3.1. Sample Preparation and Testing Methods

(1) Sample preparation

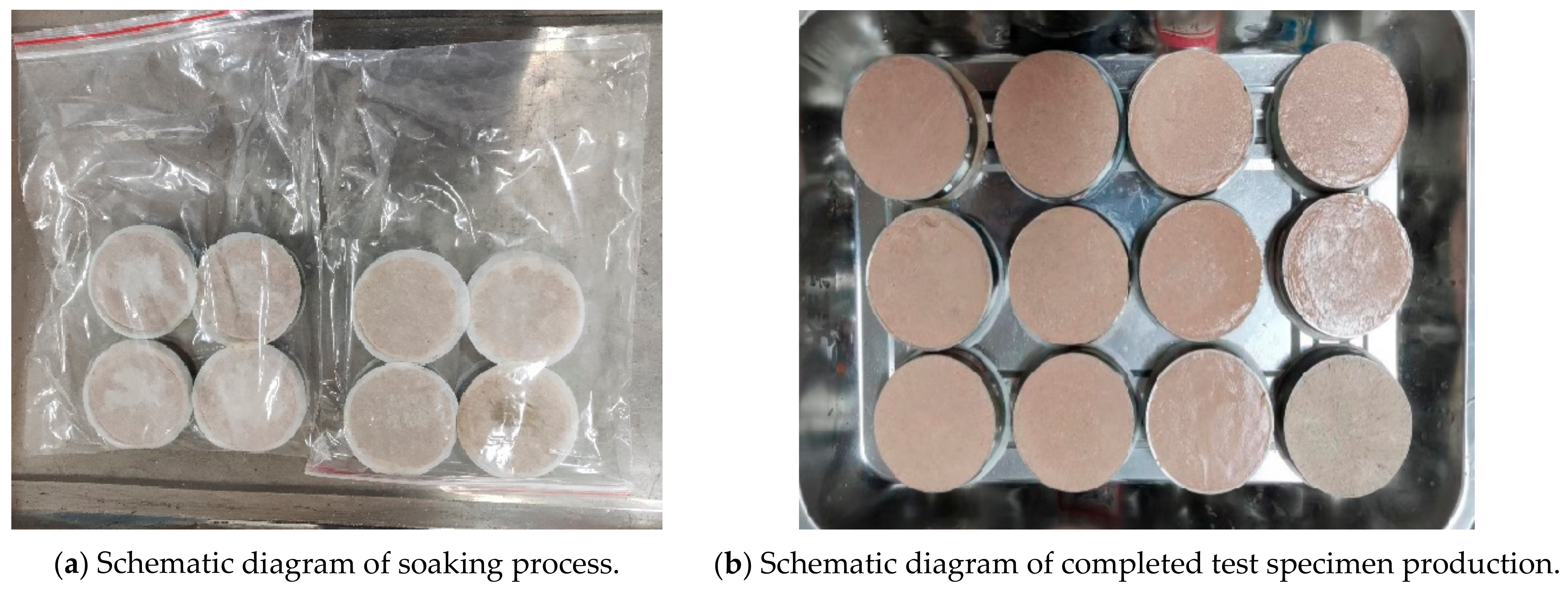

In the domain of geotechnical engineering, the ring shear specimen stands out as the preeminent choice for testing due to its straightforward preparation and the availability of diverse testing and detection apparatus. Consequently, the current study employs ring shear samples for the indoor wet–dry cycle experiments on expansive soils, which are specified to have a diameter of 61.8 mm. The thickness of these samples is determined based on the stipulations of the experimental protocol. Two types of expansive soil samples were used in the test: medium-expansivity soil and strong-expansivity soil. The initial dry density of the strong-expansivity soil sample is 1.2 g/cm3, with an initial saturation of 48.7%. The medium-expansivity soil sample has an initial dry density of 1.4 g/cm3 and an initial saturation of 46.4%. The reconstituted expansive soil ring knife samples were prepared as follows:

- 1.

Start by drying the expansive soil samples obtained from the sampling point in an oven;

- 2.

After drying, crush the soil samples using a soil crusher and pass them through a 1 mm sieve;

- 3.

Transfer the crushed and sieved expansive soil into a plastic bag and calculate the required amount of water based on the initial moisture content specified in the test design;

- 4.

As per the experimental specifications, uniformly distribute the dried expanded soil onto the container tray. Apply Vaseline to the basin of the stainless steel container to prevent it from constraining crack development at the bottom of the test block. Then, gradually and uniformly add water using a small spray bottle until reaching the predetermined value, ensuring thorough mixing with the soil. Following configuration, seal the sample in a plastic bag for 48 h to guarantee consistent moisture distribution, as depicted in

Figure 3;

- 5.

Once the soaking process is complete, take an appropriate amount of soil sample and pour it into the ring knife. Compact it with a weight and prepare the expansive soil ring knife samples with different compaction degrees and thicknesses according to the test design plan.

(2) Experimental design and methodology

The objective of this section is to investigate the characteristics of crack development in expansive soil samples under wet–dry cycles, taking into account different initial moisture contents, compaction degrees, and thicknesses.

Table 2 presents the physical parameters of the expansive soil samples under various influencing factors. The compaction degree of the expansive soil subgrade is typically maintained between 90% and 96% to ensure safe and comfortable driving conditions. However, achieving a compaction degree of over 90% under high-moisture-content conditions is challenging. Therefore, for the indoor wet–dry cycle test in this study, compaction degrees of 80% and 90% were chosen. Given that shallow instability predominantly contributes to the instability of expansive soil slopes, especially during periods of rainfall when the soil in these shallow slopes tends to be saturated, expansive soil specimens are saturated using a vacuum saturation apparatus.

