Heat Transfer Performance and Operation Scheme of the Deeply Buried Pipe Energy Pile Group

Abstract

1. Introduction

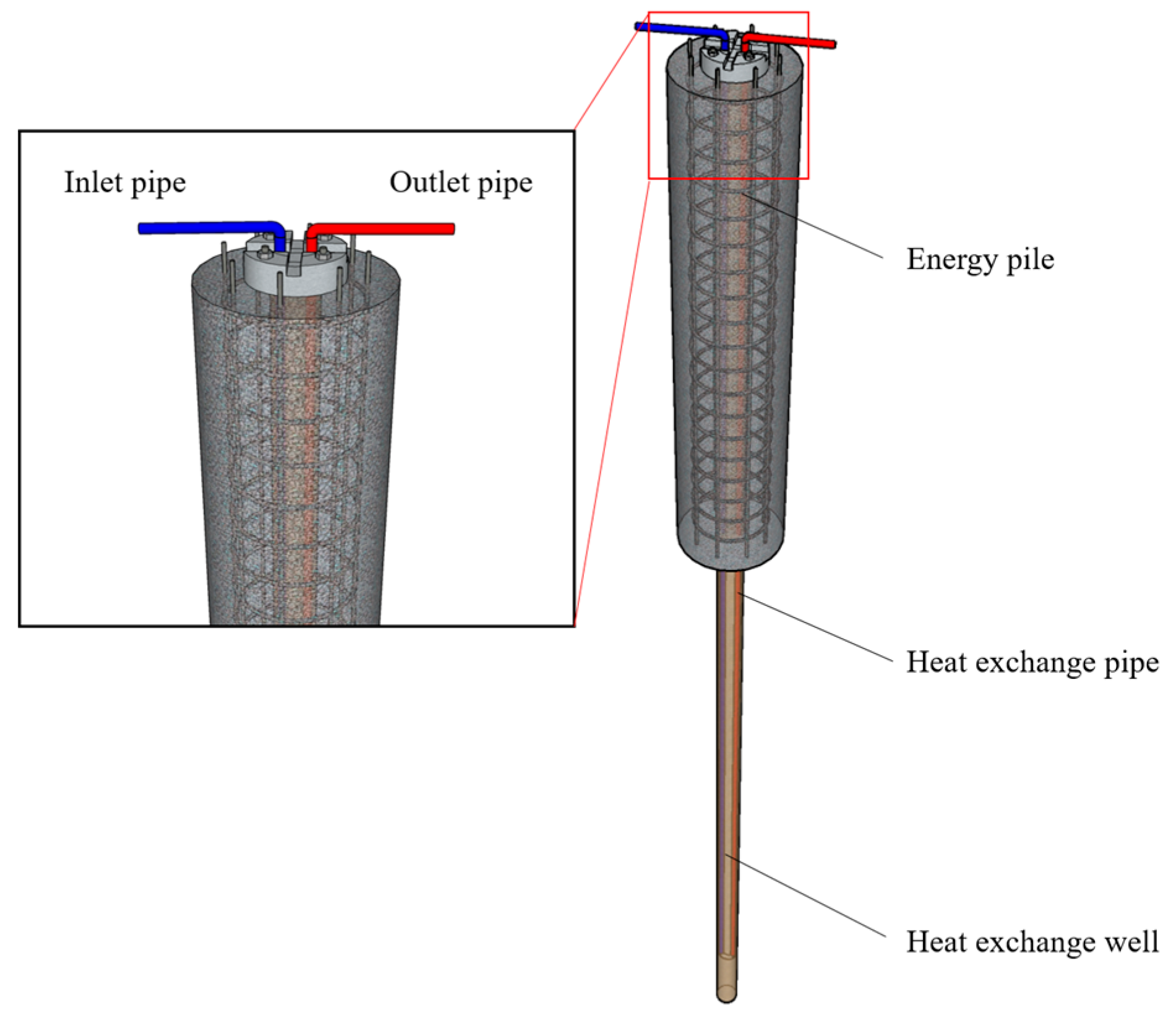

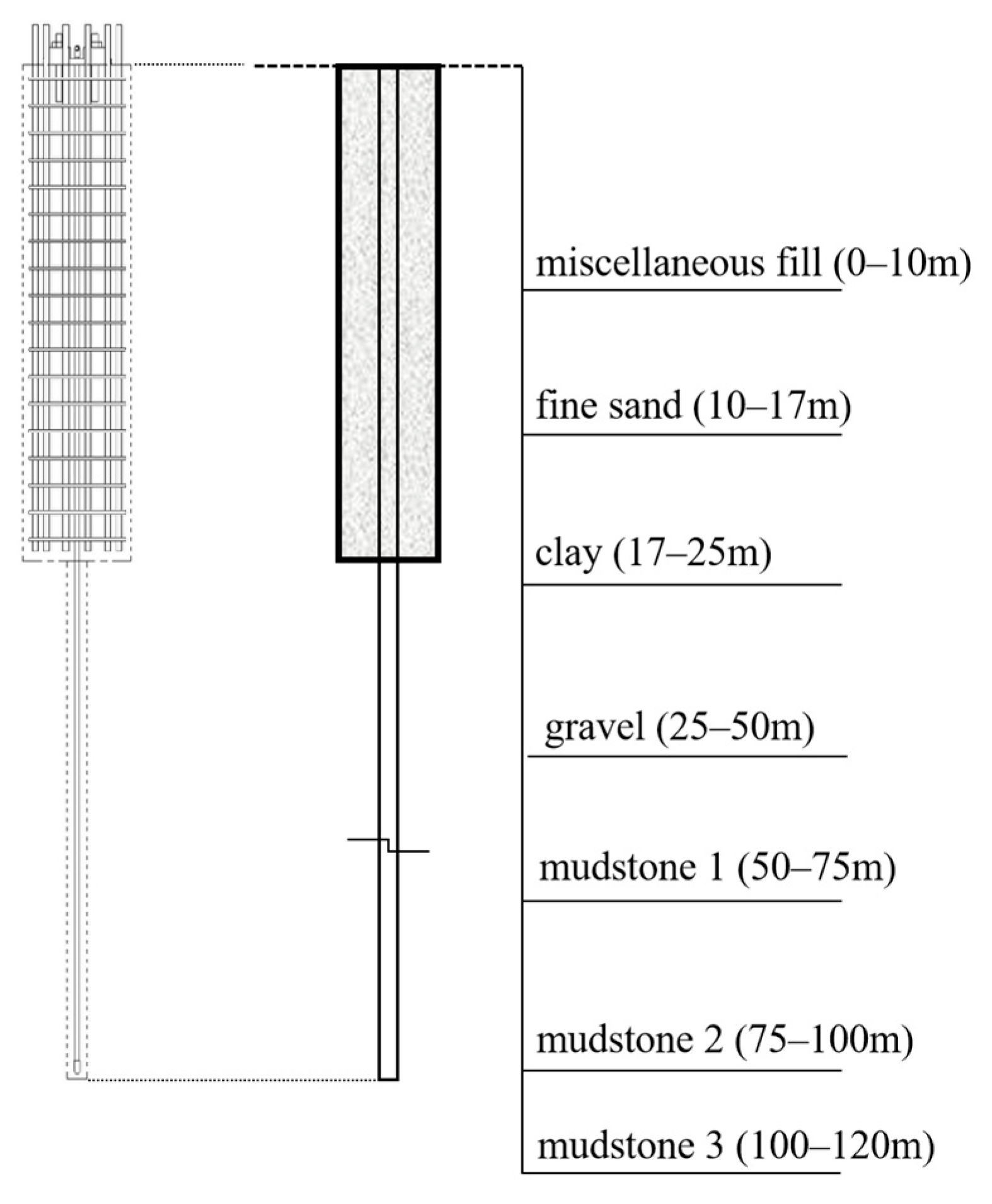

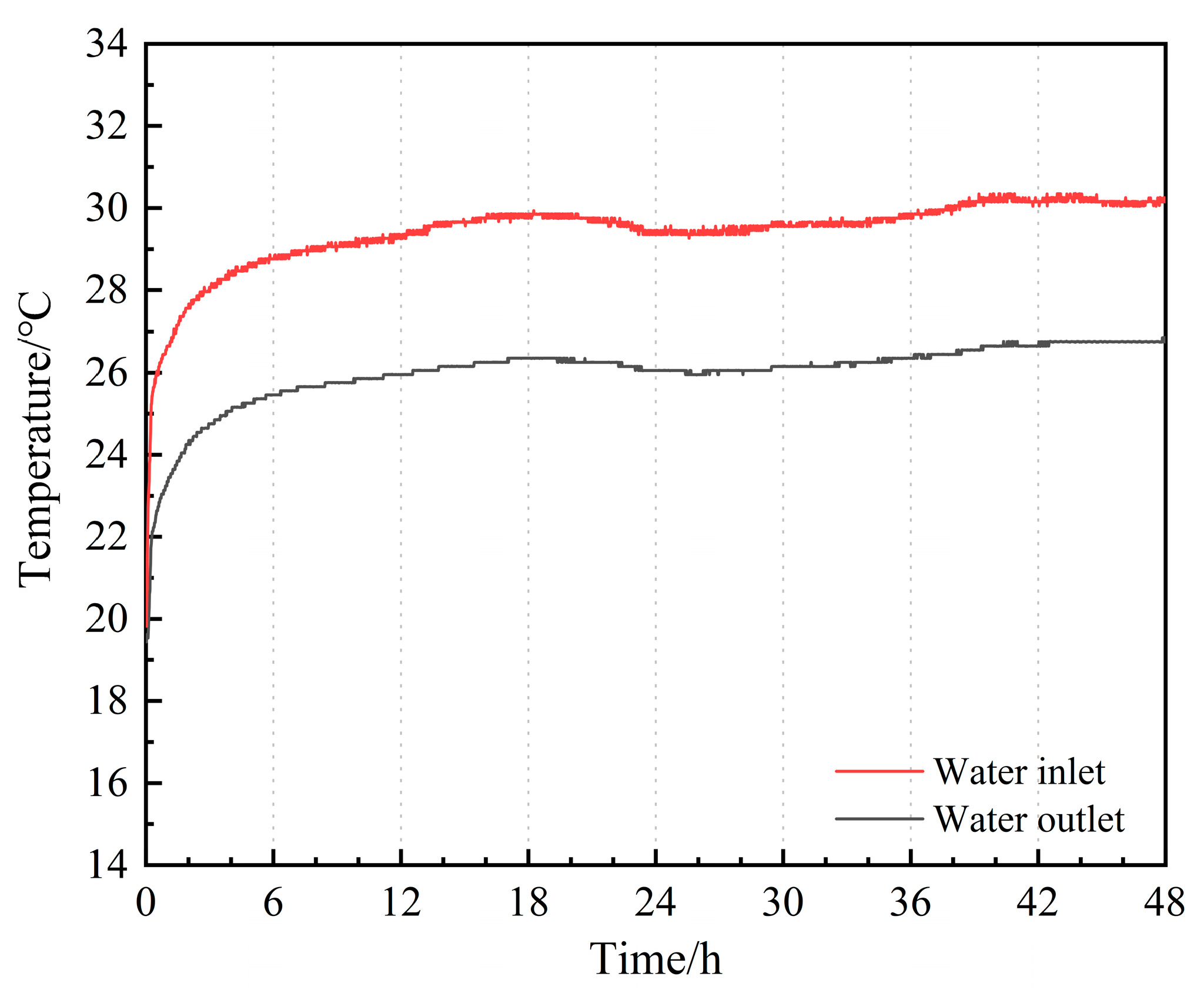

2. Summary of Field Test and Analysis of Results

2.1. Site Overview and Test Scheme

2.2. Field Test Analysis

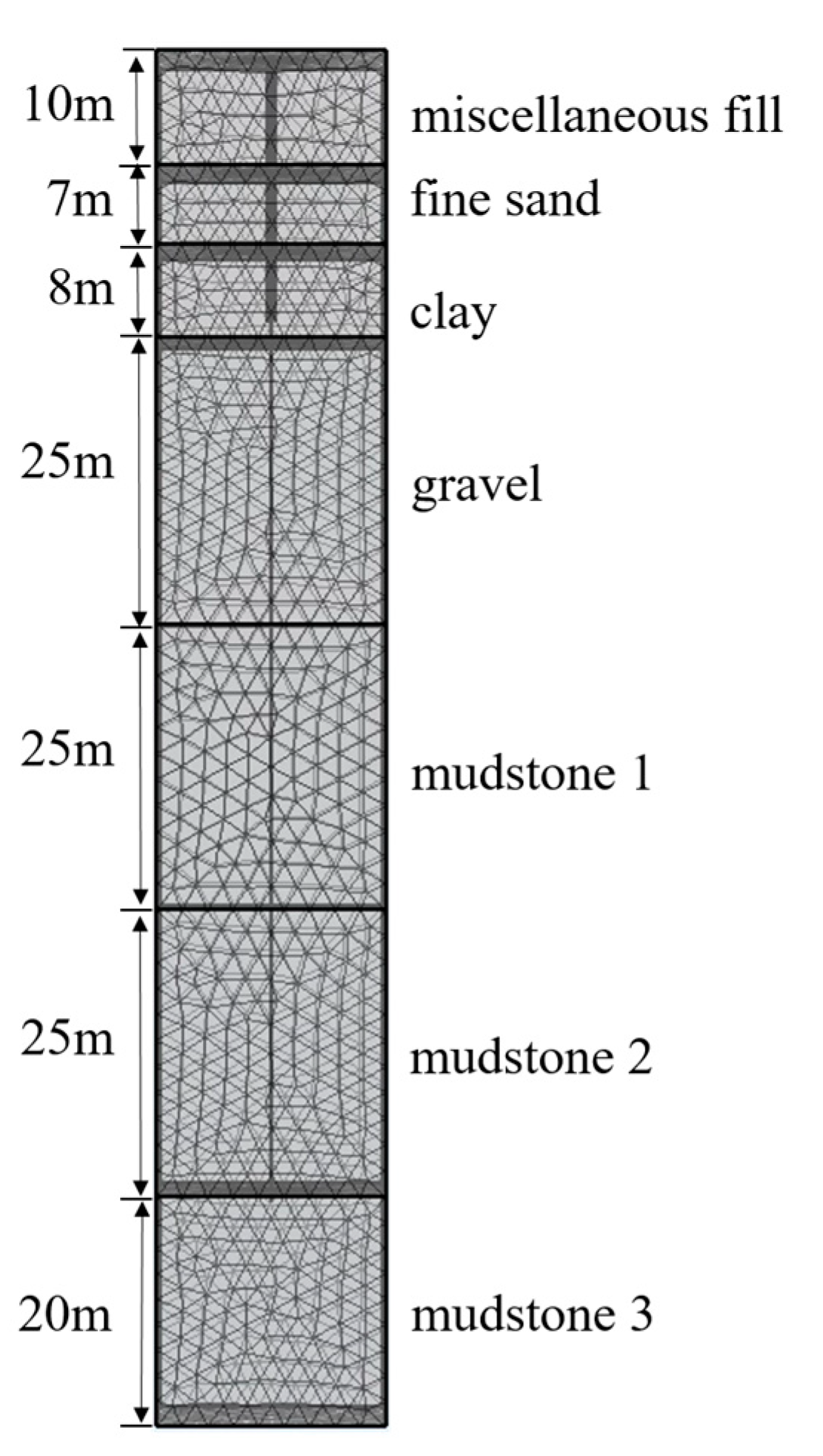

3. Numerical Simulations: Thermal Behavior of DBP-EP

3.1. Technical Features of the Used Software

3.1.1. Governing Equations Set in COMSOL

3.1.2. Boundary Condition

- ➀

- The assumption of soil homogeneity is made; the thermophysical parameters of each layer of rock and soil are isotropic and remain unchanged, with no consideration given to the influence of internally generated steam on heat migration or the effects of thermal radiation within the soil on the thermal transfer processes of DBP-EPs.

- ➁

- The material used to backfill the pile is in complete contact with the surfaces of the heat exchange pipes, ensuring uniform thermal conductivity throughout the surrounding rock and soil layers. Any contact thermal resistance is considered negligible, and the system is assumed to conduct heat purely.

- ➂

- The potential impact of groundwater seepage on the heat exchange process of the pile was not accounted for in this analysis.

