Risk Assessment of Hydrogen Cyanide for Available Safe Egress Time in Fire Simulation

Abstract

1. Introduction

2. Description of Fire Simulation

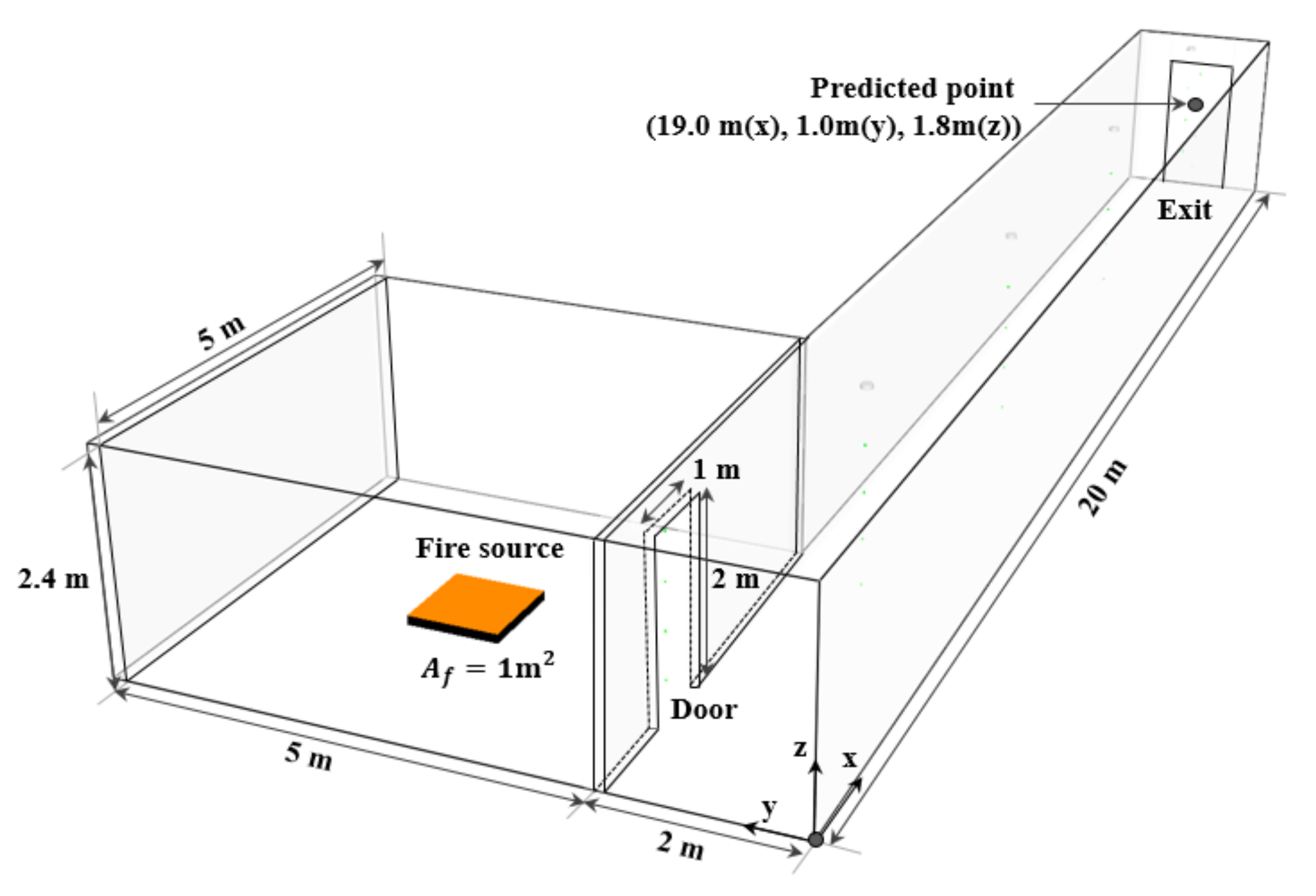

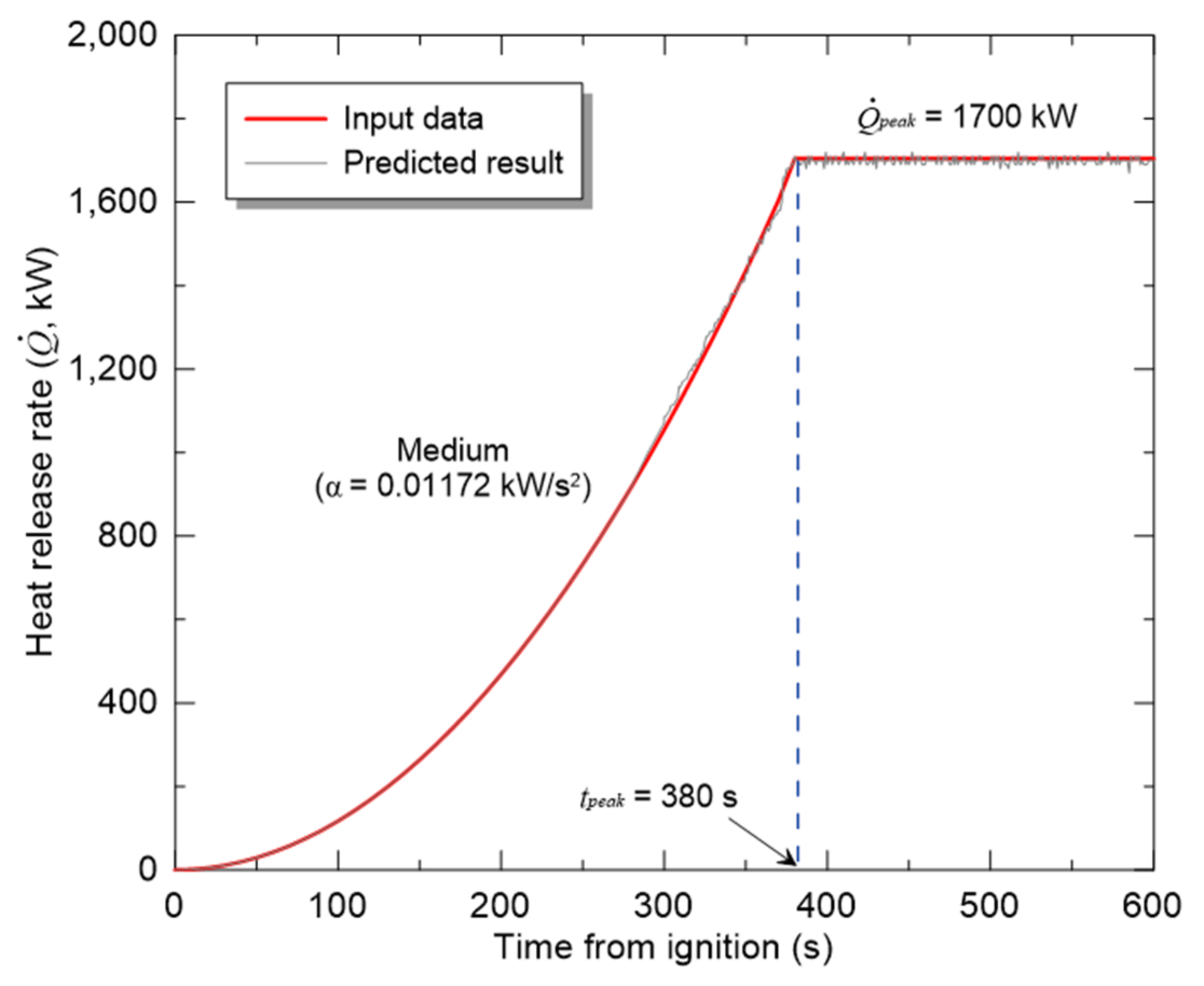

2.1. Computational Domain and Fire Source for Fire Simulation

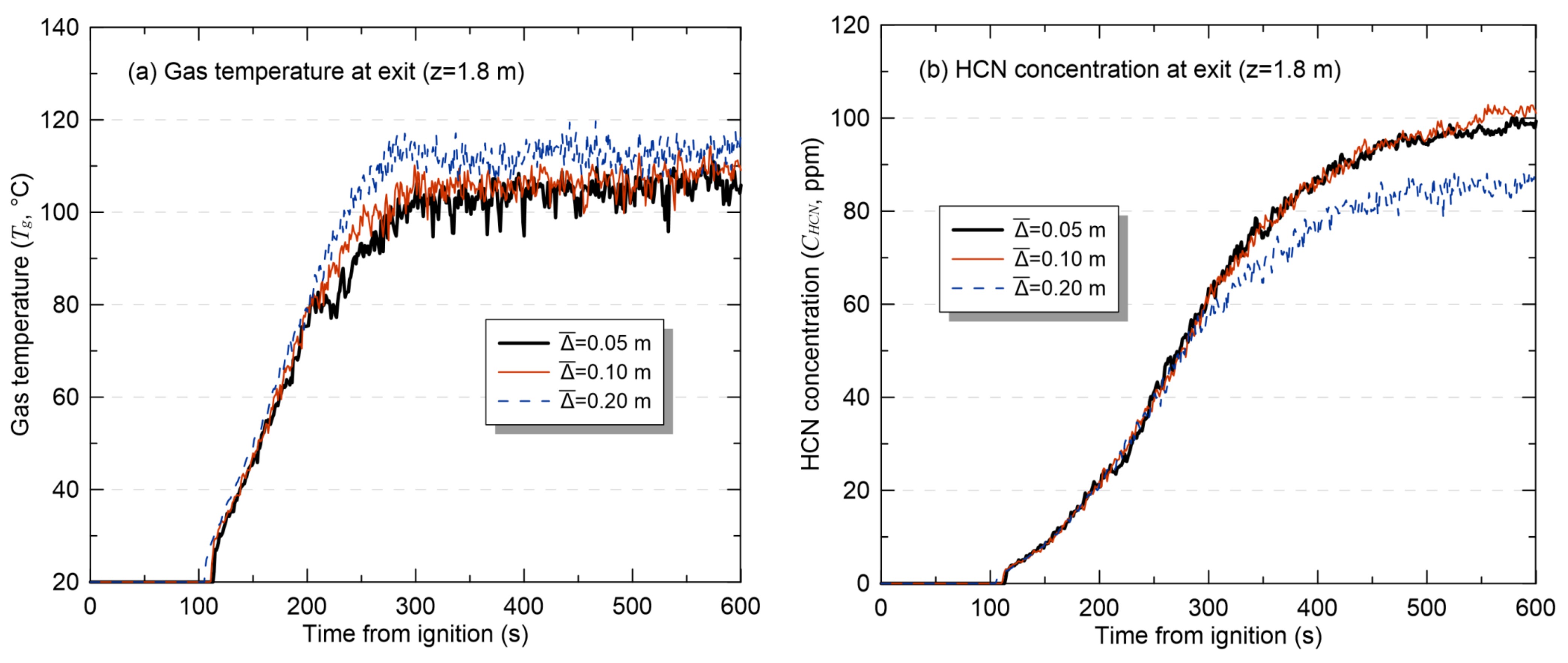

2.2. Grid Sensitivity Analysis

2.3. Analysis Method with V&V Results