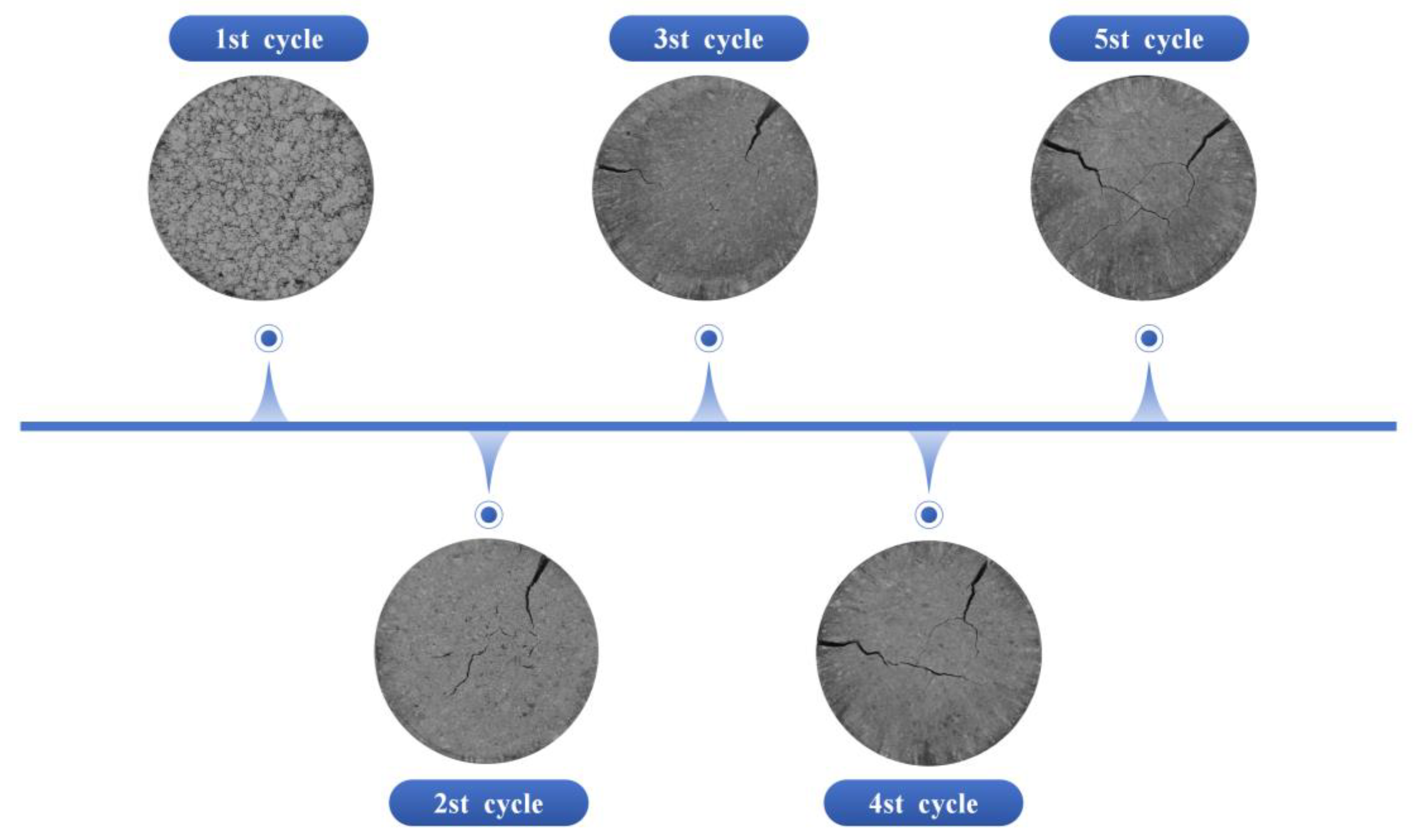

The specific steps of the wet–dry cycle test are as follows: First, the expansive soil samples sealed in plastic bags are placed in a constant temperature oven for drying. The oven temperature is set to 35 °C based on the meteorological data of the soil collection site on the Chong’ai Expressway in Guangxi. Regularly measure the samples’ weight to determine changes in moisture content. Considering that the shrinkage limit moisture content of the expansive soil specimens employed in this study is 12%, further data recording ceases once the moisture content falls below this threshold. Consequently, soil shrinkage becomes notably challenging at this juncture, with crack formation essentially halting, marking the conclusion of a single dry cycle process. Subsequently, utilize a digital camera to capture photographs of the samples’ surface and sides. Then, reassemble the samples within a ring cutter, with permeable paper and a 5 mm-thick permeable stone placed both above and below the samples. Secure the assembly using a G-clamp and subsequently subject it to saturation by placing it in a vacuum saturation device. Finally, after maintaining the samples under constant conditions for 24 h and completing the saturation process, remove them and position them back in the drying oven. Capture additional photographs when the moisture content reaches approximately 12%, marking the beginning of the second dry–wet cycle. Repeat these steps for the third to fifth dry–wet cycles. Ultimately, the diagram depicting the change in crack morphology, as illustrated in

Figure 4, is acquired.