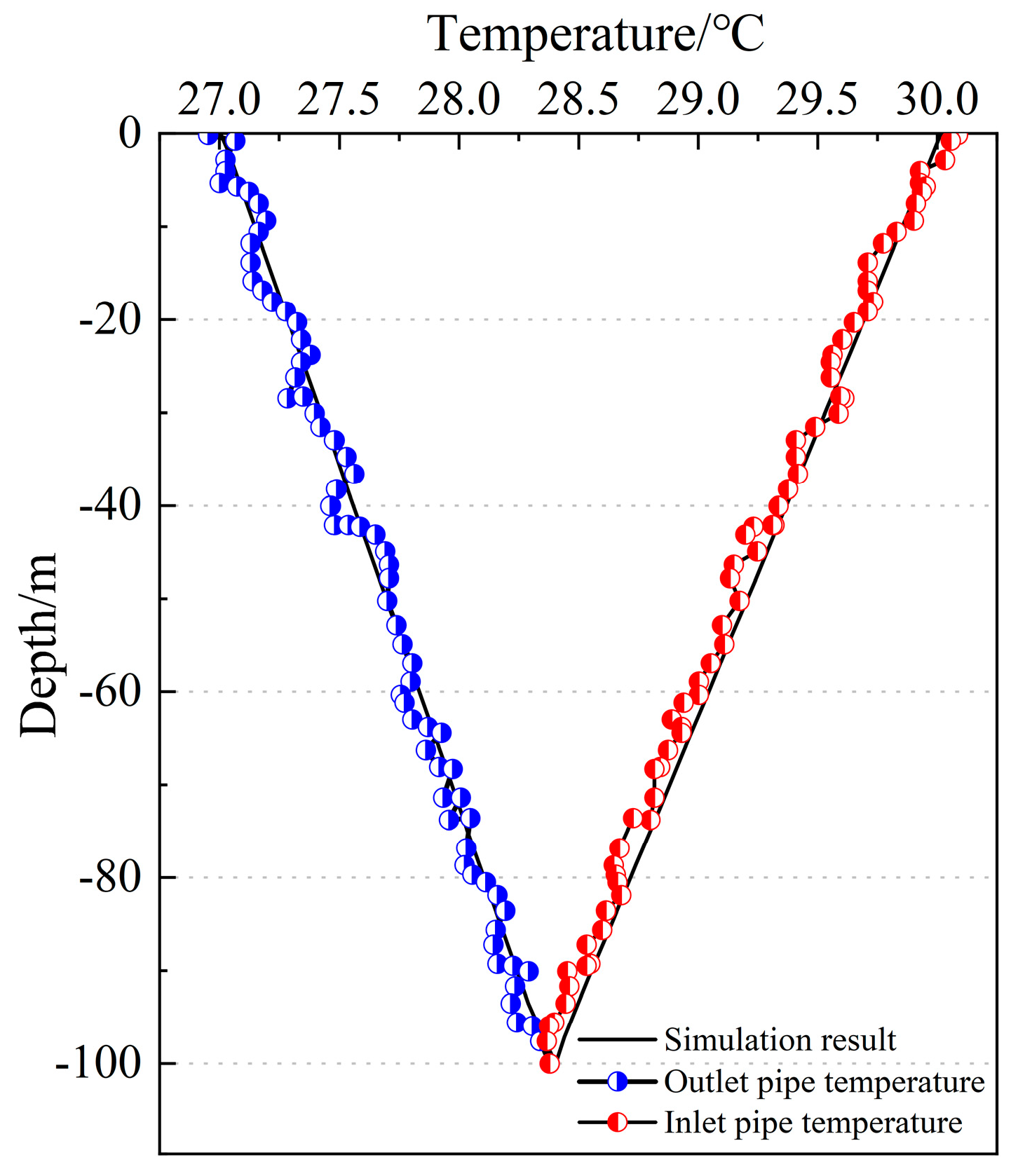

3.1.3. Model Verification

4. Results and Discussions

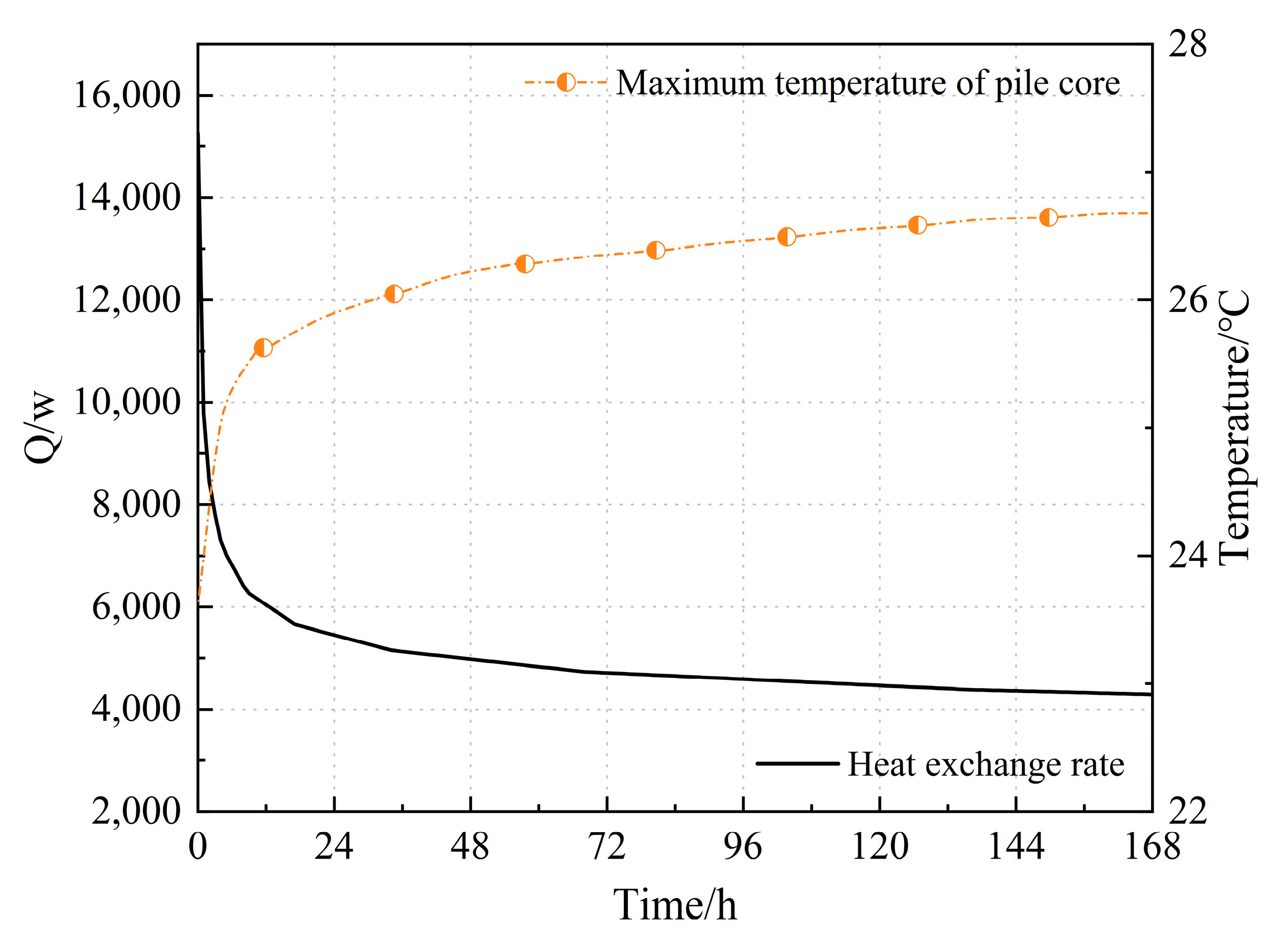

4.1. Heat Exchange Rate and Core Temperature Change of Single Pile

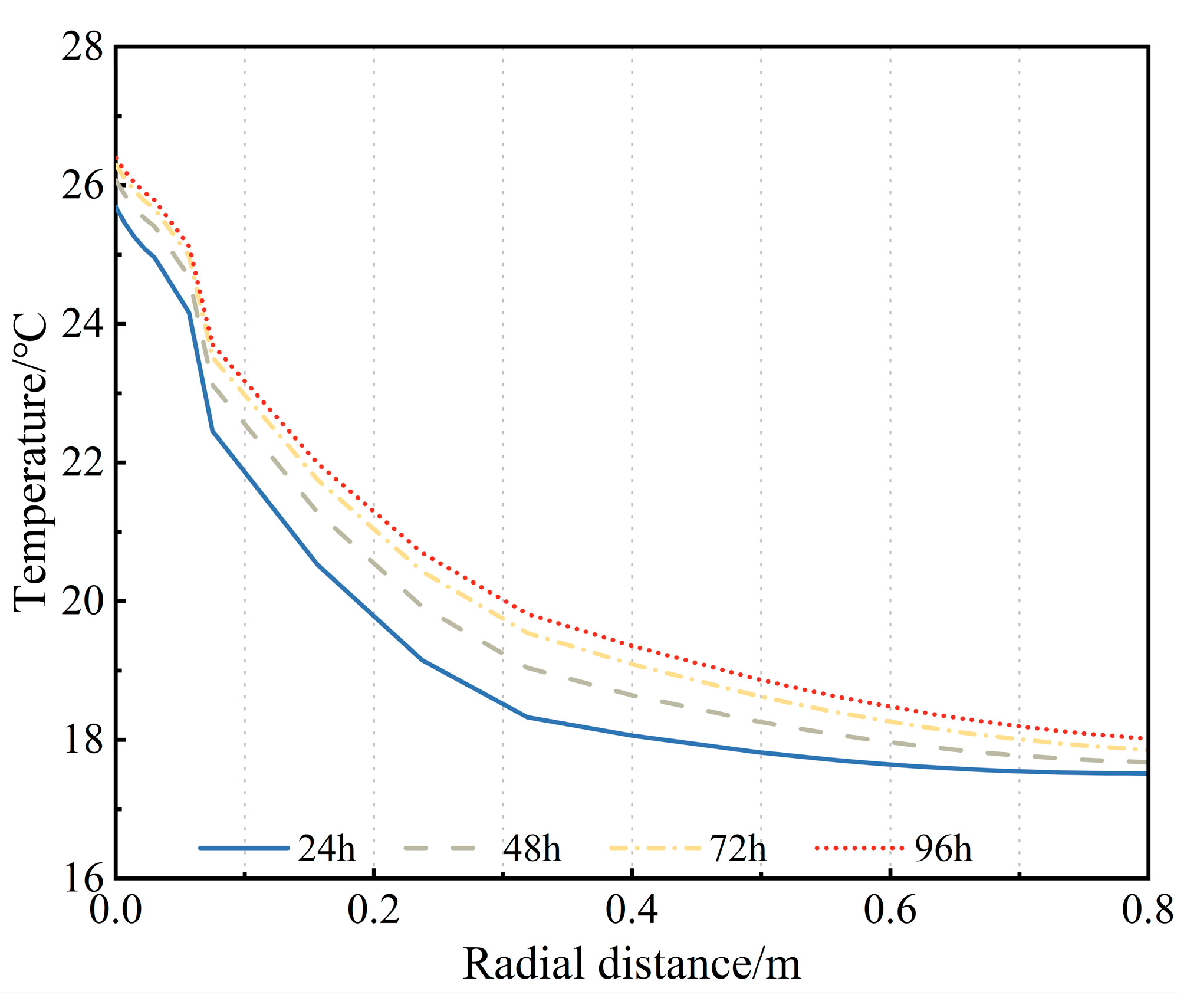

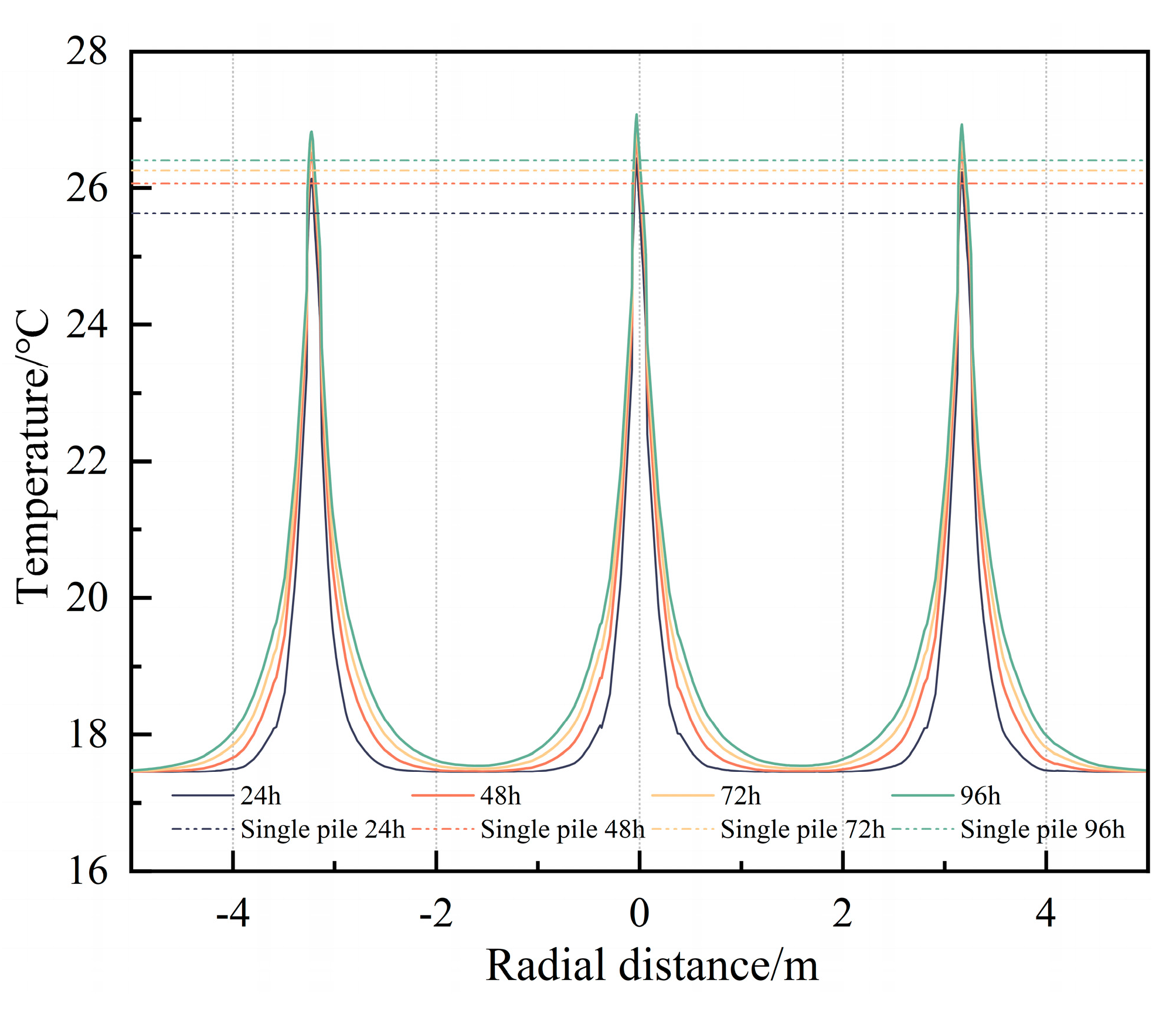

4.2. Single Pile Thermal Radius Change

