Abstract

This paper puts forth a systematic approach to evaluating the maturity level of the robotization of production processes in the context of digital transformation for manufacturing companies. The method was developed to address the absence of a sector-specific framework for assessing robotization maturity growth, in line with the Industry 5.0 guidelines (incorporating sustainability, the circular economy, and human-centeredness). The survey covers six core areas for manufacturing companies: the automation and robotization of production processes, digitization of warehouse processes, flexibility and intralogistics, and end-to-end integration of key data management processes. The study aimed to advance digitalization through improved robotization maturity. The study surveyed 200 small and medium-sized businesses operating in Poland from 2022 to 2024. The study presents a method to assess enterprise operational maturity, covering current and planned levels and development plans for the next three years.

1. Introduction

Today’s robotization of technological processes encompasses new areas beyond classic robot applications [1,2,3,4,5,6,7]. Various types of robotic implementations have been utilized for many years (e.g., machine and process line operation, pick-and-place, material handling, packaging and palletizing, assembly and disassembly, welding and soldering, batching, gluing, painting, processing, grinding, milling, cutting, quality control, testing, die casting, etc.). However, these classic implementations of robots still need to be challenged.

Robotization can be adapted to meet the requirements of Industry 5.0, emphasizing waste minimization and energy conservation [8,9,10,11]. Industry 5.0 builds on the Industry 4.0 [12,13,14,15,16] approach and expands its scope to include a regenerative purpose and focus. The goal is to transform industrial production to benefit people, the planet, and well-being rather than solely to extract value. The robotization of technological processes allows for increased production flexibility and resilience in the face of a shortage of skilled workers. The criteria mentioned above remain crucial for attaining the intended level of productivity. Industrial robots have a pivotal role in promoting sustainable development. They help increase resource productivity, reduce hazardous emissions, such as greenhouse gases and other pollutants, and improve production quality, which results in less waste. Additionally, they enhance workers’ functional safety. Collaborative robots have revolutionized production facilities by replacing or working with employees [17,18,19,20].

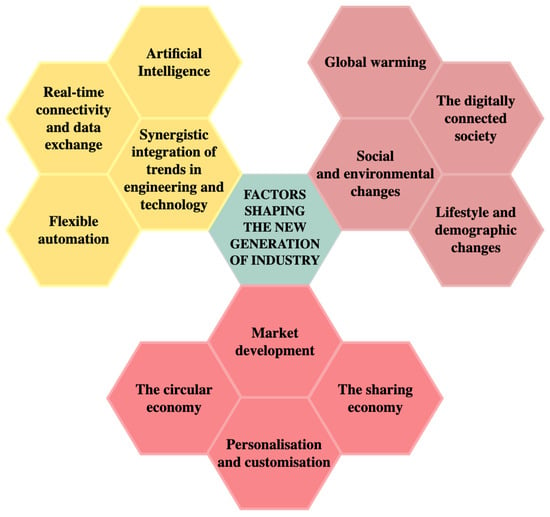

Figure 1.

Key growth drivers for Industry 5.0 [21,22,23,24,25].

Table 1 shows the notable distinctions between the objectives of Industry 4.0 and Industry 5.0. These disparities are due to the adoption of new assumptions [26,27,28,29], which serve as the foundation for a socially responsible approach to the robotization of production processes and the changes that come with companies’ digital transformation.

Table 1.

A comparison of the fundamental areas of Industry 4.0 versus Industry 5.0 [26,27,28,29].

Robotization combined with a consciously carried-out automation process meets the needs of Industry 5.0’s new challenges, as indicated by the development trends illustrated in Figure 2.

Figure 2.

Main development trends in robotization of production processes.

There is a growing interest in collaborative robots in process automation, according to recent trends [30]. This state is because flexible safety systems can replace inflexible ones with easy programming and a wide range of applications at a lower price point. The need to employ or outsource the services of skilled programmers can be significantly reduced by using low-code and no-code programming methods. It is essential to consider the requirements for End-of-Arm Tooling [30], such as tooling performance (ease of change, flexibility, adaptability, programming, and safety design) to minimize downtime between processes. Noncompliance with EoAT requirements could sometimes alter the robot–worker interaction, transitioning from collaboration to cooperation or coexistence.

Artificial intelligence and machine learning are growing, evident in their functionality. These techniques aid in diagnosing and predicting operating conditions, optimizing energy usage, and governing the course of action. Robots are now equipped with intelligent sensors [31,32]. This provides full operation autonomy and integrates quality control for products and the process.

The offline programming method using Digital Twins is changing how robots are programmed (the technology is utilized for diagnosing and simulating the robot’s performance within the production environment) [33].

One significant change is the robots’ expanded functionality and application in previously unexplored areas. Mobile robots [32,33], including autonomous vehicles used in intralogistics, play a critical role and are considered essential for various applications. To meet the requirements of security, flexibility, and reliability, it is necessary to use advanced security systems, fast and reliable wireless networks, localization methods, and conflict arbitration mechanisms. Mobile robots are used to develop internal traceability systems in warehouses and production areas [34]. Robotic workstations and individual robots are now often connected to data clouds to optimize processes and evaluate KPIs in industrial automation [32,33,34].

Attitudes towards the necessity of robots have recently undergone a shift. Robot-as-a-Service (RaaS) [35] has emerged, eliminating the need to purchase a robot and necessary tooling. RaaS offers classic advantages, such as lower initial investment costs, flexibility, and scalability to meet current needs. Additionally, it allows outsourcing maintenance and support services and accessibility to the latest market technologies. This model provides cost predictability, remote monitoring and management, rapid integration into existing production systems, and customization of provided market solutions. RaaS has lowered the barrier to entry for small and medium-sized enterprises to implement industrial process robotization solutions.

The fields of robotics and automation have been complementary for many years. However, these areas are gaining more importance in an era of widespread reshoring [36,37,38]. However, it is crucial to identify the specific application’s needs and select the appropriate robot accordingly.

The primary trend in the market is the digitalization of production processes, which neglects the aspects of robotics and automation [39,40,41,42,43,44,45,46,47,48,49]. For entrepreneurs, automation and robotization are fundamental factors in building the foundations for the development of digitally managed production [50,51,52,53,54]. The level of robotization maturity, entrepreneurs’ awareness of robot selection, necessary tooling, and infrastructure adaptation need to be evaluated.

The author has developed a method to evaluate the maturity level of manufacturing companies in terms of robotization, considering the digital transformation process and environmental factors. The basic rationale for the method’s development is the lack of knowledge about the implementation of robotization in terms of needs, expected functionalities, and the scalability and freely expandable nature of industrial systems.

