Evaluation of Petrographic and Geomechanical Properties of Inzari Formation Rocks for Their Suitability as Building Materials in the Nizampur Basin, Pakistan

Abstract

1. Introduction

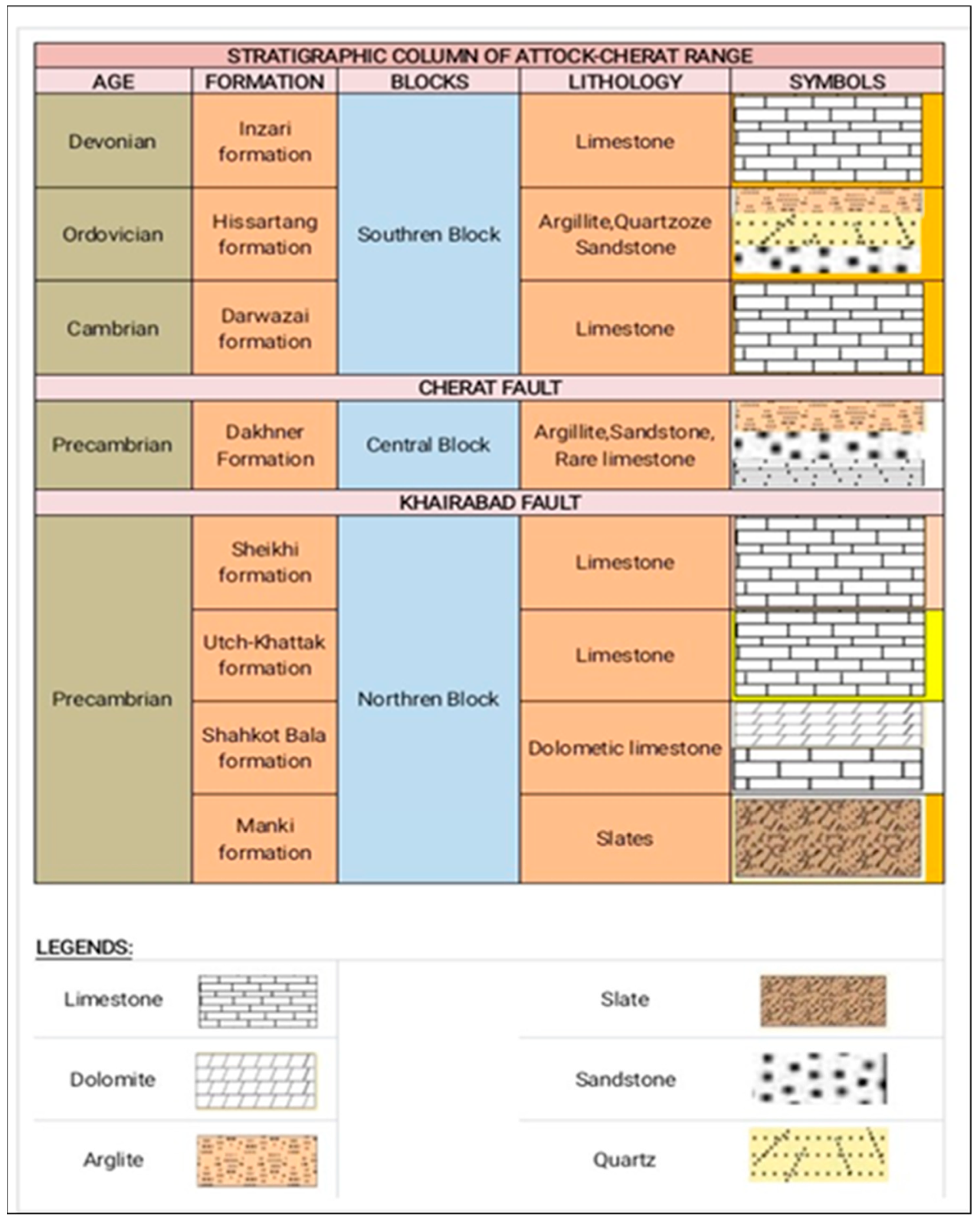

2. Geological Setting

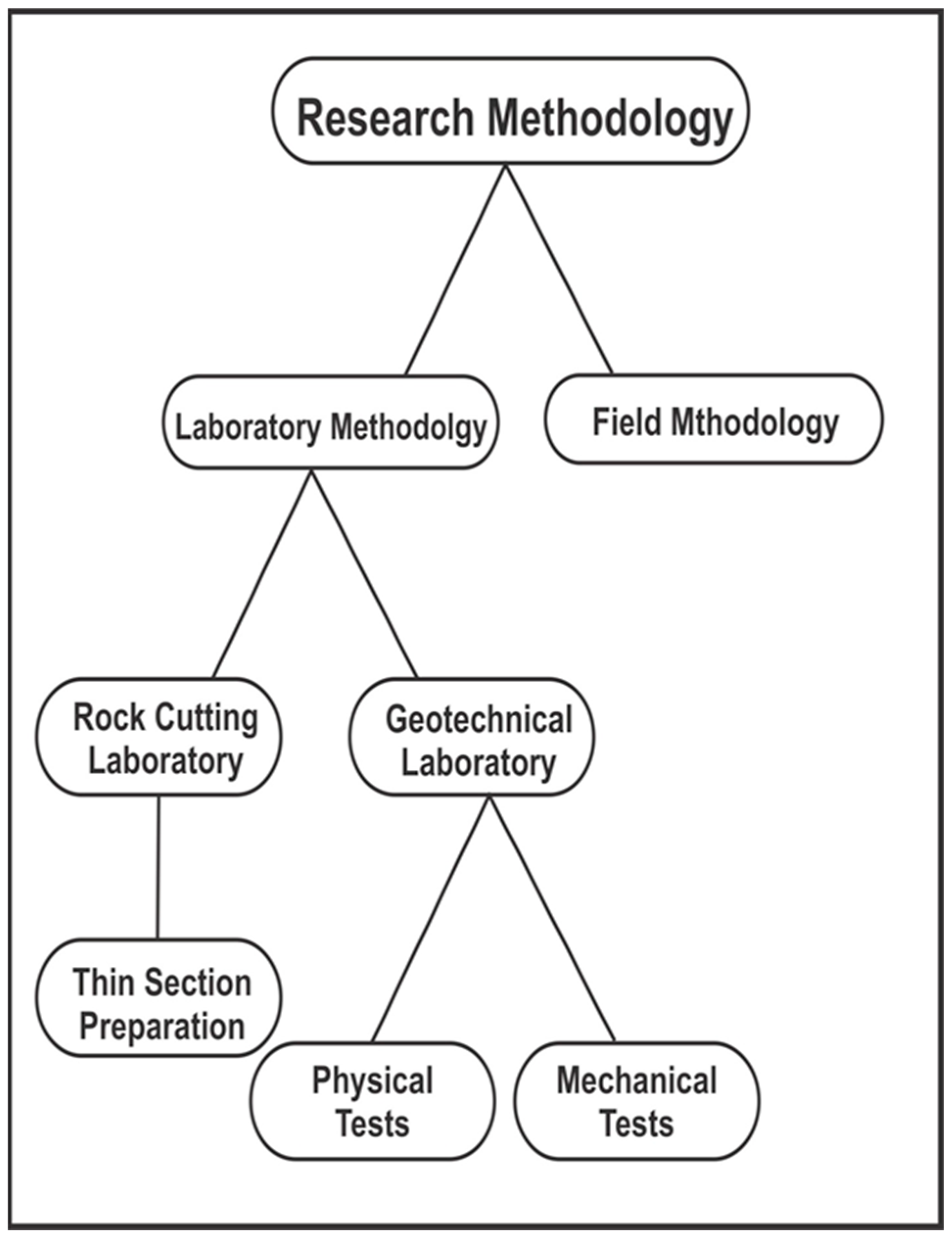

