Abstract

Using modern methodologies in the sectors and subareas of industrial design, where they currently find only marginal application, brings a potential for interrelating technology, the arts, and fine arts. To illustrate this, we present model procedures and options for designing a versatile storage cube that integrates magnetic structural components facilitating easy and quick assembly. In addition to being an item of real furniture, portable and readily convertible into a table or soft stool, the cube supports children’s creative games and helps to develop their overall skills in the present-day household and in pre-primary and primary education. The basic material rests in birch plywood, and the joint edges between the individual walls are covered with smooth plastic guards manufactured via additive 3D printing from corn fodder-based filament. Thus, an interesting structural detail, namely, plastic edges, is generated, reinforcing the entire product. The walls comprise decorative, multicolor, polyurethane foam-based elements that can be removed and reinserted. Regarding the manufacturing technology, CNC machining and laser shaping are widely employed on the main parts, and the plastic edges are 3D-printed. In terms of the original idea, the product responds to customer requirements within a specific design project. The robustness and stability tests have proved that the cubes fully satisfy the relevant standards.

1. Introduction

In the development of a product, the actual design plays a crucial role. Manufacturers, renowned ones in particular, usually collaborate with designers, developers, and structural engineers to deliver functional products that satisfy mechanical safety and strength requirements. Product and service making, however, also involves non-human factors, which markedly affect the design process from the outset. Such factors, by definition, are natural and/or artificial, comprising physical objects, materials, digital technologies, and algorithms. Importantly, artificial intelligence tools are widely relied upon, especially as they have revolutionized the entire design domain [1,2]. Content-wise, product designing incorporates and combines multiple aspects of a novel item to be marketed. This item is, above all, expected to fulfill the purposes for which it has been developed and manufactured, reflecting the needs of the target user; in this context, the product has to be conceived with respect to the relevant ergonomics, complying with the user’s anthropometric data. Further, the set of major product properties prominently includes a visually attractive layout and technical feasibility [3].

Design is frequently employed as a marketing instrument, in addition to its basic roles, which generally subsume innovation, aesthetics, visuals, ergonomics, psychological action, and social integrability; the principal task of the designer then rests in interpreting the client’s visions. Within technology, constant innovation is an imperative, and effective designing strategies embody an indispensable precondition for competitive market performance and viable manufacturing economy. The mechanisms are analyzed and theoretically refined through expert design management, a domain broadly represented in economics study programs that teach production control, corporate finance processing, and project procedures in industrial manufacturing [4,5,6,7]. Regarding the practical outputs, these are then embedded in design development and implementation as fundamental branches centered on innovative approaches.

A popular scheme is custom manufacturing, where the client may exert substantial influence on the concept and fabrication of the product by proposing preliminary drafts to set the final shape and appearance. Such a method was employed also in the storage cube designing activities described herein, one of the customer-specified requirements being the use of nontraditional technology, namely, 3D printing with corn starch-based filament to reduce the product’s ecological impact. The techniques that enabled us to implement the project are discussed in greater detail below, within Section 2. Presently, the manufacture and ecology of a product, when considered jointly, embody a widely discussed subdomain that, to a large extent, determines the success rate of an item to be marketed. Ecological, high sustainability materials have become an essential prerequisite for the economic and social acceptance of industrially manufactured items, and the environmental impacts generated by industrial processes are a focus of multiple debates on the possibilities of circular economy. In the Czech Republic, for example, the ecolabel environmentally friendly product [8] has been approved by the Ministry of the Environment to denote products or services posing low risk to the environment and human health throughout their lifecycles [9]; in the Czech market, the national and EU ecolabels are usually granted upon recommendation by the state-owned Cenia agency [10].

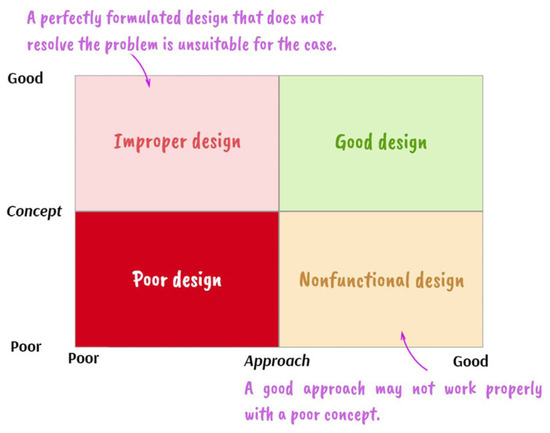

The marketing functions and qualities of design, together with its perception by the general public, currently form a major topic in the field [11,12,13,14]; interestingly, in some cases the marketing is more impressive than the actual design [15], Figure 1.

Figure 1.

Design interpretations [15].

A poor design often fails to resolve the given problem due to an inadequate formulation, while a nonfunctional one offers a fully applicable approach where the actual concept complicates the implementation and, typically, causes other minor issues. A well-conceived and processed design operates smoothly with the proposed solution, delivering not only a reliable instrument to solve the task advantageously but also real and practical implementability [15].

Another role of design lies within psychology, namely, understanding the current needs of the user. In Norman’s view, design embodies an act of communication, and the creative activity is usually meant and performed to completely understand the person intended to be the target recipient of the product [16].

In terms of the diverse facets and attributes associated with design, the visual characteristics and practical properties are exposed at the user interface and user experience levels, respectively; the latter of these criteria involves formulating various approaches in such a manner that they provide the best achievable user service and comfort [17]. According to Reiss [18], user experience is the impression acquired through a person’s interactions with devices and other humans, including the handling of events that relate to these two entities.

Bar and Neta [19] propose that a product makes itself attractive to the prospective user through not only its aesthetic and color qualities but also the contours. The balance between the subjective perception and the aesthetics is then obtained via combining sharp outlines with round ones. The project procedures and results set out in this article interconnect applied research, experimental development using an additive technology (3D printing), and nonconventional machining methods, to deliver outputs readily applicable in industrial manufacturing. Additive technologies have been available for several decades, finding use in mechanical engineering, the automotive and aeronautical industries, healthcare sectors, education, the production of consumer goods (such as electrical appliances for the home), and multiple other domains [20,21,22,23,24,25,26].

In recent years, additive manufacturing has experienced major progress, with a broad set of newly introduced techniques and materials, inclusive of innovative polymers and photopolymers (fluid resins) [27]. A procedural option utilizing such materials is 3D printing, where the substances are usually connected layer by layer, in agreement with the data of the relevant 3D model [28].

Photosensitive resins can be hardened through laser or sunlight, and their fluid form is employed in, for instance, the healthcare industry to manufacture dentures and other prostheses. In the given context, it is possible to refer to corn-based filament, which has become popular thanks to its non-toxic composition. The most widely applied and cost-effective substance rests in polylactic acid (PLA), derived from plant matter. A frequently encountered variant, the PLA-CC, exhibits improved hardness, toughness, compressive strength, wear resistance, and other favorable parametric changes, as is documented by Fouly et al. [29] on a hip joint implant.

The overall technological and scientific advancement in various domains and subsectors has intensified the interest in nonconvenional machining options (laser/CNC plotter). These approaches facilitate cutting, slicing, or engraving in different materials (cardboard, paper, wood, plywood, textiles, composites, and metals) by means of a laser beam. The actual operations are commonly preceded by traditional machining; in wood, for instance, the refining steps comprise sawing, milling, turning, carving, and grinding. Laser cutting and CNC machining embody comparatively modern procedures, and, together with the traditional routines, they are subsumed under subtractive manufacturing [30,31].

Utilizing such preconditions, the project herein was formulated to deliver technical drawings and a functional procedure that allowed building a specially designed element to customer requirements; this item, namely, an attractive, safe-to-use play cube, was materialized with current manufacturing recipes and options (including additive technologies, such as 3D printing) as well as non-conventional machining. The customer-related details are specified below, in Section 2. To reach the preset goals and to comply with the legal regulations concerning the safety of the technological and structural solutions, we respected, above all, the Czech Republic’s Act no. 102/2001 Coll., on General Product Safety [32], and standard ČSN 91 0100 Furniture—Safety requirements [33]; the product testing at an accredited laboratory was then performed accordingly and subjected to a relevant analysis.

