Advancements and Prospects of Electronic Nose in Various Applications: A Comprehensive Review

Abstract

1. Introduction

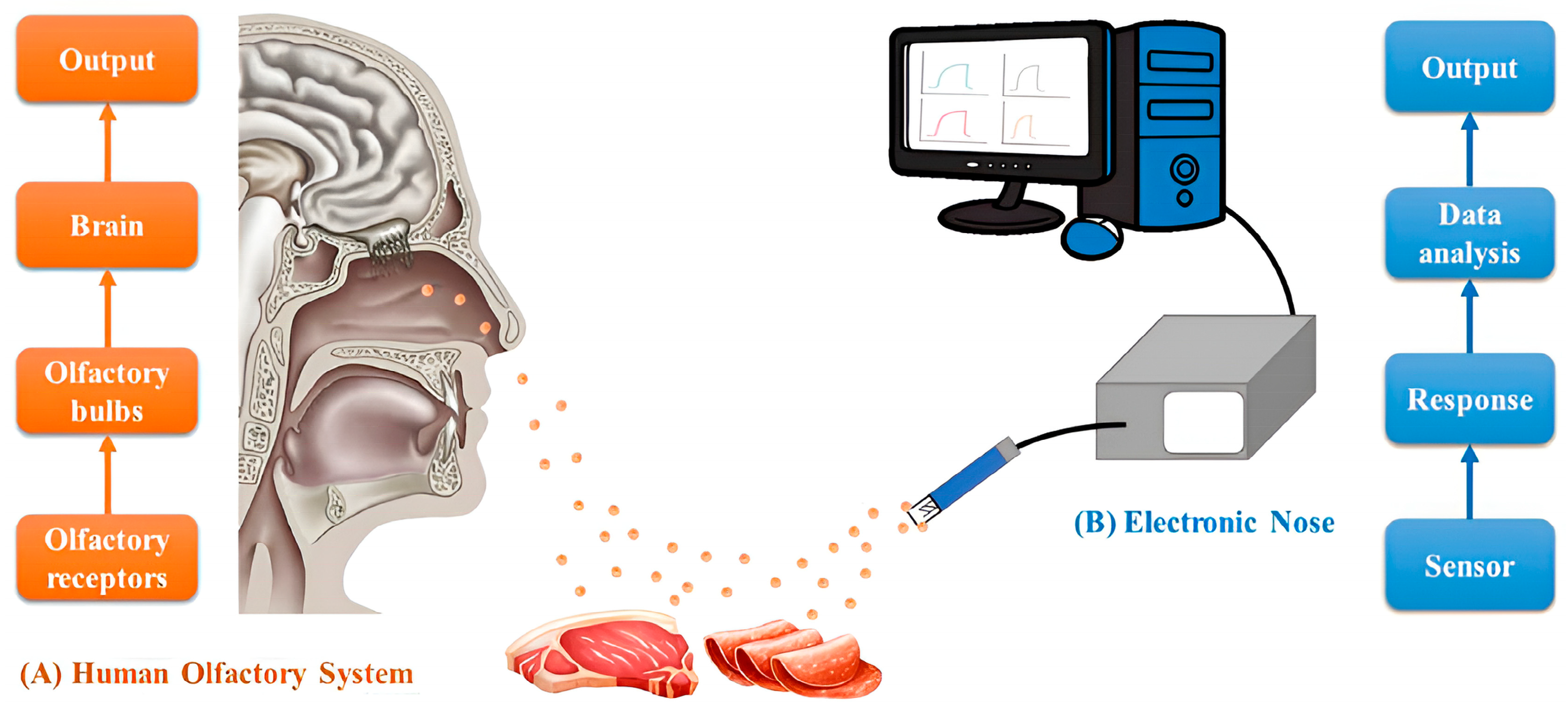

2. E-Nose System

2.1. Historical Evolution of Sensory Technologies

2.2. Principle of Odor Sensors

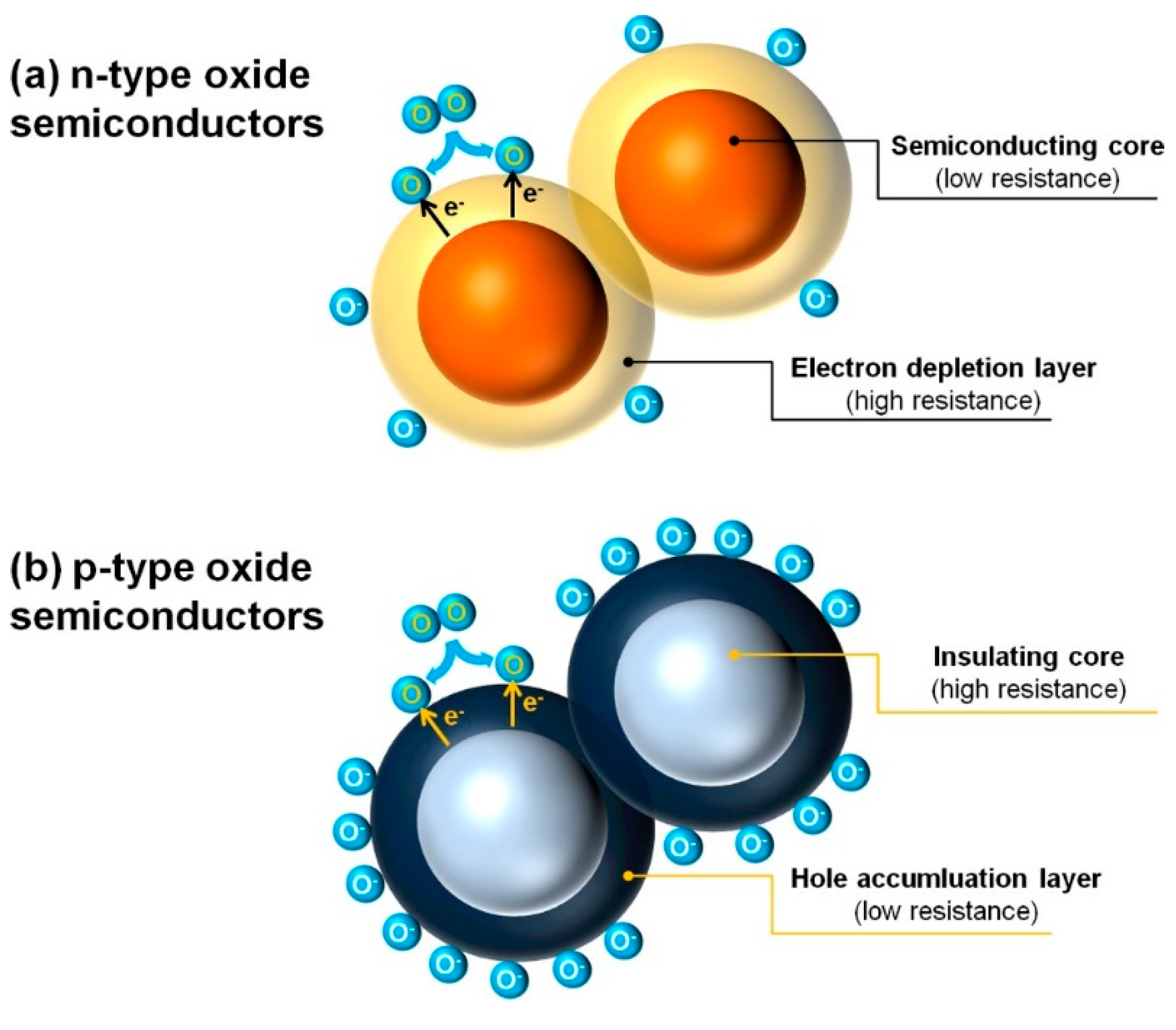

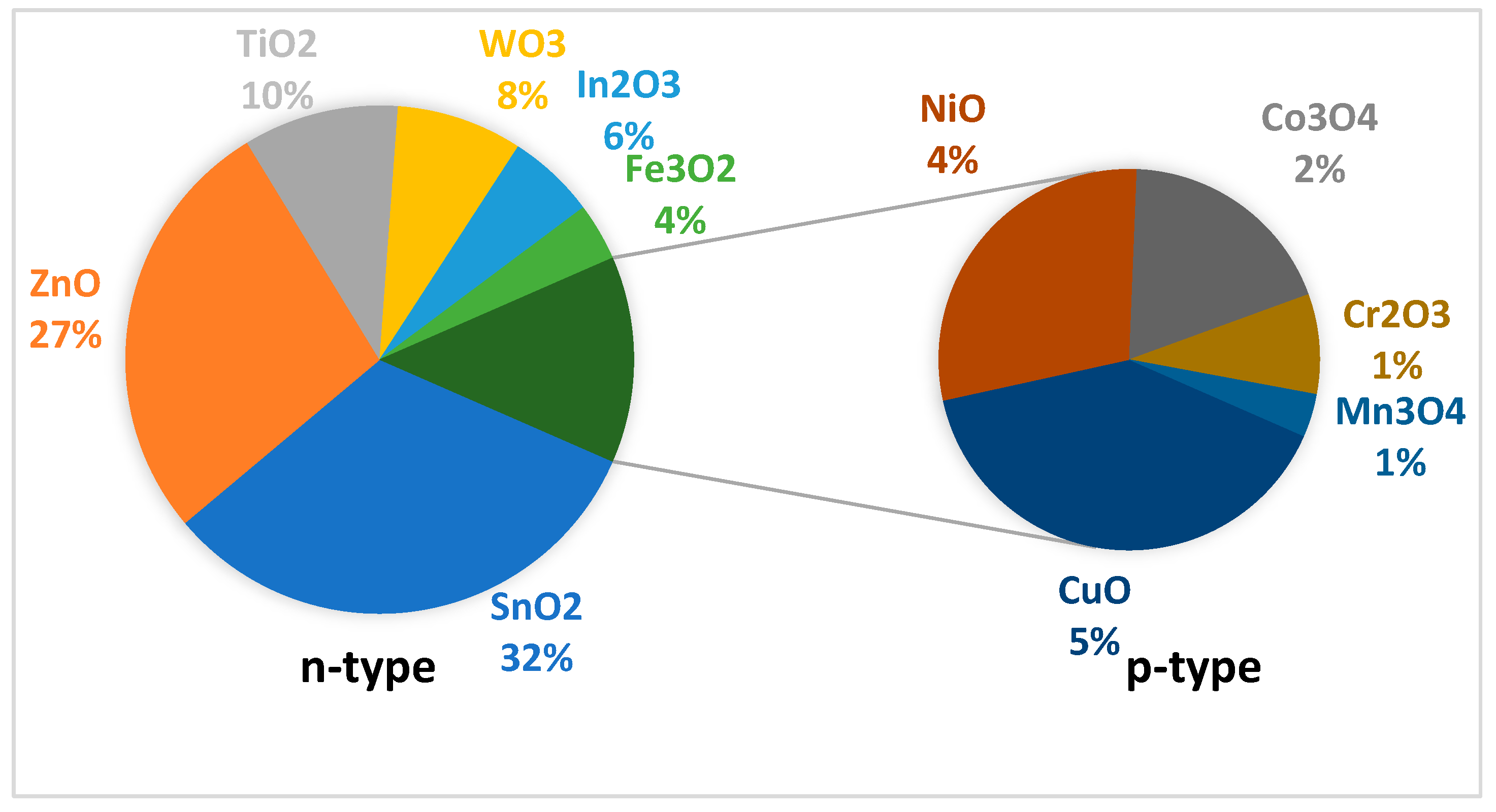

2.3. Gas Sensing Mechanism

2.4. The Electronic Nose’s Brain: Algorithms and Visualization

2.4.1. Principal Component Analysis

2.4.2. Linear Discriminant Analysis

2.4.3. Partial Least Squares Regression

2.4.4. Support Vector Machines

2.4.5. Artificial Neural Networks

3. Application Areas

3.1. Food Analysis

3.1.1. Quality Assurance

3.1.2. Applications in Different Food Sectors

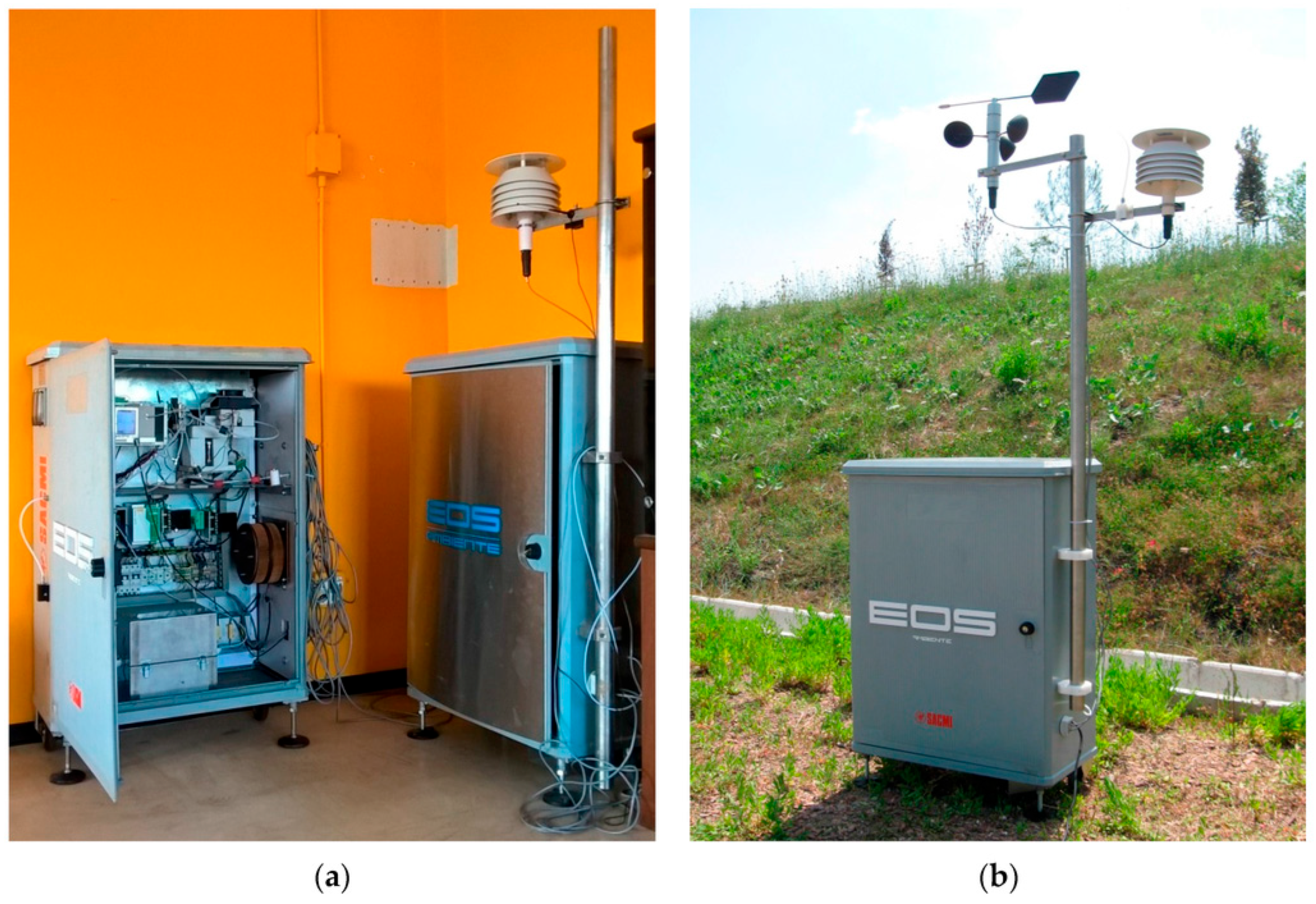

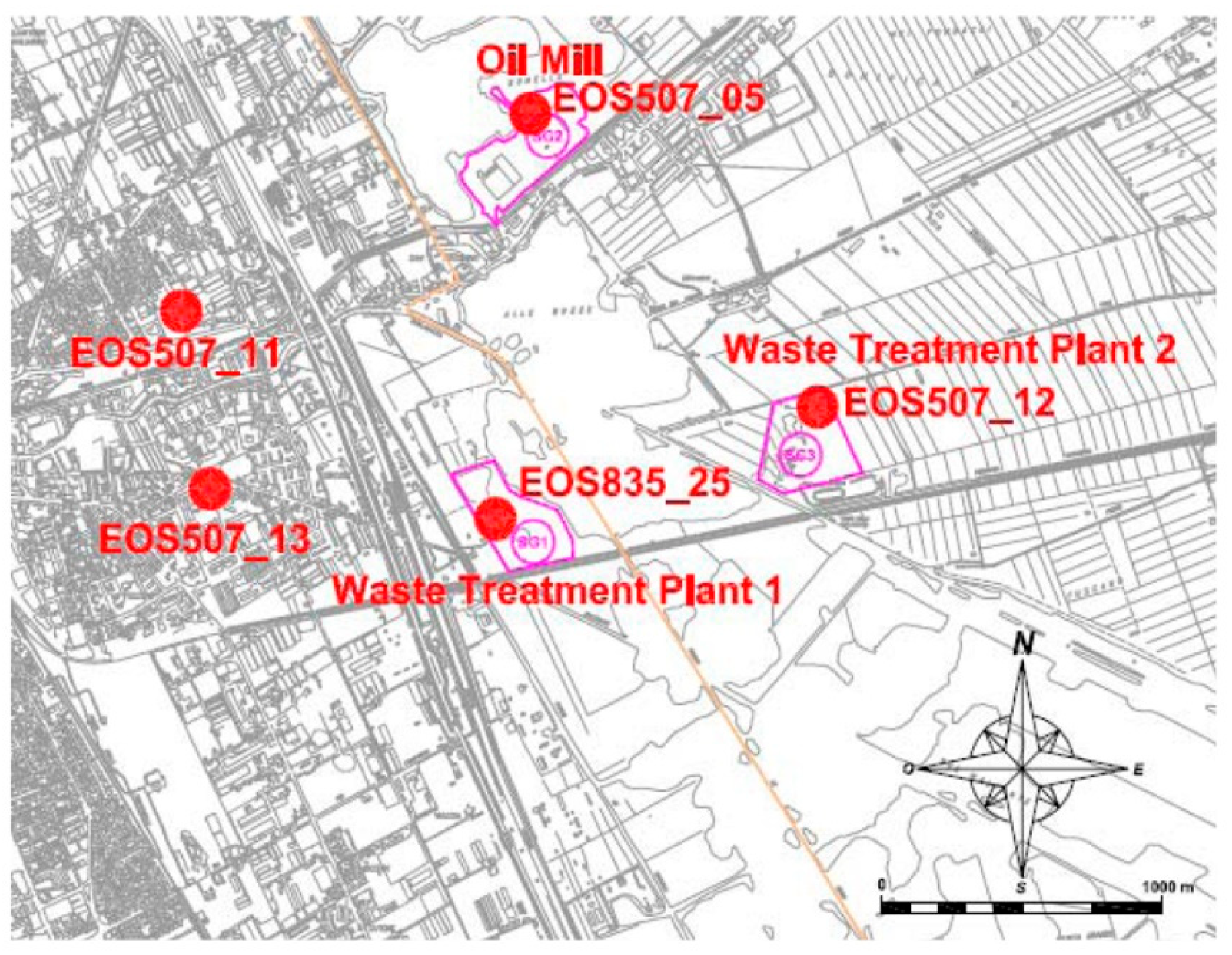

3.2. Environmental Monitoring

3.3. Disease Diagnosis

3.3.1. Human Clinical Pathology

3.3.2. Veterinary-Wildlife Pathology

3.3.3. Invasive Insect-Pest Infestations

4. Challenges

- Drift correction involves modeling sensor drift using a series of measurements and using it to correct new data.

- Calibration standardization aims to correct new measured data by establishing a relationship between two experimental conditions using a reduced set of samples measured under both conditions.

- Calibration update involves incorporating new sources of variance into the calibration model by recalculating it using initial calibration samples and a reduced set of samples measured under new conditions, which can be either standard or unknown samples.

- Sensor Cross-Sensitivity: one of the enduring challenges in the realm of electronic noses is the issue of cross-sensitivity among sensors. Each sensor in an e-nose array is designed to be sensitive to specific types of VOCs. However, many sensors may respond to multiple VOCs, leading to overlapping response patterns that can confuse the system’s ability to accurately identify and quantify specific odors. This cross-sensitivity necessitates the development of sophisticated algorithms capable of dissecting complex sensor outputs to distinguish between similar chemical signatures. Enhancing sensor selectivity or employing advanced computational techniques like machine learning for pattern recognition are potential approaches to mitigate this issue.

- System Power Consumption: e-noses, particularly those deployed in portable or remote settings, face significant constraints related to power consumption. The need for continuous operation without frequent battery replacements or recharges is essential for practical usability. This is especially challenging given that the sensor arrays and the associated data processing units typically require substantial power to operate effectively. Innovations in low-power electronics, energy-efficient sensors, and power management strategies are critical to extending the operational lifespan of e-nose systems in field applications.

- Time Acquisition: the time taken to acquire and process sensor data is another significant challenge, particularly in industrial applications where rapid decision-making is crucial. The acquisition time not only depends on the sensor’s response time to the target VOCs but also on the time required for the system to reset between samples. Reducing acquisition and processing times without compromising the accuracy and reliability of the e-nose system is a key area for technological improvement. Techniques such as optimizing sensor materials for quicker response and recovery times and enhancing data processing algorithms for speedier analysis are vital.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gardner, J.W.; Bartlett, P.N. A brief history of electronic noses. Sens. Actuators B Chem. 1994, 18, 210–211. [Google Scholar] [CrossRef]