2. A Method for Assessing the Maturity Level of Key Areas in Manufacturing Companies

2.1. The Main Obstacles to the Robotization of Production Processes

Robotizing production is complex and requires careful planning, purchasing, and integration. Fundamental issues may include:

- Analysis of the factors determining the feasibility of implementing a robot;

- Selection of a robot for a specific application—it is essential to consider various factors such as kinematic structure, load capacity, degrees of freedom, reach, mounting type, speed, motion range of joints, motion repeatability, IP class, operating temperature range, built-in/optional communication ports and IO interfaces, programming method and environment, tooling, and installation requirements;

- Estimation of implementation costs, including the purchase and maintenance expenses, in comparison to the costs of other solutions available in the market;

- Selection of sensors and additional instrumentation (grippers with tactile sensors, accelerometers, 3D vision systems, force and torque sensors, glue or paint guns, welding guns, etc.);

- The need to meet requirements for the operating environment in which humans and robots interact and the safety measures that need to be considered during operation;

- Integration of IIoT collaborative robots, including connectivity technologies such as Ethernet, Wi-Fi, Bluetooth, GSM systems, 5G, and software integration;

- The need to provide necessary additional instrumentation (e.g., utilities, gas extractors, etc.) and adaptation of infrastructure;

- Training of employees; hiring or outsourcing qualified staff.

Based on initial surveys, the most frequently used criteria (C1–C5) by entrepreneurs have been identified in the form of:

- C1—Relocating time-consuming processes to robotic workstations while transferring operators to higher-value tasks;

- C2—Elimination of routine quality problems (frequent need for scrap or rework) and areas of inconsistent quality;

- C3—Elimination of the manipulation of heavy tools or parts, workplaces, or locations with potential for dangerous accidents;

- C4—Handling monotonous and rule-based operations (e.g., sorting, simple logic);

- C5—Moving workers away from hazardous areas (exposition to gases, dust, or by-products of the production process) and eliminating manual activities (with repetitive movements and ergonomic problems and those requiring prolonged, intensive concentration or constant change of attention).

The criteria that have been indicated include issues related to technology, ergonomics, and process reorganization. However, key requirements such as energy savings, reduced adverse environmental impacts [55,56], and continuous improvement, including the possibility of integrating robots into digitized complex enterprise management systems [57,58,59,60,61,62,63], must also be included.

2.2. Aims, Objectives, and Structure of the Proposed Method

The author developed a method that uses a five-point scale to evaluate the maturity of a manufacturing company’s operations in six key areas, which include:

- Automation of production processes—a key area of development that determines the possibility of the digitalization of production, as well as the integration of production and management processes;

- Robotization of production processes—a key area of development for increasing the quality, reproducibility, productivity, and autonomy of manufacturing workstations, as well as the redeployment of employees to higher-value tasks;

- Digitization of intralogistics warehouse processes—a key area of development determining the ability to efficiently manage and optimize inventory levels, including inputs, finished products, equipment, and tools;

- Flexibility of production systems—a key area of development for achieving agility relies on improving internal processes such as dynamic path routing and increasing machine Overall Equipment Effectiveness ratios, as well as external processes such as responding quickly to market changes;

- Intralogistics of production processes (inter-station and inter-department transport)—a key development area for achieving agile automation in material and product flow streams;

- Integration of management, production, quality control, intralogistics, and warehousing systems—a key area of development for achieving Single Source of Truth data exchange status between all systems for managing and controlling company processes.

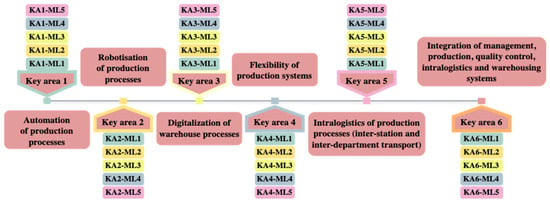

Key areas of the maturity level assessment method for manufacturing companies are illustrated in Figure 3.

Figure 3.

Key areas of the maturity level assessment method: ML1–ML5—maturity levels in a specific key area.

Figure 4 shows a matrix of the manufacturing company’s key areas and maturity levels. The rows correspond to the current and target maturity levels, while the columns represent the individual key areas.

Figure 4.

Matrix of key areas and maturity levels of the manufacturing company.

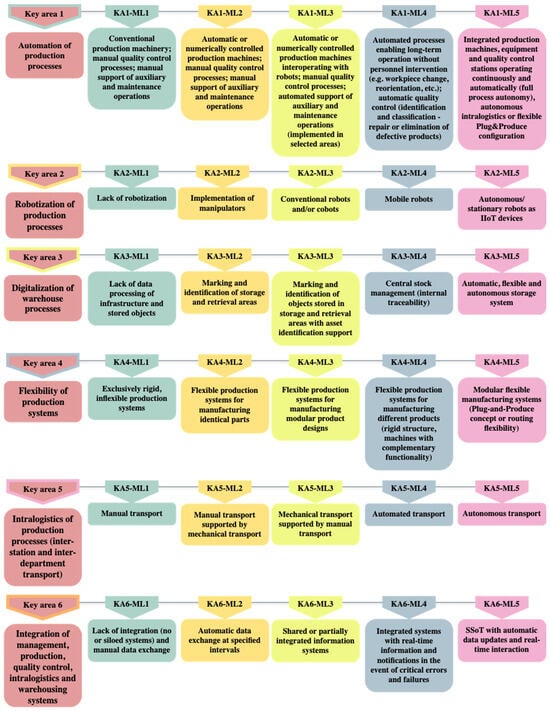

Guidelines and recommendations have been defined for each maturity level of all areas to identify current and target states, which are specified as follows:

- Current state—a set of characteristics defining the minimum requirements of a selected key area, divided into categories representing the characteristics of a specific maturity level;

- Advantages—three independent sub-areas (machinery, infrastructure, and equipment; human resources; processes) defining strengths in each maturity level of a specific key area;

- Disadvantages—three independent sub-areas (machinery, infrastructure, and equipment; human resources; processes) defining weaknesses in each maturity level of a specific key area;

- Growth opportunities—a set of necessary directions to identify technological deficiencies (machinery sub-area), skills gaps (human resources sub-area), and process optimization (processes sub-area);

- Recommendations—recommendations including the implementation of measures to achieve a higher level of maturity.

The method involves selecting a specific key area’s current and target states. Defining the initial and target states requires meeting the requirements of lower maturity levels. The key areas are closely interlinked and intersect at the development planning and implementation stages. It is possible to evaluate a company’s level of maturity in a specific area that is considered a priority. However, implementing the recommendations suggested to reach the target state will always increase the overall maturity level.

The maturity level assessment is conducted separately in the specified key areas. The area chosen for analysis depends on personal preferences and current development needs. The first step is to assess the compatibility of the solutions used with the elements in the current state scope to identify the initial level of maturity.

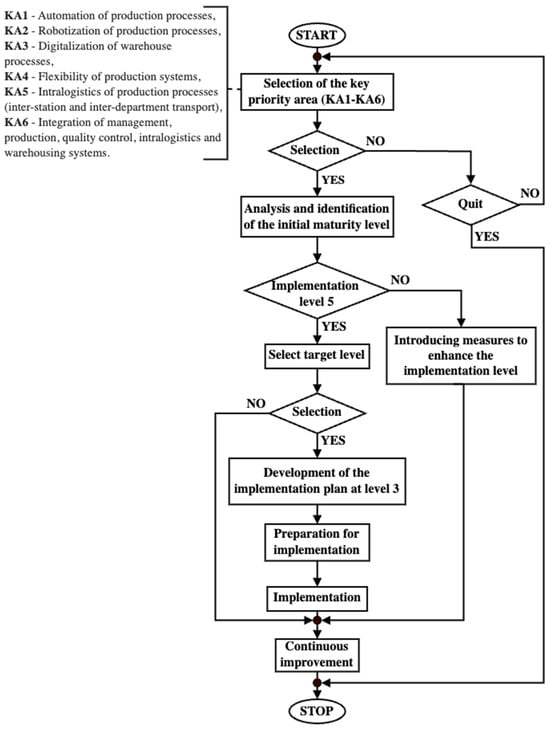

As shown in Table 2, each of the five maturity levels within a specific key area is rated on a five-point implementation scale.