The applied research exposed in this article focuses on the properties and use of a new birch plywood-based minor furniture component. To promote recycling and circular economy, the following materials and parts were preferred: joinery plywood, corn-based filament, polyurethane foams, and neodymium magnets. The resulting cube is multifunctional; suitable for the present-day home, school, and kindergarten; has been tested for robustness and stability; and exhibits a potential to influence the designing schemes in its sector. A similar scenario is outlined in a previously published paper by Svoboda et al. [34], which discusses the mechanical capabilities of design products in relation to the matter employed (plastic, wood, metal, and ceramics). The researchers examined 3D-printed samples from polycarbonate/acrylonitrile butadiene styrene (PC-ABS; PC) and alder wood, focusing on their impact toughness. In 3D printing, an essential factor rests in the typology optimization, assuming partial cutouts through a side panel of the component; the aim of such a modification is to reduce the weight of the product while improving its economy and maintaining the physical performance. Regarding the impact toughness, Svoboda et al. [34] propose that 3D-printed structural joints show values similar to those of solid wood (alder), expanding on the conclusions set out by Tauber et al. within their rod connector designing experiment [35]. Interestingly, 3D printing also finds application in anthropometry [36]. Based on the outcomes presented in the referenced studies, we then opted for the 3D-printed corner joint.

2. Materials and Methods

Within the presented concept, we employed novel technologies to produce a multi-functional play cube to custom specifications, as already mentioned above. The actual project, including the technical solution, drawings, and fabrication, had been ordered by the South Moravian Regional Council (Moravia, the Czech Republic), the basic material and structural requirements being as follows: an item fully usable by pre-school children, 3 to 7 years of age; play factors combined with a presentation of the region; colors to specification; a share of recycled plastics (polythene; polypropene; polyamide) and rubber; a sleek plastic corner joint to reinforce the panel edges; state-of-the-art technologies integrated in the manufacturing process; a firm structure and simple assembly steps, even for children; and surface finish. To fulfill the modern technologies stipulation, we employed 3D printing with starch-based, biodegradable polylactic acid.

The fundamental requirements comprised applying such a color scheme that could allow the customer to propose further steps in agreement with the Council-formulated visual style manual. Regarding the selected base colors, these subsumed blue and red, following the graphical layout of the South Moravian Region’s logo. The structure and surfaces exploited commonly available materials, inclusive of the hardware and fittings, and the overall aim involved eliminating hazardous waste at the manufacturing, use, and disposal stages.

Considering the target application and the fact that the component is to be used by children, testing embodied a key fabrication phase. We selected three fundamental tests, the assumption being that the cubes would not be regularly sat on. The procedures were as follows:

- stability testing according to the Czech Republic standard ČSN EN 1022:2020 Furniture—Seating—Determination of stability [37], Art. 7.3.1 Forwards overturning;

- static load on the seating surface to the standard ČSN EN 16139:2013 Furniture—Strength, durability and safety—Requirements for non-domestic seating [38], Art. 6, Table 1;

Table 1. The dimensions of the cube and accessories.

Table 1. The dimensions of the cube and accessories. - impact on the seating surface to the standard ČSN EN 16139:2013 Furniture—Strength, durability and safety—Requirements for non-domestic seating [38], Art. 6, Table 1.

In all of the cases, we relied on the services of the accredited Testing Laboratory for Furniture, a division of the Testing Laboratory for Joinery Products and Furniture.

When selecting convenient technologies to achieve the goals, we opted for 3D printing (an additive technology), CO2 laser, and CNC machining. The last-named approach embodies one of the most widespread procedures, with the manufacturing tool movements being controlled by a pre-compiled program. In wood and plywood, single and combined CNC units or centers find broad application; the centers, by definition, are machines expanded to perform multiple tasks simultaneously, meaning that they constitute multi-purpose tools to execute complex operations at a time on the same location. The advanced five-axis machining then facilitates fabricating even the most demanding forms and shapes.

Considering the furniture presented in this article, suitable resources comprise solid wood or plywood. In these materials, however, CO2 laser cutting results in surface soot deposits and dark edges; such spots subsequently require refining (grinding). To process the main plywood panels, we therefore employed a CNC miller, obtaining smooth edges. The PUR foam elements, namely, the M-shaped letters, nevertheless did not show any burns or dark stains. Overall, the CO2 laser method offers major advantages, including but not limited to clean machining, low noise, high precision, fine detailing, effective engraving, and fast operation (at speeds of around 500 mm/s).

Further, we utilized fused deposition modeling-based 3D printing, the device being an Original Prusa i3 MK3S printer (manufactured by the company Prusa Research a.s., the Czech Republic, Prague, Czech Republic).

The individual concepts proposed by the customer were analyzed and extensively consulted.

The source materials, i.e., furniture grade birch plywood (multiplex), polyurethane foam boards, corn starch-based PLA filament, and neodymium magnets, were then selected upon the analysis of the submitted customer requirements.

2.1. Furniture Grade Plywood

The individual wood-based materials are defined in diverse knowledge databases and on web portals, such as the Czech website titled The Furniture Maker’s Information System (Nábytkářský informační systém, [39]).

This class of materials includes plywood, and the main subclasses are defined as:

- multi-ply materials;

- agglomerated materials;

- agglomerated matter containing non-wood substances;

- modified wood;

- special wood-based matter.

The classification and terminology of plywood (Multiplex) follow the standard ČSN EN 313-2 (490013) Plywood boards [40]. Multi-ply plywood sheets are characterized as large-sized, wood-based components that comprise several layers of peeled veneer pieced together with an urea-formaldehyde glue. Thanks to their favorable properties (high strength, toughness, and elasticity; low volume weight; and size stability), the sheets have found wide and intensive application in joinery, furniture making, packaging, toy manufacturing, and the designing of musical instruments [41].

In the furniture industry, the most frequently used type of plywood is the joinery variant, whose parametric features are high strength, toughness, elasticity, and size stability, resembling those of the above-mentioned general category. The plywood (Figure 2) was employed in the manufacture of the play cube within our research.

Figure 2.

Joinery birch plywood. Source: The authors’ archive.

If the material is to be placed in a humid environment, especially in an outdoor location, the most convenient approach lies in opting for the waterproof version (Figure 3). Such plywood exhibits good strength, low volume weight, and sufficient size stability.

Figure 3.

A waterproof birch plywood sheet. Source: NIS (2014) [39].

2.2. Polyurethane Foam Boards

The plywood boards are traditionally employed in civil engineering, the packaging industry, toy production, mattress designing, and the manufacturing of orthopedic aids.

A large number of manufacturers, such as the Czech Republic-based company Gumex, also use microporous boards (EVA-PE foam); these contain enclosed microtubes, have an ultra-fine cell structure, and offer superior elasticity [42].

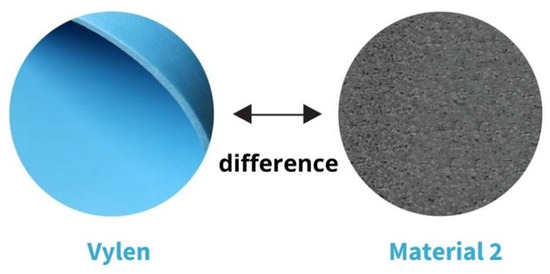

A similar target applicability is characteristic of VYLEN® (Žďár nad Sázavou, Czech Republic) a semi-solid cellular plastic with very good physico-chemical and thermal insulation properties and a long lifecycle, one of tens of years; unlike competing options, VYLEN® is meshed, features a low absorption rate, and delivers high chemical resistance (reliable with oils, water-based liquids, salty solutions, and non-oxidative acids). Another major benefit lies in the absence of adverse health impacts, as proved through a relevant sensor test. The material differs from comparable concepts in that it is finely structured, easily washable, and markedly strong (Figure 4). Further assets include high elasticity, uneven surface damping, formability upon heating, and the ability to be refined via grinding, cutting, and sawing [43].

Figure 4.

Comparing VYLEN®, with another substance [43].

Being non-toxic, as proved by relevant testing and certification, VYLEN® is employed in foam flooring, carpets, and children’s puzzle sets [43]. The board surfaces bear a manufacturing mold imprint and are delivered in 25 colors (see the samples in Figure 5); other details can be obtained from the eponymous Czech manufacturer. The material is discussed herein because it suitably represents the new developments in the sector and could be utilized as a viable alternative in manufacturing the cube panel insertables; neither VYLEN® nor its samples, with the sole exception of the blue and red colors, were nevertheless employed in the product.

Figure 5.

The VYLEN samples [44].

2.3. Corn Starch-Based PLA Filament

Filaments are polymeric fibers for FDM 3D printing, usually with a thickness of either 1.75 mm or 2.85 mm. At present, a wide range of filaments are available on the market, featuring multiple types and colors.

PLA (polylactic acid) filaments embody a basic option that, thanks to its major popularity, has prevailed over the alternatives; the source materials being corn or potato starch and/or sugar cane the item can be classified as a biopolymer. The PLA is frequently combined with other substances, including wood, plaster, PET-G, and—in some cases—carbon; the last-named approach produces tough, rugged models [45].