2.4. Analysis Method with Relative Risk Score (RRS)

3. Simulation Results and Discussion of Fire Scenarios

3.1. Predicted Results by Combustible Type

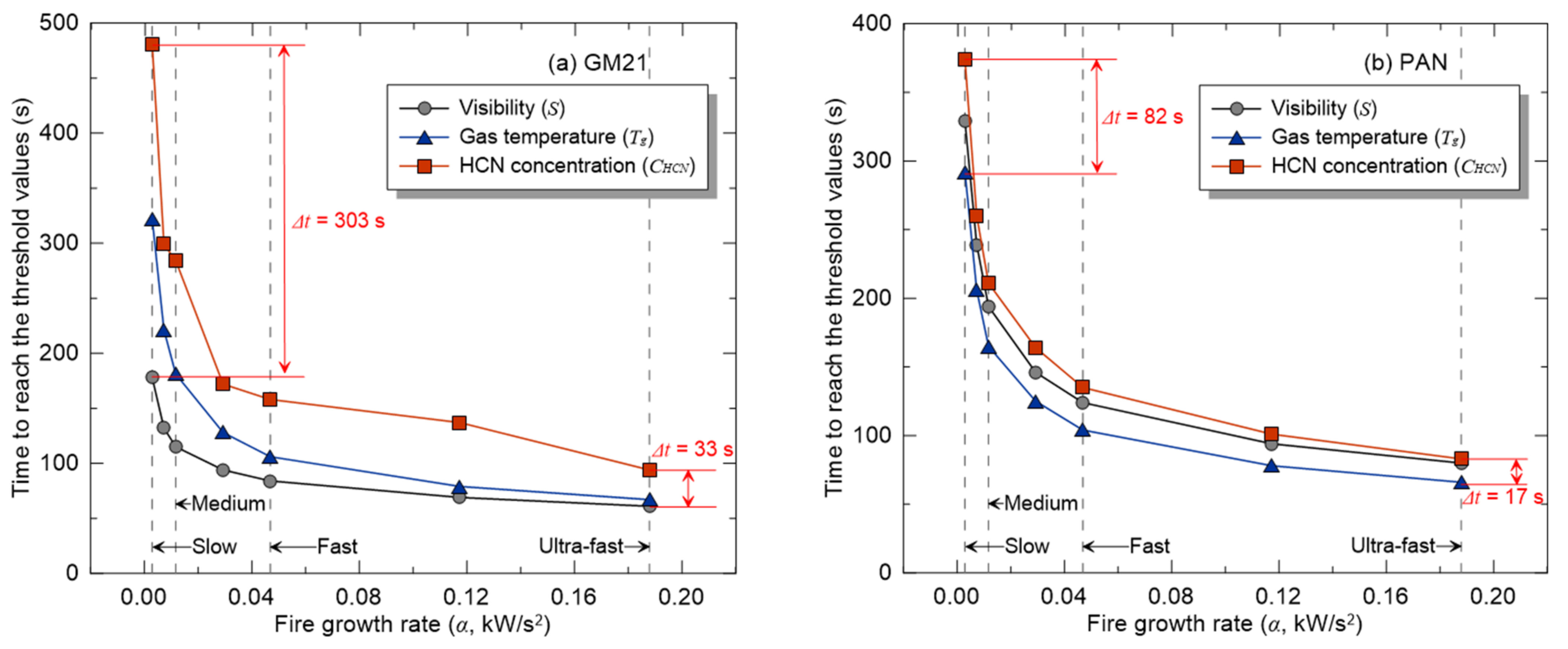

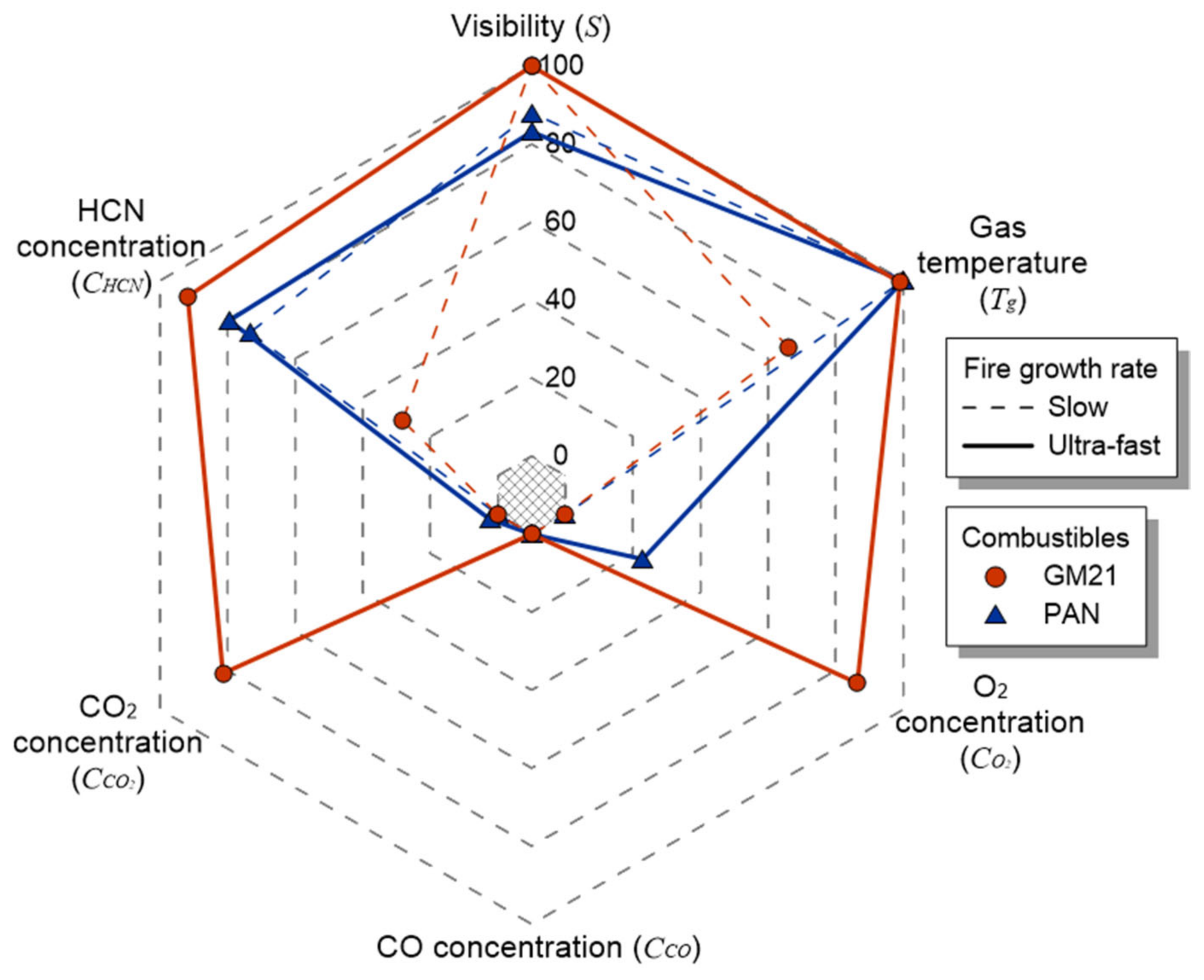

3.2. Fire Growth Rate Sensitivity Analysis Results

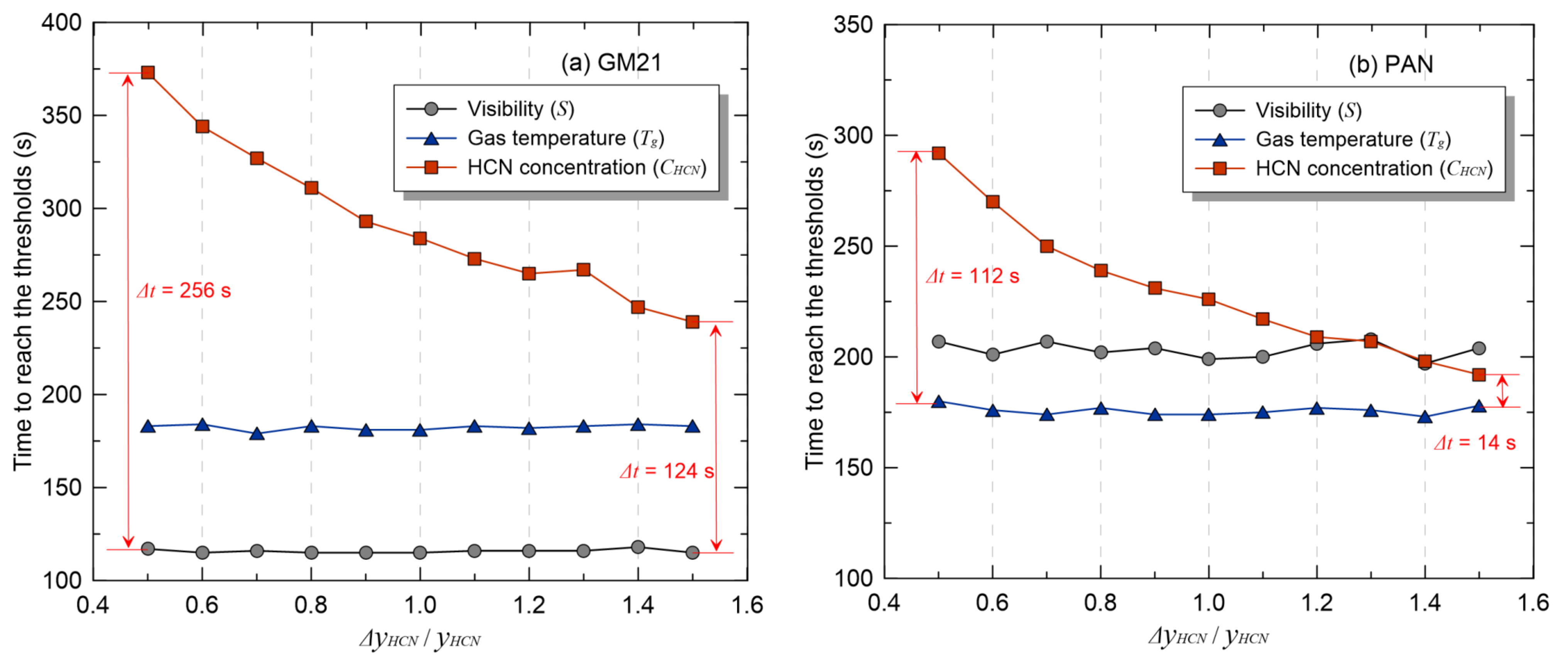

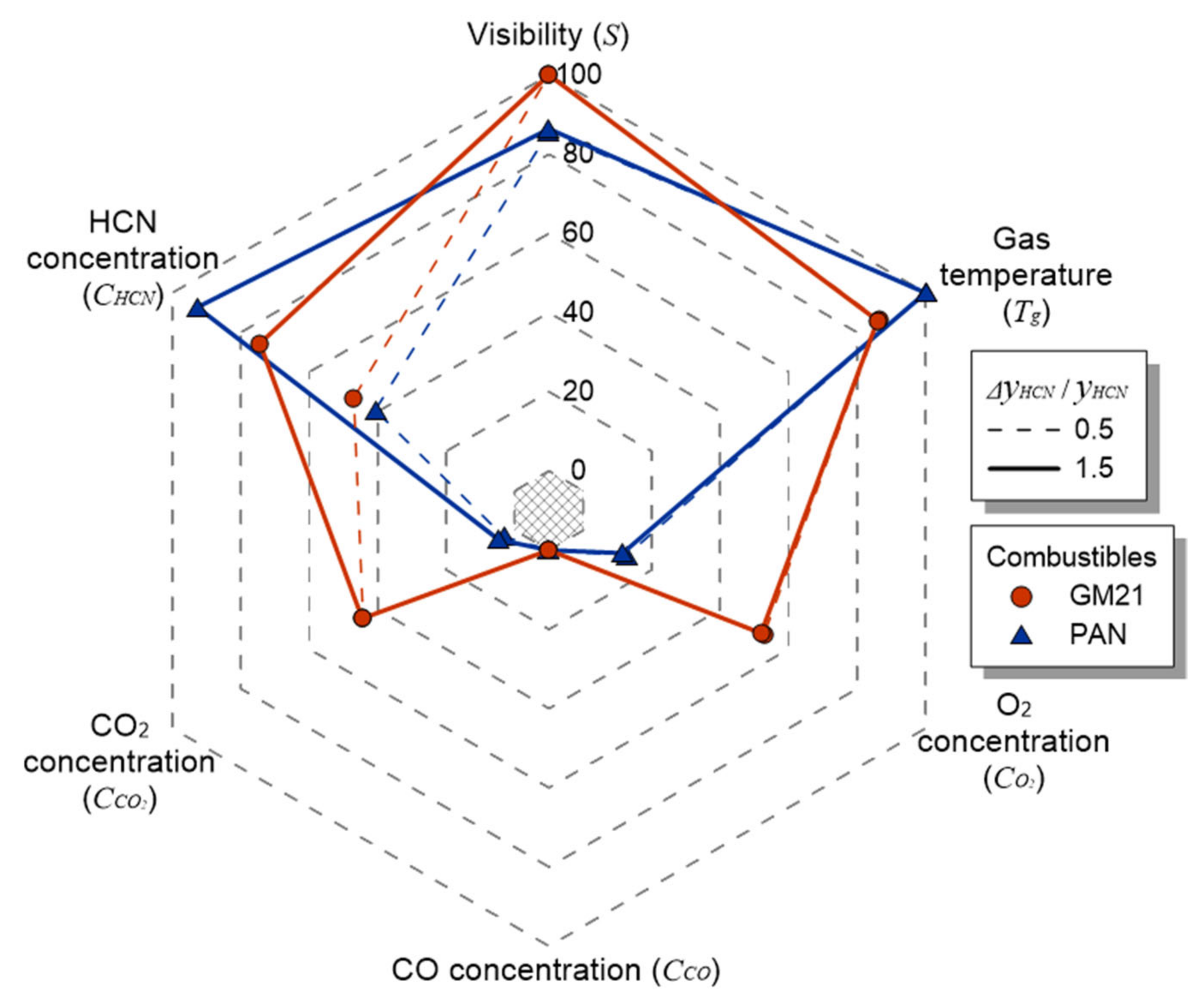

