Study on the Optical Coupling Effect of Building-Integrated Photovoltaic Modules Applied with a Shingled Technology

Abstract

1. Introduction

2. Materials and Methods

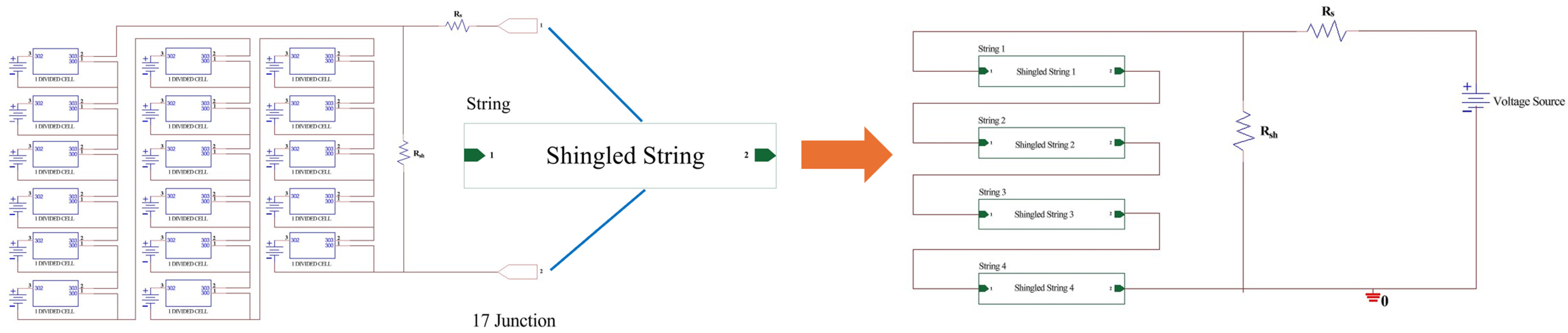

2.1. Shingled Module Circuit Modeling

2.2. Preparation of Shingled Strings

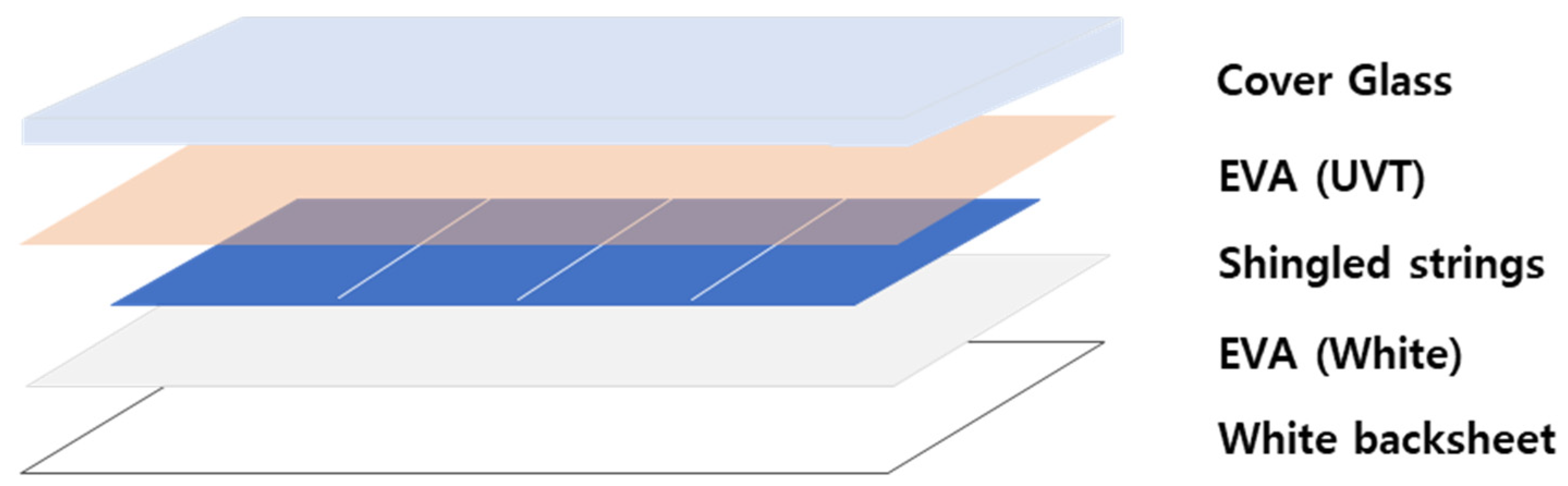

2.3. Preparation of Shingled BIPV Modules

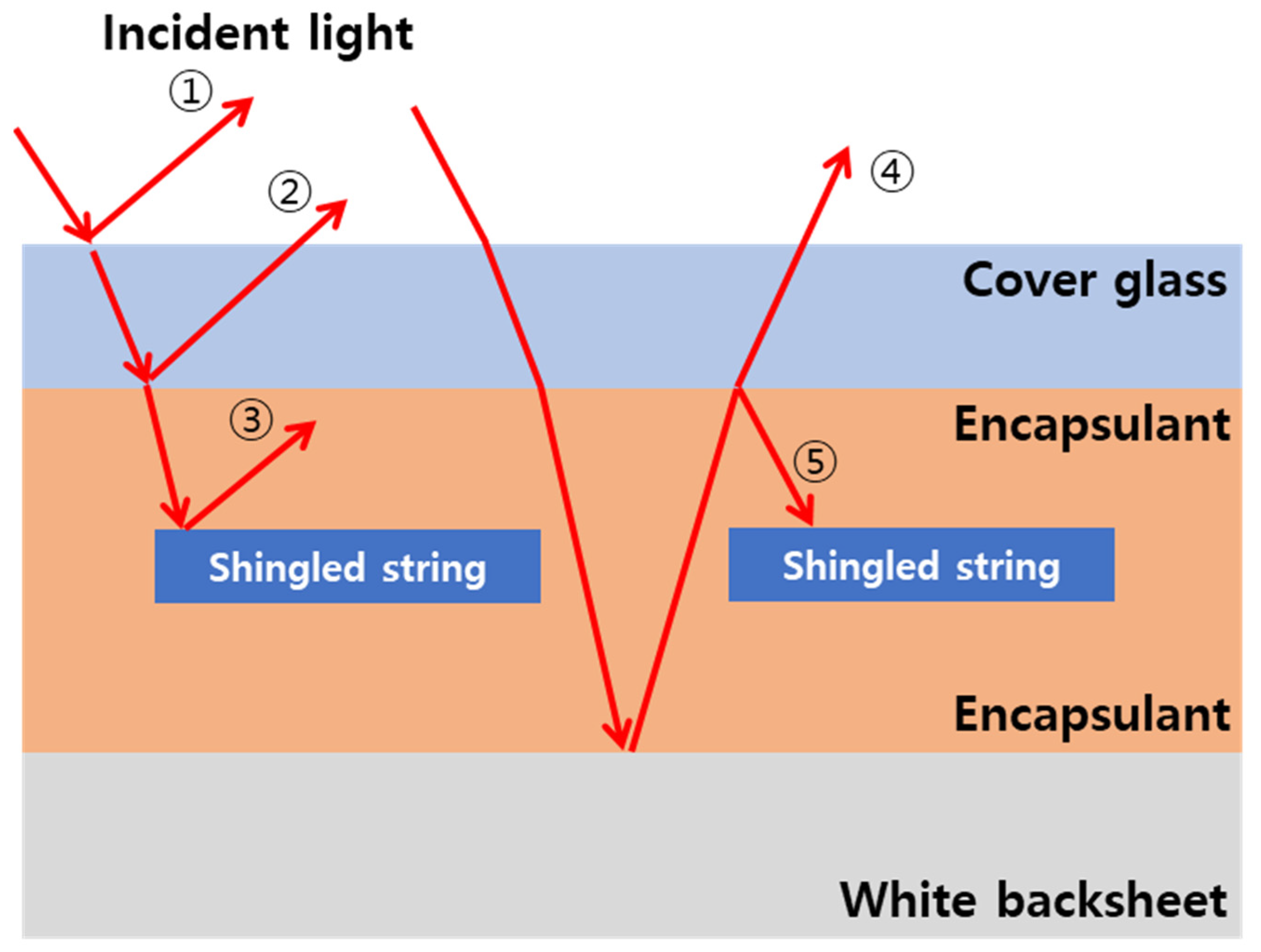

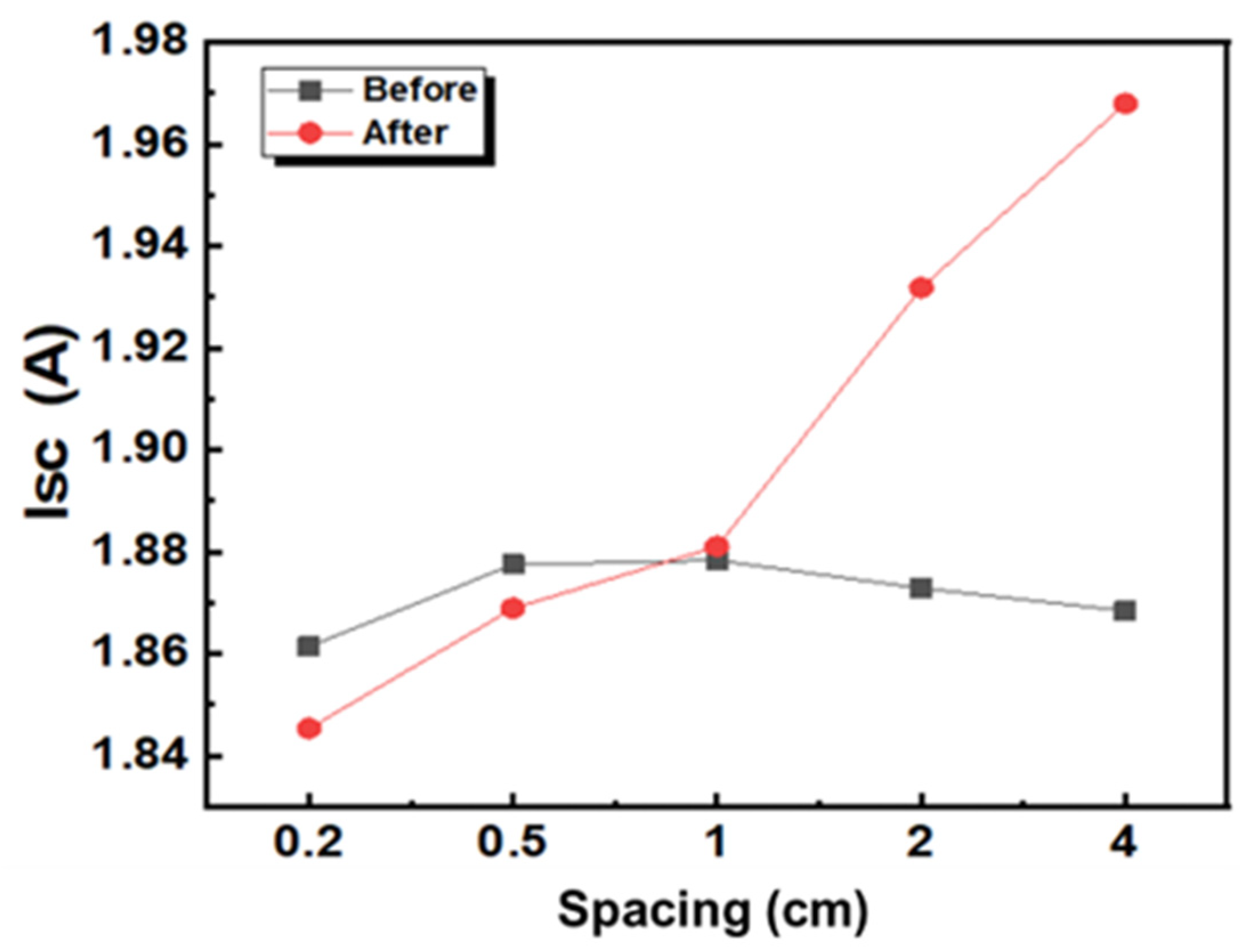

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Armstrong McKay, D.I.; Staal, A.; Abrams, J.F.; Winkelmann, R.; Sakschewski, B.; Loriani, S.; Fetzer, I.; Cornell, S.E.; Rockström, J.; Lenton, T.M. Exceeding 1.5 °C global warming could trigger multiple climate tipping points. Science 2022, 377, 6611. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Deng, Z.; He, G.; Wang, H.; Zhang, X.; Lin, J.; Qi, Y.; Liang, X. Challenges and opportunities for carbon neutrality in China. Nat. Rev. Earth Environ. 2022, 3, 141–155. [Google Scholar] [CrossRef]

- Lenton, T.M.; Held, H.; Kriegler, E.; Hall, J.W.; Lucht, W.; Rahmstorf, S.; Schellnhuber, H.J. Tipping elements in the Earth’s climate system. Proc. Natl. Acad. Sci. USA 2008, 6, 1786–1793. [Google Scholar] [CrossRef] [PubMed]

- Lenton, T.M.; Rockström, J.; Gaffney, O.; Rahmstorf, S.; Richardson, K.; Steffen, W.; Schellnhuber, H.J. Climate tipping points-too risky to bet against. Nature 2019, 575, 592–595. [Google Scholar] [CrossRef]