Combining the PLA with fresh wood, however, is not the only method to exploit the material. Tao et al. [31], for instance, propose that leftovers from subtractive manufacturing (laser cutting and CNC machining) might provide inputs for 3D printing: “… leftover veneers could be used to produce wood powder for wood/polylactic acid filaments”. Thus, the set of input sources would expand significantly, meaning a principal step towards supporting secular economics.

Further, it is worth noting that many printed products exhibit poor stability in the target environment. This problem is discussed by, among others, Popescu et al. [46], whose related study was conceived to determine whether the actual choice of a material (PLA or ABS), printing device, or slicing software influences the dimensional accuracy of 3D-printed openings.

2.4. Neodymium Magnets

The superior attractive force makes the magnets suitable in any furniture-making application where the parts have to be held together reliably and safely. The magnetic items can be glued or screwed into the component. In terms of the shape, the segments are available as cubes, cylinders, rods, and round or flat tablets. To provide an example of the embedding, let us refer to the cylinders, which are easily inserted in a pre-milled or drilled circular opening that has a specific depth, as needed. Regarding the magnet diameters, these range from 2 mm to 50 mm. Being embedded in the wood, the magnets are shielded to a certain extent and remain visible only partially, observing the aesthetics of the product. In this context, and by general definition, it is worth noting that the high-performance neodymium magnets have been used for a multitude of purposes to date in diverse branches of industry, including but not limited to electrical and electronics engineering, the healthcare sector, toy manufacturing, and jewelry designing [47].

Neodymium magnets are the strongest embodiment of the material, their performance being up to tenfold that of regular ferrites. Some neodymium parts are capable of holding a load exceeding their own weight even a thousand times or more. Overall, the quantity to be considered in magnets is the tearing force, defining the action required to separate the magnet from a surface. When joining the children’s furniture elements in our project, we apply magnets having a tearing force of 2 kg (approx. 18.63 N) or less and weighing 3.5 g; the related dimensions correspond to D20 × 1.5 mm in weight. With four magnets, the tearing force will reach slightly below 8 kg (74.52 N). In order for a magnet to be firmly seated in place, gluing or screwing are available, albeit a metal counterpart has to be used concurrently.

2.5. Multi-Functional Play Cube

2.5.1. Material, Components, Machining, and Mounting

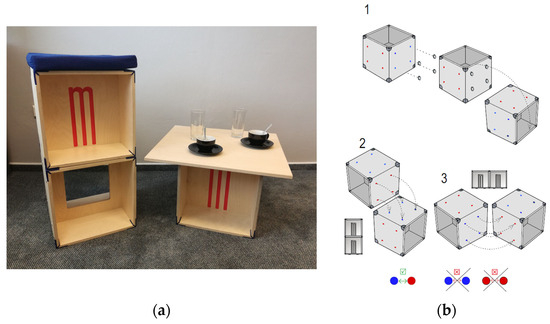

The product subsumes the actual cube and the accessories, namely, a table panel, a removable cushion, and insertable foam elements (Figure 6a). The entire setup may comprise several variable, foldable cubes, whose schemes are rendered in Figure 6b. Interestingly, the group may serve for exhibition purposes too and is occasionally employed in this manner by the customer.

Figure 6.

(a) A model play cube setup; (b) the folding schemes. In the latter image, segment 1 exposes the use of the neodymium magnets in a manner that combines individual cubes into larger units. To connect two cube walls, the magnets (represented with the red spots) are glued into these walls; the other surfaces then incorporate sheet metal items (located by means of the blue spots). The diagram shows that the walls are invariably fixed to each other over the magnet-to-metal pattern, excluding the magnet-to-magnet and metal-to-metal options. Such a procedure simplifies the actual manufacturing, as the polarities do not need to be observed in the gluing operations. the magnets into the cube. Segments 2 and 3 then illustrate the vertical and horizontal folding, respectively. Source: the authors’ design (2020–2022).

In Table 1, the product dimensions are specified in relation to both the whole unit and the individual components.

The multi-functional play cube is intended for pre-school children at 3 to 7 years of age; however, the use by school age children (6 to 12 years) is also possible. In older persons, not all of the product’s functions may be convenient, as the children already exhibit well-developed motor skills; thus, the interest in inserting the foam letters will probably have declined by that stage of a child’s life. The weight of the baseline version is 6.3 kg.

- Joinery birch plywood (multiplex): thickness of 15 mm; the high precision profiling was performed via CNC machining. The plywood contains 11 layers and complies with the E1 emission class. All of the surfaces and edges have been sealed with a lacquer.

- PUR foam: rendered in blue and red; the high precision profiling was carried out with a laser beam.

- Neodymium magnets: 20 mm in diameter and 1.5 mm in thickness; one cube contains four magnets.

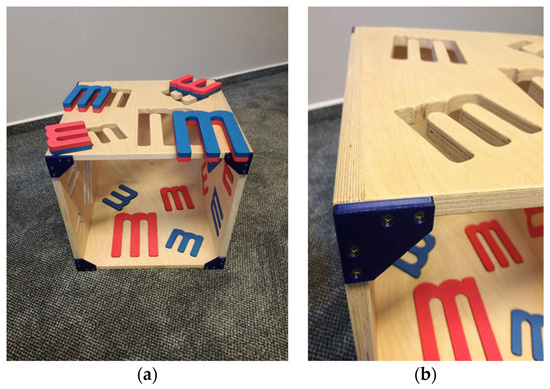

- Corner joint: dimensions of 50 × 50 mm, including the bend; the joint is 3D-printed from corn starch-based PLA.

- Glider: 3D-printed and screwed to the bottom of the cube.

2.5.2. Structure and Joints

In terms of component connectability, the set of key structural segments comprises, above all, the corner joint; the area is mitred, with 30 mm wood slats. The surface has been milled to incorporate a 3D-printed plastic corner joint item; this design element is glued into place with a binder suitable for PUR. Importantly, in addition to reinforcing the edge section, the item embodies a distinctive visual feature. The perforated side walls carry push-in M letters made of PUR foam boards through laser cutting; this processing technology seals the edges of the material, leaving them tough and strong. The profiles in the joinery plywood have been CNC-milled. Regarding the product testing, the unit and its parts have complied with the Czech Republic technical standards ČSN EN 1022 (910234) and ČSN EN 16139 (910650) A [37,38].

In the cushion, the PUR foam is wrapped in glued-on nonwoven fabric and inserted into a zipped cloth cover; sewn into the cover are neodymium magnets to fix the cushion onto the top of the cube. All outside edges have been rounded to deliver Rmin. = 2.5 mm, and the firm structural joints are glued together over dowel pins to ensure good stability. The surface is treated with a water-dilutable, semi-matt lacquer. To characterize the neodymium magnets, we can emphasize their tearing force of 8 kg and the fact that the magnets are high-sheened, similarly to the sheet metal counterparts in the related surfaces. In the testing, the tearing force proved sufficient.

The product provides a value added in that neodymium magnets are incorporated into the upper panel of the cube. The magnets are small and have great contact force, allowing the user to safely attach to the cube a table panel or a seat cushion (Figure 6); thus, the cube is converted into a practical desk or a comfortable stool.

2.5.3. Drawings and Related Documentation

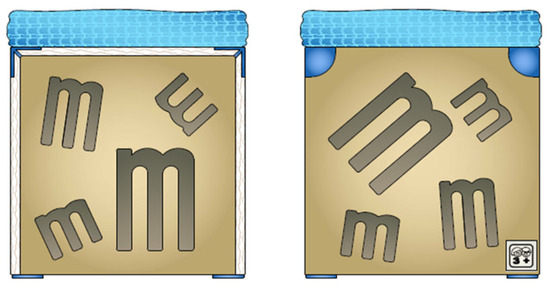

To facilitate manufacturing the sample product via CNC machining and laser cutting, we completed a set of drawings and technical documents; the individual profiles and details are shown in Figure 7 and Figure 8.

Figure 7.

The full drawings of the multi-purpose cube with perforated sides and an upholstered top surface. Source: the authors (2020).

Figure 8.

A part of the technical documentation: the basic side and bottom plan. Source: the authors (2020).

2.5.4. Manufacturing Technologies and Approaches

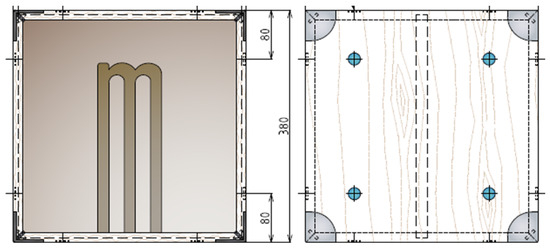

The cube is based on a simple, pure design. The fundamental material is birch plywood (PDP-BR), the boards having 15 mm in thickness. In terms of the technological procedures, we applied CNC and laser machining. Further, we employed neodymium magnets sized 20 mm to mill them into the board surfaces in such a manner that they protrude 1 mm above. The structure comprises 3D-printed protective corner joint components, which also reinforce the actual joints and are embedded in seats countersunk in the boards’ corner edges and adjacent surface segments (Figure 9). Simultaneously, in addition to their reinforcing function, these plastic components play an aesthetic role, making the cube’s appearance more attractive and being modifiable to the customer’s wishes concerning the shape and color.

