In order to fulfill the proposed objectives, the main results are presented here, concerning the in-cylinder pressure, ignition delay, heat release rate, and atomization analysis of fuel spray. Regarding performance parameters, the main results were comparable for all fuel tested in correspondence with other works reported in the literature. These results are not presented in order to emphasize the analysis of the combustion process.

3.1. In-Cylinder Pressure

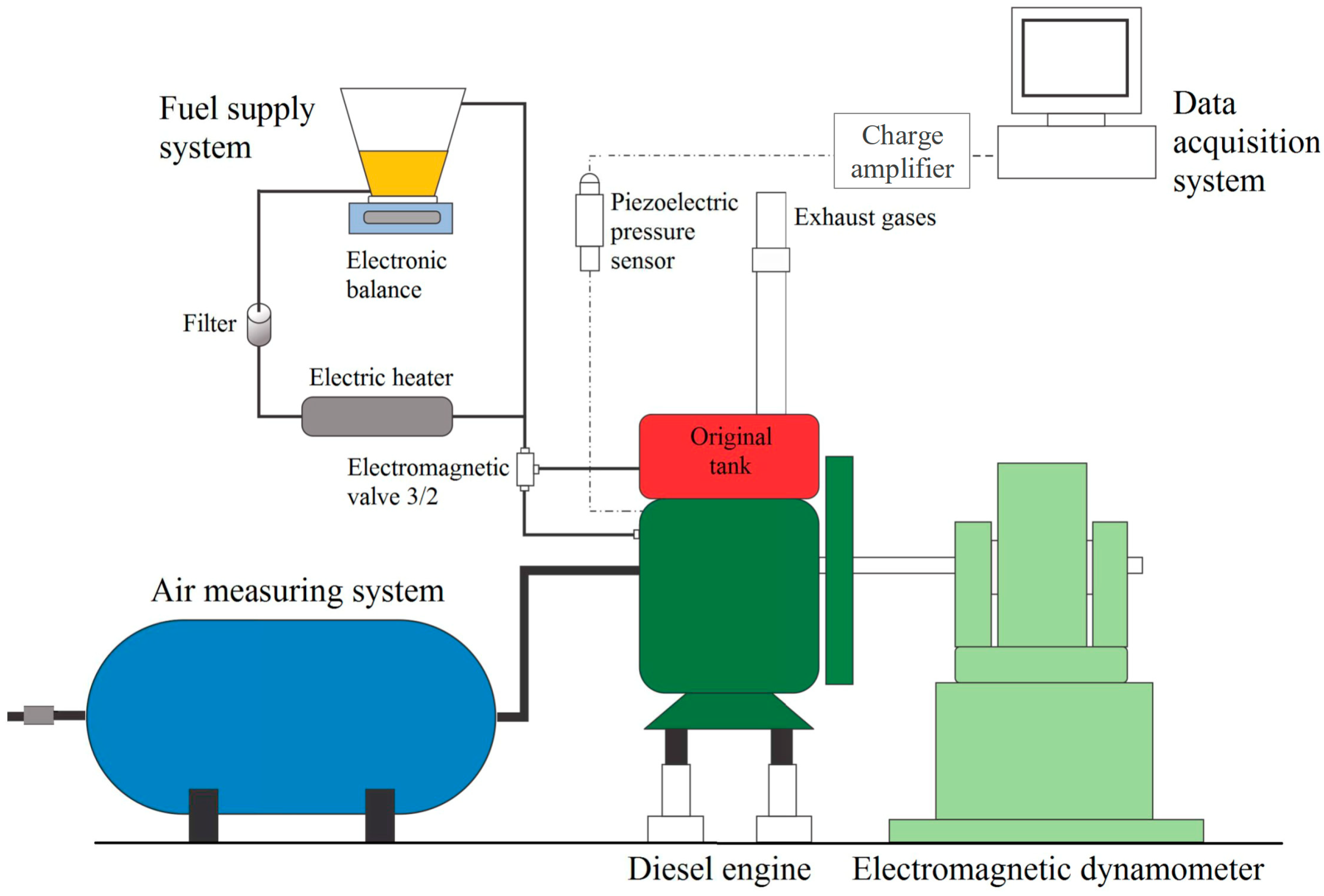