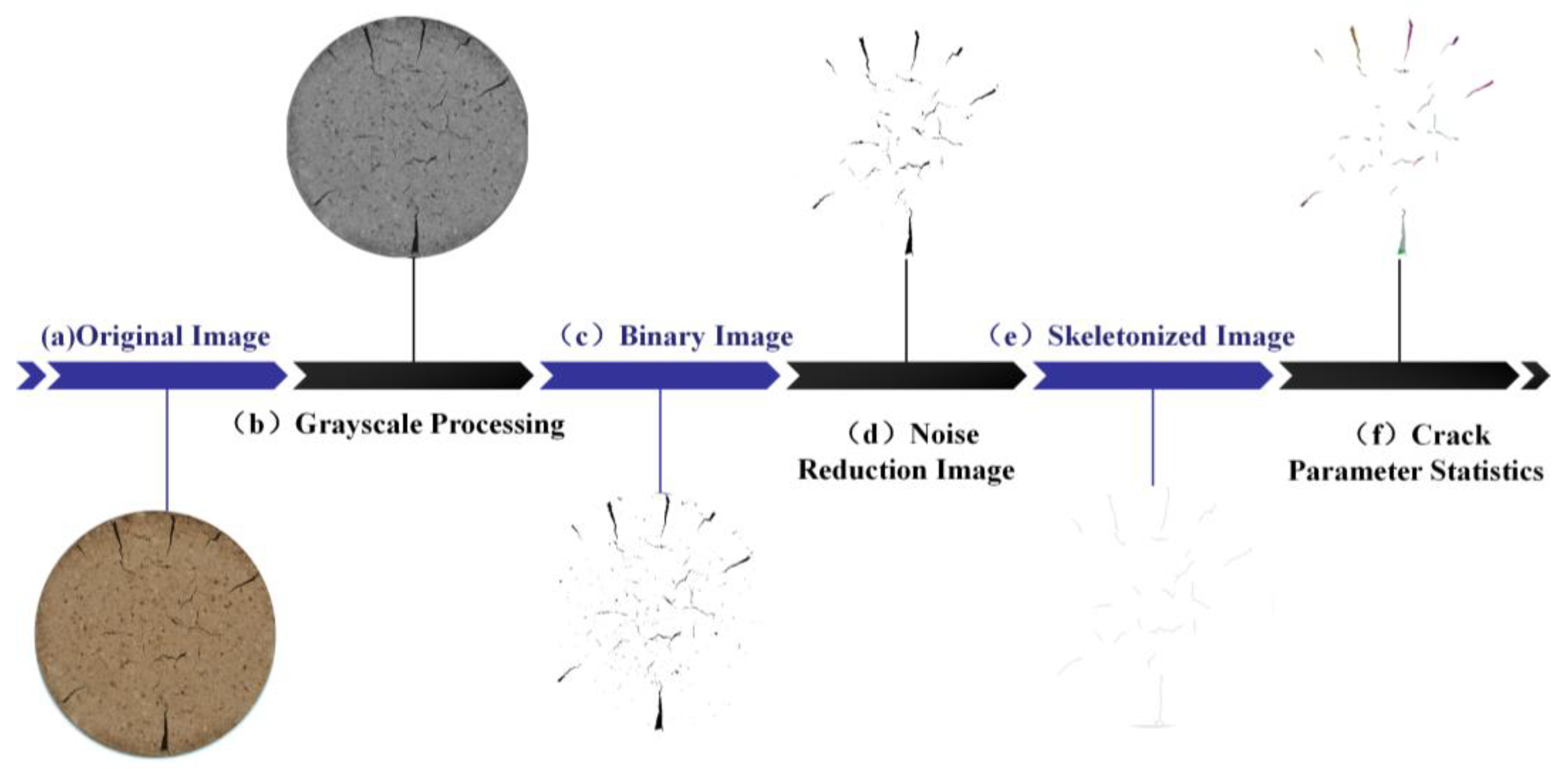

(3) Crack image processing

Digital imaging was employed to quantitatively characterize the development of cracks in expansive soil specimens. The specific procedure is outlined as follows:

- 1.

Initially, the RGB color image was grayscaled using Photoshop software (V13.0.1.3), with the grayscale value typically set to 0 or 255;

- 2.

Subsequently, the grayscale image was imported into PCAS crack image analysis and processing software for binary image processing (

Figure 5c);

- 3.

The denoising function of the PCAS software (V2.3) was then utilized to remove noise from the binary image (

Figure 5d);

- 4.

Subsequently, crack skeletonization processing was performed (

Figure 5e).

The crack ratio represents the aggregate of crack areas per unit area of soil [

27], determined through image processing. Specifically, it denotes the ratio of black cracks in binarized images of expansive soil samples to the entire image. The precise calculation formula is presented below:

In the equations, Ai and A denote the area of the ith crack and the sample area, respectively, while nb and nw represent the counts of black and white pixels, and n signifies the total number of pixels.

During crack length computation, the software automatically categorizes cracks into three groups—horizontal, vertical, and diagonal lines, with horizontal and vertical lines standardized to a length of 1 unit each, and diagonal lines treated as individual units. Subsequently, upon gathering and categorizing all cracks within the image, the lengths of the three types of cracks are summed to determine the total crack length.

The average width of cracks is represented by the ratio of the total crack area to the total crack length. The specific calculation is as follows:

In the equation above, li denotes the length of the ith crack, while the remaining parameters carry the same significance as in Equation (1).

3.2. Experimental Results and Analysis

(1) The Influence of Dry–Wet Cycle Number on Crack Development Characteristics

Expansive soil exhibits significant shrinkage and swelling effects during repeated cycles of water absorption and loss, resulting in noticeable volume changes and the continuous extension of cracks on the soil surface due to uneven deformation. For this experiment, a total of five dry–wet cycles were performed to examine the changes in fundamental crack characteristics in samples of moderately to highly expansive soil. Taking the crack development characteristics of samples of medium to highly expansive soil with 35% initial moisture content and an 80% compaction degree as examples, the influence of the dry–wet cycle number on crack development characteristics in expansive soil has been analyzed.

