Analysis and Characterization of Micro–Nano Pores in Coal Reservoirs of Different Coal Ranks

Abstract

1. Introduction

2. Coal Samples and Test

2.1. Coal Samples

2.2. Testing Device

2.3. Experimental Procedure

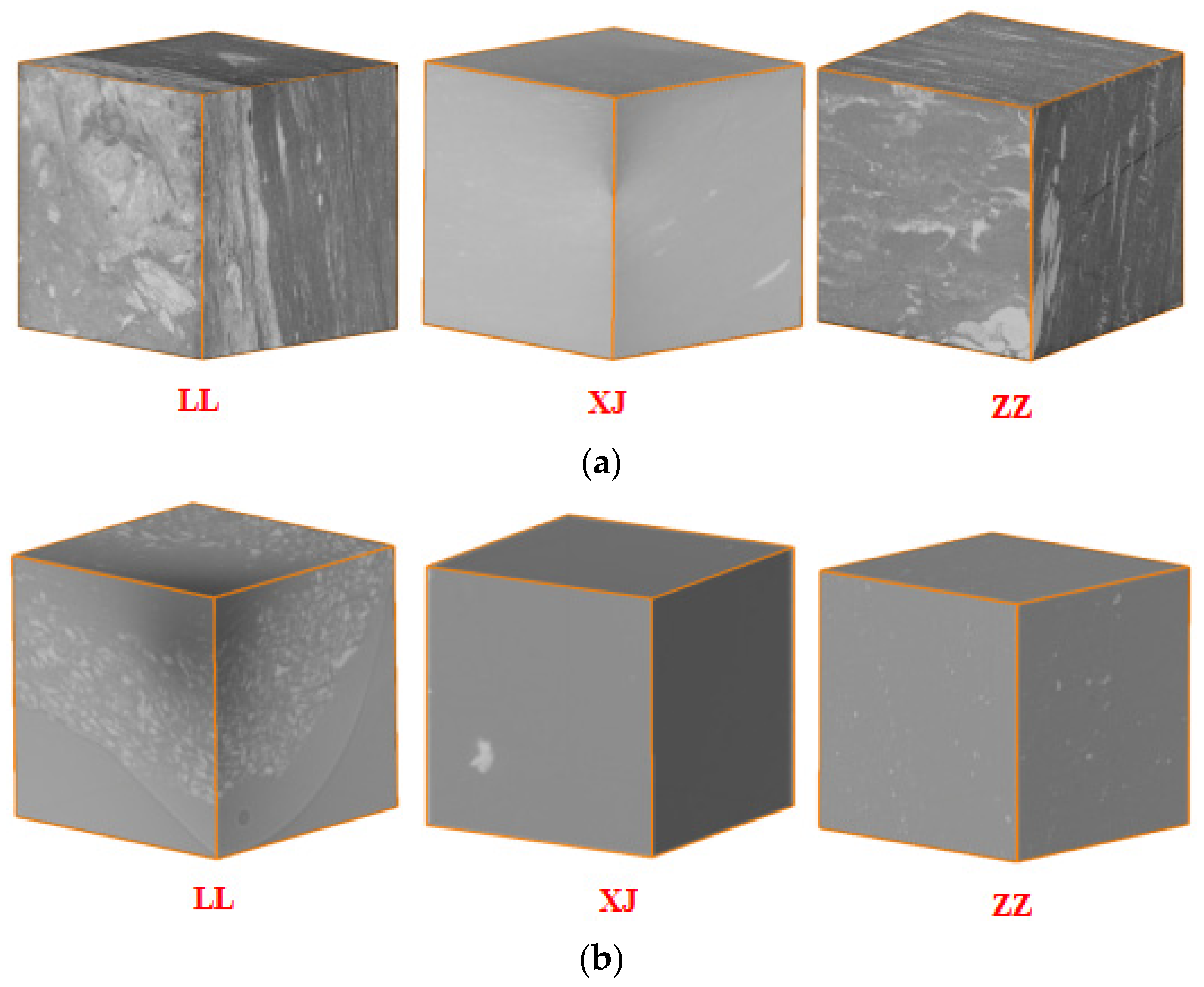

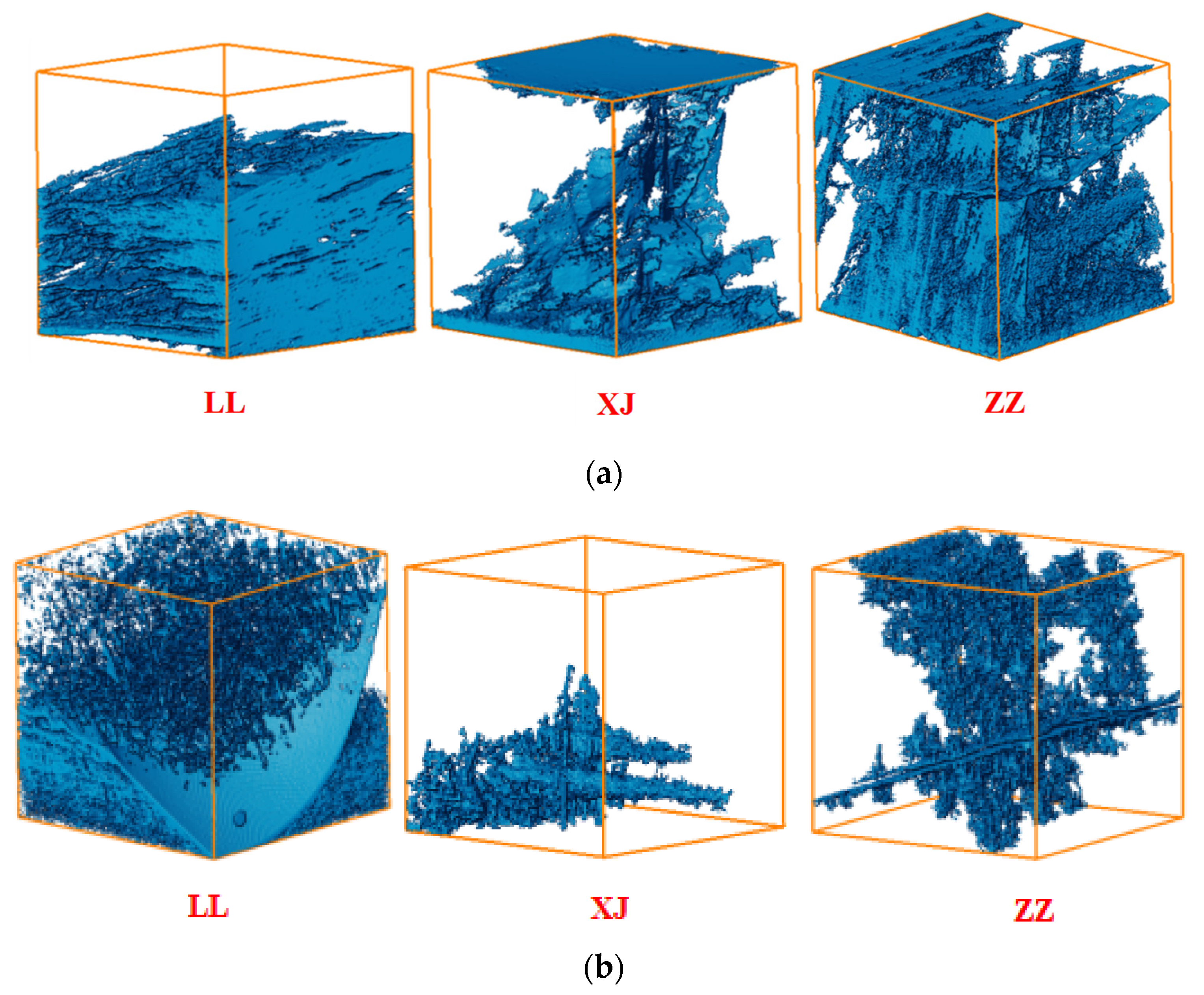

- Six samples were subjected to micro–nano-CT scanning experiments to obtain continuous two-dimensional (2D) sections, necessitating the construction of 3D pore structures;

- The 2D slices were imported into Avizo software 2020.1 for grayscale conversion, filtering, noise reduction, and stacking according to the position of the spatial coordinates to form a 3D data volume;

- The threshold segmentation method was employed to differentiate between the pore part and matrix parts in the 2D slice, that is, the binarization processing of the image;

- The pore network model (PNM) module was employed to extract pores in the coal reservoir, further analyzing the 3D spatial distribution characteristics and pore connectivity. Relevant parameters were extracted to quantitatively characterize the microscopic pore structure of the sample.

