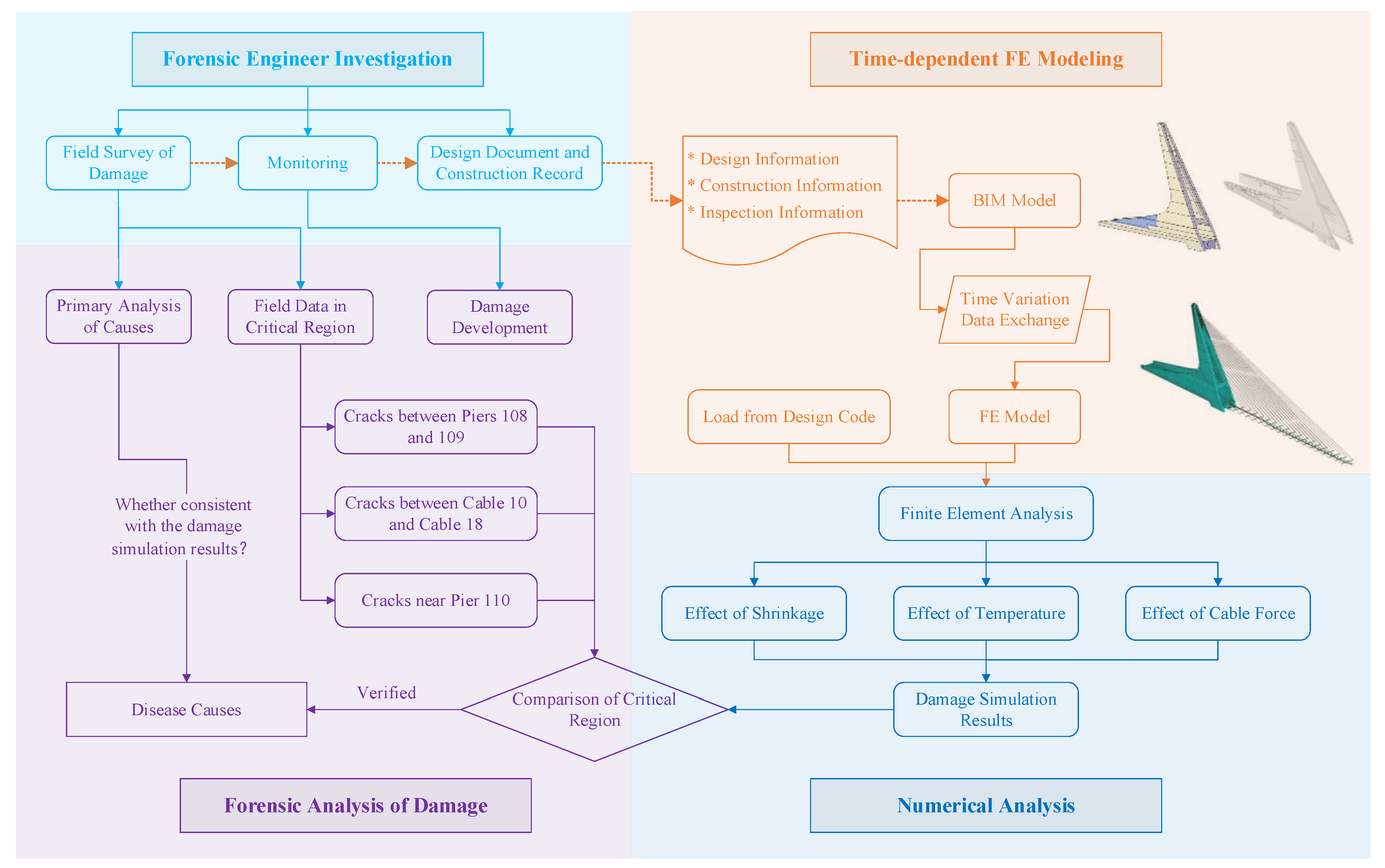

Forensic Analysis on Damage of a Cable-Stayed Bridge without Backstays Using BIM Information