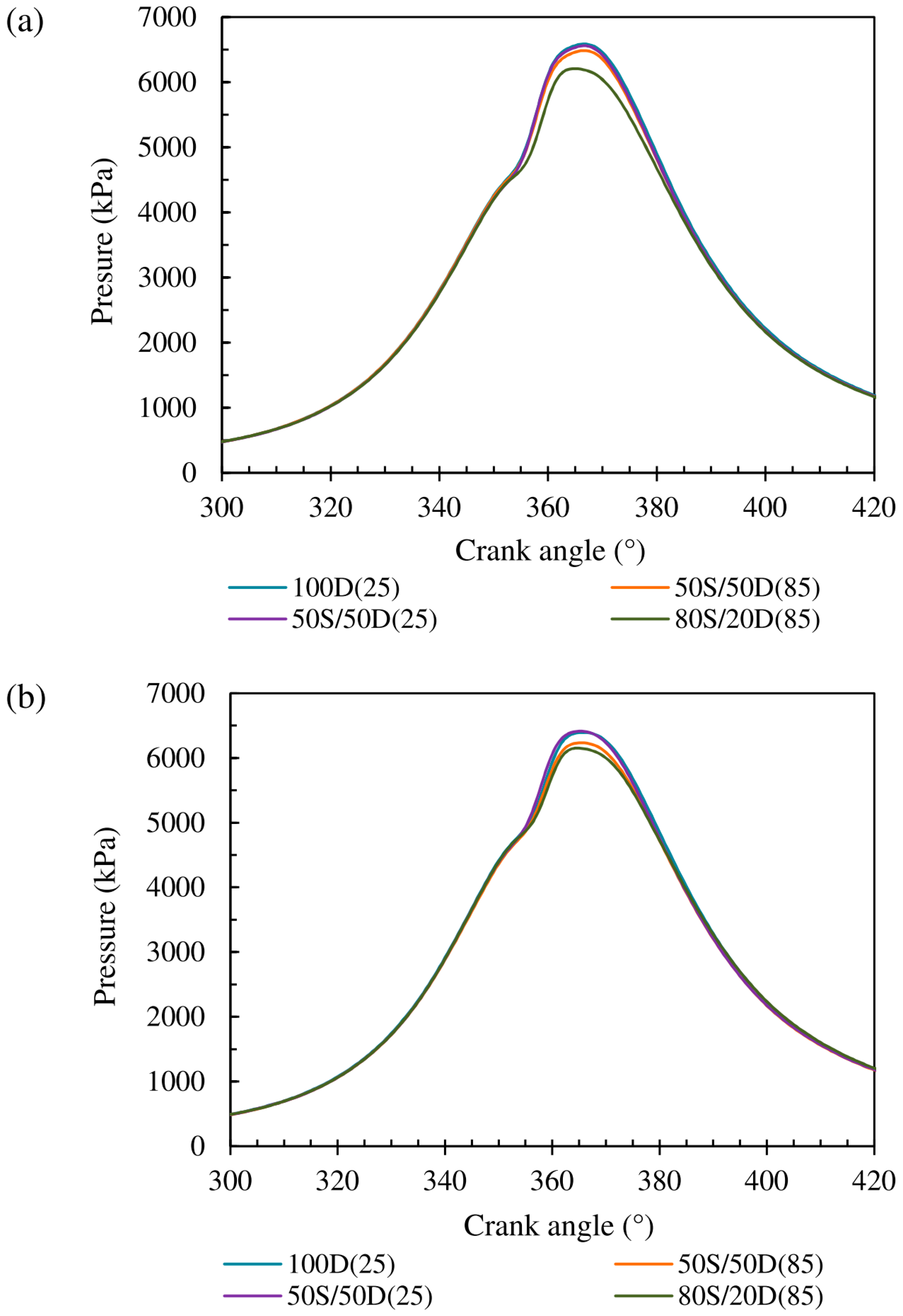

The in-cylinder pressure data as a function of crank angle for the fuels tested at 1800 and 2100 rpm are shown in

Figure 2. The highest pressures are observed at the lowest speed as a consequence of the high load and, therefore, the highest fuel amount injected per cycle. High-pressure values are related to the fuel

LHV, the ignition delay, and the development of the heat release rate in the premixed phase during the combustion of each sample.