3. Results and Discussion

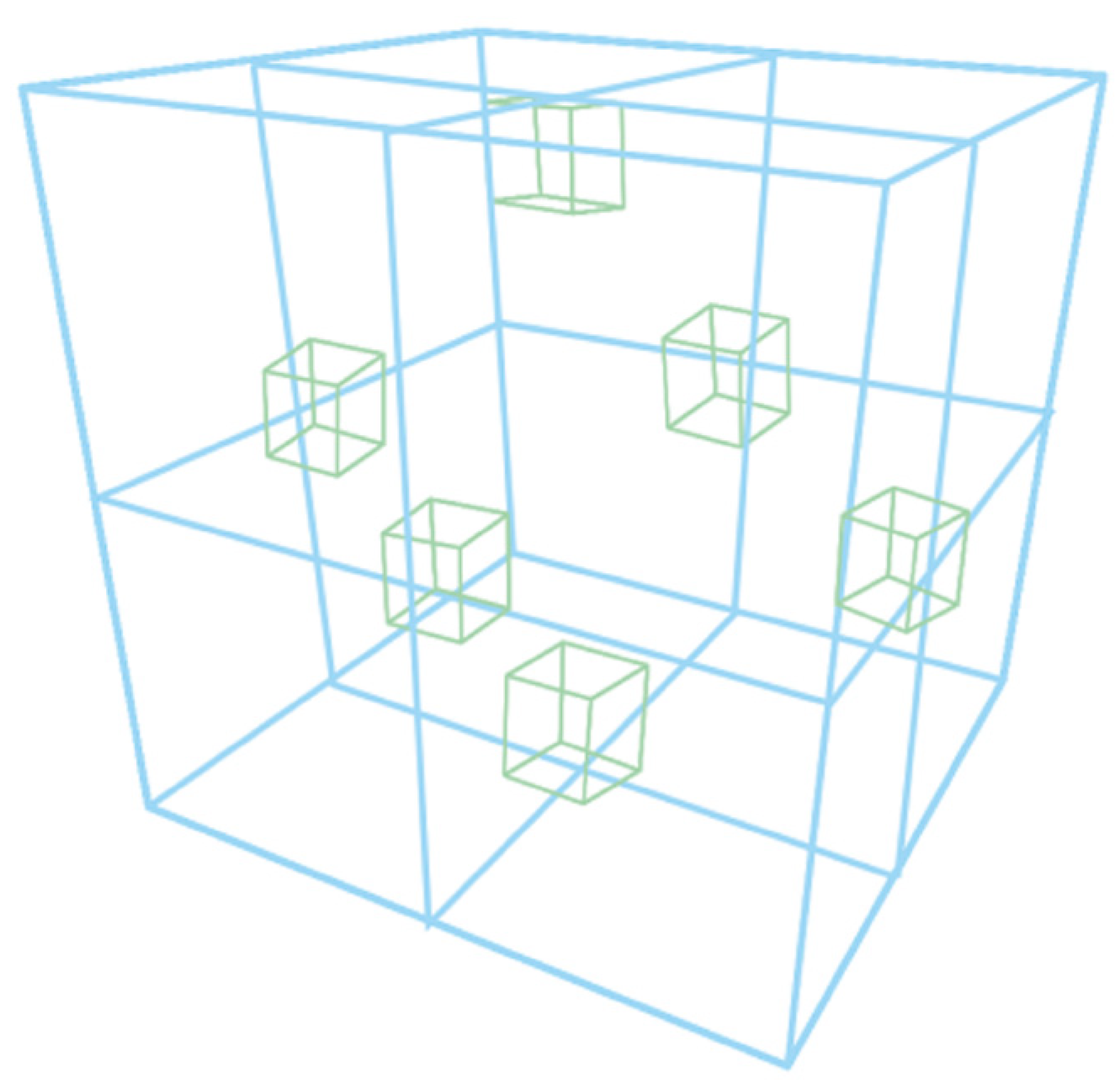

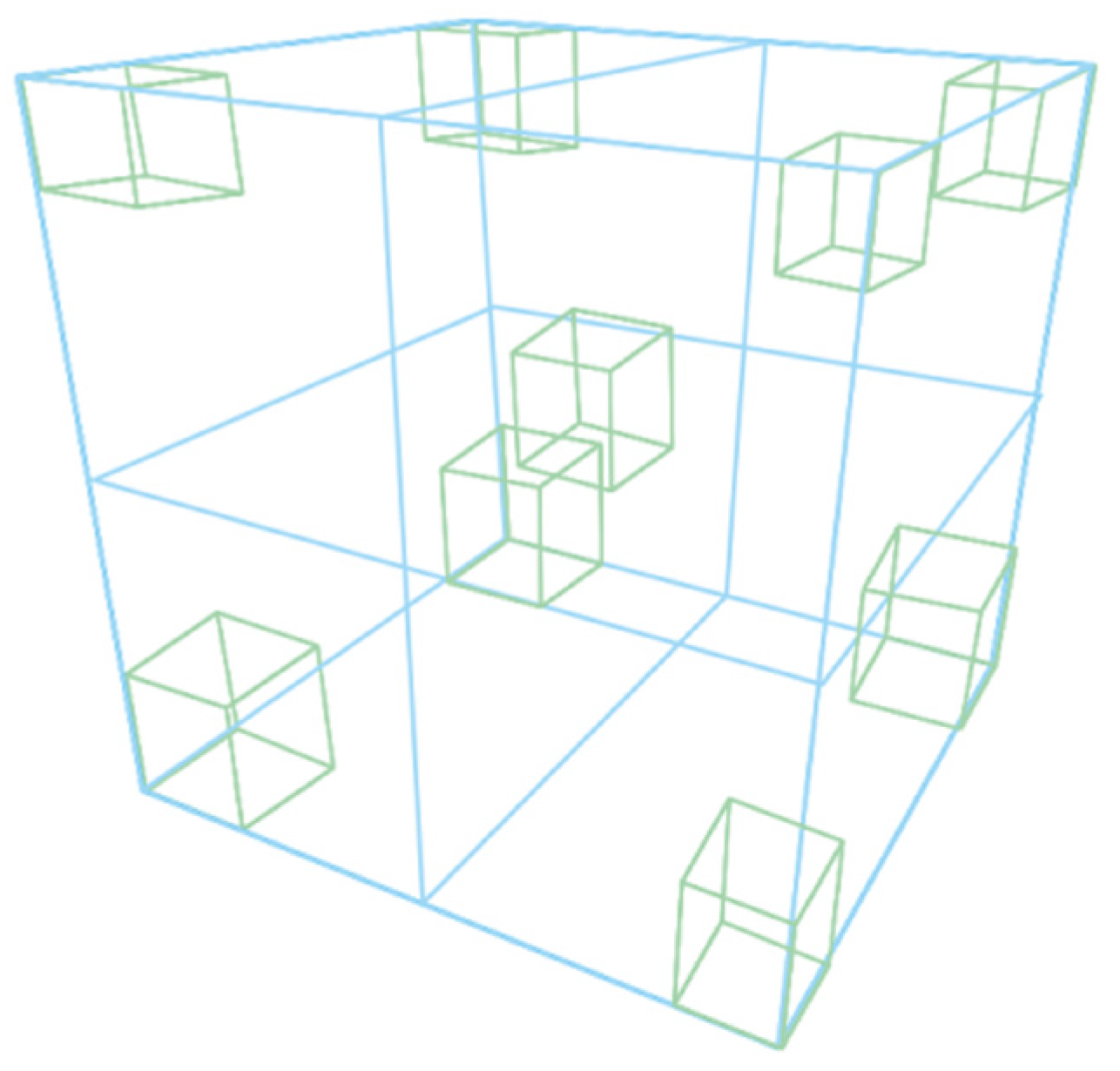

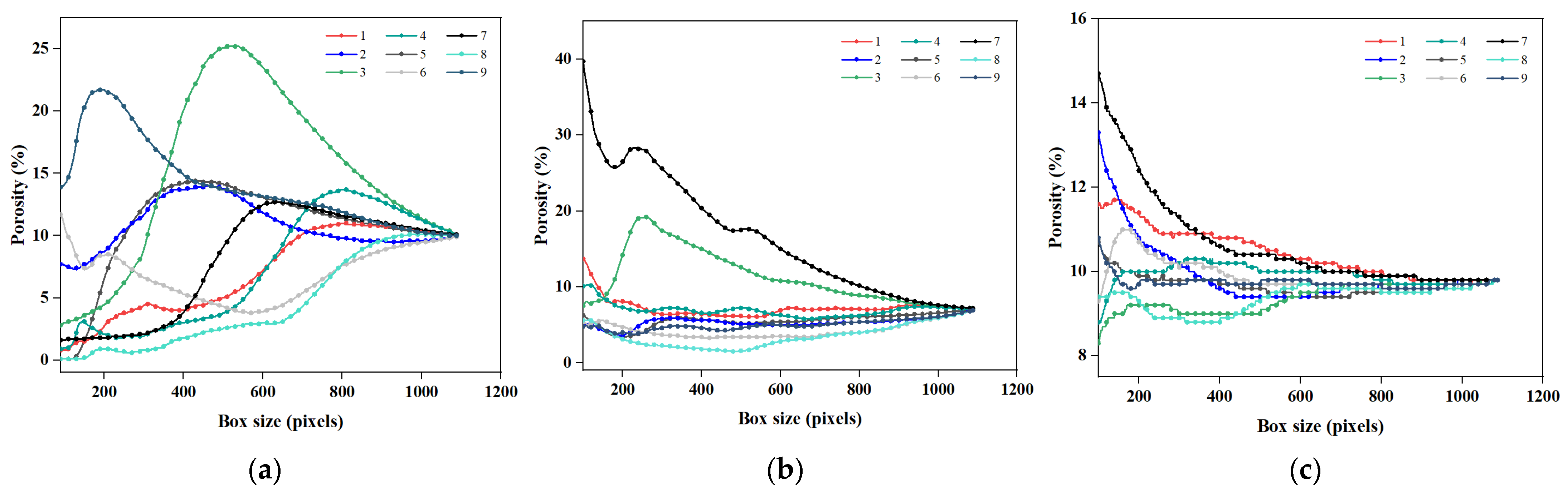

3.1. Research on Representative Elementary Volume

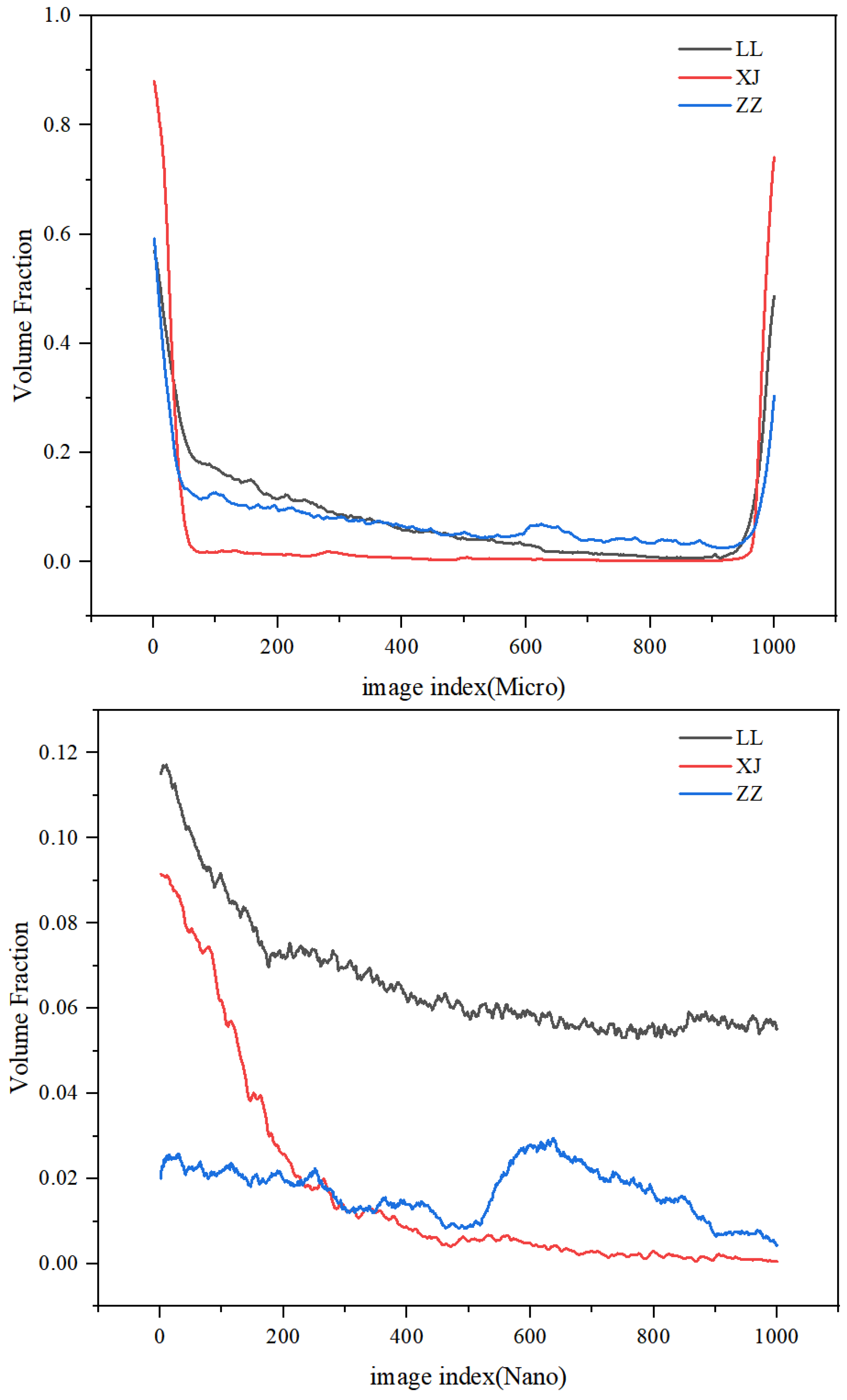

3.2. Porosity

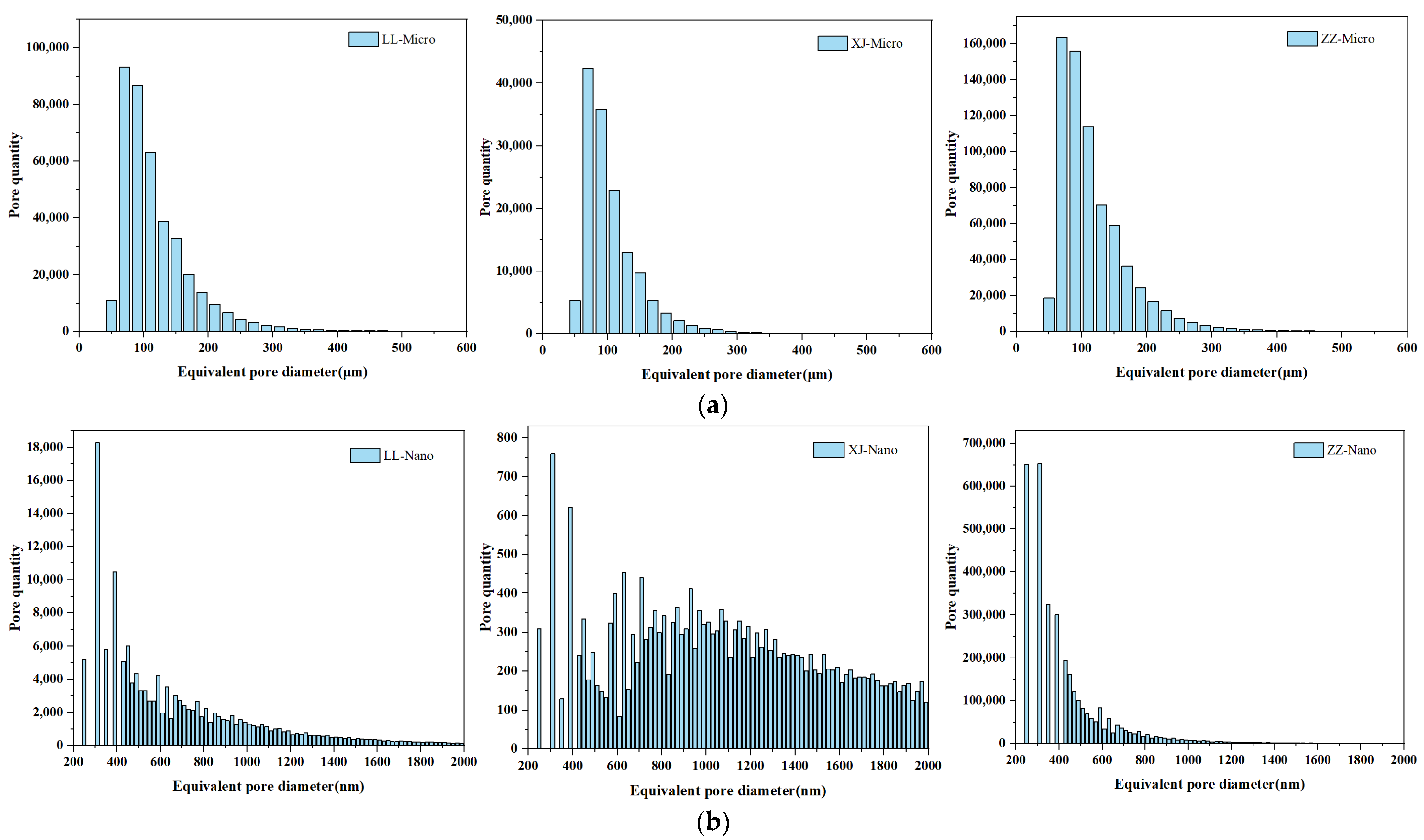

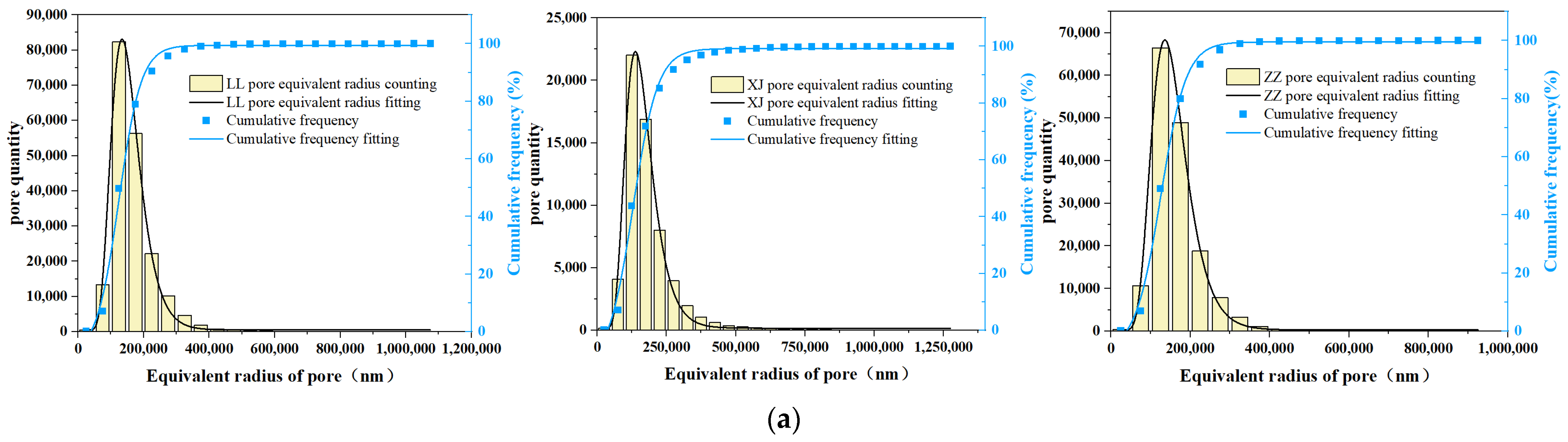

3.3. Pore Size Distribution

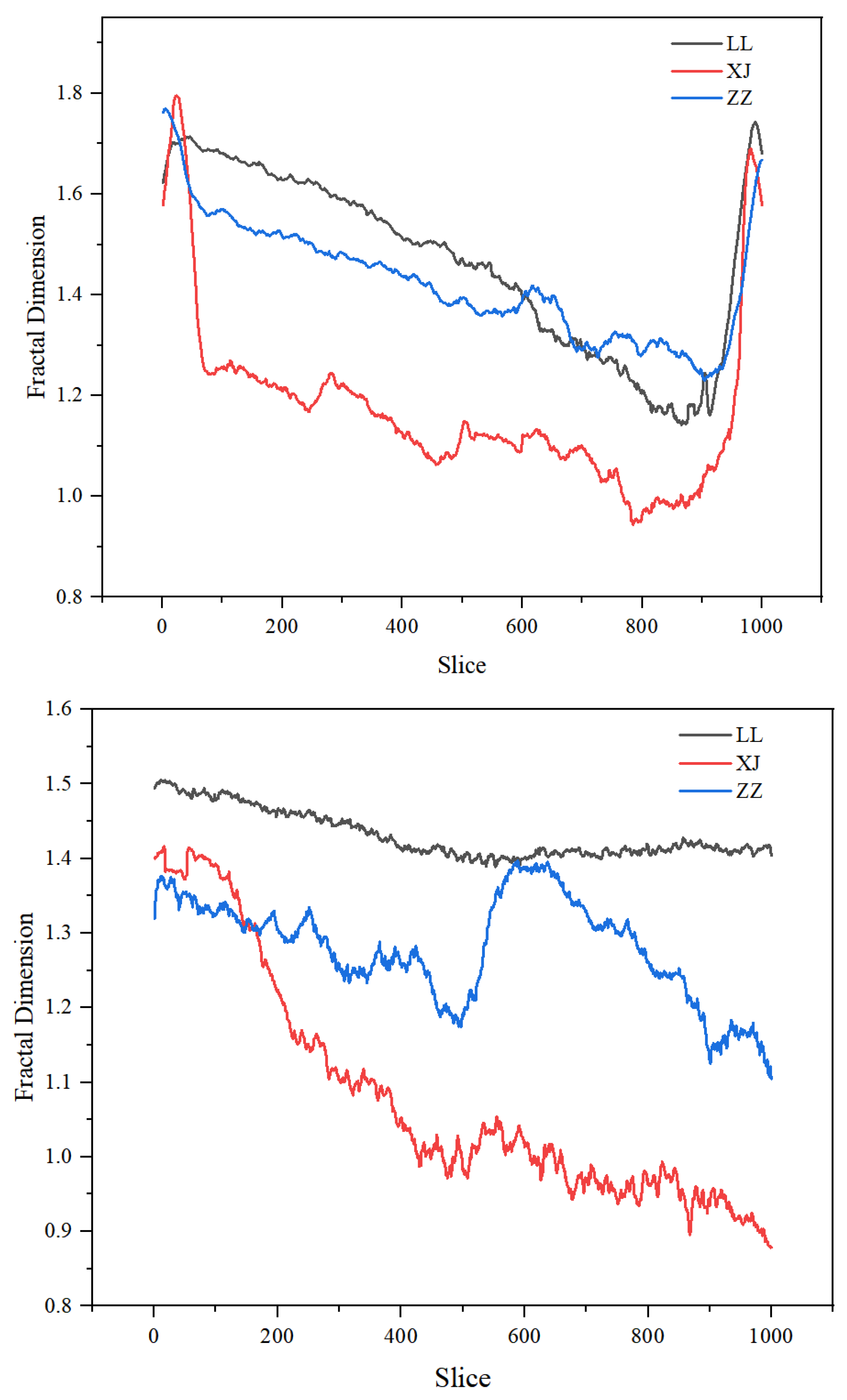

3.4. Fractal Dimension

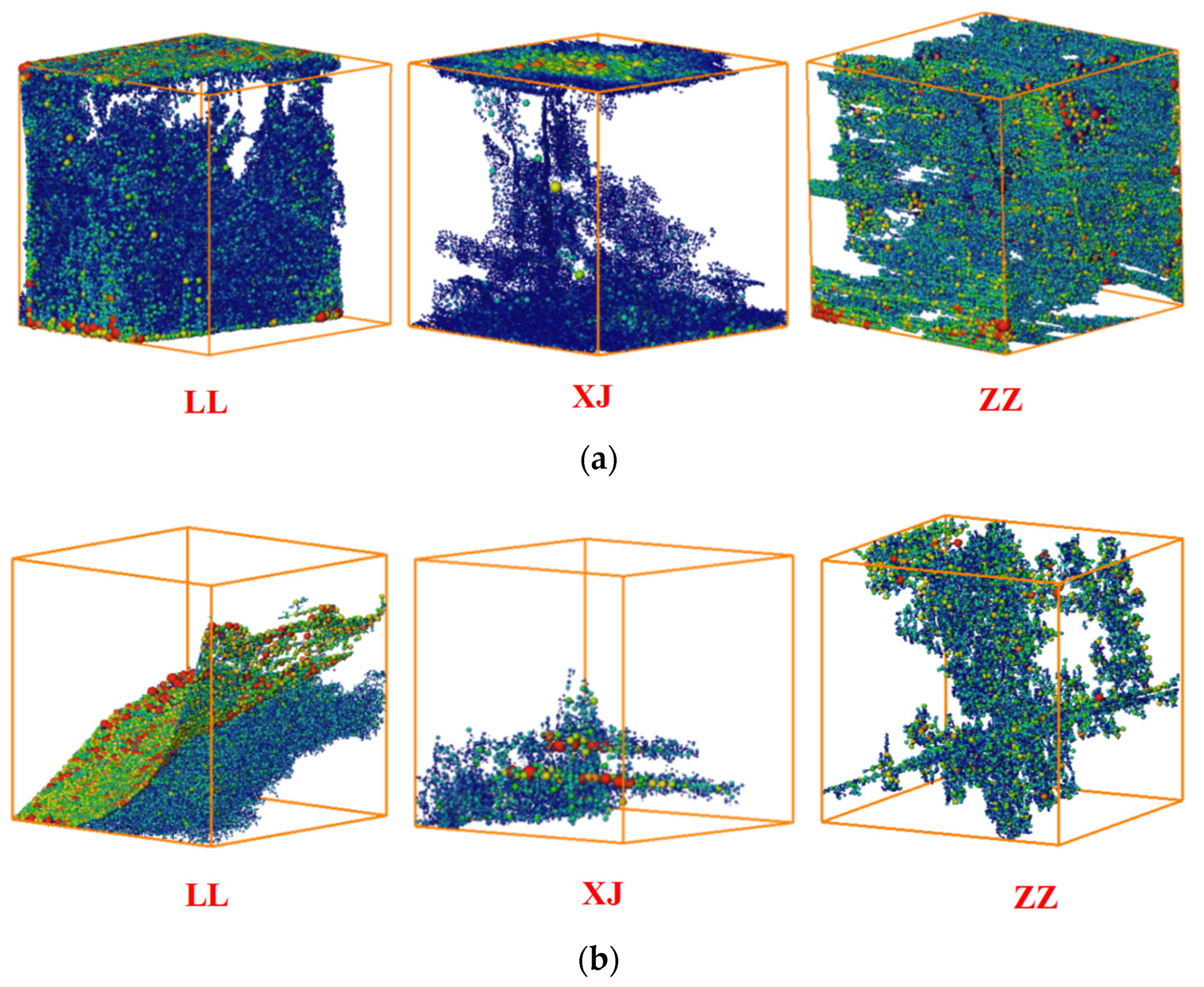

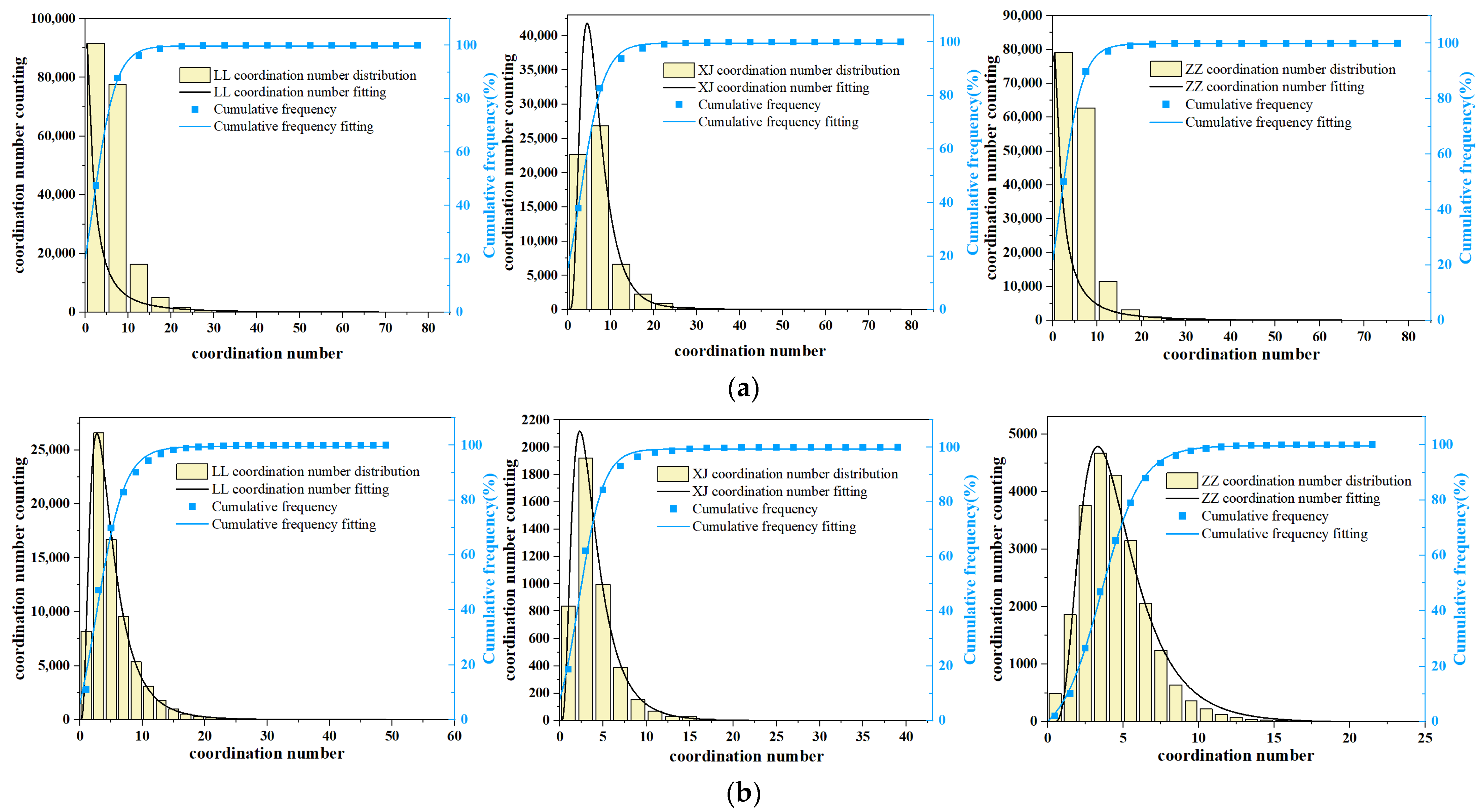

3.5. Pore Network Stick Model

4. Discussion

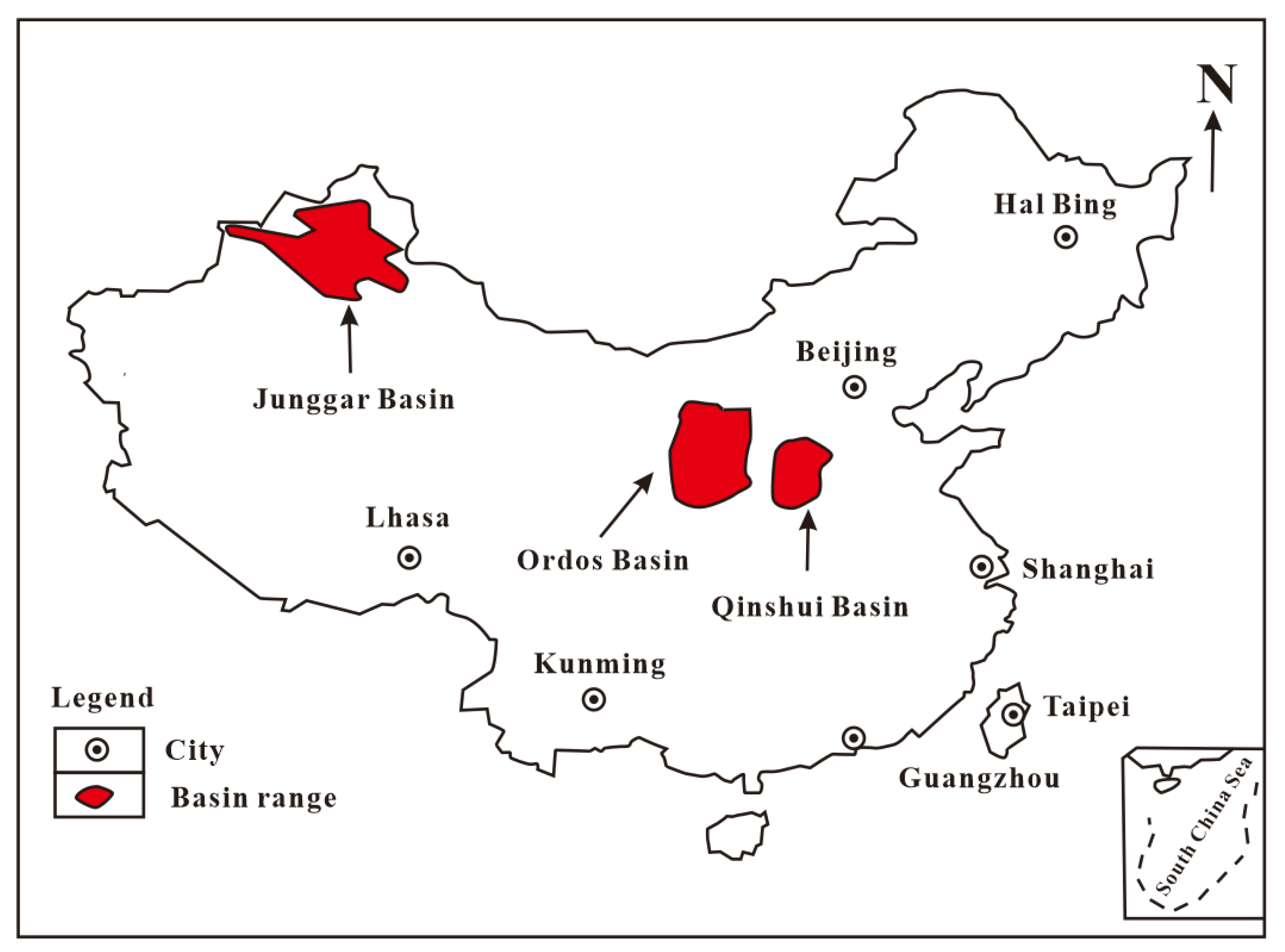