- Singh, G.K. Solar power generation by PV (photovoltaic) technology: A review. Energy 2013, 53, 1–13. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ghazvini, M.; Sadeghzadeh, M.; Alhuyi Nazari, M.; Kumar, R.; Naeimi, A.; Ming, T. Solar power technology for electricity generation: A critical review. Energy Sci. Eng. 2018, 6, 340–361. [Google Scholar] [CrossRef]

- Urbina, A. The balance between efficiency, stability and environmental impacts in perovskite solar cells: A review. J. Phys. Energy 2020, 2, 022001. [Google Scholar] [CrossRef]

- Miles, R.; Hynes, K.; Forbes, I. Photovoltaic solar cells: An overview of state-of-the-art cell development and environmental issues. Prog. Cryst. 2005, 51, 1–42. [Google Scholar] [CrossRef]

- Serrano-Lujan, L.; Espinosa, N.; Larsen-Olsen, T.T.; Abad, J.; Urbina, A.; Krebs, F.C. Tin- and Lead ased Perovskite Solar Cells under Scrutiny: An Environmental Perspective. Adv. Energy Mater. 2015, 5, 1501119. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent advancement in BIPV product technologies: A review. Energy Build. 2017, 150, 188–195. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Kuhn, T.E.; Erban, C.; Heinrich, M.; Eisenlohr, J.; Ensslen, F.; Neuhaus, D.H. Review of techno-logical design options for building integrated photovoltaics (BIPV). Energy Build. 2021, 231, 110381. [Google Scholar] [CrossRef]