3. Methodology

3.1. Field Work

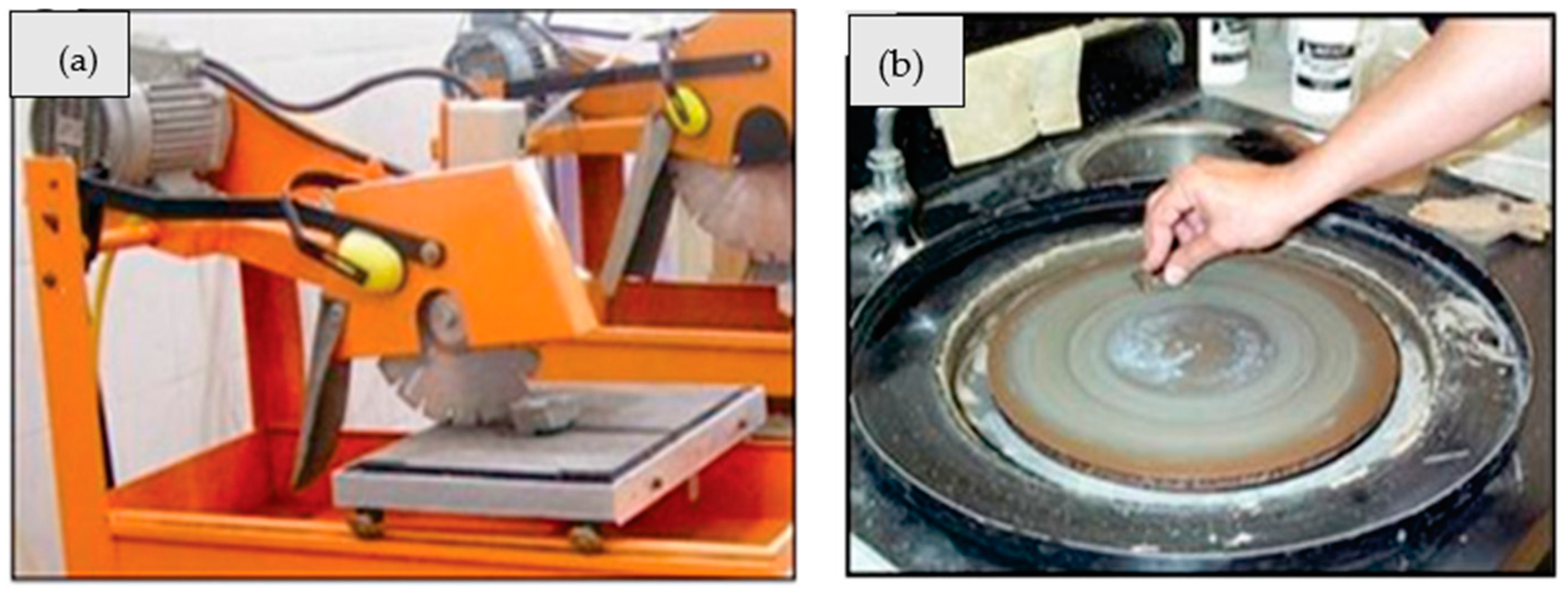

3.2. Lab Work

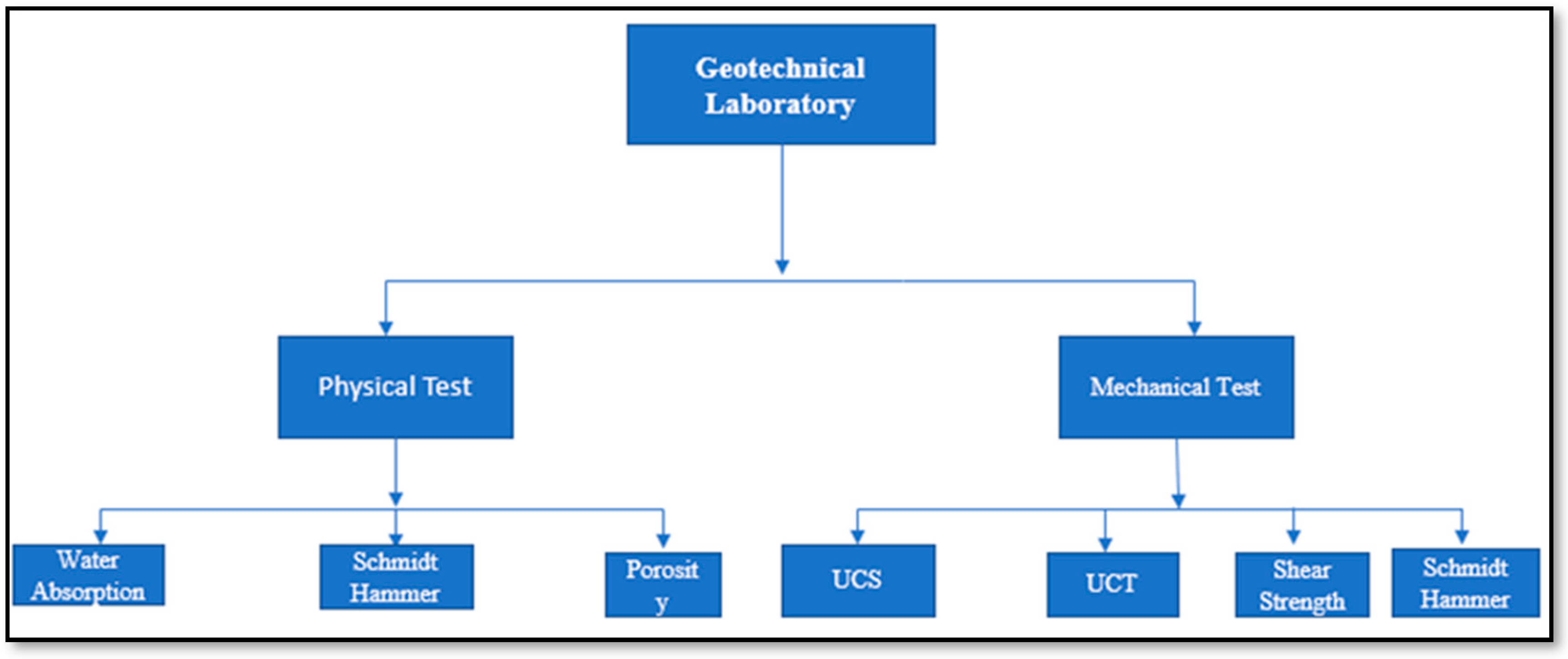

3.3. Geotechnical Laboratory

4. Results and Discussions

4.1. Physicomechanical Properties

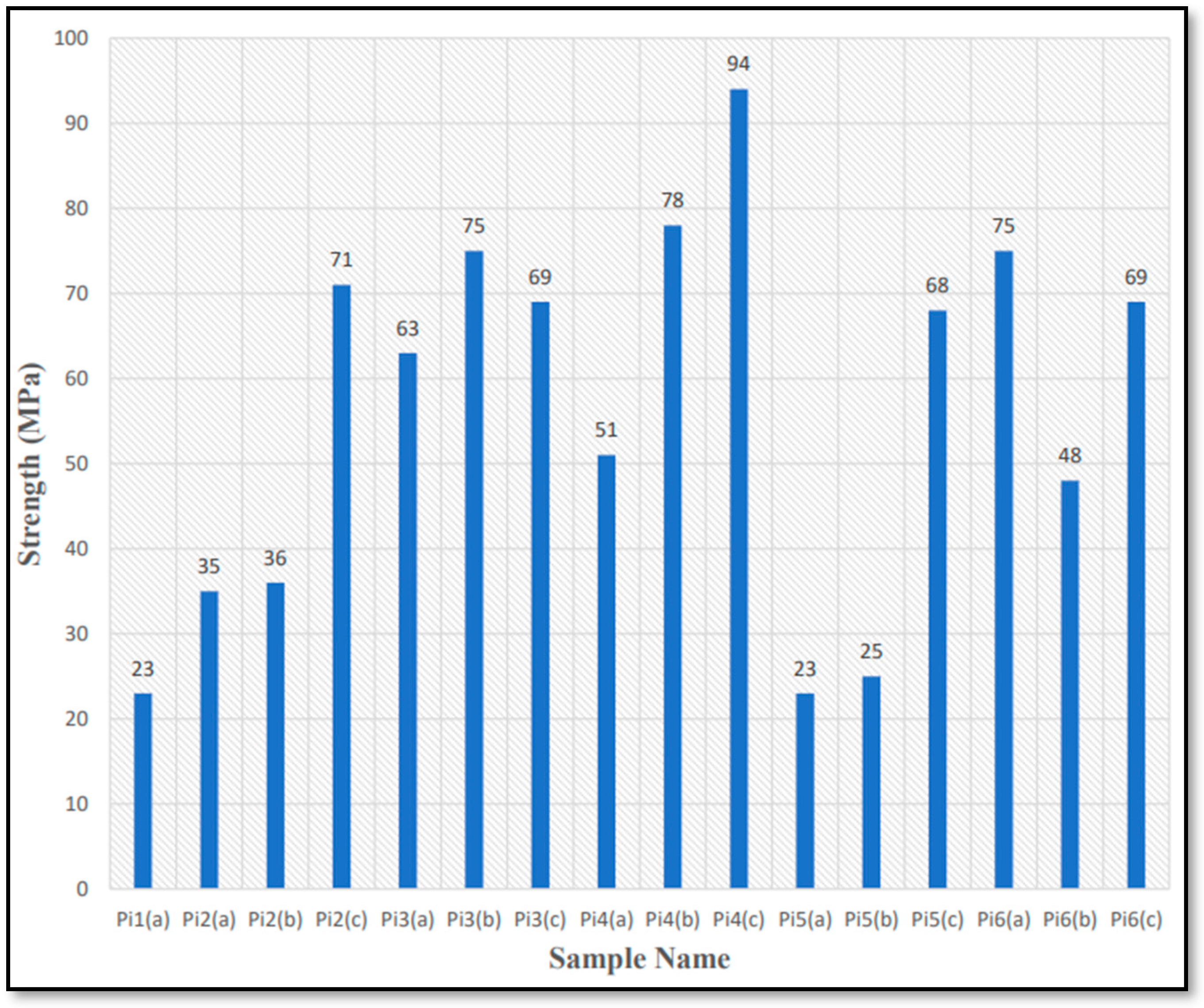