Figure 9.

The 3D-printed component on the corner edge area. Source: the authors (2022).

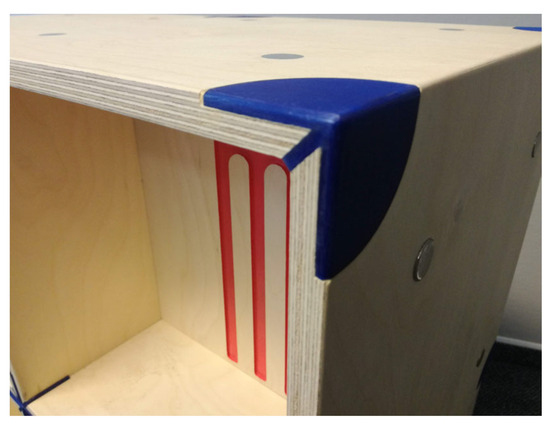

The versatile design enables the multi-functional cube to be easily converted into a plain or cushioned stool, a small desk, or a play base with large M-shaped color letters made of PUR foam that are insertable into corresponding openings in the side boards to help children develop their motor and combinatorial skills (Figure 10a,b).

Figure 10.

The bottom sectors: (a) an overall view of the 3D-printed gliders; (b) the gliders detailed on a corner edge. Source: the authors (2022).

3. Results

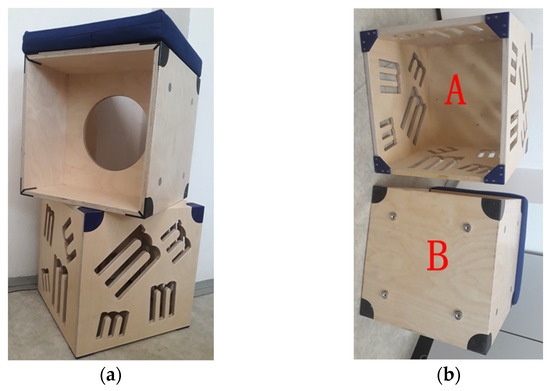

3.1. Verifying the Functionality: Product Testing at an Accredited Furniture Testing Laboratory

The cube with perforated side walls was subjected to testing, due to the product’s structure and bottom gliders being different from those of the original baseline model. Compared to this initial version, the tested cube does not include a center part but its inner space is enclosed with walls on all sides; the side boards feature M-shaped openings (as shown on the lower item in Figure 11a); no bottom board is used (Figure 11b, variant A); and the structural joints are identical with those in the prototype, including the plastic corner edge elements. Further, in the tested item the gliders are not held in place by means of magnets (Figure 11b, variant B) but rather screwed into the edges (Figure 11b, variant A).

Figure 11.

Comparing the variants, (a); zooming on the bottom, (b). The latter image presents a bottom view of the individual parts: The red letter A indicates the top section of the cube, while the corresponding letter B denotes the base. Source: the authors (2023).

Based on the intended modes of use, we performed three basic testing cycles (as specified in Section 2 and Section 3.1.1, Section 3.1.2 and Section 3.1.3), assuming that the cubes would not be permanently employed to function as seating furniture. The tested product was equipped with a cushion and metal gliders sized D20 × 7 mm; the gliders were fixed to the bottom with magnets.

Alternatively, the cube was subjected to testing together with the baseline version, the assumption being that the products would also be utilized as stools. All of the test cycles were executed at a dedicated laboratory for joinery products and furniture, accredited according to the Czech Republic standard ČSN EN ISO/IEC 17025:2018 [48]; the facility is operated by the Faculty of Forestry and Wood Technology, Mendel University in Brno.

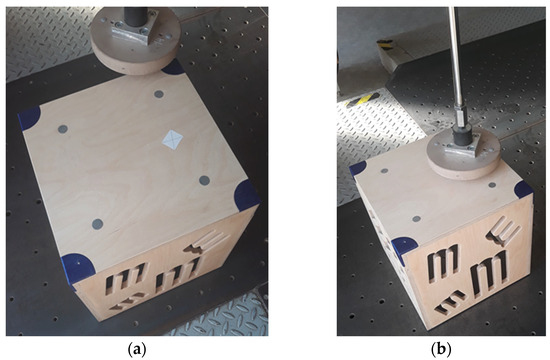

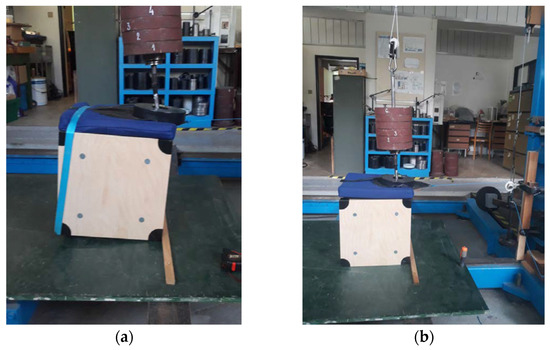

3.1.1. Stability Testing

At the first stage, we carried out stability tests in agreement with the Czech standard ČSN EN 1022:2020 (Furniture—Seating—Determination of stability) [37], art. 7.3.1 (Forwards overturning); the standard covers seating furniture for all locations and types of application. In the procedures, the load on the seating surface at the distance of 60 mm from the edge of the supporting structural board amounted to 600 N, and the applied overturning force was 20 N, both applied as per the standard (Figure 12).

Figure 12.

The stability testing configuration. Source: the authors (2023).

Outcomes: The product was not overturned by the relevant force, thus satisfying the stability requirements stipulated by the standard ČSN EN 1022:2020 [37].

By extension, we also tested the strength and durability of the structure, observing the Czech Republic standard ČSN EN 16139:2013 (Furniture—Strength, durability and safety—Requirements for non-domestic seating) [38]. With respect to the modes of use presumed in the product, the selected procedures comprised applying a static load and an impact on the seating surface; both of the test schemes conformed to the provisions of the standard ČSN EN 1728:2020 (Furniture—Seating—Test methods for the determination of strength and durability) [49].

3.1.2. Static Load Testing

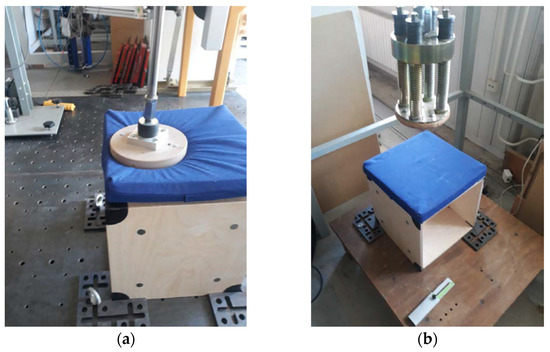

Respecting the predefined procedural measures (as set out in the standard ČSN EN 16139:2013, art. 6) [38], we applied on the seating surface, in its relevant axis, the vertical load of 1300 N at the distance of 100 mm from the edge of the supporting structural board; the force acted on the surface through a circular wood pad, invariably for 10 s, and the action was repeated 10 times (Figure 13a,b).

Figure 13.

The tests: (a) static loading on a preselected spot; (b) overall static loading. Source: the authors (2023).

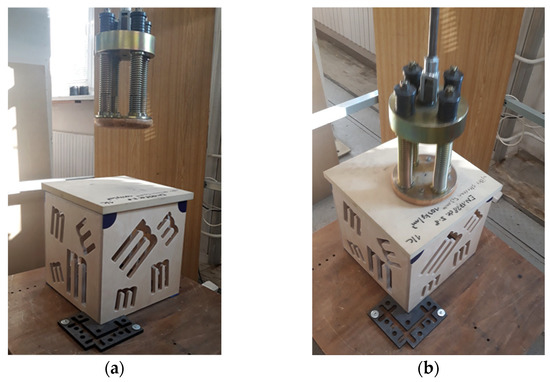

3.1.3. Impact Testing

Conforming to the provisions set forth in the standards ČSN EN 16139:2013 [38] and ČSN EN 1728 [49], we simulated a fall from the height of 240 mm, repeating the process ten times. A shock generating tool was employed to perform the action, delivering the impact weight of 25 kg (Figure 14a,b).

Figure 14.

The impact testing: (a) before the action; (b) applying the force. Source: the authors (2023).