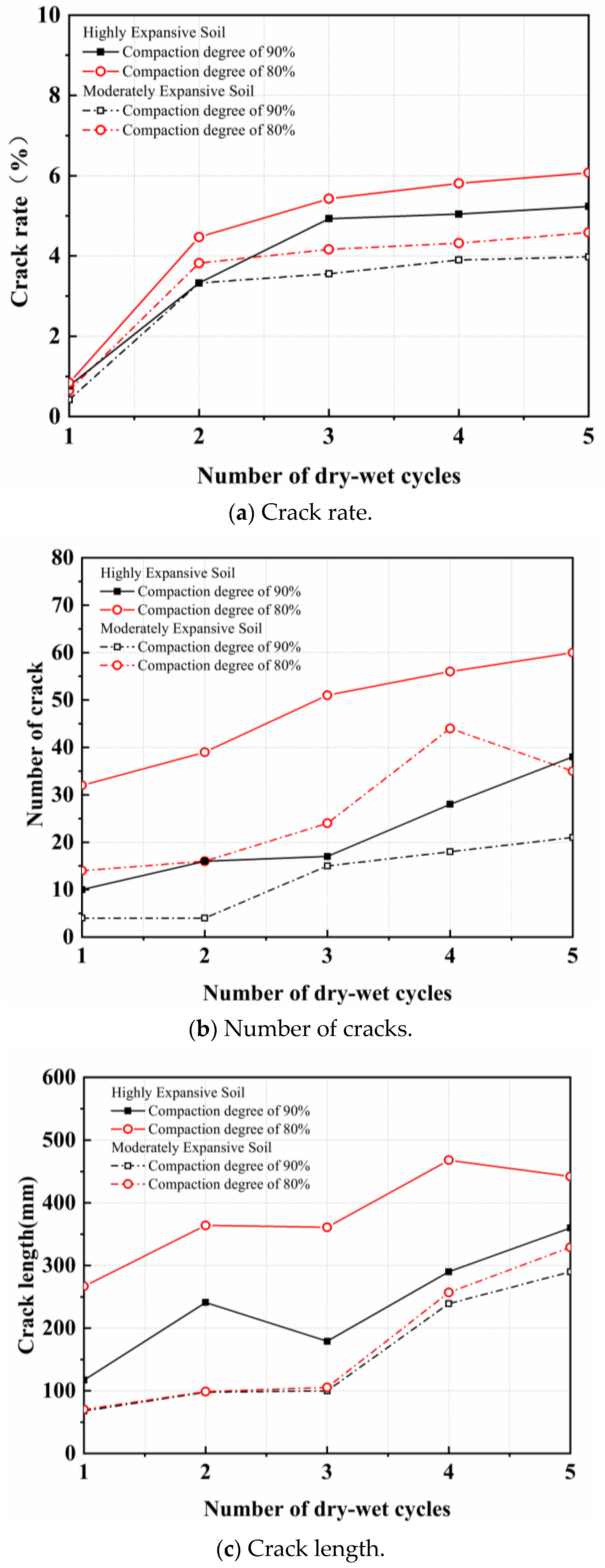

Figure 6a shows the variation curve of the ratio of crack area to sample area in samples of medium to highly expansive soil with respect to the dry–wet cycle number. The results indicate that, for different types of expansive soil, the crack ratio initially increases and then reaches stability with an increasing number of dry–wet cycles. After the first cycle, the crack ratios for the samples of medium and highly expansive soil are only 0.7% and 0.8%, respectively, indicating the absence of observable cracks or damage on the soil surface during the initial cycle. After the second cycle, the crack ratio for the samples of medium and highly expansive soil rapidly rises to 3.8% and 4.5%, respectively. Following the fifth dry–wet cycle, the crack ratios for the samples of medium expansive soils reach 4.6%, representing a 20% increase compared to the end of the second cycle. In contrast, the crack ratio for the samples of highly expansive soil exhibits a more pronounced response to the dry–wet cycle number, reaching 6.08% after the fifth cycle, which corresponds to a 35.9% increase compared to the end of the second cycle. Compared to the highly expansive soil samples, crack development in the medium expansive soil is less sensitive to the dry–wet cycle number, indicating that the influence of cycle number on crack development gradually diminishes after the third cycle. Under the same cycle conditions, the crack ratio for the highly expansive soil continues to increase in subsequent cycles, but with a decreasing rate.

Since the crack ratio represents the ratio of total crack area to sample area, it can yield the same result for different combinations of crack numbers, lengths, and widths. Therefore, the variations of the total crack numbers, lengths, and average widths on the soil surface in samples of medium to highly expansive soil under different dry–wet cycle numbers were monitored and analyzed.

Figure 6b shows the variation curves of the total crack numbers in medium to highly expansive soil samples with respect to the dry–wet cycle number. The results demonstrate that the surface crack numbers of the medium expansive soil samples remain stable after the first and second cycles, then increase rapidly to 44 after the fourth cycle and decrease to 35 after the fifth dry–wet cycle. In contrast, the highly expansive soil samples accumulate 32 cracks after the initial dry–wet cycle, which number steadily increases with the cycle number, reaching 60 by the end of the fifth cycle.

Figure 6c presents the variation curves of the total crack lengths on the soil surface in samples of medium to highly expansive soil with respect to the dry–wet cycle number. The results show an overall increasing trend in the total length of cracks on the soil surface with the dry–wet cycle number. Specifically, the total crack length of the medium expansive soil samples rapidly increases after the third cycle, rising from 99.9 mm to 290 mm after the fifth cycle. In contrast, the total crack length of the highly expansive soil samples remains relatively constant after the second and third cycles, but continues to increase in subsequent dry–wet cycles, reaching 442 mm.

