Multifunctional 3D-Printed Thermoplastic Polyurethane (TPU)/Multiwalled Carbon Nanotube (MWCNT) Nanocomposites for Thermal Management Applications

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Filament Extrusion

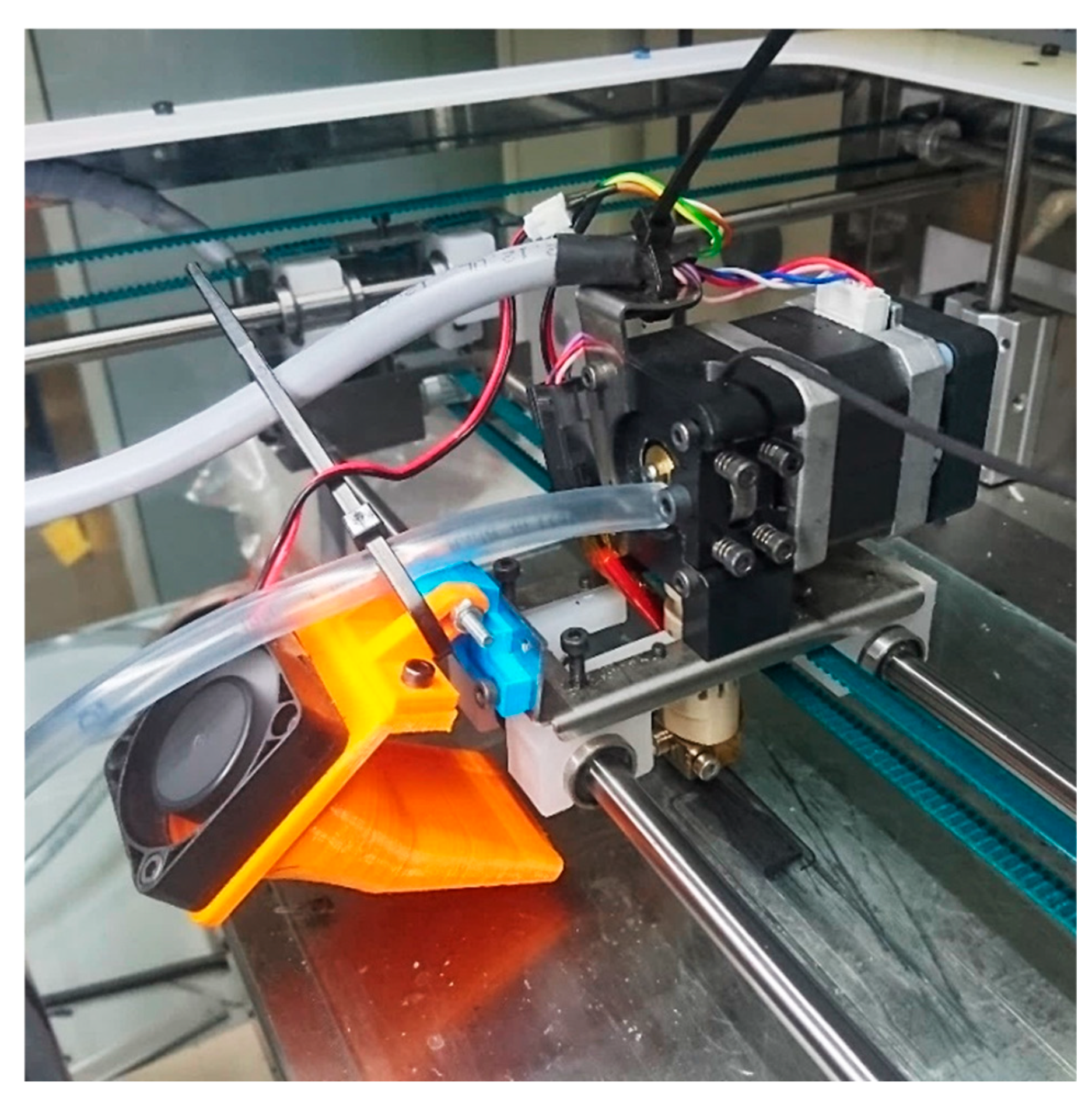

2.3. Preparation of 3D-Printed Samples

2.4. Experimental Techniques

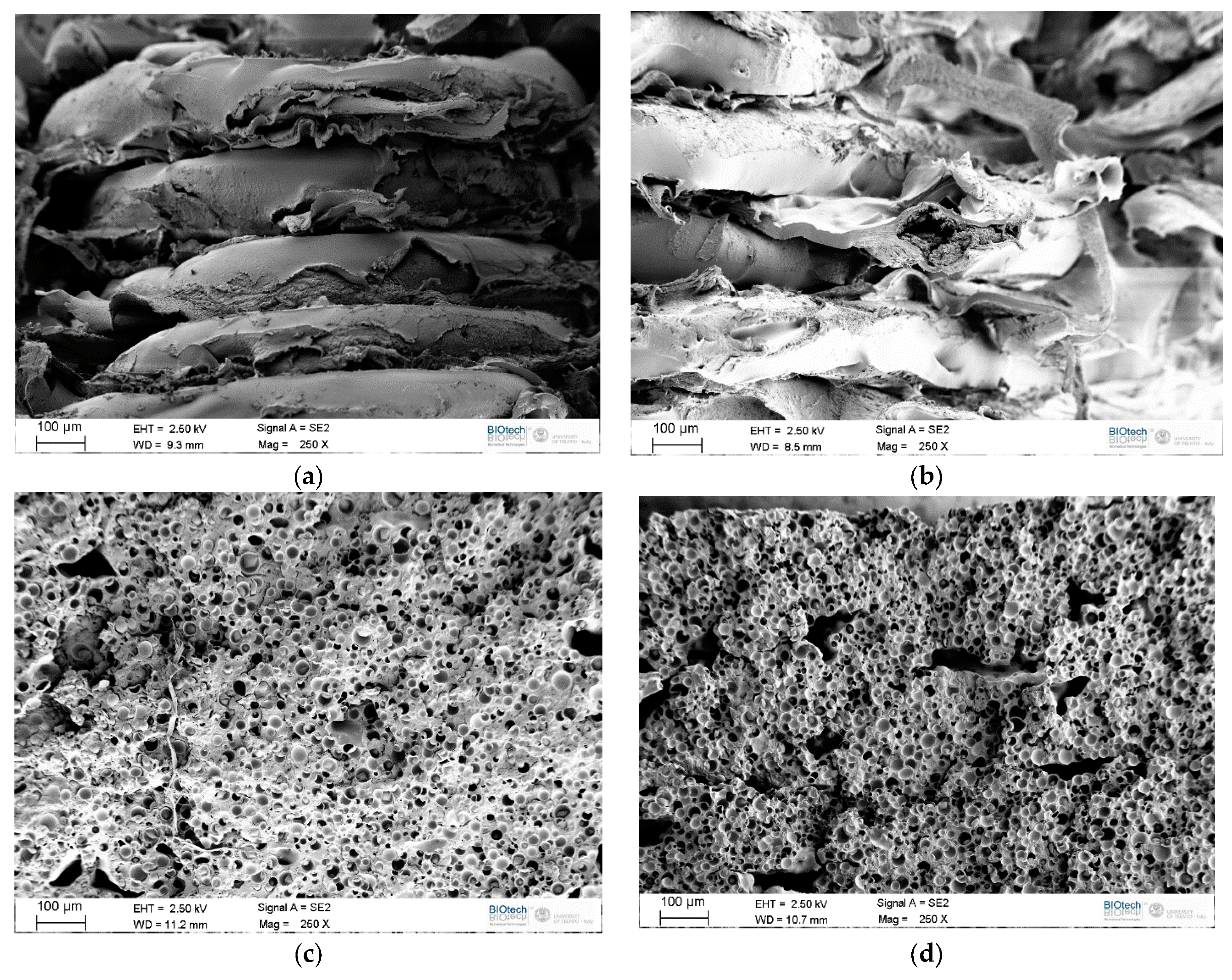

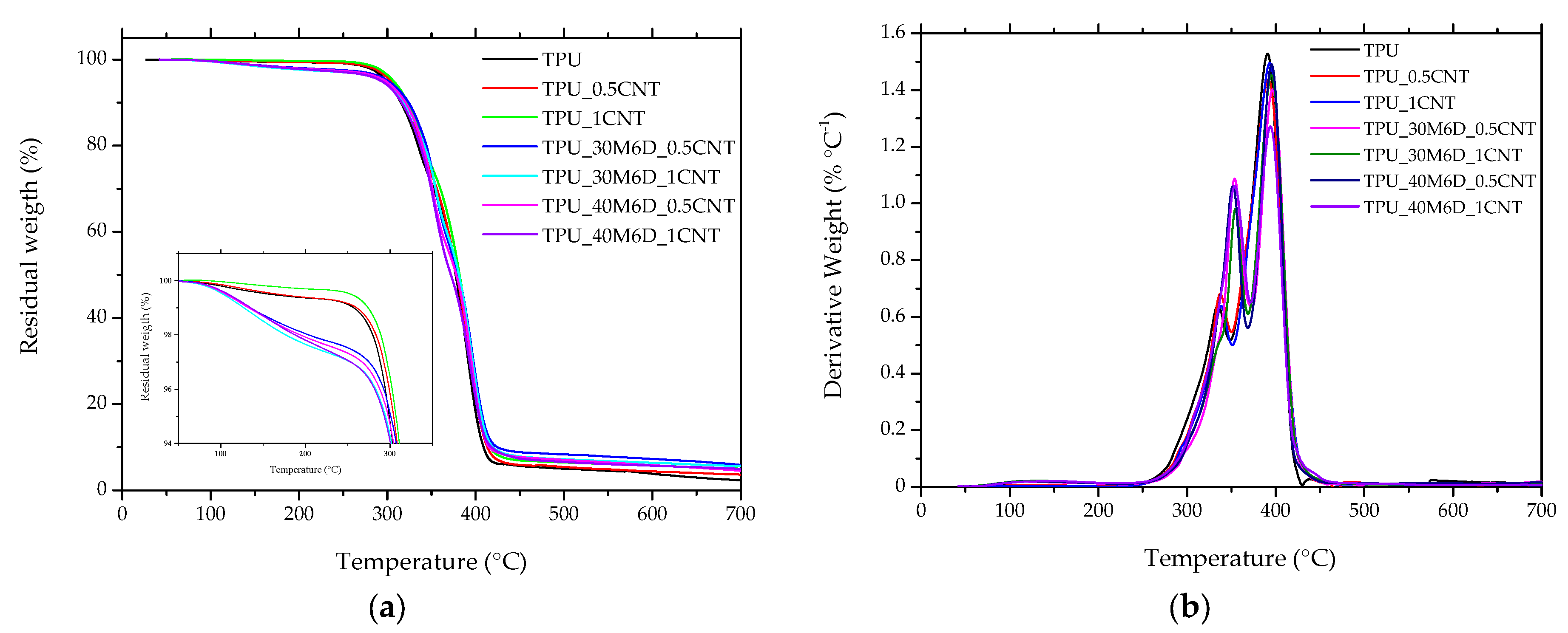

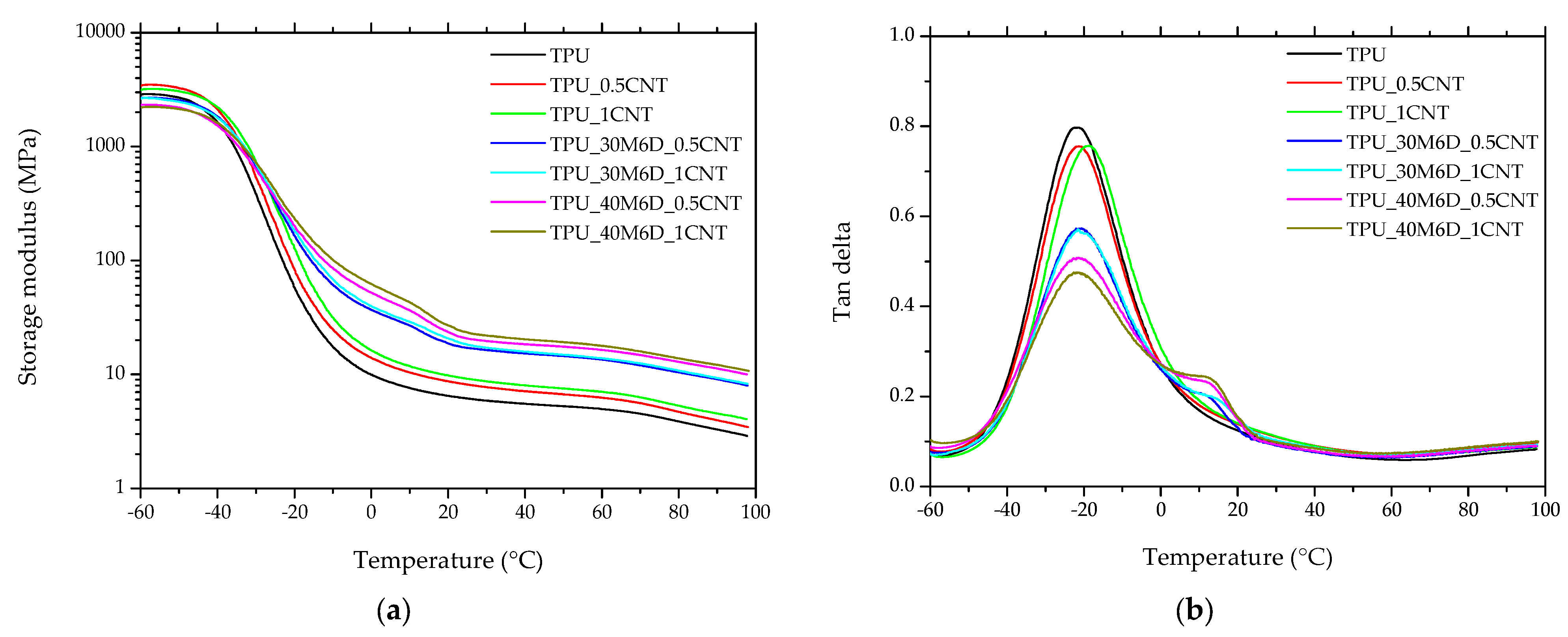

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martin, D.J.; Osman, A.F.; Andriani, Y.; Edwards, G.A. 11—Thermoplastic polyurethane (TPU)-based polymer nanocomposites. In