Evolution of Permeability and Sensitivity Analysis of Gas-Bearing Coal under Cyclic Dynamic Loading

Abstract

1. Introduction

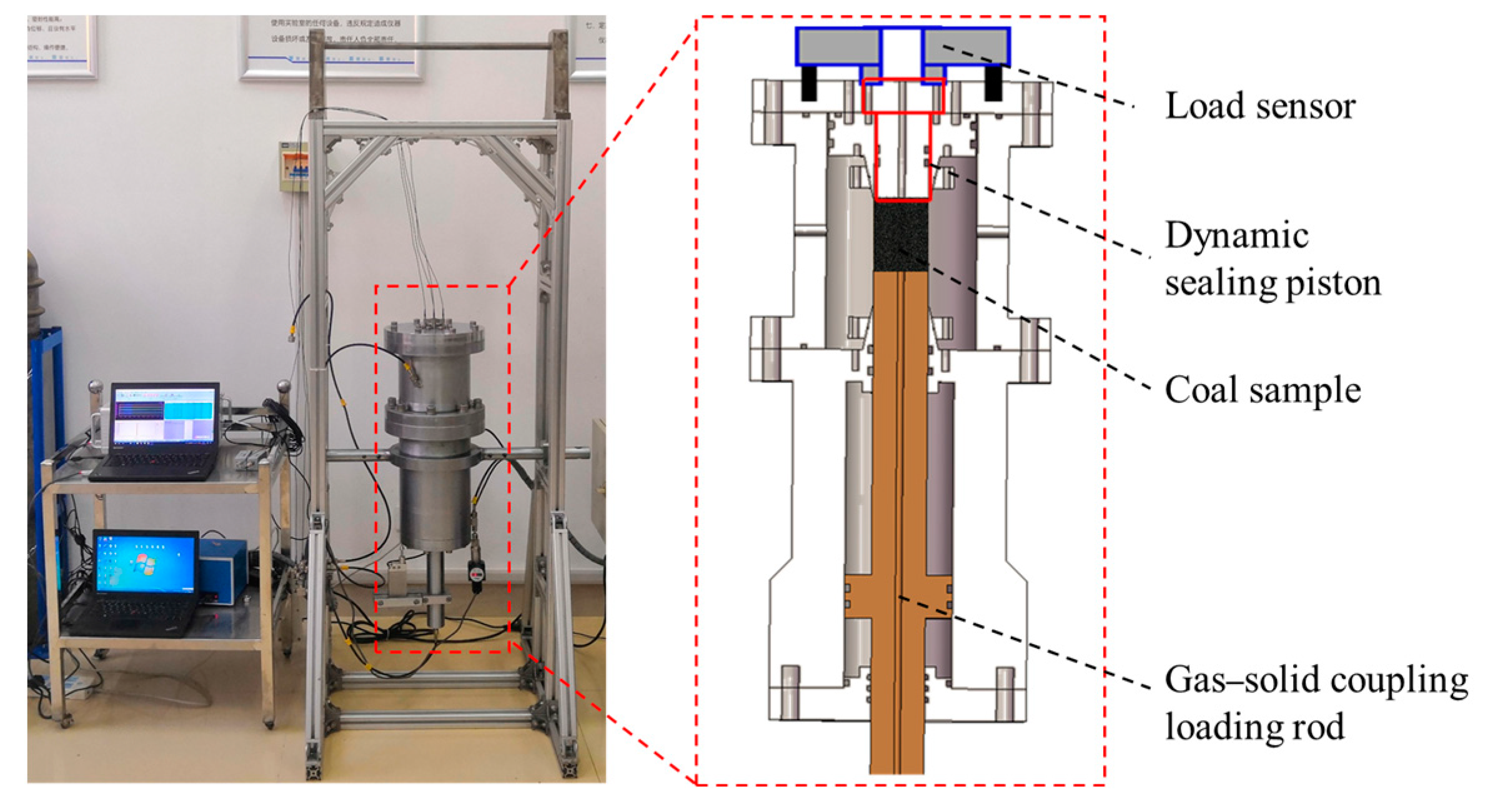

2. Experimental Apparatus

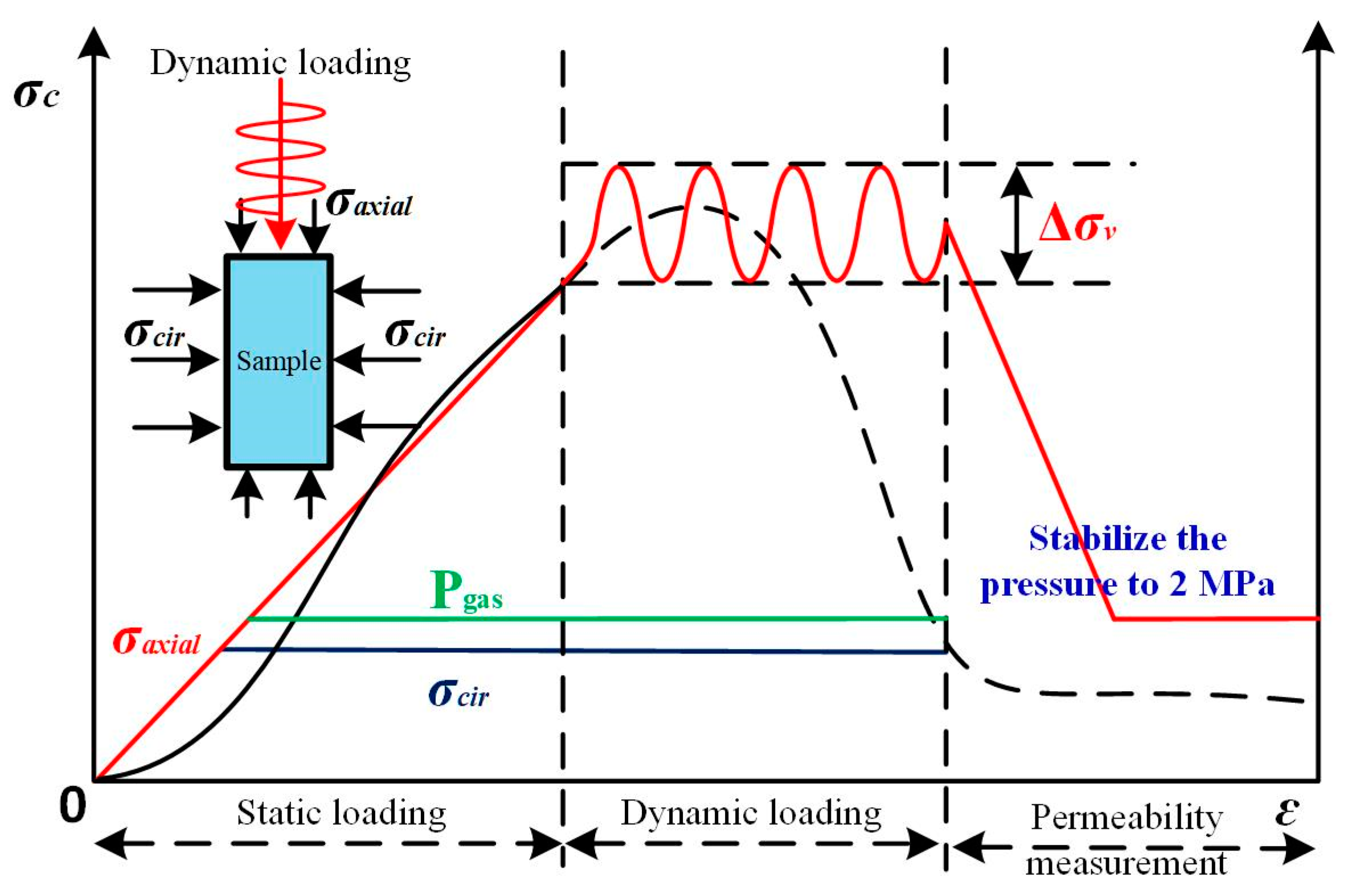

3. Experimental Scheme

4. Results and Discussion

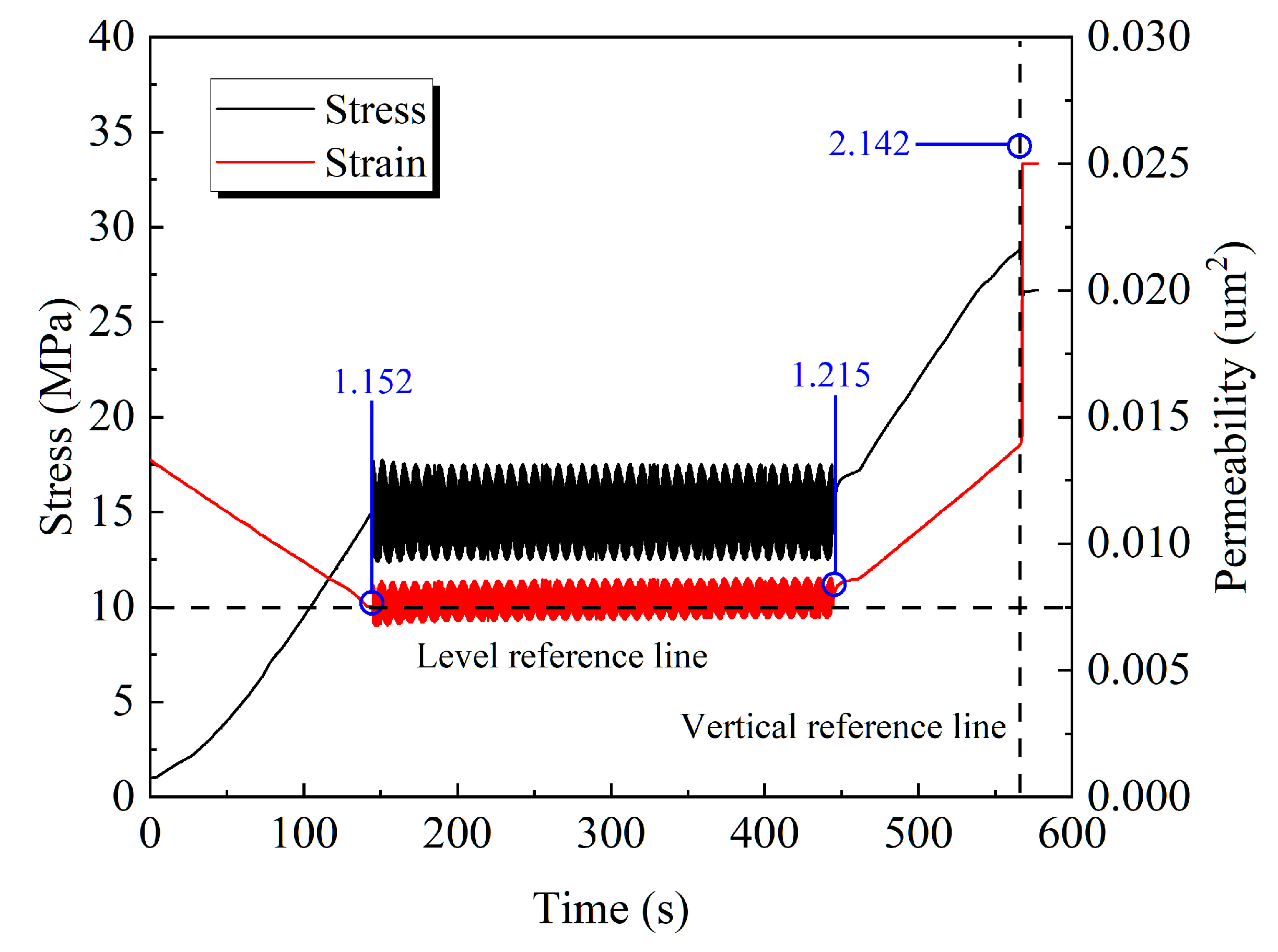

4.1. The Influence of the Cyclic Loading Frequency on the Permeability

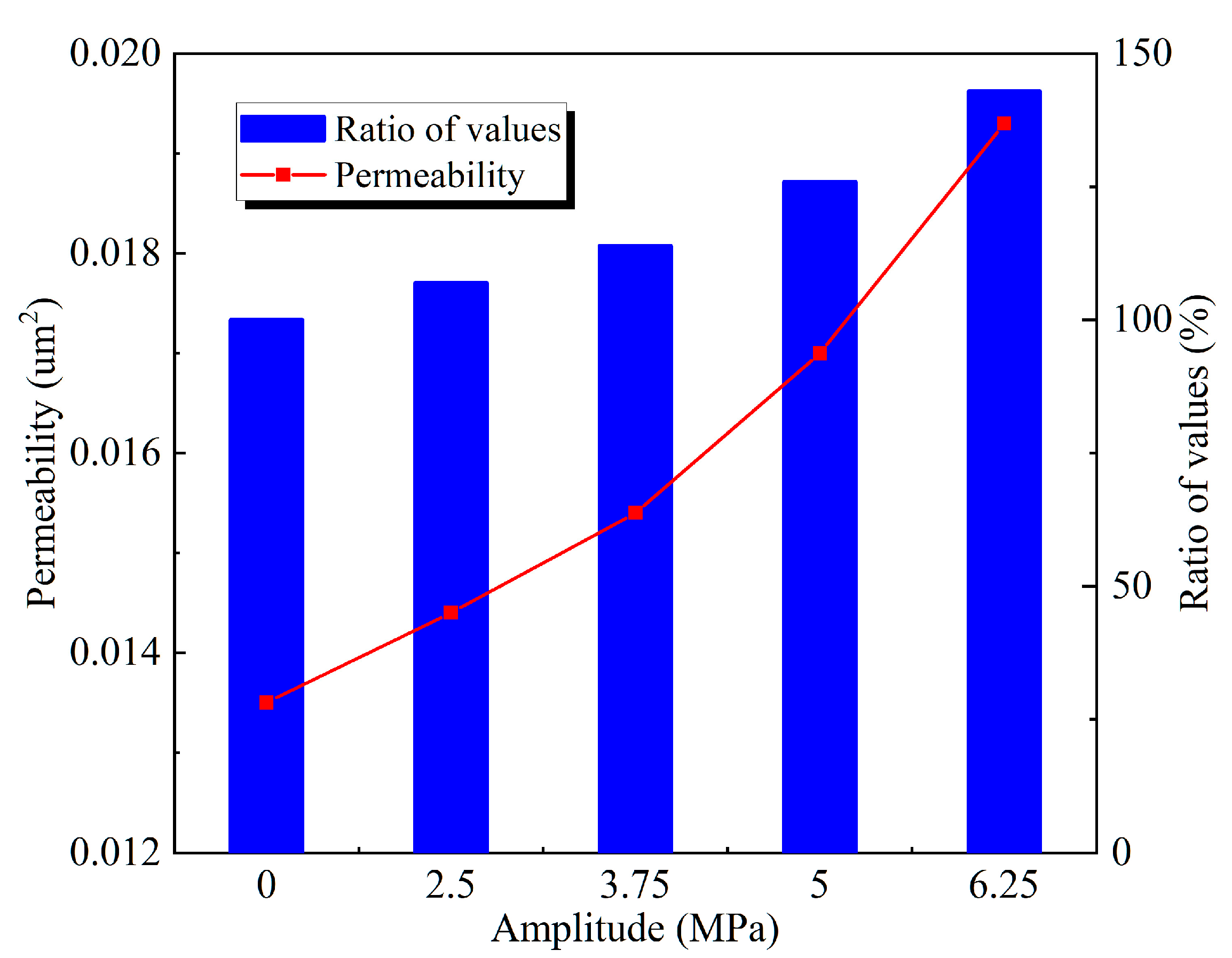

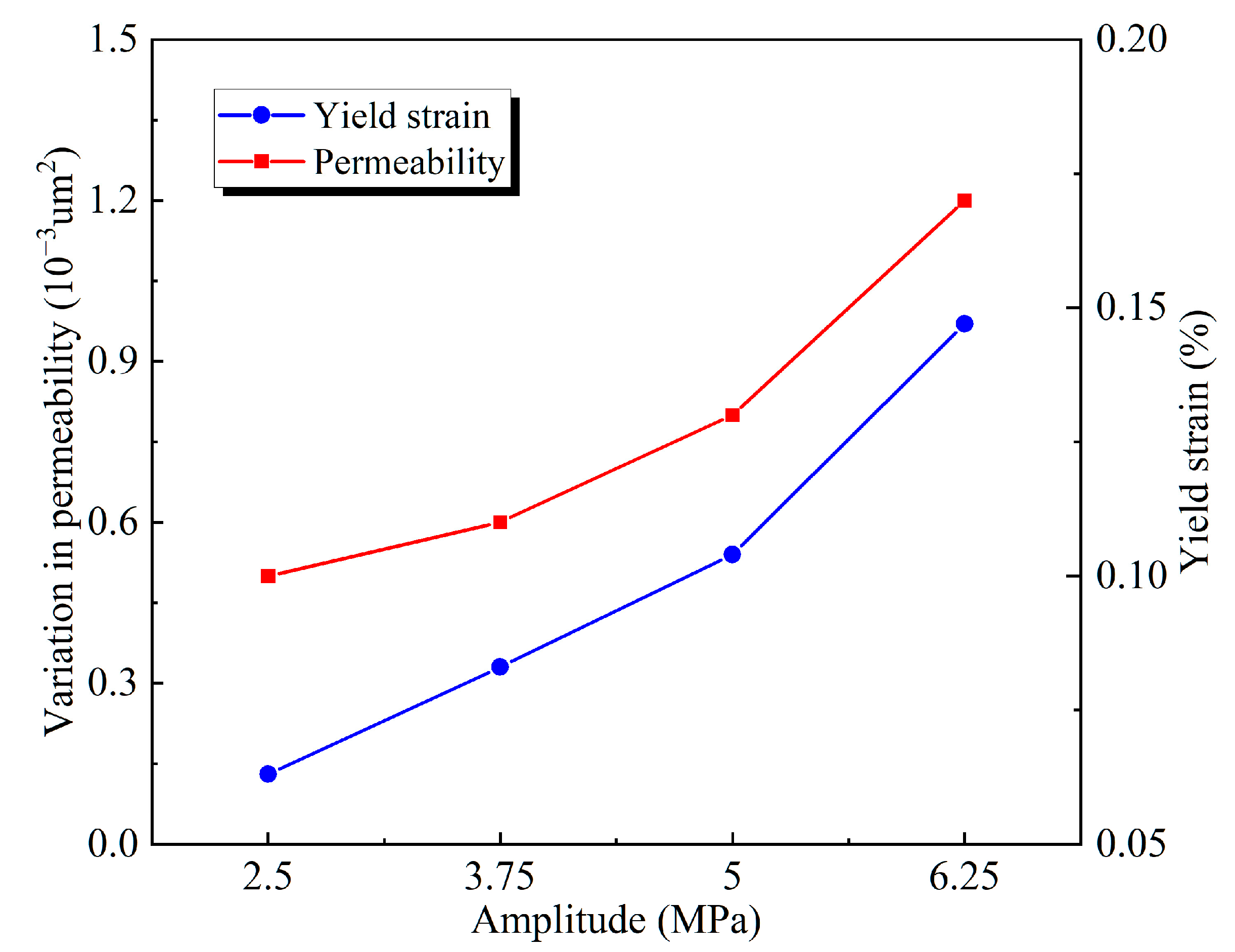

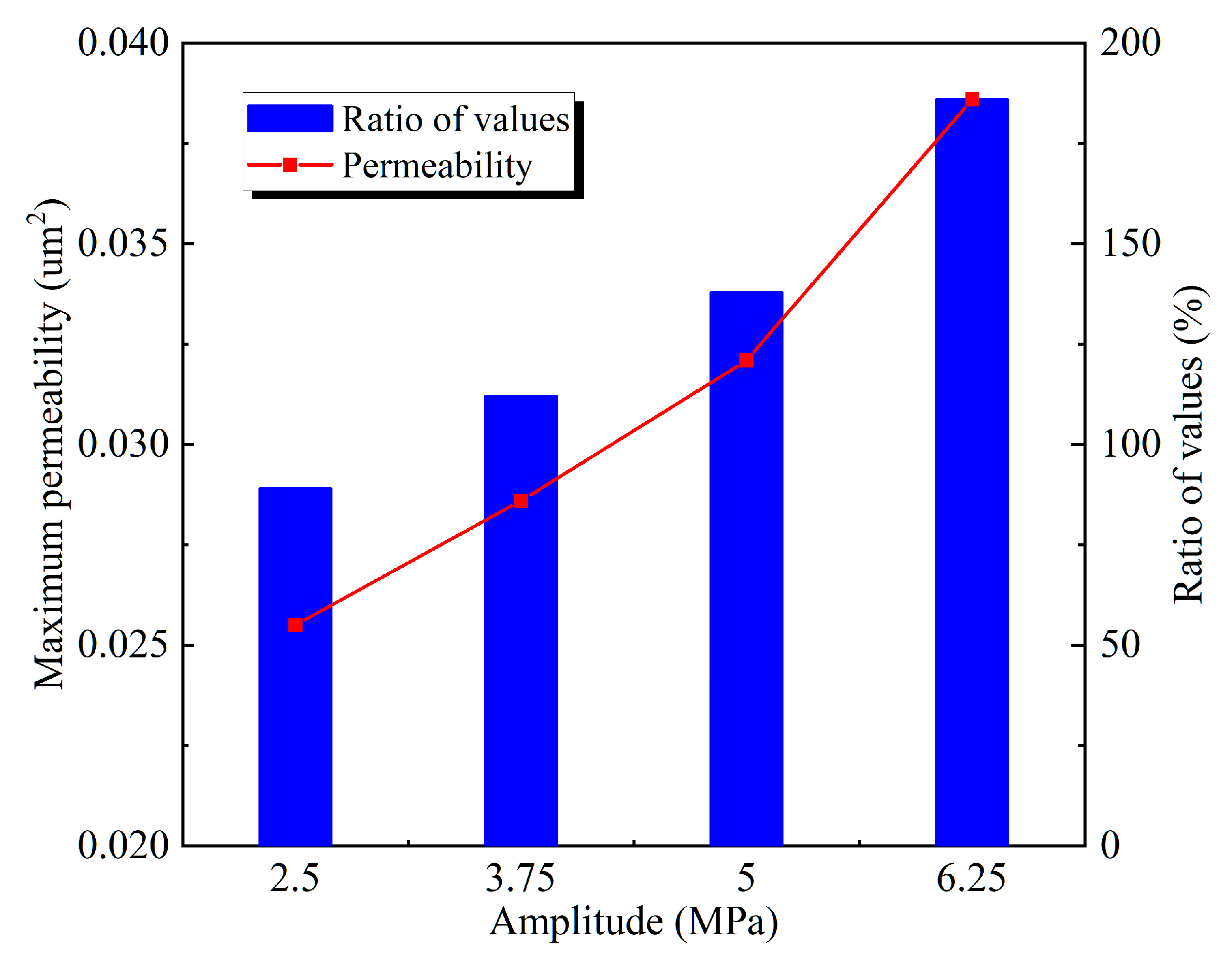

4.2. The Influence of the Cyclic Loading Amplitude on the Permeability

