A Visual Survey of Tunnel Boring Machine (TBM) Performance in Tunneling Excavation: Mainstream Direction, Brief Review and Future Prospects

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Source

2.2. Research Tool

3. Results

3.1. Mainstream Area Analysis

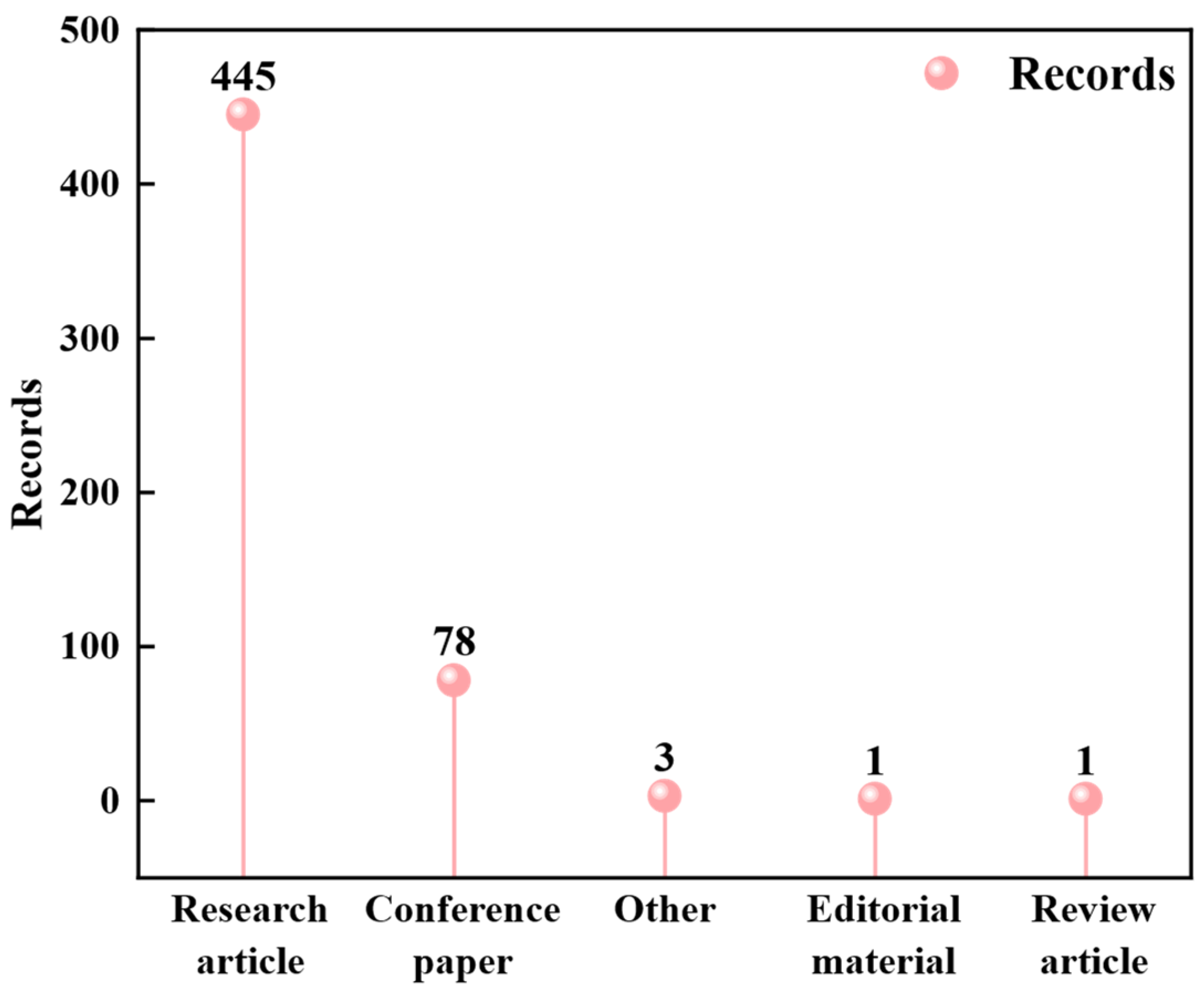

3.2. Publication Analysis

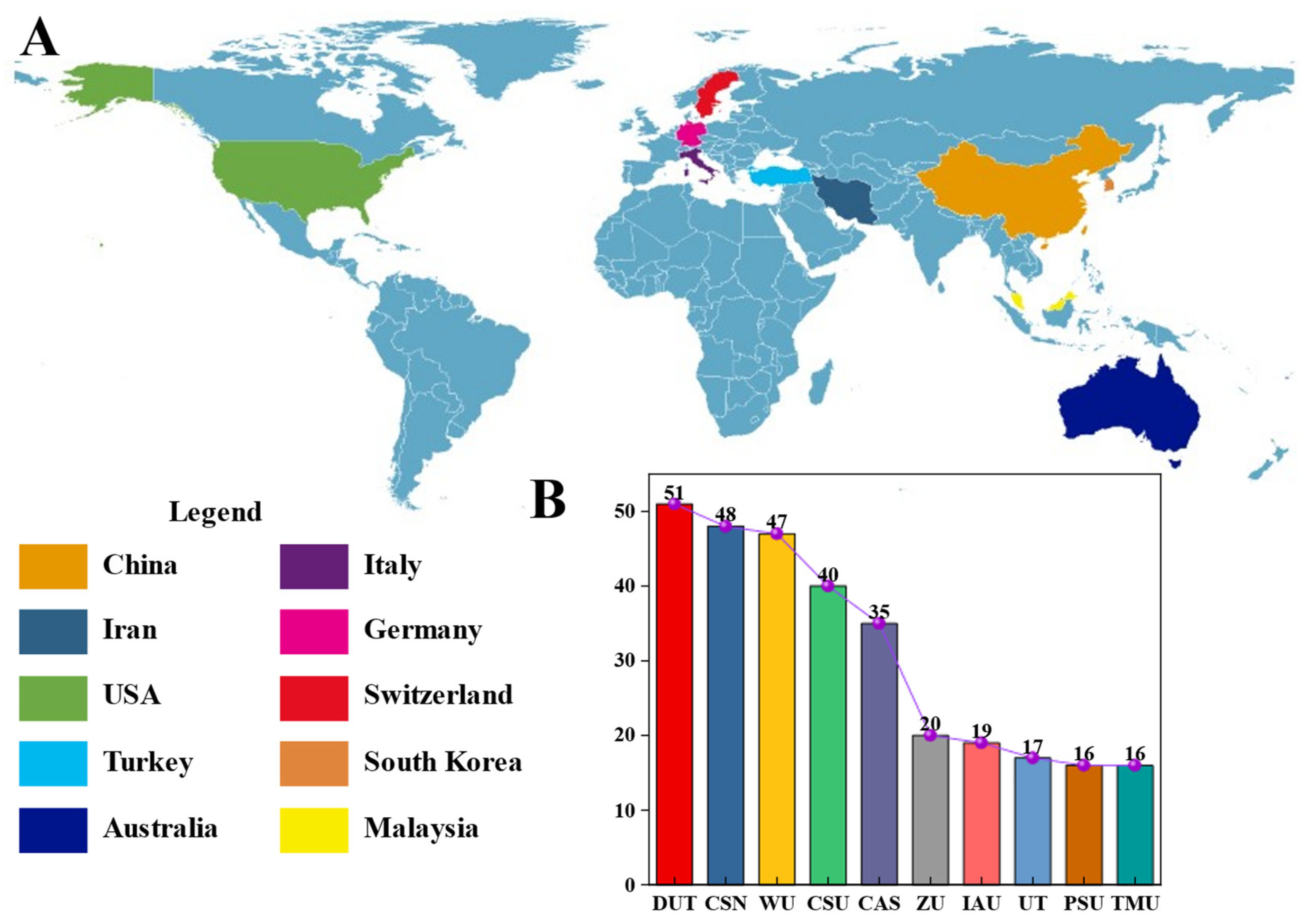

3.3. Study Countries

3.4. Research Institutions

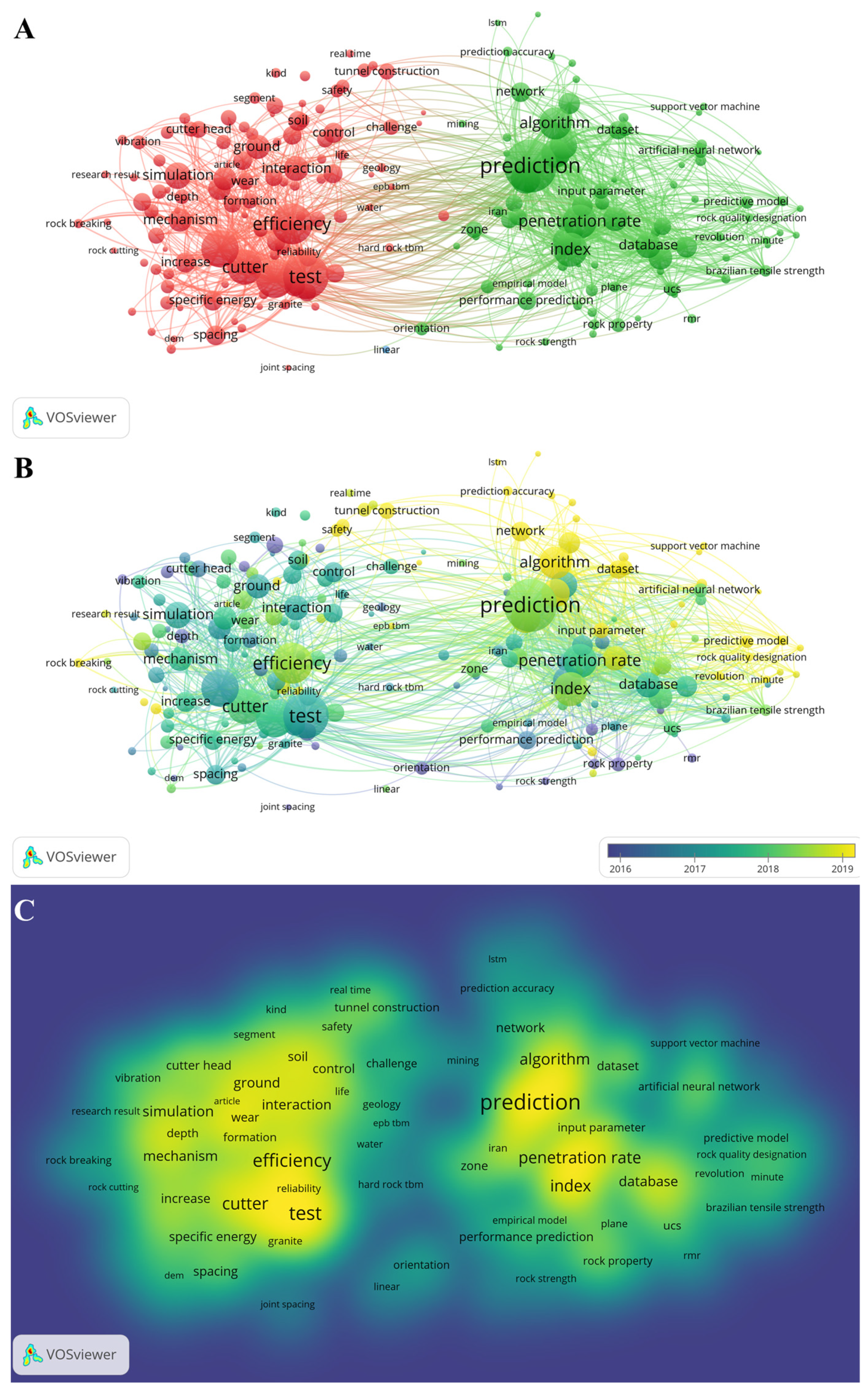

3.5. Research Hotspots

3.6. Citation Frequency Analysis

3.7. Key Literature Analysis

4. Understanding of TBM Performance