4.3. Heat Transfer of DBP-EP Group in Different Operation Schemes

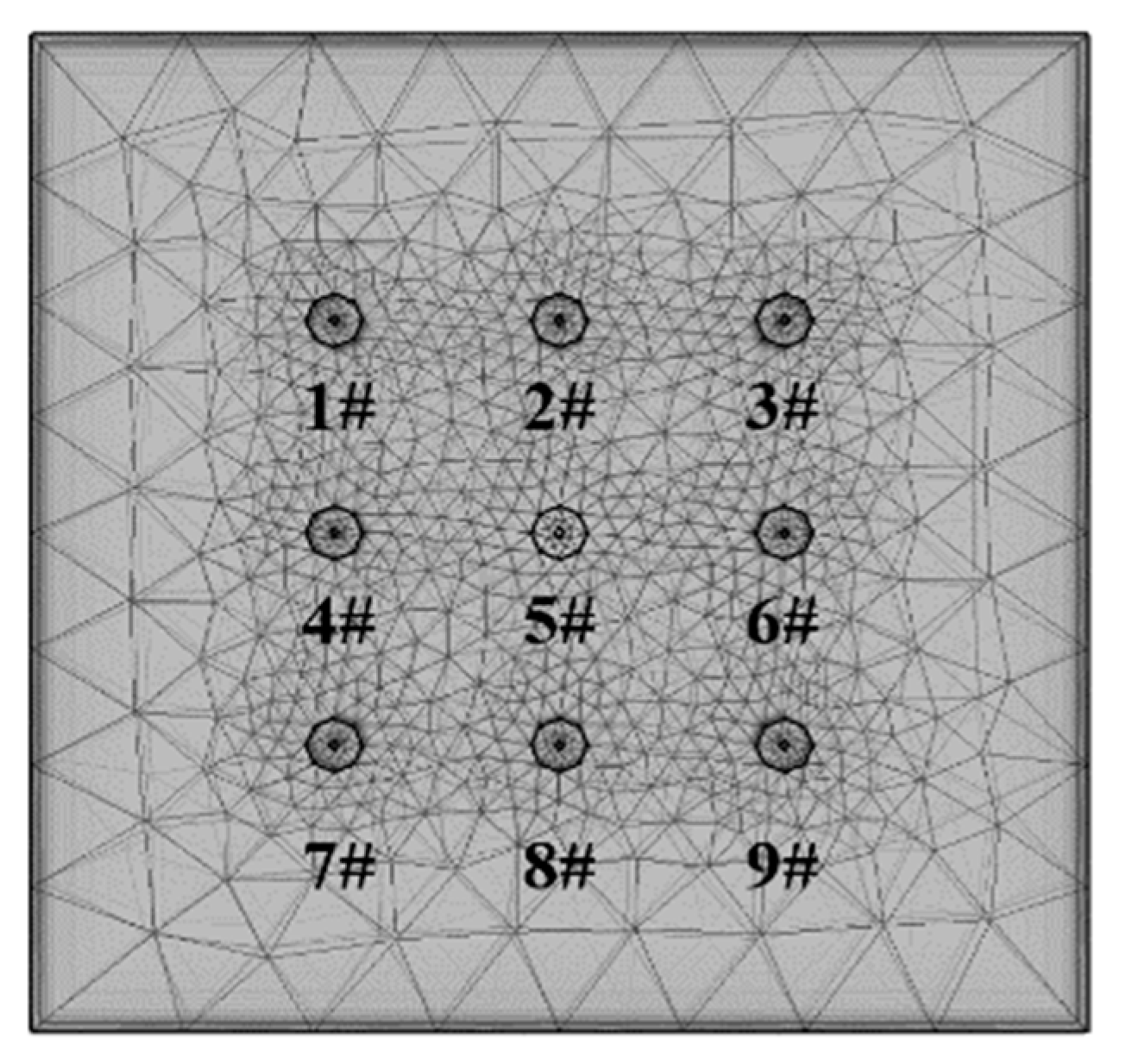

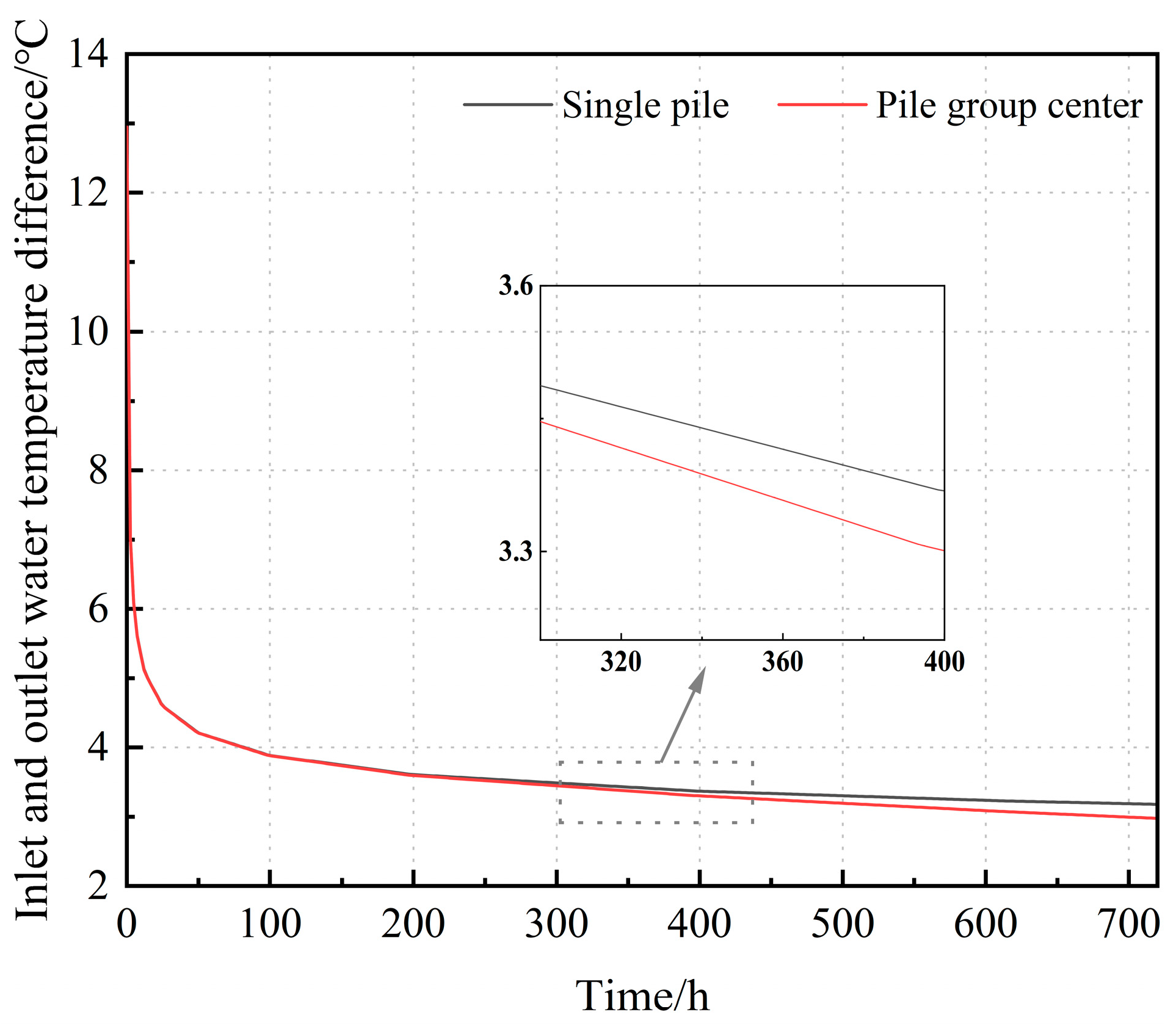

4.3.1. Continuous Heat Transfer Characteristics of Pile Group

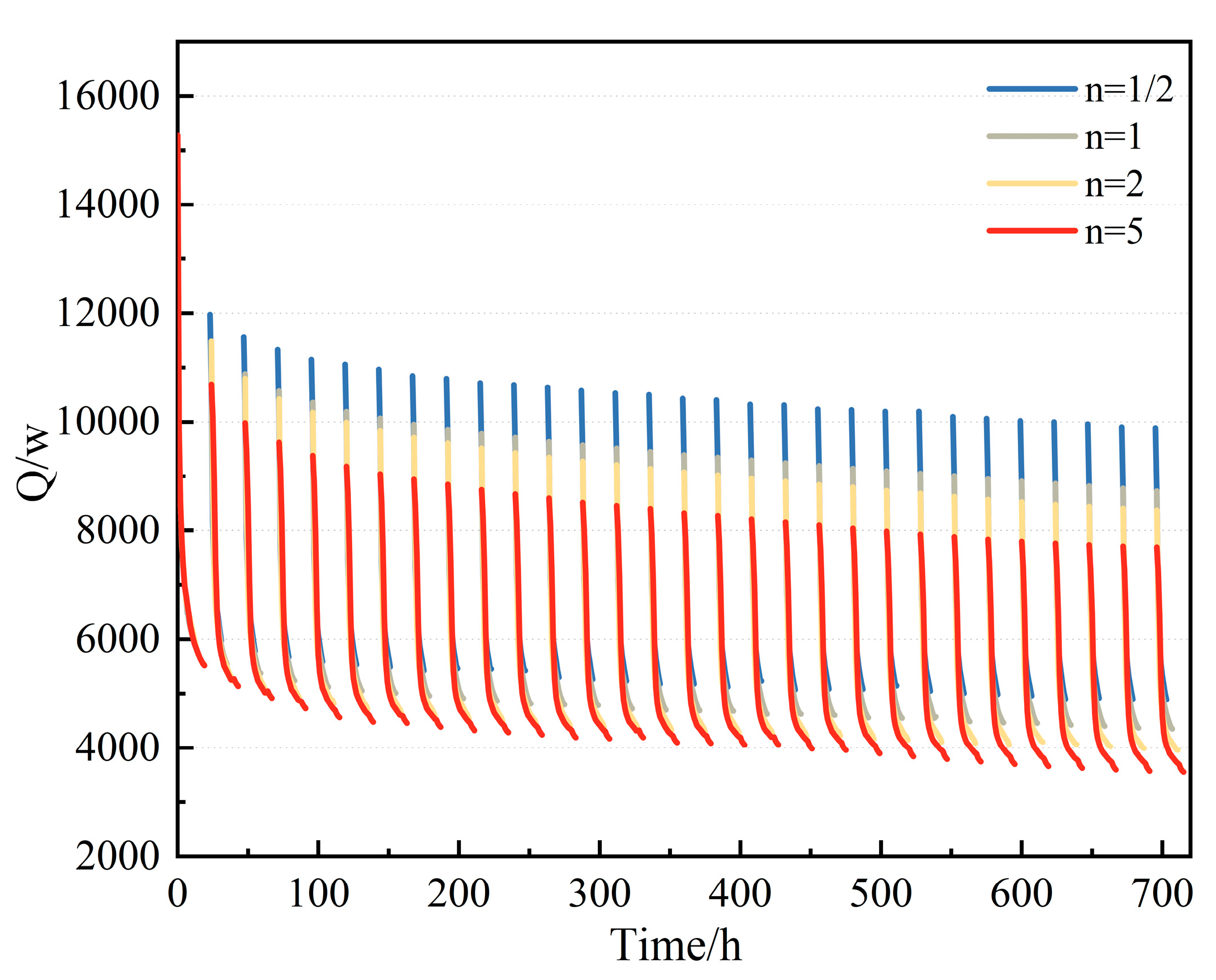

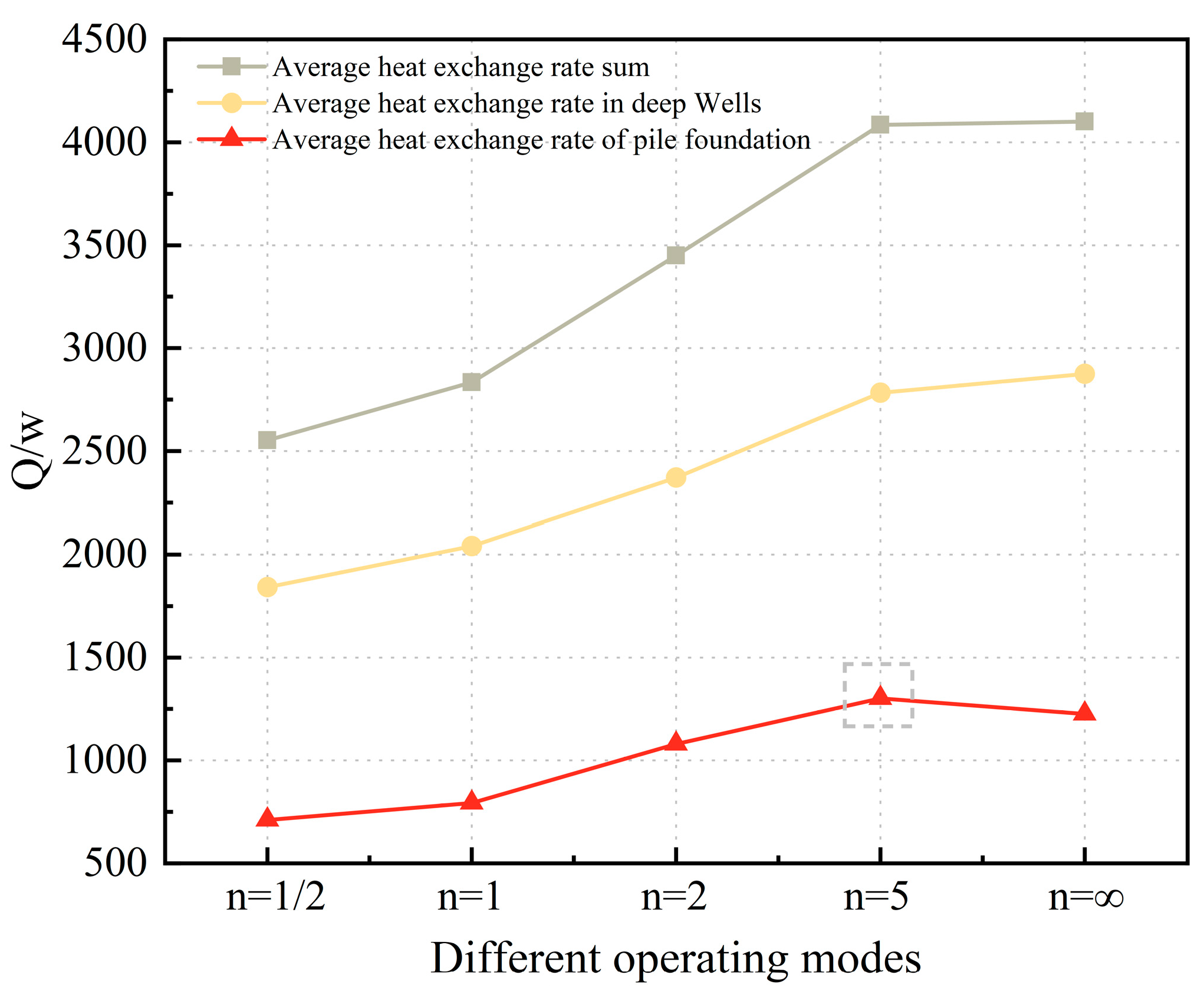