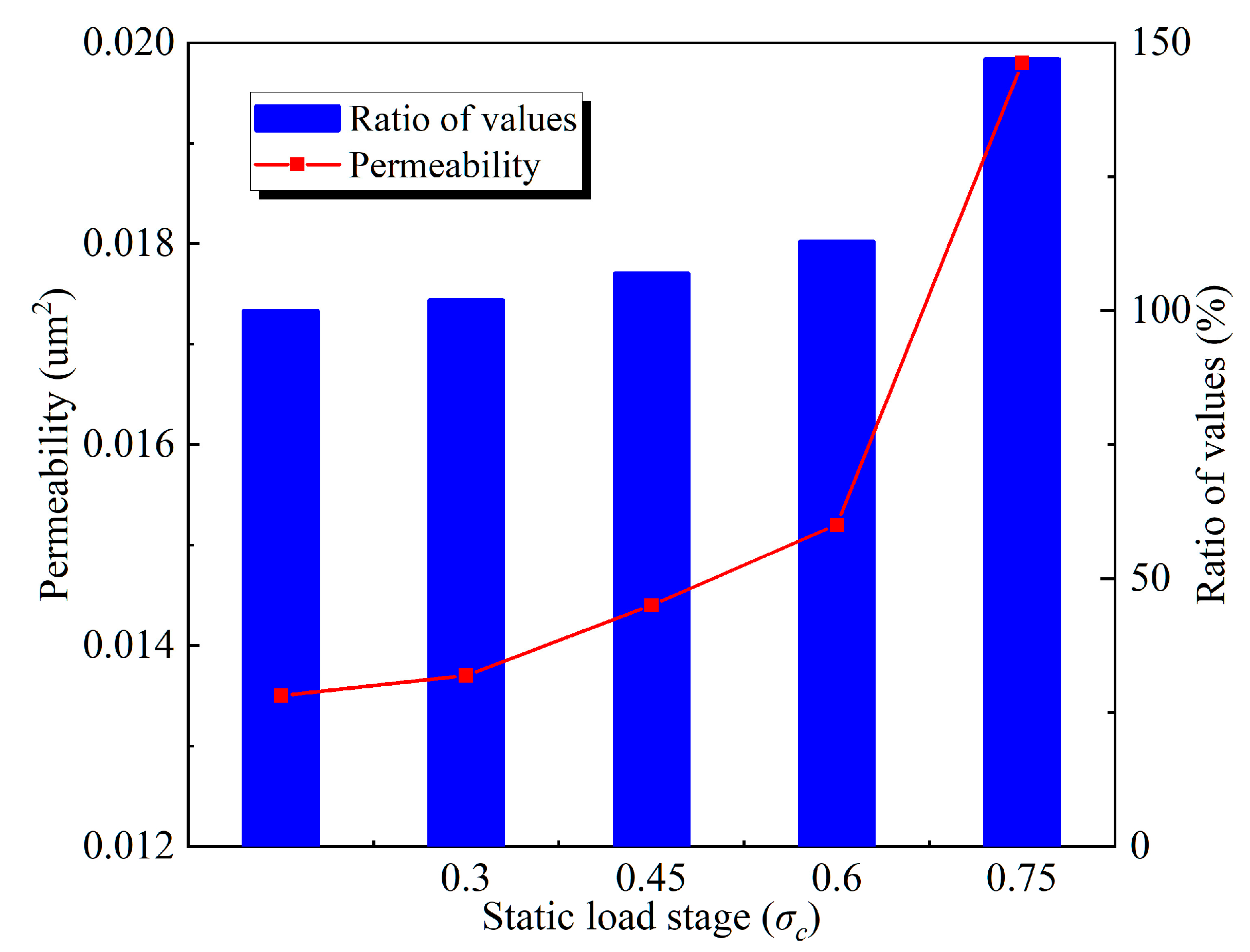

4.3. The Influence of the Static Load Stage on the Permeability

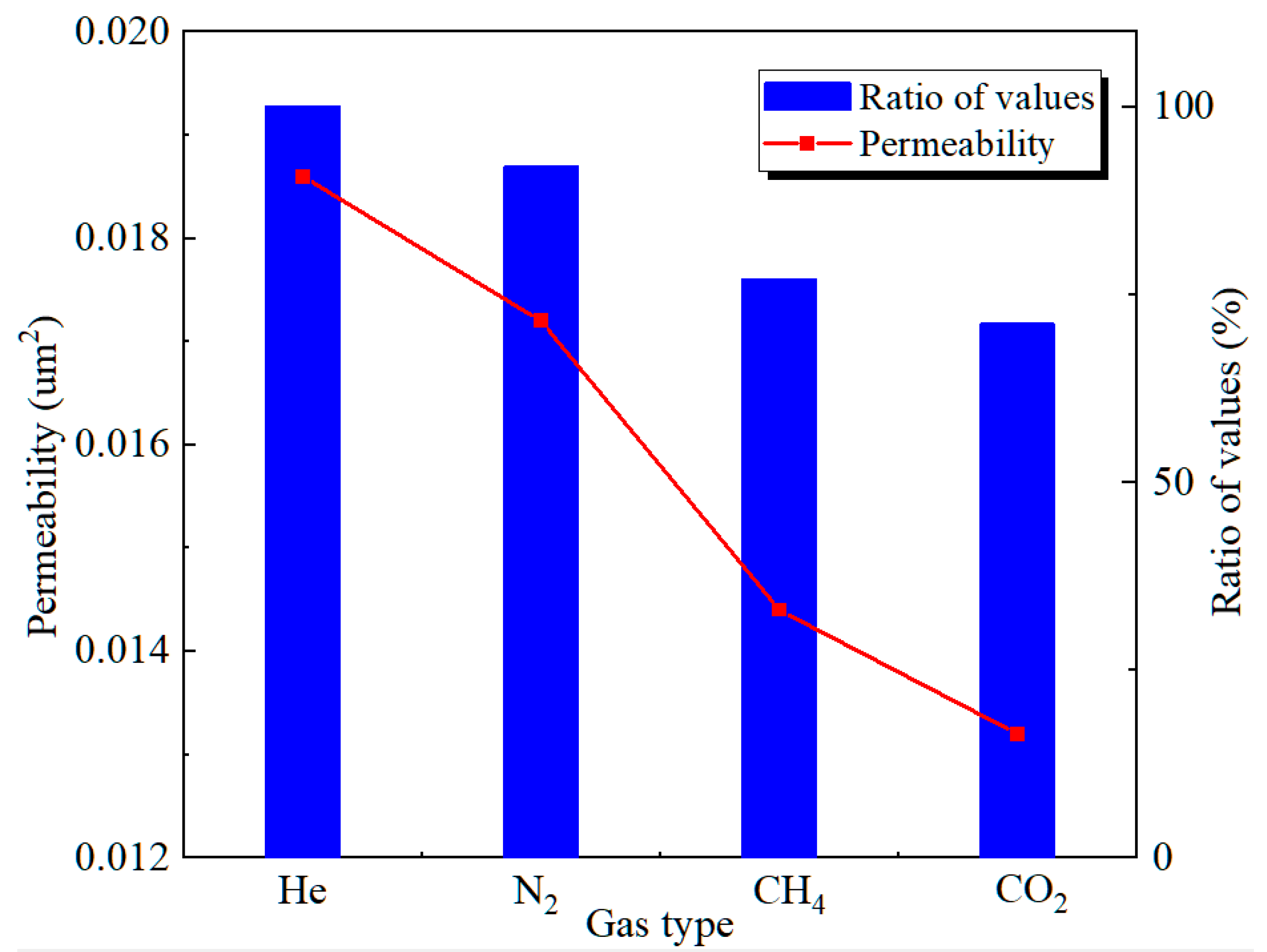

4.4. The Influence of Adsorbed Gas on the Permeability

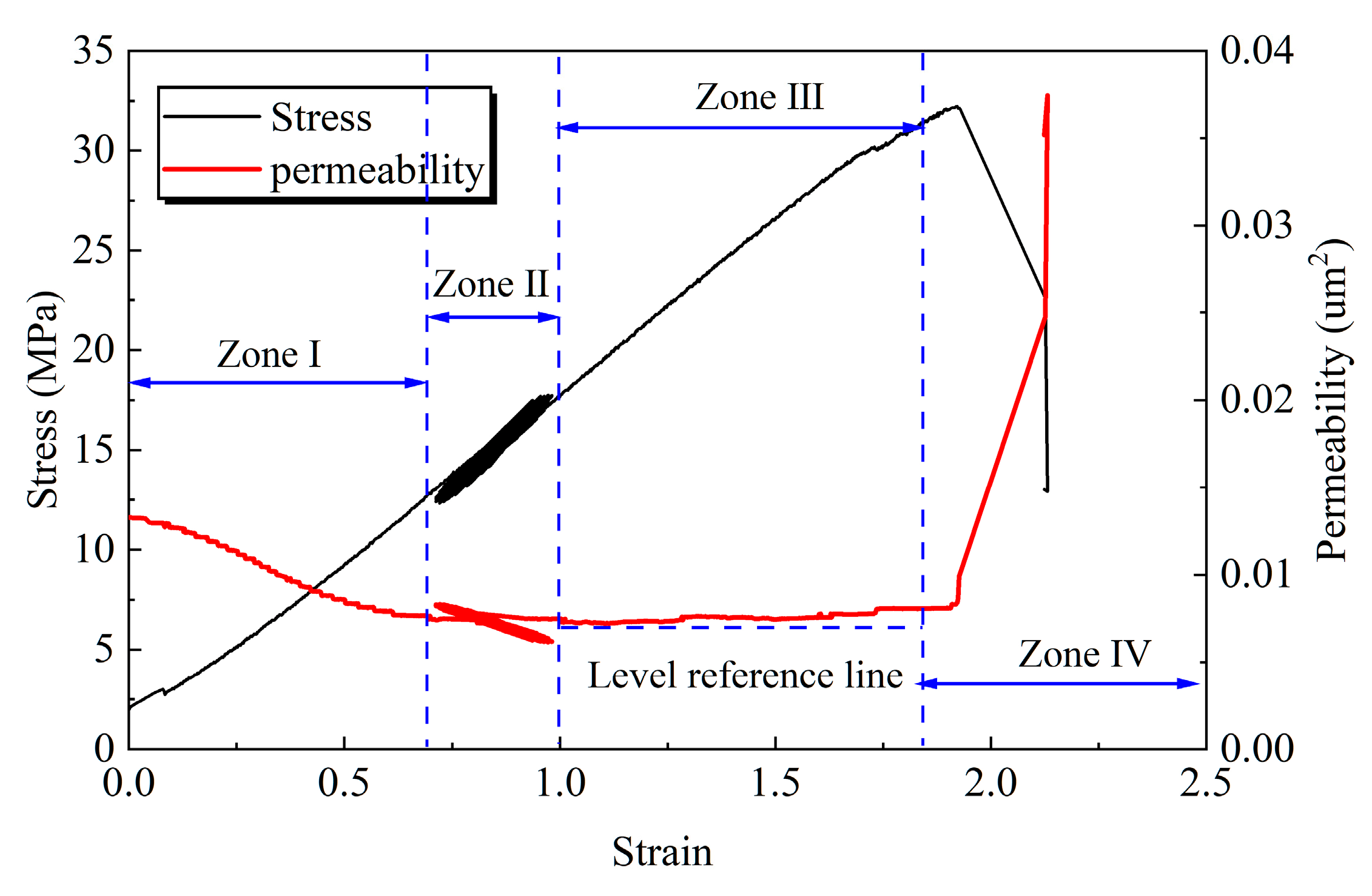

4.5. The Permeability Behavior of Coal in the Full Stress–Strain Process

5. Sensitivity Analysis of Permeability to Cyclic Loading

5.1. Fitting of the Permeability Variation Curve

5.2. Evaluation Parameters for Cyclic Load Sensitivity

5.3. Sensitivity Analysis of Cyclic Load

6. Conclusions

- (1)