- Cheng, L.; Meng, Q.-H.; Lilienthal, A.J.; Qi, P.-F. Development of compact electronic noses: A review. Meas. Sci. Technol. 2021, 32, 062002. [Google Scholar] [CrossRef]

- El Barbri, N.; Llobet, E.; El Bari, N.; Correig, X.; Bouchikhi, B. Application of a portable electronic nose system to assess the freshness of Moroccan sardines. Mater. Sci. Eng. C 2008, 28, 666–670. [Google Scholar] [CrossRef]

- Lee, J.W.; Shin, D.W.; Kim, S.M. Development of a Portable Electronic Nose System to Analyze Flavour Signal Patterns of Kochujang. Key Eng. Mater. 2006, 321–323, 1217–1220. [Google Scholar] [CrossRef]

- O’Connell, M.; Valdora, G.; Peltzer, G.; Martı, R. A practical approach for fish freshness determinations using a portable electronic nose. Sens. Actuators B Chem. 2001, 80, 149–154. [Google Scholar] [CrossRef]

- Hong, H.-K.; Kwon, C.H.; Kim, S.-R.; Yun, D.H.; Lee, K.; Sung, Y.K. Portable electronic nose system with gas sensor array and artificial neural network. Sens. Actuators B Chem. 2000, 66, 49–52. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Paknahad, M.; Ahmadi, A.; Rousseau, J.; Nejad, H.R.; Hoorfar, M. On-Chip Electronic Nose For Wine Tasting: A Digital Microfluidic Approach. IEEE Sens. J. 2017, 17, 4322–4329. [Google Scholar] [CrossRef]

- Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic Noses in Medical Diagnostics. Curr. Med. Chem. 2019, 26, 197–215. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, F.; Nie, H.; Dang, L.; Li, G.; Ye, Q.; Kadri, C. Classification of multiple indoor air contaminants by an electronic nose and a hybrid support vector machine. Sens. Actuators B Chem. 2012, 174, 114–125. [Google Scholar] [CrossRef]

- Craven, M.A.; Gardner, J.W.; Bartlett, P.N. Electronic noses—Development and future prospects. TrAC Trends Anal. Chem. 1996, 15, 486–493. [Google Scholar] [CrossRef]

- Schaller, E.; Bosset, J.O.; Escher, F. ‘Electronic Noses’ and Their Application to Food. LWT—Food Sci. Technol. 1998, 31, 305–316. [Google Scholar] [CrossRef]

- Strike, D.J.; Meijerink, M.G.H.; Koudelka-Hep, M. Electronic noses—A mini-review. Fresenius J. Anal. Chem. 1999, 364, 499–505. [Google Scholar] [CrossRef]

- Thaler, E.R.; Kennedy, D.W.; Hanson, C.W. Medical Applications of Electronic Nose Technology: Review of Current Status. Am. J. Rhinol. 2001, 15, 291–295. [Google Scholar] [CrossRef] [PubMed]

- García-González, D.L.; Aparicio López, R. Sensors: From Biosensors to the Electronic Nose. Grasa Aceites 2002, 53, 96–114. [Google Scholar] [CrossRef]

- Ampuero, S.; Bosset, J.O. The electronic nose applied to dairy products: A review. Sens. Actuators B Chem. 2003, 94, 1–12. [Google Scholar] [CrossRef]

- Turner, A.P.F.; Magan, N. Electronic noses and disease diagnostics. Nat. Rev. Microbiol. 2004, 2, 161–166. [Google Scholar] [CrossRef] [PubMed]

- James, D.; Scott, S.M.; Ali, Z.; O’Hare, W.T. Chemical Sensors for Electronic Nose Systems. Microchim. Acta 2005, 149, 1–17. [Google Scholar] [CrossRef]

- Casalinuovo, I.; Di Pierro, D.; Coletta, M.; Di Francesco, P. Application of Electronic Noses for Disease Diagnosis and Food Spoilage Detection. Sensors 2006, 6, 1428–1439. [Google Scholar] [CrossRef]

- Röck, F.; Barsan, N.; Weimar, U. Electronic Nose: Current Status and Future Trends. Chem. Rev. 2008, 108, 705–725. [Google Scholar] [CrossRef]

