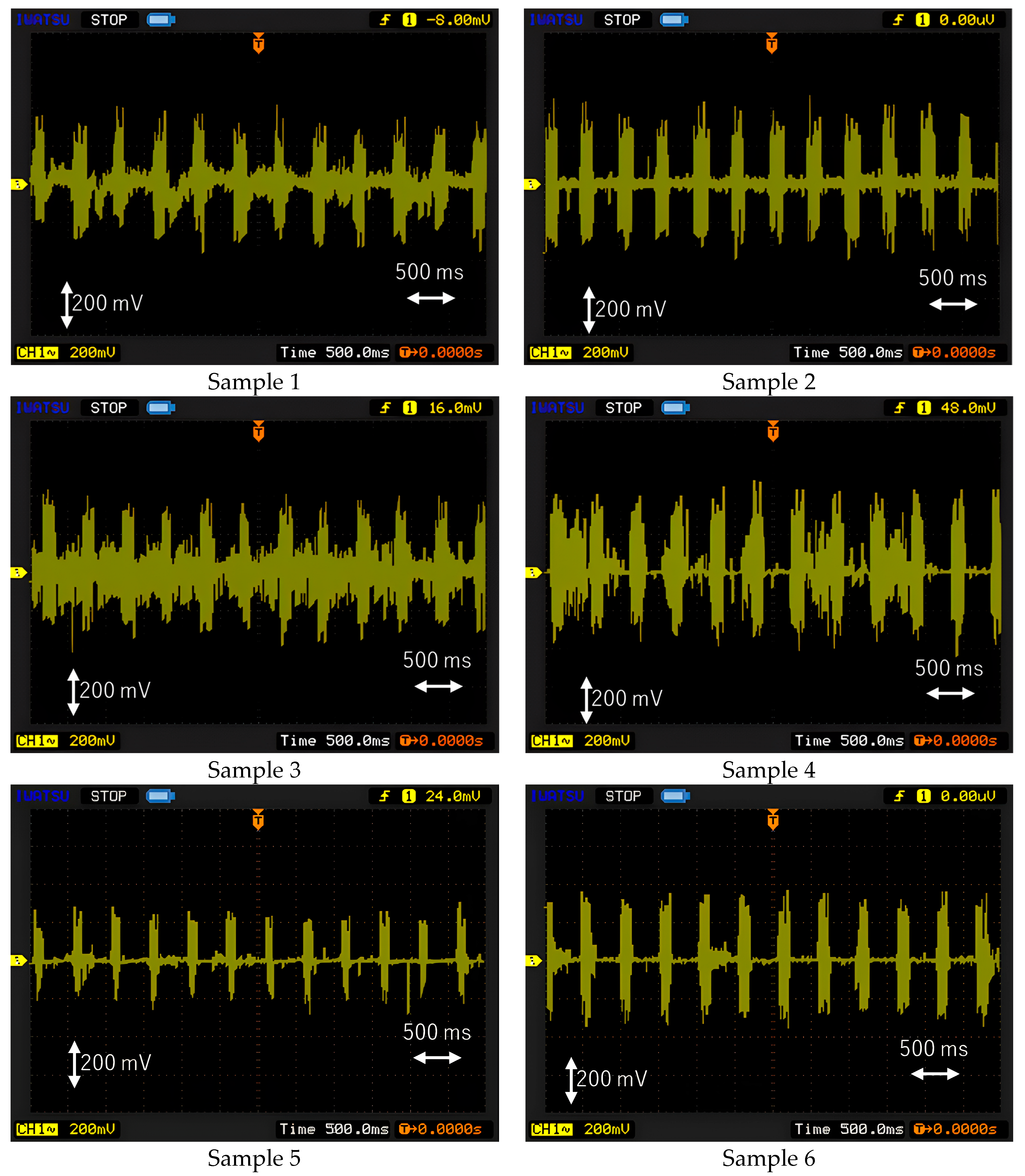

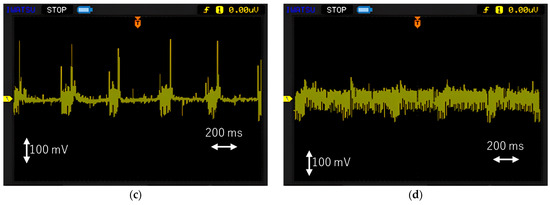

Figure 9 shows the results in terms of power generation using eight different types of CNT composite papers for TENGs with changes in the amount of pulp.