Table 2.

The scale of implementation of the defined maturity levels.

The scale has been designed to indicate increasing levels of advancement. The highest level of advancement allows for optimizing a specific key area, leading to increased maturity.

The author defined the scale in terms of criteria for ownership, management, and the utilization of specific technological and IT solutions. This allows the evaluation to encompass the identified solutions’ organizational and planning methods, competencies, knowledge, and utilization level.

Figure 5 shows the algorithm for evaluating the defined maturity levels across key areas. Reaching the fifth level of implementation makes moving to the next level of maturity achievable.

Figure 5.

Algorithm for evaluating the defined maturity levels across key areas.

The author’s fundamental premise is that acquiring and utilizing modern technology, advanced machinery, and equipment requires proper management to ensure optimization and the development of the issues identified in the respective key areas. Continuous improvement solutions should be implemented in each case.

The following section delves into the characteristics of the primary area addressed in the article.

2.3. Characteristics of the Key Area—Robotization of Production Processes

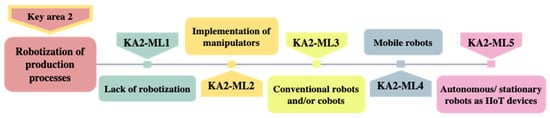

The stages of robotization in production processes are classified into maturity levels, ranging from ML1 to ML5 (as shown in Figure 6). These levels represent increasing degrees of advancement while considering the general trends and assumptions regarding the modern trends of robotization and the concept of the Factory of the Future.

Figure 6.

Maturity levels of robotization in production processes.

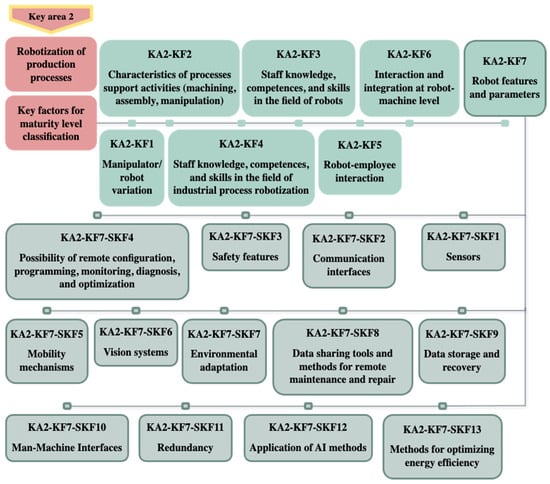

Figure 7 presents the essential aspects related to the robotization of manufacturing operations. Criteria KF1-KF6 belong to the simple criterion, while criterion KF7 belongs to the composite group. These parameters cover the basic requirements for implementing a new robot solution or modifying an existing one.

Figure 7.

Key factors that determine the maturity level of the robotization of production processes.

Table 3, Table 4, Table 5, Table 6 and Table 7 present the assumptions used to evaluate the maturity of the robotization of production processes. The levels were referred to as the lowest to the highest level of robotization sophistication.

Table 3.

The first maturity level of process robotization (KA2-ML1)—lack of robotization.

Table 4.

The second maturity level of process robotization (KA2-ML2)—implementation of manipulators.

Table 5.

The third maturity level of process robotization (KA2-ML3)—conventional robots and/or cobots.

Table 6.

The fourth maturity level of process robotization (KA2-ML4)—mobile robots.

Table 7.

The fifth maturity level of process robotization (KA2-ML4)—autonomous/stationary robots as IIoT devices.

A complete lack of robotization characterizes the first level of maturity. Robotics solutions are not utilized at this stage, although automated production lines and numerically controlled machines may be owned. Because all activities are performed manually by the employees, there is a significant reduction in both productivity and quality.

To advance to the next level, we need to enhance our understanding of robotics and the automation of technological processes. Furthermore, it is essential to identify the requirements for implementing industrial robots and analyze the competencies of human resources to work in a robotic environment.

Examining the return on investment and securing funding is necessary before purchasing a manipulator or robot. When specifying criteria for an industrial robot, it is possible to skip the second maturity level and go directly to the third level. However, the choice of a specific level must be determined by the needs of a particular enterprise and the defined objectives.

The second level of maturity involves implementing an elemental manipulator to handle loading, unloading, or manipulation tasks. These solutions are appropriate for operating injection molding machines, automated assembly stations, welding, and repetitive or physically demanding labor. Typically, they are components that utilize linear drives powered by pneumatic, hydraulic, or electric systems. Due to its kinematic structure, the application is limited to simple, repetitive actions programmed by a control system. The drawback is the limited flexibility, evident in the design dedicated to a specific solution. The advantages of such solutions are their affordability, ease of use and maintenance, and the lack of specialized knowledge required to operate them.

It is important to note that specialized manipulators are cost-effective only in mass production. The lack of rapid reconfiguration of the structure and reprogramming and the limitations of the control systems predispose them to the role of rigid support elements for robotics. In the case of unit production, line reconfiguration, or frequent changes in the production profile, it is advisable to advance to maturity level three. The trend among manufacturing companies is to eliminate rigid and non-reconfigurable manipulation devices.

To achieve a third level of maturity in implementing a manipulator (as opposed to a robot or cobot), it is recommended that the rationale behind this decision be analyzed, employees be prepared for the changes in organization and working methods, and the needs and requirements of the unit being implemented be identified.

The third level of maturity refers to using traditional industrial robots or collaborative robots (cobots). Entrepreneurs commonly choose this level; however, selecting the appropriate type of device can lead to significant improvements.

With traditional robots, the staff must possess proficiency in programming, reprogramming, maintenance, and repair. On the other hand, cobots require additional software or hardware components dedicated to programming specific applications (e.g., welding). In this scenario, it is enough to provide training on using the solution through a bench approach. When it comes to conventional robots, it is necessary to have suitable safety systems in place. Level three only includes stationary units in enclosed production workstations or collaborative robots; mobile robots are not included. The level thus covers the classic applications of robots to perform technological, assembly, and manipulation operations directly at workstations (adding an axis could allow for movement, but its ability to move is limited). The deployment of mobile robots is becoming increasingly common in intralogistics as they fill the labor shortage gap in internal transport operations. The recommended developments include deploying wireless communication network solutions, eliminating information silos, conducting a needs audit, and optimizing intralogistics processes.

