Updating Durability Models for Concrete Structures in Chlorine Environment Based on Detection Information

Abstract

1. Introduction

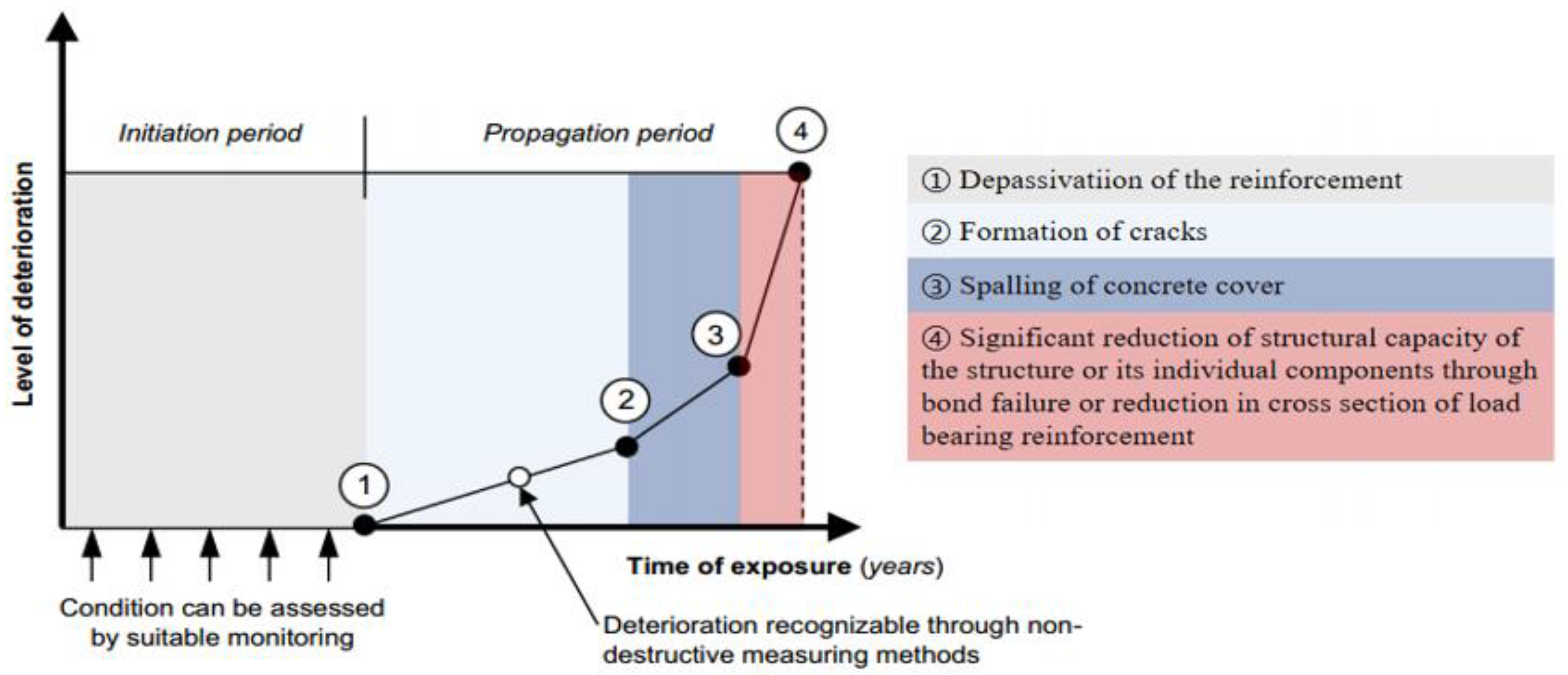

2. Existing Durability Model in Chlorine Environment

2.1. Chloride Ion Diffusion Model

2.2. Initial Corrosion Model of Steel Reinforcement

3. Bayesian Updating with Detection Information

3.1. Updating of the Chloride Diffusion Model

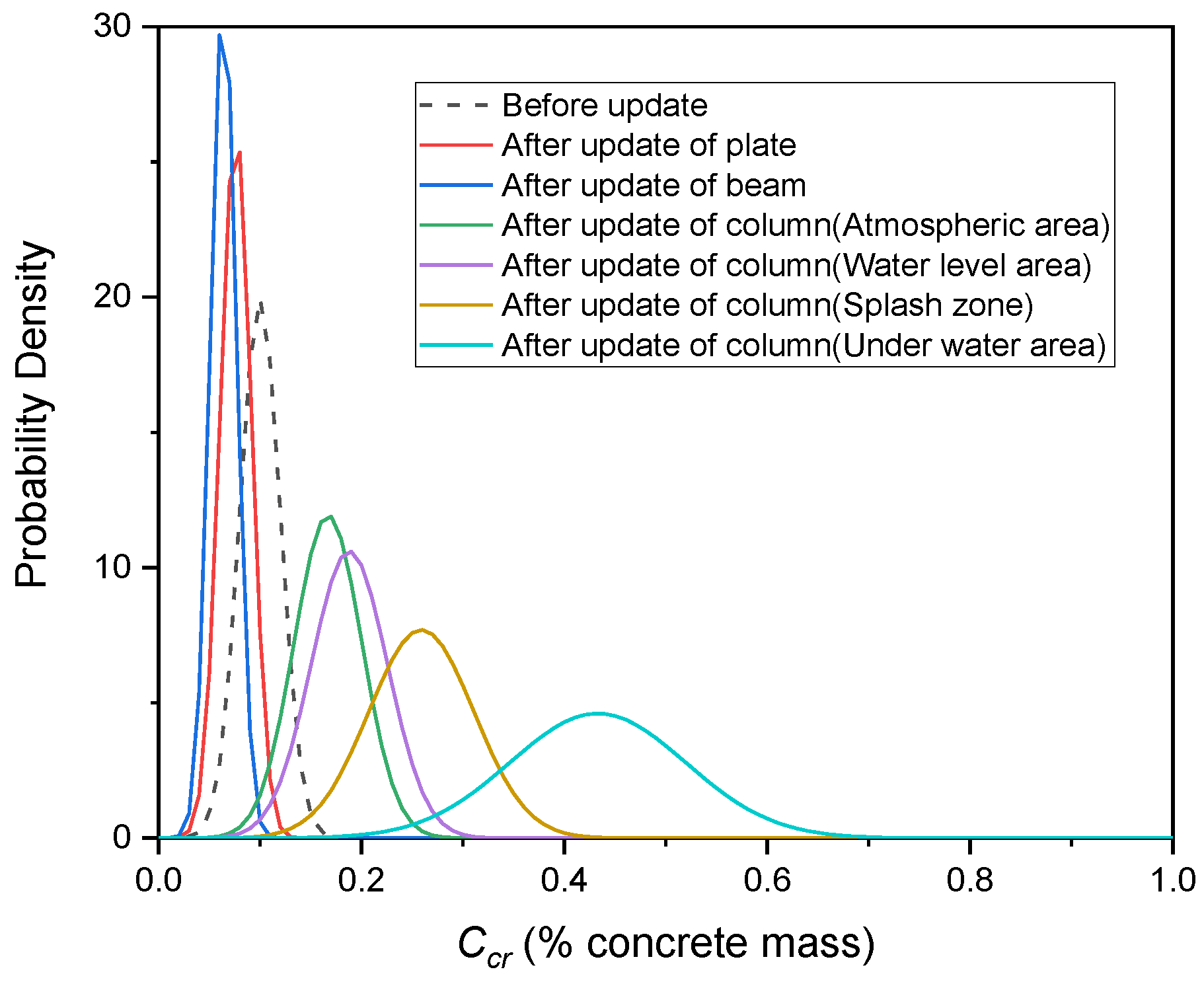