4.3.2. Comparison and Analysis of Rate of Thermal Exchange in Continuous and Intermittent Operational Mode

4.3.3. Energy Efficiency Ratio

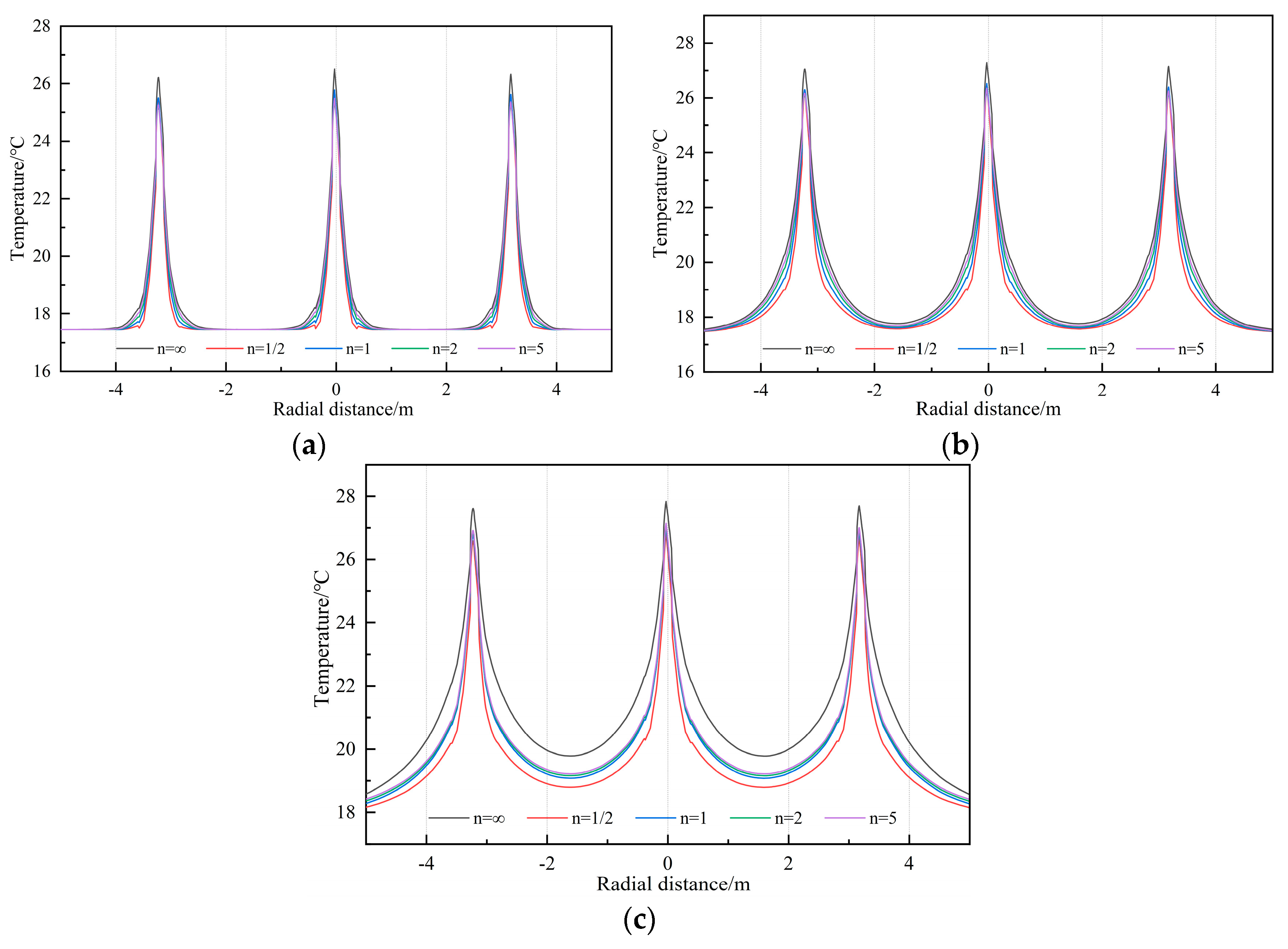

4.4. Comparison and Analysis of Thermal Radius between Continuous and Intermittent Operational Modes

4.5. Potential Applications and Developments

- The selection of the intermittent operation scheme and operation factor change is limited, and the selection range of running time should be further broadened to facilitate more extensive research and analysis.

- In the process of pile group research, numerical simulation is the main method, and the corresponding practical pile group engineering should be established.