- Chen, P.-C.; Shen, G.; Zhou, C. Chemical Sensors and Electronic Noses Based on 1-D Metal Oxide Nanostructures. IEEE Trans. Nanotechnol. 2008, 7, 668–682. [Google Scholar] [CrossRef]

- Wilson, A.; Baietto, M. Applications and Advances in Electronic-Nose Technologies. Sensors 2009, 9, 5099–5148. [Google Scholar] [CrossRef] [PubMed]

- Berna, A. Metal Oxide Sensors for Electronic Noses and Their Application to Food Analysis. Sensors 2010, 10, 3882–3910. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D.; Baietto, M. Advances in Electronic-Nose Technologies Developed for Biomedical Applications. Sensors 2011, 11, 1105–1176. [Google Scholar] [CrossRef] [PubMed]

- Falasconi, M.; Concina, I.; Gobbi, E.; Sberveglieri, V.; Pulvirenti, A.; Sberveglieri, G. Electronic Nose for Microbiological Quality Control of Food Products. Int. J. Electrochem. 2012, 2012, 715763. [Google Scholar] [CrossRef]

- Wilson, A. Diverse Applications of Electronic-Nose Technologies in Agriculture and Forestry. Sensors 2013, 13, 2295–2348. [Google Scholar] [CrossRef] [PubMed]

- Montuschi, P.; Mores, N.; Trové, A.; Mondino, C.; Barnes, P.J. The Electronic Nose in Respiratory Medicine. Respiration 2013, 85, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Zohora, S.E.; Khan, A.M.; Hundewale, N. Chemical Sensors Employed in Electronic Noses: A Review. Adv. Comput. Inf. Technol. 2013, 178, 177–184. [Google Scholar] [CrossRef] [PubMed]

- Capelli, L.; Sironi, S.; Del Rosso, R. Electronic Noses for Environmental Monitoring Applications. Sensors 2014, 14, 19979–20007. [Google Scholar] [CrossRef]

- Yan, J.; Guo, X.; Duan, S.; Jia, P.; Wang, L.; Peng, C.; Zhang, S. Electronic Nose Feature Extraction Methods: A Review. Sensors 2015, 15, 27804–27831. [Google Scholar] [CrossRef]

- Capelli, L.; Taverna, G.; Bellini, A.; Eusebio, L.; Buffi, N.; Lazzeri, M.; Guazzoni, G.; Bozzini, G.; Seveso, M.; Mandressi, A.; et al. Application and Uses of Electronic Noses for Clinical Diagnosis on Urine Samples: A Review. Sensors 2016, 16, 1708. [Google Scholar] [CrossRef]

- Górska-Horczyczak, E.; Guzek, D.; Molęda, Z.; Wojtasik-Kalinowska, I.; Brodowska, M.; Wierzbicka, A. Applications of electronic noses in meat analysis. Food Sci. Technol. 2016, 36, 389–395. [Google Scholar] [CrossRef]

- Gliszczyńska-Świgło, A.; Chmielewski, J. Electronic Nose as a Tool for Monitoring the Authenticity of Food. A Review. Food Anal. Methods 2017, 10, 1800–1816. [Google Scholar] [CrossRef]

- Liang, Z.; Tian, F.; Yang, S.; Zhang, C.; Sun, H.; Liu, T. Study on Interference Suppression Algorithms for Electronic Noses: A Review. Sensors 2018, 18, 1179. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Wan, L.; Jian, Y.; Ren, C.; Jin, K.; Su, X.; Bai, X.; Haick, H.; Yao, M.; Wu, W. Electronic Noses: From Advanced Materials to Sensors Aided with Data Processing. Adv. Mater. Technol. 2019, 4, 1800488. [Google Scholar] [CrossRef]

- Baldini, C.; Billeci, L.; Sansone, F.; Conte, R.; Domenici, C.; Tonacci, A. Electronic Nose as a Novel Method for Diagnosing Cancer: A Systematic Review. Biosensors 2020, 10, 84. [Google Scholar] [CrossRef] [PubMed]

- Karakaya, D.; Ulucan, O.; Turkan, M. Electronic Nose and Its Applications: A Survey. Int. J. Autom. Comput. 2020, 17, 179–209. [Google Scholar] [CrossRef]

- Jońca, J.; Pawnuk, M.; Arsen, A.; Sówka, I. Electronic Noses and Their Applications for Sensory and Analytical Measurements in the Waste Management Plants—A Review. Sensors 2022, 22, 1510. [Google Scholar] [CrossRef] [PubMed]

- Khorramifar, A.; Karami, H.; Lvova, L.; Kolouri, A.; Łazuka, E.; Piłat-Rożek, M.; Łagód, G.; Ramos, J.; Lozano, J.; Kaveh, M.; et al. Environmental Engineering Applications of Electronic Nose Systems Based on MOX Gas Sensors. Sensors 2023, 23, 5716. [Google Scholar] [CrossRef]

- Alfieri, G.; Modesti, M.; Riggi, R.; Bellincontro, A. Recent Advances and Future Perspectives in the E-Nose Technologies Addressed to the Wine Industry. Sensors 2024, 24, 2293. [Google Scholar] [CrossRef]

- Abideen, Z.U.; Arifeen, W.U.; Bandara, Y.M.N.D.Y. Emerging trends in metal oxide-based electronic noses for healthcare applications: A review. Nanoscale 2024, 16, 9259–9283. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Chen, Y. Electronic nose and its application in the food industry: A review. Eur. Food Res. Technol. 2024, 250, 21–67. [Google Scholar] [CrossRef]

- Hartman, J.O.H.N. A possible objective method for the rapid estimation of flavors in vegetables. Proc. Am. Soc. Hort. Sci 1954, 64, 335. [Google Scholar]

- Moncrieff, R.W. An instrument for measuring and classifying odors. J. Appl. Physiol. 1961, 16, 742–749. [Google Scholar] [CrossRef] [PubMed]

- Moncrieff, R.W. The characterization of odours. J. Physiol. 1954, 125, 453–465. [Google Scholar] [CrossRef] [PubMed]

- Ikegami, A.; Kaneyasu, M. Olfactory detection using integrated sensors. In Proceedings of the 3rd International Conference on Solid-State Sensors and Actuators, Philadelphia, PA, USA, 1–14 June 1985; pp. 136–139. [Google Scholar]

- Dymerski, T.M.; Chmiel, T.M.; Wardencki, W. Invited Review Article: An odor-sensing system—Powerful technique for foodstuff studies. Rev. Sci. Instrum. 2011, 82, 111101. [Google Scholar] [CrossRef] [PubMed]

- Behera, B.; Joshi, R.; Vishnu, G.K.A.; Bhalerao, S.; Pandya, H.J. Electronic nose: A non-invasive technology for breath analysis of diabetes and lung cancer patients. J. Breath Res. 2019, 13, 024001. [Google Scholar] [CrossRef]

- Calvini, R.; Pigani, L. Toward the Development of Combined Artificial Sensing Systems for Food Quality Evaluation: A Review on the Application of Data Fusion of Electronic Noses, Electronic Tongues and Electronic Eyes. Sensors 2022, 22, 577. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Finardi, S.; de Souza, C.K.; Meinert, C.; Pateiro, M.; Hoffmann, T.G.; Domínguez, R.; Bertoli, S.L.; Kumar, M.; Lorenzo, J.M. Applications of Electronic Nose, Electronic Eye and Electronic Tongue in Quality, Safety and Shelf Life of Meat and Meat Products: A Review. Sensors 2023, 23, 672. [Google Scholar] [CrossRef]

- Leeson, P.T. Related Titles. In The Secrets of Pirate Management; Princeton University Press: Princeton, NJ, USA, 2012; p. 14. [Google Scholar] [CrossRef]

- Otto, M.; Thomas, J.D.R. Model studies on multiple channel analysis of free magnesium, calcium, sodium, and potassium at physiological concentration levels with ion-selective electrodes. Anal. Chem. 1985, 57, 2647–2651. [Google Scholar] [CrossRef]

- Winquist, F.; Hornsten, E.G.; Sundgren, H.; Lundstrom, I. Performance of an electronic nose for quality estimation of ground meat. Meas. Sci. Technol. 1993, 4, 1493–1500. [Google Scholar] [CrossRef]

- Wijaya, D.R.; Sarno, R.; Zulaika, E.; Sabila, S.I. Development of mobile electronic nose for beef quality monitoring. Procedia Comput. Sci. 2017, 124, 728–735. [Google Scholar] [CrossRef]

- Pham, T.; Li, G.; Bekyarova, E.; Itkis, M.E.; Mulchandani, A. MoS 2 -Based Optoelectronic Gas Sensor with Sub-parts-per-billion Limit of NO2 Gas Detection. ACS Nano 2019, 13, 3196–3205. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Cho, I.; Kang, M.; Jeong, J.; Choi, M.; Woo, K.Y.; Yoon, K.J.; Cho, Y.H.; Park, I. Ultra-Low-Power E-Nose System Based on Multi-Micro-LED-Integrated, Nanostructured Gas Sensors and Deep Learning. ACS Nano 2023, 17, 539–551. [Google Scholar] [CrossRef] [PubMed]

- Barsan, N.; Weimar, U. Conduction Model of Metal Oxide Gas Sensors. J. Electroceramics 2001, 7, 143–167. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.K.; Swaminathan, S.; Abdala, A. Recent advances in graphene based gas sensors. Sens. Actuators B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, J.H. Highly sensitive and selective gas sensors using p-type oxide semiconductors: Overview. Sens. Actuators B Chem. 2014, 192, 607–627. [Google Scholar] [CrossRef]

- Kumar, M.; Bhati, V.S.; Ranwa, S.; Singh, J.; Kumar, M. Pd/ZnO nanorods based sensor for highly selective detection of extremely low concentration hydrogen. Sci. Rep. 2017, 7, 236. [Google Scholar] [CrossRef]

- Bhati, V.S.; Kumar, M.; Banerjee, R. Gas sensing performance of 2D nanomaterials/metal oxide nanocomposites: A review. J. Mater. Chem. C 2021, 9, 8776–8808. [Google Scholar] [CrossRef]

- Jing, Z.; Zhan, J. Fabrication and gas-sensing properties of porous ZnO nanoplates. Adv. Mater. 2008, 20, 4547–4551. [Google Scholar] [CrossRef]

- Wan, Q.; Li, Q.H.; Chen, Y.J.; Wang, T.H.; He, X.L.; Li, J.P.; Lin, C.L. Fabrication and ethanol sensing characteristics of ZnO nanowire gas sensors. Appl. Phys. Lett. 2004, 84, 3654–3656. [Google Scholar] [CrossRef]

- Yakovlev, N.N.; Almaev, A.V.; Nikolaev, V.I.; Kushnarev, B.O.; Pechnikov, A.I.; Stepanov, S.I.; Chikiryaka, A.V.; Timashov, R.B.; Scheglov, M.P.; Butenko, P.N.; et al. Low-resistivity gas sensors based on the In2O3-Ga2O3 mixed compounds films. Mater. Today Commun. 2023, 34, 105241. [Google Scholar] [CrossRef]

- Xie, D.; Zhang, F.; Yu, K.; Li, X.; Qu, F. A bimetallic MOF-derived α-Fe2O3/In2O3 heterojunction for a cyclohexane gas sensor. New J. Chem. 2023, 17, 7995–8001. [Google Scholar] [CrossRef]

- Kim, H.J.; Choi, K., II; Pan, A.; Kim, I.D.; Kim, H.R.; Kim, K.M.; Na, C.W.; Cao, G.; Lee, J.H. Template-free solvothermal synthesis of hollow hematite spheres and their applications in gas sensors and Li-ion batteries. J. Mater. Chem. 2011, 21, 6549–6555. [Google Scholar] [CrossRef]

- Gupta, A.; Dargar, S.K.; Dargar, A. TiO2 Thick film Gas sensor for Detection H2S Gas Using ANN and Machine Learning Technique. In Proceedings of the ICCECE 2023—International Conference on Computer, Electrical and Communication Engineering, Kolkata, India, 20–21 January 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Moon, J.; Haeng, J.I.; Gyeong, Y.; Choi, M. Selective Gas Detection of SnO2-TiO2 Gas Sensors; Kluwer Academic Publishers: Alphen aan den Rijn, The Netherlands, 2004. [Google Scholar]

- Moon, H.G.; Shim, Y.S.; Kim, D.H.; Jeong, H.Y.; Jeong, M.; Jung, J.Y.; Han, S.M.; Kim, J.K.; Kim, J.S.; Park, H.H.; et al. Self-activated ultrahigh chemosensitivity of oxide thin film nanostructures for transparent sensors. Sci. Rep. 2012, 2, 588. [Google Scholar] [CrossRef] [PubMed]