- The comparison with the mercury injection experimental data indicated a small error in the 2D slices obtained by the CT scans, indicating the accuracy of the REV model obtained under the conditions of the nano-CT scanning. It can be seen from the pore space morphology that the middle- and high-rank coal samples are located in the central and southern part of Qinshui Basin and the eastern margin of Ordos Basin, which belong to the high yield and enrichment area of coalbed methane in China. Generally, they have favorable geological conditions, such as the enrichment of coalbed methane resources and high permeability, so the pores are more developed, while the low-rank coal samples are located in the southern margin of Junggar Basin. In some areas, the coal seams are rich in CO2, and the geological conditions are complex, so the pores are not developed. The interval of the surface porosity distribution was large, indicating strong heterogeneity with each sample.

- The micro-CT scanning revealed pores with an equivalent diameter of 50–200 μm, accounting for a large proportion in each coal sample. However, the average equivalent diameter of each sample was ~110 μm, and the maximum and minimum equivalent diameters were quite different, indicating general pore homogeneity. Whereas, under nano-CT scanning, each sample was distributed within the range of 200–2000 nm, and the equivalent diameter XJ was evenly distributed in each size.

- The volume fractal dimension of each sample, observed under micro–nano-CT scanning, was ~2.5, with the surface fractal dimension exhibiting characteristics of fluctuation and general uniformity. The analysis of the fractal dimensions indicated that XJ exhibited the highest uniformity, while LL exhibited the roughest pore structure and lowest uniformity.

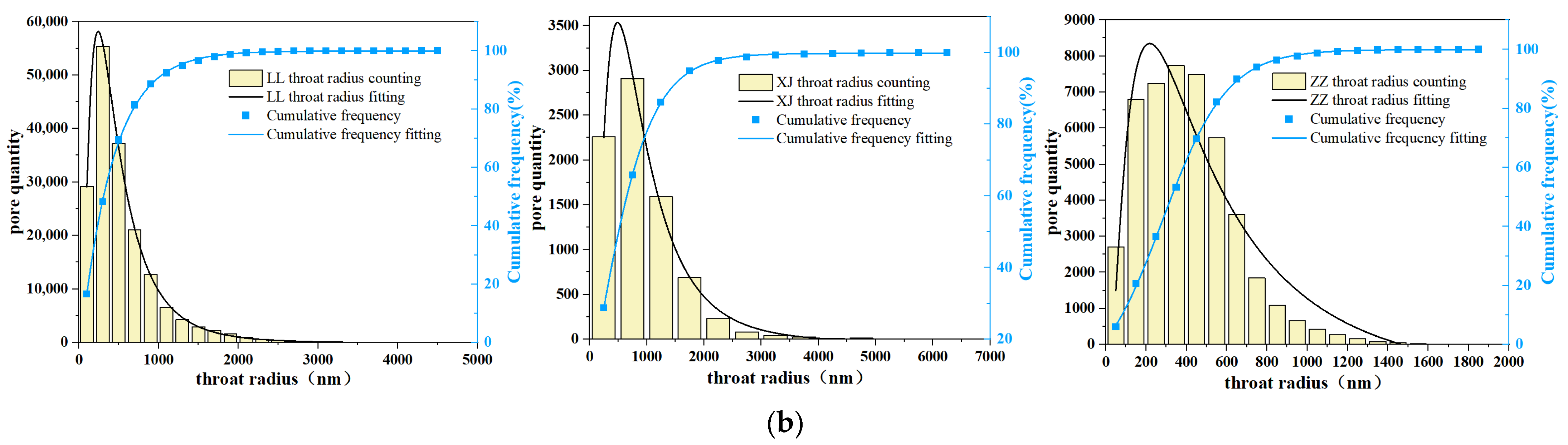

- The pore equivalent radius and throat equivalent radius of each sample exhibited unimodal distributions. Despite the topological structure of each sample being relatively complex, the coordination number proportion of 0–20 was the largest, indicating excellent connectivity and suitability for seepage simulation. The large–medium pores of the medium-rank coal were more developed compared with the low- and high-rank coal. Thus, the low- and high-rank coal exhibited relatively more micro-pores. The analysis of the pore size distributions indicated a wide span and uneven distribution.