4.1. Selection of Excavation Methods

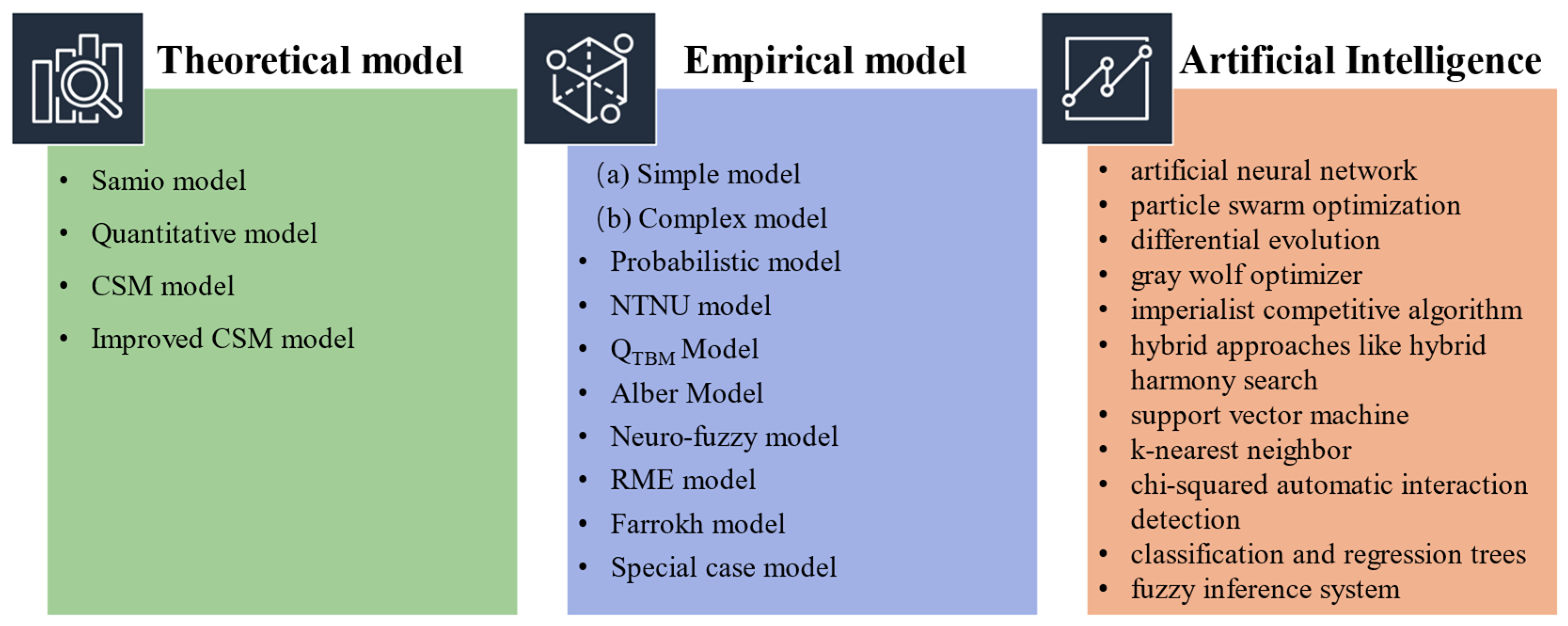

4.2. Current Developments in Performance Prediction

4.2.1. Theoretical Model

4.2.2. Empirical Model

4.2.3. Artificial Intelligence Model

- Data processing and analysis. AI models, particularly machine learning algorithms, excel in handling large datasets generated during TBM operations. These datasets encompass numerous parameters such as geological conditions, machine performance metrics, and environmental factors. AI models can efficiently process these data to provide real-time insights, which is crucial for making informed decisions and adjusting operational strategies dynamically.

- Predictive modeling and optimization. AI-driven predictive models can forecast the performance of TBMs under varying conditions, enabling operators to optimize machine settings for different segments of a tunnel project. By simulating various scenarios, AI models help in identifying the most efficient operational parameters, which can lead to significant cost savings and improved project timelines. Moreover, optimization algorithms can continuously adjust TBM parameters in real-time, ensuring optimal performance throughout the tunneling process.