- Deme Megersa, D.; Cho, H.H.; Kim, Y.; Teshome Gudena, G.; Lee, J.; Seong Bae, J.; Chae, S.; Yu, H.K. (n.d.). Supporting information Position-Selective Growth of WO3 Nanosheet for NH3 Gas Sensors. Cryst. Growth Des. 2023, 23, 3447–3454. [Google Scholar] [CrossRef]

- Yin, X.T.; Dastan, D.; Gity, F.; Li, J.; Shi, Z.; Alharbi, N.D.; Liu, Y.; Tan, X.M.; Gao, X.C.; Ma, X.G.; et al. Gas sensing selectivity of SnO2-xNiO sensors for homogeneous gases and its selectivity mechanism: Experimental and theoretical studies. Sens. Actuators A Phys. 2023, 354, 114273. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, J.; Wang, Y.; Hu, Y.; Xu, L.; Yao, L.; Zheng, C.; Yang, J.; Gao, X. Enhanced toluene gas-sensing properties of MEMS sensor based on Pt-loaded SnO2 nanoparticles. Nanotechnology 2023, 34, 365502. [Google Scholar] [CrossRef]

- Qin, L.; Gao, H.; Meng, F. Perovskite-Structured NiTiO3 Modified NiO Gas Sensor for Xylene Detection. Chemosensors 2023, 11, 264. [Google Scholar] [CrossRef]

- Guo, W.Q.; Niu, J.Y.; Hong, B.; Xu, J.C.; Han, Y.B.; Peng, X.L.; Ge, H.L.; Li, J.; Zeng, Y.X.; Wang, X.Q. Mesoporous Co3O4/In2O3 nanocomposites for formaldehyde gas sensors: Synthesis from ZIF-67 and gas-sensing behavior. Mater Res Bull 2023, 164, 112264. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Z.; Han, Y.; Xie, L.; Zhao, X.; Shahrokhian, S.; Barsan, N.; Zhu, Z. Conductometric Cr2O3/TiO2/Ti3C2Tx Gas Sensor for Detecting Triethylamine at Room Temperature. Sens Actuators B Chem 2023, 381, 133412. [Google Scholar] [CrossRef]

- Doubi, Y.; Hartiti, B.; Siadat, M.; Labrim, H.; Fadili, S.; Tahri, M.; Stitou, M.; Thevenin, P.; Losson, E. Experimental Investigation of Pure Spinel Mn3O4 Properties Synthesized through Chemical Spray Pyrolysis for Future Gas Sensor Application. Eur. J. Inorg. Chem. 2023, 26, e202300047. [Google Scholar] [CrossRef]

- Tsymbalenko, O.; Lee, S.; Lee, Y.M.; Nam, Y.S.; Kim, B.C.; Kim, J.Y.; Lee, K.B. High-sensitivity NH3 gas sensor using pristine graphene doped with CuO nanoparticles. Microchim. Acta 2023, 190, 134. [Google Scholar] [CrossRef] [PubMed]

- Borràs, E.; Ferré, J.; Boqué, R.; Mestres, M.; Aceña, L.; Busto, O. Data fusion methodologies for food and beverage authentication and quality assessment—A review. Anal. Chim. Acta 2015, 891, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Zakaria, A.; Shakaff, A.Y.; Masnan, M.J.; Saad, F.S.; Adom, A.H.; Ahmad, M.N.; Jaafar, M.N.; Abdullah, A.H.; Kamarudin , L.M. Improved Maturity and Ripeness Classifications of Magnifera Indica cv. Harumanis Mangoes through Sensor Fusion of an Electronic Nose and Acoustic Sensor. Sensors 2012, 12, 6023–6048. [Google Scholar] [CrossRef] [PubMed]

- Abdi, H. Partial least squares regression and projection on latent structure regression (PLS Regression). WIREs Comput. Stat. 2010, 2, 97–106. [Google Scholar] [CrossRef]

- Śliwińska, M.; Wiśniewska, P.; Dymerski, T.; Namieśnik, J.; Wardencki, W. Food Analysis Using Artificial Senses. J. Agric. Food Chem. 2014, 62, 1423–1448. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Wan, H.; Zhang, X.; Ha, D.; Wang, P. Electronic Nose and Electronic Tongue. In Bioinspired Smell and Taste Sensors; Springer: Dordrecht, The Netherlands, 2015; pp. 19–44. [Google Scholar] [CrossRef]

- El-Amarty, N.; Marzouq, M.; El Fadili, H.; Bennani, S.D.; Ruano, A.; Rabehi, A. A new evolutionary forest model via incremental tree selection for short-term global solar irradiance forecasting under six various climatic zones. Energy Convers. Manag. 2024, 310, 118471. [Google Scholar] [CrossRef]

- Guermoui, M.; Fezzani, A.; Mohamed, Z.; Rabehi, A.; Ferkous, K.; Bailek, N.; Bouallit, S.; Riche, A.; Bajaj, M.; Dost Mohammadi, S.A.; et al. An analysis of case studies for advancing photovoltaic power forecasting through multi-scale fusion techniques. Sci. Rep. 2024, 14, 6653. [Google Scholar] [CrossRef]

- Khelifi, R.; Guermoui, M.; Rabehi, A.; Taallah, A.; Zoukel, A.; Ghoneim, S.S.M.; Bajaj, M.; AboRas, K.M.; Zaitsev, I. Short-Term PV Power Forecasting Using a Hybrid TVF-EMD-ELM Strategy. Int. Trans. Electr. Energy Syst. 2023, 2023, 6413716. [Google Scholar] [CrossRef]

- Hamdani, M.; Youcefi, M.; Rabehi, A.; Nail, B.; Douara, A. Design and Implementation of a Medical TeleMonitoring System based on IoT. Eng. Technol. Appl. Sci. Res. 2022, 12, 8949–8953. [Google Scholar] [CrossRef]

- Guermoui, M.; Boland, J.; Rabehi, A. On the use of BRL model for daily and hourly solar radiation components assessment in a semiarid climate. Eur. Phys. J. Plus 2020, 135, 214. [Google Scholar] [CrossRef]

- Guermoui, M.; Abdelaziz, R.; Gairaa, K.; Djemoui, L.; Benkaciali, S. New temperature-based predicting model for global solar radiation using support vector regression. Int. J. Ambient Energy 2022, 43, 1397–1407. [Google Scholar] [CrossRef]

- Khelifi, R.; Guermoui, M.; Rabehi, A.; Lalmi, D. Multi-step-ahead forecasting of daily solar radiation components in the Saharan climate. Int. J. Ambient Energy 2020, 41, 707–715. [Google Scholar] [CrossRef]

- Rabehi, A.; Rabehi, A.; Guermoui, M. Evaluation of Different Models for Global Solar Radiation Components Assessment. Appl. Sol. Energy 2021, 57, 81–92. [Google Scholar] [CrossRef]

- Guermoui, M.; Gairaa, K.; Rabehi, A.; Djafer, D.; Benkaciali, S. Estimation of the daily global solar radiation based on the Gaussian process regression methodology in the Saharan climate. Eur. Phys. J. Plus 2018, 133, 211. [Google Scholar] [CrossRef]

- Guermoui, M.; Rabehi, A.; Gairaa, K.; Benkaciali, S. Support vector regression methodology for estimating global solar radiation in Algeria. Eur. Phys. J. Plus 2018, 133, 22. [Google Scholar] [CrossRef]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biol. 1990, 52, 99–115. [Google Scholar] [CrossRef] [PubMed]

- Rabehi, A.; Guermoui, M.; Lalmi, D. Hybrid models for global solar radiation prediction: A case study. Int. J. Ambient Energy 2020, 41, 31–40. [Google Scholar] [CrossRef]

- Rabehi, A.; Guermoui, M.; Khelifi, R.; Mekhalfi, M.L. Decomposing global solar radiation into its diffuse and direct normal radiation. Int. J. Ambient Energy 2020, 41, 738–743. [Google Scholar] [CrossRef]

- Guermoui, M.; Rabehi, A. Soft computing for solar radiation potential assessment in Algeria. Int. J. Ambient Energy 2020, 41, 1524–1533. [Google Scholar] [CrossRef]

- Cynkar, W.; Dambergs, R.; Smith, P.; Cozzolino, D. Classification of Tempranillo wines according to geographic origin: Combination of mass spectrometry based electronic nose and chemometrics. Anal. Chim. Acta 2010, 660, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Wang, J.; Zhang, H.; Yu, Y.; Yao, C. Identification of green tea grade using different feature of response signal from E-nose sensors. Sens. Actuators B Chem. 2008, 128, 455–461. [Google Scholar] [CrossRef]

- Cosio, M.S.; Ballabio, D.; Benedetti, S.; Gigliotti, C. Geographical origin and authentication of extra virgin olive oils by an electronic nose in combination with artificial neural networks. Anal. Chim. Acta 2006, 567, 202–210. [Google Scholar] [CrossRef]

- Romani, S.; Cevoli, C.; Fabbri, A.; Alessandrini, L.; Rosa, M.D. Evaluation of Coffee Roasting Degree by Using Electronic Nose and Artificial Neural Network for Off-line Quality Control. J. Food Sci. 2012, 77, C960–C965. [Google Scholar] [CrossRef] [PubMed]

- Panigrahi, S.; Balasubramanian, S.; Gu, H.; Logue, C.; Marchello, M. Neural-network-integrated electronic nose system for identification of spoiled beef. LWT 2006, 39, 135–145. [Google Scholar] [CrossRef]

- Gram, L.; Dalgaard, P. Fish spoilage bacteria—Problems and solutions. In Current Opinion in Biotechnology; Elsevier Ltd.: Amsterdam, The Netherlands, 2002; Volume 13, pp. 262–266. [Google Scholar] [CrossRef]

- Timsorn, K.; Thoopboochagorn, T.; Lertwattanasakul, N.; Wongchoosuk, C. Evaluation of bacterial population on chicken meats using a briefcase electronic nose. Biosyst. Eng. 2016, 151, 116–125. [Google Scholar] [CrossRef]

- Capone, S.; Epifani, M.; Quaranta, F.; Siciliano, P.; Taurino, A.; Vasanelli, L. Monitoring of rancidity of milk by means of an electronic nose and a dynamic PCA analysis. Sens. Actuators B Chem. 2001, 78, 174–179. [Google Scholar] [CrossRef]

- Rieu, M.; Camara, M.; Tournier, G.; Viricelle, J.P.; Pijolat, C.; De Rooij, N.F.; Briand, D. Inkjet printed SnO2 gas sensor on plastic substrate. Procedia Eng. 2015, 120, 75–78. [Google Scholar] [CrossRef]

- Ozmen, A.; Dogan, E. Design of a Portable E-Nose Instrument for Gas Classifications. IEEE Trans. Instrum. Meas. 2009, 58, 3609–3618. [Google Scholar] [CrossRef]

- Romain, A.C.; Godefroid, D.; Kuske, M.; Nicolas, J. Monitoring the exhaust air of a compost pile as a process variable with an e-nose. Sens. Actuators B Chem. 2005, 106, 29–35. [Google Scholar] [CrossRef]

- Heriyadi, B.; Zakri, R.S. Evaluation and Analysis of Needs for Air Ventilation Systems in Underground Coal Mine (Case Study in Underground Coal Mine, Sawahlunto City). J. Phys. Conf. Ser. 2021, 1940, 012077. [Google Scholar] [CrossRef]

- Sekhar, K.C.; Rao, S.S.C.C. John Scott Haldane: The father of oxygen therapy. Indian J. Anaesth. 2014, 58, 350–352. [Google Scholar] [CrossRef] [PubMed]

- Staerz, A.; Roeck, F.; Weimar, U.; Barsan, N. Electronic Nose. In Surface and Interface Science; Wiley: Hoboken, NJ, USA, 2020; pp. 335–379. [Google Scholar] [CrossRef]

- Barandun, G.; Gonzalez-Macia, L.; Lee, H.S.; Dincer, C.; Güder, F. Challenges and Opportunities for Printed Electrical Gas Sensors. ACS Sens. 2022, 7, 2804–2822. [Google Scholar] [CrossRef] [PubMed]

- Castelli, M.; Clemente, F.M.; Popovič, A.; Silva, S.; Vanneschi, L. A Machine Learning Approach to Predict Air Quality in California. Complexity 2020, 2020, 8049504. [Google Scholar] [CrossRef]

- Abbas, M.N.; Moustafa, G.A.; Gopel, W. Multicomponent analysis of some environmentally important gases using semiconductor tin oxide sensors. Anal. Chim. Acta 2001, 431, 181–194. [Google Scholar] [CrossRef]

- Helli, O.; Siadat, M.; Lumbreras, M. Qualitative and quantitative identification of H2S/NO2 gaseous components in different reference atmospheres using a metal oxide sensor array. Sens. Actuators B Chem. 2004, 103, 403–408. [Google Scholar] [CrossRef]

- Negri, R.M.; Reich, S. Identification of pollutant gases and its concentrations with a multisensor array. Sens. Actuators B Chem. 2001, 75, 172–178. [Google Scholar] [CrossRef]