Abstract

1. Introduction

2. Forensic Engineer Investigation

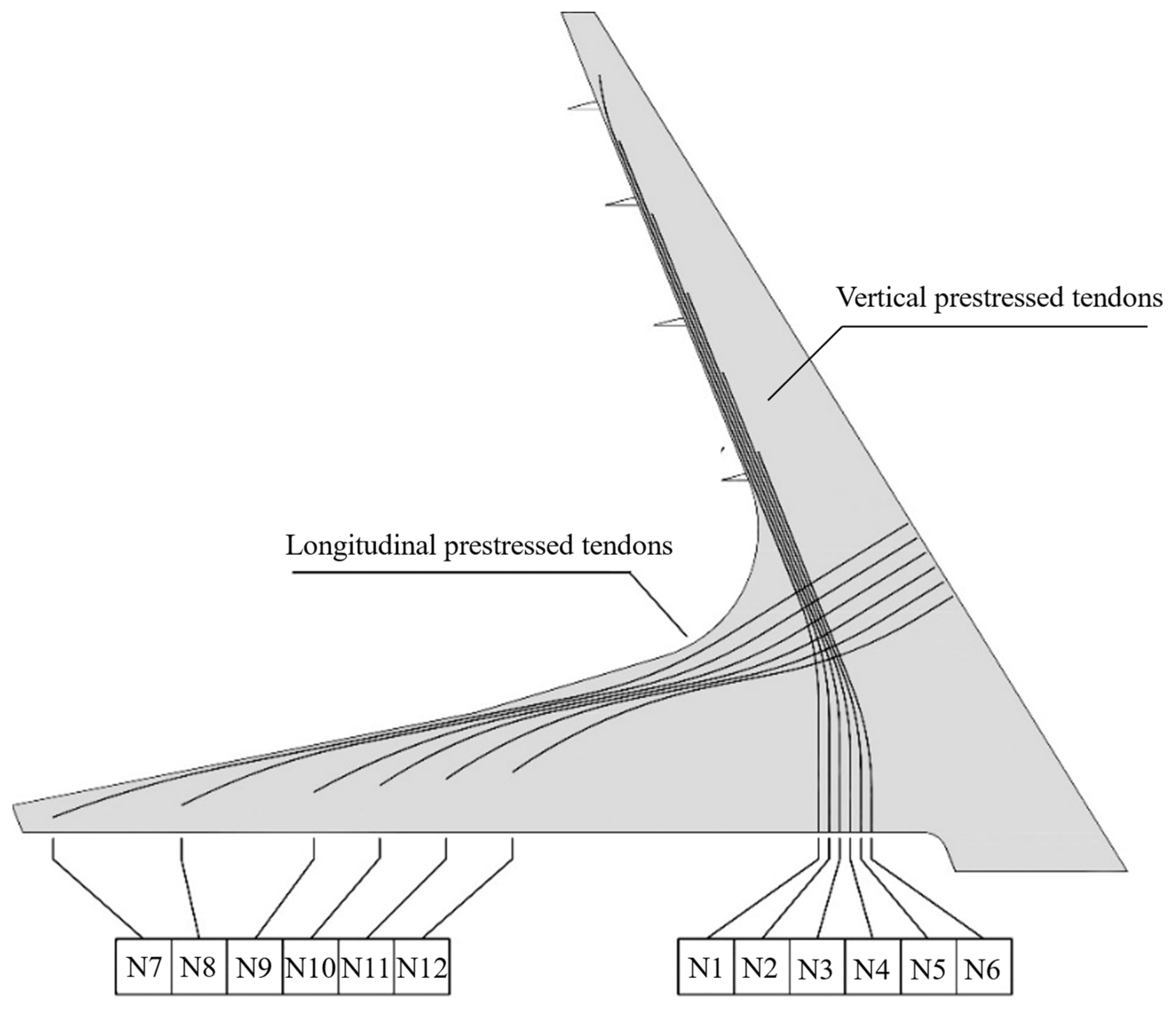

2.1. Design Document of the Bridge

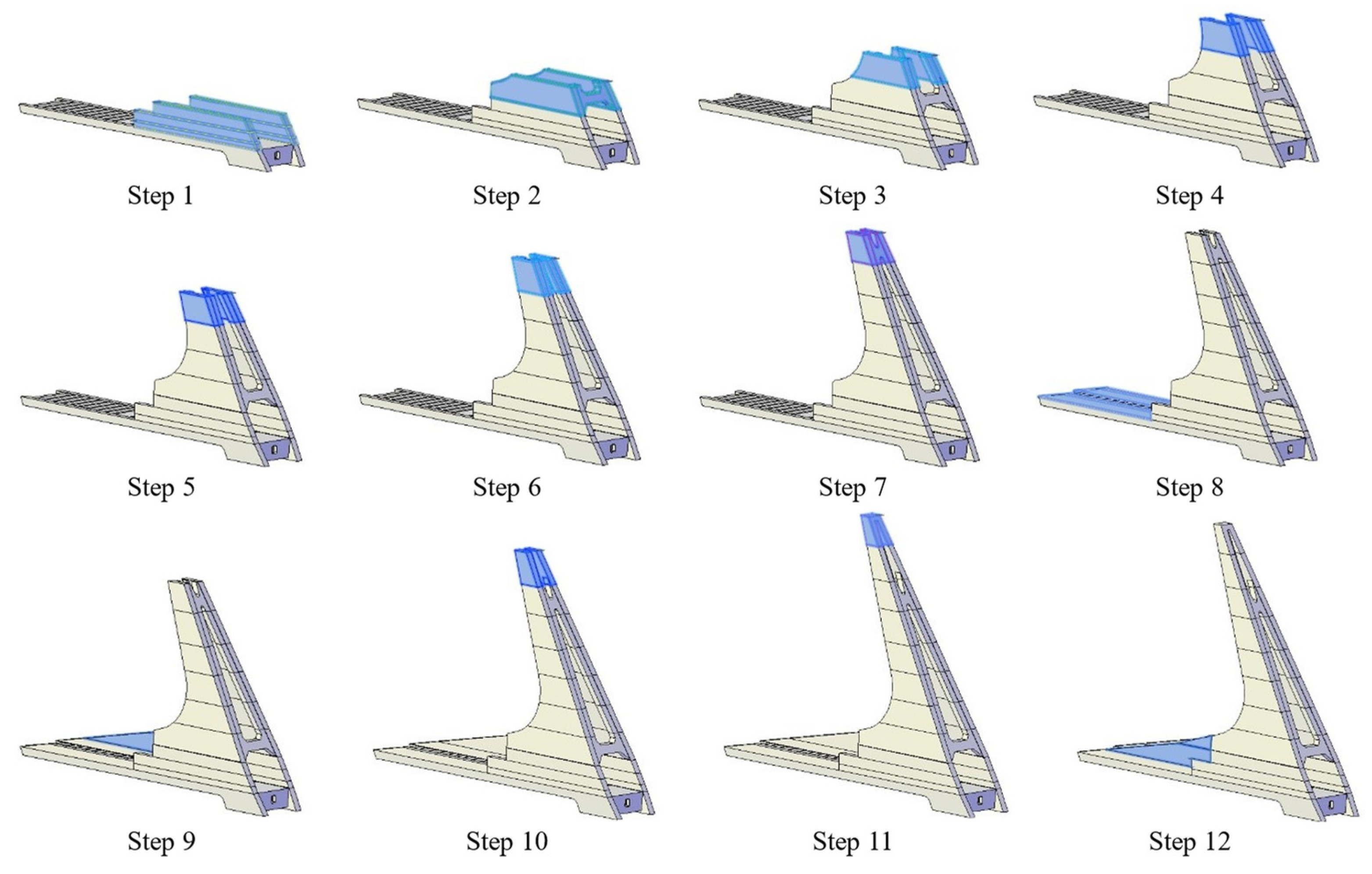

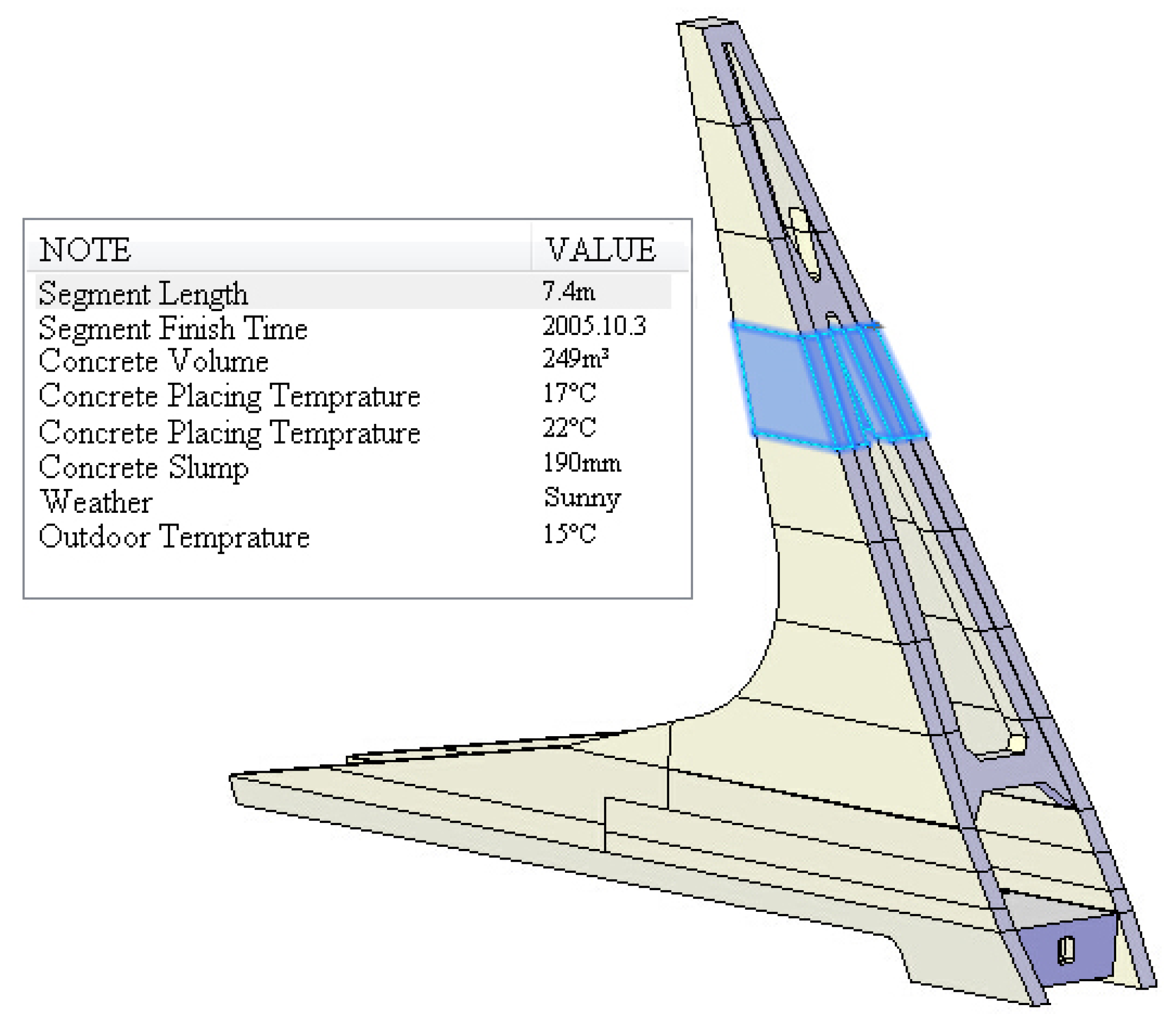

2.2. Construction Records

2.3. Field Survey of Disease

2.3.1. Cracks

2.3.2. Reduction in Prestressing Force

3. Time-Dependent FE Modeling

3.1. BIM Model

3.2. FE Model

3.2.1. Elements and Materials

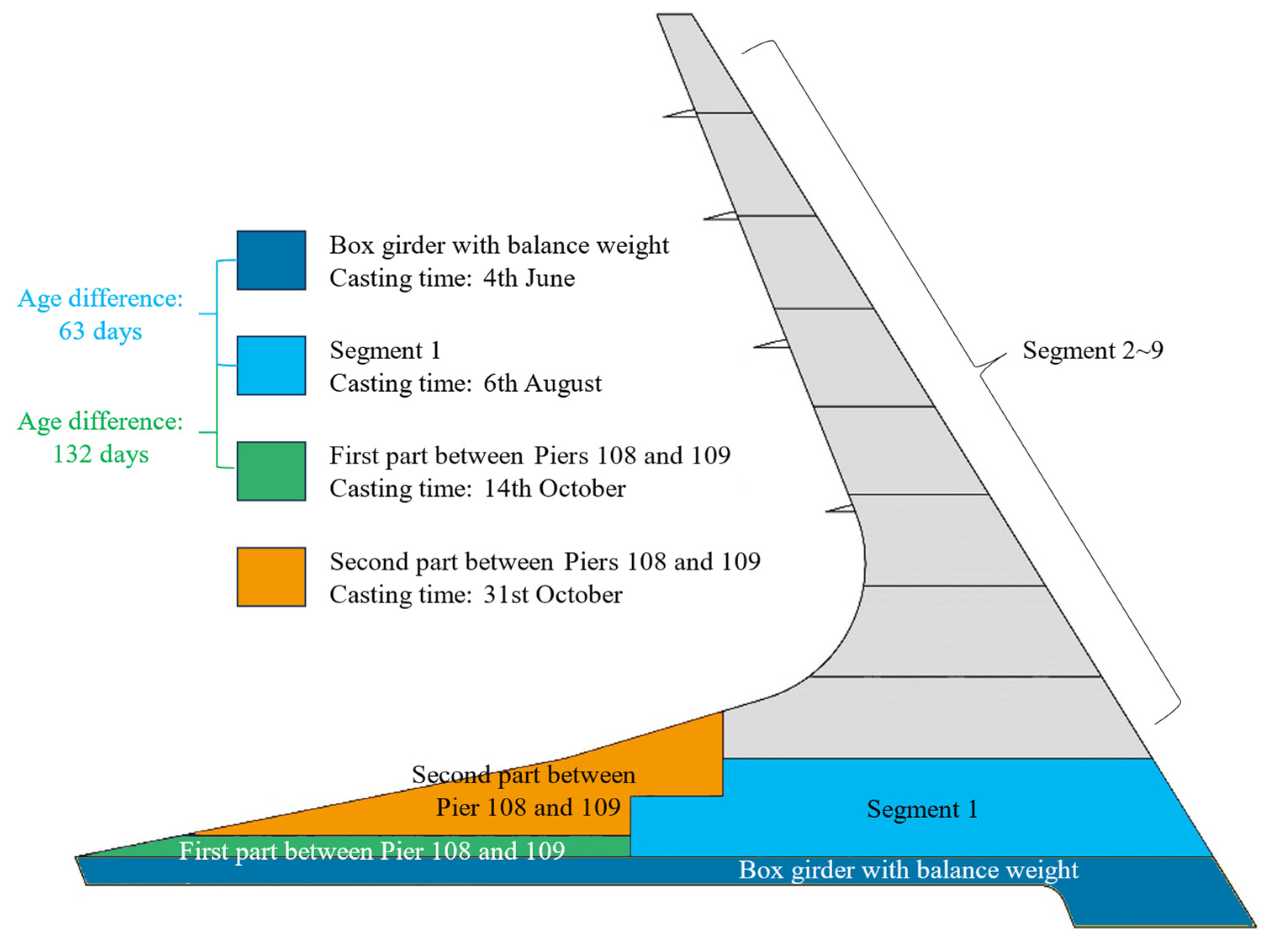

3.2.2. Construction Process Simulation

3.2.3. Concrete Shrinkage Simulation

4. Numerical Analysis

4.1. Analysis Cases and Results

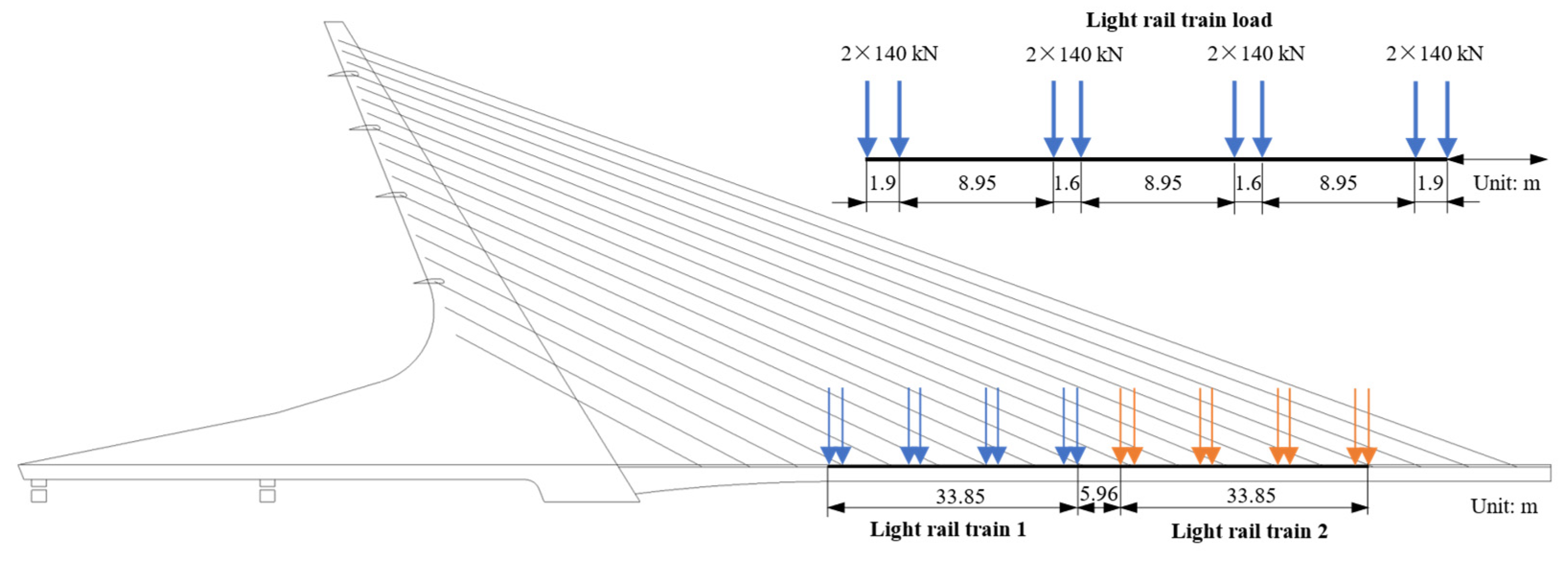

4.1.1. Analysis Cases and Load Conditions

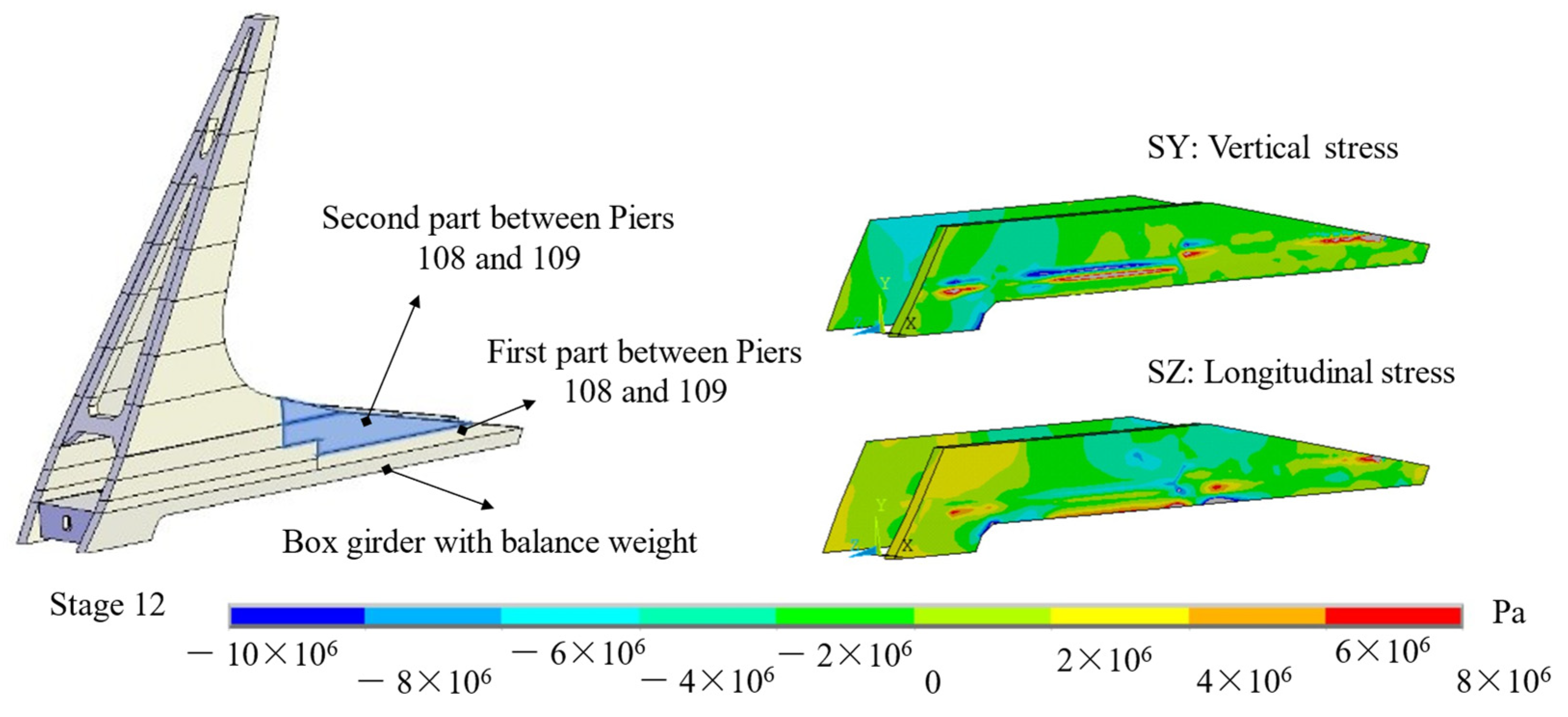

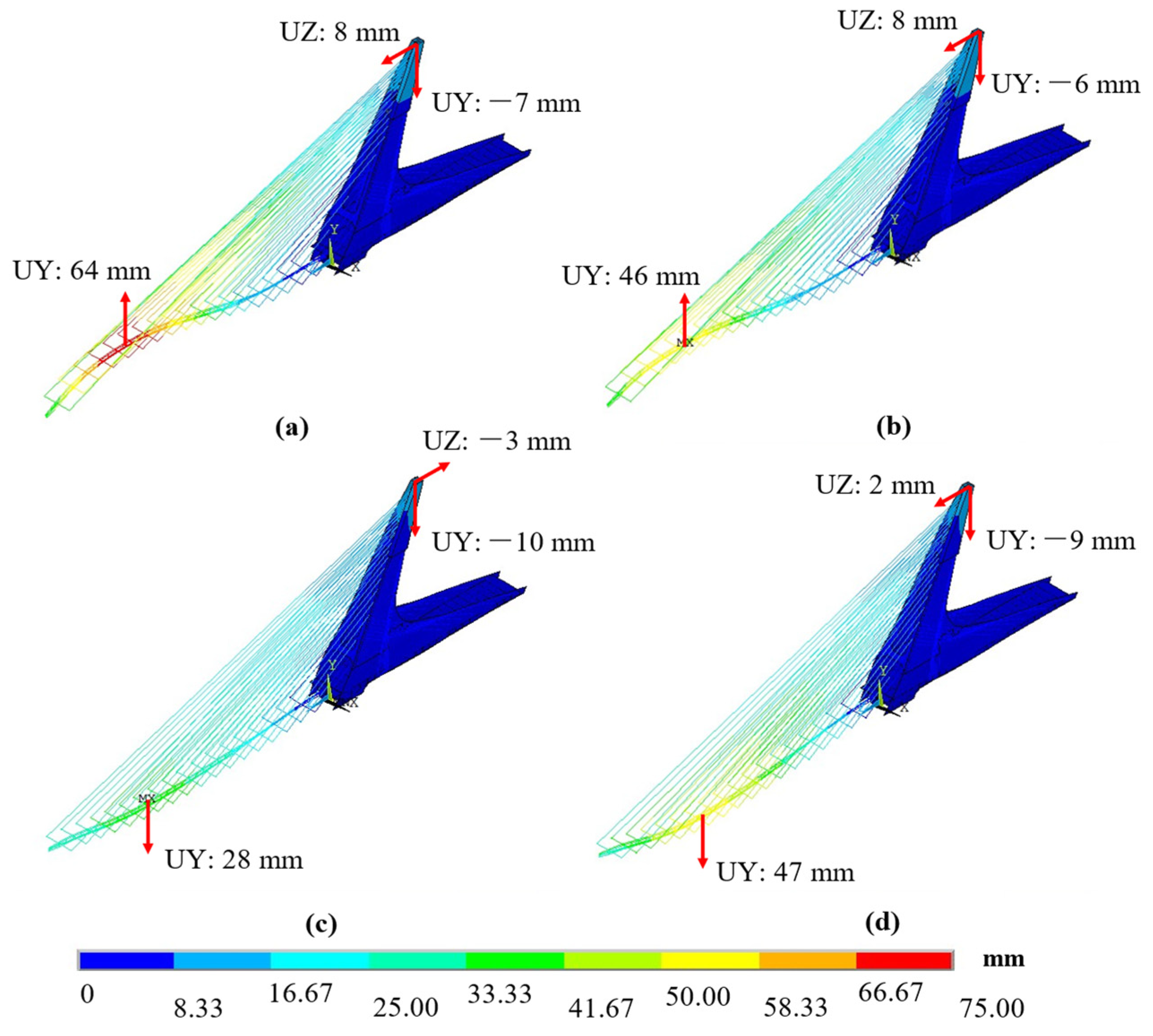

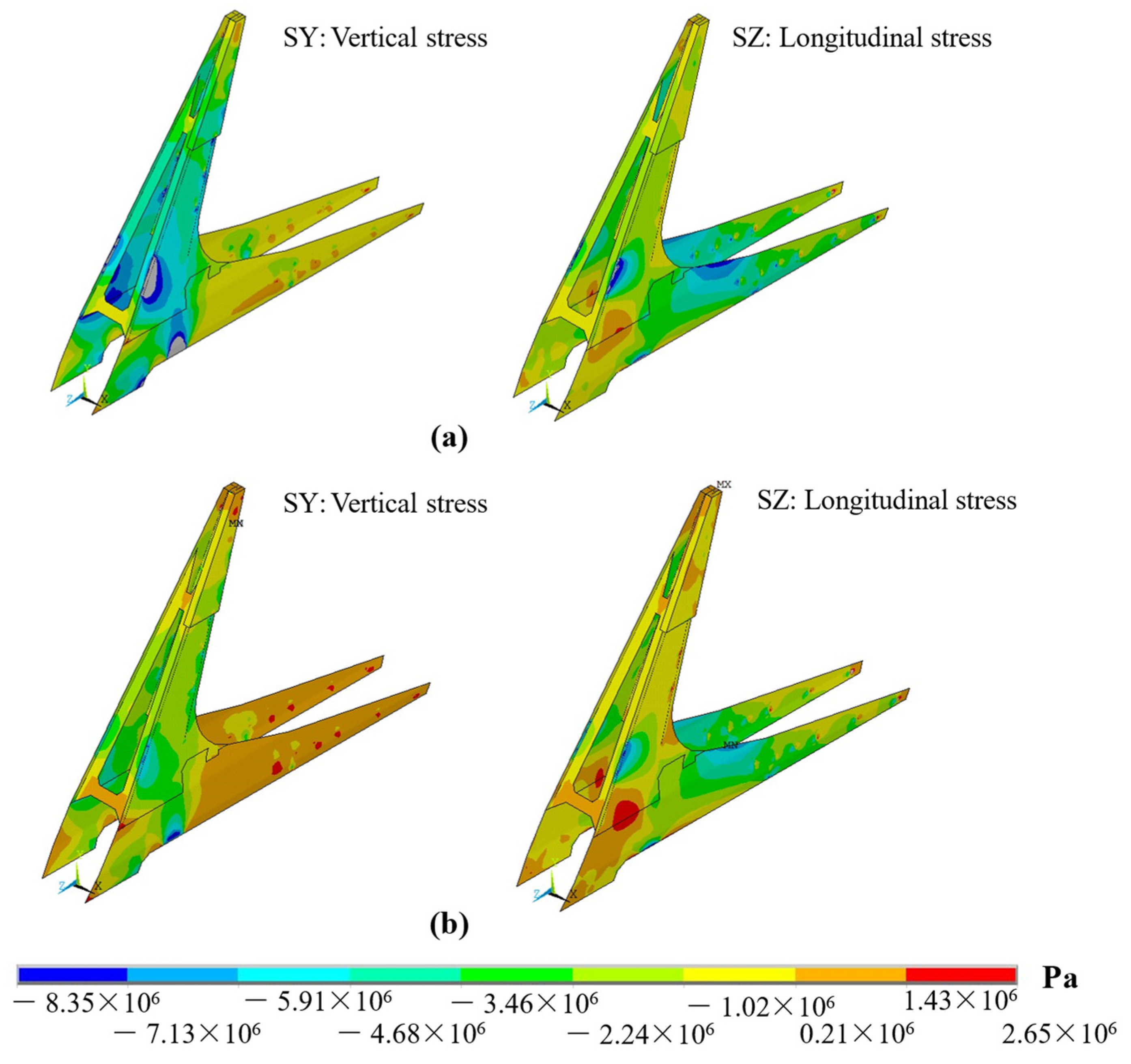

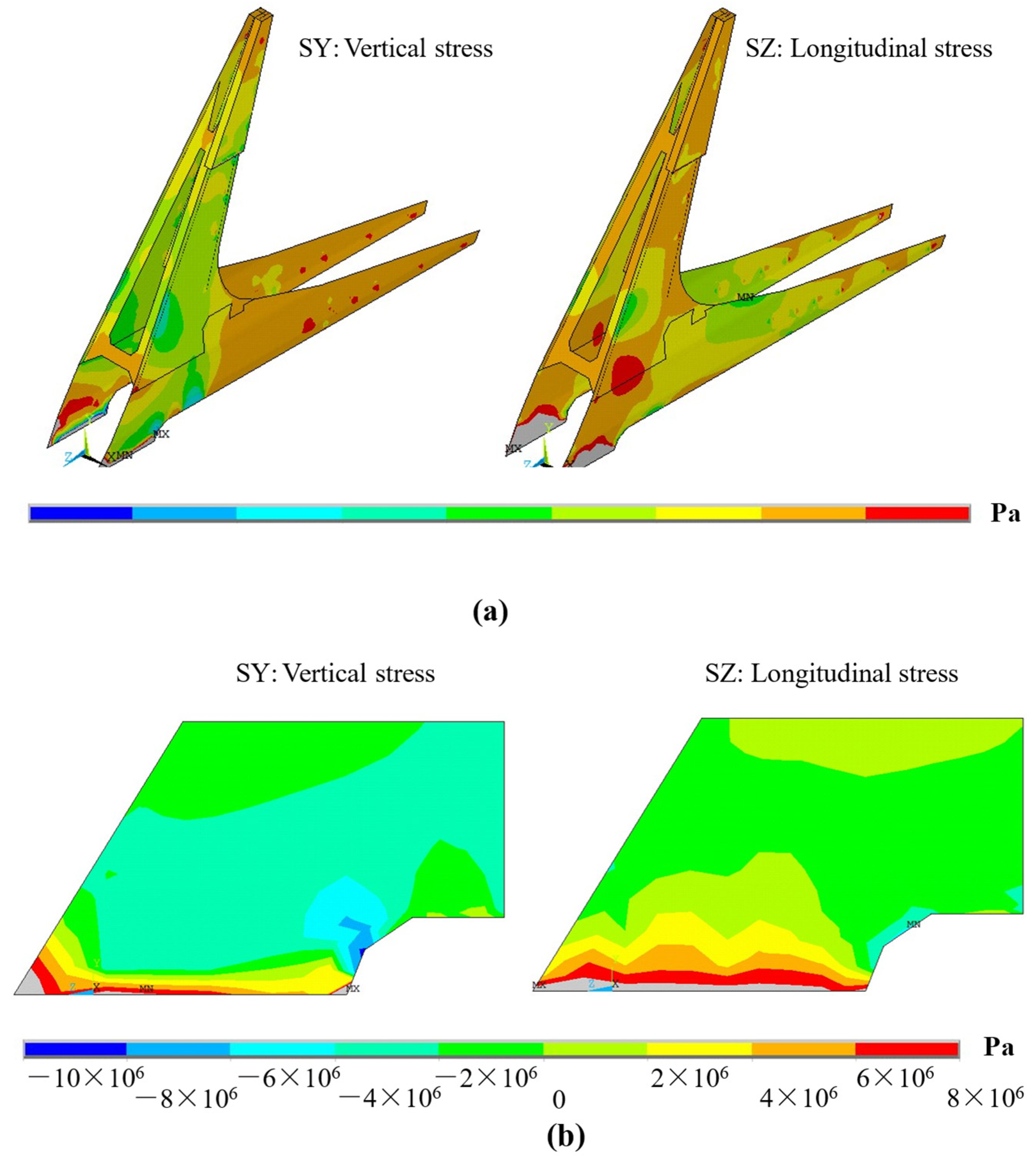

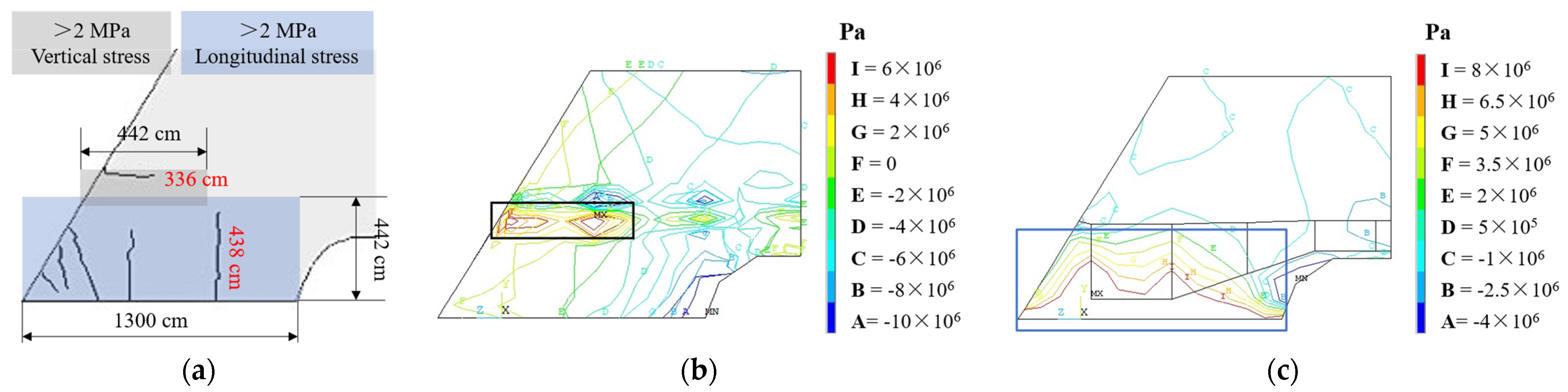

4.1.2. Analysis Results

4.2. Effect of Concrete Shrinkage

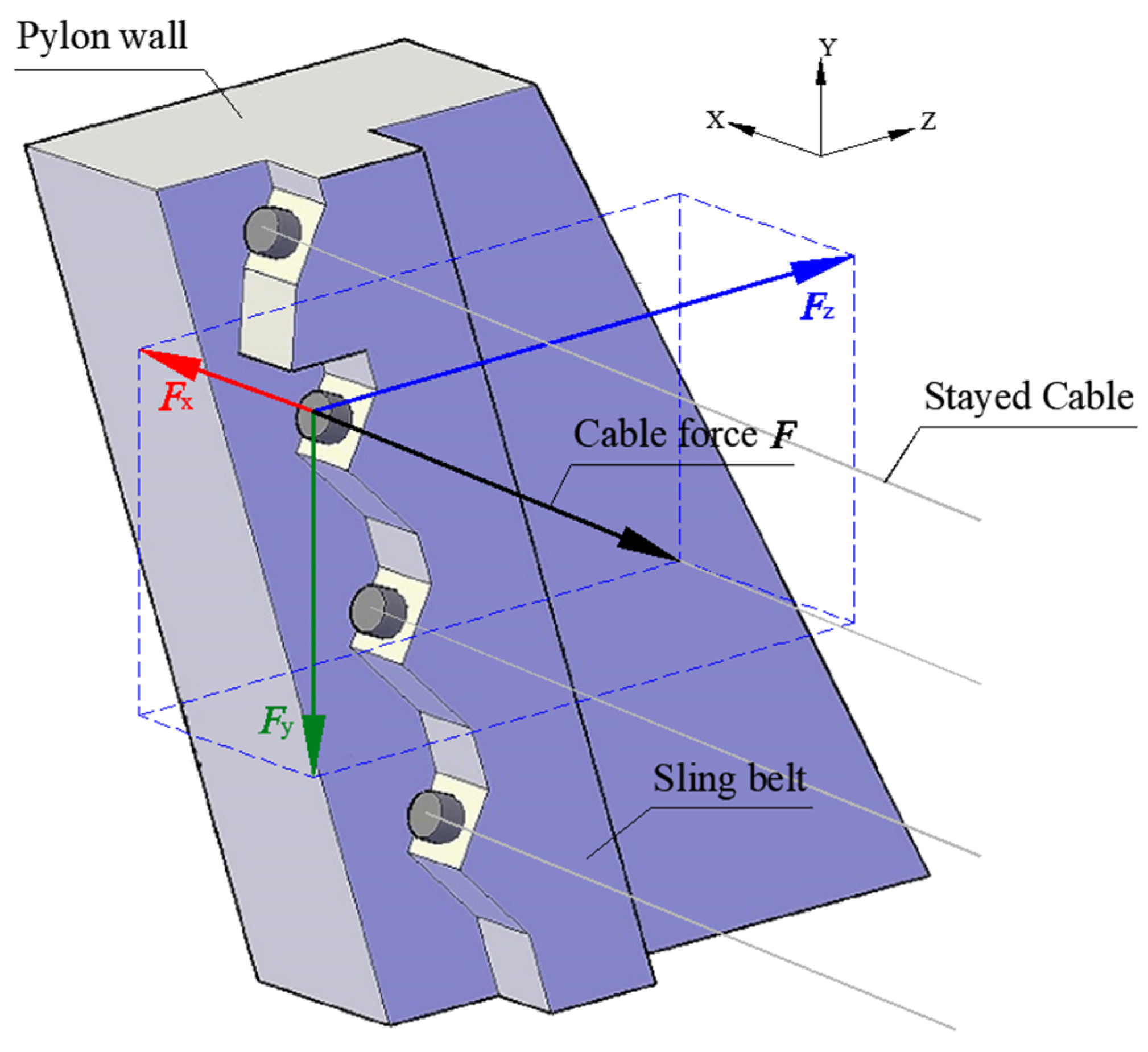

4.3. Effect of Cable Force Reduction

4.4. Effect of Temperature Load

5. Forensic Analysis of Damage