Outcomes: The cube did not exhibit any damage after either the static or the impact test, thus satisfying the requirements defined within the standards. In terms of the strength, durability, and stability, the structure can therefore be characterized as fully satisfactory.

4. Discussion

The testing procedures showed that when gliders are mounted, the cube tends to partially yield to the applied force in that it leans on the bottom edge of a structural board (Figure 15a); nevertheless, total overturning does not occur, as already indicated above.

Figure 15.

The stability testing: (a) with the gliders; (b) without the gliders. Source: the authors (2023).

In this context, it is then somewhat problematic to determine clearly whether the product conforms to the standards. If tested without the gliders, however, the cube exhibits superior stability, satisfying all the requirements (Figure 15b).

Similarly to the images in Figure 13a,b, the graphics in Figure 16a,b below represent the load and impact tests; in the latter figure, however, the testing is performed on a cushioned cube.

Figure 16.

The load and impact tests: (a) static loading; (b) impact action. Source: the authors (2023).

The obtained results confirmed the structural strength of the cube and also led to a modification of the glider mounting in response to the ambiguous overturning performance; presently, the gliders are embedded in countersunk seats and protrude beyond the surface line by 2 mm at the maximum. Another alteration lay in the gliders being fixed to their seats with screws in place of the magnets used in the initial versions (Figure 10a,b).

In furniture, a significant parameter rests in the carrying capacity. To verify this property, we first set up a standardized stability test to load the seating surfaces with a weight of 600 N at a distance of 60 mm from the edge of a main structural panel; such a configuration represents a force of 61 kg.

The measurement process and its outcomes confirmed that the product satisfies the requirements on children’s furniture in terms of the structure, ruggedness, and stability. The firm fasteners are completed with plastic, 3D-printed edge joints to provide a load capacity of between 150 and 200 kg; thus, the capacity limits for the targeted age group do not need to be estimated. Regarding the physical and safety attributes, the product is well-conceived, combining a glued structure with reinforcing plastic corner elements; in many cases, these edge parts exhibit superior strength values, as also emphasized by Svoboda et al. [34], who examined the parameters that exert an impact on furniture safety. By a more detailed definition, the researchers focused on the impact toughness testing of samples integrating 3D-printed plastics (PC-ABS; PC) with alder tree wood; the printed elements included structural joints in particular [34,35].

From the utility perspective, the cube was assessed in terms of whether its use by pre-school children can be regarded as safe. The set of monitored sectors involved, among others, the openings milled in the panels to accommodate the PUR-based letters; in this context, we reviewed the size of the gaps to avoid children’s fingers getting wedged and, subsequently, hurt or broken.

Furniture safety is generally provided for in the Czech Republic’s Act no. 102/2001 Coll., on General Product Safety [32], and standard ČSN 91 0100 Furniture—Safety requirements [33]. A product designated as safe must comply with specific national and international legal regulations; where no such regulations are in force, the attribute of safe shall denote any product that satisfies the Czech technical standards and/or expresses the state of the art at the time of being introduced to the market [50].

Overall, regarding the concept, functional capabilities, and safety, the furniture set designed within our project may be compared to items such as the multi-purpose Montessori cUbe series [51] and the Whitney Brothers Play House Cube [52]. The Montessori cUbe, however, appears to best resemble the solutions adopted by us: the traditional Montessori’s versatility is similar to ours, albeit more sophisticated, and both schemes share a portion of the basic material (birch plywood), with the comprehensive test performance outcomes being very close [53,54]. The visions and purposes formulated within the previous research and requirements on children’s furniture design [55,56] reflect in the project discussed herein, even though our team worked, in fact, independently from these: the ideas centered on supporting the play factor to facilitate effective learning and development in children are broadly (and indirectly) shared by diverse designers, manufacturers, and retailers who employ or sell, for instance, the Montessori method. Further, depending on the interpretation, the color scheme in our cube might suitably complement Montessori’s patterns, which may seem rather dry in some of the series. Arguably, the perspectives outlined within this article lie in a relatively warm and friendly rendering of the product, whose marketing potential is thus markedly enhanced. In this manner, the cube might then be perceived by other designers in the field as inspiring. By contrast, we assume that some of the mechanical properties of our cube, such as the edge stability, could be improved to match the performance of mass-produced furniture.

With respect to the examined physical quantities and product capabilities, and considering the relevant standards, we compared our procedural testing approaches discussed herein with those applied by other researchers. In seating furniture, interesting static and dynamic options, including progressive loading, are set out in the very recent study by Diler et al. [57]. These authors tested a large set of items under varying conditions and loads to establish that the strength and capacity of a product markedly depend on the loading direction. In contrast to our concept, Diler et al.’s methods are markedly broader, more detailed, and involve factors such as inherent material properties; the techniques have been formulated specifically to evaluate chairs, whose basic function nevertheless largely corresponds to that of the play cube [57]. Further, a comprehensive, optimization-oriented testing strategy had been proposed by Güray et al. [58]; in this case, a high number of wood matter and impact force types were employed, forming a model for the future studies. In the Czech-based laboratories within this article, by comparison, the scope of corresponding tasks was relatively modest, as our project had been conceived significantly less generously, due to the limited amount of materials. The associated development, refining, and (to a limited extent) basic tests of children’s or purpose-specific furniture are all exposed in the research by Zhang et al. and Jai-ai et al. [59,60], with the former outlining the role of artificial intelligence at the diverse stages of the furniture designing, manufacturing, and verification procedures; such an approach is a blueprint for the next phases of our efforts, as it provides novel baseline ideas to rethink the testing process.

In addition to the pre-formulated central function-related goal, namely, verifying the structure of the cube with respect to the stability, static load, and impact capacities, other major factors of influence on persons such as the users and manufacturing operatives have to be recognized. Prominently included in this set are chemicals, represented by, for instance, volatile organic compounds. The relevant substances then comprise, among others, formaldehyde, an ingredient of the glue that is used in diverse types of plywood. Formaldehyde, by extension, finds application also in surface finish lacquers, fabrics, carpets, stationery, and electronics. Importantly, materials for the indoor environment are subjected to testing before entering the market.

To characterize formaldehyde in a balanced manner, we should describe the substance’s benefits too: a colorless glued splice joint, superior shear strength, favorable cost, and hardening temperatures between 10 and 180 °C. Yet formaldehyde is released into the air, and this drawback reflects in the legal requirements on children’s furniture; within the European Union, the applicable regulation consists in the standard EN 71-3 [61], its Czech Republic equivalent being ČSN EN 71-3+A1 (94 3095) [62], that sets forth stipulations concerning the safety of toys and the migration of selected chemical elements [62].

During the 1970s, the emission value reached 100 mg/100 g of the mass. Since 2004, European producers have been supplying chipboard and plywood boards in two emission classes, E1 and E2. In view of the released volumes of formaldehyde, plywoods are categorized into the A group (ČSN EN 1084, canceled in 2014) [63], and multiplex plywoods are classified according to their response to fire with the C designation in the standard ČSN EN 13501-1 [64]. The class E1 stipulates emissions below 0.1 ppm (0.124 mg/m3, as set out in ČSN 717-1/EN 717-1) [65]; in chip- and plywood boards, formaldehyde contents are specified as up to 8 mg/100 g of mass, according to EN 120 (an already invalid standard that has been substituted with ČSN EN ISO 12460-5 [66]. Materials characterized in the class E2 are suitable for outdoors only because the formaldehyde volume may attain 8 to 30 mg/100 g mass. Another finding lies in that the European Commission has set a new limit for the concentration of formaldehyde in “ambient” air: Regulation 2023/1464, published on 14 July 2023. This provision reduces the previous values to a half by setting the limit of 0.062 mg/m3 on the emissions, particularly with regard to wood-based products and furniture as possible “sources” of formaldehyde. Currently, there is chipboard/plywood furniture on the European market that has not been treated with formaldehyde or even has lower formaldehyde emissions than wood. The manufacturer or seller of such furniture shall provide an indication of the emission class. Each product and plywood material has to be described with a technical data sheet containing information on the properties and applicability of the product [41,67,68].

The Multiplex birch plywood complies with the E1 emission class; the central Europe-based company Demos Trade may serve in this context as a convenient reference subject, declaring that formaldehyde-free E0 plywood is available upon request (boards made from beech wood being the most affordable ones). An optional solution for the cube would rest in using beech plywood multiplex with an E0 emission class glue. To prevent the release of formaldehyde, all surfaces and edges of relevant products must be sealed with lacquer. The multifunctional play cube is protected with a water-based polyurethane varnish, meaning that even when using an E1 class plywood the release of formaldehyde is avoided [41,69].