- The application of the intermittent operational mode should be popularized, and more practical data in the actual project will facilitate the further study.

5. Conclusions

- (1)

- The continuous operation of deep energy single piles exacerbates the accumulation of heat within the pile foundation, expanding the thermal radius distribution of the pile, also reducing its heat transfer efficiency; furthermore, this exerts adverse effects on the heat transfer performance of the DBP-EP.

- (2)

- The accumulation of heat and the rate of expansion of the thermal radius within the pile group in continuous operational mode are more pronounced compared to single piles. Under continuous operational conditions, the heat interference generated by the peripheral piles of the pile group has a negative impact on the heat transfer of the inner piles, resulting in a greater reduction in the thermal conductivity characteristics of the inner piles compared to the peripheral piles.

- (3)

- Combining the analysis of the energy efficiency ratio (EER) and comparing the heat exchange performance between continuous operation and intermittent operational modes, the optimal conclusion was obtained for the intermittent operational mode with an intermittency ratio of n = 5. When the intermittency ratio is n = 5, the total sum of the pile group’s average heat exchange rate decreases by only 0.51% compared to continuous operation, but its single-pile EER is improved by over 19.6%, and to some extent, it alleviates the accumulation of heat within the pile base.

- (4)

- Analyzing the change of the pile group’s thermal radius during the heat exchange operation in the initial phase, it was found that in the continuous heat exchange operation, thermal interference exerts minimal influence concerning the dynamics of the heat exchange within the pile group. However, as the duration of the heat exchange operation increases, the thermal interference in the pile group gradually becomes more pronounced, leading to a decrease in heat exchange performance. In the intermittent operational mode, the variance in temperature between pile and the soil is recoverable, weakening the pile group effect and favoring the heat exchange operation of the pile group. Therefore, adopting an intermittent operational scheme can effectively improve the thermal exchange performance of the DBP-EP group, providing favorable conditions for the low-energy and efficient operation of the piles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, Y.-S.; Wang, X.-W.; Shen, S.-L.; Zhou, A. Distribution Characteristics and Utilization of Shallow Geothermal Energy in China. Energy Build. 2020, 229, 110479. [Google Scholar] [CrossRef]

- Ramos-Escudero, A.; Gil-García, I.C.; García-Cascales, M.S.; Molina-Garcia, A. Energy, Economic and Environmental GIS–Based Analysis of Shallow Geothermal Potential in Urban Areas—A Spanish Case Example. Sustain. Cities Soc. 2021, 75, 103267. [Google Scholar] [CrossRef]

- Lyu, W.; Li, X.; Yan, S.; Jiang, S. Utilizing Shallow Geothermal Energy to Develop an Energy Efficient HVAC System. Renew. Energy 2020, 147, 672–682. [Google Scholar] [CrossRef]

- Chicco, J.M.; Antonijevic, D.; Bloemendal, M.; Cecinato, F.; Goetzl, G.; Hajto, M.; Hartog, N.; Mandrone, G.; Vacha, D.; Vardon, P.J. Improving the Efficiency of District Heating and Cooling Using a Geothermal Technology: Underground Thermal Energy Storage (UTES). In New Metropolitan Perspectives; Calabrò, F., Della Spina, L., Piñeira Mantiñán, M.J., Eds.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2022; Volume 482, pp. 1699–1710. ISBN 978-3-031-06824-9. [Google Scholar]

- Kong, G.; Fang, J.; Lv, Z.; Yang, Q. Effects of Pile and Soil Properties on Thermally Induced Mechanical Responses of Energy Piles. Comput. Geotech. 2023, 154, 105176. [Google Scholar] [CrossRef]

- Tian, W.; Cheng, X.; Liu, Z.; Wei, Q.; Wang, T.; Guo, H. Heat Exchange Performance of an Energy-Pile Group in a Hybrid GSHP System and Effects of Pile Spacing. Energy Build. 2024, 316, 114347. [Google Scholar] [CrossRef]

- Shang, Y.; Dong, M.; Mu, L.; Liu, X.; Huang, X.; Li, S. The Analysis of the Evaporation Effect on Moisture Soil under Intermittent Operation of Ground-Source Heat Pump. Energy Procedia 2019, 158, 1508–1513. [Google Scholar] [CrossRef]

- Yuan, T.; Yu, M.; Mao, Y.; Cui, P.; Zhang, W.; Zhuang, Z. Study on Long-Term Operation Characteristics of the Medium-Deep Ground Source Heat Pump System with Solar Heat Storage. Appl. Therm. Eng. 2024, 241, 122345. [Google Scholar] [CrossRef]

- Pourier, C.; Beltrán, F.; Sommerfeldt, N. Solar Photovoltaic/Thermal (PVT) Technology Collectors and Free Cooling in Ground Source Heat Pump Systems. Sol. Energy Adv. 2024, 4, 100050. [Google Scholar] [CrossRef]

- Linfeng, Z.; Quan, Z.; Min, L.; Yaxing, D. A New Analytical Model for the Underground Temperature Profile under the Intermittent Operation for Ground-Coupled Heat Pump Systems. Energy Procedia 2015, 75, 840–846. [Google Scholar] [CrossRef][Green Version]

- Zhang, X.; Wang, E.; Liu, L.; Qi, C.; Zhen, J.; Meng, Y. Analysis of the Operation Performance of a Hybrid Solar Ground-Source Heat Pump System. Energy Build. 2022, 268, 112218. [Google Scholar] [CrossRef]

- Qiu, G.; Li, K.; Cai, W.; Yu, S. Optimization of an Integrated System Including a Photovoltaic/Thermal System and a Ground Source Heat Pump System for Building Energy Supply in Cold Areas. Appl. Energy 2023, 349, 121698. [Google Scholar] [CrossRef]

- Gao, B.; Zhu, X.; Yang, X.; Yuan, Y.; Yu, N.; Ni, J. Operation Performance Test and Energy Efficiency Analysis of Ground-Source Heat Pump Systems. J. Build. Eng. 2021, 41, 102446. [Google Scholar] [CrossRef]

- You, T.; Zeng, W. Zoning Operation of Energy Piles to Alleviate the Soil Thermal Imbalance of Ground Source Heat Pump Systems. Energy Built Environ. 2023, 4, 57–63. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, J.; Pan, P.; Xiao, H.; Ma, Q. Research on the Heat Exchange Characteristics of the Deeply Buried Pipe Type of Energy Pile. Case Stud. Therm. Eng. 2021, 27, 101268. [Google Scholar] [CrossRef]

- Sadeghi, H.; Singh, R.M. Driven Precast Concrete Geothermal Energy Piles: Current State of Knowledge. Build. Environ. 2023, 228, 109790. [Google Scholar] [CrossRef]

- Sani, A.K.; Singh, R.M. Response of Unsaturated Soils to Heating of Geothermal Energy Pile. Renew. Energy 2020, 147, 2618–2632. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wang, K.; Zhu, Y.; Zhu, Y. Numerical Analysis of Ground Temperature Response Characteristics of a Space-Heating Ground Source Heat Pump System by Utilizing Super-Long Flexible Heat Pipes for Heat Extraction. Energy Build. 2021, 244, 110991. [Google Scholar] [CrossRef]

- Xu, Y.; Zeng, Z.; Sun, D. Experimental and Numerical Investigation on Heat Transfer Characteristics of Vertical Ground Heat Exchangers in Karst Areas. Energy Build. 2022, 275, 112481. [Google Scholar] [CrossRef]

- Li, C.; Jiang, C.; Guan, Y.; Meng, Q.; Chen, H.; Zhang, S. Evaluation of Heating Capacity of Shallow Ground Heat Exchangers in Different Locations—A Case Study of Two Administrative Districts of Xi’an. Energy Build. 2023, 294, 113276. [Google Scholar] [CrossRef]

- Rajeh, T.; Al-Kbodi, B.H.; Li, Y.; Zhao, J.; Zhang, Y. Modeling and Techno-Economic Comparison of Two Types of Coaxial with Double U-Tube Ground Heat Exchangers. Appl. Therm. Eng. 2023, 225, 120221. [Google Scholar] [CrossRef]

- Sutman, M.; Speranza, G.; Ferrari, A.; Larrey-Lassalle, P.; Laloui, L. Long-Term Performance and Life Cycle Assessment of Energy Piles in Three Different Climatic Conditions. Renew. Energy 2020, 146, 1177–1191. [Google Scholar] [CrossRef]