3.3. HCN Yield Sensitivity Analysis Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Beck, V.R. Performance-based Fire Engineering Design and Its Application in Australia. Fire Saf. Sci. 1997, 5, 23–40. [Google Scholar] [CrossRef][Green Version]

- Babrauskas, V.; Fleming, J.M.; Russell, B.D. RSET/ASET, A flawed concept for fire safety assessment. Fire Mater. 2010, 40, 738–755. [Google Scholar] [CrossRef]

- Han, H.S.; Mun, S.Y.; Hwang, C.H. Effects of User Dependence on the Prediction Results of Visibility in Fire Simulations. Korean Inst. Fire Sci. Eng. 2021, 35, 14–22. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Flo, J.; Wein, C.; Over, K. Fire Dynamics Simulator: Technical Reference Guide, NIST SP 1018-1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2022; p. 6. [Google Scholar]

- Karter, M.J., Jr. Fire Loss in the United States during 2013; Fire Analysis Research Division; National Fire Protection Association: Quincy, MA, USA, 2014. [Google Scholar]

- McKenna, S.T.; Hull, T.R. The fire toxicity of polyurethane foams. Fire Sci. Rev. 2016, 5, 3. [Google Scholar] [CrossRef]

- Terrill, J.B.; Montgomery, R.R.; Reinhardt, C.F. Toxic Gases from Fires. Science 1978, 200, 1343–1347. [Google Scholar] [CrossRef] [PubMed]

- Hartzell, G.E. Overview of Combustion Toxicology. Toxicology 1996, 115, 7–23. [Google Scholar] [CrossRef] [PubMed]

- Purser, D.A.; Grimshaw, P. The Incapacitative Effects of Exposure to the thermal decomposition products of polyurethane foams. Fire Mater. 1984, 8, 10–16. [Google Scholar] [CrossRef]