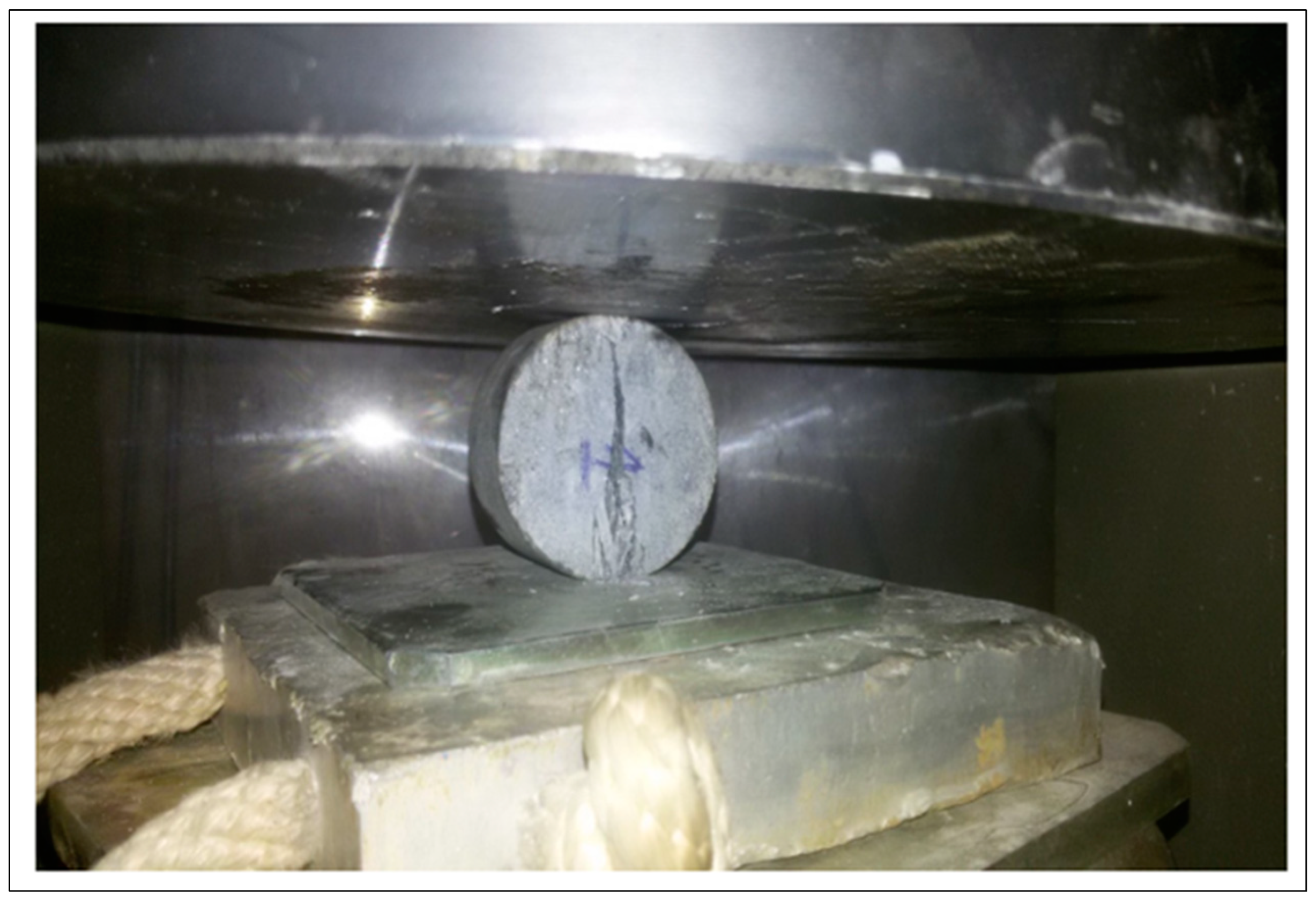

4.1.1. Unconfined Compressive Strength or Uniaxial Strength

- P = load of rock failure (kN).

- A = rock sample cube’s cross-sectional area ).

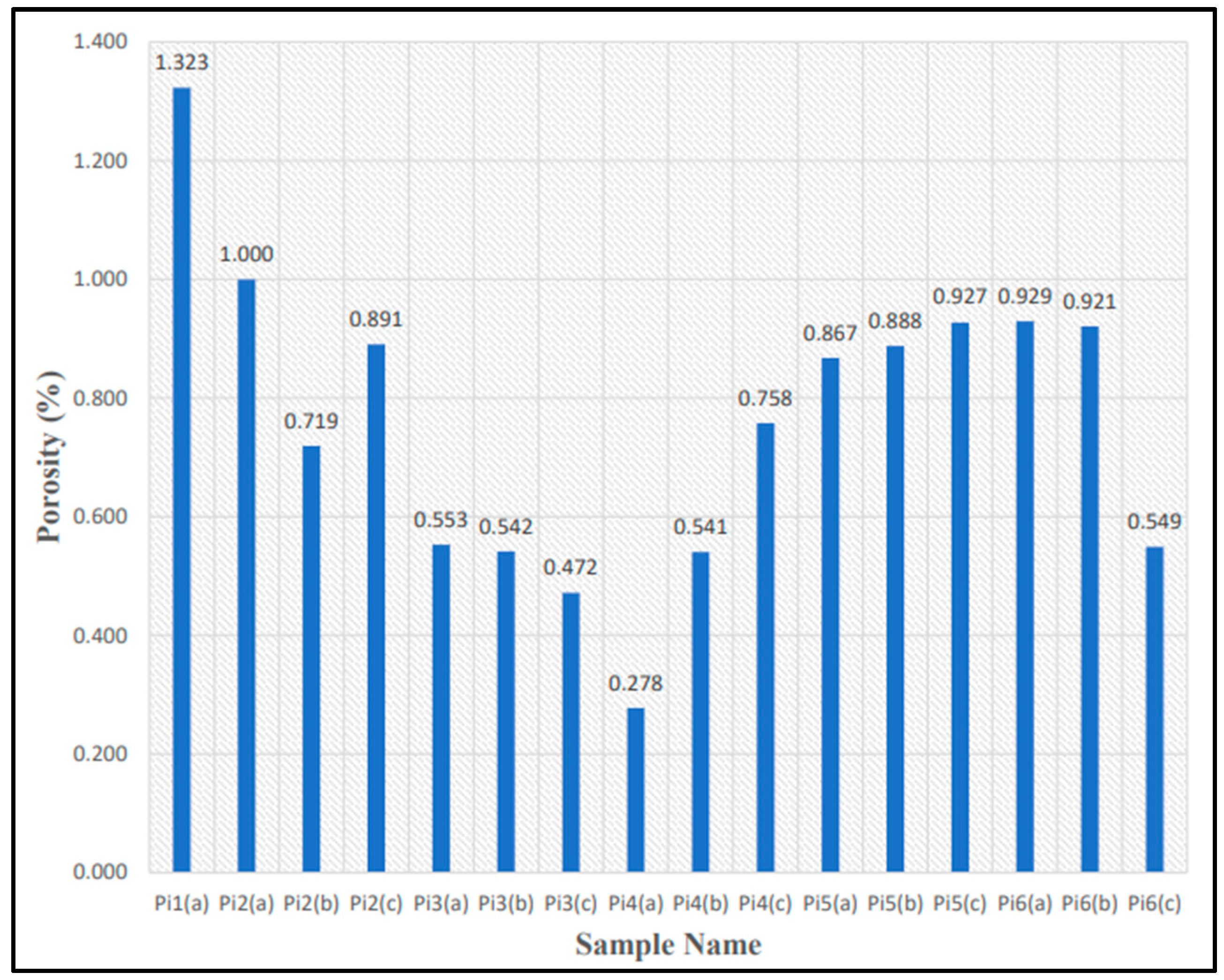

4.1.2. Porosity

- = weight in the air.