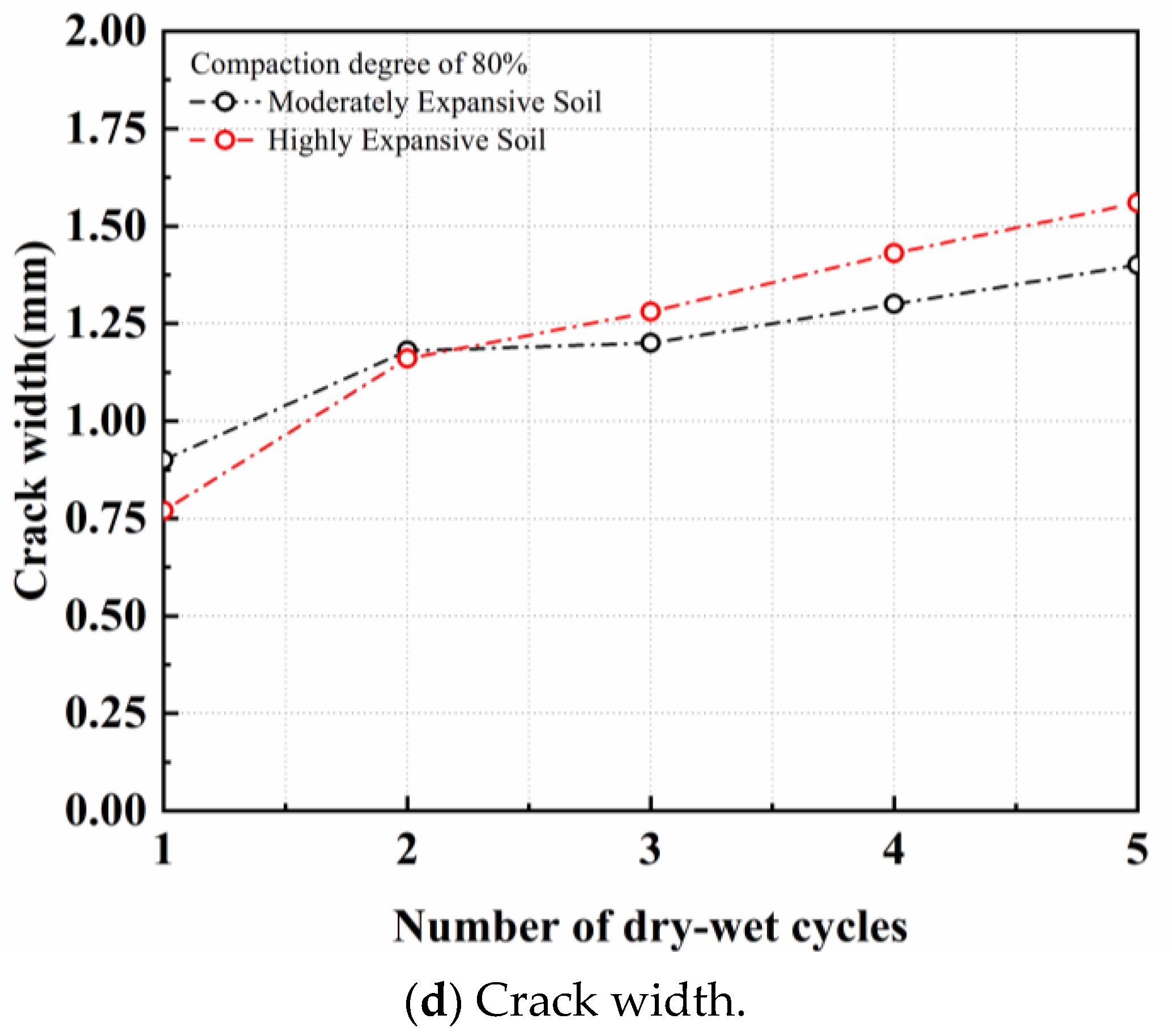

Figure 6d shows the variation curve of the average crack width on the soil surface in samples of medium to highly expansive soil with respect to the dry–wet cycle number. The results demonstrate that the average crack width increases with an increasing number of dry–wet cycles in both the medium and highly expansive soil samples. Specifically, the average crack width of the medium expansive soil samples increases from 0.9 mm to 1.4 mm, while the average crack width of the highly expansive soil samples increases from 0.8 mm to 1.6 mm. This phenomenon indicates that cracks on the sample surface expand continuously as a result of repeated tension and healing during the drying–shrinkage–wetting–expansion process, leading to an increasing width of surface cracks as the cracks extend deeper.

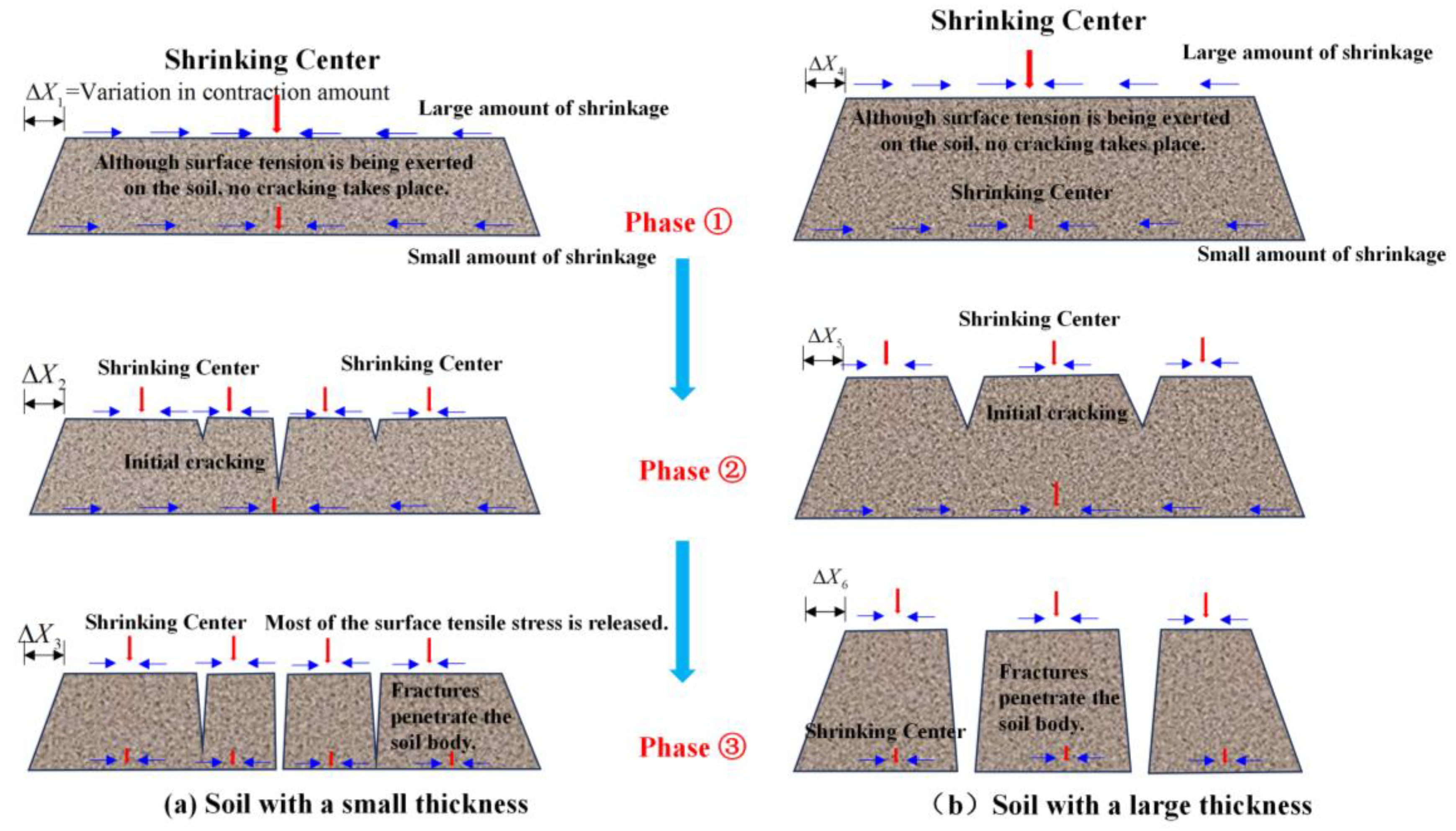

Based on the evolution of the cracks’ basic morphological parameters with the number of dry–wet cycles, it is evident that the crack ratio of the expansive soil tends to stabilize as the number of dry–wet cycles increases. This observation suggests that the degree of crack development in the soil gradually decreases under the influence of moisture variations following multiple dry–wet cycles. During the heating and dehydration process of the samples, the surface soil loses water at a significantly faster rate than the interior soil, resulting in notable moisture content gradients across different parts of the samples. Consequently, this lack of coordination or constraint in the deformation between the surface and interior soil generates corresponding tensile stresses within the soil. If the tensile strength provided by the soil is smaller than the tensile stress caused by moisture loss, stress concentration is released in the surrounding area of the developing crack, leading to the occurrence of tensile cracks in the expansive soil. The repeated process of cracking–closing–cracking during multiple dry–wet cycles causes the crack to continuously expand, ultimately resulting in the formation of interconnected multiple cracks. At this point, the sample has been completely fragmented into different-sized soil blocks, and the influence of dry–wet cycles on the development of cracks in the expansive soil gradually weakens. This observation aligns with the trend demonstrated by the experimental results, where the total number of cracks, total length, and width increases with the number of dry–wet cycles.