5. Future Perspectives

5.1. Immersive Training and Learning

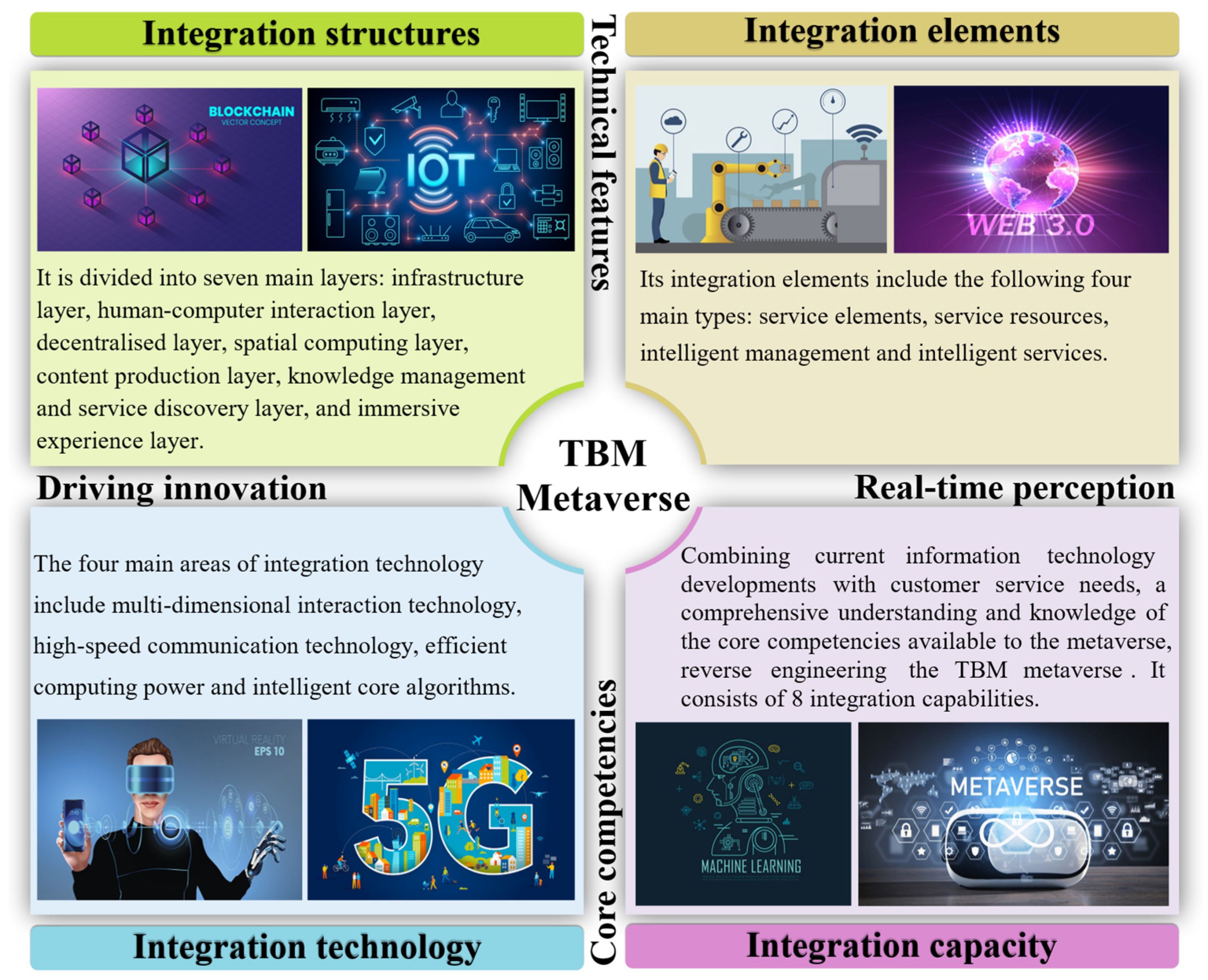

5.2. TBM Metaverse Architecture

6. Conclusions

- This study illuminates the noteworthy contributions made by various nations and institutions to TBM performance research, with a focus on leading contributors such as China, Iran, the United States, and Turkey. The analysis underscores the global scope of TBM research initiatives and emphasizes the necessity of tackling a wide array of tunnelling challenges on a global scale.

- The examination of 40 distinct domains and significant focal points in the study of TBM performance reveals its interdisciplinary character.

- By scrutinizing highly cited articles and essential references, this research offers nuanced insights into pivotal research directions and significant findings.

- Through a comparative analysis of the merits and drawbacks associated with drill and blast methods as opposed to TBM methods, this research provides valuable guidance for stakeholders in the selection of excavation techniques for tunneling projects. It emphasizes the significance of weighing technical and economic indicators to mitigate project risks and optimize efficiency.

- The study further accentuates the potential ramifications of metaverse technology on the future of TBMs, particularly focusing on immersive training and learning concepts and the conceptualization of a TBM metaverse architecture. This integration unveils thrilling prospects for innovation in tunnelling technology and training methodologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Macias, F.J. Hard Rock Tunnel Boring: Performance Predictions and Cutter Life Assessments. Ph.D. Theses, NTNU, Trondheim, Norway, 2016. [Google Scholar]

- Liu, Q.S.; Liu, J.P.; Pan, Y.C.; Kong, X.X.; Cui, X.Z.; Huang, S.B.; Wei, L. Research advances of tunnel boring machine performance prediction models for hard rock. Chin. J. Rock Mech. Eng. 2016, 35, 2766–2786. [Google Scholar]

- Gong, Q.; Zhao, J.; Zhang, X. Performance prediction of hard rock TBM tunneling. Chin. J. Rock Mech. Eng. 2004, 23, 4709–4714. [Google Scholar]

- Bruland, A. Hard Rock Tunnel Boring; Fakultet for Ingeniørvitenskap og Teknologi; NTNU: Trondheim, Norway, 2000; Available online: http://hdl.handle.net/11250/231256 (accessed on 17 May 2024).

- Nelson, P.P.; Al-Jalil, Y.A.; Laughton, C. Tunnel Boring Machine Project Data Bases and Construction Simulation; Geotechnical Engineering Center Report GR; Geotechnical Engineering Center: New York, NY, USA, 1994; p. 94. [Google Scholar]

- Alber, M. Advance rates of hard rock TBMs and their effects on project economics. Tunn. Undergr. Space Technol. 2000, 15, 55–64. [Google Scholar] [CrossRef]

- Farmer, I.W.; Glossop, N.H. Mechanics of disc cutter penetration. Tunn. Tunn. 1980, 12, 22–25. [Google Scholar]

- Innaurato, N.; Mancini, A.; Rondena, E.; Zaninetti, A. Forecasting and effective TBM performances in a rapid excavation of a tunnel in Italy. In ISRM Congress; ISRM-7CONGRESS; ISRM: Aachen, Germany, 1991. [Google Scholar]

- Rostami, J. Development of a Force Estimation Model for Rock Fragmentation with Disc Cutters through Theoretical Modeling and Physical Measurement of Crushed Zone Pressure; Colorado School of Mines: Golden, CO, USA, 1997. [Google Scholar]

- Sanio, H.P. Prediction of the performance of disc cutters in anisotropic rock. In International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts; Pergamon: Oxford, UK, 1985; Volume 22, pp. 153–161. [Google Scholar]

- Ma, W.; Alimo, P.K.; Wang, L.; Abdel-Aty, M. Mapping pedestrian safety studies between 2010 and 2021: A scientometric analysis. Accid. Anal. Prev. 2022, 174, 106744. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhou, W. The exploration of travel motivation research: A scientometric analysis based on CiteSpace. COLLNET J. Scientometr. Inf. Manag. 2020, 14, 257–283. [Google Scholar] [CrossRef]

- Jiang, C.; Bhat, C.R.; Lam, W.H.K. A bibliometric overview of Transportation Research Part B: Methodological in the past forty years (1979–2019). Transp. Res. Part B Methodol. 2020, 138, 268–291. [Google Scholar] [CrossRef]

- Meyer, T. Decarbonizing road freight transportation–A bibliometric and network analysis. Transp. Res. Part D Transp. Environ. 2020, 89, 102619. [Google Scholar] [CrossRef]

- Sood, S.K.; Kumar, N.; Saini, M. Scientometric analysis of literature on distributed vehicular networks: VOSViewer visualization techniques. Artif. Intell. Rev. 2021, 54, 6309–6341. [Google Scholar] [CrossRef]