The fourth level of maturity involves using AGV/AMR mobile robots for transportation, handling, loading, and unloading purposes. To transition to the mobile robot level, it is essential to integrate with existing OT and IT infrastructure. This involves transferring data to other IT systems to manage business processes in the short term. Robots collect data for advanced analysis and integration into company process management systems. Connecting with WMS, MES, or ERP systems to schedule and delegate tasks is possible. For mobile units, there are additional requirements beyond platform selection. These include navigation systems, power supply, recharging methods, and adapting existing shop floor infrastructure to meet regulations.

A commonly overlooked issue is the improper management of material and product flows between production sites and warehouses. Implementing mobile vehicles without proper intralogistics organization is a common mistake that hinders investment and development. Under certain circumstances, reorganizing the machine setup or grouping into production cells may be required.

It is also necessary to organize and optimize the space of the production facilities (separation of storage bays, designation of staging and loading areas, setting up of additional inter-operational storage facilities, and reorganization of working methods).

The type of mobile vehicle chosen determines the kind of navigation system needed. Physical paths (following lines—magnetic guide tape, inductive cable; markers—magnetic points embedded in the floor, QR codes, or other types of codes) usually interfere with the existing construction of the production facilities (marking out planned movement routes). Laser guidance (laser triangulation), vision guidance, natural navigation (scan matching—SLAM, feature matching—natural feature navigation ANT), inertial navigation (gyroscopic), and geo-guidance require the preparation of infrastructure for data exchange and robot integration. In vision systems, it is crucial to eliminate dust and harmful fumes. The method of charging and battery replacement is vital. Battery replacement can be manual or automatic, and charging can be automatic contact or wireless inductive. One frequently overlooked criterion is the quality and deviation of the floor, as well as the size of expansion gaps and the floor’s load-bearing capacity. When implementing mobile units, it is essential to consider integrating robots with existing OT/IT infrastructure, warehouse management, or other production systems.

Using autonomous or stationary robots as IIoT devices may mark the final stage of industrial maturity. In this case, the mobile robot can gather information and connect to other machines for real-time monitoring and diagnostics (possible use of AI/ML algorithms). One of the additional features is to analyze data from the units, identify patterns, and optimize processes.

Devices classified at this level allow remote operator access via dashboards and the Digital Twin. The primary advantage of configuring a robot as an IIoT device is its simple integration into existing digital systems. This enables full bi-directional data exchange functionality and a digital shell compliant with RAMI 4.0 architecture [64,65,66,67,68,69]. Thanks to advanced analytics, it is possible to determine not only performance indicators but also those relating to environmental impact and the development process of the entire company within the framework of the adopted continuous improvement plan.

Section 3 presents the research results conducted to assess the level of maturity in the robotization of production processes.

3. Results

The method was used to evaluate the maturity of 200 Polish manufacturing companies. The surveyed entities belonged to small and medium-sized enterprises (SMEs) and operated in diverse sectors. These sectors included food, chemicals, textiles and clothing, electronics, machinery, wood and furniture, packaging, household appliance manufacturing, and suppliers of components to the automotive industry.

SMEs are the largest employers and contribute the most to EU development. However, their development needs help accessing capital, external funding sources, modern technology, innovation, and a highly skilled workforce. A disruptive factor is more familiarity with modern process management methods.

In each case, the company has been classified into the described group based on fulfilling the following conditions: having less than 250 employees and an annual turnover of not less than EUR 50 million or an annual balance sheet total of not more than EUR 43 million.

The participants who responded were individuals with managerial or decision-making positions in investment planning, corporate digital vision, and strategy creation. During the survey, we identified the current level of maturity in a key area and defined a target state for the next three years.

Table 8 summarizes the study on initial and target maturity levels for robotizing technological processes.

Table 8.

Summary survey of the initial and target maturity levels in robotization of production processes.

According to the survey results, 66% of the respondents reported having no robots in their organization. Maturity level KA2-ML1 characterizes this lack of robotization. Only 14% of SME representatives are not planning any changes around industrial robot implementation, remaining deliberately at the first level of maturity. However, the group surveyed does not exclude entrepreneurs who own CNC and PLC-controlled machines.

The absence of change is determined by the nature of the production process, which includes its inherent characteristics as follows:

- Type of production—most often unit production with low production volumes (with a high degree of variability and customization) that require frequent development of new robot programs or modifications to existing ones;

- Lack of a consistent supplier who can provide production orders regularly;

- Difficulties in planning material supply and production due to the high variability in orders;

- Aspects related to the factories’ locations—e.g., the need for local integrators and partner companies offering support in servicing the robots or employees with the right level of competence.

According to the survey, 10% of the respondents plan to use manipulators in the coming three years. This indicates a shift from KA2-ML1 to KA2-ML2. These manipulators’ applications include integration in automated assembly or machining stations. Such integration is dedicated to specific parts produced on a large scale for customers with long-term contracts.

In total, 42% of respondents plan to upgrade to level three by integrating industrial robots or cobots. This exhibits well-structured production processes and seamless integration of machines with industrial robots.

At maturity level KA2-ML2, it was determined that the utilization of manipulators was at 8%. Enterprises with manipulators declared they will no longer install these units in their factories. All those declared at this level indicated a planned transition to level three (KA2-ML3). The primary reasons for replacing manipulators with freely programmable industrial robots were the limited functionality of manipulators, rigid structure, reprogramming difficulties, low productivity, inefficiency, and lack of flexibility.

According to a recent survey, 26% of the respondents reported that their companies use either conventional industrial robots or cobots. However, 18% of companies plan to stay the same, and 8% intend to move to automated intralogistics, achieved with mobile robots (level KA2-ML4). Decided enterprises have modern infrastructure and production halls that eliminate some barriers inhibiting the implementation of mobile units.

None of the surveyed companies plan to move to the fifth maturity level (KA2-ML5) due to the need for significant investments, which remains a major barrier to SME development.

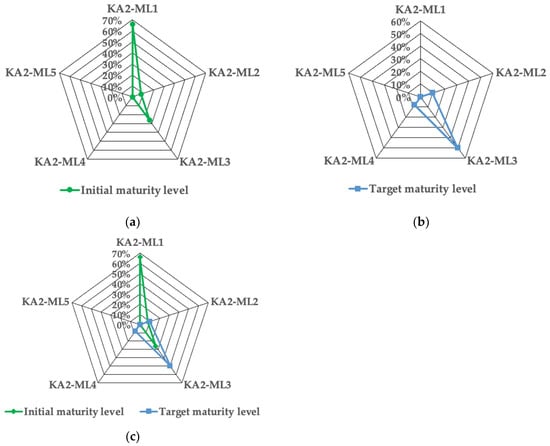

Production process robotization maturity level measures are summarized in Figure 8.

Figure 8.

Summary of maturity level measures in the key area of the robotization of production processes: (a) initial maturity level, (b) target maturity level, (c) summary comparison.

The transition rate between different maturity levels can also be used to conclude that the surveyed companies primarily focused on robotization using traditional industrial robots or cobots. This state-of-the-art technology is integrated with the existing machinery and infrastructure. By retrofitting with industrial robots, the production facilities can increase productivity, repeatability, and quality with minimal capital expenditure and reorganization.

Of all the respondents, 32% plan to maintain their current level of automation in their processes. Of the entities considered, 26% already have solutions involving manipulators or robots/cobots and 26% of SMEs plan to increase their maturity level by one, but a significant 42% aim to increase their maturity level by two on the scale.