Figure 9.

Comparison of output results from samples with different pulp volumes.

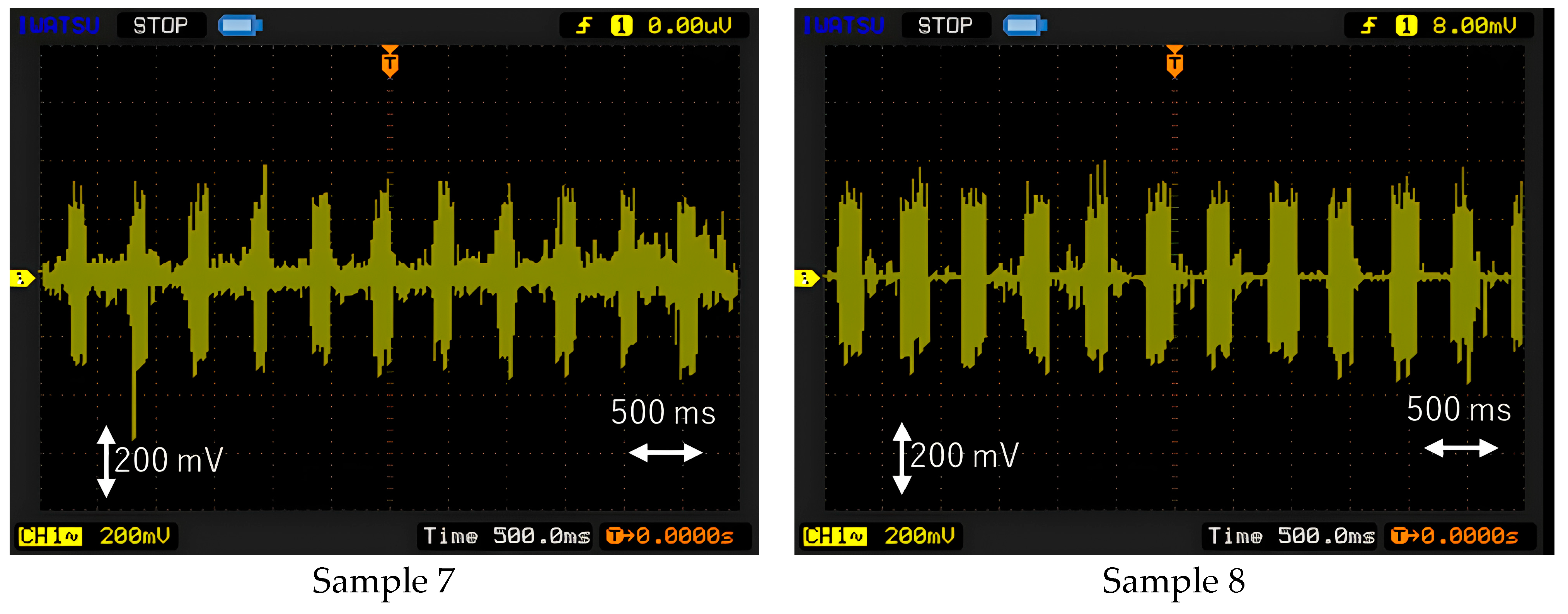

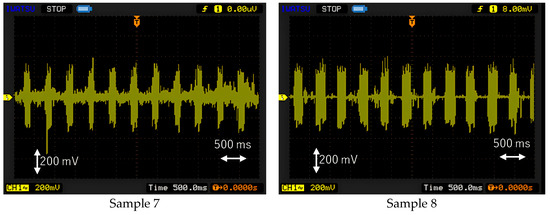

Figure 10 shows the RMS values calculated based on the oscilloscope measurements.

Figure 10.

RMS values of output derived from Figure 9.

In the experiment, it was expected that increasing the amount of pulp from 100 mg to 200 mg would result in a significant increase in the output; however, contrary to this, there was no significant difference in the output. There was only a slight trend toward an increase in the output. This suggests that increasing the amount of pulp will increase the output, although it is presumed that there is a limit to this increase. In addition, for samples 4 and 8, which were pulp-only samples without CNTs, triboelectricity generation could be confirmed. While the waveform provided in Section 3.2.1 was dominated by noise, in these experiments, a waveform characteristic of triboelectricity generation was found. However, compared to the CNT composite paper examined under the same conditions, there was more noise. There is a possibility that a small amount of CNTs from other samples was accidentally incorporated at the time of fabrication. In terms of durability, increasing the amount of pulp rendered the CNT composite paper harder and stronger, and the output did not drop, even after repeated tapping over a long period of time. This may have occurred because the increased strength of the CNT composite paper ensured that the tapped surface remained even and stabilized the power generation (we believe that this was a problem associated with the apparatus).