- = weight in water.

- = oven-dried weight.

4.1.3. Water Absorption

- Absorption =.

- = weight in the air.

- = oven-dried weight.

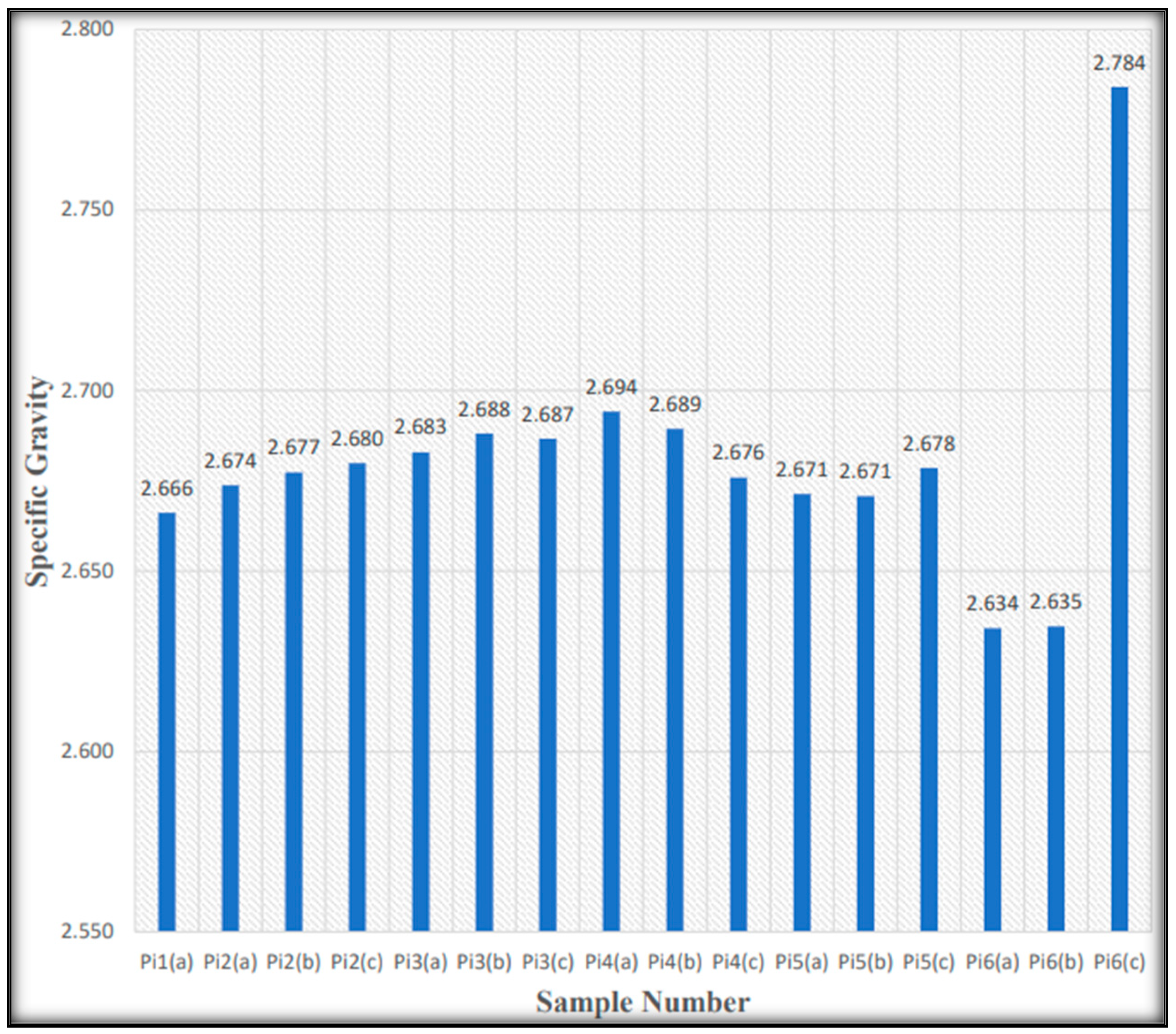

4.1.4. Specific Gravity

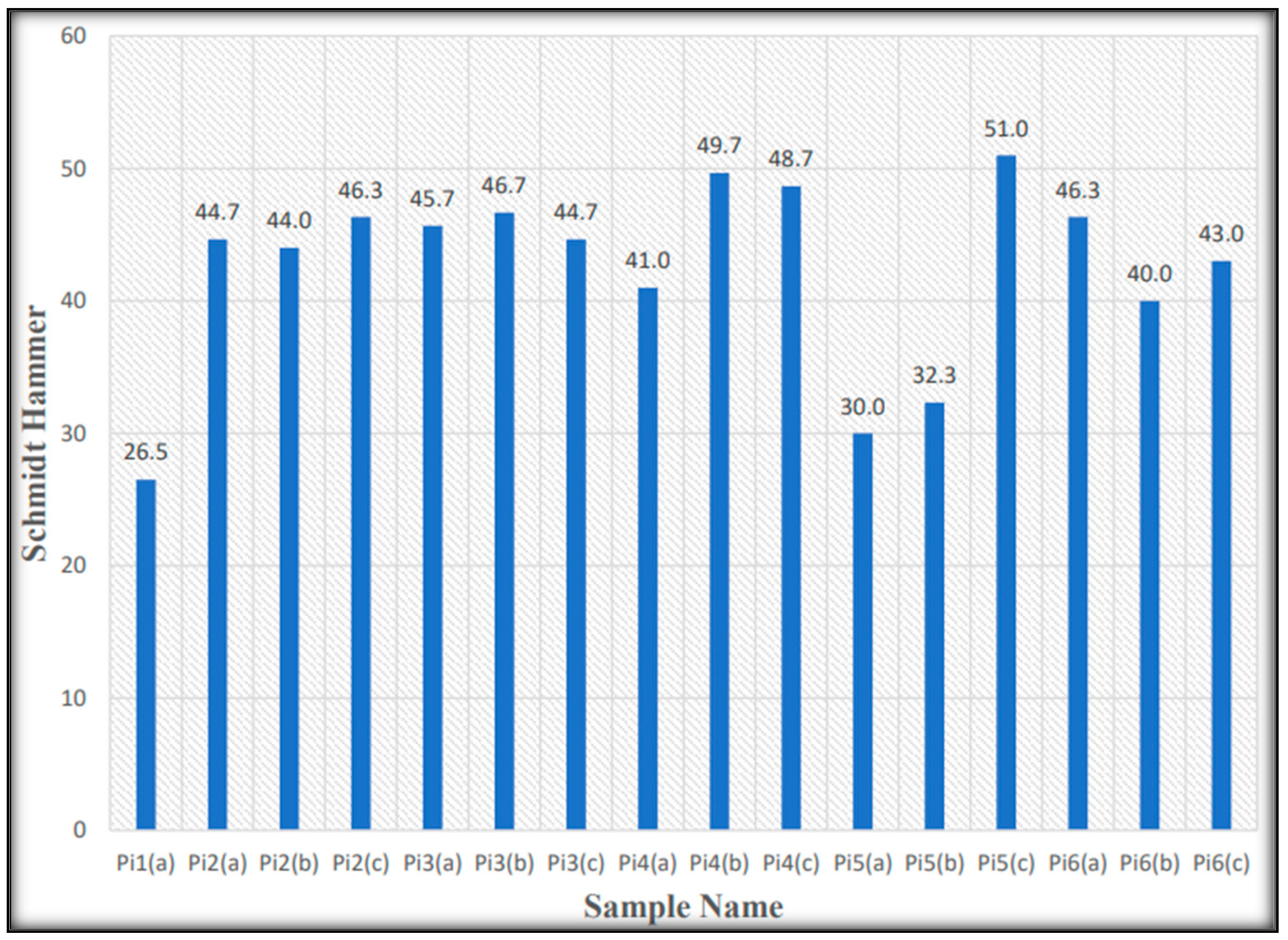

4.1.5. Schmidt Hammer Test

4.1.6. Shear Strength

4.1.7. Unconfined Tensile Strength (UTS)

- P = load (kN).