- Henemann, A. BIPV: Built-in solar energy, Renew. Energy Focus 2008, 9, 14–19. [Google Scholar] [CrossRef]

- Yang, R.J. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Shukla, A.K.; Baredar, P.; Mamat, R.; Sudhakar, K. BIPV in Southeast Asian countries–opportunities and challenges. Renew. Energy Focus 2017, 21, 25–32. [Google Scholar] [CrossRef]

- Kamel, R.S.; Fung, A.S. Modeling, simulation and feasibility analysis of residential BIPV/T+ASHP system in cold climate—Canada. Energy Build. 2014, 82, 758–770. [Google Scholar] [CrossRef]

- Do, S.L.; Shin, M.; Baltazar, J.; Kim, J. Energy benefits from semi-transparent BIPV window and daylight-dimming systems for IECC code-compliance residential buildings in hot and humid climates. Sol. Energy 2017, 155, 291–303. [Google Scholar] [CrossRef]

- Saretta, E.; Caputo, P.; Frontini, F. A review study about energy renovation of building facades with BIPV in urban environment. Energy Sustain. Soc. 2019, 44, 343–355. [Google Scholar] [CrossRef]

- Aguacil, S.; Lufkin, S.; Rey, E. Active surfaces selection method for building-integrated photovoltaics (BIPV) in renovation projects based on self-consumption and self-sufficiency. Energy Build. 2019, 193, 15–28. [Google Scholar] [CrossRef]

- Lee, H.M.; Yoon, J.H. Power performance analysis of a transparent DSSC BIPV window based on 2 year measurement data in a full-scale mock-up. Appl. Energy 2018, 225, 1013–1021. [Google Scholar] [CrossRef]