- Wolfrum, E.J.; Meglen, R.M.; Peterson, D.; Sluiter, J. Metal oxide sensor arrays for the detection, differentiation, and quantification of volatile organic compounds at sub-parts-per-million concentration levels. Sens. Actuators B Chem. 2006, 115, 322–329. [Google Scholar] [CrossRef]

- Lee, D.-S.; Jung, J.-K.; Lim, J.-W.; Huh, J.-S.; Lee, D.-D. Recognition of volatile organic compounds using SnO2 sensor array and pattern recognition analysis. Sens. Actuators B Chem. 2001, 77, 228–236. [Google Scholar] [CrossRef]

- Cho, J.; Kim, Y.; Na, K.; Jeon, G. Wireless electronic nose system for real-time quantitative analysis of gas mixtures using micro-gas sensor array and neuro-fuzzy network. Sens. Actuators B Chem. 2008, 134, 104–111. [Google Scholar] [CrossRef]

- Lilienthal, A.; Loutfi, A.; Duckett, T. Airborne Chemical Sensing with Mobile Robots. Sensors 2006, 6, 1616–1678. [Google Scholar] [CrossRef]

- Conti, P.P.; Andre, R.S.; Mercante, L.A.; Fugikawa-Santos, L.; Correa, D.S. Discriminative detection of volatile organic compounds using an electronic nose based on TiO2 hybrid nanostructures. Sens. Actuators B Chem. 2021, 344, 130124. [Google Scholar] [CrossRef]

- Shooshtari, M.; Salehi, A. An electronic nose based on carbon nanotube -titanium dioxide hybrid nanostructures for detection and discrimination of volatile organic compounds. Sens. Actuators B Chem. 2022, 357, 131418. [Google Scholar] [CrossRef]

- Licen, S.; Di Gilio, A.; Palmisani, J.; Petraccone, S.; de Gennaro, G. Barbieri Pattern recognition and anomaly detection by self-organizing maps in a multi month e-nose survey at an industrial site. Sensors 2020, 20, 1887. [Google Scholar] [CrossRef] [PubMed]

- Pace, C.; Khalaf, W.; Latino, M.; Donato, N.; Neri, G. E-nose development for safety monitoring applications in refinery environment. Procedia Eng. 2012, 46, 1267–1270. [Google Scholar] [CrossRef]

- Giungato, P.; de Gennaro, G.; Barbieri, P.; Briguglio, S.; Amodio, M.; de Gennaro, L.; Lasigna, F. Improving recognition of odors in a waste management plant by using electronic noses with different technologies, gas chromatography–mass spectrometry/olfactometry and dynamic olfactometry. J. Clean. Prod. 2016, 133, 1395–1402. [Google Scholar] [CrossRef]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Céntola, P.; Grande, M.I. A comparative and critical evaluation of odour assessment methods on a landfill site. Atmos. Environ. 2008, 42, 7050–7058. [Google Scholar] [CrossRef]

- Gostelow, M.P.; Parsons, S.A.; Stuetz, R.M. Odour measurements for sewage treatment works. Water Res. 2001, 35, 579–597. [Google Scholar] [CrossRef]

- Bax, C.; Sironi, S.; Capelli, L. Definition and application of a protocol for electronic nose field performance testing: Example of odor monitoring from a tire storage area. Atmosphere 2020, 11, 426. [Google Scholar] [CrossRef]

- Eusebio, L.; Capelli, L.; Sironi, S. Electronic nose testing procedure for the definition of minimum performance requirements for environmental odor monitoring. Sensors 2016, 16, 1548. [Google Scholar] [CrossRef] [PubMed]

- Milan, B.; Bootsma, S.; Bilsen, I. Advances in Odour Monitoring with E-Noses in the Port of Rotterdam. 2012. Available online: www.aidic.it/cet (accessed on 9 January 2023).

- Dentoni, L.; Capelli, L.; Sironi, S.; Rosso, R.; Zanetti, S.; Torre, M. Development of an Electronic Nose for Environmental Odour Monitoring. Sensors 2012, 12, 14363–14381. [Google Scholar] [CrossRef]

- Micone, P.G.; Guy, C. Odour quantification by a sensor array: An application to landfill gas odours from two different municipal waste treatment works. Sens. Actuators B Chem. 2007, 120, 628–637. [Google Scholar] [CrossRef]

- Sironi, S.; Capelli, L.; Céntola, P.; Del Rosso, R. Development of a system for the continuous monitoring of odours from a composting plant: Focus on training, data processing and results validation methods. Sens. Actuators B Chem. 2007, 124, 336–346. [Google Scholar] [CrossRef]

- Haas, T.; Lammers, P.; Diekmann, B.; Horner, G.; Boeker, P. A method for online measurement of odour with a chemosensor system. Sens. Actuators B Chem. 2008, 132, 545–550. [Google Scholar] [CrossRef]

- Dewettinck, T.; Van Hege, K.; Verstraete, W. The electronic nose as a rapid sensor for volatile compounds in treated domestic wastewater. Water Res. 2001, 35, 2475–2483. [Google Scholar] [CrossRef] [PubMed]

- Nicolas, J.; Romain, A.-C.; Ledent, C. The electronic nose as a warning device of the odour emergence in a compost hall. Sens. Actuators B Chem. 2006, 116, 95–99. [Google Scholar] [CrossRef]

- Pan, L.; Yang, S.X. A new intelligent electronic nose system for measuring and analysing livestock and poultry farm odours. Environ. Monit. Assess. 2007, 135, 399–408. [Google Scholar] [CrossRef]

- Boholt, K.; Andreasen, K.; den Berg, F.; Hansen, T. A new method for measuring emission of odour from a rendering plant using the Danish Odour Sensor System (DOSS) artificial nose. Sens. Actuators B Chem. 2005, 106, 170–176. [Google Scholar] [CrossRef]

- Bitter, F.; Müller, B.; Müller, D. Estimation of odour intensity of indoor air pollutants from building materials with a multi-gas sensor system. Build. Environ. 2010, 45, 197–204. [Google Scholar] [CrossRef]

- Sohn, J.H.; Pioggia, G.; Craig, I.P.; Stuetz, R.M.; Atzeni, M.G. Identifying major contributing sources to odour annoyance using a non-specific gas sensor array. Biosyst. Eng. 2009, 102, 305–312. [Google Scholar] [CrossRef]

- Thorn, R.M.S.; Greenman, J. Microbial volatile compounds in health and disease conditions. J. Breath Res. 2012, 6, 024001. [Google Scholar] [CrossRef] [PubMed]

- Belizário, J.E.; Faintuch, J.; Malpartida, M.G. Breath Biopsy and Discovery of Exclusive Volatile Organic Compounds for Diagnosis of Infectious Diseases. Front. Cell Infect. Microbiol. 2021, 10, 564194. [Google Scholar] [CrossRef] [PubMed]

- Trefz, P.; Obermeier, J.; Lehbrink, R.; Schubert, J.K.; Miekisch, W.; Fischer, D.-C. Exhaled volatile substances in children suffering from type 1 diabetes mellitus: Results from a cross-sectional study. Sci. Rep. 2019, 9, 15707. [Google Scholar] [CrossRef] [PubMed]

- Brownlee, M. Biochemistry and molecular cell biology of diabetic complications. Nature 2001, 414, 813–820. [Google Scholar] [CrossRef] [PubMed]

- Zaccardi, F.; Pitocco, D.; Ghirlanda, G. Glycemic risk factors of diabetic vascular complications: The role of glycemic variability. Diabetes Metab. Res. Rev. 2009, 25, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Smith-Palmer, J.; Brändle, M.; Trevisan, R.; Federici, M.O.; Liabat, S.; Valentine, W. Assessment of the association between glycemic variability and diabetes-related complications in type 1 and type 2 diabetes. Diabetes Res. Clin. Pr. 2014, 105, 273–284. [Google Scholar] [CrossRef]

- Epstein, F.H.; Atkinson, M.A.; Maclaren, N.K. The Pathogenesis of Insulin-Dependent Diabetes Mellitus. N. Engl. J. Med. 1994, 331, 1428–1436. [Google Scholar] [CrossRef] [PubMed]

- Hanson, C.W.; Thaler, E.R. Electronic Nose Prediction of a Clinical Pneumonia Score: Biosensors and Microbes. Anesthesiology 2005, 102, 63–68. [Google Scholar] [CrossRef]

- Franchina, F.A.; Mellors, T.R.; Aliyeva, M.; Wagner, J.; Daphtary, N.; Lundblad, L.K.A.; Fortune, S.M.; Rubin, E.J.; Hill, J.E. Towards the use of breath for detecting mycobacterial infection: A case study in a murine model. J. Breath Res. 2018, 12, 026008. [Google Scholar] [CrossRef]

- Purcaro, G.; Nasir, M.; Franchina, F.A.; Rees, C.A.; Aliyeva, M.; Daphtary, N.; Wargo, M.J.; Lundblad, L.K.A.; Hill, J.E. Breath metabolome of mice infected with Pseudomonas aeruginosa. Metabolomics 2019, 15, 10. [Google Scholar] [CrossRef] [PubMed]

- Sukul, P.; Oertel, P.; Kamysek, S.; Trefz, P. Oral or nasal breathing? Real-time effects of switching sampling route onto exhaled VOC concentrations. J. Breath Res. 2017, 11, 027101. [Google Scholar] [CrossRef] [PubMed]

- Xiang, L.; Wu, S.; Hua, Q.; Bao, C.; Liu, H. Volatile Organic Compounds in Human Exhaled Breath to Diagnose Gastrointestinal Cancer: A Meta-Analysis. Front. Oncol. 2021, 11, 606915. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Broza, Y.Y.; Ionsecu, R.; Tisch, U.; Ding, L.; Liu, H.; Song, Q.; Pan, Y.; Xiong, F.; Gu, K.; et al. A nanomaterial-based breath test for distinguishing gastric cancer from benign gastric conditions. Br. J. Cancer 2013, 108, 941–950. [Google Scholar] [CrossRef] [PubMed]

- Mazzone, P.J.; Wang, X.-F.; Xu, Y.; Mekhail, T.; Beukemann, M.C.; Na, J.; Kemling, J.W.; Suslick, K.S.; Sasidhar, M. Exhaled Breath Analysis with a Colorimetric Sensor Array for the Identification and Characterization of Lung Cancer. J. Thorac. Oncol. 2012, 7, 137–142. [Google Scholar] [CrossRef]

- Hakim, M.; Broza, Y.Y.; Barash, O.; Peled, N.; Phillips, M.; Amann, A.; Haick, H. Volatile Organic Compounds of Lung Cancer and Possible Biochemical Pathways. Chem. Rev. 2012, 112, 5949–5966. [Google Scholar] [CrossRef]

- Tiele, A.; Wicaksono, A.; Kansara, J.; Arasaradnam, R.P.; Covington, J.A. Breath Analysis Using eNose and Ion Mobility Technology to Diagnose Inflammatory Bowel Disease—A Pilot Study. Biosensors 2019, 9, 55. [Google Scholar] [CrossRef] [PubMed]

- Parry, A.D.; Chadwick, P.R.; Simon, D.; Oppenheim, B.; McCollum, C.N. Leg ulcer odour detection identifies β-haemolytic streptococcal infection. J. Wound Care 1995, 4, 404–406. [Google Scholar] [CrossRef] [PubMed]

- Gardner, J.W.; Craven, M.; Dow, C.; Hines, E.L. The prediction of bacteria type and culture growth phase by an electronic nose with a multi-layer perceptron network. Meas. Sci. Technol. 1998, 9, 120–127. [Google Scholar] [CrossRef]

- Kodogiannis, V.; Wadge, E. The use of gas-sensor arrays to diagnose urinary tract infections. Int. J. Neural. Syst. 2005, 15, 363–376. [Google Scholar] [CrossRef]

- Guernion, N.; Ratcliffe, N.M.; Spencer-Phillips, P.T.N.; Howe, R.A. Identifying Bacteria in Human Urine: Current Practice and the Potential for Rapid, Near-Patient Diagnosis by Sensing Volatile Organic Compounds. Clin. Chem. Lab. Med. 2001, 39, 893–906. [Google Scholar] [CrossRef] [PubMed]

- Aathithan, S.; Plant, J.C.; Chaudry, A.N.; French, G.L. Diagnosis of Bacteriuria by Detection of Volatile Organic Compounds in Urine Using an Automated Headspace Analyzer with Multiple Conducting Polymer Sensors. J. Clin. Microbiol. 2001, 39, 2590–2593. [Google Scholar] [CrossRef] [PubMed]

- Pavlou, A.K.; Magan, N.; McNulty, C.; Jones, J.M.; Sharp, D.; Brown, J.; Turner, A.P.F. Use of an electronic nose system for diagnoses of urinary tract infections. Biosens. Bioelectron. 2002, 17, 893–899. [Google Scholar] [CrossRef] [PubMed]