3.2. Updating of the Reinforcement Initial Corrosion Model

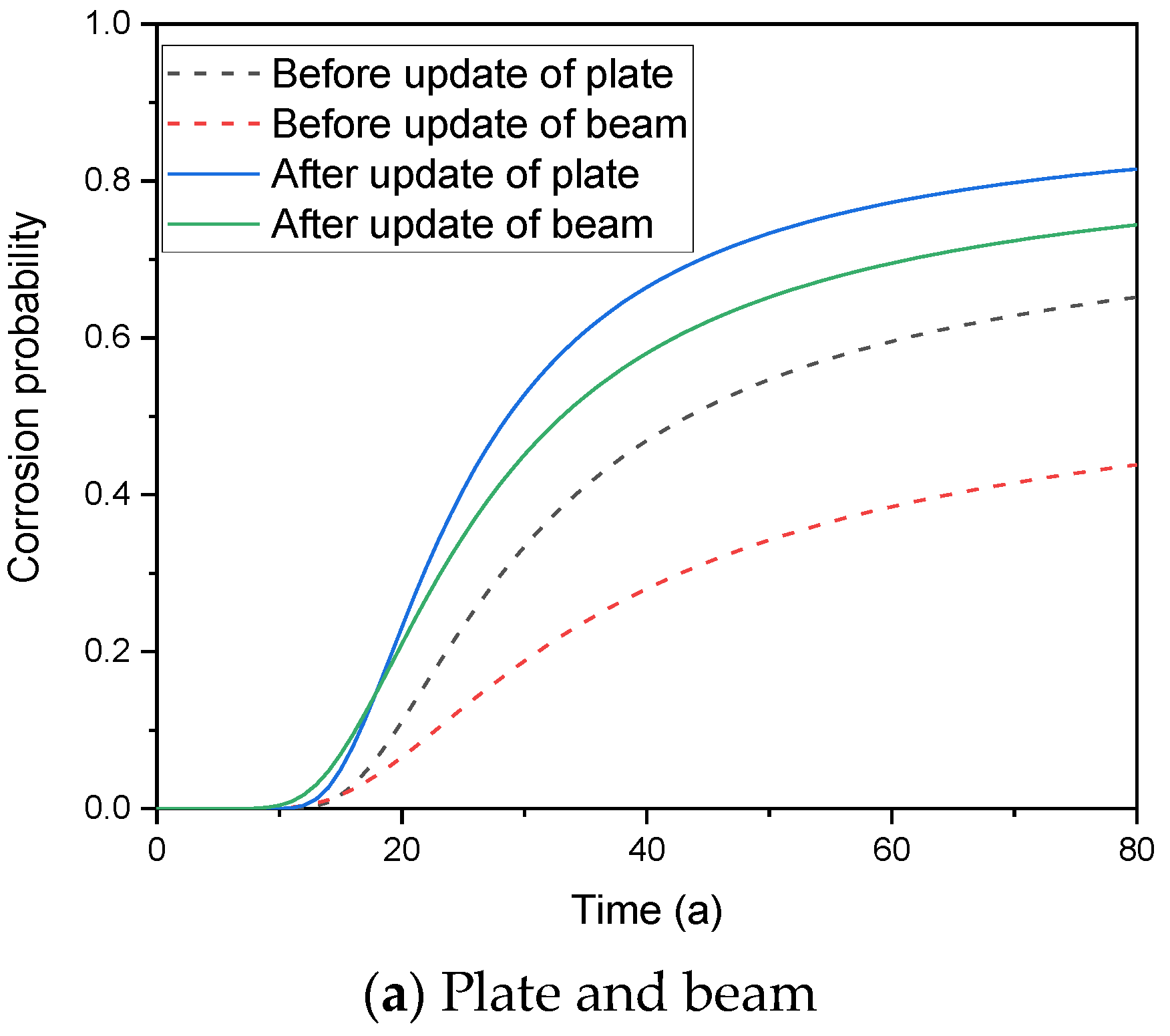

- Calculate the mean value of the prior corrosion probability of reinforcement using Formula (14) with the updated chloride diffusion model in Section 3.1. List the mean value of the prior probability and the coefficient of variation as 0.5.

- In the case of the test result H (number of corrosion samples in a number of test samples), calculate the mean value and the standard deviation of the posterior probability density function of the corrosion probability as and using Formula (17).

- Calculate the updated mean value (assuming constant of standard deviation) of as using Formula (18).

- Calculate the updated initial corrosion time tini and the future corrosion probability in time t with the updated chloride diffusion model and the updated mean value (assuming constant of standard deviation) of using Formulas (14) and (19).