- This study covers the coal samples of three low–medium–high coal ranks, but the different geographical locations will lead to some pore structure differences in coal samples of the same coal rank. Therefore, the pore structure characteristics of each coal rank in this study cannot represent the coal samples in all places. The follow-up work can select coal samples from different places for the same coal rank for the quantitative analysis of the pore structure, which is convenient for the optimization of CBM surface development blocks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, Y.; Wang, X.; Zhao, C. Experimental study on multi-scale pore structure characteristics of tar-rich coal in Yushenfu mining area. Coalf. Geol. Explor. 2021, 49, 33–41. [Google Scholar]

- Guo, H.; Wang, K.; Cui, H. Experimental investigation on the pore and fracture structure of the reconstructed coal and its fractal characteristics. J. China Univ. Min. Technol. 2019, 48, 1206–1214. [Google Scholar]

- Ding, L.; Zhao, M.; Wei, Y. Impact from Medium to Low Rank Coal Vitrinite Micropore Structure on Methane Adsorptivity. China Coal Geol. 2021, 33, 17–21+30. [Google Scholar]

- Wang, L.; Wang, A.; Chen, L. Dynamic characteristics and crack propagation characteristics of gas-bearing coal under cyclic impact. J. Rock Mech. Eng. 2023, 42, 2628–2642. [Google Scholar]

- Nie, B.; Zhao, D.; Wang, M. Micro-damage model of gas-bearing coal under load and instability identification criteria. Coal J. 2024, 49, 707–719. [Google Scholar]

- Li, H.; Yao, Z.; Li, N. Analysis of Main Geological Controlling Factors of CBM Occurrence in Yanan Formation of Binchang Mining Area. China Coalbed Methane 2019, 16, 14–18. [Google Scholar]

- Liu, H.; Song, D.; He, X. Influence of coalification on microstructure characteristics of coal surface. Chin. J. Saf. Sci. 2020, 30, 121–127. [Google Scholar]

- Mou, P.; Pan, J.; Niu, Q.; Wang, Z.; Li, Y.; Song, D. Coal Pores: Methods, Types, and Characteristics. Energy Fuels 2021, 35, 7467–7484. [Google Scholar] [CrossRef]

- Jia, M.; Huang, W.; Li, Y. Quantitative Characterization of Pore Structure Parameters in Coal Based on Image Processing and SEM Technology. Energies 2023, 16, 1663. [Google Scholar] [CrossRef]

- Li, X.; Shao, Y.; Zhu, Y. Fractal Characteristics of Coal and Rock Pore Based on Low Temperature Liquid Nitrogen Adsorption Method. Sci. Technol. Eng. 2022, 22, 65–70. [Google Scholar]

- Yang, M.; Liu, L.; Zhang, X. Nuclear magnetic resonance experimental study on pore structure and fluid characteristics of coal at different ranks. Chin. J. Saf. Sci. 2021, 31, 81–88. [Google Scholar]

- Li, Y.; Zhang, Y.; Zhang, L. Characterization on pore structure of tectonic coals based on the methods of mercury injection, carbon dioxide adsorption and nitrogen adsorption. J. Coal 2019, 44, 1188–1196. [Google Scholar]

- Nie, B.; Ma, Y.; He, X. Micro-scale mechanism of coal and gas outburst: A preliminary study. J. China Univ. Min. Technol. 2022, 51, 207–220. [Google Scholar]

- Zhao, H.; Qin, F.; Li, Z. The influence of coal seam nano-pore structure on gas migration characteristics. J. Min. Saf. Eng. 2022, 39, 1256–1264+1271. [Google Scholar]

- Fan, C.; Jiang, X.; Fan, N. Scale Effect of Coal Porosity and Permeability Characteristics Based on CT 3D Reconstruction from a Micro perspective. Energy Fuels 2024, 38, 1813–1821. [Google Scholar] [CrossRef]

- Shang, S.; Gao, K.; Gao, Q. Influence of Fracture Development on Seepage Characteristics of Low porosity Rocks. Sci. Technol. Eng. 2023, 23, 9809–9819. [Google Scholar]

- Fan, N.; Wang, J.; Deng, C. Quantitative characterization of coal microstructure and visualization seepage of macropores using CT-based 3D reconstruction. J. Nat. Gas Sci. Eng. 2020, 81, 103384. [Google Scholar] [CrossRef]

- Wang, H.; Shi, Y.; Xu, D. Unconventional reservoirs pore structure characterization techniques and progress. Oil Gas Geol. Recovery 2019, 26, 21–30. [Google Scholar]

- Zhang, W.; Qiu, L. Characterization and Analysis of Pore Structure of Coal Based on CT 3D Reconstruction. Coal Technol. 2018, 37, 327–329. [Google Scholar]

- Wang, Y.; Meng, Q.; Gao, L. Research on Reconstruction and Quantitative Characterization of Three-dimensional Cracks in Pyrolysis Anthracite. J. Taiyuan Univ. Technol. 2021, 52, 211–218. [Google Scholar]

- Wang, X.; Pan, J.; Wang, K. Characteristics of micro-CT scale pore-fracture of tectonic ally deformed coal and their controlling effect on permeability. J. Coal 2023, 48, 1325–1334. [Google Scholar]

- Hao, J.; Shu, L.; Huo, Z.; Fan, Y.; Wu, S.; Li, Y.; Guo, X. Quantitative characterization of pore-fracture structure of medium and high-rank coal based on Micro-CT technology. Int. J. Coal Prep. Util. 2024, 44, 358–375. [Google Scholar] [CrossRef]

- GB 474-2008; Method for Preparation of Coal Sample. General Administration of Quality Supervision: Beijing, China, 2008.

- GB/T212-2008; Proximate Analysis of Coal. General Administration of Quality Supervision: Beijing, China, 2008.

- GB/T476-2008; Determination of Carbon and Hydrogen in Coal. General Administration of Quality Supervision: Beijing, China, 2008.

- GB/T19227-2008; Determination of Nitrogen in Coal. General Administration of Quality Supervision: Beijing, China, 2008.

- GB/T1574-2007; Test Method for Analysis of Coal Ash. General Administration of Quality Supervision: Beijing, China, 2007.