In general, the path to offering and supplying a product in which the amount of emissions is clearly demonstrable rests in certification, i.e., labeling according to the volume of VOC emissions. This step has already been taken by France, Germany, and some Russian-speaking countries, to provide applicable examples. In France, products are tested according to EN ISO 16000, A+ being the best rating [70]. In Germany, all products introduced to the market must be tested. Other states use a recognized label, such as the Finnish M1 certificate, which monitors the TVOC for more than 2000 items [67,71].

Regarding the structure, strength, ruggedness, and stability, the product appears to be excessively massive to be used by children, considering the 15 mm plywood. In further research, we intend to examine the capabilities of 12 mm thick multiplex plywood, reducing the overall weight of the basic element down to approximately 5.0 kg.

A potential direction for the future investigation may lie in other items where the technologies involved (CO2 laser, 3D printing, CNC milling) at both the development and the application stages facilitate design progression. Using the combination of options specified herein often results in a multitude of convenient materials, new shape possibilities, innovative structural solutions, different designs, and a higher product strength.

Utilizing laser technology (PUR perforation cutting) together with PUR foam and birch plywood multiplex delivers a final product that supports and develops the motor skills of pre-school children. Here, the fact that (as a new direction for the research) a similar solution could support fine motor skills in pre-school children experiencing developmental dyspraxia and/or related disorders should be seriously considered.

5. Conclusions

The article discusses a multi-faceted product design that is based on functional tests at an officially approved furniture testing laboratory. The aim lies in exposing various application options for state-of-the-art designing technologies that facilitate the fabrication of a novel and interesting product with value-added features. In the case of the storage cubes, such properties are embodied especially in the actual use of the neodymium magnets and corner components, the latter being manufactured through the additive technology of 3D printing. The magnets function as fastening elements to hold either further parts of the play cube or a whole other cube. Despite their small size, the magnets exhibit a great contact force, and the tearing force equals 8 kg. The original design relied on the tearing force of 2.5 kg, but this lower value did not prove sufficient to satisfy the relevant testing requirements. Regarding the proportion of plastic materials, the largest amount is found in the product-specific corner components, as these were 3D-printed from the PLA (polylactic acid obtained via enzymatic hydrolysis from corn starch); importantly, the plastic is fully biodegradable. The acid, however, despite being the most favored option for the purpose thanks to its non-toxic character, lack of printing deformities, and easy recycling, is somewhat hampered by its relatively low temperature resistance of up to 65 °C. In comparable materials, relevant deformations occur at higher levels (ABS = 100 °C, PETG/HT-PETG = 110 °C). The reason to substantiate the use of PLA filament rests in the recyclability, ruggedness, and positional stability, the latter two properties being ensured by the edge joint. The recycling is commonly performed in industry-scale composting plants, where the conditions allow bioplastics to decay.

From the child’s perspective, the most significant aspect is the play factor, which, by extension, supports the motor skills and helps to develop the overall set of abilities. A further major asset is embedded in the visual and shape characteristics of the cube, being most prominent on the side surfaces through the insertion and extraction of the PUR foam-based, M letter-shaped color segments. The cube is a multi-purpose, structurally attractive, and playful item. In the ruggedness, stability, and safety testing, the sample involved did not show any damage or breakage, thus complying with the standards and confirming the structural design approach selected. As a matter of fact, when evaluated via the results, the product appears to be excessively massive, meaning that the future fabrication efforts might rely on thinner birch plywood (12 mm in thickness, for instance) to reduce the weight and to obtain a less bulky but sufficiently rugged product.

In the development procedures, we have combined suitable applied research and experimental manufacturing options, using nonconventional machining processes (laser and CNC plotter tasks) and additive technologies, namely, product design-oriented 3D printing. Such technologies then bring substantial benefits to both the designer and the market in terms of the economic, social, and environmental impacts.

Author Contributions

Conceptualization, M.Z. and P.D.; methodology, M.Z.; software, J.T.; validation, M.Z., J.S. and P.D.; formal analysis, M.Z.; investigation, J.T.; resources, M.Z.; data curation, M.Z.; writing—original draft preparation, J.S., J.T. and M.Z.; writing—review and editing, M.Z. and P.D.; visualization, J.T.; supervision, M.Z. and J.S.; project administration, J.S.; funding acquisition, J.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data created within this study are fully incorporated in the article and will be fully available from the corresponding author upon request.

Acknowledgments

The presented design tasks and operations were performed to complete a customer order (a play cube development project). The authors thank Mendel University in Brno for all their support and for permission to use the university’s official furniture testing laboratory, a part of the industrial Testing Laboratory for Joinery Products and Furniture, in the series of tests to verify the properties of the product.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Černý, J. Ne-Humánní Aktéři a Jejich Role v Designu (Non-Human Factors and Their Roles in Design); Design Kisk: Brno, Czech Republic, 2023; p. 6. Available online: https://medium.com/design-kisk/ne-hum%C3%A1nn%C3%AD-akt%C3%A9%C5%99i-a-jejich-role-v-designu-c4779236d4be (accessed on 15 September 2023).

- Huang, M.H.; Rust, R.T. Artificial Intelligence in Service. J. Serv. Res. 2018, 21, 155–172. [Google Scholar] [CrossRef]

- Produktový Designér vs Konstruktér (Product vs Structural Designers). Blog. 2018, Article 41, p. 3. Cotu s.r.o. Available online: https://www.cotu.cz/blog/41/produktovy-designer-vs-konstrukter (accessed on 21 September 2023).

- Utomo, C.; Astarini, S.D.; Mertha, D.M.S.W.; Rahmawati, Y.; Aqsha; Nurcahyo, C.B.; Nahdiyah, M. Decision Factors of Stakeholder Integration in Connected Construction for Circular Economics. Sustainability 2022, 14, 16200. [Google Scholar] [CrossRef]

- Nam, K.; Kim, G.; a Borja de Mozota, B. Design Management Knowledge: Identifying Learning Objectives of Various Stakeholders for Needs-Driven Learning. In Proceedings of the Academy for Design Innovation Management, Hong Kong, 7–9 June 2017; Volume 4, pp. 1439–1455. Available online: https://www.designresearchsociety.org/articles/design-management-academy-2017-conferee-proceedings-available-online (accessed on 25 August 2023).

- Bruce, M.; Cooper, R.; Vazquez, D. Effective design management for small businesses. Des. Stud. 1999, 20, 297–315. [Google Scholar] [CrossRef]

- Miller, C.Z.; Palsikar, S.; Spears, J.M. Evolving Praxis in Design Management: The transdisciplinary trajectory. Des. Manag. J. 2022, 17, 91–102. [Google Scholar] [CrossRef]

- Ekoznačení Výrobků (Product Ecolabeling). Zo Čsop Veronica. Veronika. 2020. Available online: https://www.veronica.cz/ekoznaceni-vyrobku (accessed on 16 September 2023).

- Envic. Co Znamená Ekologicky Šetrný Výrobek? (What Is an Environmentally Friendly Product?). In Environmentální Informační Centra Plzeňského Kraje; Envic: Plzeň, Czech Republic, 2013; Available online: http://www.envic.cz/faq/co-znamena-ekologicky-setrny-vyrobek.htm (accessed on 18 September 2023).

- Czech Environmental Information Agency. Ekoznačení (Ecolabeling). In Česká Informační Agentura Životního Prostředí; Cenia: Praha, Czech Republic, 2023; Available online: https://www.cenia.cz/spolecenska-odpovednost/ekoznaceni/ (accessed on 18 September 2023).

- Kostík, O. Design Jako Marketingový Nástroj, Jeho Role a Vnímání u Veřejnosti (Design As a Marketing Instrument: Roles and Perception by the General Public). Master’s Thesis, Vysoká Škola Ekonomická v Praze, Praha, Czech Republic, 2008. [Google Scholar]

- Roper, S.; Micheli, P.; Love, J.H.; Vahter, P. The roles and effectiveness of design in new product development: A study of Irish manufacturers. Res. Policy 2016, 45, 319–329. [Google Scholar] [CrossRef]

- Henseler, J.; Guerreiro, M.; de Matos, N. The interplay of marketing and design. Rev. Manag. Sci. 2021, 15, 1129–1137. [Google Scholar] [CrossRef]

- Henseler, J.; Guerreiro, M. Design and marketing: Intersections and challenges. Creat. Innov. Manag. 2020, 29, 3–10. [Google Scholar] [CrossRef]

- Maňák, M. Dobrý a Špatný Design (The Good and the Bad Design). Online. Blog. 2015, p. 8. Available online: https://www.manakmichal.cz/blog/user-experience/dobry-a-spatny-design/. (accessed on 1 October 2023).

- Norman, D.A. Design of Everyday Things; Perseus Books: New York, NY, USA, 2013. [Google Scholar]

- Leška, Š. Co je to UX a UI design? (Defining UX and UI design). BlueGhost 2020, 1, 3. Available online: https://www.blueghost.cz/clanek/co-je-to-ux-a-ui-design/ (accessed on 21 September 2023).