- D = the rock core’s diameter.

- T = the rock core’s diameter (m).

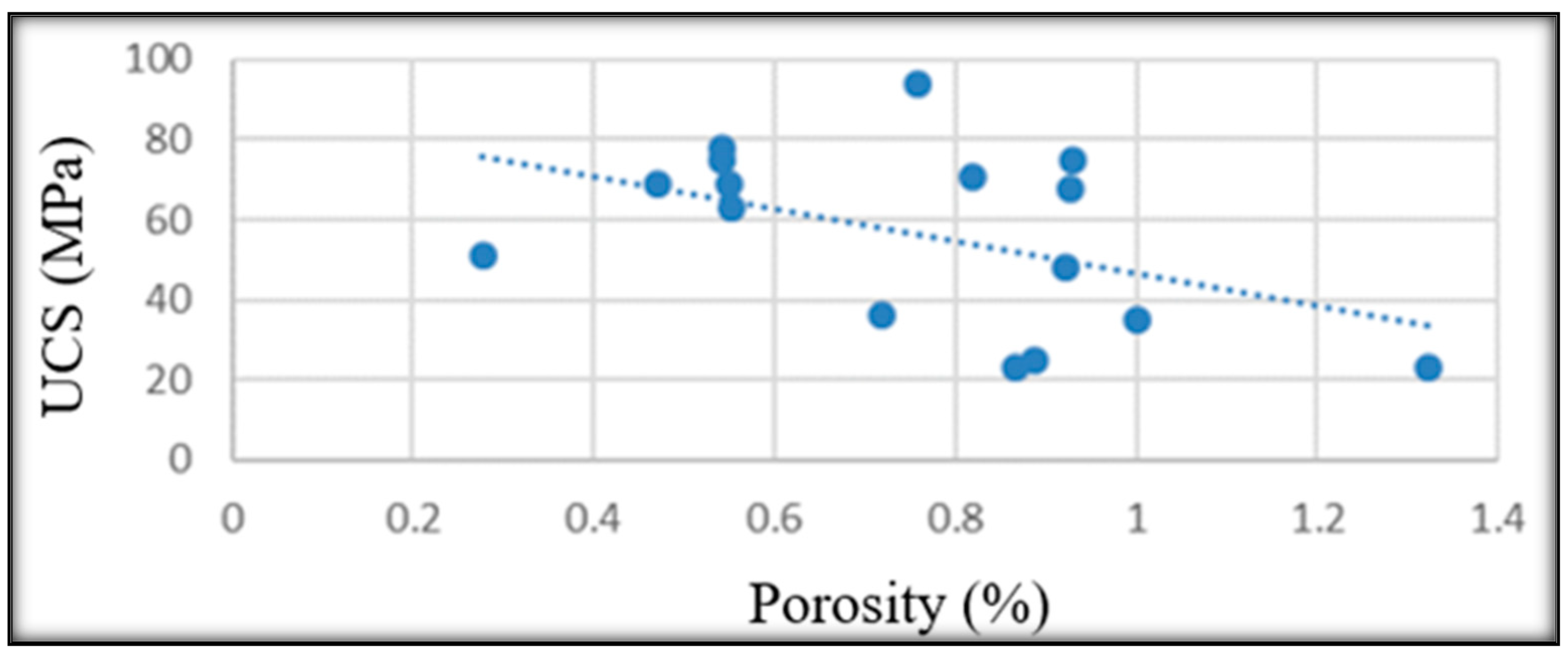

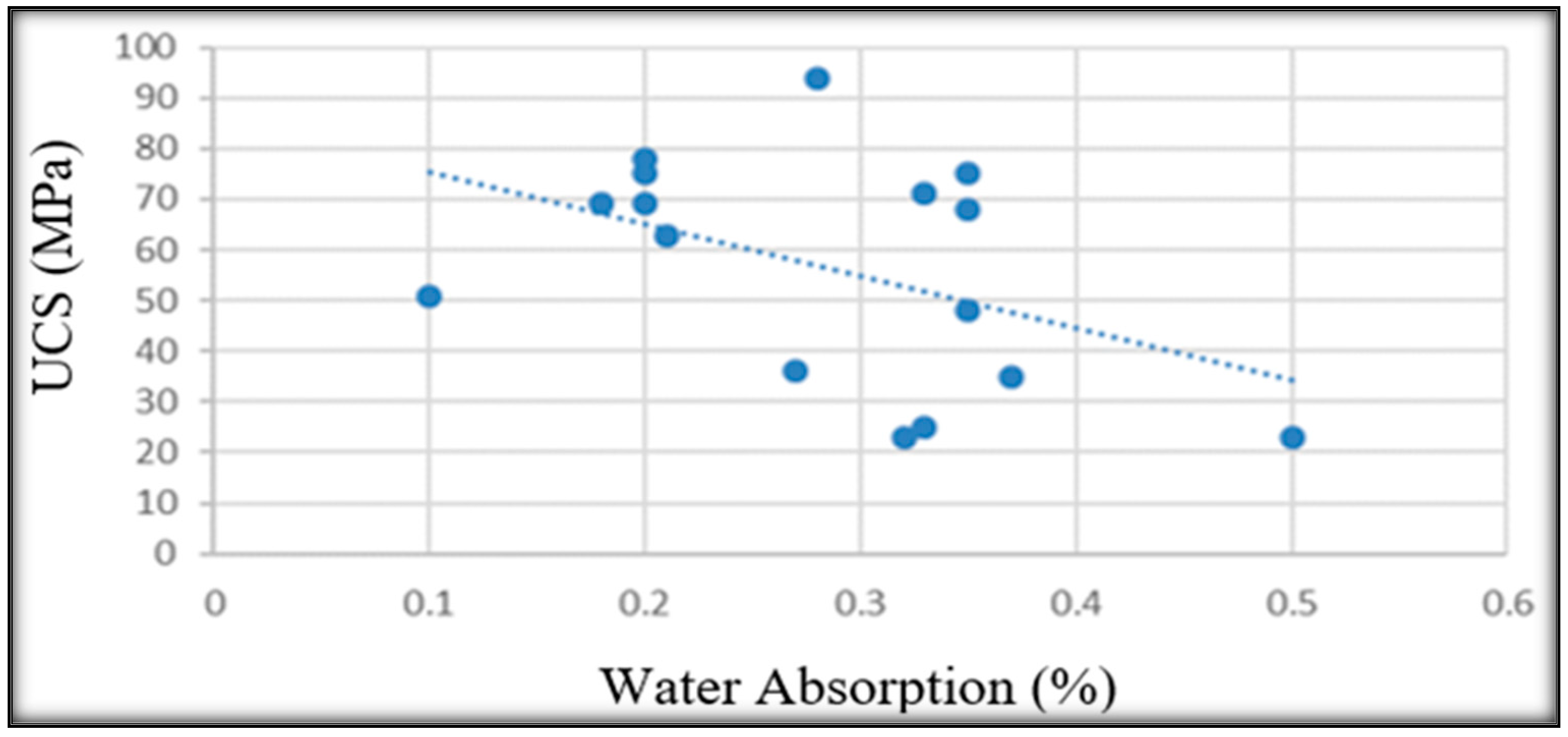

4.2. Relationship between the Inzari Formation’s Mechanical and Physical Characteristics

4.3. Petrographic Analysis of the Inzari Formation

- (i)

- Binding during deposition, a feature that sets bound stone apart from fine-grained carbonate rocks;

- (ii)