- Si, H.; Shi, J.G.; Wu, G.; Chen, J.; Zhao, X. Mapping the bike sharing research published from 2010 to 2018: A scientometric review. J. Clean. Prod. 2019, 213, 415–427. [Google Scholar] [CrossRef]

- Van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Nadzar, N.; Bakri, A.; Ibrahim, R. A bibliometric mapping of Malaysian publication using co-word analysis. Int. J. Adv. Soft Comput. Appl. 2017, 9, 90–113. [Google Scholar]

- Wong, D. VOSviewer. Tech. Serv. Q. 2018, 35, 219–220. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Y.; Qiu, Y. State-of-the-art review of machine learning and optimization algorithms applications in environmental effects of blasting. Artif. Intell. Rev. 2024, 57, 1–54. [Google Scholar] [CrossRef]

- Zhang, Y.; He, H.; Khandelwal, M.; Du, K.; Zhou, J. Knowledge mapping of research progress in blast-induced ground vibration from 1990 to 2022 using CiteSpace-based scientometric analysis. Environ. Sci. Pollut. Res. 2023, 30, 103534–103555. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Y.; Li, C.; He, H.; Li, X. Rockburst prediction and prevention in underground space excavation. Undergr. Space 2023, 14, 70–98. [Google Scholar] [CrossRef]

- Han, Z.; Li, B.; Zhang, K.; Li, X. Knowledge structure of China’s marine economy research: An analysis based on CiteSpace map. Sci. Geogr. Sin. 2016, 36, 643–652. [Google Scholar]

- Osiński, S.; Weiss, D. Clustering Search Results with Carrot2. 2007. Available online: https://docs.huihoo.com/carrot2/carrot2-dresden-2007.pdf (accessed on 17 May 2024).

- Singh, P.K.; Suryawanshi, A.; Gupta, S.; Saindane, P. Elasticsearch and Carrot2-Based Log Analytics and Management. In Innovations in Computer Science and Engineering: Proceedings of the Third ICICSE, 2015; Springer: Singapore, 2016; pp. 71–78. [Google Scholar]

- Gertsch, R.; Gertsch, L.; Rostami, J. Disc cutting tests in Colorado Red Granite: Implications for TBM performance prediction. Int. J. Rock Mech. Min. Sci. 2007, 44, 238–246. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Mohamad, E.T.; Narayanasamy, M.S.; Narita, N.; Yagiz, S. Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition. Tunn. Undergr. Space Technol. 2017, 63, 29–43. [Google Scholar] [CrossRef]

- Gong, Q.M.; Jiao, Y.Y.; Zhao, J. Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn. Undergr. Space Technol. 2006, 21, 46–55. [Google Scholar] [CrossRef]

- Gong, Q.M.; Zhao, J.; Jiao, Y.Y. Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn. Undergr. Space Technol. 2005, 20, 183–191. [Google Scholar] [CrossRef]

- Grima, M.A.; Bruines, P.A.; Verhoef, P.N.W. Modeling tunnel boring machine performance by neuro-fuzzy methods. Tunn. Undergr. Space Technol. 2000, 15, 259–269. [Google Scholar] [CrossRef]

- Qiu, D.; Fu, K.; Xue, Y.; Tao, Y.; Kong, F.; Bai, C. TBM tunnel surrounding rock classification method and real-time identification model based on tunneling performance. Int. J. Geomech. 2022, 22, 04022070. [Google Scholar] [CrossRef]

- Kelsall, P.C.; Case, J.B.; Chabannes, C.R. Evaluation of excavation-induced changes in rock permeability. In International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts; Pergamon: Oxford, UK, 1984; Volume 21, pp. 123–135. [Google Scholar]

- Ji, F.; Lu, J.; Shi, Y.; Zhou, C. Mechanical response of surrounding rock of tunnels constructed with the TBM and drill-blasting method. Nat. Hazards 2013, 66, 545–556. [Google Scholar] [CrossRef]

- Bilgin, N.; Demircin, M.A.; Copur, H.; Balci, C.; Tuncdemir, H.; Akcin, N. Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int. J. Rock Mech. Min. Sci. 2006, 43, 139–156. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Khandelwal, M.; Mohamad, E.T. Estimation of the TBM advance rate under hard rock conditions using XGBoost and Bayesian optimization. Undergr. Space 2021, 6, 506–515. [Google Scholar] [CrossRef]

- Robbins, R.J. Present trends and future directions in tunnelling. In Proceedings of the Yugoslav Symposium on Rock Mechanics and Underground Actions, Yugoslavia, Belgrade; 1980; Volume 11. [Google Scholar]

- Nelson, P.P. TBM performance analysis with reference to rock properties. Compr. Rock Eng. 2016, 4, 261–291. [Google Scholar]

- Xu, C.; Jia, W.; Wang, R.; Luo, X.; He, X. MorphText: Deep Morphology Regularized Accurate Arbitrary-shape Scene Text Detection. IEEE Trans. Multimed. 2022, 25, 4199–4212. [Google Scholar] [CrossRef]

- Yagiz, S. Development of Rock Fracture and Brittleness Indices to Quantify the Effects of Rock Mass Features and Toughness in the CSM Model Basic Penetration for Hard Rock Tunneling Machines; Colorado School of Mines: Golden, CO, USA, 2002. [Google Scholar]

- Ramezanzadeh, A. Performance Analysis and Development of New Models for Performance Prediction of Hard ROCK TBMs in rock Mass. Ph.D. Theses, INSA, Lyon, France, 2005. [Google Scholar]

- Boyd, R.J. Hard rock continuous mining machine: Mobile Miner MM-120. In Rock Excavation Engineering Seminar; The Department of Mining and Metallurgical Engineering, University of Queensland: Gatton, Australia, 1986. [Google Scholar]

- Tarkoy, P.J. Predicting Tunnel Boring Machine (TBM) Penetration Rates and Cutter Costs in Selected Rock Types. 1974. Available online: https://trid.trb.org/View/44530 (accessed on 17 May 2024).

- Graham, P.C. Rock Exploration for Machine Manufacturer. 1976. Available online: http://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=PASCALGEODEBRGM7720383388 (accessed on 17 May 2024).