Advances in Polymer Nanocomposites; Gao, F., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 321–350. [Google Scholar]

- Drobny, J.G. 15—Applications of Thermoplastic Elastomers. In Handbook of Thermoplastic Elastomers; Drobny, J.G., Ed.; William Andrew Publishing: Norwich, NY, USA, 2007; pp. 281–315. [Google Scholar]

- Huang, C.; Qian, X.; Yang, R. Thermal conductivity of polymers and polymer nanocomposites. Mater. Sci. Eng. R Rep. 2018, 132, 1–22. [Google Scholar] [CrossRef]

- Hussain, A.R.J.; Alahyari, A.A.; Eastman, S.A.; Thibaud-Erkey, C.; Johnston, S.; Sobkowicz, M.J. Review of polymers for heat exchanger applications: Factors concerning thermal conductivity. Appl. Therm. Eng. 2017, 113, 1118–1127. [Google Scholar] [CrossRef]

- Kim, P.; Shi, L.; Majumdar, A.; McEuen, P.L. Thermal Transport Measurements of Individual Multiwalled Nanotubes. Phys. Rev. Lett. 2001, 87, 215502. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Tijing, L.D.; Park, C.-H.; Choi, W.L.; Ruelo, M.T.G.; Amarjargal, A.; Pant, H.R.; Im, I.-T.; Kim, C.S. Characterization and mechanical performance comparison of multiwalled carbon nanotube/polyurethane composites fabricated by electrospinning and solution casting. Compos. B Eng. 2013, 44, 613–619. [Google Scholar] [CrossRef]

- Fernández-d’Arlas, B.; Khan, U.; Rueda, L.; Martin, L.; Ramos, J.A.; Coleman, J.N.; González, M.L.; Valea, A.; Mondragon, I.; Corcuera, M.A.; et al. Study of the mechanical, electrical and morphological properties of PU/MWCNT composites obtained by two different processing routes. Compos. Sci. Technol. 2012, 72, 235–242. [Google Scholar] [CrossRef]

- Raja, M.; Ryu, S.H.; Shanmugharaj, A.M. Thermal, mechanical and electroactive shape memory properties of polyurethane (PU)/poly (lactic acid) (PLA)/MWCNT nanocomposites. Eur. Polym. J. 2013, 49, 3492–3500. [Google Scholar] [CrossRef]