(2) The Impact of Initial Moisture Content on Crack Development Characteristics

Figure 7 presents the variation curves of basic crack parameters of expansive soil specimens with different initial moisture contents under different dry–wet cycling conditions. As shown in

Figure 7a, the crack ratios of different initial moisture content expansive soil specimens show an increasing trend followed by stabilization with the increase in dry–wet cycling times. The crack ratio of medium-expansion soil specimens exhibits obvious differences under different initial moisture content conditions, increasing with the increase in initial moisture content. After the first dry–wet cycle, the crack ratio of medium-expansion soil specimens with an initial moisture content of 30% is only 52.9% of that with an initial moisture content of 40%. With the increase in dry–wet cycling times, the difference between the two gradually decreases. After the fifth dry–wet cycle, the crack ratio of the latter only increases by 16% compared to the former. For high-expansion soil, the influences of different initial moisture contents on the crack ratios of specimens are relatively complex. Among them, the crack ratio variation curves of high-expansion soil specimens with an initial moisture content of 30% and 35% almost overlap, while the crack ratios of specimens with an initial moisture content of 40% significantly increase compared to the former two. This phenomenon indicates that the influence of initial moisture content on the crack ratio of expansive soil under multiple dry–wet cycling conditions is affected by its own expansibility. For medium-expansion soil, an increase in initial moisture content will enhance the soil’s shrinkage and swelling characteristics. In contrast, for high-expansion soil, the influence of initial moisture content on its shrinkage and swelling characteristics can only be observed when the initial moisture content is above 35%.

Figure 7b shows the variation curves of the total number of cracks of different initial moisture content expansive soil specimens under different dry–wet cycling conditions. The total number of cracks of both medium- and high-expansion soil specimens increases with the increase in dry–wet cycling times. Among them, the total number of cracks in medium-expansion soil specimens is not strongly correlated with the initial moisture content, and the total number of cracks is basically the same under different initial moisture content conditions. The total number of cracks in high-expansion soil specimens is more sensitive to changes in initial moisture content. After the first dry–wet cycle, the total number of cracks in high-expansion soil specimens with initial moisture contents of 30% and 40% are 23 and 36, respectively. After the fifth dry–wet cycle, the total numbers of cracks in the two specimens become 42 and 80. This phenomenon indicates that the higher the initial moisture content, the greater the total number of cracks, and the difference in the total number of cracks becomes more significant with the increase in cycling times.

Figure 7c shows the variation curve of the total length of cracks of different initial moisture content expansive soil specimens under different dry–wet cycling conditions. The total length of cracks in both medium- and high-expansion soil specimens generally increases with the increase in initial moisture content. The difference in the influence of initial moisture content on the total length of cracks in medium-expansion soil specimens gradually decreases with the increase in dry–wet cycling times. The total lengths of cracks in high-expansion soil specimens under initial moisture content conditions of 35% and 30% are relatively similar, and tend to stabilize after the second dry–wet cycle. The total length of cracks in high-expansion soil specimens with an initial moisture content of 40% is significantly higher compared to the other two groups of specimens, and continues to increase with the increase in dry–wet cycling times.

Figure 7d shows the variation curve of the average width of cracks of different initial moisture content expansive soil specimens under different dry–wet cycling conditions. The results indicate that the average width of cracks in expansive soil specimens is significantly influenced by the initial moisture content. When the initial moisture content is higher than 35%, the average width of cracks is significantly increased compared to specimens with an initial moisture content of 30%. The average width of cracks in high-expansion soil specimens is more sensitive to changes in dry–wet cycling times, and shows an overall increasing trend. Under multiple dry–wet cycling conditions, the average width of cracks in medium-expansion soil specimens changes relatively less, especially for specimens with an initial moisture content of 30%, maintaining a range of 0.47–0.74 mm.

Based on the evolution of basic crack parameters of medium- and high-expansion soil specimens with different initial moisture contents under multiple dry–wet cycling conditions, it can be concluded that as the initial moisture content decreases, the crack distribution of specimens tends to become simpler, and the crack ratio, quantity, and geometric dimensions decrease. From a microscopic perspective, the binding water film between clay particles in expansive soil with a higher initial moisture content is relatively thick, and the free water content increases. During the dehydration process, more significant water loss occurs, resulting in volume shrinkage. From a macroscopic perspective, in the process of crack development caused by the dehydration of expansive soil, the increase in initial moisture content directly leads to a larger gradient difference between the surface area and the internal moisture content after water loss. This leads to more significant uneven shrinkage and confinement in the depth direction, accelerates crack development and extension, and causes more obvious crack damage in specimens. This result is consistent with previous research findings.