The start of the ignition produces a slope change of the pressure curves, close to 360° CA. In this context, one observes an ignition more delayed for the blend 80S/20D(85) for both engine speeds. The maximum pressure value presented for each fuel at each speed and the corresponding crank angle are shown in

Table 5, including the percentage difference relative to diesel oil. At 1800 rpm, the highest maximum pressure was presented for diesel oil 100D(25) and the blend 50S/50D(25). The lowest maximum pressure was presented by the blend 80S/20D(85), being about 6% lower than the maximum pressure of the diesel oil. Similar behavior was observed at 2100 rpm, decreasing to 4% of the difference between the maximum pressure of the diesel oil and the blend 80S/20D(85).

3.3. Heat Release Rate

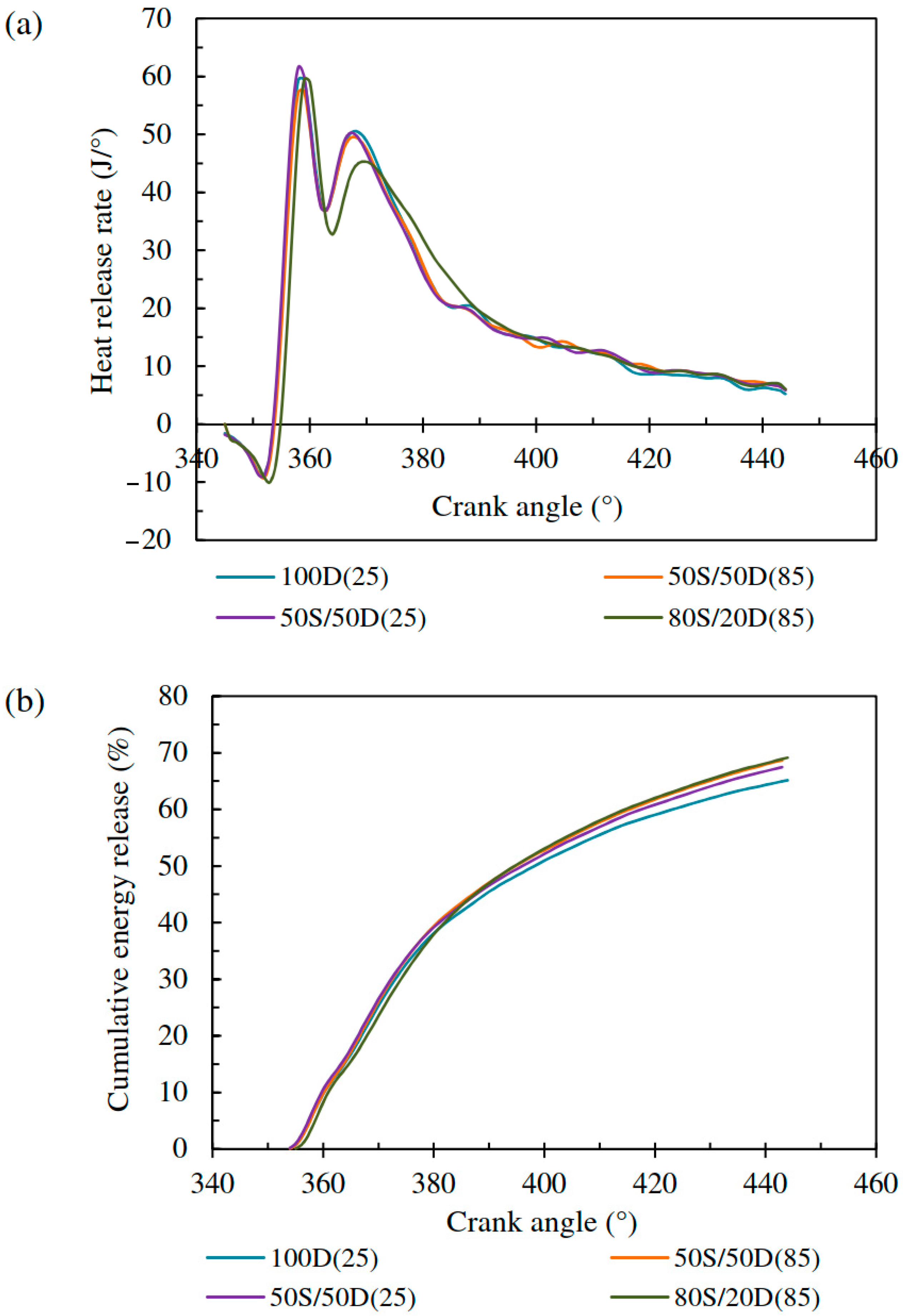

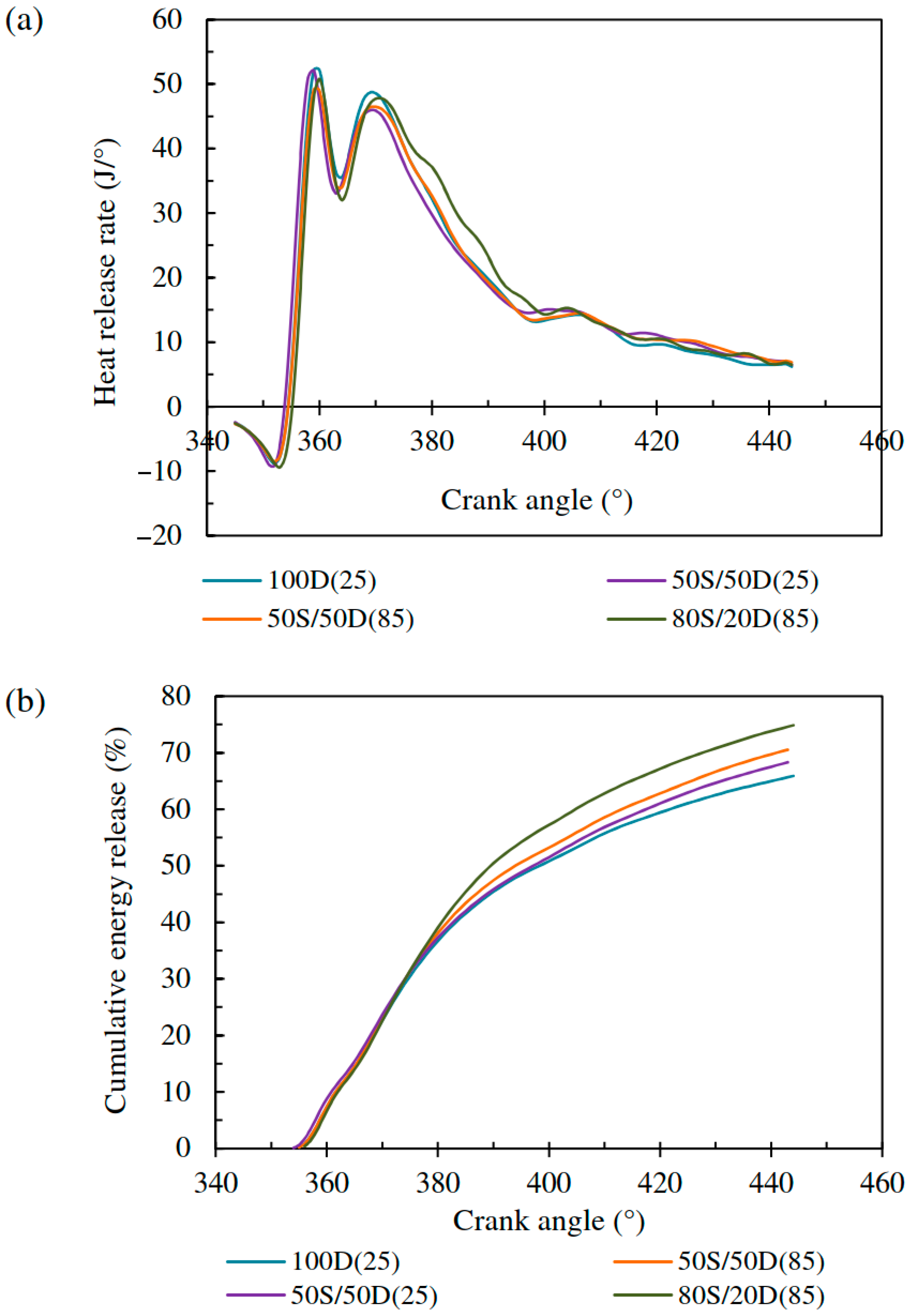

The heat release rate and the corresponding cumulative energy release obtained for the fuels at 1800 and 2100 are presented in

Figure 3 and

Figure 4, respectively. The heat release rate curves evidence the premixed and nonpremixed (diffusive) combustion phases. Additionally, a significant residual combustion phase is also observed.

The heat release rate increases with the load, i.e., with the speed reduction, where the mass fuel injected per cycle increases. Observing the curves of cumulative energy release, the combustion performance presented a similar behavior in the premixed combustion phase for all fuels tested, changing in the nonpremixed combustion phase, where we observed a significant difference among the fuels.