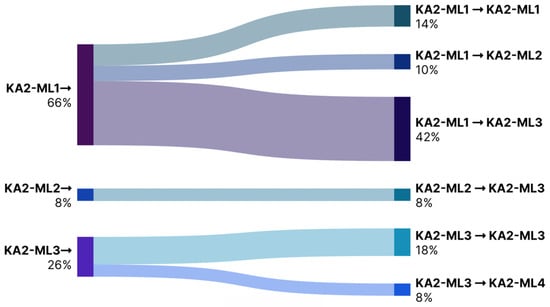

Table 9 summarizes the percentage transition rate between the different maturity levels.

Table 9.

Summary of the transition rate between different maturity levels.

Figure 9 shows the transition rate between different maturity levels based on the data from Table 9.

Figure 9.

Diagram of the transition rate between different maturity levels.

Taking a holistic approach to research findings, SMEs are moving towards a logical strategy of robotizing their processes while prioritizing flexible and scalable infrastructure based on conventional robots or cobots.

4. Discussion

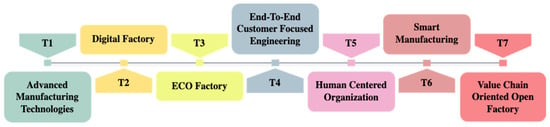

It is worth mentioning that all participating companies have familiarized themselves with the Advanced Manufacturing digital maturity survey methodology [70]. The ADMA covers seven areas of transformation, including those shown in Figure 10, to provide a comprehensive analysis.

Figure 10.

Transformation areas defined within the Advanced Manufacturing methodology.

ADMA offers insights into a manufacturing company’s processes and opportunities for digitalization, streamlining, and optimization.

The ADMA methodology emphasizes the digitalization of manufacturing companies by implementing specialized IT solutions.

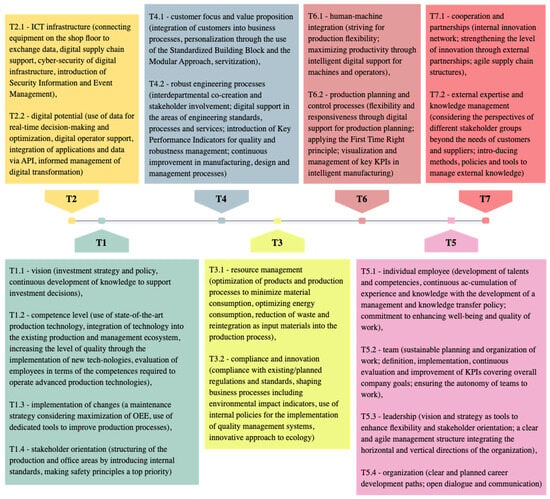

When small and medium-sized enterprises (SMEs) perform an ADMA scan, they often try to focus on all aspects of the transformation process. However, they tend to overlook the workload and costs associated with upgrading their employees’ competencies, integrating hardware and software, ensuring adequate cyber security, dealing with technology dependencies, managing changes in employee roles, maintaining new machinery and equipment, and complying with environmental regulations, managing sensitive data, and protecting the company’s intellectual property. The diagram in Figure 11 shows the main issues in the transformation areas of the ADMA methodology.

Figure 11.

Key issues in the ADMA methodology transformation areas.

The author’s method outlines key areas of development for companies to ensure business continuity and gain a competitive advantage while adhering to the ADMA methodology. The method proposed in this article provides a targeted approach to specific areas of factories that complement ADMA.

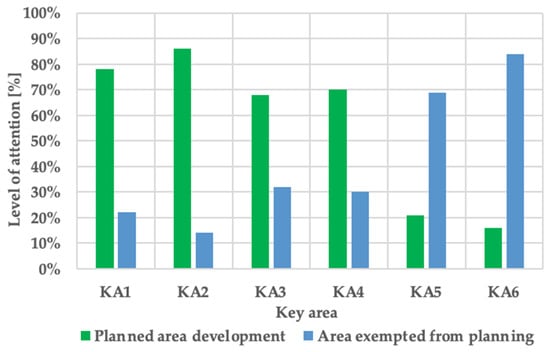

In the next stage, the study analyzed the impact of robotizing production processes on the development of other areas. The main goal was to pinpoint the key areas related to the robotization of production processes. Entrepreneurs have identified areas where robotization maturity is forecast to increase and should be included in development plans.

Figure 12 presents the analysis results of key enterprise areas developed due to the growing robotization of production processes.

Figure 12.

Level of interest in individual key areas of manufacturing companies, where KA1 is the automation of production processes, KA2 is the robotization of production processes, KA3 is the digitization of warehouse processes, KA4 is the flexibility of production systems, KA5 is the intralogistics of production processes (inter-station and inter-department transport), and KA6 is the integration of management, production, quality control, intralogistics, and warehousing systems.

A total of 86% of survey respondents plan to further develop production process robotization (KA2). Surveys indicated that investing in the automation of industrial processes is necessary for implementing robotization, as seen in the desire to develop area KA1 (78%). In total, 70% of the respondents identified increasing production process flexibility (KA4) as an area for improvement. Three previous areas influence the need to develop digitalization of warehouse processes. According to a recent survey, 68% of the respondents consider KA3 a crucial area for advancing robotics (KA2).

The integration of management, production, quality control, intralogistics, and warehousing systems (KA6) was indicated for long-term realization. A total of 21% of respondents noted the need to improve intralogistics (KA5), but solutions are being developed to streamline current processes.

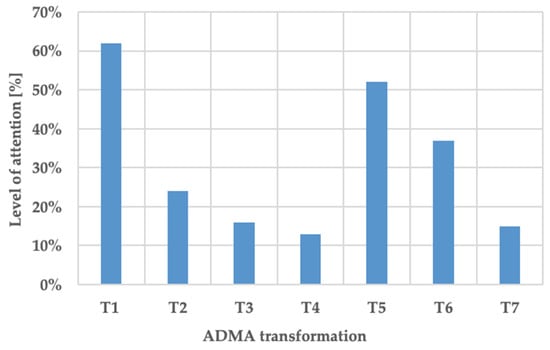

Figure 13 shows the interest levels in each ADMA transformation, indicating a long-term (5-year) perspective.

Figure 13.

Level of interest in individual ADMA transformations, where T1 is the Advanced Manufacturing Technologies, T2 is the Digital Factory, T3 is the ECO Factory, T4 is the End-To-End Customer-Focused Engineering, T5 is the Human-Centered Organization, T6 is the Smart Manufacturing, T7 is the Value Chain-Oriented Open Factory.

The development of robotization changes priorities from a long-term perspective. According to the entrepreneurs interviewed, the development roadmap should be directed towards advanced technologies in robotics (T1, 62%), the development of a human-centered organization (T5, 52%), and the transition to Smart Manufacturing (T6, 37%). The holistic digitalization described by the T2 transformation is receding into the background due to infrastructure development at the Operational Technology level. The decline in customer-driven engineering (T4) is tied to companies’ possession of technologies classified to the areas of transformation.

Table 10 presents the primary development directions of the companies within the surveyed industries.