- Yates, J.W.T.; Chappell, M.J.; Gardner, J.W.; Dow, C.S.; Dowson, C.; Hamood, A.; Bolt, F.; Beeby, L. Data reduction in headspace analysis of blood and urine samples for robust bacterial identification. Comput. Methods Programs Biomed. 2005, 79, 259–271. [Google Scholar] [CrossRef] [PubMed]

- Shafiek, H.; Fiorentino, F.; Merino, J.L.; López, C.; Oliver, A.; Segura, J.; de Paul, I.; Sibila, O.; Agustí, A.; Cosío, B.G. Using the Electronic Nose to Identify Airway Infection during COPD Exacerbations. PLoS ONE 2015, 10, e0135199. [Google Scholar] [CrossRef] [PubMed]

- Fens, N.; de Nijs, S.B.; Peters, S.; Dekker, T.; Knobel, H.H.; Vink, T.J.; Willard, N.P.; Zwinderman, A.H.; Krouwels, F.H.; Janssen, H.-G.; et al. Exhaled air molecular profiling in relation to inflammatory subtype and activity in COPD. Eur. Respir. J. 2011, 38, 1301–1309. [Google Scholar] [CrossRef] [PubMed]

- de Heer, K.; van der Schee, M.P.; Zwinderman, K.; van den Berk, I.A.H.; Visser, C.E.; van Oers, R.; Sterk, P.J. Electronic Nose Technology for Detection of Invasive Pulmonary Aspergillosis in Prolonged Chemotherapy-Induced Neutropenia: A Proof-of-Principle Study. J. Clin. Microbiol. 2013, 51, 1490–1495. [Google Scholar] [CrossRef]

- Dutta, R.; Hines, E.L.; Gardner, J.W.; Boilot, P. Bacteria classification using Cyranose 320 electronic nose. Biomed. Eng. Online 2002, 1, 4. [Google Scholar] [CrossRef]

- Zamora-Mendoza, B.N.; de León-Martínez, L.D.; Rodríguez-Aguilar, M.; Mizaikoff, B.; Flores-Ramírez, R. Chemometric analysis of the global pattern of volatile organic compounds in the exhaled breath of patients with COVID-19, post-COVID and healthy subjects. Proof of concept for post-COVID assessment. Talanta 2022, 236, 122832. [Google Scholar] [CrossRef]

- Dragonieri, S.; Schot, R.; Mertens, B.J.A.; Le Cessie, S.; Gauw, S.A.; Spanevello, A.; Resta, O.; Willard, N.P.; Vink, T.J.; Rabe, K.F.; et al. An electronic nose in the discrimination of patients with asthma and controls. J. Allergy Clin. Immunol. 2007, 120, 856–862. [Google Scholar] [CrossRef]

- Santonico, M.; Zompanti, A.; Vernile, C.; Pennazza, G.; Brinkman, P.; Wagener, A.H.; Sterk, P.J.; D’Amico, A.; Montuschi, P. An investigation on e-nose platform relevance to respiratory diseases. In Proceedings of the IEEE Sensors 2014 Proceedings, Valencia, Spain, 2–5 November 2014; pp. 688–690. [Google Scholar] [CrossRef]

- Cavaleiro Rufo, J.; Paciência, I.; Mendes, F.C.; Farraia, M.; Rodolfo, A.; Silva, D.; de Oliveira Fernandes, E.; Delgado, L.; Moreira, A. Exhaled breath condensate volatilome allows sensitive diagnosis of persistent asthma. Allergy 2019, 74, 527–534. [Google Scholar] [CrossRef] [PubMed]

- Hattesohl, A.D.M.; Jörres, R.A.; Dressel, H.; Schmid, S.; Vogelmeier, C.; Greulich, T.; Noeske, S.; Bals, R.; Koczulla, A.R. Discrimination between COPD patients with and without alpha 1-antitrypsin deficiency using an electronic nose. Respirology 2011, 16, 1258–1264. [Google Scholar] [CrossRef] [PubMed]

- Dymerski, T.; Gębicki, J.; Wiśniewska, P.; Śliwińska, M.; Wardencki, W.; Namieśnik, J. Application of the Electronic Nose Technique to Differentiation between Model Mixtures with COPD Markers. Sensors 2013, 13, 5008–5027. [Google Scholar] [CrossRef] [PubMed]

- Bos, L.D.; Schultz, M.J.; Sterk, P.J. Exhaled breath profiling for diagnosing acute respiratory distress syndrome. BMC Pulm. Med. 2014, 14, 72. [Google Scholar] [CrossRef] [PubMed]

- Saasa, V.; Malwela, T.; Beukes, M.; Mokgotho, M.; Liu, C.-P.; Mwakikunga, B. Sensing Technologies for Detection of Acetone in Human Breath for Diabetes Diagnosis and Monitoring. Diagnostics 2018, 8, 12. [Google Scholar] [CrossRef]

- Bruins, M.; Rahim, Z.; Bos, A.; van de Sande, W.W.J.; Endtz, H.P.; van Belkum, A. Diagnosis of active tuberculosis by e-nose analysis of exhaled air. Tuberculosis 2013, 93, 232–238. [Google Scholar] [CrossRef] [PubMed]

- Coronel Teixeira, R.; Rodríguez, M.; Jiménez de Romero, N.; Bruins, M.; Gómez, R.; Yntema, J.B.; Chaparro Abente, G.; Gerritsen, J.W.; Wiegerinck, W.; Pérez Bejerano, D.; et al. The potential of a portable, point-of-care electronic nose to diagnose tuberculosis. J. Infect. 2017, 75, 441–447. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, E.I.; Mohamed, M.A.; Moustafa, M.H.; Abdel-Mageed, S.M.; Moro, A.M.; Baess, A.I.; El-Kholy, S.M. Qualitative analysis of biological tuberculosis samples by an electronic nose-based artificial neural network. Int. J. Tuberc. Lung Dis. 2017, 21, 810–817. [Google Scholar] [CrossRef]

- Dragonieri, S.; van der Schee, M.P.; Massaro, T.; Schiavulli, N.; Brinkman, P.; Pinca, A.; Carratú, P.; Spanevello, A.; Resta, O.; Musti, M.; et al. An electronic nose distinguishes exhaled breath of patients with Malignant Pleural Mesothelioma from controls. Lung Cancer 2012, 75, 326–331. [Google Scholar] [CrossRef]

- D’Amico, A.; Pennazza, G.; Santonico, M.; Martinelli, E.; Roscioni, C.; Galluccio, G.; Paolesse, R.; Di Natale, C. An investigation on electronic nose diagnosis of lung cancer. Lung Cancer 2010, 68, 170–176. [Google Scholar] [CrossRef]

- Paff, T.; van der Schee, M.P.; Daniels, J.M.A.; Pals, G.; Postmus, P.E.; Sterk, P.J.; Haarman, E.G. Exhaled molecular profiles in the assessment of cystic fibrosis and primary ciliary dyskinesia. J. Cyst. Fibros. 2013, 12, 454–460. [Google Scholar] [CrossRef] [PubMed]

- Chiu, S.-W.; Wang, J.-H.; Chang, K.-H.; Chang, T.-H.; Wang, C.-M.; Chang, C.-L.; Tang, C.-T.; Chen, C.-F.; Shih, C.-H.; Kuo, H.-W.; et al. A Fully Integrated Nose-on-a-Chip for Rapid Diagnosis of Ventilator-Associated Pneumonia. IEEE Trans Biomed. Circuits Syst. 2014, 8, 765–778. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D. Applications of Electronic-Nose Technologies for Noninvasive Early Detection of Plant, Animal and Human Diseases. Chemosensors 2018, 6, 45. [Google Scholar] [CrossRef]

- Blehert, D.S.; Hicks, A.C.; Behr, M.; Meteyer, C.U.; Berlowski-Zier, B.M.; Buckles, E.L.; Coleman, J.T.H.; Darling, S.R.; Gargas, A.; Niver, R.; et al. Bat White-Nose Syndrome: An Emerging Fungal Pathogen? Science 1979 2009, 323, 227. [Google Scholar] [CrossRef] [PubMed]

- Frick, W.F.; Pollock, J.F.; Hicks, A.C.; Langwig, K.E.; Reynolds, D.S.; Turner, G.G.; Butchkoski, C.M.; Kunz, T.H. An Emerging Disease Causes Regional Population Collapse of a Common North American Bat Species. Science 1979 2010, 329, 679–682. [Google Scholar] [CrossRef] [PubMed]

- Ballmann, A.E.; Torkelson, M.R.; Bohuski, E.A.; Russell, R.E.; Blehert, D.S. Dispersal Hazards of Pseudogymnoascus Destructans by Bats and Human Activity at Hibernacula in Summer. J. Wildl. Dis. 2017, 53, 725. [Google Scholar] [CrossRef] [PubMed]

- Lorch, J.M.; Meteyer, C.U.; Behr, M.J.; Boyles, J.G.; Cryan, P.M.; Hicks, A.C.; Ballmann, A.E.; Coleman, J.T.H.; Redell, D.N.; Reeder, D.M.; et al. Experimental infection of bats with Geomyces destructans causes white-nose syndrome. Nature 2011, 480, 376–378. [Google Scholar] [CrossRef] [PubMed]

- Verant, M.L.; Meteyer, C.U.; Speakman, J.R.; Cryan, P.M.; Lorch, J.M.; Blehert, D.S. White-nose syndrome initiates a cascade of physiologic disturbances in the hibernating bat host. BMC Physiol. 2014, 14, 10. [Google Scholar] [CrossRef] [PubMed]

- Warnecke, L.; Turner, J.M.; Bollinger, T.K.; Misra, V.; Cryan, P.M.; Blehert, D.S.; Wibbelt, G.; Willis, C.K.R. Pathophysiology of white-nose syndrome in bats: A mechanistic model linking wing damage to mortality. Biol. Lett. 2013, 9, 20130177. [Google Scholar] [CrossRef]

- Reeder, D.M.; Frank, C.L.; Turner, G.G.; Meteyer, C.U.; Kurta, A.; Britzke, E.R.; Vodzak, M.E.; Darling, S.R.; Stihler, C.W.; Hicks, A.C.; et al. Frequent Arousal from Hibernation Linked to Severity of Infection and Mortality in Bats with White-Nose Syndrome. PLoS ONE 2012, 7, e38920. [Google Scholar] [CrossRef]

- Cryan, P.M.; Meteyer, C.U.; Boyles, J.G.; Blehert, D.S. Wing pathology of white-nose syndrome in bats suggests life-threatening disruption of physiology. BMC Biol. 2010, 8, 135. [Google Scholar] [CrossRef] [PubMed]

- Doty, A.C.; Wilson, A.D.; Forse, L.B.; Risch, T.S. Assessment of the Portable C-320 Electronic Nose for Discrimination of Nine Insectivorous Bat Species: Implications for Monitoring White-Nose Syndrome. Biosensors 2020, 10, 12. [Google Scholar] [CrossRef]

- Cramp, A.P.; Sohn, J.H.; James, P.J. Detection of cutaneous myiasis in sheep using an ‘electronic nose’. Vet. Parasitol. 2009, 166, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Scholtz, A.J.; Cloete, S.W.P.; Laubscher, J.M.; De Beer, E.F. A preliminary evaluation of a sheep blowfly trap in the Western Cape. J. S. Afr. Vet. Assoc. 2000, 71, 148–152. [Google Scholar] [CrossRef] [PubMed]

- Heath, A.C.G.; Bishop, D.M. Flystrike in New Zealand: An overview based on a 16-year study, following the introduction and dispersal of the Australian sheep blowfly, Lucilia cuprina Wiedemann (Diptera: Calliphoridae). Vet. Parasitol. 2006, 137, 333–344. [Google Scholar] [CrossRef]

- Cellini, A.; Blasioli, S.; Biondi, E.; Bertaccini, A.; Braschi, I.; Spinelli, F. Potential Applications and Limitations of Electronic Nose Devices for Plant Disease Diagnosis. Sensors 2017, 17, 2596. [Google Scholar] [CrossRef] [PubMed]

- Biondi, E.; Blasioli, S.; Galeone, A.; Spinelli, F.; Cellini, A.; Lucchese, C.; Braschi, I. Detection of potato brown rot and ring rot by electronic nose: From laboratory to real scale. Talanta 2014, 129, 422–430. [Google Scholar] [CrossRef] [PubMed]

- Chang, Z.; Lv, J.; Qi, H.; Ma, Y.; Chen, D.; Xie, J.; Sun, Y. Bacterial Infection Potato Tuber Soft Rot Disease Detection Based on Electronic Nose. Open Life Sci. 2017, 12, 379–385. [Google Scholar] [CrossRef]

- Wilson, A.D.; Forse, L.B.; Babst, B.A.; Bataineh, M.M. Detection of Emerald Ash Borer Infestations in Living Green Ash by Noninvasive Electronic-Nose Analysis of Wood Volatiles. Biosensors 2019, 9, 123. [Google Scholar] [CrossRef]