- Bharadwaj, S.; Gupta, T.K.; Chauhan, G.S.; Sehrawat, M.; Kumar, A.; Dhakate, S.R.; Singh, B.P. Long Length MWCNT/TPU Composite Materials for Stretchable and Wearable Strain Sensors. Sens. Actuators A Phys. 2023, 357, 114364. [Google Scholar] [CrossRef]

- Jun, Y.-S.; Hyun, B.G.; Hamidinejad, M.; Habibpour, S.; Yu, A.; Park, C.B. Maintaining electrical conductivity of microcellular MWCNT/TPU composites after deformation. Compos. B Eng. 2021, 223, 109113. [Google Scholar] [CrossRef]

- Wang, X.; Xue, R.; Li, M.; Guo, X.; Liu, B.; Xu, W.; Wang, Z.; Liu, Y.; Wang, G. Strain and stress sensing properties of the MWCNT/TPU nanofiber film. Surf. Interfaces 2022, 32, 102132. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, T.K.; Varadarajan, K.M. Strong, stretchable and ultrasensitive MWCNT/TPU nanocomposites for piezoresistive strain sensing. Compos. B Eng. 2019, 177, 107285. [Google Scholar] [CrossRef]

- Rigotti, D.; Pegoretti, A. 23—Additive manufacturing with biodegradable polymers. In Biodegradable Polymers, Blends and Composites; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Ramesh, M., Eds.; Woodhead Publishing: Cambridge, UK, 2022; pp. 611–679. [Google Scholar]

- Rigotti, D.; Fambri, L.; Pegoretti, A. Polyvinyl alcohol reinforced with carbon nanotubes for fused deposition modeling. J. Reinf. Plast. Compos. 2018, 37, 716–727. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments production and fused deposition modelling of ABS/carbon nanotubes composites. Nanomaterials 2018, 8, 49. [Google Scholar] [CrossRef] [PubMed]

- Dul, S.; Ecco, L.G.; Pegoretti, A.; Fambri, L. Graphene/carbon nanotube hybrid nanocomposites: Effect of compression molding and fused filament fabrication on properties. Polymers 2020, 12, 101. [Google Scholar] [CrossRef] [PubMed]

- Dul, S.; Pegoretti, A.; Fambri, L. Fused Filament Fabrication of Piezoresistive Carbon Nanotubes Nanocomposites for Strain Monitoring. Front. Mater. 2020, 7. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Development of new nanocomposites for 3D printing applications. In Structure and Properties of Additive Manufactured Polymer Components; Friedrich, K., Walter, R., Soutis, C., Advani, S.G., Fiedler, I.H.B., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 17–59. [Google Scholar]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.H.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Dul, S.; Gutierrez, B.J.A.; Pegoretti, A.; Alvarez-Quintana, J.; Fambri, L. 3D printing of ABS Nanocomposites. Comparison of processing and effects of multi-wall and single-wall carbon nanotubes on thermal, mechanical and electrical properties. J. Mater. Sci. Technol. 2022, 121, 52–66. [Google Scholar] [CrossRef]

- Hohimer, C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. 3D printed conductive thermoplastic polyurethane/carbon nanotube composites for capacitive and piezoresistive sensing in soft pneumatic actuators. Addit. Manuf. 2020, 34, 101281. [Google Scholar] [CrossRef]

- Hohimer, C.; Aliheidari, N.; Mo, C.; Ameli, A. Mechanical Behavior of 3D Printed Multiwalled Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. In Proceedings of the ASME 2017 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Snowbird, UT, USA, 18–20 September 2017. [Google Scholar]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.-h.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using carbon nanotube (MWCNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Cao, H. Smart coatings for protective clothing. In Active Coatings for Smart Textiles; Woodhead Publishing: Cambridge, UK, 2016; pp. 375–389. [Google Scholar]

- Iqbal, K.; Khan, A.; Sun, D.; Ashraf, M.; Rehman, A.; Safdar, F.; Basit, A.; Maqsood, H.S. Phase change materials, their synthesis and application in textiles—A review. J. Text. Inst. 2019, 110, 625–638. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Shim, H.; McCullough, E.A.; Jones, B.W. Using Phase Change Materials in Clothing. Text. Res. J. 2001, 71, 495–502. [Google Scholar] [CrossRef]