4. Discussion

In this study, several experiments were conducted to investigate the triboelectricity generation performance achieved with our CNT composite papers.

4.1. Performance Evaluation of TENG Using CNT Composite Paper

First, we investigated whether triboelectricity generation could be achieved using the CNT composite papers. This was confirmed. For these experiments, SG101, (6,5)-chirality, and (7,6)-chirality CNTs with semiconducting properties and NC7000 CNT with metallic properties were used. Triboelectricity generation was observed in both cases. Therefore, it is considered that CNTs do not serve to increase the output in triboelectric power generation with these CNT composite papers; rather, they act as a conductive material to assist charge transfer within the composite papers, regardless of their metallic or semiconducting nature. As discussed in Section 3.1, this is assumed to be due to the mixture of surfaces that are advantageous for triboelectricity generation (pulp area) and those that enable the collection of the generated charge (CNT network area) if viewed locally. This feature can be realized due to the CNT composite paper. In contrast, many splits and small peaks in the output peak are observed in addition to noise, as commonly observed in Figure 5, Figure 7 and Figure 9. We think the reason for these is the surface irregularities of the CNT composite paper. Ideally, the surfaces of the two materials should make contact and separate at completely the same timing, and when this is achieved, charge transfer occurs simultaneously and a large output peak can be obtained. However, the CNT composite paper has surface irregularities on the order of tens μm at the maximum in the height direction depending on the position within the surface, so the timing of contact and separation can be considered to shift due to differences in height, even within the same sample. This timing shift is considered to have led to a shift in the timing of charge transfer during triboelectric generation, resulting in the generation of a large number of small peaks.

4.2. Effect of Changing Amount of CNTs

It was found that changing the amount of CNTs did not cause a reduction in the triboelectricity generation performance but did cause a difference in the output intensity. In this experiment, the amount of CNTs contained in the CNT composite paper was varied among three different values (5 mg, 15 mg, and 30 mg), and the maximum output was observed when the CNT composite paper contained 15 mg of CNTs. There was no significant difference in the output when the amount of CNTs was 5 mg or 30 mg, and an approximately 3.7 times higher output was acquired when the amount of CNTs was 15 mg than when the amount of CNTs was 5 mg or 30 mg. This suggests that there is an optimal amount of CNTs. This is because the CNTs are not fully dispersed in the CNT composite paper when the amount of CNTs is small. However, when the amount of CNTs is large, the area of direct contact between the CNTs and the aluminum electrode becomes larger, which is thought to reduce the output. Based on this, as well as the discussion in Section 4.1, CNTs are believed to play a role in triboelectricity generation by efficiently transferring the electric charge generated by the pulp and electrode to the counter electrode.

4.3. Effect of Changes in Pulp Amount in CNT Composite Paper

A significant increase in the output was expected upon increasing the amount of pulp from 100 mg to 200 mg; however, no significant difference in the output was observed. Nonetheless, some samples showed a slight increase in the output, suggesting that an increase in the output can be expected when increasing the amount of pulp, although it is assumed that there is an upper limit. As discussed in Section 3.2 and Section 4.2, the degree of CNT content may affect the power generation efficiency. In particular, the manner in which the CNT network in the CNT composite paper is constructed and whether the edges of the CNT network that appear on the surface of the composite paper are indeed connected to the electrodes will be important.

As an additional study on TENG with the CNT composite paper, we also investigated the change in the output when the load resistance was changed. In particular, we used Sample 5 as a trial and measured the change in output using four types of load resistance: 1 k, 3.3 k, 100 k, and 1 MΩ. The obtained output waveforms and RMS values are summarized in the Supplementary Materials (Figures S1 and S2). The obtained outputs showed a tendency to increase as the load resistance increased, almost as expected.