4. Case Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alexander, M.; Beushausen, H. Durability, service life prediction, and modelling for reinforced concrete structures-review and critique. Cem. Concr. Res. 2019, 122, 17–29. [Google Scholar] [CrossRef]

- Maaddawy, T.E.; Soudki, K. A model for prediction of time from corrosion initiation to corrosion cracking. Cem. Concr. Compos. 2007, 29, 168–175. [Google Scholar] [CrossRef]

- Kim, A.V.; Stewart, M.G. Structural reliability of concrete bridges including improved chloride-induced corrosion models. Struct. Saf. 2000, 22, 313–333. [Google Scholar]

- Fakhri, H.; Fishman, K.L.; Ranade, R. Rapid determination of critical chloride content in cement-based composites. Constr. Build. Mater. 2020, 268, 121–148. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete-a review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Nganga, G.; Alexander, M.; Beushausen, H. Practical implementation of the durability index performance-based design approach. Constr. Build. Mater. 2013, 45, 251–261. [Google Scholar] [CrossRef]

- Zhu, W.; François, R.; Fang, Q.; Zhang, D. Influence of long-term chloride diffusion in concrete and the resulting corrosion of reinforcement on the serviceability of RC beams. Cem. Concr. Compos. 2016, 71, 144–152. [Google Scholar] [CrossRef]

- Angst, U.; Ronnquist, A.; Elsener, B.; Larsen, C.K.; Vennesland, O. Probabilistic considerations on the effect of specimen size on the critical chloride content in reinforced concrete. Corros. Sci. 2011, 53, 177–187. [Google Scholar] [CrossRef]

- Ke Ler, S.; Fischer, J.; Straub, D.; Gehlen, C. Updating of service-life prediction of reinforced concrete structures with potential mapping. Cem. Concr. Compos. 2014, 47, 47–52. [Google Scholar] [CrossRef]

- Gu, H.; Li, Q. Updating deterioration models of reinforced concrete structures in carbonation environment using in-situ inspection data. Struct. Infrastruct. Eng. 2022, 18, 266–277. [Google Scholar] [CrossRef]

- Heitner, B.; OBrien, E.J.; Yalamas, T.; Schoefs, F.; Leahy, C.; Décatoire, R. Updating probabilities of bridge reinforcement corrosion using health monitoring data. Eng. Struct. 2019, 190, 41–51. [Google Scholar] [CrossRef]

- Suo, Q.; Stewart, M.G. Corrosion cracking prediction updating of deteriorating RC structures using inspection information. Reliab. Eng. Syst. Saf. 2009, 94, 1340–1348. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, Z.; Li, Q.; Cao, M. Bayesian model updating based on structural reliability method: Case study for chloride-induced durability analysis. Eng. Mech. 2022, 39, 336–341. [Google Scholar] [CrossRef]

- Gu, H.; Li, Q.; Hou, G. Updating method for durability models of concrete structures in carbonation environment. Eng. Mech. 2021, 38, 113–121. [Google Scholar]

- Tuutti, K. Corrosion of Steel in Concrete; Report No. CBI Research 4; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1982; p. 82. [Google Scholar]

- FIB. Model Code for Service Life Design; Fib Bulletin 34; FIB: Lausanne, Switzerland, 2006. [Google Scholar]

- Angst, U.M. Predicting the time to corrosion initiation in reinforced concrete structures exposed to chlorides. Cem. Concr. Res. 2019, 115, 559–567. [Google Scholar] [CrossRef]

- Cao, Y.; Gehlen, C.; Angst, U.; Wang, L.; Yao, Y. Critical chloride content in reinforced concrete-an updated review considering chinese experience. Cem. Concr. Res. 2019, 117, 58–68. [Google Scholar] [CrossRef]

- GB/T50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- American Concrete Institute. ACI 318 Standard: Building Code Requirements for Structural Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2020. [Google Scholar]

- American Concrete Institute. Life-365 Service Life Prediction Model TM Version 2.0; American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- Li, Q.; Li, K.; Zhou, X.; Zhang, Q.; Fan, Z. Model-based durability design of concrete structures in Hong Kong-Zhuhai-Macau sea link project. Struct. Saf. 2015, 53, 1–12. [Google Scholar] [CrossRef]

- GB/T 50344-2004; Technical Standards for Building Structure Testing. China Architecture & Building Press: Beijing, China, 2004.

- GB/T 50784-2013; Technical Standards for On-Site Testing of Concrete Structures. China Architecture & Building Press: Beijing, China, 2013.

- JGJ/T 23-2011; Technical Specification for Testing Compressive Strength of Concrete Using Rebound Method. China Architecture & Building Press: Beijing, China, 2011.

- JTJ/T272-99; Technical Specification for Non-Destructive Testing of Concrete in Port Engineering. China Architecture & Building Press: Beijing, China, 2016.