(3) The effect of compaction level on crack development characteristics

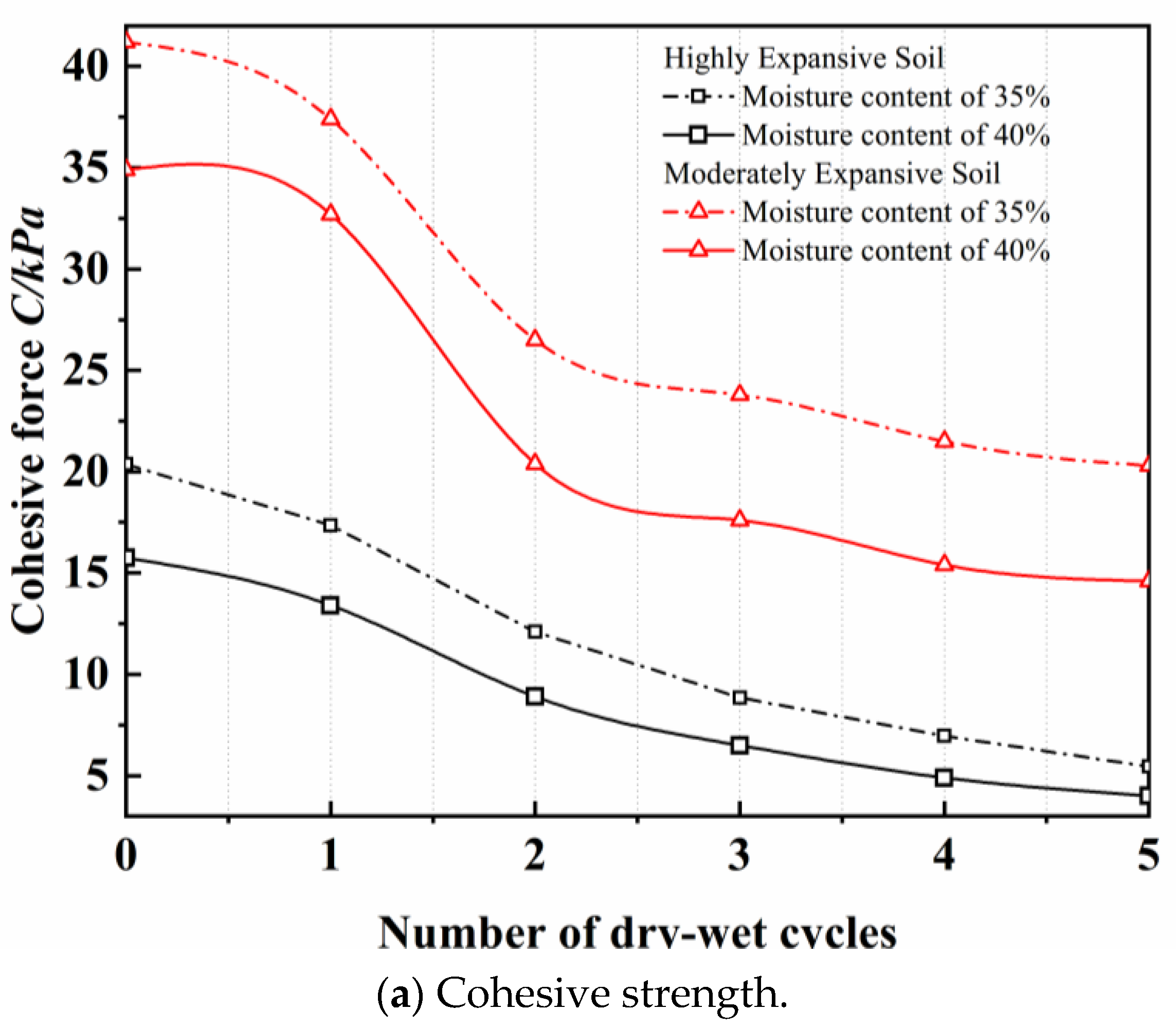

Figure 8 illustrates the variation curves of the fundamental crack morphological parameters of various compacted expansive soil specimens under different dry–wet cycling conditions. The figure indicates that increased compactness leads to a decrease in the crack ratio, total crack count, total crack length, and average crack width of the expansive soil specimens. Additionally, the range of variation in the basic crack morphological parameters decreases with increasing compactness under multiple dry–wet cycles, suggesting that compactness imposes restrictions on the shrinkage and swelling characteristics of the expansive soil (

Figure 8a). For example, the crack ratio difference between specimens with 90% and 80% compactness ranges from 0.23% to 0.61%. This influence of compactness on the crack ratio is most noticeable in highly expansive soil samples, with crack ratios after the second dry–wet cycle reaching 4.47% and 3.33%, respectively, for specimens with 80% and 90% compactness, indicating a difference of over 1%. Furthermore, the impacts of different compactness levels on the crack ratio stabilize as the number of dry–wet cycles increases, primarily due to the self-expansive nature of the soil samples.

Figure 8b demonstrates the variation curves of the total crack counts of different compacted expansive soil specimens with the number of dry–wet cycles. Unlike the crack ratio, compactness significantly influences the total crack count. In comparison to the specimen with 80% compactness, taken as the reference value, increasing compactness by 10% results in a reduction in the total crack count of moderately expansive soil samples varying from 37.5% to 71.4%, and the decrease is from 36.7% to 68.8% for highly expansive soil samples. With 80% compactness, the total crack count generally increases with the number of dry–wet cycles for moderately and highly expansive soil samples. In contrast, the variation in total crack count of specimens with 90% compactness after the first and second dry–wet cycles is insignificant, indicating that increasing compactness limits the generation and extension of cracks in the expansive soil samples (

Figure 8c). The total crack length of moderately expansive soil samples is minimally affected by compactness, with noticeable differences observed only after multiple dry–wet cycles. In contrast, the total crack length of highly expansive soil doubles under 80% compactness compared to 90% compactness. The number of dry–wet cycles affects the average crack width of the soil samples in relation to compactness. The crack width of the 80% compactness specimen is significantly higher than that of the 90% compactness specimen, with the former being more than 1.5 times higher. As the number of dry–wet cycles increases, the difference in average crack width between the two specimens gradually grows, indicating that decreased compactness intensifies the enhancement of the shrinkage and swelling characteristics of the expansive soil during multiple water absorption and desorption processes.

During the preparation of expansive soil samples with varying compaction levels, increased compaction results in the greater fragmentation of larger soil particles, thereby compromising the soil’s structural integrity. The resultant fine particles from this fragmentation efficiently fill soil pores, thereby diminishing the sample’s porosity. Microscopically, this reduction in porosity constricts the pathways for free water flow within the soil, curtailing the capacity for volumetric expansion. Macroscopically, the lowered porosity impedes water infiltration during absorption and wet cycling, thereby dampening the soil’s propensity to absorb water and swell. Additionally, it diminishes the gradient in moisture content from the sample’s surface to its core, leading to a more uniform distribution of tensile stresses throughout the soil mass. This uniformity in stress distribution, in turn, restricts the propagation and expansion of cracks.

(4) The impact of thickness on the characteristics of crack development

To investigate the effect of thickness on crack development in expansive soil, specimens of medium and highly expansive soil were prepared with thicknesses of 1 cm, 2 cm, 3 cm, and 4 cm. The crack development characteristics of the specimens were analyzed after multiple dry–wet cycles.