- Reiss, E. Usable Usability: Simple Steps for Making Stuff Better; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Bar, M.; Neta, M. Visual elements of subjective preference modulate amygdala activation. Neuropsychologia 2007, 45, 2191–2200. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, D.-Y.; Park, J.-H.; Kim, J.-H.; Hwang, J.-H.; Jung, H.-I. Optimization of electrohydrodynamic writing technique to print collagen. Exp. Technol. 2007, 31, 15–19. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Functionally graded Nylon-11/silica nanocomposites produced by selective laser sintering. Mater. Sci. Eng. A 2008, 487, 251–257. [Google Scholar] [CrossRef]

- Eshraghi, S.; Das, S. Mechanical and microstructural properties of polycaprolactone scaffolds with one-dimensional, two-dimensional, and three-dimensional orthogonally oriented porous architectures produced by selective laser sintering. Acta Biomater. 2010, 6, 2467–2476. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-S.; Chu, W.-S.; Kim, Y.-M.; Avila, A.P.G.; Ahn, S.-H. Direct metal printing of 3D electrical circuit using rapid prototyping. Int. J. Precis. Eng. Manuf. 2009, 10, 147–150. [Google Scholar] [CrossRef]

- Im, Y.; Cho, B.; Seo, S.; Son, J.; Chung, S.; Jeong, H. Functional prototype development of multi-layer board (MLB) using rapid prototyping technology. J. Mater. Process. Technol. 2007, 187, 619–622. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- ASTM F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- Fouly, A.; Assaifan, A.K.; Alnaser, I.A.; Hussein, O.A.; Abdo, H.S. Evaluating the Mechanical and Tribological Properties of 3D Printed Polylactic-Acid (PLA) Green-Composite for Artificial Implant: Hip Joint Case Study. Polymers 2022, 14, 5299. [Google Scholar] [CrossRef]

- Wimmer, R.; Steyrer, B.; Woess, J.; Koddenberg, T.; Mundigler, N. 3D printing and wood. Pro Ligno 2015, 11, 144–149. Available online: https://publik.tuwien.ac.at/files/PubDat_243647.pdf (accessed on 28 September 2023).

- Tao, Y.; Yin, Q.; Li, P. An Additive Manufacturing Method Using Large-Scale Wood Inspired by Laminated Object Manufacturing and Plywood Technology. Polymers 2021, 13, 144. [Google Scholar] [CrossRef]

- Zákon, č. 102/2001 Sb., o Obecné Bezpečnosti Výrobků a o Změně Některých Zákonů (Zákon o Obecné Bezpečnosti Výrobků) (Act No. 102/2001 Coll., On General Product Safety and on the Amendment of Certain Laws (Act on General Product Safety)). Available online: www.aspi.cz (accessed on 15 October 2023).

- ČSN 91 0100 (910100); Nábytek—Bezpečnostní Požadavky (Czech Technical Standard ČSN 91 0100 (910100); Furniture—Safety requirements). Český Normalizační Institut: Praha, Czech Republic, 2006. Available online: http://csnonline.agentura-cas.cz/. (accessed on 15 October 2023).

- Svoboda, J.; Tauber, J.; Zach, M. 3D print application in furniture manufacturing. In Proceedings of the 12th WoodEMA Annual International Scientific Conference—“Digitalisation and Circular Economy: Forestry and Forestry Based Industry Implications”, Union of Scientists of Bulgaria and WoodEMA, Varna, Bulgaria, 11–13 September 2019; pp. 131–140, ISBN 978-954397042-1. Available online: https://www.woodema.org/proceedings/WoodEMA_2019_Proceedings.pdf (accessed on 1 December 2023).

- Tauber, J.; Začal, J.; Šustr, M.; Brabec, M. Design and mechanical performance of 3-D printed T-shaped rod connector manufactured by FDM technology. In Proceedings of the 12th WoodEMA Annual International Scientific Conference—"Digitalisation and Circular Economy: Forestry and Forestry Based Industry Implications”, Union of Scientists of Bulgaria and WoodEMA, Varna, Bulgaria, 11–13 September 2019; pp. 155–160, ISBN 978-954397042-1. [Google Scholar]

- Paramés-González, A.; Prieto-Lage, I.; Gutiérrez-Santiago, A. 3D printing in fitting furniture to student anthropometry. ESHPA—Educ. Sport Health Phys. Act. 2021, 5, 76–89. [Google Scholar] [CrossRef]

- ČSN EN 1022 (910234); Nábytek Bytový—Sedací Nábytek—Hodnocení Stability (Czech Technical Standard ČSN EN 1022 (910234) Domestic Furniture—Seating-Determination of Stability). Úřad Pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 2020. Available online: https://csnonline.agentura-cas.cz/Detailnormy.aspx?k=509494 (accessed on 14 October 2023).

- ČSN EN 16139 (910650); A Nábytek—Pevnost, Trvanlivost a Bezpečnost—Požadavky na Nebytový Sedací Nábytek (Czech Technical Standard ČSN EN 16139 (910650) A Furniture—Strength, Durability, and Safety—Requirements for Non-Residential Seating). Úřad Pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 2013. Available online: https://csnonline.agentura-cas.cz/Detailnormy.aspx?k=93760 (accessed on 12 October 2023).

- INT, S.R.O. Nábytkářský Informační System (Furniture Maker’s Information System); Brunecký, P., Hála, B., Jičínský, M., Jančová, V., Tauber, J., Svoboda, J., Zach, M., Šimek, M., Dvouletá, K., Káňová, D., et al., Eds.; Software. INT, S.R.O.: Brno, Czech Republic, 2014; Available online: http://www.n-i-s.cz/. (accessed on 12 December 2023).

- ČSN EN 313-2 (490013); Překližované desky—Klasifikace a terminologie—Část 2: Terminologie (Czech Technical Standard ČSN EN 313-2 (490013); Plywood—Classification and terminology—Part 2: Terminology). Český Normalizační Institut: Praha, Czech Republic, 2000. Available online: https://www.technicke-normy-csn.cz/csn-en-313-2-490013-207631.html# (accessed on 14 December 2023).

- Překližované Materiály (Plywood Materials). Nábytkářský Informační Systém. (Furniture Maker’s Information System) 2014, article 215, p. 33. Licence: Nábytkářský Informační Server (Furniture Maker’s Information Server). INT, S.R.O.: Brno, Czech Republic, 2013. Available online: https://www.n-i-s.cz/cz/preklizovane-materialy/page/215/ (accessed on 1 October 2023).

- GUMEX, spol. s r.o. Mikroporézní Deska Eva 100—Červená (The EVA 100 Microporous Board); GUMEX: Strážnice, Czech Republic, 2023; Available online: https://www.gumex.cz/h/mikroporezni-deska-eva-100-cervena-10501#sekce=variant-table-placeholder (accessed on 30 September 2023).

- Materiál VYLEN® (The VYLEN® Material). Blog. 2023, article 2, p. 2. Available online: https://www.penovysvet.cz/blog/vylen/ (accessed on 1 October 2023).

- VYLEN, s.r.o. Vzorník Barev—Kulatý (The Material Colors: A Ring of Samples); Pěnový svět: Žďár nad Sázavou, Czech Republic, 2023; Available online: https://www.penovysvet.cz/podlahy/vzornik-barev/ (accessed on 1 October 2023).

- PLA Filament. Materialpro3d.cz. Available online: https://www.materialpro3d.cz/pla-1-75/pla-filament-1-75-mm-bily-regshare-1-kg/ (accessed on 1 October 2023).

- Popescu, D.; Gheorghe Amza, C.; Marinescu, R.; Cristiana Iacob, M.; Luminiţa Căruţaşu, N. Investigations on Factors Affecting 3D-Printed Holes Dimensional Accuracy and Repeatability. Appl. Sci. 2023, 13, 41. [Google Scholar] [CrossRef]

- Cui, J.; Ormerod, J.; Parker, D.; Ott, R.; Palasyuk, A.; Mccall, S.; Paranthaman, M.P.; Kesler, M.S.; McGuire, M.A.; Nlebedim, I.C.; et al. Manufacturing Processes for Permanent Magnets: Part I—Sintering and Casting. JOM 2022, 74, 1279–1295. [Google Scholar] [CrossRef]

- ČSN EN ISO/IEC 17025 (015253); Všeobecné PožAdavky na Kompetenci Zkušebních a Kalibračních Laboratoří (Czech Technical Standard ČSN EN ISO/IEC 17025 (015253); General Requirements for the Competence of Testing and Calibration Laboratories). Český Institut pro Akreditaci, o. p. s.: Praha, Czech Republic,, 2018. Available online: https://csnonline.agentura-cas.cz/Detailnormy.aspx?k=504810 (accessed on 28 December 2023).