- Konduru, T.; Rains, G.C.; Li, C. Detecting sour skin infected onions using a customized gas sensor array. J.Food Eng. 2015, 160, 19–27. [Google Scholar] [CrossRef]

- Spinelli, F.; Noferini, M.; Vanneste, J.L.; Costa, G. Potential of the electronic-nose for the diagnosis of bacterial and fungal diseases in fruit trees. EPPO Bull. 2010, 40, 59–67. [Google Scholar] [CrossRef]

- Jiarpinijnun, A.; Osako, K.; Siripatrawan, U. Visualization of volatomic profiles for early detection of fungal infection on storage Jasmine brown rice using electronic nose coupled with chemometrics. Measurement 2020, 157, 107561. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, Z.; Li, K.; Jamir, S.; Luo, X. Recognition of the Duration and Prediction of Insect Prevalence of Stored Rough Rice Infested by the Red Flour Beetle (Tribolium castaneum Herbst) Using an Electronic Nose. Sensors 2017, 17, 688. [Google Scholar] [CrossRef] [PubMed]

- Mishra, G.; Srivastava, S.; Panda, B.K.; Mishra, H.N. Sensor array optimization and determination of Rhyzopertha dominica infestation in wheat using hybrid neuro-fuzzy-assisted electronic nose analysis. Anal. Methods 2018, 10, 5687–5695. [Google Scholar] [CrossRef]

- Fuentes, S.; Tongson, E.; Unnithan, R.R.; Viejo, C.G. Early Detection of Aphid Infestation and Insect-Plant Interaction Assessment in Wheat Using a Low-Cost Electronic Nose (E-Nose), Near-Infrared Spectroscopy and Machine Learning Modeling. Sensors 2021, 21, 5948. [Google Scholar] [CrossRef]

- Ghaffari, R.; Laothawornkitkul, J.; Iliescu, D.; Hines, E.; Leeson, M.; Napier, R.; Moore, J.P.; Paul, N.D.; Hewitt, C.N.; Taylor, J.E. Plant pest and disease diagnosis using electronic nose and support vector machine approach. J. Plant Dis. Prot. 2012, 119, 200–207. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, D. Domain Adaptation Extreme Learning Machines for Drift Compensation in E-Nose Systems. IEEE Trans. Instrum. Meas. 2015, 64, 1790–1801. [Google Scholar] [CrossRef]

- Yan, K.; Zhang, D.; Xu, Y. Correcting Instrumental Variation and Time-Varying Drift Using Parallel and Serial Multitask Learning. IEEE Trans. Instrum. Meas. 2017, 66, 2306–2316. [Google Scholar] [CrossRef]

- Yan, K.; Zhang, D. Improving the transfer ability of prediction models for electronic noses. Sens. Actuators B Chem. 2015, 220, 115–124. [Google Scholar] [CrossRef]

- Ropodi, A.I.; Panagou, E.Z.; Nychas, G.-J.E. Data mining derived from food analyses using non-invasive/non-destructive analytical techniques; determination of food authenticity, quality & safety in tandem with computer science disciplines. Trends Food Sci. Technol. 2016, 50, 11–25. [Google Scholar] [CrossRef]

- Rudnitskaya, A. Calibration Update and Drift Correction for Electronic Noses and Tongues. Front. Chem. 2018, 6, 433. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, D. Efficient Solutions for Discreteness, Drift, and Disturbance (3D) in Electronic Olfaction. IEEE Trans. Syst. Man. Cybern. Syst. 2018, 48, 242–254. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, L.; Tian, F.; Zhang, D. Temperature Modulated Gas Sensing E-Nose System for Low-Cost and Fast Detection. IEEE Sens. J. 2016, 16, 464–474. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, D.; Yin, X.; Liu, Y. A Novel Semi-Supervised Learning Approach in Artificial Olfaction for E-Nose Application. IEEE Sens. J. 2016, 16, 4919–4931. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohtasebi, S.S.; Siadat, M.; Ahmadi, H.; Razavi, S.H. From simple classification methods to machine learning for the binary discrimination of beers using electronic nose data. Eng. Agric. Environ. Food 2015, 8, 44–51. [Google Scholar] [CrossRef]

- Di Rosa, A.R.; Leone, F.; Cheli, F.; Chiofalo, V. Fusion of electronic nose, electronic tongue and computer vision for animal source food authentication and quality assessment—A review. J. Food Eng. 2017, 210, 62–75. [Google Scholar] [CrossRef]

- Yan, K.; Zhang, D. Correcting Instrumental Variation and Time-Varying Drift: A Transfer Learning Approach With Autoencoders. IEEE Trans. Instrum. Meas. 2016, 65, 2012–2022. [Google Scholar] [CrossRef]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. Fusion of artificial senses as a robust approach to food quality assessment. J. Food Eng. 2016, 171, 230–239. [Google Scholar] [CrossRef]

- Peng, Q.; Tian, R.; Chen, F.; Li, B.; Gao, H. Discrimination of producing area of Chinese Tongshan kaoliang spirit using electronic nose sensing characteristics combined with the chemometrics methods. Food Chem. 2015, 178, 301–305. [Google Scholar] [CrossRef]

- Hong, X.; Wang, J.; Qi, G. E-nose combined with chemometrics to trace tomato-juice quality. J. Food Eng. 2015, 149, 38–43. [Google Scholar] [CrossRef]

- Wijaya, D.R.; Sarno, R.; Daiva, A.F. Electronic nose for classifying beef and pork using Naïve Bayes. In Proceedings of the 2017 International Seminar on Sensors, Instrumentation, Measurement and Metrology (ISSIMM), IEEE, Surabaya, Indonesia, 25–26 August 2017; pp. 104–108. [Google Scholar] [CrossRef]

| Title of the Review | Focus | Content | Year | Ref |

|---|---|---|---|---|

| Gardner et al.: A Brief History of Electronic Noses | Sensors, applications | The authors provide an overview of the advancements in e-nose technology and its application domains over the past 25 years. | 1994 | [1] |

| Craven et al.: Electronic Nose Development and Future Prospects | Sensors, trends | The authors conduct a retrospective analysis of the initial stages of e-nose device development, encompassing their measurement capabilities and their relationship with human olfaction, among other aspects. Furthermore, they anticipate that forthcoming advancements will revolve around sensing materials, improving sensor interference suppression performance, and exploring more intricate applications. | 1996 | [11] |

| Schaller et al.: Electronic Noses and their Application to Food | Sensors, applications (food analysis) | This paper provides an introduction to e-nose sensor technology and statistical data analysis techniques. Additionally, it enumerates various applications of e-noses in the realm of food analysis. | 1998 | [12] |

| Strike et al.: Electronic Noses—A Mini-Review | Sensor technologies | The paper centers on electronic noses as novel analytical tools, highlighting sensor arrays and their role in creating odor fingerprints. It also discusses sensor technologies, briefly touches on data processing, and concludes with an assessment of the field’s current status and future possibilities. | 1999 | [13] |

| Erica et al.: Medical Applications of Electronic Nose Technology: Review of Current Status | Sensors, medical applications | This article offers an in-depth exploration of electronic nose technology and delves into its early investigative applications within the medical field. | 2001 | [14] |

| García-González et al.: Sensors: From Biosensors to the Electronic Nose | Sensor technology, food applications | This review provides an up-to-date assessment of sensor technology, with a particular focus on its applications in the food industry. It comprehensively examines the design, technology, and sensing mechanisms of various sensor types, including electronic noses and electronic tongues for taste detection. Additionally, the review briefly outlines the utilization of statistical procedures in sensor systems. | 2002 | [15] |

| Ampuero et al.: The Electronic Nose Applied to Dairy Products: A Review | Aroma analysis using electronic noses | This review focuses on the use of electronic noses for aroma analysis, particularly in the dairy product industry. It covers sensor technology advancements, challenges, and emerging techniques. The article highlights the potential benefits of electronic noses in areas like cheese evaluation, milk classification, and bacterial identification. | 2003 | [16] |

| Turner et al.: Electronic Noses and Disease Diagnostics | Detecting microbial infections using electronic noses | This paper explores the capabilities of electronic noses (e-noses) in detecting volatile compounds related to microbial infections and discusses their potential applications in early disease diagnosis and disease epidemiology monitoring. | 2004 | [17] |

| James et al.: Chemical Sensors for Electronic Nose Systems | Sensor technology | This paper discusses the use of chemical sensors in an array format for the analysis of volatile organic compounds, leading to the creation of “electronic noses.” It covers the various types of gas sensors used, their transducer principles, and current technological advancements. | 2005 | [18] |

| Casalinuovo et al.: Application of Electronic Noses for Disease Diagnosis and Food Spoilage Detection | Electronic noses for medical diagnosis and food quality control | The paper discusses how e-noses have enabled the analysis of odors. It highlights their applications in different fields, particularly in medicine and the food industry, wherein rapid detection methods are crucial. The paper also emphasizes the use of e-noses for classifying and quantifying bacteria and fungi, with the aim of achieving accurate medical diagnoses and ensuring food quality. The review includes examples of bacterial and fungal species producing volatile compounds linked to infectious diseases or food spoilage. Overall, the paper suggests the potential of e-nose technology in both medical diagnostics and food management. | 2006 | [19] |

| Röck et al.: Electronic Nose: Current Status and Future Trends | Sensors, applications | The authors examine emerging e-nose technologies, encompassing optical sensor systems, mass spectrometry (MS), ion mobility spectrometry, gas chromatography (GC), infrared spectroscopy, and specialized substance-class-specific sensors. They explore these technologies’ applications across diverse domains, expanding the conventional definition of ‘e-nose.’ The paper concludes by outlining future trends in three key areas: sample handling, filtration, analyte gas separation, and data analysis. | 2008 | [20] |

| Chen et al.: Chemical Sensors and Electronic Noses Based on 1-D Metal Oxide Nanostructures | 1-D metal oxide nanostructures for detection of industrial gases | The review covers various aspects of this chemical sensing field, including the synthesis of 1-D metal oxide nanostructures, the electronic properties of nanowire-based FETs, and their behavior in chemical sensing applications. It also discusses the recent advancements in electronic nose systems based on metal oxide nanowires, highlighting their potential to enhance sensing selectivity. | 2008 | [21] |

| Wilson et al.: Applications and Advances in Electronic-Nose Technologies | Electronic nose technology | This paper reviews the evolution of electronic nose technologies over the past two decades, up to the year of publication, and explores their diverse applications across various industries. It emphasizes significant advancements in sensors, materials, software, and microcircuitry, which have led to the emergence of novel sensor types and applications. | 2009 | [22] |

| Berna et al.: Metal Oxide Sensors for Electronic Noses and their Application to Food Analysis | Sensors, food applications | The review covers various applications of e-noses in food and beverage quality control, including freshness determination, contaminant and adulteration identification, and analysis of diverse food and beverage categories such as meat, fish, grains, alcoholic and non-alcoholic drinks, fruits, dairy products, oils, nuts, vegetables, and eggs. | 2010 | [23] |

| Wilson et al.: Advances in Electronic-Nose Technologies Developed for Biomedical Applications | Applications of electronic noses in the biomedical field | This review discusses the rapid development of electronic nose technologies in the biomedical field. It covers various applications in healthcare, including diagnostics, pathology, drug delivery, and patient condition monitoring. The paper highlights the potential of e-nose technologies to address complex biomedical challenges and improve healthcare services. | 2011 | [24] |

| Falasconi et al.: Electronic Nose for Microbiological Quality Control of Food Products | Electronic noses, food applications | This review paper provides an overview of electronic nose (EN) technology and its application in microbiological screening across various food scenarios. It covers the detection of microbial contamination in fruit juices, processed tomatoes, maize grains (fungal and fumonisin contamination), and green coffee beans. The paper offers insights into both the achievements and obstacles related to employing sensor technology for food quality control. It underscores the inherent variability in food samples and the limitations of sensor technology. Furthermore, it outlines current trends and potential future directions in this domain. | 2012 | [25] |

| Wilson et al.:Diverse Applications of Electronic-Nose Technologies in Agriculture and Forestry | Electronic nose, agriculture applications | This paper offers a comprehensive review of electronic nose instruments and their applications in agriculture and forestry. It highlights recent advancements in e-nose technologies and their benefits to both industries. Applications in agriculture encompass agronomy, plant selection, and environmental monitoring. In forestry, these instruments find uses in wood processing, forest management, and waste management. The review emphasizes how e-nose applications have improved product quality and consistency in these sectors, enhancing production processes. Overall, this paper provides an overview of e-nose technologies’ impact on agriculture and forestry over the past three decades. | 2013 | [26] |

| Montuschi et al.: The Electronic Nose in Respiratory Medicine | Applications of electronic noses in the biomedical field | This paper examines electronic noses made for detecting volatile organic compounds in exhaled breath as biomarkers for lung diseases. | 2013 | [27] |