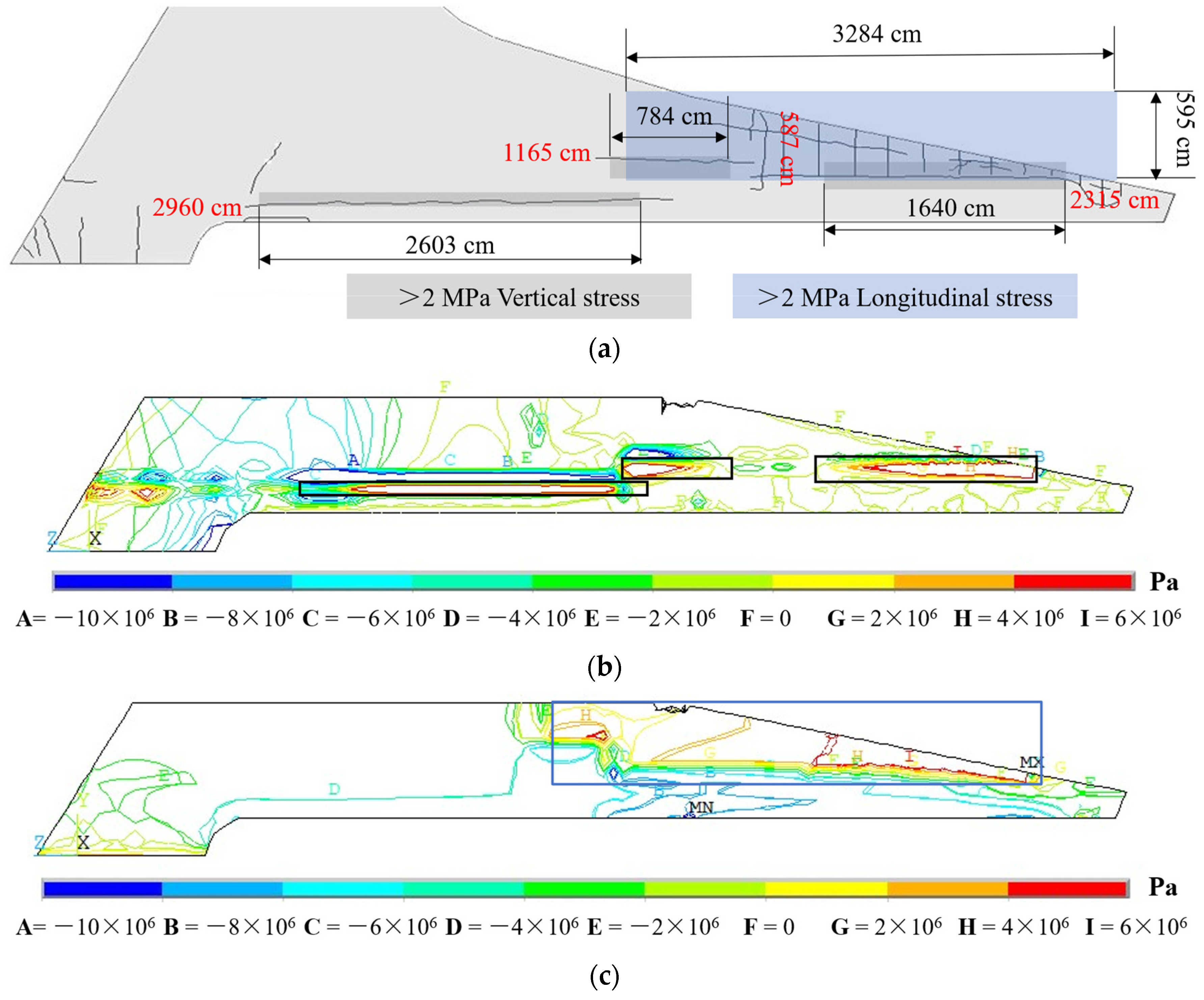

5.1. Crack Category L1

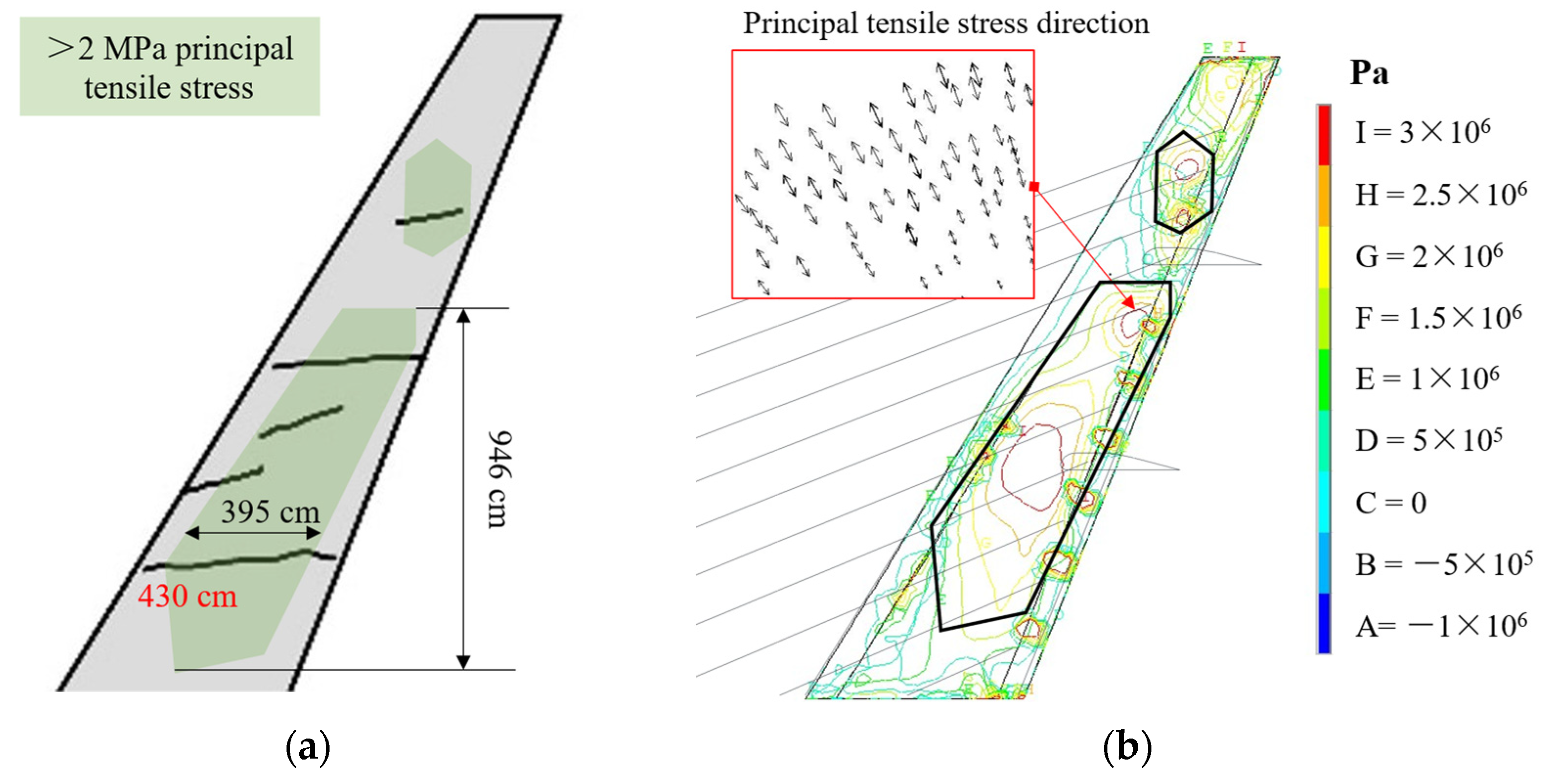

5.2. Crack Category L2

5.3. Crack Category L3

6. Conclusions

- (1)

- A large difference in concrete age and shrinkage exists in the pylon due to the unreasonable process of concrete casting in construction, which results in longitudinal and vertical cracks in the pylon walls between Piers 108 and 109.

- (2)

- The Poisson effect and the component of the cable force lead to incline cracks in the anchorage zone of C10~C18 cables. Moreover, the unsuitable positions of the anchorage of the prestressed tendons in the pylon exacerbate the development of cracks in the region.

- (3)

- The combination of temperature load and shrinkage results in short vertical and longitudinal cracks in the pylon near Pier 110. The measured force of stayed cables is less than the corresponding design force, which results in a negative bending moment at the bottom of the pylon, exacerbating the cracking.

- (4)

