Research on the Characteristic State of Rockfill Materials and the Evolution Mechanism at the Microscopic Scale

Abstract

1. Introduction

2. Numerical Model Construction

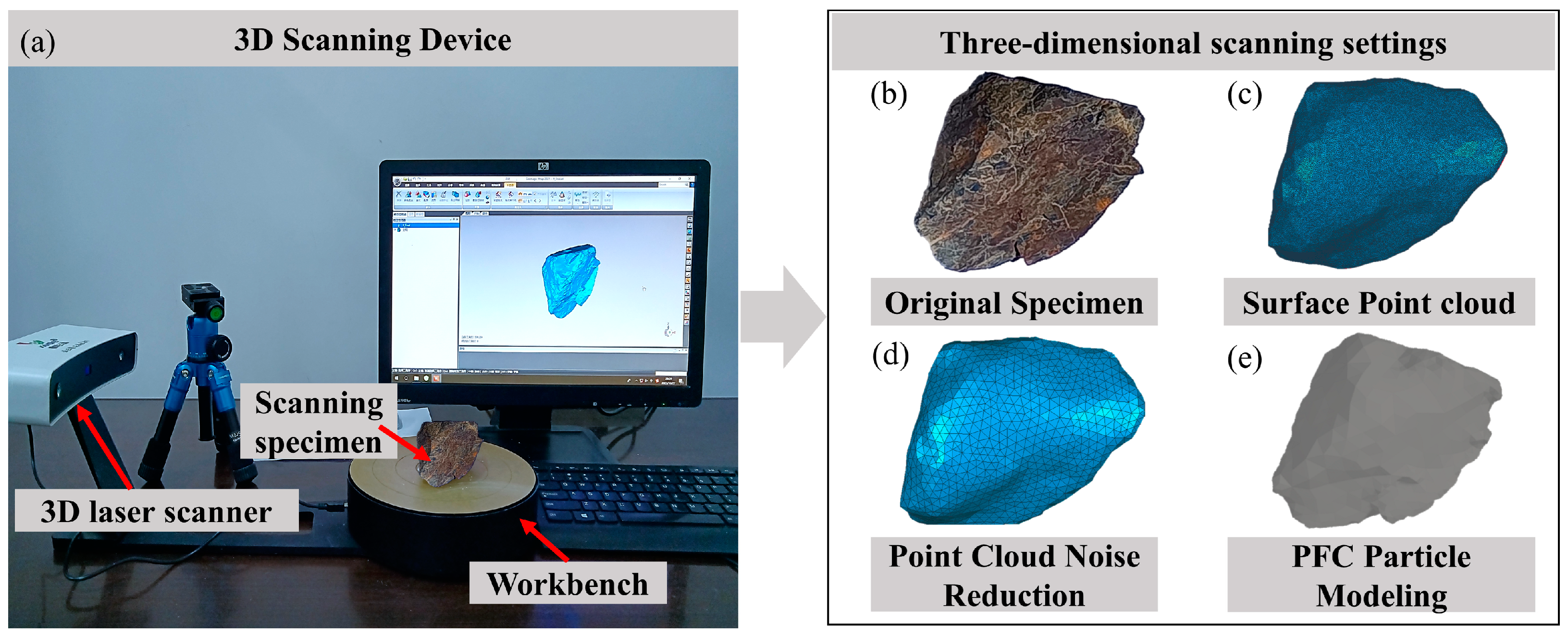

2.1. Three-Dimensional Shape Recognition of Rockfill Materials