- As the frequency and amplitude of dynamic loading increase, the development of pore and fissure structures within the coal body becomes increasingly pronounced during the dynamic loading cycles, resulting in a gradual rise in permeability. Notably, as the coal approaches its yielding stage, the permeability can increase by up to 47%. However, with the enhancement of gas adsorption, the permeability of the coal body gradually diminishes.

- (2)

- The permeability curve is divided into four regions: the compaction reduction zone, the oscillation zone, the gradual recovery zone, and the abrupt increase zone of failure. It is noteworthy that the permeability and stress–strain relationship exhibit a phenomenon of resonance at the same frequency, with the permeability of the coal body gradually increasing during dynamic load cycling. Ultimately, in the failure phase, the permeability surges dramatically, potentially reaching values of four to five times the initial permeability.

- (3)

- A sensitivity analysis of permeability to dynamic and static loading and gas adsorption was conducted, defining two evaluation parameters: the rate of change in permeability and the dynamic loading sensitivity coefficient of permeability. When the static load stage was constant, the rate of change in permeability of the coal under dynamic loading decreased with increasing adsorption amounts. When the adsorption amount was constant, the rate of change in permeability of the coal under dynamic loading increased with the increase in the static loading stress stage, with the maximum increase reaching 75.2%. It can thus be concluded from the rate of change in permeability and the dynamic loading sensitivity coefficient that the permeability of coal is highly sensitive to cyclic dynamic loading, with an increased sensitivity associated with larger static loading stages and decreased sensitivity with greater adsorption amounts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Cao, J.; Cheng, X.; Liu, Y.; Li, X.; Sun, Z.; Guo, J. Mechanical response characteristics and permeability evolution of coal samples under cyclic loading. Energy Sci. Eng. 2019, 7, 1588–1604. [Google Scholar] [CrossRef]

- Guo, J.; Qin, Q.; Zhang, R. Evaluation of the damages of permeability and effective porosity of tectonically deformed coals. Arab. J. Geosci. 2017, 10, 357. [Google Scholar] [CrossRef]