4.4. Future Issues

In this study, the feasibility of triboelectricity generation using the CNT composite paper was confirmed. In addition, the optimal amount of CNTs required to create a CNT composite paper and the conditions of the pulp material were examined. Although an effective method to improve the output could not be found, it may be possible to improve the output by optimizing the amount of CNTs and compositing pulp. According to the results obtained in this study, the challenge is to establish a more direct and efficient method of improving the output. The core materials involved in triboelectric power generation in this study were considered to be the paper (pulp) and aluminum, which are relatively close in the triboelectric series of the paper. Therefore, the specific optimization conditions regarding the amount of CNTs, the pulp material, and the mixing ratio of pulp material required to improve the output will be studied. In addition, although it was confirmed that the triboelectricity performance of the CNT composite paper did not decline for approximately 30 min, it is necessary to evaluate how TENGs operate over longer timescales and with repeated use in the next stage of our research.

In this study, the measured voltages as outputs were also discussed. We should extend the discussion to the output power for the TENGs with the CNT composite paper. Actually, the power estimates can be derived by the equation P = V2/R or by the integral formula corresponding to the time variation of the voltage. For example, using the RMS value of the voltage obtained from Sample 5 above, 36.21 nW can be derived with 1 MΩ of the load resistance. If we also use the RMS value obtained from Sample 3, which is the largest voltage obtained, we can derive 83.39 nW (the power estimations based on the other measured values are given in the Supplementary Materials (Tables S1–S3)). As we have already explained, the CNT composite paper is a non-uniform material, including locally large variations in resistance (on a fine scale, they have a mixture of surfaces that are advantageous for triboelectric power generation (pulp area) and surfaces that can easily collect the generated charge (CNT network area), etc.). Since we considered it necessary to examine whether it is acceptable to estimate power in the same way as other TENGs using plain materials, we discussed the results of the actual measured voltages in this study. In addition to them, there were several samples that did not show clear triboelectric signals in this study. That is, not only pulse-like outputs but also outputs with some width were observed (e.g., samples 1 and 5 in Figure 9). To consider the cause of this, we prepared new CNT composite papers with higher resistivity values by reducing the amount of CNTs and measuring them. Specifically, two types of the CNT composite papers were prepared with 3 mg of SG101-CNT and 100 mg and 200 mg of pulp. These are samples with 1/5 the amount of contained CNTs of samples 1 and 5 in the paper, respectively. The measured outputs and data are given in the Supplementary Materials (Figures S3 and S4 and Table S4). As a result, a noise signal with an amplitude of approximately ±50 mV was observed. In the measurement, the signal was observed with the CNT composite paper set in the apparatus in contact with the electrode and kept stationary without tapping. The amplitude of the observed noise was approximately the same as the small amplitude signal seen between the peaks, as shown in Figure 5, Figure 7 and Figure 9. Therefore, the periodic peaks with large amplitude shown in the figures can be considered to originate from triboelectric generation. Then, focusing on these large positive and negative peaks that approximately matched the tap period, we believe that a clear triboelectric peak was observed. In addition, a comparison of Figure S4a,b shows that the peaks appear in roughly the same positions, and from this point of view, it can be concluded that the peaks originate from the tapping apparatus. In triboelectricity generation, using the CNT composite papers with reduced CNT amounts to 1/5 of those in samples 1 and 5, pulses particular to triboelectricity generation were observed, as shown in Figure S4. From these results, there is a possibility that when the amount of CNTs contained exceeds a certain amount, for example, migration of charge also occurs within the sample before it reaches the electrode. Namely, considering what we have already discussed, the surface geometry of the CNT composite paper and the network condition of the contained CNTs may be the cause of the wide range of peak outputs. Those points will also be discussed in the next stage of our research.

In summary, although there are still some issues to be addressed, the sample that obtained the maximum output in this study was fabricated using 15 mg of (7,6)-chirality CNTs and 200 mg of pulp, which resulted in an experimentally obtained output of 288.77 mV. We consider the results of this research to be significant because we were able to successfully demonstrate the feasibility of triboelectricity generation using CNT composite papers and identify the conditions necessary to improve this performance. In the future, it may be possible to create a “paper TENG” by simply combining composite papers with different CNT ratios.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/app142110030/s1, Figure S1: Measured outputs for each load resistance; Figure S2: RMS for each load resistance; Figure S3: Obtained output signal; Figure S4: Observed signal (noise); Table S1: Estimated power based on results presented in Figure 6; Table S2: Estimated power based on results presented in Figure 8; Table S3: Estimated power based on results presented in Figure 10; Table S4: Characteristics of CNT composite papers with 3 mg of CNTs contained.