- Cassinelli, F.; Cina, S.; Innaurato, N.; Mancini, R.; Sampaolo, A. Power Consumption and Metal Wear in Tunnel-Boring Machines: Analysis of Tunnel-Boring Operation in Hard Rock. 1982. Available online: http://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=PASCALBTP83X0218704 (accessed on 17 May 2024).

- Bamford, W.E. Rock test indices are being successfully correlated with tunnel boring machine performance. In Proceedings of the Fifth Australian Tunnelling Conference: State of the Art in Underground Development and Construction, Sydney, Australia, 22–24 October 1984; Preprints of Papers, ACT. Institution of Engineers: Barton, Australia, 1984; pp. 218–221. [Google Scholar]

- Farrokh, E.; Rostami, J.; Laughton, C. Study of various models for estimation of penetration rate of hard rock TBMs. Tunn. Undergr. Space Technol. 2012, 30, 110–123. [Google Scholar] [CrossRef]

- Gong, Q.; Zhao, J. Development of a rock mass characteristics model for TBM penetration rate prediction. Int. J. Rock Mech. Min. Sci. 2009, 46, 8–18. [Google Scholar] [CrossRef]

- Hassanpour, J.; Rostami, J.; Khamehchiyan, M.; Bruland, A. Developing new equations for TBM performance prediction in carbonate-argillaceous rocks: A case history of Nowsood water conveyance tunnel. Geomech. Geoengin. Int. J. 2009, 4, 287–297. [Google Scholar] [CrossRef]

- Yagiz, S. Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn. Undergr. Space Technol. 2008, 23, 326–339. [Google Scholar] [CrossRef]

- Barton, N.R. TBM Tunnelling in Jointed and Faulted Rock; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Bieniawski, Z.T.; Celada, B.; Galera, J.M. TBM excavability: Prediction and machine-rock interaction. In Proceedings of the Rapid Excavation and Tunneling Conference, Toronto, Canada; 2007; pp. 1118–1130. [Google Scholar]

- Bieniawski, Z.T.; Celada, B.; Galera, J.M.; Tardáguila, I. New applications of the excavability index for selection of TBM types and predicting their performance. In Proceedings of the ITA World Tunneling Congress, Agra, India, 19 September 2008; pp. 1618–1628. [Google Scholar]

- Yagiz, S.; Gokceoglu, C.; Sezer, E.; Iplikci, S. Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng. Appl. Artif. Intell. 2009, 22, 808–814. [Google Scholar] [CrossRef]

- Khademi Hamidi, J.; Shahriar, K.; Rezai, B.; Bejari, H. Application of fuzzy set theory to rock engineering classification systems: An illustration of the rock mass excavability index. Rock Mech. Rock Eng. 2010, 43, 335–350. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, J.; Asteris, P.G.; Jahed Armaghani, D.; Tahir, M.M. Supervised machine learning techniques to the prediction of tunnel boring machine penetration rate. Appl. Sci. 2019, 9, 3715. [Google Scholar] [CrossRef]

- Asteris, P.G.; Nikoo, M. Artificial bee colony-based neural network for the prediction of the fundamental period of infilled frame structures. Neural Comput. Appl. 2019, 31, 4837–4847. [Google Scholar] [CrossRef]

- Cavaleri, L.; Chatzarakis, G.E.; Di Trapani, F.; Douvika, M.G.; Roinos, K.; Vaxevanidis, N.M.; Asteris, P.G. Modeling of surface roughness in electro-discharge machining using artificial neural networks. Adv. Mater. Res. 2017, 6, 169. [Google Scholar]

- Chen, H.; Asteris, P.G.; Jahed Armaghani, D.; Gordan, B.; Pham, B.T. Assessing dynamic conditions of the retaining wall: Developing two hybrid intelligent models. Appl. Sci. 2019, 9, 1042. [Google Scholar] [CrossRef]

- Moayedi, H.; Jahed Armaghani, D. Optimizing an ANN model with ICA for estimating bearing capacity of driven pile in cohesionless soil. Eng. Comput. 2018, 34, 347–356. [Google Scholar] [CrossRef]

- Yang, H.; Hasanipanah, M.; Tahir, M.M.; Bui, D.T. Intelligent prediction of blasting-induced ground vibration using ANFIS optimized by GA and PSO. Nat. Resour. Res. 2020, 29, 739–750. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Armaghani, D.J.; Zhang, W.; Li, C.; Zhu, S.; Tarinejad, R. Predicting TBM penetration rate in hard rock condition: A comparative study among six XGB-based metaheuristic techniques. Geosci. Front. 2021, 12, 101091. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Li, C.; Nguyen, H.; Yagiz, S. Optimization of support vector machine through the use of metaheuristic algorithms in forecasting TBM advance rate. Eng. Appl. Artif. Intell. 2021, 97, 104015. [Google Scholar] [CrossRef]

- Yu, Z.; Li, C.; Zhou, J. Tunnel Boring Machine Performance Prediction Using Supervised Learning Method and Swarm Intelligence Algorithm. Mathematics 2023, 11, 4237. [Google Scholar] [CrossRef]

- Zhou, J.; Yazdani Bejarbaneh, B.; Jahed Armaghani, D.; Tahir, M.M. Forecasting of TBM advance rate in hard rock condition based on artificial neural network and genetic programming techniques. Bull. Eng. Geol. Environ. 2020, 79, 2069–2084. [Google Scholar] [CrossRef]

- Zeng, J.; Roy, B.; Kumar, D.; Mohammed, A.S.; Armaghani, D.J.; Zhou, J.; Mohamad, E.T. Proposing several hybrid PSO-extreme learning machine techniques to predict TBM performance. Eng. Comput. 2022, 38, 3811–3827. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Yagiz, S.; Mohamad, E.T.; Zhou, J. Prediction of TBM performance in fresh through weathered granite using empirical and statistical approaches. Tunn. Undergr. Space Technol. 2021, 118, 104183. [Google Scholar] [CrossRef]

- Li, C.; Zhou, J.; Tao, M.; Du, K.; Wang, S.; Armaghani, D.J.; Mohamad, E.T. Developing hybrid ELM-ALO, ELM-LSO and ELM-SOA models for predicting advance rate of TBM. Transp. Geotech. 2022, 36, 100819. [Google Scholar] [CrossRef]