- ČSN EN 1728 (910235); Nábytek—Sedací nábytek—Metody zkoušení pro stanovení pevnosti a trvanlivosti (Czech Technical Standard ČSN EN 1728 (910235); Furniture—Seating—Test methods for the determination of strength and durability). Textilní zkušební ústav s. p.: Brno, Czech Republic, 2020. Available online: https://www.technicke-normy-csn.cz/csn-en-1728-910235-239251.html (accessed on 28 December 2023).

- Bezpečnost (Safety). Nábytkářský Informační Systém. (Furniture Maker’s Information System) 2014, article 183, p. 2. Licencse: Nábytkářský Informační Server. (Furniture Maker’s Information System). INT, S.R.O.: Brno, Czech Republic, 2013. Available online: https://www.n-i-s.cz/cz/bezpecnost/page/183/ (accessed on 14 December 2023).

- Brubi, s.r.o. Big Set of Montessori Cube Chairs 1+2+3—3 PIECES; Brubi: Banská Bystrica, Slovakia, 2023; Available online: https://brubi.eu/kids-furniture/big-set-montessori-cube-chairs-123-3-pieces (accessed on 14 December 2023).

- Today’s Classroom. Play House Cube—Whitney Brothers; TODAY’S CLASSROOM: Canton, OH, USA, 2023; Available online: https://www.todaysclassroom.com/play-house-cube-whitney-brothers/ (accessed on 14 December 2023).

- Montessori Furniture—A Guide for Every Room. KATANABANA. © 2023, KATANABANA: Montessori Learning. Blog, 2023. Available online: https://katanabana.com/blogs/montessori-learning/montessori-furniture (accessed on 14 December 2023).

- Woodandhearts. Montessori Cube Chair. Wood and Hearts; Woodandhearts: Wilmington, DE, USA, 2023; Available online: https://woodandhearts.com/products/montessori-cube-chair (accessed on 14 December 2023).

- Lillard, A.S. Playful Learning and Montessori Education. Am. J. Play. 2013, 5, 157–186. Available online: https://www.proquest.com/scholarly-journals/playful-learning-montessori-education/docview/1459141902/se-2 (accessed on 14 December 2023).

- Mohammed, M.; Qi, W. Exploring Conceptual Play Furniture for Children. Int. J. Sci. Technol. Res. 2020, 9, 255–259. Available online: https://www.academia.edu/64427823/Exploring_Conceptual_Play_Furniture_For_Children (accessed on 14 December 2023).

- Diler, H.; Kasal, A.; Kuşkun, T.; Erdil, Y.Z.; Güray, E. Strength Classification of Wooden Chairs under Cyclic Loads Based on an Experimental Study. Materials 2023, 16, 6580. [Google Scholar] [CrossRef] [PubMed]

- Güray, E.; Ceylan, E.; Kasal, A. Weight-strength optimization of wooden household chairs based on member section size. Maderas, Cienc. Tecnol. 2022, 24, 31. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S. The Integrated Development of Furniture Design and Children’s Characteristics Based on Artificial Intelligence. Sci. Program. Vol. 2022, 2022, 6036160. [Google Scholar] [CrossRef]

- Jai-ai, N.; Seviset, S.; Saribut, U. The Study and Development for the Set of Activity Table to Support the Activity Learning of Grade 4 Students by Department of Arts. In Proceedings of the 2019 International Conference on Modeling, Simulation and Big Data Analysis (MSBDA 2019), Wuhan, China, 23–24 June 2019; pp. 432–439. [Google Scholar] [CrossRef]

- European Standard EN 71-3:2019+A1:2021; Safety of Toys—Part 3: Migration of Certain Elements. European Committee for Standardization—CEN-CENELEC: Brussels, Belgium, 2021. Available online: https://standards.cencenelec.eu/dyn/www/f?p=CEN:110:0::::FSP_PROJECT,FSP_ORG_ID:73357,6036&cs=1873D18444192856EC27A3175B45C822D (accessed on 14 December 2023).

- ČSN EN 71-3+A1 (943095); Bezpečnost Hraček—Část 3: Migrace Určitých Prvků (Czech Technical Standard ČSN EN 71-3+A1 (943095) Safety of Toys—Part 3: Migration of Certain Elements). Úřad Pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 2021. Available online: https://csnonline.agentura-cas.cz/Detailnormy.aspx?k=513409 (accessed on 14 December 2023).

- ČSN EN 1084 (492407); Překližované Desky—Třídy úniku Formaldehydu Podle Metody Plynové Analýzy (Czech Technical Standard ČSN EN 1084 (492407) Plywood—Formaldehyde Release Classes Determined by the Gas Analysis Method). Český Normalizační Institut: Praha, Czech Republic, 1997. Available online: https://www.technicke-normy-csn.cz/csn-en-1084-492407-208081.html# (accessed on 14 December 2023)Norma Není Platná (The Standard Is Not Valid).

- ČSN EN 13501-1 (730860); Požární Klasifikace Stavebních Výrobků a Konstrukcí Staveb—Část 1: Klasifikace Podle Výsledků Zkoušek Reakce na Oheň (Czech Technical Standard ČSN EN 13501-1 (730860) Fire Classification of Construction Products and Building Elements – Part 1: Classification Using Test Data from Reaction to Fire Tests). Úřad Pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 2019. Available online: https://www.technicke-normy-csn.cz/csn-en-13501-1-730860-222113.html# (accessed on 14 December 2023).

- ČSN EN 717-1 (490163); Desky ze Dřeva—Stanovení úniku Formaldehydu–Část 1: Emise Formaldehydu Komorovou Metodou (Czech Technical Standard ČSN EN 717-1 (490163)/European Standard EN 717/1 Wood-Based Panels—Determination of Formaldehyde Release—Part 1: Formaldehyde Emission by the Chamber Method). Český Normalizační Institu: Praha, Czech Republic, 2005. Available online: https://www.technicke-normy-csn.cz/csn-en-717-1-490163-207748.html# (accessed on 14 December 2023).

- ČSN EN ISO 12460-5 (490163); Desky na Bázi Dřeva—Stanovení úniku Formaldehydu—Část 5: Extrakční Postup Zvaný “Perforátová Metoda” (Czech Technical Standard ČSN EN ISO 12460-5 (490163) Wood-Based Panels — Determination of Formaldehyde Release—Part 5: Extraction Method (Called the Perforator Method)). Úřad Pro Technickou Normalizaci, Metrologii a Státní Zkušebnictví: Praha, Czech Republic, 2015. Available online: https://www.technicke-normy-csn.cz/csn-en-iso-12460-5-490163-207759.html# (accessed on 14 December 2023).

- Havel, M. Vnitřní Prostředí Staveb a Chemické Látky. (Indoor Building Environments and Chemicals). Portál TZB-Info. 2014, Article 11134, s. 4. Available online: https://stavba.tzb-info.cz/podlahy-pricky-povrchy/11134-vnitrni-prostredi-staveb-a-chemicke-latky#pozn4 (accessed on 14 December 2023).

- Čapka, R. Nové Limity Pro Emise Formaldehydu—Poloviční Hodnoty Evropské Klasifikace E1. (New Formaldehyde Emission Limits—European Classification Values Reduced to a Half). Online. 2023, s. 1. Licensee: © 2023 Dřevařský Magazín—drevmag.com. Trendwood—twd, s.r.o. Available online: https://drevmag.com/cs/2023/08/09/nove-limity-pro-emise-formaldehydu-polovicni-hodnoty-evropske-klasifikace-e1/ (accessed on 14 December 2023).

- Démos Trade, A.S. Překližky a Laťovky: Velký Přehled Dřevin, Kvalit a Jejich Vlastností. (Plywoods and Blockboards: A Major Survey of Woody Plants, Qualities, and Properties). PDF. Ostrava-Kunčičky. Available online: https://www.demos-trade.cz/file/39328/ (accessed on 14 December 2023).

- European Standard EN ISO 16000-1-11:2006; Indoor air—Part 1: General aspects of sampling strategy. European Committee for Standardization—CEN-CENELEC: Brussels, Belgium, 2006. Available online: https://standards.cencenelec.eu/dyn/www/f?p=CEN:110:0::::FSP_PROJECT,FSP_ORG_ID:25725,6245&cs=1EEBCCC04C6EF14384DC9473A1702C577 (accessed on 14 December 2023).

- Eurofins. French VOC Regulations. PDF. Galten and Folsom, 2012. © Eurofins Scientific 2023. Available online: https://www.eurofins.com/media/1579/french-voc-regulations-en.pdf.https://www.product-testing.eurofins.com/ (accessed on 15 December 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).