- Zhang, G.; Yao, G.; Li, J.; Wu, H.; Liu, Z.; Li, D. A new experimental method for measuring the three-phase relative permeability of oil, gas, and water. J. Petrol. Sci. Eng. 2018, 170, 611–619. [Google Scholar] [CrossRef]

- Xiao, F.; Meng, X.; Li, L.; Liu, J.; Liu, G.; Liu, Z.; Xu, L. Thermos-Solid-Gas Coupling Dynamic Model and Numerical Simulation of Coal Containing Gas. Geofluids 2020, 2020, 8837425. [Google Scholar]

- Du, F.; Wang, K.; Wang, G.; Jiang, Y.; Xin, C.; Zhang, X. Investigation of the acoustic emission characteristics during deformation and failure of gas-bearing coal-rock combined bodies. J. Loss Prevent. Proc. 2018, 55, 253–266. [Google Scholar] [CrossRef]

- Guo, H.; Cheng, Z.; Wang, K.; Qu, B.; Yuan, L.; Xu, C. Coal permeability evolution characteristics: Analysis under different loading conditions. Greenh. Gases 2020, 10, 347–363. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, K.; Du, F.; Guo, H.; Li, K.; Wang, Y. Mechanical-permeability characteristics of composite coal rock under different gas pressures and damage prediction model. Phys. Fluids 2024, 36, 036615. [Google Scholar] [CrossRef]

- Bustin, R.M.; Cui, X.; Chikatamarla, L. Impacts of volumetric strain on CO2 sequestration in coals and enhanced CH4 recovery. AAPG Bull. 2008, 92, 15–29. [Google Scholar] [CrossRef]

- Wang, G.X.; Wei, X.R.; Wang, K.; Massarotto, P.; Rudolph, V. Sorption-induced swelling/shrinkage and permeability of coal under stressed adsorption/desorption conditions. Int. J. Coal Geol. 2010, 83, 46–54. [Google Scholar] [CrossRef]

- Niu, Q.; Cao, L.; Sang, S.; Zhou, X.; Wang, Z.; Wu, Z. The adsorption-swelling and permeability characteristics of natural and reconstituted anthracite coals. Energy 2017, 141, 2206–2217. [Google Scholar] [CrossRef]

- Mosleh, M.H.; Turner, M.; Sedighi, M.; Vardon, P.J. Carbon dioxide flow and interactions in a high rank coal: Permeability evolution and reversibility of reactive processes. Int. J. Greenh. Gas Con. 2018, 70, 57–67. [Google Scholar] [CrossRef]

- Larsen, J.W. The effects of dissolved CO2 on coal structure and properties. Int. J. Coal Geol. 2004, 57, 63–70. [Google Scholar] [CrossRef]

- Liu, C.J.; Wang, G.X.; Sang, S.X.; Rudolph, V. Changes in pore structure of anthracite coal associated with CO2 sequestration process. Fuel 2010, 89, 2665–2672. [Google Scholar] [CrossRef]

- Li, C.; Dong, L.; Xu, X.; Hu, P.; Tian, J.; Zhang, Y.; Yang, L. Theoretical and experimental evaluation of effective stress-induced sorption capacity change and its influence on coal permeability. J. Geophys. Eng. 2017, 14, 654–665. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Fu, X.; Liu, S. A new approach modeling permeability of mining-disturbed coal based on a conceptual model of equivalent fractured coal. J. Nat. Gas Sci. Eng. 2020, 79, 103366. [Google Scholar] [CrossRef]

- Zhao, B.; Wen, G.; Sun, H.; Zhao, X. Experimental Study of the Pore Structure and Permeability of Coal by Acidizing. Energies 2018, 11, 1162. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, Z.; Zhao, Y.; Wan, Z. Experimental investigation on thermal cracking, permeability under HTHP and application for geothermal mining of HDR. Energy 2017, 132, 305–314. [Google Scholar] [CrossRef]

- Meng, T.; You, Y.; Chen, J.; Hu, Y. Investigation on the Permeability Evolution of Gypsum Interlayer Under High Temperature and Triaxial Pressure. Rock Mech. Rock Eng. 2017, 50, 2059–2069. [Google Scholar]

- Bai, X.; Wang, Y.; He, G.; Zhou, Z.; Wang, D.; Zhang, D. Research on a permeability model of coal damaged under triaxial loading and unloading. Fuel 2023, 354, 129375. [Google Scholar] [CrossRef]

- Lu, J.; Yin, G.; Deng, B.; Zhang, W.; Li, M.; Chai, X.; Liu, C.; Liu, Y. Permeability characteristics of layered composite coal-rock under true triaxial stress conditions. J. Nat. Gas Sci. Eng. 2019, 66, 60–76. [Google Scholar] [CrossRef]

- Fan, C.; Wen, H.; Sun, H.; Zhou, L.; Zhang, X.; Zhu, C.; Su, W. Experimental Investigation on the Effect of Loading and Unloading on Coal Permeability with Different Sediment Beddings. Lithosphere 2022, 2022, 9949201. [Google Scholar] [CrossRef]

- Mitra, A.; Harpalani, S.; Liu, S. Laboratory measurement and modeling of coal permeability with continued methane production: Part 1-Laboratory results. Fuel 2012, 94, 110–116. [Google Scholar] [CrossRef]

- Tang, J.; Yu, H.; Wei, Z.; Zhang, X. Influence of fracture parameters on hydraulic shear seepage characteristics of granite. Case Stud. Therm. Eng. 2024, 56, 104220. [Google Scholar] [CrossRef]

- Zhao, Y.; Qu, F.; Wan, Z.; Zhang, Y.; Liang, W.; Meng, Q. Experimental Investigation on Correlation Between Permeability Variation and Pore Structure During Coal Pyrolysis. Transp. Porous Med. 2010, 82, 401–412. [Google Scholar]

- Li, Y.; Zhang, C.; Sun, Y.; Song, Z.; Zhang, L. Experimental Study on the Influence Mechanism of Coal-Rock Fracture Differential Deformation on Composite Permeability. Nat. Resour. Res. 2022, 31, 2853–2868. [Google Scholar] [CrossRef]

- Peng, S.; Loucks, B. Permeability measurements in mudrocks using gas-expansion methods on plug and crushed-rock samples. Mar. Petrol. Geol. 2016, 73, 299–310. [Google Scholar] [CrossRef]