- Liu, B.; Duan, S.; Cai, T. Photovoltaic DC-Building-Module-Based BIPV System—Concept and Design Considerations. IEEE Trans. Power Electron. 2011, 26, 1418–1429. [Google Scholar] [CrossRef]

- Song, J.H.; An, Y.S.; Kim, S.G.; Lee, S.J.; Choung, Y.K.; Yoon, J.H. Power output analysis of transparent thin-film module in building integrated photovoltaic system (BIPV). Energy Build. 2008, 40, 2067–2075. [Google Scholar] [CrossRef]

- Jee, H.; Song, J.; Moon, D.; Lee, J.; Jeong, C. Improvement in power of shingled solar cells for photo-voltaic module. J. Nanosci. Nanotechnol. 2020, 20, 7096–7099. [Google Scholar] [CrossRef] [PubMed]

- Oh, W.; Jee, H.; Bae, J.; Lee, J. Busbar-free electrode patterns of crystalline silicon solar cells for high density shingled photovoltaic module. Sol. Energy Mater. Sol. Cells 2022, 243, 111802. [Google Scholar] [CrossRef]

- Oh, W.; Park, J.; Dimitrijev, S.; Kim, E.K.; Park, Y.S.; Lee, J. Metallization of crystalline silicon solar cells for shingled photovoltaic module application. Sol. Energy 2020, 195, 527–535. [Google Scholar] [CrossRef]

- Ravyts, S.; Vecchia, M.D.; Broeck, G.V.; Yordanov, G.H.; Goncalves, J.E.; Moschner, J.D.; Saelens, D.; Driesen, J. Embedded BIPV module-level DC/DC converters: Classification of optimal ratings. Renew. Energy 2020, 146, 880–889. [Google Scholar] [CrossRef]

- Oh, W.; Park, J.; Jeong, C.; Park, J.; Yi, J.; Lee, J. Design of a solar cell electrode for a shingled photovoltaic module application. Appl. Surf. Sci. 2020, 510, 145420. [Google Scholar] [CrossRef]

- Schulte-Huxel, H.; Blankemeyer, S.; Morlier, A.; Brendel, R.; Koentges, M. Interconnect-shingling: Maximizing the active module area with conventional module processes. Sol. Energy Mater. Sol. Cells 2019, 200, 109991. [Google Scholar] [CrossRef]

- Shen, L.; Li, Z.; Ma, T. Analysis of the power loss and quantification of the energy distribution in PV module. Appl. Energy 2020, 260, 114333. [Google Scholar] [CrossRef]

- Roy, J.N. Comprehensive analysis and modeling of cell to module (CTM) conversion loss during c-Si Solar Photovoltaic (SPV) module manufacturing. Sol. Energy 2016, 130, 184–192. [Google Scholar] [CrossRef]

- Bermudez, V.; Perez-Rodriguez, A. Understanding the cell-to-module efficiency gap in Cu(In,Ga)(S,Se)2 photovoltaics scale-up. Nat. Energy 2018, 3, 466–475. [Google Scholar] [CrossRef]

- Jung, T.H.; Lee, J.I.; Song, H.E.; Ju, Y.C.; Ko, S.W.; Jung, Y.S.; Kang, G.H. Classification conditions of cells to reduce cell-to-module conversion loss at the production stage of PV modules. Renew. Energy 2017, 103, 582–593. [Google Scholar] [CrossRef]

- Yousuf, H.; Zahid, M.A.; Khokhar, M.Q.; Park, J.; Ju, M.; Lim, D.; Kim, Y.; Cho, E.-C.; Yi, J. Cell-to-Module Simulation Analysis for Optimizing the Efficiency and Power of the Photovoltaic Module. Energies 2022, 15, 1176. [Google Scholar] [CrossRef]

| Before Lamination | After Lamination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Spacing [cm] | Isc [A] | Voc [V] | FF [%] | Eff [%] | Pm [W] | Isc [A] | Voc [V] | FF [%] | Eff [%] | Pm [W] |