- The cause of cracks in the bridge is closely related to the shrinkage effect of the mass concrete bridge pylon cast in stages. It is necessary to carry out the construction process simulation and crack resistance analysis during the design.

- (5)

- The combined analyses using the BIM and FE methods agree well with the field inspection and provide a better way to reveal and understand the causes and distribution of cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Virlogeux, M. Recent Evolution of Cable-stayed Bridges. Eng. Struct. 1999, 21, 737–755. [Google Scholar] [CrossRef]

- Pollalis, S.N. What Is a Bridge? The Making of Calatrava’s Bridge in Seville; The MIT Press: Cambridge, MA, USA, 1999; pp. 2–16. [Google Scholar]

- Gimsing, N.J.; Georgakis, C.T. Cable Supported Bridges: Concept and Design; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Kominek, M. The Marian Bridge, Czech Republic. Struct. Eng. Int. 1998, 8, 283–284. [Google Scholar] [CrossRef]

- Shao, X.D.; Zhao, H.; Li, L.F. Design and Experimental Study of a Harp Shaped Single Span Cable-stayed Bridge. J. Bridge Eng. 2005, 10, 658–665. [Google Scholar] [CrossRef]

- Peng, W.H.; Shao, X.D.; Li, L.F. The Concept, Design, and Construction of Cable-stayed Bridges without Backstays. China Civ. Eng. J. 2007, 5, 26–33. [Google Scholar]

- Chen, D.W.; Au, F.T.K.; Tham, L.G.; Lee, P.K.K. Determination of Initial Cable Forces in Prestressed Concrete Cable-stayed Bridges for Given Design Deck Profiles Using the Force Equilibrium Method. Comput. Struct. 2000, 74, 1–9. [Google Scholar] [CrossRef]

- Chen, A.J.; He, G.J. Analysis on Reasonable Structure of Main Girder of Harp Shaped Cable-stayed Bridge without Backstays. Appl. Mech. Mater. 2011, 90–93, 1061–1068. [Google Scholar] [CrossRef]

- Wu, Y.; Li, J.; Sun, Q. Study on Human-induced Vibration of a Cable-stayed Bridge without Backstays Located in Abrupt Valley. Adv. Struct. Eng. 2021, 24, 3101–3117. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, X.; Li, J.; Xin, H.; Sun, Q.; Wang, J. Investigation of Vortex-induced Vibration of a Cable-stayed Bridge without Backstays Based on Wind Tunnel Tests. Eng. Struct. 2022, 250, 113436. [Google Scholar] [CrossRef]

- Kang, H.J.; Qian, D.Y.; Su, X.Y.; Zhang, X.Y.; Cong, Y.Y. A New Technique for Calculating the Effective Length Factor of the Tower in Cable-Stayed Bridge. Int. J. Struct. Stab. Dyn. 2023, 23, 2350130. [Google Scholar] [CrossRef]