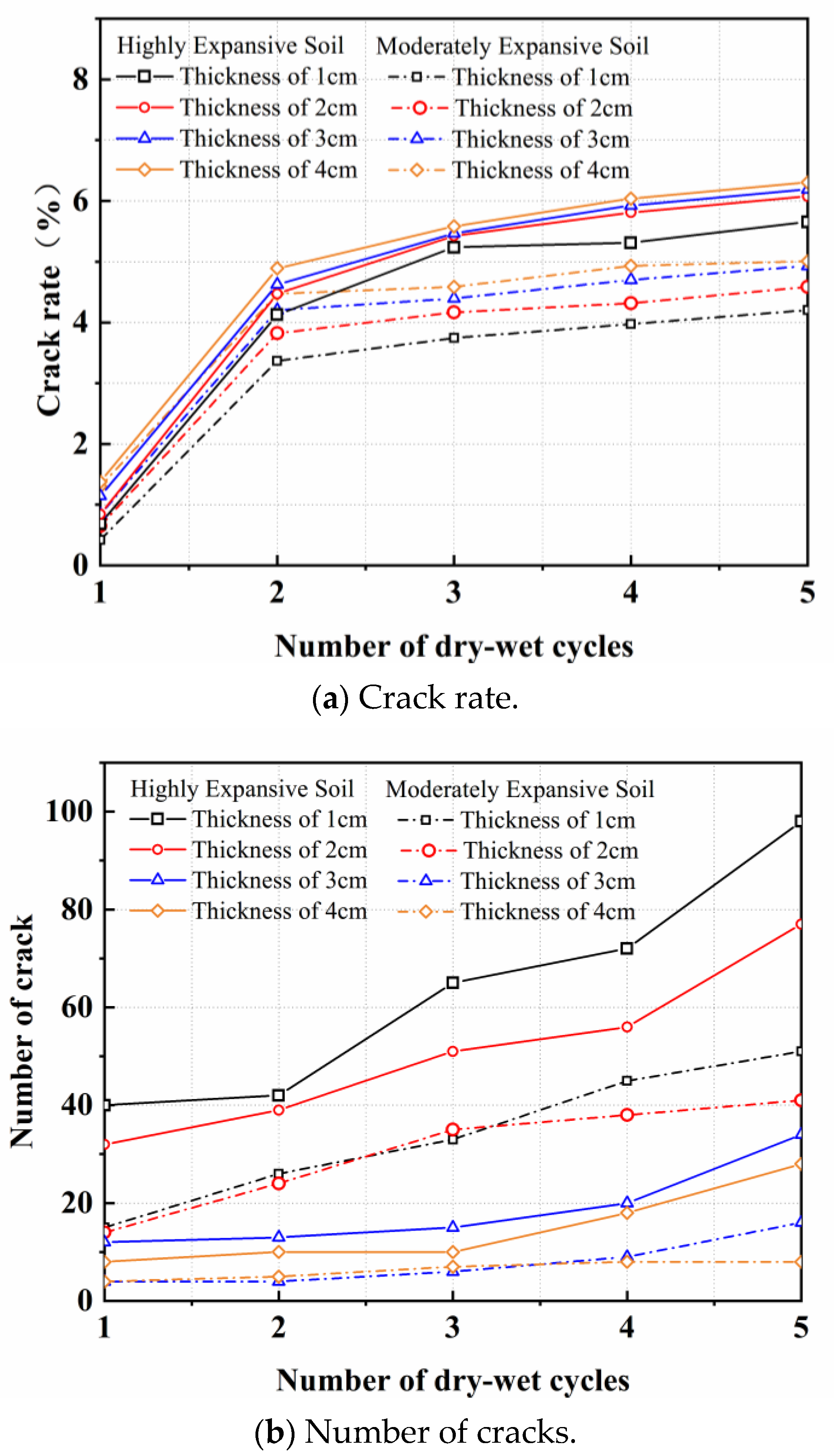

Figure 9 illustrates the curves of the basic morphological parameters of the cracks.

Figure 9a displays the crack ratio variation with the number of dry–wet cycles for different thicknesses of expansive soil specimens. The results demonstrate that thicker specimens exhibit higher crack ratios. The influence of thickness on the crack ratio is relatively small under different dry–wet cycle conditions. The crack ratio of the highly expansive soil specimens remains between 5.65% and 6.3%, while for the medium expansive soil specimens, it ranges from 4.2% to 5%. After five dry–wet cycles, the final crack ratio of the 4 cm-thick specimens is 6.3% (for the highly expansive soil) and 5% (for the medium expansive soil). In contrast, the final crack ratio of the 1 cm-thick specimens is 5.65% (for the highly expansive soil) and 4.2% (for the medium expansive soil). This represents an increase of 10.3% and 16% in crack ratio, respectively. The crack ratio represents the ratio of the crack area to the total area of the specimen. Analyses of experimental data reveal that thickness does influence the development of cracks in expansive soil; however, the exact nature and extent of this influence are not readily apparent. This phenomenon is primarily attributed to the specimen size effect and the imposed maximum thickness of 4 cm under experimental conditions.

Figure 9b,c depict the variations of total crack length and total number of cracks with the number of dry–wet cycles for different thicknesses. The results indicate that, with increasing thickness, the total crack length decreases while the total number of cracks increases. The final total crack lengths of the 1 cm-thick specimens of medium and highly expansive soil are 341.4 mm and 634 mm, respectively. On the other hand, the final total crack lengths of the 4 cm-thick specimens of medium and highly expansive soil are 160.8 mm and 193 mm, respectively. The final total numbers of cracks in the 1 cm-thick specimens of medium and highly expansive soil are 51 and 98, respectively. In contrast, the final total numbers of cracks for the 4 cm-thick specimens of medium and highly expansive soils are 8 and 28, respectively. This phenomenon suggests that samples with smaller thickness have more divided soil blocks and larger total crack lengths during the dry–wet cycle process.

Figure 9d shows the variation in average crack width with the number of dry–wet cycles for different specimen thicknesses. The average crack width reflects the extent of crack opening in expansive soil during the influence of dry–wet cycles. The curve demonstrates that the crack width increases with increased thickness. The average crack widths of the 4 cm-thick specimens of medium and highly expansive soil are 1.77 mm and 3.7 mm, respectively. In contrast, the average crack widths of the 1 cm-thick specimens of medium and highly expansive soil are only 0.78 mm and 1.39 mm, respectively. There are significant differences in average crack width among different thicknesses. This phenomenon indicates that thickness noticeably influences the width development of cracks in expansive soil, with an increase in thickness promoting crack widening.

The influence of specimen thickness on the crack development characteristics of expansive soil samples is relatively complex. Generally, an increase in thickness leads to a decrease in the total number and length of cracks, while the crack ratio and average crack width of the specimens increase. With an increase in specimen thickness, the influences of boundary effects on volume deformation become more apparent. The water loss shrinkage process mainly occurs at the surface of the specimens, and thicker specimens face more difficulty in evaporating moisture, which inhibits crack development and expansion to some extent. Meanwhile, existing cracks provide fast flow channels for rainwater infiltration and evaporation, and the repeated dry–wet cycles further intensify the transverse expansion of cracks, resulting in an upward trend in average crack width with increased specimen thickness.

Analysis indicates that the initial moisture content, compaction level, and thickness significantly affect the development of cracks in expansive soil. Higher initial moisture content, lower compaction, and reduced thickness correlate with enhanced crack development, aligning with previous studies [

11,

12,

21]. This research further explores the intricate evolution of cracks under the influence of multiple factors (initial water content, thickness, compaction degree, and the number of different wet–dry cycles) during repetitive wet–dry cycles, revealing a more complex pattern of crack progression.