- Gao, C. Phase-Change Materials (PCMs) for Warming or Cooling in Protective Clothing; Woodhead Publishing: Cambridge, UK, 2014; pp. 227–249. [Google Scholar]

- Yazdi, M.; Sheikhzadeh, M.; Borhani, S. Modeling the heat transfer in a PCM cooling vest. J. Text. Inst. 2015, 106, 1003–1012. [Google Scholar] [CrossRef]

- Abuzaid, A.; Reichard, G. An Assessment of Utilizing Phase Change Materials (PCM) Towards Energy Performance in Building Enclosures. In Proceedings of the 3rd Residential Building Design & Construction Conference, State College, PA, USA, 2–3 March 2016. [Google Scholar]

- Pielichowska, K.; Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Dorigato, A.; Rigotti, D.; Pegoretti, A. Thermoplastic Polyurethane Blends with Thermal Energy Storage/Release Capability. Front. Mater. 2018, 5. [Google Scholar] [CrossRef]

- Rigotti, D.; Dorigato, A.; Pegoretti, A. Low-cycle fatigue behavior of flexible 3D printed thermoplastic polyurethane blends for thermal energy storage/release applications. J. Appl. Polym. Sci. 2021, 138, 49704. [Google Scholar] [CrossRef]

- Khadiran, T.; Hussein, M.Z.; Zainal, Z.; Rusli, R. Encapsulation techniques for organic phase change materials as thermal energy storage medium: A review. Sol. Energy Mater. Sol. Cells 2015, 143, 78–98. [Google Scholar] [CrossRef]

- Rigotti, D.; Dorigato, A.; Pegoretti, A. 3D printable thermoplastic polyurethane blends with thermal energy storage/release capabilities. Mater. Today Commun. 2018, 15, 228–235. [Google Scholar] [CrossRef]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- Venkataraman, N.; Rangarajan, S.; Matthewson, M.J.; Harper, B.; Safari, A.; Danforth, S.C.; Wu, G.; Langrana, N.; Guceri, S.; Yardimci, A. Feedstock material property—Process relationships in fused deposition of ceramics (FDC). Rapid Prototyp. J. 2000, 6, 244–253. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Herrera, M.; Matuschek, G.; Kettrup, A. Thermal degradation of thermoplastic polyurethane elastomers (TPU) based on MDI. Polym. Degrad. Stab. 2002, 78, 323–331. [Google Scholar] [CrossRef]

- Kolařík, J.; Pegoretti, A. Proposal of the Boltzmann-like superposition principle for nonlinear tensile creep of thermoplastics. Polym. Test. 2008, 27, 596–606. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. Tensile creep behaviour of polymethylpentene–silica nanocomposites. Polym. Int. 2010, 59, 719–724. [Google Scholar] [CrossRef]

- Mahmood, H.; Vanzetti, L.; Bersani, M.; Pegoretti, A. Mechanical properties and strain monitoring of glass-epoxy composites with graphene-coated fibers. Compos. A Appl. Sci. Manuf. 2018, 107, 112–123. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modelling with ABS–graphene nanocomposites. Compos. A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

| Tg (°C) | Tm (°C) | Melting Enthalpy (J/g) | Relative Melting Enthalpy (%) | Tc (°C) | Crystallization Enthalpy (J/g) | Relative Crystallization Enthalpy (%) | |