Table 10.

The fundamental development directions of the industries being surveyed.

Table 11 contains guidance for entrepreneurs on applying the proposed maturity assessment method [26,27,28,29] to address concerns outlined in the Industry 4.0/5.0 definition.

Table 11.

Guidance for entrepreneurs in the case of guidelines outlined in the Industry 4.0/5.0 definition [26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69].

5. Conclusions

The presented approach aims to help entrepreneurs achieve digital maturity for their company by improving the automation of the production process. The digital transformation process involves designing, managing, optimizing, and monitoring business, production, and logistics processes to implement continuous improvement and sustainability practices. The objective of digital transformation is to attain a state of digital maturity. The term can be described as a measure of an organization’s ability to create value by integrating organizational operations and human capital with digital processes, leading to increased responsiveness to the development of products, processes, business models, and marketing innovations. The correct implementation of change requires digital awareness, which determines the possession of the knowledge, skills, and attitudes needed to use digital tools effectively.

The method presented in this article was developed for small and medium-sized enterprises but is not limited to this type of entity. The primary objective was to address the issues in the first ADMA transformation (i.e., Advanced Manufacturing Technologies).

Entrepreneurs were surveyed to identify the principal risks and barriers associated with digital transformation as follows:

- Lack of clear strategy and vision—lack of a defined direction for change, tools, and methods to set short and long-term goals;

- Resistance to change—employees’ fear of being replaced by modern technology, fear of increasing productivity and quality levels;

- Lack of understanding or acceptance of the culture of innovation—fear of creative and out-of-the-box thinking, lack of open communication and team collaboration;

- Lack of consistency in change management and communication—lack of adequate change management, competency gaps, inadequately mapped staff resources, lack of teams responsible for the different stages of the transformation and their scope, lack of measurable indicators and assessment of unforeseen risks;

- Lack of resources and support—lack of a change leader, staff with the right competencies and skills, lack of integrators or subcontractors;

- Changes in areas of the company’s operation—new production technologies, changing management methods (disintermediation, data-driven decision making, reorientation of revenue streams, regulatory challenges, need for continuous learning and development, ensuring cyber security and data privacy, the introduction of performance indicators and KPIs for evaluation purposes), employees (automation of tasks, remote and flexible working arrangements, reskilling and upskilling, digital channels for collaboration and communication, changing job roles and responsibilities, emphasis on innovation and creativity, greater professional autonomy, changes in work culture, potential job change);

- Breach of data confidentiality and security, loss of know-how—lack of security policies, software, and hardware protection;

- Difficulties in integration with existing systems—lack of use of standards and consideration of scalability requirements of systems under development;

- Budgetary constraints—lack of funds or purchase of solutions with redundant and underutilized functionality;

- Regulatory and compliance restrictions—maintaining the guidelines of norms, regulations, and standards;

- Existing systems and infrastructure—constraints related to integration and incorporation of newly designed technical systems;

- Supplier dependency and interoperability issues—problems of factory locations, lack of support, and local integrators.

Robotization is a crucial addition to automation and CNC machining processes and a fundamental part of modern intralogistics for mobile units. Retrofitting with collaborative robots allows for the flexible shaping of production flow characteristics and movement paths. The described functionalities provide flexibility, enabling optimal shaping of the machine’s load and reinforcing their functionality and utilization.

Small and medium-sized enterprises in Poland are among the entities that need to start using robots at the current development stage or applying conventional industrial robots to operate technological processes. The metalworking industry is the sector that uses industrial robots the most, where the cost and degree of robot adaptation are the lowest. There is a growing trend to use easier cobots in applications that do not require complex integration with machine tools.

Companies are also choosing to use mobile vehicles to a lesser degree. In most cases, AGVs are abandoned in favor of Autonomous Mobile Robots. In addition, mobile units are being adapted in newly built factories or production halls because the infrastructure can be designed accordingly. Increasingly, robots are being seen through the lens of corporate sustainability, as they allow for increased comfort at work and move workers away from dangerous or strenuous work.

At this stage of development, robotization is not a solution available only to large companies; market changes and the introduction of the Robot-as-a-Service business model have significantly lowered the entry threshold to a level of investment possible for small and medium-sized enterprises.

Another aspect of the robotization event is the possibility of a comprehensive pre-implementation simulation of the designed solution using Digital Twins, which are also used for monitoring and diagnosing existing implementations.

Robotization goes beyond the areas initially defined, and its position in the industry needs to be addressed. The development trends aim to boost the application of industrial robots and cobots.

Funding

Publication supported by the Excellence Initiative—Research University program implemented at the Silesian University of Technology in 2024.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The dataset results from 200 surveys of Polish SMEs using a self-developed maturity assessment method collected between 2022 and 2024. The data is presented in the form of charts in the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Dzedzickis, A.; Subaciute-Žemaitiene, J.; Šutinys, E.; Samukaite-Bubniene, U.; Bucinskas, V. Advanced Applications of Industrial Robotics: New Trends and Possibilities. Appl. Sci. 2022, 12, 135. [Google Scholar] [CrossRef]

- Arents, J.; Greitans, M. Smart Industrial Robot Control Trends, Challenges and Opportunities within Manufacturing. Appl. Sci. 2022, 12, 937. [Google Scholar] [CrossRef]

- Weidemann, C.; Mandischer, N.; van Kerkom, F.; Corves, B.; Hüsing, M.; Kraus, T.; Garus, C. Literature Review on Recent Trends and Perspectives of Collaborative Robotics in Work 4.0. Robotics 2023, 12, 84. [Google Scholar] [CrossRef]

- Vaisi, B. A review of optimization models and applications in robotic manufacturing systems: Industry 4.0 and beyond. Decis. Anal. J. 2022, 2, 100031. [Google Scholar] [CrossRef]

- Westcott, J.R.; Gupta, A.K.; Arora, S.K. Industrial Automation and Robotics, 2nd ed.; Mercury Learning and Information: Duxbury, MA, USA, 2023; pp. 266–347. [Google Scholar]

- Verma, D. Systems Engineering for the Digital Age: Practitioner Perspectives, 1st ed.; Wiley: Hoboken, NJ, USA, 2023; pp. 583–712. [Google Scholar]

- Westerman, G.; Bonnet, D.; McAfee, A. Leading Digital: Turning Technology into Business Transformation, 1st ed.; Harvard Business Review Press: Brighton, MA, USA, 2014; pp. 29–96. [Google Scholar]

- Coronado, E.; Ueshiba, T.; Ramirez-Alpizar, I.G. A Path to Industry 5.0 Digital Twins for Human-Robot Collaboration by Bridging NEP+ and ROS. Robotics 2024, 13, 28. [Google Scholar] [CrossRef]

- Lessi, C.C.; Gavrielides, A.; Solina, V.; Qiu, R.; Nicoletti, L.; Li, D. 5G and Beyond 5G Technologies Enabling Industry 5.0: Network Applications for Robotics. Procedia Comput. Sci. 2024, 232, 675–687. [Google Scholar] [CrossRef]