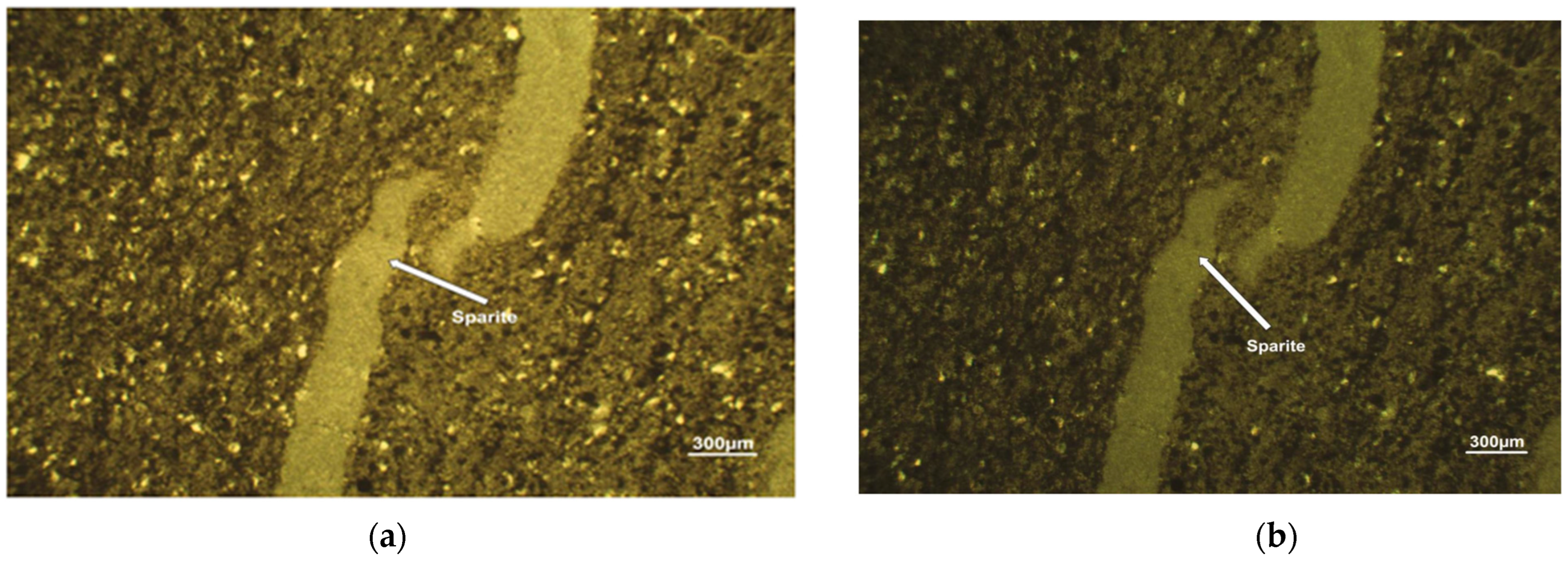

- The characteristic that sets grain stone apart from muddy carbonates: the presence of sparry calcite cement in fine-grained carbonate minerals;

- (iii)

- Grains are abundant in muddy carbonates, allowing for their division into mudstone, wacke stone, and pack stone. After the rock thin sections were analyzed for the petrographic description, these rock specimens were classified as “a siliciclastic mudstone” based on their texture, calcite cement (diabase), and mud matrix (micrite) [10]. The mineralogical composition of the studied samples is shown in Table 7.

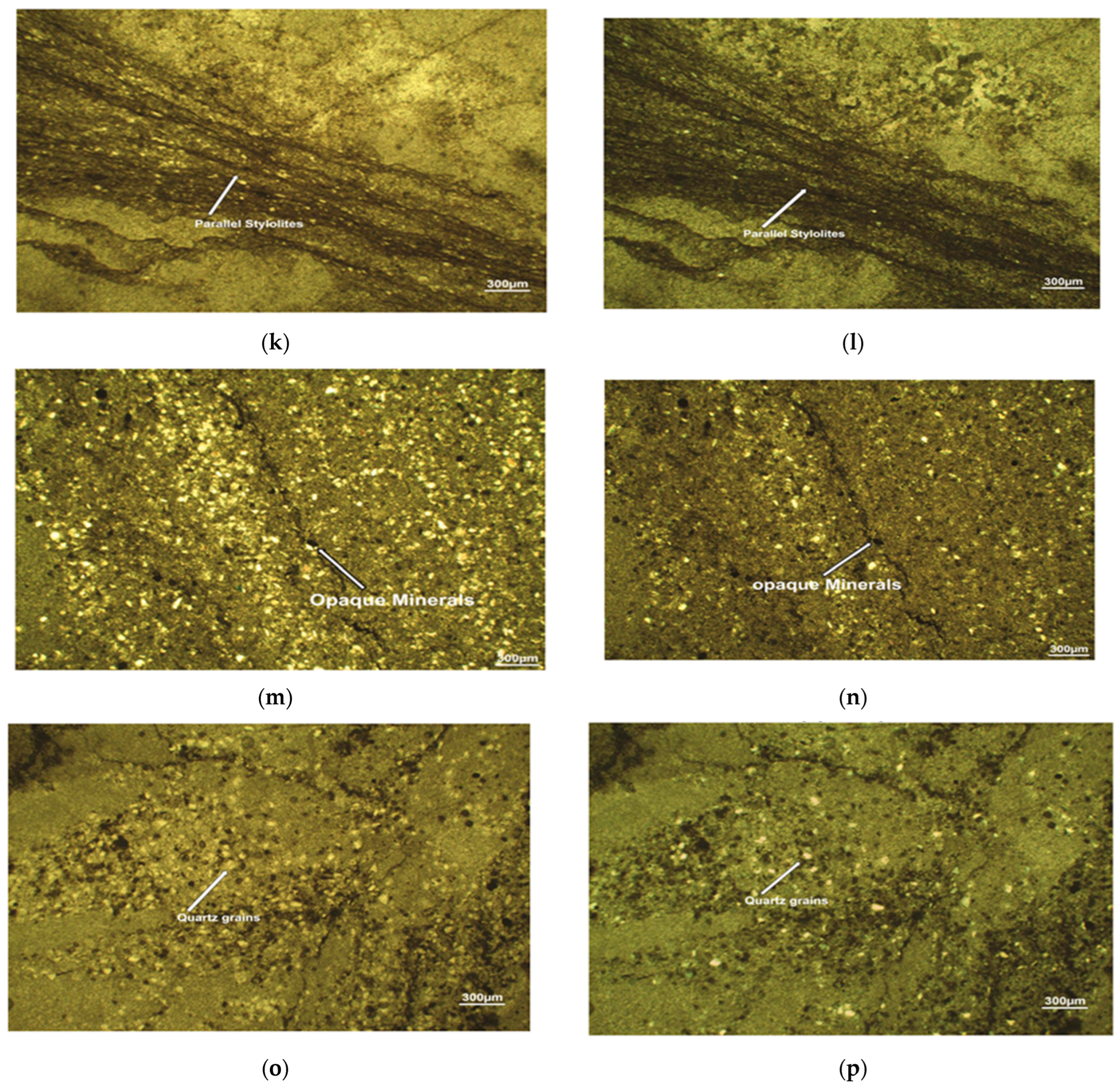

4.3.1. Fractures

4.3.2. Porosity

4.3.3. Microstylolites

4.3.4. Classification of the Studied Rocks

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, N.; Rehman, K. Petrophysical evaluation and fluid substitution modeling for reservoir depiction of Jurassic Datta Formation in the Chanda oil field, Khyber Pakhtunkhwa, northwest Pakistan. J. Pet. Explor. Prod. Technol. 2019, 9, 159–176. [Google Scholar] [CrossRef]

- Amuda, A.; Uche, O.; Amuda, A. Physicomechanical Characterization of Basement Rocks for Construction Aggregate: A Case Study of Kajuru Area, Kaduna, Nigeria. IOSR J. Mech. Civ. Eng. 2014, 11, 46–51. [Google Scholar] [CrossRef]

- Wang, J.; Jung, W.; Li, Y.; Ghassemi, A. Eomechanical characterization of Newberry Tuf. Geothermics 2016, 63, 74–96. [Google Scholar] [CrossRef]

- Ghobadi, M.; Babazadeh, R. Experimental Studies on the Effects of Cyclic Freezing–Thawing, Salt Crystallization, and Thermal Shock on the Physical and Mechanical Characteristics of Selected Sandstones. Rock Mech. Rock Eng. 2015, 48, 1001–1016. [Google Scholar] [CrossRef]

- Tomassi, A.; Trippetta, F.; de Franco, R.; Ruggieri, R. How petrophysical properties influence the seismic signature of carbonate fault damage zone: Insights from forward-seismic modelling. J. Struct. Geol. 2023, 167, 104802. [Google Scholar] [CrossRef]

- Aksoy, C.; Ozacar, V.; Demirel, N.; Ozer, S.; Safak, S. Determination of instantaneous breaking rate by Geological Strength Index, Block Punch Index and power of impact hammer for various rock mass conditions. Tunn. Undergr. Space Technol. 2011, 26, 534–540. [Google Scholar] [CrossRef]

- Ademila, O. Engineering geological evaluation of some rocks from Akure, Southwestern Nigeria as aggregates for concrete and pavement construction, Geology. Geophys. Environ. 2019, 45, 31. [Google Scholar]