| Zohora et al.: Chemical Sensors Employed in Electronic Noses: A Review | Sensors | This review paper explores the operational principles of each chemical sensor type and their applications within the e-nose system. The sensor array comprises various gas sensors, including Metal Oxide Semiconductor (MOS) sensors, optical and amperometric gas sensors, Surface Acoustic Wave (SAW) sensors, and piezoelectric gas sensors. | 2013 | [28] |

| Capelli et al.: Electronic Noses for Environmental Monitoring Applications | Sensors, environmental applications | This article reviews recent scientific studies on electronic nose applications in environmental monitoring. It particularly focuses on their use in analyzing environmental quality parameters, process control, and assessing odor control system efficiency. The studies generally show that electronic noses are well suited for these applications, especially when customized and optimized. However, the review also highlights challenges and the need for standardization due to the complexity of these instruments and their various applications. | 2014 | [29] |

| Loutfi et al.: Electronic Noses for Food Quality: A Review | Electronic noses, food applications | This paper reviews recent electronic nose applications in the food industry, particularly in food quality monitoring, including meat, milk, fish, tea, coffee, and wines. It highlights commonalities in sensor usage and data processing methods across these applications and offers insights into the necessary advancements for practical industrial implementation. | 2015 | [7] |

| Yan et al.: Electronic Nose Feature Extraction Methods: A Review | Data analysis (feature extraction), trends | This review delves into the enhancement of electronic nose (e-nose) systems through optimizations in sensitive material selection, sensor array design, feature extraction methods, and pattern recognition techniques. It summarizes various feature extraction methods used in e-noses, offering insights for future developments in this technology. | 2015 | [30] |

| Capelli et al.: Application and Uses of Electronic Noses for Clinical Diagnosis on Urine Samples: A Review | Electronic noses for clinical diagnosis | This paper provides a comprehensive review of e-nose studies and their applications in the domain of medical diagnosis, focusing on the analysis of gaseous compounds present in human urine. The aim is to present an in-depth assessment of the current state of the art technologies and promote further advancements in this area. | 2016 | [31] |

| Horczyczak et al.: Applications of Electronic Noses in Meat Analysis | Electronic noses, food applications | This study explores the use of electronic noses in assessing and distinguishing the aroma profiles of various foods, particularly meat products. Electronic noses are praised for their quick, cost-effective, and non-destructive approach to food quality control. The paper provides an overview of this technology, its applications, commonly used sensor types and patterns, and potential future developments. It serves as a practical guide for utilizing electronic noses in food analysis. | 2016 | [32] |

| Gliszczyńska-Świgło et al.: Electronic Nose as a Tool for Monitoring the Authenticity of Food. A Review | Electronic noses, food applications | This article examines the utilization of diverse e-noses and chemometrics for assessing food authenticity, which encompasses detecting adulteration and verifying origin. | 2017 | [33] |

| Liang et al.: Study on Interference Suppression Algorithms for Electronic Noses: A Review | Data analysis | This paper provides an overview of interference sources in e-noses and evaluates recent advancements in suppressing e-noise interference. Interference is categorized into two types: changes in working conditions and hardware failures. The existing suppression methods are analyzed based on these factors. | 2018 | [34] |

| Hu et al.: Electronic Noses: From Advanced Materials to Sensors Aided with Data Processing | Electronic noses, data analysis | This paper emphasizes three critical elements: the diverse applications of e-noses in various industries, advancements in sensor technology, and the use of artificial neural networks for odor pattern recognition. | 2019 | [35] |

| Wojnowski et al.: Electronic Noses in Medical Diagnostics | Electronic noses, medical applications | This review provides a comprehensive overview of electronic nose applications in medical diagnostics, with a focus on how these devices and sensor technologies align with current trends in medicine. | 2019 | [9] |

| Baldini et al.: Electronic Nose as a Novel Method for Diagnosing Cancer: A Systematic Review | Electronic noses, medical applications | This systematic review assesses e-nose technology in cancer research, particularly for early detection. Among 60 articles reviewed up to 31 January 2020, promising results are seen in lung cancer diagnosis, achieving over 80% accuracy with the Aeonose tool. However, challenges, such as sample diversity and limited early-stage data, underscore the necessity for further research to enhance e-nose’s role in cancer diagnosis. | 2020 | [36] |

| Karakaya et al.: Electronic Nose and its Applications: A Survey | Sensors, data analysis | The authors examine the components of e-nose systems, including sensors, machine learning algorithms, current challenges, and future development directions. | 2020 | [37] |

| Cheng et al.: Development of Compact Electronic Noses: A Review | Sensor technologies | This paper reviews the evolution of compact e-nose design and calculation in recent decades and outlines potential future directions. It covers advancements in sensor array design, hardware circuitry, gas path optimization, sampling mechanisms, and portability in compact e-nose design. | 2021 | [2] |

| Tonezzer et al.: Electronic Noses Based on Metal Oxide Nanowires: A Review | Electronic noses, metal oxide nanowires | This review discusses electronic noses (e-noses) that utilize metal oxide nanowires as gas sensors. It focuses on their applications and performance, particularly addressing the challenge of achieving selectivity when using sensitive but non-selective metal oxide sensors. The review covers various sectors, including fundamental research, agrifood, health, and security, and analyzes recent literature in these areas. It explores the types of metal oxides used, surface modifications, sensor array characteristics, applications, algorithms, and the information obtained from these e-noses. The review aims to provide insights into the current state of this technology and its requirements for practical real-world applications. | 2022 | [2] |

| Jońca et al.: Electronic Noses and Their Applications for Sensory and Analytical Measurements in the Waste Management Plants—A Review | Electronic noses for waste management plants | This review discusses methods for monitoring odor emissions from waste management plants, focusing on sensory and analytical approaches. It emphasizes electronic noses and their design, sensor arrays, and data processing challenges. The review also highlights real-world applications of electronic nose devices in waste treatment processes and odor assessment near waste management facilities. | 2023 | [38] |

| Khorramifar et al.: Environmental Engineering Applications of Electronic Nose Systems Based on MOX Gas Sensors | Electronic nose, environmental engineering applications | This review focuses on the electronic nose (e-nose) technology and its applications in environmental monitoring. Specifically, it delves into the use of metal oxide semiconductor sensors (MOXs) for detecting volatile compounds in the air, particularly at low concentrations. The review discusses the advantages and disadvantages of MOX sensors and explores various research studies related to environmental contamination monitoring using e-noses. It emphasizes that e-noses have proven suitable for multiple applications, especially when tailored to specific tasks such as water and wastewater management systems. However, the main challenge lies in the complexity of e-noses and the lack of specific standards, which can potentially be addressed through improved data processing methods. | 2023 | [39] |

| Alfieri, Gianmarco, et al.: Recent Advances and Future Perspectives in E-Nose Technologies Addressed to the Wine Industry | Exploration of electronic nose use in wine industry | This review examines prevailing trends in the utilization of e-nose technology within the wine industry, particularly focusing on the evaluation of wine quality attributes such as geographical origin, sensory defects, and monitoring of production trends. It discusses the integration of e-nose analysis with classical methods and highlights the importance of human sensory analysis in wine evaluation. The review also explores the potential of e-nose devices combined with artificial intelligence and algorithms to revolutionize the wine industry in the future. | 2024 | [40] |

| Abideen, Zain Ul et al.:Emerging Trends in Metal Oxide-Based Electronic Noses for Healthcare Applications: A Review | Exploration of electronic nose technology for healthcare | The review explores recent advancements in e-nose technology and its applications in healthcare, such as medical diagnostics through breath analysis and monitoring hazardous gases. The review addresses challenges like miniaturization and low power consumption and examines different sensing materials used to overcome them. It also covers the integration of metal oxide sensors into portable e-noses and various data analysis techniques. | 2024 | [41] |

| Wang, Mingyang et al.:Electronic Nose and its Application in the Food Industry: A Review | Exploration of e-nose use in food industry | The review explores the significance of food testing technology, focusing on the electronic nose (e-nose) as an efficient, fast, and non-destructive tool in the food industry. It covers the basic principle and components of the e-nose, including gas sensor selection, sampling methods, and data processing. This review discusses various applications of e-noses in the food industry, such as freshness assessment, process monitoring, flavor evaluation, authenticity verification, quality control, origin traceability, and pesticide residue detection. Finally, it addresses current challenges and suggests future research directions in the field. | 2024 | [42] |

| Computational Treatment | Advantages | Disadvantages | Trends |

|---|---|---|---|

| PCA |

|

| Continued usage with efforts to enhance objectivity through algorithmic autonomy and automation. Increased integration with machine learning for automated interpretation and decision-making. |

| LDA |

|

| Increasing popularity due to robustness in classification tasks and ability to handle complex datasets. Adoption in real-time applications for immediate decision-making, especially in industrial settings. |

| PLSR |

|

| Growing adoption for predictive modeling tasks, especially in forecasting dependent variables from extensive independent variables. |

| SVM |

|

| Continued use, especially for effective class separation and handling nonlinear data distributions. Ongoing advancements in kernel methods for improved performance and scalability. |

| ANN |

|

| Increasing adoption due to advancements in deep learning techniques, improving accuracy and reliability. |

| Gas Target | Type of Sensor | Description and Results | Reference |

|---|---|---|---|

| CO, NO2, CH4 | Tin oxide sensors (Keeling & Walker, Stoke-on-Trent, UK) | The objective of the research was to establish the most suitable duration for substances and sensors to interact. To achieve this, MOX sensors underwent exposure to different concentrations of nitrogen oxide, methane, and carbon monoxide, spanning the range of 500 ppb to 2000 ppm. It was observed that after approximately half an hour, the responses of the sensors stabilized when exposed to air mixtures containing these compounds. This 30 min time frame was subsequently adopted for additional examinations involving varying concentrations of compounds. The study took into consideration variables such as humidity and temperature. The investigation underlined the impact of these variables on sensor reactions and their role in enhancing the electronic nose’s ability to discern and quantify substances. Under conditions of unchanging temperature and humidity, the system adeptly distinguished between compounds with a high level of precision. | [113] |

| Acetone, chloroform, methanol | QCM sensors (NDK Ltd., Tokyo, Japan) | Employing an e-nose fitted with QCM sensors, the investigation aimed to scrutinize gas mixtures encompassing acetone, chloroform, and methanol, exhibiting concentrations ranging from 4000 to 10,000 ppm. The primary objective was to evaluate the system’s capacity to differentiate among distinct compounds while ascertaining their respective concentrations through principal component analysis (PCA). The outcomes showcased the electronic nose’s prowess in discerning mixtures comprising a sole compound versus binary combinations, with marked fluctuations in sensor responses as the levels of these chemical compounds fluctuated. Nevertheless, the study shed light on the influence of humidity levels on the findings, emphasizing the necessity to consider humidity variations in outdoor settings to minimize interference and ensure dependable results. | [106] |

| H2S, NO2 | Six Taguchi gas sensors (TGS-800, -813, -822, -825, -832, -2105) (Figaro Engineering Inc., Osaka, Japan) | Helli et al. conducted a study focused on detecting H2S and NO2. They employed MOX sensors to analyze atmospheres containing varying levels of humidity and CO2, investigating gas concentrations within the range of 1 to 11 ppm for H2S and 1 to 5 ppm for NO2. Utilizing discriminant factor analysis, the e-nose precisely predicted the mix composition. However, the research highlighted that the accuracy of recognition was impacted by the presence of CO2 and humidity in the mixture, and the reliability of results was contingent on understanding these two parameters. | [114] |

| CO, ISBU, CH4, EtOH | Tin oxide sensors | Negri and Reich utilized an e-nose equipped with MOX sensors to detect CO, C₄H₁₀, CH₄, and C₂H₅OH within atmospheres containing interfering gases. Their system accurately estimated 85% of the compound concentrations tested, with errors staying below 10%. Notably, these encouraging outcomes were achieved using relatively elevated concentrations (ranging from 1000 to 5000 ppm) compared to typical ambient air levels. The study effectively showcased the system’s potential in identifying compounds, especially at higher concentration levels. | [115] |

| Different VOCs | MOX (Figaro TGS2602) | Wolfrum et al. used 14 MOX sensors to recognize and quantify volatile organic compounds (VOCs) such as C₆H₅CH₃, CH₃COCH₃, and CH₃COCH₃, even at very low concentration levels (ppb). They pre-processed acquired data to establish a linear correlation between e-nose responses and VOC concentrations. This linear correlation facilitated the estimation of VOC concentrations, with (MSE) prediction values of 0.008, 0.011, and 0.026 for C₆H₅CH₃, CH₃COCH₃, and CH₃COCH₃, respectively. | [116] |

| Different VOCs | 10 tin oxide sensors (Keeling & Walker, Stoke-on-Trent, UK) | Lee et al. aimed to develop an electronic nose capable of detecting VOCs at concentrations below their threshold limit values (TLV). Using MOX sensors, they analyzed samples containing benzene, toluene, ethyl alcohol, methyl alcohol, and acetone. While promising results were obtained, the study identified sensor drift over time as a challenge, impacting the reliability of recognition over extended periods. | [117] |