Author Contributions

All authors contributed equally. Conceptualization, K.O. and T.O.; methodology, K.O.; validation, K.O. and T.O.; formal analysis, K.O.; investigation, K.O. and T.O.; resources, K.O. and T.O.; data curation, K.O.; model, K.O.; writing—original draft preparation, K.O.; writing—review and editing, K.O.; visualization, K.O. and T.O.; supervision, T.O.; funding acquisition, T.O.; project administration, T.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partly funded by JSPS KAKENHI, grant number JP23K17814.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

We are grateful to Takashi Ikuno of the Tokyo University of Science and Koya Arai of Mitsubishi Materials Corporation, Japan, for their valuable comments and support and to Mitsubishi Paper Mills, Ltd., for providing the pulp material.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, Y.; Yang, Y.; Wang, Z.L. Triboelectric nanogenerators as flexible power sources. NPJ Flex. Electron. 2017, 1, 10. [Google Scholar] [CrossRef]

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric nanogenerator: Structure, mechanism, and applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef] [PubMed]

- Choi, D.; Lee, Y.; Lin, Z.-H.; Cho, S.; Kim, M.; Ao, C.K.; Soh, S.; Sohn, C.; Jeong, C.K.; Lee, J.; et al. Recent advances in triboelectric nanogenerators: From technological progress to commercial applications. ACS Nano 2023, 17, 11087–11219. [Google Scholar] [CrossRef] [PubMed]

- Oh, J.; Kang, M.; Park, J.; Kim, T.Y.; Park, K.; Seo, J. Autonomously self-healing, adhesive, and stretchable triboelectric nanogenerator using multifunctional hydrogel-elastomer double layer with a power management circuit. Adv. Electron. Mater. 2024, 10, 2400013. [Google Scholar] [CrossRef]

- Pinming, C.; Wongwiriyapan, W.; Rattanamai, S.; Ketama, N.; Treetong, A.; Ikuno, T.; Tumcharern, G.; Klamchuen, A. Carbon nanotube/polydimethylsiloxane composite micropillar arrays using non-lithographic silicon nanowires as a template for performance enhancement of triboelectric nanogenerators. Nanotechnology 2021, 32, 095303. [Google Scholar] [CrossRef]

- Zhou, Q.; Takita, R.; Ikuno, T. Improving the performance of a triboelectric nanogenerator by using anasymmetric TiO2/PDMS composite layer. Nanomaterials 2023, 13, 832. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, J.; Si, Y.; Li, T. Multi-grating triboelectric nanogenerator for harvesting low-frequency ocean wave energy. Nano Energy 2019, 61, 132–140. [Google Scholar] [CrossRef]

- Rodrigues, C.; Nunes, D.; Clemente, D.; Mathias, N.; Correia, J.M.; Rosa-Santos, P.; Taveira-Pinto, F.; Morais, T.; Pereira, A.; Ventura, J. Emerging triboelectric nanogenerators for ocean wave energy harvesting: State of the art and future perspectives. Energy Environ. Sci. 2020, 13, 2657–2683. [Google Scholar] [CrossRef]

- Chen, X.; Gao, L.; Chen, J.; Lu, S.; Zhou, H.; Wang, T.; Wang, A.; Zhang, Z.; Guo, S.; Mu, X.; et al. A chaotic pendulum triboelectric-electromagnetic hybridized nanogenerator for wave energy scavenging and self-powered wireless sensing system. Nano Energy 2020, 69, 104440. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Q.; Ding, Z.; Li, Z.; Zheng, H.; Fu, J.; Diao, C.; Zhang, X.; Tian, J.; Zi, Y. A fully-packaged ship-shaped hybrid nanogenerator for blue energy harvesting toward seawater self-desalination and self-powered positioning. Nano Energy 2019, 57, 616–624. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Li, Z.; Fan, X.; Zi, Y.; Jing, Q.; Guo, H.; Wen, Z.; Pradel, K.C.; Niu, S.; et al. Networks of triboelectric nanogenerators for harvesting water wave energy: A potential approach toward blue energy. ACS Nano 2015, 9, 3324–3331. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Helical micro-tubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Popov, V.N. Carbon nanotubes: Properties and application. In Materials Science and Engineering: R: Reports; Elsevier: Amsterdam, The Netherlands, 2004; Volume 43, pp. 61–102. [Google Scholar]