- Zafar, M.H.; Langås, E.F.; Sanfilippo, F. Exploring the synergies between collaborative robotics, digital twins, augmentation, and industry 5.0 for smart manufacturing: A state-of-the-art review. Robot. Comput.–Integr. Manuf. 2024, 89, 102769. [Google Scholar] [CrossRef]

- Marinelli, M. From Industry 4.0 to Construction 5.0: Exploring the Path towards Human–Robot Collaboration in Construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Hanna, A.; Larsson, S.; Götvall, P.L.; Bengtsson, K. Deliberative safety for industrial intelligent human–robot collaboration: Regulatory challenges and solutions for taking the next step towards industry 4.0. Robot. Comput.–Integr. Manuf. 2022, 78, 102386. [Google Scholar] [CrossRef]

- Baratta, A.; Cimino, A.; Gnoni, M.G.; Longo, F. Human Robot Collaboration in Industry 4.0: A literature review. Procedia Comput. Sci. 2023, 217, 1887–1895. [Google Scholar] [CrossRef]

- Ghosh, A.; Paredes Soto, D.A.; Veres, S.M.; Rossiter, A. Human Robot Interaction for Future Remote Manipulations in Industry 4.0. IFAC Pap. 2020, 53, 10223–10228. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial capabilities of robotics in enhancing Industry 4.0 implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Ghodsian, N.; Benfriha, K.; Olabi, A.; Gopinath, V.; Arnou, A.; El zant, C.; Charrier, Q.; El helou, M. Toward designing an integration architecture for a mobile manipulator in production systems: Industry 4.0. Procedia CIRP 2022, 109, 443–448. [Google Scholar] [CrossRef]

- Boschetti, G.; Faccio, M.; Granata, I. Human-Centered Design for Productivity and Safety in Collaborative Robots Cells: A New Methodological Approach. Electronics 2023, 12, 167. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human-Robot Collaboration Trends and Safety Aspects: A Systematic Review. J. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- Castro, A.; Silva, F.; Santos, V. Trends of Human-Robot Collaboration in Industry Contexts: Handover, Learning, and Metrics. Sensors 2021, 21, 4113. [Google Scholar] [CrossRef]

- Patil, S.; Vasu, V.; Srinadh, K.V.S. Advances and perspectives in collaborative robotics: A review of key technologies and emerging trends. Discov. Mech. Eng. 2023, 2, 13. [Google Scholar] [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Silvestri, C.; Fici, L.; Silvestri, L. Metaverse: A possible sustainability enabler in the transition from Industry 4.0 to 5.0. Procedia Comput. Sci. 2024, 232, 1839–1848. [Google Scholar] [CrossRef]

- Golovianko, M.; Terziyan, V.; Branytskyi, V.; Malyk, D. Industry 4.0 vs. Industry 5.0: Co-existence, Transition, or a Hybrid. Procedia Comput. Sci. 2023, 217, 102–113. [Google Scholar] [CrossRef]

- Introna, V.; Santolamazza, A.; Cesarotti, V. Integrating Industry 4.0 and 5.0 Innovations for Enhanced Energy Management Systems. Energies 2024, 17, 1222. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Publications Office of the European Union. Available online: https://op.europa.eu/en/publication-detail/-/publication/9167a698-180e-11eb-b57e-01aa75ed71a1/ (accessed on 30 April 2024).

- Publications Office of the European Union. Available online: https://op.europa.eu/en/publication-detail/-/publication/6dabb3da-8c55-11eb-b85c-01aa75ed71a1/language-en/format-PDF/source-196325752# (accessed on 30 April 2024).

- Publications Office of the European Union. Available online: https://op.europa.eu/en/web/eu-law-and-publications/publication-detail/-/publication/38a2fa08-728e-11ec-9136-01aa75ed71a1 (accessed on 30 April 2024).

- Publications Office of the European Union. Available online: https://op.europa.eu/en/publication-detail/-/publication/468a892a-5097-11eb-b59f-01aa75ed71a1/ (accessed on 30 April 2024).

- Soldatos, J.; Lazaro, O.; Cavadini, F. The Digital Shopfloor—Industrial Automation in the Industry 4.0 Era: Performance Analysis and Applications, 1st ed.; River Publishers: Gistrup, Denmark, 2018; pp. 27–69. [Google Scholar]

- Liu, Y.; Wang, S.; Xie, Y.; Xiong, T.; Wu, M. A Review of Sensing Technologies for Indoor Autonomous Mobile Robots. Sensors 2024, 24, 1222. [Google Scholar] [CrossRef] [PubMed]

- Rogers, A.; Eshaghi, K.; Nejat, G.; Benhabib, B. Occupancy Grid Mapping via Resource-Constrained Robotic Swarms: A Collaborative Exploration Strategy. Robotics 2023, 12, 70. [Google Scholar] [CrossRef]

- da Silva, E.R.; Schou, C.; Hjorth, S.; Tryggvason, F.; Sørensen, M.S. Plug & Produce robot assistants as shared resources: A simulation approach. J. Manuf. Syst. 2022, 63, 107–117. [Google Scholar]

- Goecks, L.S.; Habekost, A.F.; Coruzzolo, A.M.; Sellitto, M.A. Industry 4.0 and Smart Systems in Manufacturing: Guidelines for the Implementation of a Smart Statistical Process Control. Appl. Syst. Innov. 2024, 7, 24. [Google Scholar] [CrossRef]

- Buerkle, A.; Eaton, W.; Al-Yacoub, A.; Zimmer, M.; Kinnell, P.; Henshaw, M.; Coombes, M.; Chen, W.H.; Lohse, N. Towards industrial robots as a service (IRaaS): Flexibility, usability, safety and business models. Robot. Comput.-Integr. Manuf. 2023, 81, 102484. [Google Scholar] [CrossRef]

- Gilchrist, A. Industry 4.0 The Industrial Internet of Things, 1st ed.; Apress: New York City, NY, USA, 2016; pp. 217–230. [Google Scholar]

- Schwab, K. The Fourth Industrial Revolution: Klaus Schwab, 1st ed.; Penguin Books Ltd.: London, UK, 2017. [Google Scholar]

- Gallego-García, S.; Groten, M.; Halstrick, J. Integration of Improvement Strategies and Industry 4.0 Technologies in a Dynamic Evaluation Model for Target-Oriented Optimization. Appl. Sci. 2022, 12, 1530. [Google Scholar] [CrossRef]

- Ferreira, D.V.; de Gusmao, P.H.; de Almeida, J.A. A multicriteria model for assessing maturity in industry 4.0 context. J. Ind. Inf. Integr. 2024, 38, 100579. [Google Scholar] [CrossRef]

- Senna, P.P.; Barros, A.C.; Bonnin Roca, J.; Azevedo, A. Development of a digital maturity model for Industry 4.0 based on the technology-organization-environment framework. Comput. Ind. Eng. 2023, 185, 109645. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Cavalieri, S. Development and application of a maturity model for Industrial Agile Working. Comput. Ind. Eng. 2024, 188, 109877. [Google Scholar] [CrossRef]

- Zamora Iribarren, M.; Garay-Rondero, C.L.; Lemus-Aguilar, I.; Peimbert-García, R.E. A Review of Industry 4.0 Assessment Instruments for Digital Transformation. Appl. Sci. 2024, 14, 1693. [Google Scholar] [CrossRef]