- Lyu, H.; Zou, J.; Zhao, J. Review on Development of Nano-Computed Tomography Imaging Technology. Adv. Laser Optoelectron. 2020, 57, 9–24. [Google Scholar]

- Ding, Z.; Gao, C.; Wang, Y. Quantitative analysis of meso-structured and representative elementary volume determination of low rank long flame coal. Coal Sci. Technol. 2023, 51, 116–129. [Google Scholar]

- Ding, Z.; Li, X.; Tang, Q. Study on the correlation between fractal characteristics of pore distribution and strength of sandstone particles. J. Rock Mech. Eng. 2020, 39, 1787–1796. [Google Scholar]

- Wu, J. Characteristics of coal micropores and their relationship with hydrocarbon migration and accumulation. China Sci. (B) 1993, 01, 77–84. [Google Scholar]

- Guo, Y.; Chen, X.; Chen, B. Analysis of foamed concrete pore structure of railway roadbed based on X-ray computed tomography. Constr. Build. Mater. 2021, 273, 121773. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.; Yang, J. Fractal analysis of CT images of tight sandstone with anisotropy and permeability prediction. J. Pet. Sci. Eng. 2021, 205, 108919. [Google Scholar] [CrossRef]

- Guan, Q.; Dong, D.; Sun, S. Fractal characteristics of organic-rich shale pore structure and its geological implications: A case study of the Lower Silurian Longmaxi Formation in the Weiyuan block, Sichuan Basin. Nat. Gas Ind. 2024, 44, 108–118. [Google Scholar]

- Dong, H.; Blunt, M.J. Pore-network extraction from micro-computerized-tomography images. Phys. Rev. E 2009, 80(Pt2), 036307. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Cheng, M.; Cheng, Y. Reservoir modification effect of Ophiomorpha-Talassinoides ichnofabric in the Neogene Sanya Formation in northern Qiongdongnan Basin. Palaeogeography 2023, 25, 1407–1420. [Google Scholar]

- Sheng, J.; Yang, X.; Li, G. Application of Multiscale X-CT Imaging Digital Core Technique on Observing Micro-pore Structure of Carbonate Reservoirs. Mod. Geol. 2019, 33, 653–661+671. [Google Scholar]

- Silin, D.; Patzek, T. Pore space morphology analysis using maximal inscribed spheres. Phys. A Stat. Mech. Its Appl. 2006, 371, 336–360. [Google Scholar] [CrossRef]

- Shi, X.; Pan, J.; Pang, L. 3D Microfracture network and seepage characteristics of low-volatility bituminous coal based on Nano-CT. J. Nat. Gas Sci. Eng. 2020, 83, 103556. [Google Scholar] [CrossRef]

- Zhang, K.; Cheng, Y.; Wang, L. Pore network structure characterization based on gas occurrence and migration in coal. Coal J. 2022, 47, 3680–3694. [Google Scholar]

| Samples | RO/% | Porosity/% | Industrial Analysis | Elemental Analysis | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mad/% | Aad/% | Vad/% | Fcad/% | C/% | H/% | O/% | N/% | |||

| XJ | 0.64 | 5.1787 | 3.24 | 1.92 | 28.42 | 66.42 | 79.55 | 4.13 | 10.09 | 0.80 |

| LL | 1.52 | 9.3114 | 0.95 | 18.93 | 10.35 | 69.77 | 79.43 | 3.28 | 2.89 | 1.54 |

| ZZ | 3.46 | 7.8654 | 1.14 | 8.48 | 10.91 | 79.47 | 71.65 | 3.16 | 3.97 | 1.50 |

| CT Type | Sample Name | Total Porosity | Connected Porosity | Pressurized Mercury | Error |

|---|---|---|---|---|---|

| Micro-CT | LL | 9.94% | 8.59% | 9.31% | 0.63% |

| XJ | 5.01% | 4.64% | 5.18% | 0.17% | |

| ZZ | 7.93% | 6.10% | 7.87% | 0.06% | |

| Nano-CT | LL | 8.87% | 6.65% | 9.31% | 0.44% |

| XJ | 6.13% | 1.71% | 5.18% | 0.95% | |

| ZZ | 7.89% | 1.70% | 7.87% | 0.02% |

| CT Type | Sample Name | Equivalent Pore Diameter (μm/nm) | ||

|---|---|---|---|---|

| Max | Avg | Min | ||

| Micro-CT | LL | 22,444 | 117 | 51 |

| XJ | 18,278 | 106 | 51 | |

| ZZ | 20,028 | 116 | 51 | |

| Nano-CT | LL | 10,0741 | 761 | 248 |

| XJ | 63,889 | 1656 | 248 | |

| ZZ | 63,861 | 454 | 248 | |

| CT Type | Sample Name | Fractal Dimension Dv | Surface Fractal Dimension D | ||

|---|---|---|---|---|---|

| Dmin | Davg | Dmax | |||

| Micro-CT | LL | 2.57 | 1.14 | 1.47 | 1.74 |

| XJ | 2.36 | 0.94 | 1.17 | 1.79 | |

| ZZ | 2.49 | 1.23 | 1.42 | 1.77 | |

| Nano-CT | LL | 2.51 | 1.38 | 1.43 | 1.50 |

| XJ | 2.30 | 0.87 | 1.08 | 1.41 | |

| ZZ | 2.33 | 1.10 | 1.28 | 1.39 | |

| CT Type | Samples | Total Pores | Equivalent Radius of Pore (μm/nm) | Coordination Number | Surface Area (μm2/nm2) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Avg | Min | Max | Avg | Min | Max | Avg | Min | |||

| Micro-CT | LL | 193,056 | 1062 | 166 | 25 | 79 | 5.67 | 0 | 2.52 × 1010 | 6.36 × 108 | 5.05 × 106 |

| XJ | 59,998 | 1272 | 182 | 25 | 75 | 6.58 | 0 | 4.19 × 1010 | 8.20 × 108 | 5.05 × 106 | |

| ZZ | 158,137 | 921 | 163 | 25 | 78 | 5.36 | 0 | 1.72 × 1010 | 6.19 × 108 | 5.05 × 106 | |

| Nano-CT | LL | 73,724 | 5223 | 993 | 124 | 49 | 4.76 | 0 | 5.83 × 108 | 2.22 × 107 | 1.20 × 105 |

| XJ | 4450 | 8058 | 1592 | 197 | 38 | 3.53 | 0 | 1.49 × 109 | 5.23 × 107 | 4.05 × 105 | |

| ZZ | 23,047 | 3278 | 982 | 124 | 21 | 3.98 | 0 | 1.29 × 109 | 4.07 × 107 | 1.20 × 105 | |

| CT Type | Sample Name | Total Throat | Throat Equivalent Radius (μm/nm) | Throat Length (μm/nm) | Surface Area (μm2/nm2) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Avg | Min | Max | Avg | Min | Max | Avg | Min | |||

| Micro-CT | LL | 547,493 | 1110 | 80 | 10 | 3045 | 478 | 38 | 3.86 × 109 | 2.91 × 107 | 3.08 × 105 |

| XJ | 197,303 | 998 | 99 | 10 | 4317 | 548 | 50 | 3.12 × 109 | 4.78 × 107 | 3.08 × 105 | |

| ZZ | 423,852 | 953 | 76 | 8 | 914 | 469 | 38 | 2.85 × 109 | 2.44 × 107 | 2.24 × 105 | |

| Nano-CT | LL | 175,483 | 4569 | 535 | 41 | 1.27 × 104 | 2887 | 153 | 6.55 × 107 | 1.45 × 106 | 5331 |

| XJ | 7846 | 6255 | 898 | 48 | 1.64 × 104 | 4516 | 591 | 1.22 × 108 | 3.81 × 106 | 7353 | |

| ZZ | 45,909 | 1865 | 407 | 48 | 1.60 × 104 | 2891 | 263 | 1.09 × 107 | 6.90 × 105 | 7352 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Yue, Y.; Liu, Y. Analysis and Characterization of Micro–Nano Pores in Coal Reservoirs of Different Coal Ranks. Appl. Sci. 2024, 14, 5198. https://doi.org/10.3390/app14125198

Song J, Yue Y, Liu Y. Analysis and Characterization of Micro–Nano Pores in Coal Reservoirs of Different Coal Ranks. Applied Sciences. 2024; 14(12):5198. https://doi.org/10.3390/app14125198

Chicago/Turabian StyleSong, Jinxing, Yulu Yue, and Yufang Liu. 2024. "Analysis and Characterization of Micro–Nano Pores in Coal Reservoirs of Different Coal Ranks" Applied Sciences 14, no. 12: 5198. https://doi.org/10.3390/app14125198

APA StyleSong, J., Yue, Y., & Liu, Y. (2024). Analysis and Characterization of Micro–Nano Pores in Coal Reservoirs of Different Coal Ranks. Applied Sciences, 14(12), 5198. https://doi.org/10.3390/app14125198