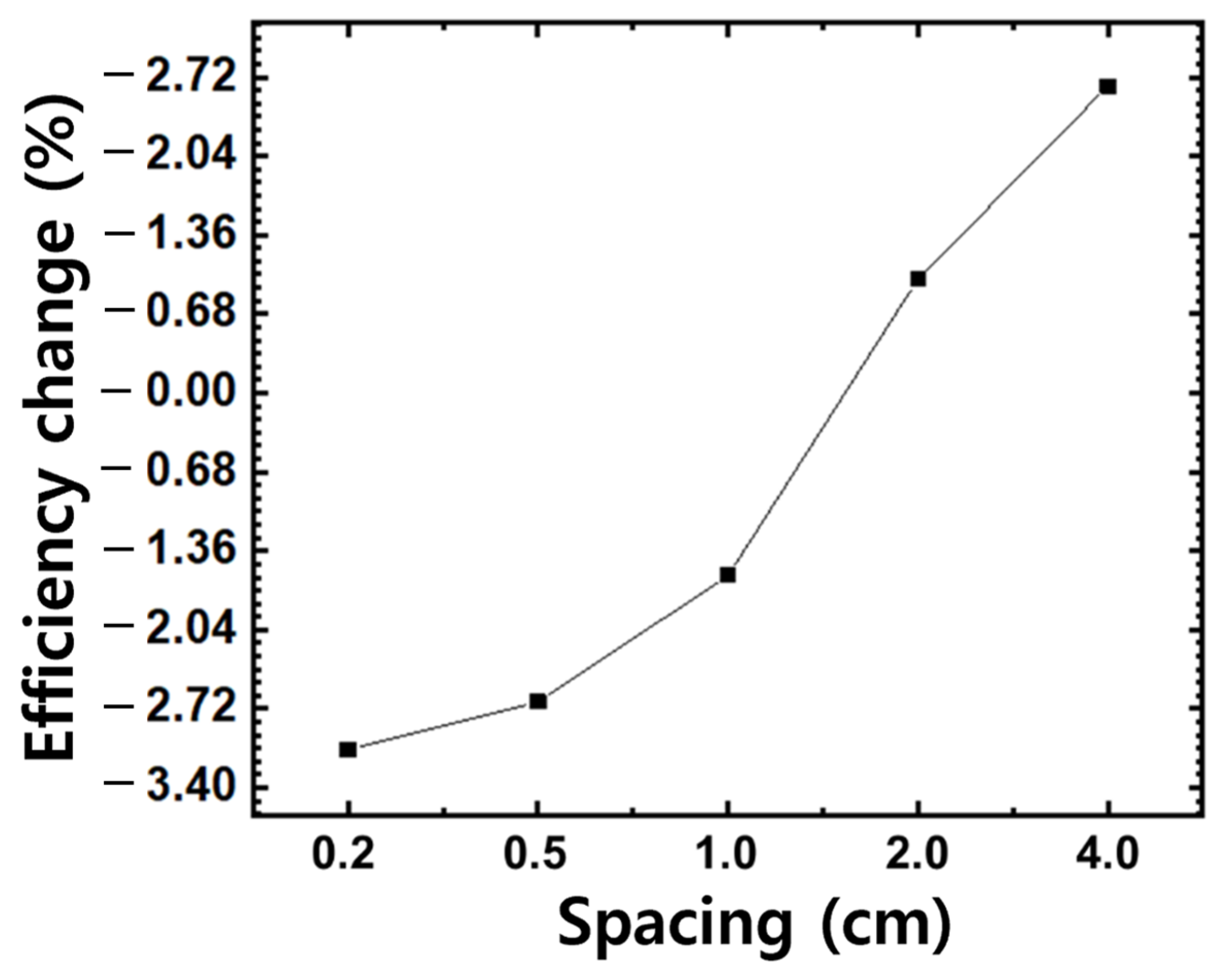

| 0.2 | 1.83 | 11.12 | 77.41 | 19.68 | 15.75 | 1.79 | 11.11 | 77.4 | 19.23 | 15.39 |

| 0.5 | 1.83 | 11.12 | 77.48 | 19.70 | 15.76 | 1.81 | 11.11 | 77.51 | 19.48 | 15.59 |

| 1 | 1.83 | 11.12 | 77.51 | 19.71 | 15.77 | 1.82 | 11.12 | 77.41 | 19.56 | 15.66 |

| 2 | 1.87 | 11.13 | 77.64 | 20.12 | 16.10 | 1.83 | 11.12 | 77.48 | 19.70 | 15.77 |

| 4 | 1.90 | 11.14 | 77.72 | 20.55 | 16.45 | 1.83 | 11.12 | 77.57 | 19.73 | 15.79 |

| Before Lamination | After Lamination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Spacing [cm] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] |

| 0.2 | 1 | 1.882 | 11.132 | 75.3 | 19.703 | 1 | 1.838 | 11.027 | 74.8 | 18.947 |

| 2 | 1.880 | 11.138 | 75.5 | 19.747 | 2 | 1.849 | 11.036 | 75.0 | 19.138 | |

| 3 | 1.862 | 11.127 | 75.9 | 19.647 | 3 | 1.845 | 11.016 | 75.0 | 19.045 | |

| 4 | 1.873 | 11.117 | 75.7 | 19.707 | 4 | 1.851 | 11.012 | 75.5 | 19.222 | |

| Before Lamination | After Lamination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Spacing [cm] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] |

| 0.5 | 5 | 1.872 | 11.140 | 75.6 | 19.704 | 5 | 1.873 | 11.034 | 74.7 | 19.294 |

| 6 | 1.873 | 11.117 | 75.5 | 19.65 | 6 | 1.864 | 10.999 | 74.9 | 19.188 | |

| 7 | 1.878 | 11.124 | 75.6 | 19.739 | 7 | 1.869 | 10.994 | 74.8 | 19.215 | |

| 8 | 1.873 | 11.133 | 75.8 | 19.745 | 8 | 1.875 | 11.009 | 75.0 | 19.347 | |

| Before Lamination | After Lamination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Spacing [cm] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] |

| 1.0 | 9 | 1.874 | 11.119 | 75.7 | 19.713 | 9 | 1.877 | 11.019 | 75.4 | 19.488 |

| 10 | 1.869 | 11.119 | 75.7 | 19.667 | 10 | 1.879 | 11.019 | 75.0 | 19.41 | |

| 11 | 1.878 | 11.13 | 75.2 | 19.652 | 11 | 1.881 | 11.03 | 74.6 | 19.343 | |

| 12 | 1.868 | 11.143 | 75.7 | 19.696 | 12 | 1.877 | 11.025 | 74.9 | 19.363 | |

| Before Lamination | After Lamination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Spacing [cm] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] |

| 2.0 cm | 13 | 1.876 | 11.124 | 75.5 | 19.683 | 13 | 1.931 | 11.036 | 74.8 | 19.915 |