- Haryanti, T.; Rakhmawati, N.A.; Subriadi, A.P. The Extended Digital Maturity Model. Big Data Cogn. Comput. 2023, 7, 17. [Google Scholar] [CrossRef]

- Han, X.; Zhang, M.; Hu, Y.; Huang, Y. Study on the Digital Transformation Capability of Cost Consultation Enterprises Based on Maturity Model. Sustainability 2022, 14, 10038. [Google Scholar] [CrossRef]

- Elhusseiny, H.K.; Crispim, J. A Review of Industry 4.0 Maturity Models: Theoretical Comparison in The Smart Manufacturing Sector. Procedia Comput. Sci. 2024, 232, 1869–1878. [Google Scholar] [CrossRef]

- Spaltini, M.; Acerbia, f.; Pinzonea, M.; Gusmerolia, S.; Taischa, M. Defining the Roadmap towards Industry 4.0: The 6Ps Maturity Model for Manufacturing SMEs. Procedia CIRP 2022, 105, 631–636. [Google Scholar] [CrossRef]

- Semeraro, C.; Alyousuf, N.; Kedir, N.I.; Abu Lail, E. A maturity model for evaluating the impact of Industry 4.0 technologies and principles in SMEs. Manuf. Lett. 2023, 37, 61–65. [Google Scholar] [CrossRef]

- Kalendera, Z.T.; Žilkaa, M. A Comparative Analysis of Digital Maturity Models to Determine Future Steps in the Way of Digital Transformation. Procedia Comput. Sci. 2024, 232, 903–912. [Google Scholar] [CrossRef]

- Trstenjak, M.; Opetuk, T.; Cajner, H.; Hegedic, M. Industry 4.0 Readiness Calculation-Transitional Strategy Definition by Decision Support Systems. Sensors 2022, 22, 1185. [Google Scholar] [CrossRef] [PubMed]

- Spaltini, M.; Terzi, S.; Taisch, M. Development and implementation of a roadmapping methodology to foster twin transition at manufacturing plant level. Comput. Ind. 2024, 154, 104025. [Google Scholar] [CrossRef]

- Issa, A.; Hatiboglu, B.; Bildstein, A.; Bauernhansl, T. Industrie 4.0 roadmap: Framework for digital transformation based on the concepts of capability maturity and alignment. Procedia CIRP 2018, 72, 973–978. [Google Scholar] [CrossRef]

- Förster, M.; Kürpick, C.; Hobscheidt, D.; Kühn, A.; Dumitrescu, R. Cross-industry methods for strategic planning of the digital transformation of small and medium sized enterprises. Procedia CIRP 2022, 109, 322–327. [Google Scholar] [CrossRef]

- Angreani, L.S.; Vijaya, A.; Wicaksono, H. Systematic Literature Review of Industry 4.0 Maturity Model for Manufacturing and Logistics Sectors. Procedia Manuf. 2020, 52, 337–343. [Google Scholar] [CrossRef]

- Berx, N.; Decre, W.; Pintelon, L. A tool to evaluate industrial cobot safety readiness from a system-wide perspective: An empirical validation. Saf. Sci. 2024, 170, 106380. [Google Scholar] [CrossRef]

- Mavropoulos, A.; Nilsen, A.W. Industry 4.0 and Circular Economy, 1st ed.; Wiley: Hoboken, NJ, USA, 2020; pp. 251–290. [Google Scholar]

- Blokdyk, G. Digital Maturity A Complete Guide-2020 Edition, 1st ed.; 5STARCooks: Toronto, ON, Canada, 2021; pp. 142–221. [Google Scholar]

- Chong, Z.Q.; Low, C.Y.; Mohammad, U.; Rahman, R.A.; Bahari Shaari, M.S. Conception of Logistics Management System for Smart Factory. Int. J. Eng. Technol. 2018, 7, 126–131. [Google Scholar] [CrossRef]

- Schumacher, S.; Hall, R.; Bildstein, A.; Bauernhansl, T. Toolbox Lean 4.0—Development and Implementation of a Database Approach for the Management of Digital Methods and Tools. Procedia CIRP 2022, 107, 776–781. [Google Scholar] [CrossRef]

- Wang, Y.; Tran, T.; Anderl, R. Toolbox Approach for the Development of New Business Models in Industrie 4.0. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 23–25 October 2018. [Google Scholar]

- Wang, Y.; Tran, T.; Anderl, R. Generic Procedure Model to Introduce Industrie 4.0 in Small and Medium-sized Enterprises. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 19–21 October 2016. [Google Scholar]

- Wang, Y.; Faath, A.; Goerne, T.; Anderl, R. Development of a Toolbox for Engineering in Project Teams for Industrie 4.0. In Proceedings of the World Congress on Engineering and Computer Science, Hong Kong, 14–16 March 2018. [Google Scholar]

- Anderl, R. Industrie 4.0—Digital Transformation in Product Engineering and Production. In Proceedings of the 21st International Seminar on High Technology—Smart Products and Smart Production, Piracicaba, Brazil, 8 October 2016. [Google Scholar]

- Anderl, R. Industrie 4.0-Advanced Engineering of Smart Products and Smart Production. In Proceedings of the 19th International Seminar on High Technology, Technological Innovations in the Product Development, Piracicaba, Brazil, 9 October 2014. [Google Scholar]

- Pischinga, M.A.; Pessoaa, M.A.O.; Junqueiraa, F.; Filho, D.J.S.; Miyagi, P.E. An architecture based on RAMI 4.0 to discover equipment to process operations required by products. Comput. Ind. Eng. 2018, 125, 574–591. [Google Scholar] [CrossRef]

- Baptista, L.F.; Barata, J. Piloting Industry 4.0 in SMEs with RAMI 4.0: An enterprise architecture approach. Procedia Comput. Sci. 2021, 192, 2826–2835. [Google Scholar] [CrossRef]

- Resman, M.; Pipan, M.; Šimic, M.; Herakovič, N. A new architecture model for smart manufacturing: A performance analysis and comparison with the RAMI 4.0 reference model. Adv. Prod. Eng. Manag. 2019, 14, 153–165. [Google Scholar] [CrossRef]

- Alemão, D.; Rocha, A.D.; Nikghadam-Hojjati, S.; Barata, J. How to Design Scheduling Solutions for Smart Manufacturing Environments Using RAMI 4.0? IEEE Access 2022, 10, 71284–71298. [Google Scholar] [CrossRef]

- Bastos, A.; Sguario, M.; Andrade, C.D.; Yoshino, R.T.; Santos, M.M.D. Industry 4.0 Readiness Assessment Method Based on RAMI 4.0 Standards. IEEE Access 2021, 9, 119778–119799. [Google Scholar] [CrossRef]

- Wang, Y.; Towara, T.; Anderl, R. Topological Approach for Mapping Technologies in Reference Architectural Model Industrie 4.0 (RAMI 4.0). In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 25–27 October 2017. [Google Scholar]

- Trans4mers. Available online: https://trans4mers.eu/assets/content/attachments/20210702-ADMA-booklet_final.pdf (accessed on 30 April 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).