- Qiu, Y.; Huang, S.; Armaghani, D.J.; Pradhan, B.; Zhou, A.; Zhou, J. An optimized system of random forest model by global harmony search with generalized opposition-based learning for forecasting TBM advance rate. Comput. Model. Eng. Sci. 2023, 138, 2873–2897. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, P.; Yong, W.; Khandelwal, M.; Huang, S. A comparative analysis of hybrid RF models for efficient lithology prediction in hard rock tunneling using TBM working parameters. Acta Geophys. 2024, 72, 1847–1866. [Google Scholar] [CrossRef]

- Simoes, M.G.; Kim, T. Fuzzy modeling approaches for the prediction of machine utilization in hard rock tunnel boring machines. In Proceedings of the Conference Record of the 2006 IEEE Industry Applications Conference Forty-First IAS Annual Meeting, Tampa, FL, USA, 8–12 October 2006; Volume 2, pp. 947–954. [Google Scholar]

- Mahdevari, S.; Shahriar, K.; Yagiz, S.; Shirazi, M.A. A support vector regression model for predicting tunnel boring machine penetration rates. Int. J. Rock Mech. Min. Sci. 2014, 72, 214–229. [Google Scholar] [CrossRef]

- Benardos, A.G.; Kaliampakos, D.C. Modelling TBM performance with artificial neural networks. Tunn. Undergr. Space Technol. 2004, 19, 597–605. [Google Scholar] [CrossRef]

- Yagiz, S.; Karahan, H. Application of various optimization techniques and comparison of their performances for predicting TBM penetration rate in rock mass. Int. J. Rock Mech. Min. Sci. 2015, 80, 308–315. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Koopialipoor, M.; Marto, A.; Yagiz, S. Application of several optimization techniques for estimating TBM advance rate in granitic rocks. J. Rock Mech. Geotech. Eng. 2019, 11, 779–789. [Google Scholar] [CrossRef]

- Stephenson, N. Snow Crash. Penguin UK, 1994.

- De Freitas, S.; Neumann, T. The use of ‘exploratory learning’for supporting immersive learning in virtual environments. Comput. Educ. 2009, 52, 343–352. [Google Scholar] [CrossRef]

- Olbrish, K. Immersive Learning: Designing for Authentic Practice; American Society for Training & Development (ASTD): Alexandria, VA, USA, 2013. [Google Scholar]

- Macias, F.J.; Bruland, A. D&B versus TBM: Review of the parameters for a right choice of the excavation method. In Proceedings of the ISRM Regional Symposium—EUROCK 2014, Vigo, Spain, 27 May 2014. [Google Scholar]

- Yu, G.; Geng, X. Metaverse: The Ecological Landscape of the Mediated Society of the Future. J. Xinjiang Norm. Univ. (Ed. Philos. Soc. Sci.) 2022, 43, 110–118. [Google Scholar]

- Pesce, M. Mirror Worlds The metaverse could help us better understand reality. IEEE Spectr. 2021, 58, 25. [Google Scholar]

- Xu, C.; Fu, H.; Ma, L.; Jia, W.; Zhang, C.; Xia, F.; Ai, X.; Li, B.; Zhang, W. Seeing text in the dark: Algorithm and benchmark. arXiv 2024, arXiv:2404.08965. [Google Scholar]

- Zhang, Y.; Qi, H.; Li, C.; Zhou, J. Enhancing safety, sustainability, and economics in mining through innovative pillar design: A state-of-the-art review. J. Saf. Sustain. 2024, 1, 53–73. [Google Scholar] [CrossRef]

| No. | Fund Institutions | Region | Articles |

|---|---|---|---|

| 1 | National Natural Science Foundation of China | China | 155 |

| 2 | National Basic Research Program of China | China | 78 |

| 3 | Fundamental Research Funds for The Central Universities | China | 20 |

| 4 | National Key Research and Development Program of China | China | 18 |

| 5 | National High Technology Research and Development Program of China | China | 10 |

| 6 | China Postdoctoral Science Foundation | China | 8 |

| 7 | National Key Research and Development Program of China | China | 8 |

| 8 | China Scholarship Council | China | 7 |

| 9 | German Research Foundation | German | 7 |

| 10 | The Scientific and Technical Research Council of Turkey | Turkey | 7 |

| 11 | China Postdoctoral Science Foundation Program | China | 6 |

| 12 | Key Research and Development Program of Shandong Province | China | 5 |

| 13 | National Funded Program for Graduate Students Studying Abroad of China Scholarship Council | China | 5 |

| 14 | Malaysian University of Technology | Malaysia | 5 |

| 15 | Natural Science Foundation of Hunan Province | China | 4 |

| 16 | Natural Science Foundation of Liaoning Key Fund | China | 4 |

| 17 | European Commission | European | 3 |

| 18 | Hunan Provincial Innovation Foundation for Postgraduate | China | 3 |

| 19 | Innovation Driven Project of Central South University | China | 3 |

| 20 | Interdisciplinary Development Program of Shandong University | China | 3 |

| No. | Keyword | Frequency | Relevance | No. | Keyword | Frequency | Relevance |

|---|---|---|---|---|---|---|---|

| 1 | Prediction | 152 | 0.3335 | 11 | Accuracy | 71 | 0.442 |

| 2 | Test | 126 | 0.4792 | 12 | Estimation | 71 | 0.6167 |

| 3 | Efficiency | 110 | 0.4838 | 13 | Technique | 68 | 0.4818 |

| 4 | Disc cutter | 100 | 0.9397 | 14 | Simulation | 66 | 1.1793 |

| 5 | Force | 99 | 0.6139 | 15 | Database | 62 | 1.0776 |

| 6 | Cutter | 93 | 0.6988 | 16 | Interaction | 61 | 0.5368 |

| 7 | Index | 88 | 0.4663 | 17 | Coefficient | 59 | 0.7648 |

| 8 | Penetration rate | 88 | 0.6442 | 18 | Ground | 58 | 0.9006 |

| 9 | Algorithm | 83 | 0.5215 | 19 | Uniaxial compressive strength | 57 | 1.1401 |