- Val, D.V.; Stewart, M.G. Life-cycle cost analysis of reinforced concrete structures in marine environments. Struct. Saf. 2003, 25, 343–362. [Google Scholar] [CrossRef]

- Fluge, F. Marine chlorides: A probabilistic approach to derive provisions for EN 206-1. In Proceedings of the 3rd Workshop on Service Life Design of Concrete Structures: From Theory to Standardisation, DuraNet. Troms¢: 47–68, Tromso, Norway, 10–12 July 2001. [Google Scholar]

- General Guidelines for Durability Design and Redesign: DuraCrete, Probabilistic Performance Based Durability Design of Concrete Structures; The European Union-Brite EuRam: Lyngby, Denmark, 2000.

- Li, Q.; Ye, X. Surface deterioration analysis for probabilistic durability design of RC structures in marine environment. Struct. Saf. 2018, 75, 13–23. [Google Scholar] [CrossRef]

- Stewart, M.G. Spatial and time-dependent reliability modelling of corrosion damage, safety and maintenance for reinforced concrete structures. Struct. Infrastruct. Eng. 2012, 8, 607–619. [Google Scholar] [CrossRef]

- Matsushima, M.; Tsutsumi, T.; Seki, H.; Matsui, K. Optimum thickness of concrete cover of RC structure based on reliability theory. Concr. Libr. JSCE 1995, 25, 45–57. [Google Scholar] [CrossRef]

- Horiguchi, K.; Yamaguchi, T.; Maruya, T.; Takewaka, K. Study on the Method of Measuring the Chloride Threshold Value of Corrosion and Estimation of the Values in Durability Design of Concrete Structures. J. Adv. Concr. Technol. 2020, 18, 571–587. [Google Scholar] [CrossRef]

| Project | Plate | Beam | Column |

|---|---|---|---|

| Mean/mm | 41.1 | 39.75 | 56.5 |

| Standard Deviation/mm | 0.82 | 4.37 | 4.52 |

| Coefficient of Variation | 0.02 | 0.11 | 0.08 |

| Position | Service Years/a | Surface Chloride Ion Concentration /% of the Concrete Mass | Diffusion Coefficient /10−8 cm2.s−1 | Mean Value of | Standard Deviation of |

|---|---|---|---|---|---|

| Plate | 12 | 0.0670 | 1.4909 | 2.5459 | 1.8535 |

| Beam | 0.0494 | ||||

| Column (Atmospheric area) | 12 | 0.1624 | 5.7675 | 1.3688 | 0.1648 |

| Column (Water level change area) | 0.2101 | ||||

| Column (Splash zone) | 0.3178 | ||||

| Column (Underwater area) | 0.5129 |

| Position | Number of Test Samples | Number of Corrosion Samples | ||||

|---|---|---|---|---|---|---|

| Plate | 0.0011 | 48 | 12 | 0.0042 | 0.0010 | 0.076 |

| Beam | 0.0040 | 48 | 15 | 0.0180 | 0.0041 | 0.064 |

| Column (Atmospheric area) | 0.6935 | 30 | 6 | 0.2123 | 0.0726 | 0.167 |

| Column (Water level change area) | 0.8829 | 30 | 10 | 0.3246 | 0.0847 | 0.188 |

| Column (splash zone) | 0.9897 | 30 | 13 | 0.4150 | 0.0899 | 0.259 |

| Column (Underwater area) | 0.9999 | 30 | 12 | 0.3793 | 0.0886 | 0.433 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, H.; Meng, Z. Updating Durability Models for Concrete Structures in Chlorine Environment Based on Detection Information. Appl. Sci. 2024, 14, 4516. https://doi.org/10.3390/app14114516

Gu H, Meng Z. Updating Durability Models for Concrete Structures in Chlorine Environment Based on Detection Information. Applied Sciences. 2024; 14(11):4516. https://doi.org/10.3390/app14114516

Chicago/Turabian StyleGu, Hui, and Zhaobo Meng. 2024. "Updating Durability Models for Concrete Structures in Chlorine Environment Based on Detection Information" Applied Sciences 14, no. 11: 4516. https://doi.org/10.3390/app14114516

APA StyleGu, H., & Meng, Z. (2024). Updating Durability Models for Concrete Structures in Chlorine Environment Based on Detection Information. Applied Sciences, 14(11), 4516. https://doi.org/10.3390/app14114516