- Přikryl, R. Assessment of rock geomechanical quality by quantitative rock fabric coefficients: Limitations and possible source of misinterpretations. Eng. Geol. 2006, 87, 149–162. [Google Scholar] [CrossRef]

- Aligholi, S.; Lashkaripour, G.R.; Ghafoori, M. Estimating engineering properties of igneous rocks using semi-automatic petrographic analysis. Bull. Eng. Geol. Environ. 2018, 78, 2299–2314. [Google Scholar] [CrossRef]

- Shah, S.A.; Qadir, A. Fracture Analysis of Rocks for Slope Stability Assessment in SiriKot Area, District Haripur, Khyber Pakhtunkhwa, Pakistan. Int. J. Econ. Environ. Geol. 2020, 11, 53–56. [Google Scholar]

- Tenze, D.; Braitenberg, C.; Sincich, E.; Mariani, P. Detecting the Elevated Crust to Mantle Section in the Kohistan-Ladakh Arc, Himalaya, from GOCE Observations. GOCE Obs. 2014, 141, 299–307. [Google Scholar]

- Yeats, R.S.; Hussain, A. Timing of structural events in the Himalayan foothills of northwestern Pakistan. Geol. Soc. Am. Bull. 1987, 99, 161–176. [Google Scholar] [CrossRef]

- Fahad, M.; Iqbal, Y.; Riaz, M.; Ubic, R.; Redfern, S.A. Metamorphic temperature investigation of coexisting calcite and dolomit e marble––examples from Nikani Ghar marble and Nowshera Formation. J. Earth Sci. 2016, 27, 989–997. [Google Scholar] [CrossRef][Green Version]

- Iqbal, J.; Ullah, I.; Razzaq, A.M.; Ghaffar, A.; Murad, F.; Ahmed, J. Petrographic and sem-edx characterization of mafic-felsic plutonic rock of washapikaur west Raskoh Arc, Pakistan. J. Mt. Area Res. 2022, 7, 23–36. [Google Scholar] [CrossRef]

- Anjum, M.N.; Shah, M.T.; Ali, F.; Hussain, E.; Ali, L. Geochemical studies of fluoride in drinking water of Union Council Ganderi, district Nowshera, Khyber Pakhtunkhwa, Pakistan. World Appl. Sci. J. 2013, 27, 632–636. [Google Scholar]

- Nisar, U.B.; Ehsan, S.A.; Farooq, M.; Pant, R.R.; Khan, N.G.; Qaiser, F.U.R.; Butt, F.M. Integrated Geoelectrical and Geological Investigation of a Quaternary Paleo-Depositional Environment in the Haripur Basin, Northern Pakistan. Implications for Groundwater System. Geofluids 2023, 2023, 1057457. [Google Scholar] [CrossRef]

- Bubeck, A.; Walker, R.; Healy, D.; Dobbs, M.; Holwell, D. Pore geometry as a control on rock strength. Earth Planet. Sci. Lett. 2017, 457, 38–48. [Google Scholar] [CrossRef]

- Wang, J.; Vandevyvere, B.; Vanhessche, S.; Schoon, J.; Boon, N.; Belie, N. Microbial carbonate precipitation for the improvement of quality of recycled aggregates. J. Clean. Prod. 2017, 156, 355–366. [Google Scholar] [CrossRef]

- Malham, I.; Bureau, L. Density effects on collapse, compression, and adhesion of thermoresponsive polymer brushes. Langmuir. ACS J. Surf. Colloids 2009, 26, 4762–4768. [Google Scholar] [CrossRef]

- Son, M.; Kim, M. Estimation of the Compressive Strength of Intact Rock Using Non-Destructive Testing Method Based on Total Sound-Signal Energy. Geotech. Test. J. 2017, 40, 643–657. [Google Scholar] [CrossRef]

- Fereidooni, D.; Khajevand, R. Determining the Geotechnical Characteristics of Some Sedimentary Rocks from Iran with an Emphasis on the Correlations between Physical, Index, and Mechanical Properties. Geotech. Test. J. 2018, 41, 555–573. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Wei, Y.; Ali, M. Experimental Study of Electric Potential Response Characteristics of Different Lithological Samples Subject to Uniaxial Loading. Rock Mech. Rock Eng. 2020, 54, 397–408. [Google Scholar] [CrossRef]

- Wright, V. A revised classification of limestones. Sediment. Geol. 1992, 76, 177–185. [Google Scholar] [CrossRef]

- Gomez, L.A.; Laubach, S.E. Rapid digital quantification of microfracture populations. J. Struct. Geol. 2006, 28, 408–420. [Google Scholar] [CrossRef]

- Stockdale, P. Stylolites, primary or secondary? J. Sediment. Res. 1943, 13, 3–12. [Google Scholar]

- Afolagboye, L.; Talabi, A.; Akinola, O. Evaluation of selected basement complex rocks from Ado-Ekiti, SW Nigeria, as source of road construction aggregates. Bull. Eng. Geol. Environ. 2016, 75, 853–865. [Google Scholar] [CrossRef]

| Sample Number | Cube Sample | Diameter | Area | Load | Strength | ||||

|---|---|---|---|---|---|---|---|---|---|

| in | m | in2 | m2 | Ibf | ton | psi | MPa | ||

| Pi1 | Pi1 (a) | 2.25 | 0.05 | 4.0 | 0.002 | 13,235 | 6.61 | 3309 | 23 |

| Pi2 | Pi2 (a) | 3.28 | 0.08 | 8.5 | 0.005 | 43,590 | 21.79 | 5128 | 35 |

| Pi2 (b) | 3.28 | 0.08 | 8.5 | 0.005 | 44,212 | 22.10 | 5201 | 36 | |

| Pi2 (c) | 3.28 | 0.08 | 8.5 | 0.005 | 87,930 | 43.96 | 10,345 | 71 | |

| Pi3 | Pi3 (a) | 3.28 | 0.08 | 8.5 | 0.005 | 78,179 | 39.08 | 9198 | 63 |

| Pi3 (b) | 3.28 | 0.08 | 8.5 | 0.005 | 92,526 | 46.26 | 10,885 | 75 | |

| Pi3 (c) | 3.28 | 0.08 | 8.5 | 0.005 | 85,567 | 42.78 | 10,067 | 69 | |

| Pi4 | Pi4 (a) | 3.28 | 0.08 | 8.5 | 0.005 | 63,284 | 31.64 | 7445 | 51 |

| Pi4 (b) | 3.28 | 0.08 | 8.5 | 0.005 | 95,640 | 47.82 | 11,252 | 78 | |

| Pi4 (c) | 3.28 | 0.08 | 8.5 | 0.005 | 115,501 | 57.75 | 13,588 | 94 | |

| Pi5 | Pi5 (a) | 2.22 | 0.05 | 4.0 | 0.002 | 13,435 | 6.71 | 3359 | 23 |

| Pi5 (b) | 2.22 | 0.05 | 4.0 | 0.002 | 14,224 | 7.11 | 3556 | 25 | |

| Pi5 (c) | 3.28 | 0.08 | 8.5 | 0.005 | 84,322 | 42.16 | 9920 | 68 | |

| Pi6 | Pi6 (a) | 3.28 | 0.08 | 8.5 | 0.005 | 92,490 | 46.24 | 10,881 | 75 |

| Pi6 (b) | 3.28 | 0.08 | 8.5 | 0.005 | 59,687 | 29.84 | 7022 | 48 | |

| Pi6 (c) | 3.28 | 0.08 | 8.5 | 0.005 | 85,114 | 42.55 | 10,013 | 69 | |

| Sample Number | Cube Sample | Weight in Air (W1) | Weight in Water (W2) | Oven-Dried Weight (W3) | Porosity |