- Zhang, Q.C.; Sun, Q.S. Analysis of Parameter Sensitivity in Construction Control of Inclined Pylon Cable-Stayed Bridge without Backstays. Adv. Mater. Res. 2011, 255–260, 851–855. [Google Scholar] [CrossRef]

- Antonio Lozano-Galant, J.; Turmo, J. Creep and Shrinkage Effects in Service Stresses of Concrete Cable-stayed Bridges. Comput. Concr. 2014, 13, 483–499. [Google Scholar] [CrossRef]

- Duan, H.; Liu, H.; Sun, Y.; Gao, H.S. Determination of Reasonable Internal Force State for Cable-stayed Bridge without Backstays. J. Civ. Struct. Health Monit. 2023, 13, 1243–1263. [Google Scholar] [CrossRef]

- Ratay, R.T.; Peraza, D.B. Investigation and Analysis of Structural Collapse. Encycl. Forensic Sci. 2013, 2, 461–465. [Google Scholar]

- Saeed, M.K.; Rahman, M.K.; Baluch, M.H.; Tooti, L.A. Cracking in Concrete Water Tank due to Restrained Shrinkage and Heat of Hydration: Field Investigations and 3d Finite Element Simulation. J. Perform. Constr. Facil. 2020, 34, 04019100. [Google Scholar] [CrossRef]