- Purser, D.A. Toxic product yields and hazard assessment for fully enclosed design fires. Polym. Int. 2000, 49, 1033–1265. [Google Scholar] [CrossRef]

- Mori, T. Toxicity Evaluation of Fire Effluent Gases from Experimental Fires in building. Fire Sci. 1976, 5, 248–271. [Google Scholar]

- Mori, T. Evaluation of Toxic Gases from Building Polymeric Materials in a Small-scale Box Model. Fire Mater. 1988, 12, 43–49. [Google Scholar] [CrossRef]

- National Standards of the Republic of Korea. Performance Based Design Methods and Standards on Fire-Fighting System Design Installation Act; National Fire Agency: Sejong-si, Republic of Korea, 2013; Annex 1, p. 3-a. [Google Scholar]

- Buchanan, A.H. Fire Engineering Design Guide; Centre for Advanced Engineering, University of Canterbury: Canterbury, New Zealand, 1994. [Google Scholar]

- Hurley, M.J.; Rosebaum, E.R. Performance-Based Design. In The SFPE Handbook of Fire Protection Engineering; National Fire Protection Association: Quincy, MA, USA, 2016; pp. 1233–1261. [Google Scholar] [CrossRef]

- Hadjisophocleous, G.V.; Bénichou, N. NRCC-43976, Development of performance-based codes performance criteria and fire safety engineering methods. Int. J. Eng. Perform. Based Fire Codes 2000, 2, 127–142. [Google Scholar]

- BSI, PD 7974-6; The Application of Fire Safety Engineering Principles to Fire Safety Design of Buildings Part 6: Human factors: Life Safety strategies—Occupant Evacuation, Behavior and Condition. British Standards: London, UK, 2004.

- Hartzell, G.E.; Emmons, H.W. The Fractional Effective Dose Model for Assessment of Toxic Hazards in Fires. J. Fire Sci. 1988, 6, 356–362. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; Floyd, J.; McDermott, R.; Vanella, M. Fire Dynamics Simulator: User’s Guide, NIST SP 1019; NIST: Gaithersburg, MD, USA, 2022; Volume 6. [CrossRef]

- Anderson, R.A.; Harland, W.A. Fire Deaths in the Glasgow Area: III the Role of Hydrogen Cyanide. Med. Sci. Law 1982, 22, 318–321. [Google Scholar] [CrossRef] [PubMed]

- He, Y. Evaluating visibility using FDS modeling result. In Proceedings of the Fire Safety Engineering International Conference, Melbourne, VIC, Australia, 18–19 March 2009. [Google Scholar]

- An, S.H.; Mun, S.Y.; Ryu, I.H.; Choi, J.H.; Hwang, C.H. Analysis on the Implementation Status of Domestic PBD (Performance Based Design)—Focusing on the Fire Scenario and Simulation. J. Korean Soc. Saf. 2017, 32, 32–40. [Google Scholar] [CrossRef]

- Purser, D.A. Combustion Toxicity. In The SFPE Handbook of Fire Protection Engineering; National Fire Protection Association: Quincy, MA, USA, 2016; Volume 5, pp. 2207–2307. [Google Scholar] [CrossRef]

- Orzel, R.A.; Womble, S.E.; Ahmed, F.; Brasted, H.S. Flexible Polyurethane Foam: A Literature Review of Thermal Decomposition Products and Toxicity. J. Am. Coll. Toxicol. 1989, 8, 1139–1175. [Google Scholar] [CrossRef]

- Hidalgo, J.P.; Torero, J.L.; Welch, S. Fire performance of charring closed-cell polymeric insulation materials: Polyisocyanurate and phenolic foam. Fire Mater. 2018, 42, 358–373. [Google Scholar] [CrossRef]

- Levin, B.C.; Paabo, M.; Fultz, M.L.; Bailey, C.S. Generation of Hydrogen Cyanide from Flexible Polyurethane Foam Decomposed under Different Combustion Condition. Fire Mater. 1985, 9, 125–134. [Google Scholar] [CrossRef]

- Witkowski, A.; Stec, A.; Hull, T.R. Thermal Decomposition of Polymeric Materials. In The SFPE Handbook of Fire Protection Engineering; National Fire Protection Association: Quincy, MA, USA, 2016; Volume 5, pp. 167–254. [Google Scholar] [CrossRef]

- Purser, D.A.; Purser, J.A. HCN Yields and Fate of Fuel Nitrogen for Materials under Different Combustion Conditions in the ISO 19700 Tube Furnace and Large-scale Fires. Fire Saf. Sci. 2008, 9, 1117–1128. [Google Scholar] [CrossRef]