- Li, R.; Kong, G.; Chen, Y.; Yang, Q. Thermomechanical Behaviour of an Energy Pile–Raft Foundation under Intermittent Cooling Operation. Geomech. Energy Environ. 2021, 28, 100240. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, G.; Liu, Y.; Zhao, X.; Li, C. Influence of Backfilling Phase Change Material on Thermal Performance of Precast High-Strength Concrete Energy Pile. SSRN J. 2021. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, J. CFD Assessment of Multiple Energy Piles for Ground Source Heat Pump in Heating Mode. Appl. Therm. Eng. 2018, 139, 99–112. [Google Scholar] [CrossRef]

- Jahangir, M.H.; Ghazvini, M.; Pourfayaz, F.; Ahmadi, M.H. A Numerical Study into Effects of Intermittent Pump Operation on Thermal Storage in Unsaturated Porous Media. Appl. Therm. Eng. 2018, 138, 110–121. [Google Scholar] [CrossRef]

- Liang, B.; Chen, M.; An Fu, B.; Guan, J. Thermal and Flow Characteristics in a Vertical Spiral-Type Ground Heat Exchanger Based on Linear Non-Equilibrium Thermodynamic Principle. Energy Build. 2022, 266, 112111. [Google Scholar] [CrossRef]

- Yang, J.; Xu, L.; Hu, P.; Zhu, N.; Chen, X. Study on Intermittent Operation Strategies of a Hybrid Ground-Source Heat Pump System with Double-Cooling Towers for Hotel Buildings. Energy Build. 2014, 76, 506–512. [Google Scholar] [CrossRef]

- Behbehani, F.; McCartney, J.S. Energy Pile Groups for Thermal Energy Storage in Unsaturated Soils. Appl. Therm. Eng. 2022, 215, 119028. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, H.; Chen, Z. Study on Heat Transfer Performance of Geothermal Pile-Foundation Heat Exchanger with 3-U Pipe Configuration. Int. J. Heat Mass Transf. 2020, 147, 119020. [Google Scholar] [CrossRef]

- Noye, S.; Mulero Martinez, R.; Carnieletto, L.; De Carli, M.; Castelruiz Aguirre, A. A Review of Advanced Ground Source Heat Pump Control: Artificial Intelligence for Autonomous and Adaptive Control. Renew. Sustain. Energy Rev. 2022, 153, 111685. [Google Scholar] [CrossRef]

- Hou, G.; Taherian, H.; Song, Y.; Jiang, W.; Chen, D. A Systematic Review on Optimal Analysis of Horizontal Heat Exchangers in Ground Source Heat Pump Systems. Renew. Sustain. Energy Rev. 2022, 154, 111830. [Google Scholar] [CrossRef]

- Zhou, K.; Mao, J.; Zhang, H.; Li, Y.; Yu, X.; Chen, F.; Li, M. Design Strategy and Techno-Economic Optimization for Hybrid Ground Heat Exchangers of Ground Source Heat Pump System. Sustain. Energy Technol. Assess. 2022, 52, 102140. [Google Scholar] [CrossRef]

- Huang, G.; Liao, Z.; Li, S.; Zhuang, C.; Zhang, H.; Cheng, L.; Gan, F.; Xu, N. A Novel Independent Heat Extraction-Release Double Helix Energy Pile: Numerical and Experimental Investigations of Heat Extraction Effect. Energy Convers. Manag. 2022, 254, 115249. [Google Scholar] [CrossRef]

- Lee, S.; Park, S.; Kim, D.; Ahn, D.; Choi, H. Dual Performance of Novel Steel Pipe Heat Exchangers Equipped in Cast-in-Place Energy Pile. Energy Build. 2021, 234, 110725. [Google Scholar] [CrossRef]

- Han, C.; Zhu, C.; Shen, Y.; Yu, X.B. Energy, Environmental and Economic Performance Evaluation of Energy Pile System under Different Climate Conditions. Energy Convers. Manag. 2022, 252, 115041. [Google Scholar] [CrossRef]

- Lyu, W.; Pu, H.; Xiao, H.; Hu, D.; Ma, Q. Thermal Performance of Energy Pile with Deeply Penetrating 1-U-Shape Heat Exchanger. Geothermics 2021, 91, 102023. [Google Scholar] [CrossRef]

- Nicholls, P. Formate as an Inhibitor of Cytochrome c Oxidase. Biochem. Biophys. Res. Commun. 1975, 67, 610–616. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Thermal Conductivity (W/(m⋅°C)) | Porosity |

|---|---|---|---|

| Backfill (fine sand) | 1750 | 0.58 | 0.45 |

| Pile (concrete) | 2350 | 2.20 | 0 |

| Fine sand | 2350 | 2.50 | 0.45 |

| Clay | 2000 | 1.00 | 0.40 |

| Gravel | 2000 | 2.31 | 0.30 |

| Mudstone 1 | 2000 | 1.90 | 0.25 |

| Mudstone 2 | 2000 | 1.90 | 0.20 |

| Mudstone 3 | 2000 | 1.90 | 0.15 |

| Intermittent Condition | 1# | 2# | 3# | 4# | 5# |

|---|---|---|---|---|---|

| n = ∞ (Q/W) | 4145.50 | 4123.92 | 4147.41 | 4124.91 | 4100.55 |

| n = 5 (Q/W) | 4119.89 (↓0.62%) | 4103.04 (↓0.51%) | 4122.55 (↓0.60%) | 4103.78 (↓0.51%) | 4084.17 (↓0.40%) |

| n = 2 (Q/W) | 3474.04 (↓16.20%) | 3461.67 (↓16.06%) | 3475.53 (↓16.20%) | 3463.23 (↓16.04%) | 3449.75 (↓15.87%) |

| n = 1 (Q/W) | 2849.55 (↓31.26%) | 2840.92 (↓31.11%) | 2850.52 (↓31.27%) | 2842.67 (↓31.09%) | 2833.64 (↓30.90%) |

| n = 1/2 (Q/W) | 2562.22 (↓38.19%) | 2555.89 (↓38.02%) | 2562.69 (↓38.20%) | 2557.66 (↓37.99%) | 2551.54 (↓37.78%) |

| 6# | 7# | 8# | 9# | Total | |

| n = ∞ (Q/W) | 4123.83 | 4141.55 | 4123.53 | 4146.01 | 37,177.21 |

| n = 5 (Q/W) | 4108.07 (↓0.38%) | 4117.24 (↓0.59%) | 4105.99 (↓0.43%) | 4121.68 (↓0.59%) | 36,986.41 (↓0.51%) |

| n = 2 (Q/W) | 3466.32 (↓15.94%) | 3471.75 (↓16.17%) | 3464.91 (↓15.97%) | 3474.68 (↓16.19%) | 31,201.88 (↓16.07%) |

| n = 1 (Q/W) | 2845.12 (↓31.01%) | 2847.78 (↓31.24%) | 2844.21 (↓31.02%) | 2849.82 (↓31.26%) | 25,604.23 (↓31.13%) |

| n = 1/2 (Q/W) | 2559.77 (↓37.93%) | 2560.67 (↓38.17%) | 2559.05 (↓37.94%) | 2562.34 (↓38.19%) | 23,031.83 (↓38.05%) |

| Intermittent Ratio (n) | n = ∞ | n = 5 | n = 2 | n = 1 | n = 1/2 |

|---|---|---|---|---|---|

| EER | 4.32 | 5.37 | 5.61 | 6.10 | 7.20 |

| Temperature at 0.8 m (°C) | n = ∞ | n = 1/2 | n = 1 | n = 2 | n = 5 |

|---|---|---|---|---|---|

| 24 h | 17.50 | 17.45 | 17.46 | 17.46 | 17.47 |

| 168 h | 18.45 | 18.00 | 18.13 | 18.26 | 18.34 |

| 178 h | 20.61 | 19.30 | 19.69 | 19.77 | 19.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Chen, Z.; Yuan, J.; Mao, A. Heat Transfer Performance and Operation Scheme of the Deeply Buried Pipe Energy Pile Group. Appl. Sci. 2024, 14, 5928. https://doi.org/10.3390/app14135928

Tian Y, Chen Z, Yuan J, Mao A. Heat Transfer Performance and Operation Scheme of the Deeply Buried Pipe Energy Pile Group. Applied Sciences. 2024; 14(13):5928. https://doi.org/10.3390/app14135928

Chicago/Turabian StyleTian, Yuhan, Zhi Chen, Jianghuai Yuan, and Anqi Mao. 2024. "Heat Transfer Performance and Operation Scheme of the Deeply Buried Pipe Energy Pile Group" Applied Sciences 14, no. 13: 5928. https://doi.org/10.3390/app14135928

APA StyleTian, Y., Chen, Z., Yuan, J., & Mao, A. (2024). Heat Transfer Performance and Operation Scheme of the Deeply Buried Pipe Energy Pile Group. Applied Sciences, 14(13), 5928. https://doi.org/10.3390/app14135928