|---|---|---|---|---|---|---|---|

| TPU | −48.9 | - | - | ||||

| TPU_30 M6D * | 6.6 | 45.6 | 28.8 | −8.6 | 42.1 | 26.6 | |

| TPU_30M6D_0.5MWCNT | 4.4 | 27.0 | 17.0 | −1.1 | 29.1 | 18.4 | |

| TPU_30M6D_1MWCNT | −50.5 | 5.1 | 32.8 | 20.7 | −2.1 | 37.4 | 23.6 |

| TPU_40 M6D * | 8.0 | 56.1 | 35.4 | −10.1 | 52.6 | 33.2 | |

| TPU_40M6D_0.5MWCNT | 5.4 | 48.7 | 30.7 | −2.6 | 54.2 | 34.2 | |

| TPU_40M6D_1MWCNT | −53.9 | 6.4 | 47.6 | 30.0 | −2.0 | 54.1 | 34.2 |

| M6D * | 5.0 | 158.5 | 100.0 | −9.4 | 158.4 | 100.0 |

| Tg * (°C) | E’ at −60 °C (GPa) | E’ at 25 °C (MPa) | tanδ Peak Value | |

|---|---|---|---|---|

| TPU | −39.3 | 2.856 | 6.1 | 0.80 |

| TPU_0.5MWCNT | −37.9 | 3.134 | 8.1 | 0.75 |

| TPU_1MWCNT | −36.5 | 3.422 | 9.2 | 0.75 |

| TPU_30M6D_0.5MWCNT | −36.9 | 2.672 | 17.1 | 0.57 |

| TPU_30M6D_1MWCNT | −36.4 | 2.647 | 18.3 | 0.56 |

| TPU_40M6D_0.5MWCNT | −36.5 | 2.319 | 20.7 | 0.50 |

| TPU_40M6D_1MWCNT | −33.3 | 2.206 | 23.4 | 0.47 |

| Modulus Chord (MPa) | Stress at Break (MPa) | Strain at Break (mm/mm) | Specific Energy at Break (J/mm2) | |