- Stec, A.A.; Hull, T.R.; Lebek, K.; Purser, J.A.; Purser, D.A. The effect of temperature and ventilation condition on the toxic product yields from burning polymers. Fire Mater. 2008, 32, 49–60. [Google Scholar] [CrossRef]

- Purser, D.A.; Maynard, R.L.; Wakefield, J.C. Toxicology, Survival and Health Hazards of Combustion Products; Issues in Toxicology No. 23; The Royal Society of Chemistry: Cambridge, UK, 2015. [Google Scholar] [CrossRef]

- Bounagui, A.; Benichou, N.; McCartney, C.; Kashef, A. Optimizing the Grid Size Used in CFD Simulations to Evaluate Fire Safety in Houses. In Proceedings of the 3rd NRC Symposium on Computational Fluid Dynamics, High Performance Computing and Virtual Reality, Ottawa, ON, Canada, 4 December 2003. [Google Scholar]

- U.S. Nuclear Regulatory Commission (NRC); Electric Power Research Institute (EPRI). Verification and Validation of Selected Fire Models for Nuclear Power Plant Applications; NUREG-1824 and EPRI 3002002182, Final Report; U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2016.

- Han, H.S.; Hwang, C.H. Study on the Available Safe Egress Time (ASET) Considering the Input Parameters and Model Uncertainties in Fire Simulation. Korean Inst. Fire Sci. Eng. 2019, 33, 112–120. [Google Scholar] [CrossRef]

| Critical Criterion | Republic of Korea [13] | New Zealand [14] | Unite States of America [15,18] | Canada [16] | United Kingdom [17] | |

|---|---|---|---|---|---|---|

| Lower | Upper | |||||

| Layer Height | 1.8 m | 2.0 m | 2.5 m | - | 2.5 m | |

| Gas Temperature | 60 °C | 65 °C | 60 °C | 183 °C (Upper Layer) | 200 °C (Upper Layer) | 200 °C (Upper Layer) |

| * Visibility | 10 m 7 m 5 m | 5 m 10 m | - | 2 m 10 m | 3 m - | 5 m 10 m |

| O2 Concentration | 15% | 12% | FED ≤ 0.3 | 10% | 15% | FED ≤ 0.3 |

| CO2 Concentration | 5% | 5% | FED ≤ 0.3 | 5% | 6% | FED ≤ 0.3 |

| CO Concentration | 1400 ppm | 1400 ppm | FED ≤ 0.3 | 1400 ppm | 1700 ppm | FED ≤ 0.3 |

| HCN Concentration | - | 80 ppm | FED ≤ 0.3 | - | 80 ppm | - |

| HCl Concentration | - | - | 5 ppm | - | - | - |

| Combustibles | Formula | (kJ/kg) | (g/g) | (g/g) | (g/g) | |

|---|---|---|---|---|---|---|

| GM21 | CH1.8O0.3N0.05 | 3.19 | 26,200 | 0.010 | 0.131 | 0.0038 |

| PIR | C3H3O3N3 | 0.56 | 31,300 | 0.048 | 0.033 | 0.0030 |

| PAN | C3H3N | 2.26 | 30,800 | 0.039 | 0.025 | 0.0080 |

| Wool | C6H10O5 | 1.18 | 20,500 | 0.060 | 0.026 | 0.0010 |

| Output Quantity | ||

|---|---|---|

| HGL Temperature | 0.07 | 1.05 |

| Oxygen Concentration | 0.12 | 0.99 |

| Carbon Dioxide Concentration | 0.11 | 0.98 |

| Carbon Monoxide Concentration | 0.42 | 0.98 |

| Smoke Concentration | 0.59 | 2.57 |

| Species Concentration | 0.15 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, O.-S.; Han, H.-S.; Hwang, C.-H. Risk Assessment of Hydrogen Cyanide for Available Safe Egress Time in Fire Simulation. Appl. Sci. 2024, 14, 6890. https://doi.org/10.3390/app14166890

Kwon O-S, Han H-S, Hwang C-H. Risk Assessment of Hydrogen Cyanide for Available Safe Egress Time in Fire Simulation. Applied Sciences. 2024; 14(16):6890. https://doi.org/10.3390/app14166890

Chicago/Turabian StyleKwon, Oh-Soo, Ho-Sik Han, and Cheol-Hong Hwang. 2024. "Risk Assessment of Hydrogen Cyanide for Available Safe Egress Time in Fire Simulation" Applied Sciences 14, no. 16: 6890. https://doi.org/10.3390/app14166890

APA StyleKwon, O.-S., Han, H.-S., & Hwang, C.-H. (2024). Risk Assessment of Hydrogen Cyanide for Available Safe Egress Time in Fire Simulation. Applied Sciences, 14(16), 6890. https://doi.org/10.3390/app14166890