The heat release rate in the premixed combustion phase is influenced by the ignition delay. Consequently, for both engine speeds, one observes that all fuels present a similar premixed combustion phase, corresponding to a similar ignition delay, as shown in

Table 6. In the case of the blend 80S/20D(85), the heat release curve begins slightly delayed as a result of its ignition delay that is slightly higher with respect to the other fuels. At 1800 rpm, the higher premixed combustion rate is related to the load increase and the time increase per each crank angle degree corresponding to the speed reduction, which favors the air–fuel mixing and the burning.

At 1800 rpm, the diesel oil 100D(25) and the blends 50S/50D(25) and 50S/50D(85) presented the highest peak of the heat release rate in the diffusive phase. From 380° CA, approximately, the heat release rate increased for the blend 80S/20D(85) in comparison with the other fuels (residual combustion phase), which shows the combustion delay of this blend and the effect of the highest oxygen content in the fuel that favors the burning, such that the cumulative energy release is high for the blends 80S/20D(85) and 50S/50D(85). The 100D(25) oil presented the lowest cumulative energy release. Similar results were reported by Kannan et al. [

45] in their work with oxygenated fuels.

At 2100 rpm, the diesel oil 100D(25) and the blend 80S/20D(85) presented the highest peak of the heat release rate in the diffusive phase. In the residual combustion phase, the blend 80S/20D(85) presented the highest heat release rate. Once more, the blend 80S/20D(85) presented the highest cumulative energy release, increasing the overall reactive rate in the diffusive and residual combustion phases. The burning of the blends 50S/50D(25) and 50S/50D(85) presented similar cumulative energy release, being slightly higher for the blend 50S/50D(85). The diesel oil presented the lowest cumulative energy release. For the blends, the cumulative release energy was higher at 2100 rpm than at 1800 rpm.

In general, for fuels 100D(25), 50S/50D(25), and 50S/50D(85), the highest diffusive combustion rate was obtained at 1800 rpm (higher mass fuel injected), decreasing in the residual combustion phase as a consequence of high heat transfer (higher time per crank angle and higher gas temperature). At 2100 rpm, we observed the highest residual combustion rate, favored by the tumble and swirl effects, possibly present in the combustion chamber at that engine speed. In the case of the blend 80S/20D(85), the highest diffusive and residual combustion rates were observed at 2100 rpm as a consequence of the combustion delay and the effect of the turbulence and blend oxygen content that favor the burning at this speed.