|---|---|---|---|---|---|

| Pi1 | Pi1 (a) | 370.26 | 232.27 | 368.75 | 1.323 |

| Pi2 | Pi2 (a) | 905.80 | 569.24 | 903.95 | 1.000 |

| Pi2 (b) | 961.49 | 604.15 | 960.21 | 0.719 | |

| Pi2 (c) | 931.97 | 585.99 | 929.89 | 0.891 | |

| Pi3 | Pi3 (a) | 942.35 | 592.35 | 941.24 | 0.553 |

| Pi3 (b) | 959.33 | 603.47 | 957.89 | 0.542 | |

| Pi3 (c) | 963.07 | 605.55 | 961.88 | 0.472 | |

| Pi4 | Pi4 (a) | 961.24 | 605.09 | 960.67 | 0.278 |

| Pi4 (b) | 961.92 | 604.79 | 959.72 | 0.541 | |

| Pi4 (c) | 944.91 | 593.34 | 943.13 | 0.758 | |

| Pi5 | Pi5 (a) | 395.1 | 247.94 | 394.24 | 0.867 |

| Pi5 (b) | 940.53 | 590.23 | 938.52 | 0.888 | |

| Pi5 (c) | 923.13 | 580.71 | 921.59 | 0.927 | |

| Pi6 | Pi6 (a) | 939.93 | 585.34 | 938.19 | 0.929 |

| Pi6 (b) | 910.19 | 567.51 | 909.56 | 0.921 | |

| Pi6 (c) | 923.15 | 593.15 | 922.78 | 0.549 |

| Sample Number | Cube Sample | Weight in Water (W1) | Oven-Dried Weight (W3) | Water Absorption | Water Absorption (%) |

|---|---|---|---|---|---|

| Pi1 | Pi1 (a) | 232.27 | 368.75 | 1.83 | 0.50 |

| Pi2 | Pi2 (a) | 569.24 | 903.95 | 3.38 | 0.37 |

| Pi2 (b) | 604.15 | 960.21 | 2.58 | 0.27 | |

| Pi2 (c) | 585.99 | 929.89 | 3.09 | 0.33 | |

| Pi3 | Pi3 (a) | 592.35 | 941.24 | 1.94 | 0.21 |

| Pi3 (b) | 603.47 | 957.89 | 1.93 | 0.20 | |

| Pi3 (c) | 605.55 | 961.88 | 1.69 | 0.18 | |

| Pi4 | Pi4 (a) | 605.09 | 960.67 | 0.99 | 0.10 |

| Pi4 (b) | 604.79 | 959.72 | 1.93 | 0.20 | |

| Pi4 (c) | 593.34 | 943.13 | 2.67 | 0.28 | |

| Pi5 | Pi5 (a) | 247.94 | 394.24 | 1.28 | 0.32 |

| Pi5 (b) | 590.23 | 938.52 | 3.12 | 0.33 | |

| Pi5 (c) | 580.71 | 921.59 | 3.19 | 0.35 | |

| Pi6 | Pi6 (a) | 585.34 | 938.19 | 3.31 | 0.35 |

| Pi6 (b) | 567.51 | 909.56 | 3.18 | 0.35 | |

| Pi6 (c) | 593.15 | 922.78 | 1.82 | 0.20 |

| Sample Number | Cube Sample | Weight in Water (W2) | Oven-Dried Weight (W3) | Specific Gravity |

|---|---|---|---|---|

| Pi1 | Pi1 (a) | 232.27 | 368.75 | 2.666 |

| Pi2 | Pi2 (a) | 569.24 | 903.95 | 2.674 |

| Pi2 (b) | 604.15 | 960.21 | 2.677 | |

| Pi2 (c) | 585.99 | 929.89 | 2.680 | |

| Pi3 | Pi3 (a) | 592.35 | 941.24 | 2.683 |

| Pi3 (b) | 603.47 | 957.89 | 2.688 | |

| Pi3 (c) | 605.55 | 961.88 | 2.687 | |

| Pi4 | Pi4 (a) | 605.09 | 960.67 | 2.694 |

| Pi4 (b) | 604.79 | 959.72 | 2.689 | |

| Pi4 (c) | 593.34 | 943.13 | 2.676 | |

| Pi5 | Pi5 (a) | 247.94 | 394.24 | 2.671 |

| Pi5 (b) | 590.23 | 938.52 | 2.671 | |

| Pi5 (c) | 580.71 | 921.59 | 2.678 | |

| Pi6 | Pi6 (a) | 585.34 | 938.19 | 2.634 |

| Pi6 (b) | 567.51 | 909.56 | 2.635 | |

| Pi6 (c) | 593.15 | 922.78 | 2.784 |

| Sample Number | Cube Sample | Schmidt Hammer Values |

|---|---|---|

| Pi1 | Pi1 (a) | 26.5 |

| Pi2 | Pi2 (a) | 44.7 |

| Pi2 (b) | 44.0 | |

| Pi2 (c) | 46.3 | |

| Pi3 | Pi3 (a) | 45.7 |

| Pi3 (b) | 46.7 | |

| Pi3 (c) | 44.7 | |

| Pi4 | Pi4 (a) | 41.0 |

| Pi4 (b) | 49.7 | |

| Pi4 (c) | 48.7 | |

| Pi5 | Pi5 (a) | 30.0 |

| Pi5 (b) | 32.3 | |

| Pi5 (c) | 51.0 | |

| Pi6 | Pi6 (a) | 46.3 |

| Pi6 (b) | 40.0 | |

| Pi6 (c) | 43.0 |

| Sample Number | Cube Sample | UCS (MPa) | Water Absorption (%) | Specific Gravity |

|---|---|---|---|---|

| Pi1 | Pi1 (a) | 23 | 0.50 | 2.666 |

| Pi2 | Pi2 (a) | 35 | 0.37 | 2.674 |

| Pi2 (b) | 36 | 0.27 | 2.677 | |

| Pi2 (c) | 71 | 0.33 | 2.680 | |

| Pi3 | Pi3 (a) | 63 | 0.21 | 2.683 |

| Pi3 (b) | 75 | 0.20 | 2.688 | |

| Pi3 (c) | 69 | 0.18 | 2.687 | |

| Pi4 | Pi4 (a) | 51 | 0.10 | 2.694 |

| Pi4 (b) | 78 | 0.20 | 2.689 | |

| Pi4 (c) | 94 | 0.28 | 2.676 | |

| Pi5 | Pi5 (a) | 23 | 0.32 | 2.671 |

| Pi5 (b) | 25 | 0.33 | 2.671 | |

| Pi5 (c) | 68 | 0.35 | 2.678 | |

| Pi6 | Pi6 (a) | 75 | 0.35 | 2.634 |

| Pi6 (b) | 48 | 0.35 | 2.635 | |

| Pi6 (c) | 69 | 0.20 | 2.784 |

| Sample Name | Core Sample | Micrite (%) | Sparite (%) | Calcite (%) | Quartz (%) | Opaque Minerals (%) |

|---|---|---|---|---|---|---|

| Pi1 | Pi1 (1) | 60 | 15 | 14 | 9 | 2 |

| Pi1 (2) | 56 | 19 | 13 | 9 | 3 | |

| Pi2 | Pi2 (1) | 62 | 13 | 16 | 6 | 3 |

| Pi2 (2) | 59 | 20 | 10 | 10 | 1 | |

| Pi3 | Pi3 (1) | 61 | 14 | 13 | 10 | 2 |

| Pi3 (2) | 55 | 20 | 13 | 9 | 3 | |

| Pi4 | Pi4 (1) | 60 | 21 | 12 | 5 | 2 |

| Pi4 (2) | 59 | 19 | 9 | 10 | 3 | |

| Pi5 | Pi5 (1) | 61 | 15 | 14 | 8 | 2 |

| Pi5 (2) | 59 | 18 | 15 | 7 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayaz, H.; Xu, J.; Aslam, M.U.; Ahmad, S. Evaluation of Petrographic and Geomechanical Properties of Inzari Formation Rocks for Their Suitability as Building Materials in the Nizampur Basin, Pakistan. Appl. Sci. 2024, 14, 9395. https://doi.org/10.3390/app14209395

Ayaz H, Xu J, Aslam MU, Ahmad S. Evaluation of Petrographic and Geomechanical Properties of Inzari Formation Rocks for Their Suitability as Building Materials in the Nizampur Basin, Pakistan. Applied Sciences. 2024; 14(20):9395. https://doi.org/10.3390/app14209395

Chicago/Turabian StyleAyaz, Hassan, Jiancong Xu, Muhammad Usama Aslam, and Sohail Ahmad. 2024. "Evaluation of Petrographic and Geomechanical Properties of Inzari Formation Rocks for Their Suitability as Building Materials in the Nizampur Basin, Pakistan" Applied Sciences 14, no. 20: 9395. https://doi.org/10.3390/app14209395

APA StyleAyaz, H., Xu, J., Aslam, M. U., & Ahmad, S. (2024). Evaluation of Petrographic and Geomechanical Properties of Inzari Formation Rocks for Their Suitability as Building Materials in the Nizampur Basin, Pakistan. Applied Sciences, 14(20), 9395. https://doi.org/10.3390/app14209395