- Yin, G.; Jiang, C.; Xu, J.; Guo, L.; Peng, S.; Li, W. An Experimental Study on the Effects of Water Content on Coalbed Gas Permeability in Ground Stress Fields. Transp. Porous Med. 2012, 94, 87–99. [Google Scholar] [CrossRef]

- Yin, G.; Li, M.; Wang, J.G.; Xu, J.; Li, W. Mechanical behavior and permeability evolution of gas infiltrated coals during protective layer mining. Int. J. Rock Mech. Min. 2015, 80, 292–301. [Google Scholar] [CrossRef]

- Pirzada, M.A.; Zoorabadi, M.; Ramandi, H.L.; Canbulat, I.; Roshan, H. CO2 sorption induced damage in coals in unconfined and confined stress states: A micrometer to core scale investigation. Int. J. Coal Geol. 2018, 198, 167–176. [Google Scholar] [CrossRef]

- Talapatra, A.; Karim, M.M. The influence of moisture content on coal deformation and coal permeability during coalbed methane (CBM) production in wet reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 1907–1920. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, P.; Wei, J.; Yu, C. The seepage properties and permeability enhancement mechanism in coal under temperature shocks during unloading confining pressures. J. Nat. Gas Sci. Eng. 2020, 77, 103242. [Google Scholar] [CrossRef]

- Liu, Z.Z.; Wang, H.P.; Wang, S.; Zhang, B.; Wang, S.G. A high-precision and user-friendly triaxial apparatus for the measurement of permeability of gassy coal. Measurement 2020, 154, 107496. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, H.; Wang, Z.; Zhang, L.; Kong, L.; Li, S.; Zhang, C. Experimental study on the prediction of rockburst hazards induced by dynamic structural plane shearing in deeply buried hard rock tunnels. Int. J. Rock Mech. Min. Sci. 2016, 86, 210–223. [Google Scholar] [CrossRef]

| Number | Frequency and Magnitude of Dynamic Load | Static Load Stress Phase | Gas |

|---|---|---|---|

| 1 | 2.50 MPa, 3 Hz | 0.45 σc | CH4 |

| 2 | 2.50 MPa, 4 Hz | 0.45 σc | CH4 |

| 3 | 2.50 MPa, 5 Hz | 0.45 σc | CH4 |

| 4 | 2.50 MPa, 6 Hz | 0.45 σc | CH4 |

| 5 | 3.75 MPa, 3 Hz | 0.45 σc | CH4 |

| 6 | 5.00 MPa, 3 Hz | 0.45 σc | CH4 |

| 7 | 6.25 MPa, 3 Hz | 0.45 σc | CH4 |

| 8 | 2.50 MPa, 3 Hz | 0.3 σc | CH4 |

| 9 | 2.50 MPa, 3 Hz | 0.6 σc | CH4 |

| 10 | 2.50 MPa, 3 Hz | 0.75 σc | CH4 |

| 11 | 2.50 MPa, 3 Hz | 0.45 σc | CO2 |

| 12 | 2.50 MPa, 3 Hz | 0.45 σc | N2 |

| 13 | 2.50 MPa, 3 Hz | 0.45 σc | He |

| Static Load Stage | Gas Type | a0 | b0 | R2 |

|---|---|---|---|---|

| 0.3σc | He | 0.0123 | 0.0693 | 0.9973 |

| N2 | 0.0116 | 0.0688 | 0.9813 | |

| CH4 | 0.0107 | 0.0683 | 0.9963 | |

| CO2 | 0.0105 | 0.0667 | 0.9972 | |

| 0.45σc | He | 0.0129 | 0.0705 | 0.9980 |

| N2 | 0.0121 | 0.0758 | 0.9967 | |

| CH4 | 0.0116 | 0.0686 | 0.9732 | |

| CO2 | 0.0113 | 0.0629 | 0.9651 | |

| 0.6σc | He | 0.0133 | 0.0814 | 0.9584 |

| N2 | 0.0131 | 0.0777 | 0.9663 | |

| CH4 | 0.0122 | 0.0723 | 0.9913 | |

| CO2 | 0.0119 | 0.0695 | 0.9842 |

| Static Load Stage | Dv (%) | |||

|---|---|---|---|---|

| He | N2 | CH4 | CO2 | |

| 0.3σc | 48.8 | 45.6 | 29.6 | 25.6 |

| 0.45σc | 57.6 | 52 | 40.8 | 32.8 |

| 0.6σc | 75.2 | 68.8 | 51.2 | 45.6 |

| Static Load Stage | Gas Type | a1 | b1 |

|---|---|---|---|

| 0.3σc | He | 0.0682 | 0.0693 |

| N2 | 0.0638 | 0.0688 | |

| CH4 | 0.0585 | 0.0683 | |

| CO2 | 0.0560 | 0.0667 | |

| 0.45σc | He | 0.0728 | 0.0705 |

| N2 | 0.0734 | 0.0758 | |

| CH4 | 0.0637 | 0.0686 | |

| CO2 | 0.0569 | 0.0629 | |

| 0.6σc | He | 0.0866 | 0.0814 |

| N2 | 0.0814 | 0.0777 | |

| CH4 | 0.0706 | 0.0723 | |

| CO2 | 0.0662 | 0.0695 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Liu, Y.; Wang, Z.; Huang, W. Evolution of Permeability and Sensitivity Analysis of Gas-Bearing Coal under Cyclic Dynamic Loading. Appl. Sci. 2024, 14, 8373. https://doi.org/10.3390/app14188373

Liu Z, Liu Y, Wang Z, Huang W. Evolution of Permeability and Sensitivity Analysis of Gas-Bearing Coal under Cyclic Dynamic Loading. Applied Sciences. 2024; 14(18):8373. https://doi.org/10.3390/app14188373

Chicago/Turabian StyleLiu, Zhongzhong, Yuxuan Liu, Zonghao Wang, and Wentao Huang. 2024. "Evolution of Permeability and Sensitivity Analysis of Gas-Bearing Coal under Cyclic Dynamic Loading" Applied Sciences 14, no. 18: 8373. https://doi.org/10.3390/app14188373

APA StyleLiu, Z., Liu, Y., Wang, Z., & Huang, W. (2024). Evolution of Permeability and Sensitivity Analysis of Gas-Bearing Coal under Cyclic Dynamic Loading. Applied Sciences, 14(18), 8373. https://doi.org/10.3390/app14188373