The curves of the heat release rate were developed over compression and expansion strokes of the engine operating cycle when valves were closed. Consequently, the final point of the curves was 444° CA, where the exhaust valve started to open. Based on the curves of cumulative energy release, one can observe that the total mass fuel injected did not burn completely, continuing the burning during the exhaust stroke.

Table 7 presents the mass fraction burned at 444° CA for all fuels at the two speeds tested. The values of the mass fraction burned are lower than 100%. One can consider that the low values calculated for the total mass fraction burned are a consequence of the model employed for the heat transfer coefficient, which probably underestimates the heat transfer for the walls; therefore, the heat release rate is also underestimated, signifying low mass fraction burned.

As shown in

Table 7, the mass fraction burned increased with the speed increase or load reduction where the mass fuel injected per cycle and the global equivalence ratio were less (see

Table 8). The highest mass fraction burned was presented for the blend 80S/20D(85) at both speeds, with the difference in comparison to 100D(25) at 2100 rpm being more significant. Additionally, one can see that the lowest global equivalence ratio and the turbulence produced by high speeds favor the air–fuel mixing and, consequently, the mass fraction burned.

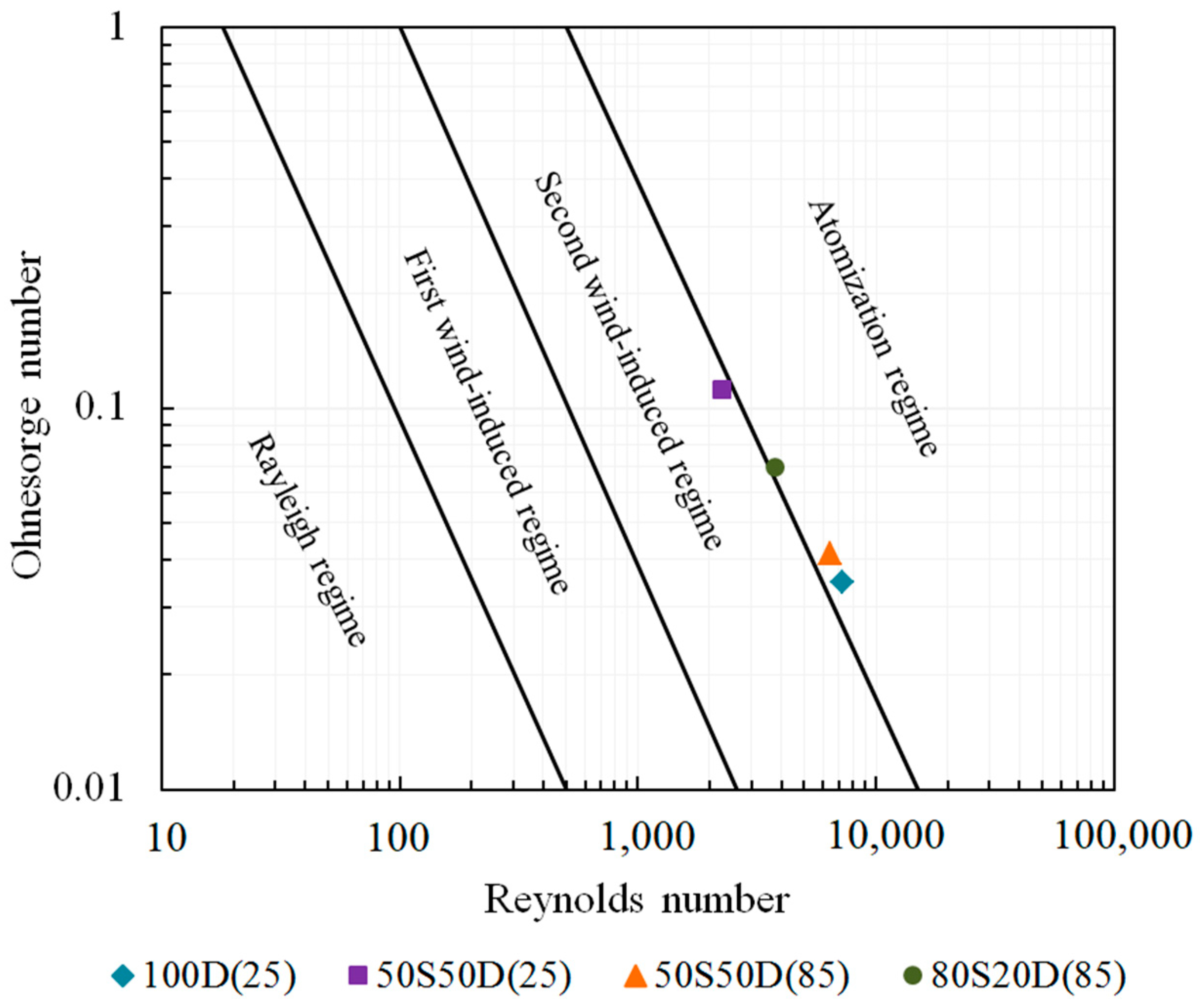

3.4. Atomization Analysis

The jet pattern is a significant factor in the combustion process. It is influenced by the injection parameters and the physical fuel properties. The primary disintegration or break-up regime of the fuel jet in diesel engines must be the atomization regime. The Ohnesorge diagram permits the identification of the break-up regime, relating the Ohnesorge number with the Reynolds number of the spray. The dimensionless numbers required to build the Ohnesorge diagram are

where

,

, and

Oh are Reynolds, Weber, and Ohnesorge dimensionless numbers of the spray, respectively;

is the spray velocity;

is the injector nozzle hole diameter; and

,

, and

are the density, dynamic viscosity, and surface tension of the fuel, respectively. The injector nozzle hole diameter was 0.3 mm, and the fuel properties were calculated at respective injection temperatures using the correlations previously reported in Garzón et al. [

37].

In order to help understand the combustion process, the break-up regime (Ohnesorge diagram),