- Etemadi, A.; Balkaya, C. Collapsed-RC Building Failure Mechanisms with a Forensic Engineering Approach. J. Perform. Constr. Facil. 2020, 33, 04020086. [Google Scholar] [CrossRef]

- Cuoco, D.A.; Scarangello, T.Z.; Peraza, D.B. Investigation of L’Ambiance Plaza Building collapse. J. Perform. Constr. Facil. 1992, 6, 211–231. [Google Scholar] [CrossRef]

- Delatte, N.J. Beyond Failure; ASCE: Reston, VA, USA, 2007. [Google Scholar]

- Brando, F.; Iannitelli, A.; Cao, L.; Malsch, E.A.; Panariello, G.; Abruzzo, J.; Pinto, M.J. Forensic Investigation Modeling (FIM) Approach: I35 West Bridge Collapse Case Study. In Proceedings of the Forensic Engineering 2012: Gateway to a Safer Tomorrow, San Francisco, CA, USA, 31 October 2012. [Google Scholar]

- Campione, G.; Giambanco, G. Analysis of a Collapsed Long span Reinforced Concrete Roof in South Italy: Design Mistakes and Material Degradation. J. Perform. Constr. Facil. 2020, 34, 04020001. [Google Scholar] [CrossRef]

- Palmisano, F.; Vitone, A.; Vitone, C.; Vitone, V. Collapse of the Giotto Avenue Building in Foggia. Struct. Eng. Int. 2007, 17, 166–171. [Google Scholar] [CrossRef]