| 14 | 1.882 | 11.13 | 75.5 | 19.762 | 14 | 1.928 | 11.05 | 75.1 | 19.988 | |

| 15 | 1.873 | 11.123 | 75.6 | 19.68 | 15 | 1.932 | 11.033 | 74.6 | 19.872 | |

| 16 | 1.875 | 11.123 | 75.5 | 19.686 | 16 | 1.933 | 11.037 | 74.7 | 19.918 | |

| Before Lamination | After Lamination | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Spacing [cm] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] | String No. | Isc [A] | Voc [V] | FF [%] | Eff [%] |

| 4.0 cm | 17 | 1.876 | 11.13 | 75.4 | 19.68 | 17 | 1.976 | 11.037 | 74.7 | 20.347 |

| 18 | 1.881 | 11.154 | 75.4 | 19.766 | 18 | 1.97 | 11.078 | 74.5 | 20.319 | |

| 19 | 1.869 | 11.149 | 76.0 | 19.773 | 19 | 1.968 | 11.056 | 74.6 | 20.296 | |

| 20 | 1.874 | 11.129 | 75.6 | 19.691 | 20 | 1.964 | 11.047 | 74.8 | 20.27 | |

| String No. | Pm [W] | Isc [A] | Voc [V] | FF [%] | Eff [%] | |

|---|---|---|---|---|---|---|

| Before lamination | 1 | 15.769 | 1.872 | 11.139 | 75.6 | 19.704 |

| 2 | 15.725 | 1.873 | 11.117 | 75.5 | 19.649 | |

| 3 | 15.797 | 1.878 | 11.123 | 75.6 | 19.739 | |

| 4 | 15.801 | 1.873 | 11.132 | 75.8 | 19.744 | |

| After lamination | 1 | 15.440 | 1.873 | 11.033 | 74.7 | 19.293 |

| 2 | 15.355 | 1.864 | 10.999 | 74.9 | 19.187 | |

| 3 | 15.377 | 1.869 | 10.994 | 74.8 | 19.215 | |

| 4 | 15.483 | 1.875 | 11.009 | 75.0 | 19.347 |

| String No. | Pm [W] | Isc [A] | Voc [V] | FF [%] | Eff [%] | |

|---|---|---|---|---|---|---|

| Before lamination | 5 | 15.734 | 1.870 | 11.122 | 75.7 | 19.661 |

| 6 | 15.725 | 1.875 | 11.119 | 75.4 | 19.649 | |

| 7 | 15.724 | 1.874 | 11.138 | 75.3 | 19.648 | |

| 8 | 15.801 | 1.873 | 11.132 | 75.8 | 19.744 | |

| After lamination | 5 | 14.878 | 1.745 | 10.994 | 77.6 | 18.591 |

| 6 | 14.894 | 1.752 | 10.994 | 77.3 | 18.611 | |

| 7 | 14.895 | 1.757 | 11.012 | 77.0 | 18.612 | |

| 8 | 14.864 | 1.760 | 10.987 | 76.9 | 18.574 |

| String No. | Pm [W] | Isc [A] | Voc [V] | FF [%] | Eff [%] | |

|---|---|---|---|---|---|---|

| Before lamination | 9 | 15.785 | 1.880 | 11.144 | 75.3 | 19.724 |

| 10 | 15.716 | 1.866 | 11.114 | 75.8 | 19.638 | |

| 11 | 15.777 | 1.863 | 11.134 | 76.1 | 19.714 | |

| 12 | 15.788 | 1.877 | 11.123 | 75.6 | 19.728 | |

| After lamination | 9 | 15.565 | 1.913 | 11.036 | 74.9 | 19.449 |

| 10 | 15.585 | 1.877 | 11.028 | 75.3 | 19.474 | |

| 11 | 15.617 | 1.880 | 11.027 | 75.3 | 19.514 | |

| 12 | 15.638 | 1.889 | 11.019 | 75.1 | 19.540 |

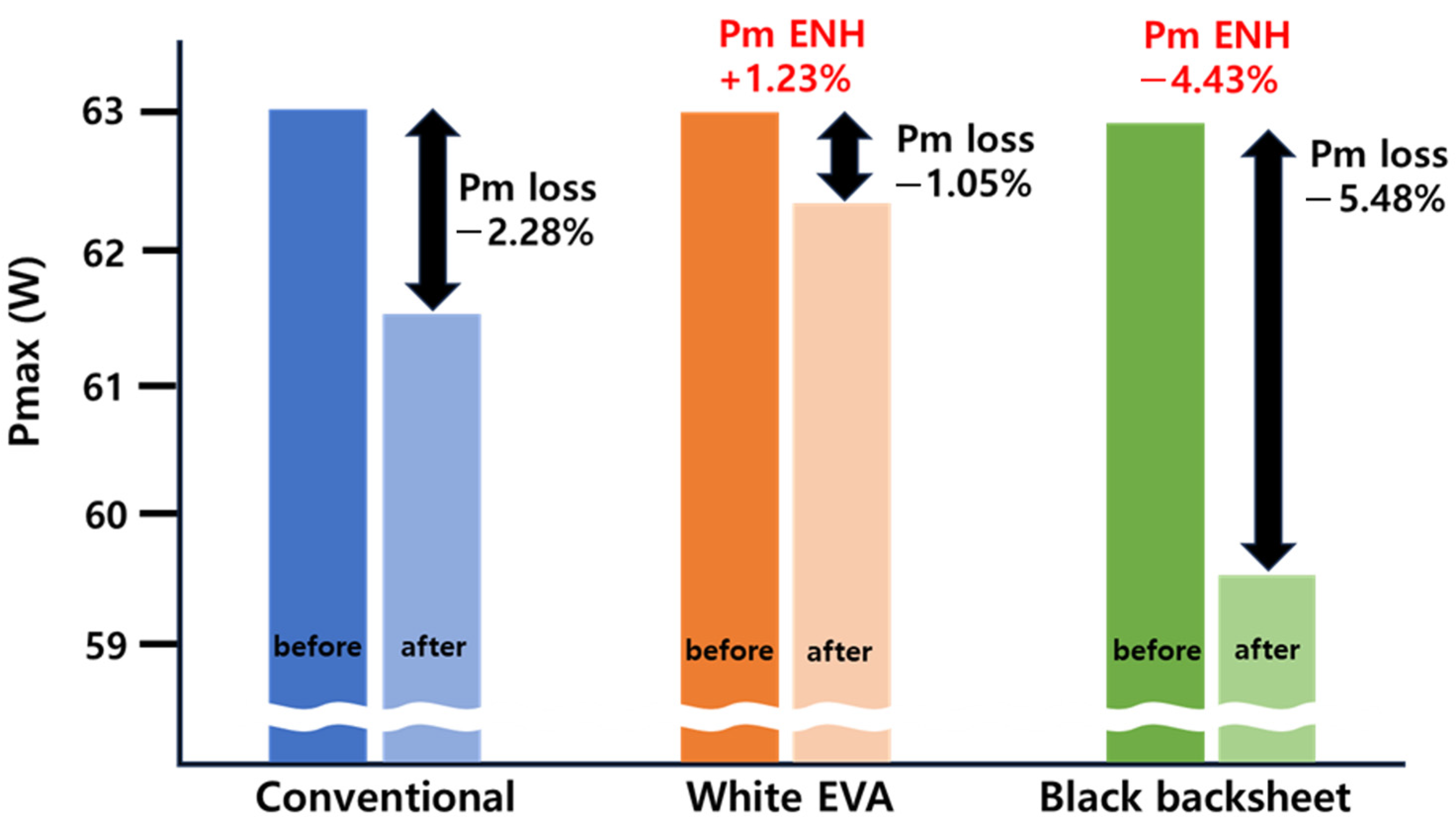

| Type | Pm Before Lamination (W) | Pm After Lamination (W) | Pm Loss (%) | Enhanced Pm Loss of White EVA vs. UVT EVA, Black Backsheet Structure (%) |