SMD (Sauter mean diameter), droplet Reynold number, and oxygen content were estimated for all fuels tested at 1800 rpm. The results are shown in

Figure 5 and

Table 9. The

SMD was calculated using the correlation proposed by Hiroyasu and Arai [

46]. Thus,

where

and

are the dynamic viscosity and density of the gas, respectively. The gas dynamic viscosity was calculated as

, according to Annand [

47]. The droplet Reynold number was calculated as follows:

where

is the piston velocity (gas velocity).

According to Ohnesorge diagram, the blend 50S/50D(25) does not present the atomization regime required for diesel engine combustion, and the break-up regime of the blend 80S/20D(85) is between second-wind-induced and atomization regimes. In the case of the blend 50S/50D(85), the heating favored the break-up, reaching the atomization regime.

Concerning the results shown in

Table 9, the blend 50S/50D(25) presents the highest

SMD, being 15.5% higher than the

SMD of 100D(25). The highest droplet Reynold number is also presented by blend 50S/50D(25), and the blend 80S/20D(85) has the maximum oxygen content.

Although blends 80S/20D(85) and 50S/50D(25) are not in an atomization regime and present the highest SMD, the diesel engine operated satisfactorily with these blends and the combustion results were comparable with the other two fuels. In the case of the blend 50S/50D(25), one can suggest that the highest SMD favored the droplet Reynold number and, therefore, its evaporation constant or average area reduction rate of the droplet. For the blend 80S/20D(85), the high SMD and the highest fraction of vegetable oil led to a combustion delay, characterized by high diffusive and residual combustion phases; however, the oxygen content favored its combustion.

Additionally, in relation to the combustion of a binary liquid blend droplet (diesel + straight vegetable oil), products of oil degradation can help or can inhibit the ignition; therefore, it is not clear what occurs in the premixed combustion phase when comparing the blends 50S/50D(25) and 50S/50D(85).

The results analyzed confirm that the jet pattern is influenced by the injection parameters and the physical fuel properties. The combustion of soybean oil blends will be enhanced with high fuel temperature, high engine speed, low injection timing, high injection pressure, and high compression ratio (high in-cylinder temperature and pressure at injection timing).