- Palmisano, F.; Vitone, A. Partial Collapse of One of the Most Important Historical Building in Salerno, Italy. J. Perform. Constr. Facil. 2015, 29, 04014164. [Google Scholar] [CrossRef]

- Korkmaz, H.H.; Yakut, A.; Bayraktar, A. Analysis of a Multistory Reinforced Concrete Residential Building Damaged under Its Self Weight. Eng. Fail. Anal. 2019, 98, 38–48. [Google Scholar] [CrossRef]

- Balkaya, C. Lessons Learned from Collapse of Zumrut Building under Gravity Loads. Int. J. Eng. Technol. 2017, 3, 44–49. [Google Scholar] [CrossRef]

- Park, J.; Cai, H.; Dunston, P.S.; Ghasemkhani, H. Database-supported and Web-based Visualization for Daily 4D BIM. J. Constr. Eng. Manag. 2017, 143, 04017078. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, J. BIM-and 4D-based Integrated Solution of Analysis and Management for Conflicts and Structural Safety Problems during Construction: 2. Development and Site Trials. Autom. Constr. 2011, 20, 167–180. [Google Scholar] [CrossRef]

- Mcguire, B.; Atadero, R.; Clevenger, C.; Ozbek, M. Bridge information modeling for inspection and evaluation. J. Bridge Eng. 2016, 21, 04015076. [Google Scholar] [CrossRef]

- Kim, S.; Ma, J.; Lee, J.; Hong, T.; An, J.; Jeong, K. Framework of BIM-Based Quantitative Evaluation for Enhancing Fire Safety Performance of Buildings. J. Manag. Eng. 2024, 40, 04023061. [Google Scholar] [CrossRef]

- Levine, N.M.; Spencer, B.F., Jr. Post-Earthquake Building Evaluation Using UAVs: A BIM-Based Digital Twin Framework. Sensors 2022, 22, 873. [Google Scholar] [CrossRef]

- Computer Software, Version 15.0; ANSYS Release 15.0; ANSYS, Inc.: Canonsburg, PA, USA, 2015.

- ANSYS, Inc. ANSYS Manual; ANSYS, Inc.: Canonsburg, PA, USA, 2015. [Google Scholar]

- JTG 3362-2018; Ministry of Communications and Transport (MOCAT). Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. China Communications Press: Beijing, China, 2018.

- JTG D60-2015; Ministry of Communications and Transport (MOCAT). General Specifications for Design of Highway Bridges and Culverts. China Communications Press: Beijing, China, 2015.

| Step | Content | Time | Volume (m3) | Concrete Slump (mm) | Temperature (℃) | Relative Humidity |

|---|---|---|---|---|---|---|

| 1 | Segment 1 | 2005/8/6 | 846 | 180 | 24.5 | 73% |

| 2 | Segment 2 | 2005/8/24 | 527 | 200 | 23.0 | 69% |

| 3 | Segment 3 | 2005/9/4 | 339 | 190 | 14.0 | 63% |

| 4 | Segment 4 | 2005/9/14 | 263 | 200 | 14.0 | 63% |

| 5 | Segment 5 | 2005/9/23 | 213 | 200 | 16.0 | 58% |

| 6 | Segment 6 | 2005/10/3 | 249 | 190 | 14.5 | 51% |

| 7 | Segment 7 | 2005/10/11 | 151 | 200 | 10.0 | 51% |

| 8 | The first part between Piers 108 and 109 | 2005/10/14 | 335 | 190 | 6.0 | 51% |

| 9 | The second part between Piers 108 and 109 in the south | 2005/10/17 | 133 | 190 | 2.5 | 51% |

| 10 | Segment 8 | 2005/10/18 | 112 | 190 | 3.0 | 51% |

| 11 | Segment 9 | 2005/10/26 | 90 | 190 | 6.0 | 51% |

| 12 | The second part between Piers 108 and 109 in the north | 2005/10/31 | 133 | 190 | −2.0 | 51% |

| State | Cases | Cable Force | Load Conditions |

|---|---|---|---|

| Initial design | Case 1 | Design cable force | Self-weight |

| Case 2 | Design cable force | Self-weight + Temperature load | |

| Case 3 | Design cable force | Self-weight + Live load | |

| Construction stage | Case 4 | Measured cable force | Self-weight + Shrinkage |

| Service state | Case 5 | Measured cable force | Self-weight |

| Case 6 | Measured cable force | Self-weight + Temperature load | |

| Case 7 | Measured cable force | Self-weight + Live load |

| Regions | Stress or Deformation | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 |

|---|---|---|---|---|---|---|---|---|

| Region 1 | SY (MPa) | −3~1.5 | −3~1.5 | −2.5~1.5 | −10~8 | −1~2.5 | −2.5~1.5 | −3~2 |

| SZ (MPa) | −7~1 | −7~1 | −6.5~0.5 | −4~8 | −7~1 | −7~0.5 | −7~1 | |

| Region 2 | SY (MPa) | −7~1 | −7~1 | −7~1 | −4~6 | −2~2.5 | −2~2.5 | −2~2.5 |

| SZ (MPa) | −3~0.5 | −3~0.5 | −3~0.5 | −4~2 | −1~1.5 | −1~1.5 | −1~1.5 | |

| Region 3 | SY (MPa) | −7~1 | −9~2 | −8~1 | −2~4 | −8~2 | −12~6 | −8~1 |

| SZ (MPa) | −2~1 | −2~6 | −2~0.5 | −2~4 | −2~1.5 | −4~8 | −2~1 | |

| Box girder | UY (mm) | 64 (↑ *) | 74 (↑) | 46 (↑) | −30 (↓) | −28 (↓) | −19 (↓) | −47 (↓) |

| Pylon top | UY (mm) | −7 (↓) | −33 (↓) | −6 (↓) | −10 (↓) | −10 (↓) | −36 (↓) | −9 (↓) |

| UZ (mm) | 8 (←) | 26 (←) | 8 (←) | −5 (→) | −3 (→) | 21 (←) | 2 (←) |

| Construction Stage | Stresses in Region 1 | Stresses in Region 2 | Stresses in Region 3 | ||||

|---|---|---|---|---|---|---|---|

| Stage | Construction Content | SY (MPa) | SZ (MPa) | SY (MPa) | SZ (MPa) | SY (MPa) | SZ (MPa) |

| 1 | Segment 1 | + | - | / | / | + | + |

| 2 | Segment 2 | + | - | / | / | + | + |

| 3 | Segment 3 | + | - | / | / | + | + |

| 4 | Segment 4 | + | - | / | / | + | + |

| 5 | Segment 5 | + | - | / | / | + | + |

| 6 | Segment 6 | + | - | / | / | + | + |

| 7 | Segment 7 | + | - | / | / | + | + |

| 8 | The first part between Piers 108 and 109 | ++ | + | / | / | ++ | ++ |

| 9 | The second part between Piers 108 and 109 in the south | ++ | + | / | / | ++ | ++ |

| 10 | Segment 8 | ++ | + | / | / | ++ | ++ |

| 11 | Segment 9 | ++ | + | - | - | ++ | ++ |

| 12 | The second part between Piers 108 and 109 in the north | ++ | + | - | - | ++ | ++ |

| 13 | Pour main girder, tension stayed cables, and prestressing tendons | ++ | + | + | + | ++ | ++ |

| 14 | Long-term shrinkage simulation | +++ | ++ | + | + | +++ | +++ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Q.; Shi, X.; Xu, Z.; Ma, H. Forensic Analysis on Damage of a Cable-Stayed Bridge without Backstays Using BIM Information. Appl. Sci. 2024, 14, 5538. https://doi.org/10.3390/app14135538

Xu Q, Shi X, Xu Z, Ma H. Forensic Analysis on Damage of a Cable-Stayed Bridge without Backstays Using BIM Information. Applied Sciences. 2024; 14(13):5538. https://doi.org/10.3390/app14135538

Chicago/Turabian StyleXu, Qi, Xuefei Shi, Ziqi Xu, and Haiying Ma. 2024. "Forensic Analysis on Damage of a Cable-Stayed Bridge without Backstays Using BIM Information" Applied Sciences 14, no. 13: 5538. https://doi.org/10.3390/app14135538

APA StyleXu, Q., Shi, X., Xu, Z., & Ma, H. (2024). Forensic Analysis on Damage of a Cable-Stayed Bridge without Backstays Using BIM Information. Applied Sciences, 14(13), 5538. https://doi.org/10.3390/app14135538