|---|---|---|---|---|

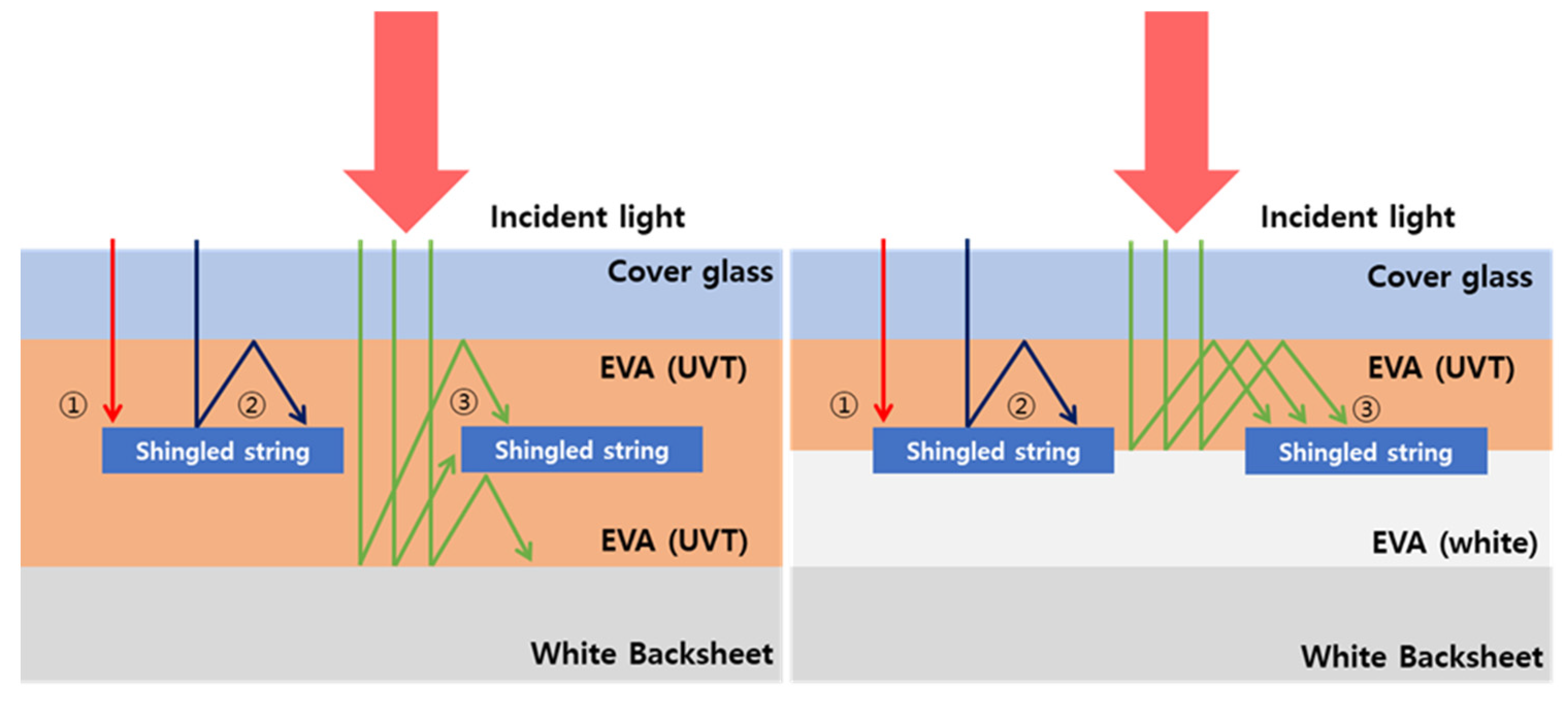

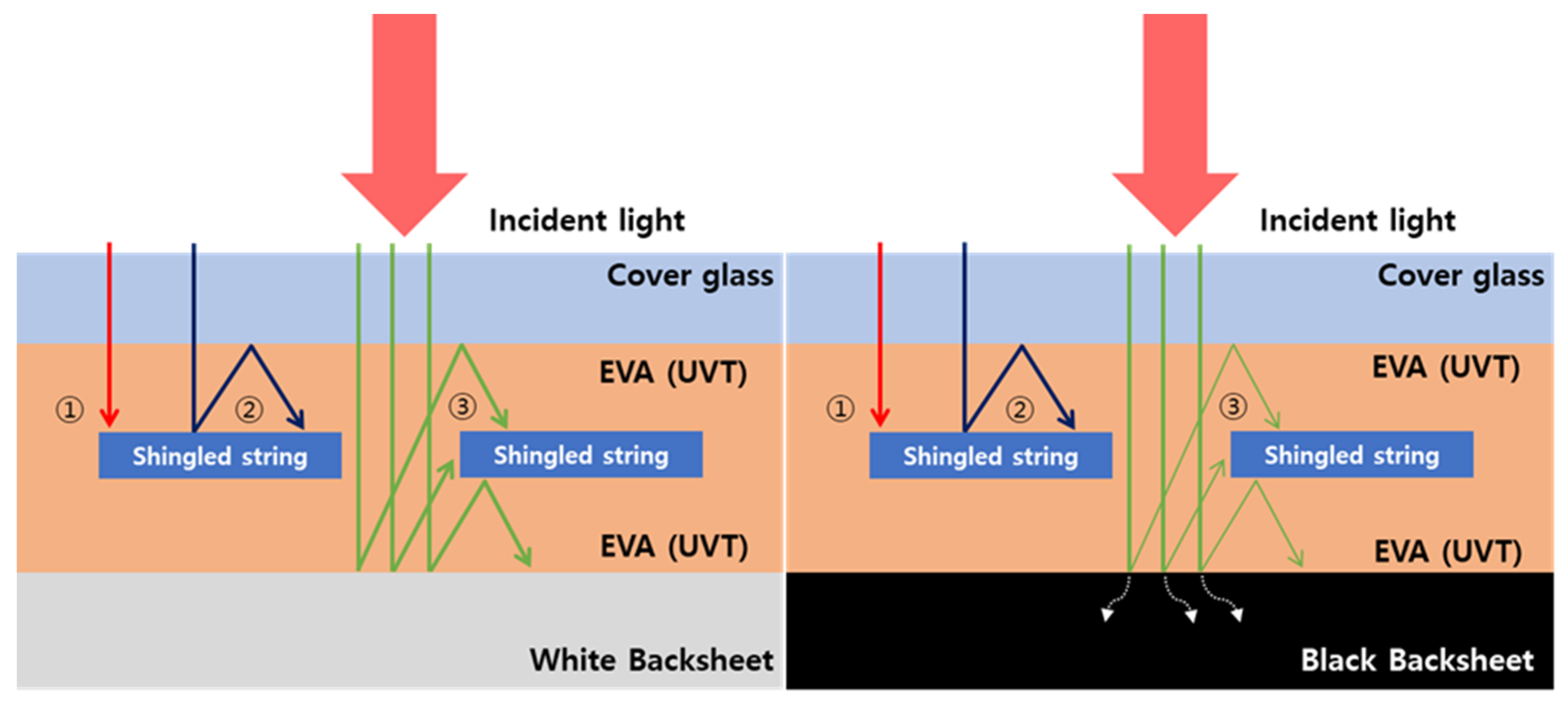

| UVT EVA | 63.092 | 61.655 | 2.28 | 117.14 |

| White EVA | 63.066 | 62.405 | 1.05 | - |

| Black backsheet | 62.984 | 59.531 | 5.48 | 521.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jee, H.; Ur, S.; Kim, J.; Lee, J. Study on the Optical Coupling Effect of Building-Integrated Photovoltaic Modules Applied with a Shingled Technology. Appl. Sci. 2024, 14, 5759. https://doi.org/10.3390/app14135759

Jee H, Ur S, Kim J, Lee J. Study on the Optical Coupling Effect of Building-Integrated Photovoltaic Modules Applied with a Shingled Technology. Applied Sciences. 2024; 14(13):5759. https://doi.org/10.3390/app14135759

Chicago/Turabian StyleJee, Hongsub, Seungah Ur, Juwhi Kim, and Jaehyeong Lee. 2024. "Study on the Optical Coupling Effect of Building-Integrated Photovoltaic Modules Applied with a Shingled Technology" Applied Sciences 14, no. 13: 5759. https://doi.org/10.3390/app14135759

APA StyleJee, H., Ur, S., Kim, J., & Lee, J. (2024). Study on the Optical Coupling Effect of Building-Integrated Photovoltaic Modules Applied with a Shingled Technology. Applied Sciences, 14(13), 5759. https://doi.org/10.3390/app14135759