| 10 | Prediction model | 74 | 0.3399 | 20 | Mechanism | 56 | 1.4459 |

| No. | First Author | Time | Title | Journal | Cited Frequency |

|---|---|---|---|---|---|

| 1 | Gertsch, R | 2007 | Disc cutting tests in Colorado red granite: Implications for TBM performance prediction | INTERNATIONAL JOURNAL OF ROCK MECHANICS AND MINING SCIENCES | 268 |

| 2 | Armaghani, Danial Jahed | 2017 | Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 218 |

| 3 | Gong, QM | 2006 | Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 218 |

| 4 | Gong, QM | 2005 | Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 216 |

| 5 | Gong, QM | 2009 | Development of a rock mass characteristics model for TBM penetration rate prediction | INTERNATIONAL JOURNAL OF ROCK MECHANICS AND MINING SCIENCES | 208 |

| 6 | Yagiz, Saffet | 2008 | Utilizing rock mass properties for predicting TBM performance in hard rock condition | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 200 |

| 7 | Yagiz, Saffet | 2009 | Application of two non-linear prediction tools to the estimation of tunnel boring machine performance | ENGINEERING APPLICATIONS OF ARTIFICIAL INTELLIGENCE | 182 |

| 8 | Hassanpour, J. | 2011 | A new hard rock TBM performance prediction model for project planning | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 181 |

| 9 | Zhao, J. | 2007 | Tunnelling through a frequently changing and mixed ground: A case history in Singapore | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 169 |

| 10 | Grima, MA | 2000 | Modeling tunnel boring machine performance by neuro-fuzzy methods | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 159 |

| No. | First Author | Time | Title | Journal | Cited Frequency |

|---|---|---|---|---|---|

| 1 | Armaghani, Danial Jahed;Mohamad, Edy Tonnizam | 2017 | Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition | TUNNELLING AND UNDERGROUND SPACE TECHNOLOGY | 218 |

| 2 | Armaghani, Danial Jahed | 2019 | Application of several optimization techniques for estimating TBM advance rate in granitic rocks | JOURNAL OF ROCK MECHANICS AND GEOTECHNICAL ENGINEERING | 107 |

| 3 | Xu, Hai;Zhou, Jian | 2019 | Supervised Machine Learning Techniques to the Prediction of Tunnel Boring Machine Penetration Rate | APPLIED SCIENCES-BASEL | 98 |

| 4 | Zhou, Jian; Qiu, Yingui; Zhu, Shuangli | 2021 | Optimization of support vector machine through the use of metaheuristic algorithms in forecasting TBM advance rate | ENGINEERING APPLICATIONS OF ARTIFICIAL INTELLIGENCE | 86 |

| 5 | Koopialipoor, Mohammadreza;Nikouei, Sayed Sepehr | 2019 | Predicting tunnel boring machine performance through a new model based on the group method of data handling | BULLETIN OF ENGINEERING GEOLOGY AND THE ENVIRONMENT | 84 |

| 6 | Koopialipoor, Mohammadreza | 2020 | Development of a new hybrid ANN for solving a geotechnical problem related to tunnel boring machine performance | ENGINEERING WITH COMPUTERS | 80 |

| 7 | Zhou, J | 2021 | Predicting TBM penetration rate in hard rock condition: A comparative study among six XGB-based metaheuristic techniques | GEOSCIENCE FRONTIERS | 71 |

| 8 | Liu, Bolong;Yang, Haiqing | 2020 | Effect of Water Content on Argillization of Mudstone During the Tunnelling process | ROCK MECHANICS AND ROCK ENGINEERING | 57 |

| 9 | Zhou, Jian; Qiu, Yingui; Zhu, Shuangli | 2021 | Estimation of the TBM advance rate under hard rock conditions using XGBoost and Bayesian optimization | UNDERGROUND SPACE | 51 |

| 10 | Elbaz, Khalid; Shen, Shuilong | 2020 | Prediction of Disc Cutter Life During Shield Tunneling with AI via the Incorporation of a Genetic Algorithm into a GMDH-Type Neural Network | ENGINEERING | 49 |

| Comparison | Drill and Blast Method | Tunnel Boring Machine |

|---|---|---|

| Advantages |

|

|

| Disadvantages |

|

|

| Parameters to Be Considered When Choosing an Excavation Method | |

|---|---|

| Project design factors | Costs budget |

| Ultimate purpose | Overbreak and tunnel profile quality |

| Excellent working environment | Surrounding rock conditions |

| Boring speed | Construction time and tunnel layout |

| Flexibility and acceptable risk | Project contract conditions |

| Geological situation | Protected buildings |

| Comparison | Drill and Blast Method | Tunnel Boring Machine |

|---|---|---|

| Theoretical |

|

|

| Empirical |

|

|

| Artificial intelligence |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhou, J.; Qiu, Y.; Armaghani, D.J.; Xie, Q.; Yang, P.; Xu, C. A Visual Survey of Tunnel Boring Machine (TBM) Performance in Tunneling Excavation: Mainstream Direction, Brief Review and Future Prospects. Appl. Sci. 2024, 14, 4512. https://doi.org/10.3390/app14114512

Zhang Y, Zhou J, Qiu Y, Armaghani DJ, Xie Q, Yang P, Xu C. A Visual Survey of Tunnel Boring Machine (TBM) Performance in Tunneling Excavation: Mainstream Direction, Brief Review and Future Prospects. Applied Sciences. 2024; 14(11):4512. https://doi.org/10.3390/app14114512

Chicago/Turabian StyleZhang, Yulin, Jian Zhou, Yingui Qiu, Danial Jahed Armaghani, Quanmin Xie, Peixi Yang, and Chengpei Xu. 2024. "A Visual Survey of Tunnel Boring Machine (TBM) Performance in Tunneling Excavation: Mainstream Direction, Brief Review and Future Prospects" Applied Sciences 14, no. 11: 4512. https://doi.org/10.3390/app14114512

APA StyleZhang, Y., Zhou, J., Qiu, Y., Armaghani, D. J., Xie, Q., Yang, P., & Xu, C. (2024). A Visual Survey of Tunnel Boring Machine (TBM) Performance in Tunneling Excavation: Mainstream Direction, Brief Review and Future Prospects. Applied Sciences, 14(11), 4512. https://doi.org/10.3390/app14114512