|---|---|---|---|---|

| TPU | 6.3 ± 0.4 | 9.1 ± 0.9 | 7.1 ± 0.5 | 0.90 ± 1.35 |

| TPU_0.5MWCNT | 7.8 ± 0.7 | 8.3 ± 1.1 | 6.1 ± 1.1 | 0.91 ± 1.77 |

| TPU_1MWCNT | 7.9 ± 0.5 | 7.6 ± 0.7 | 4.8 ± 0.3 | 0.62 ± 0.86 |

| TPU_30M6D_0.5MWCNT | 10.5 ± 1.0 | 5.2 ± 1.7 | 2.2 ± 0.5 | 0.29 ± 0.28 |

| TPU_30M6D_1MWCNT | 10.9 ± 0.4 | 5.3 ± 0.3 | 0.8 ± 0.1 | 0.08 ± 0.12 |

| TPU_40M6D_0.5MWCNT | 12.3 ± 0.8 | 4.9 ± 0.4 | 0.6 ± 0.1 | 0.05 ± 0.09 |

| TPU_40M6D_1MWCNT | 12.7 ± 0.1 | 3.8 ± 0.3 | 0.3 ± 0.1 | 0.01 ± 0.06 |

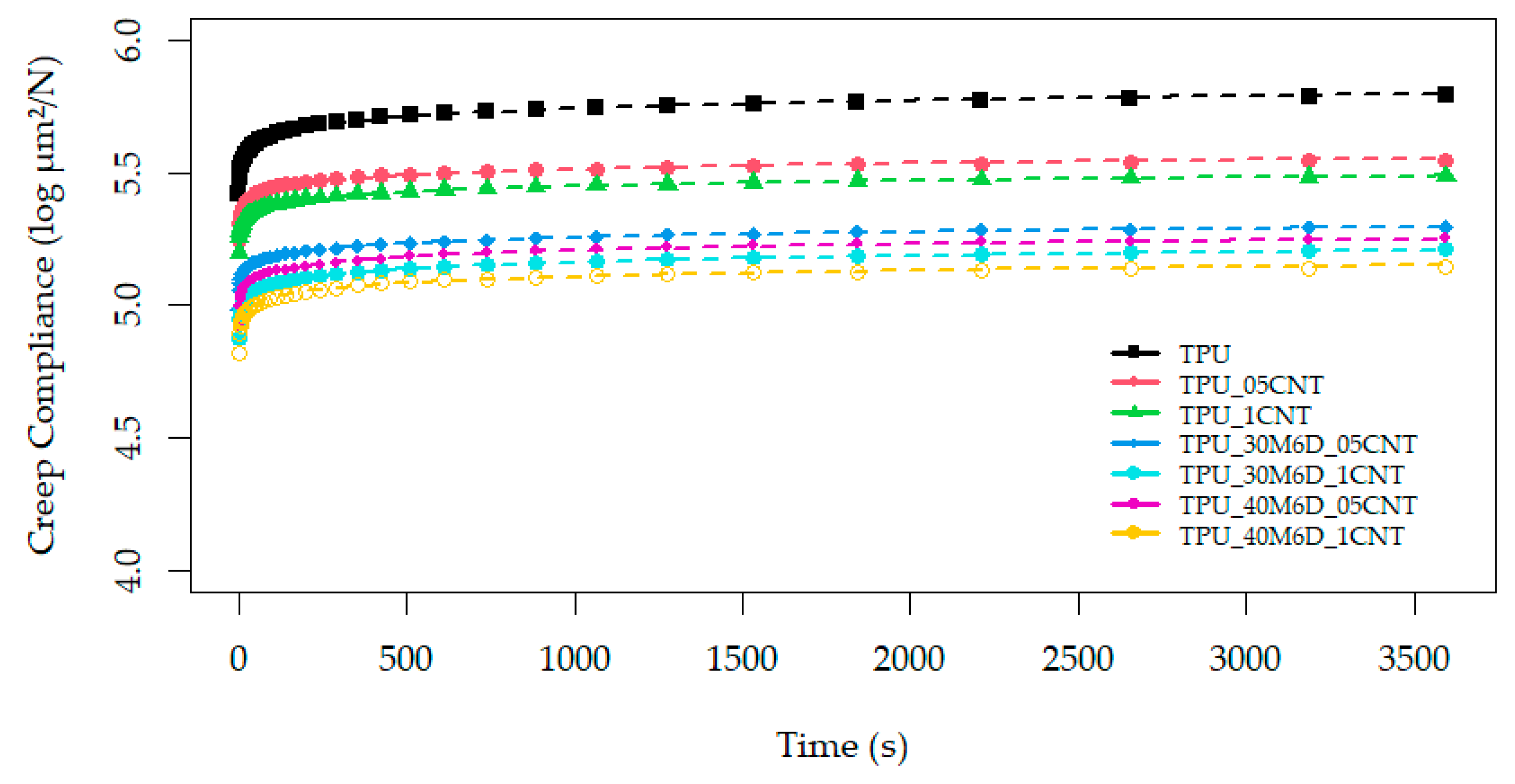

| De (MPa−1) | k (MPa−1 s−n) | n | Adj R2 | |

|---|---|---|---|---|

| TPU | 262,091 | 275,612 ± 1 | 0.1002 ± 0.0007 | 0.9980 |

| TPU_0.5MWCNT | 175,707 | 194,208 ± 1 | 0.0747 ± 0.0008 | 0.9960 |

| TPU_1MWCNT | 158,298 | 172,607 ± 1 | 0.0705 ± 0.0001 | 0.9998 |

| TPU_30M6D_0.5MWCNT | 96,351 | 110,359 ± 1 | 0.0709 ± 0.0003 | 0.9992 |

| TPU_30M6D_1MWCNT | 74,770 | 83,555 ± 1 | 0.0802 ± 0.0004 | 0.9988 |

| TPU_40M6D_0.5MWCNT | 83,523 | 93,255 ± 1 | 0.0790 ± 0.0005 | 0.9984 |

| TPU_40M6D_1MWCNT | 65,904 | 74,451 ± 1 | 0.0786 ± 0.0005 | 0.9985 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rigotti, D.; Dorigato, A.; Pegoretti, A. Multifunctional 3D-Printed Thermoplastic Polyurethane (TPU)/Multiwalled Carbon Nanotube (MWCNT) Nanocomposites for Thermal Management Applications. Appl. Sci. 2024, 14, 9614. https://doi.org/10.3390/app14209614

Rigotti D, Dorigato A, Pegoretti A. Multifunctional 3D-Printed Thermoplastic Polyurethane (TPU)/Multiwalled Carbon Nanotube (MWCNT) Nanocomposites for Thermal Management Applications. Applied Sciences. 2024; 14(20):9614. https://doi.org/10.3390/app14209614

Chicago/Turabian StyleRigotti, Daniele, Andrea Dorigato, and Alessandro Pegoretti. 2024. "Multifunctional 3D-Printed Thermoplastic Polyurethane (TPU)/Multiwalled Carbon Nanotube (MWCNT) Nanocomposites for Thermal Management Applications" Applied Sciences 14, no. 20: 9614. https://doi.org/10.3390/app14209614

APA StyleRigotti, D., Dorigato, A., & Pegoretti, A. (2024). Multifunctional 3D-Printed Thermoplastic Polyurethane (TPU)/Multiwalled Carbon Nanotube (MWCNT) Nanocomposites for Thermal Management Applications. Applied Sciences, 14(20), 9614. https://doi.org/10.3390/app14209614