- Odom, T.W.; Huang, J.L.; Kim, P.; Lieber, C.M. Atomic structure and electronic properties of single-walled carbon nanotubes. Nature 1998, 391, 62–64. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Lezec, H.J.; Hiura, H.; Bennett, J.W.; Ghaemi, H.F.; Thio, T. Electrical conductivity of individual carbon nanotubes. Nature 1996, 382, 54–56. [Google Scholar] [CrossRef]

- Yu, M.F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Avouris, P. (Eds.) Carbon Nanotubes: Synthesis, Structure, Properties, and Applications; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Jorio, A.; Dresselhaus, M.S.; Dresselhaus, G. (Eds.) Carbon Nanotubes: Advanced Topics in the Synthesis, Structure, Properties, and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Hata, K. Great expectations for a dream material, 21st century industrial revolution. AIST Stories 2013, 1, 18–19. [Google Scholar]

- Lau, A.K.-T.; Hui, D. The revolutionary creation of new advanced materials—Carbon nanotube composites. Compos. Part B Eng. 2002, 33, 263–277. [Google Scholar] [CrossRef]

- Khare, R.; Bose, S. Carbon nanotube based composites—A review. J. Miner. Mater. Charact. Eng. 2005, 4, 31–46. [Google Scholar] [CrossRef]

- Byrne, M.T.; Gun’ko, Y.K. Recent advances in research on carbon nanotube–polymer composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef]

- Esawi, A.M.K.; Farag, M.M. Carbon nanotube reinforced composites: Potential and current challenges. Mater. Des. 2007, 28, 2394–2401. [Google Scholar] [CrossRef]

- Oya, T.; Ogino, T. Production of electrically conductive paper by adding carbon nanotubes. Carbon 2008, 46, 169–171. [Google Scholar] [CrossRef]

- Kou, Y.; Oya, T. Unique dye-sensitized solar cell using carbon nanotube composite-papers with gel electrolyte. J. Compos. Sci. 2023, 7, 232. [Google Scholar] [CrossRef]

- Ampo, T.; Oya, T. Development of paper actuators based on carbon-nanotube-composite paper. Molecules 2021, 26, 1463. [Google Scholar] [CrossRef]

- Miyama, A.; Oya, T. Improved performance of thermoelectric power generating paper based on carbon nanotube composite papers. Carbon Trends 2022, 7, 100149. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, W.; Liu, Y.; Zhao, J.; Yuan, J.; Chi, M.; Meng, X.; Du, G.; Cai, C.; Wang, S.; et al. Cellulosic gel-based triboelectric nanogenerators for energy harvesting and emerging applications. Nano Energy 2023, 106, 108079. [Google Scholar] [CrossRef]

- Zhang, S.; Long, Q.; Jiang, G.; Li, X.; Zhou, J.; Shao, L.; Zeng, S.; Zhao, D. A robust, high-temperature-resistant, protective cellulose gel enabled by multiscale structural engineering. Int. J. Biol. Macromol. 2024, 277, 134520. [Google Scholar] [CrossRef]

- Feng, X.; Xing, C.; Wang, C.; Tian, Y.; Shang, S.; Liu, H.; Huang, X.; Jiang, J.; Song, Z.; Zhang, H. Degradable, anti-swelling, high-strength cellulosic hydrogels via salting-out and ionic coordination. Int. J. Biol. Macromol. 2024, 267, 131536. [Google Scholar] [CrossRef]

- Mata, A.; Fleischman, A.J.; Roy, S. Characterization of polydimethylsiloxane (PDMS) properties for biomedical micro/nanosystems. Biomed. Microdevices 2005, 7, 281–293. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Toyomasu, R.; Oya, T. Development and improvement of “paper actuator” based on carbon-nanotube composite paper with its unique structures. J. Compos. Sci. 2024, 8, 391. [Google Scholar] [CrossRef]

- Shan, C.; Li, K.; Cheng, Y.; Hu, C. Harvesting environment mechanical energy by direct current triboelectric nanogenerators. Nano-Micro Lett. 2023, 15, 127. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lin, L.; Wang, Z.L. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano Lett. 2012, 12, 6339–6346. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).