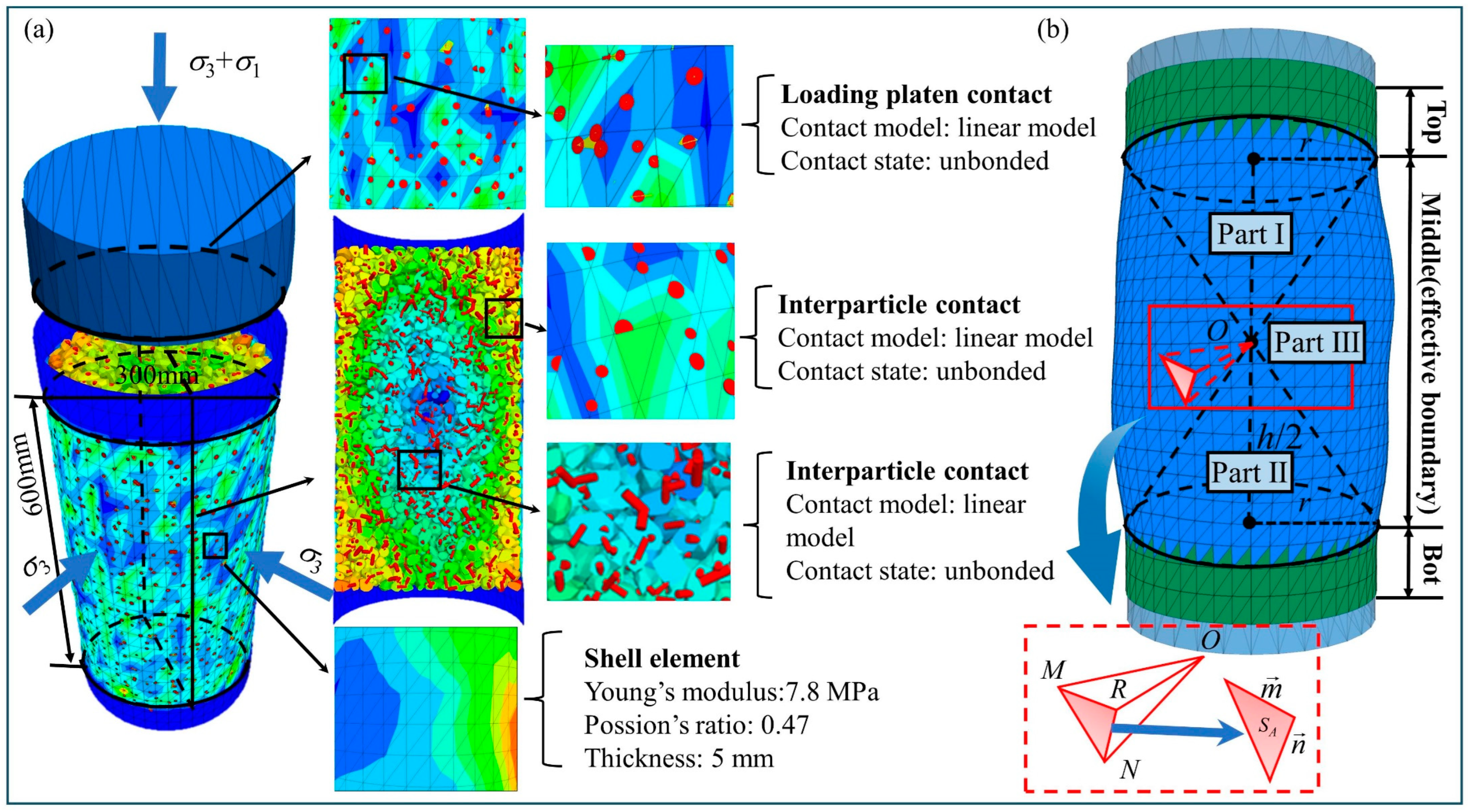

2.2. Rigid Block Contact Modeling in Particle Flow Algorithms

2.3. Discrete Element Triaxial Test Servo Mechanism

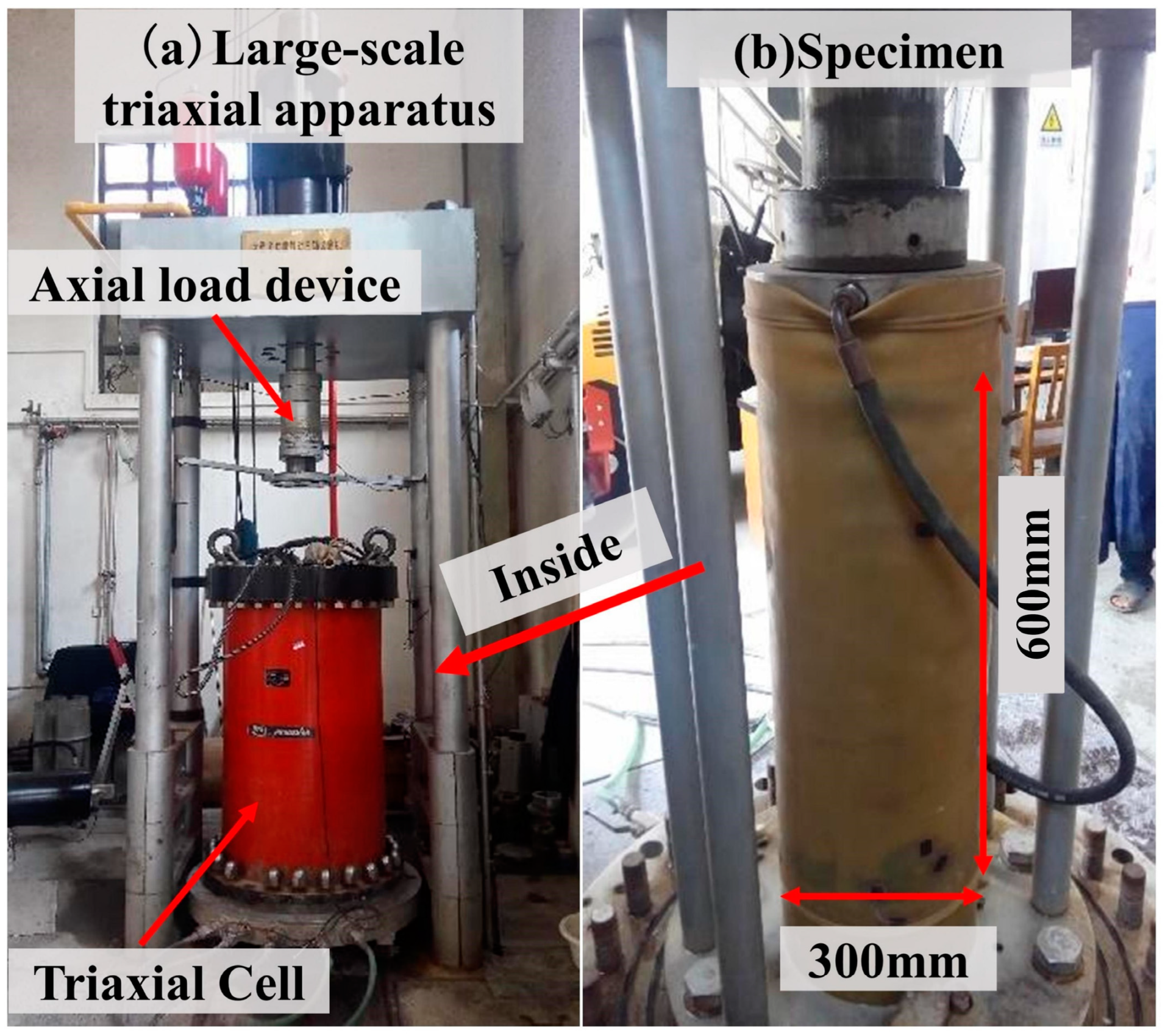

2.4. Specimen Generation

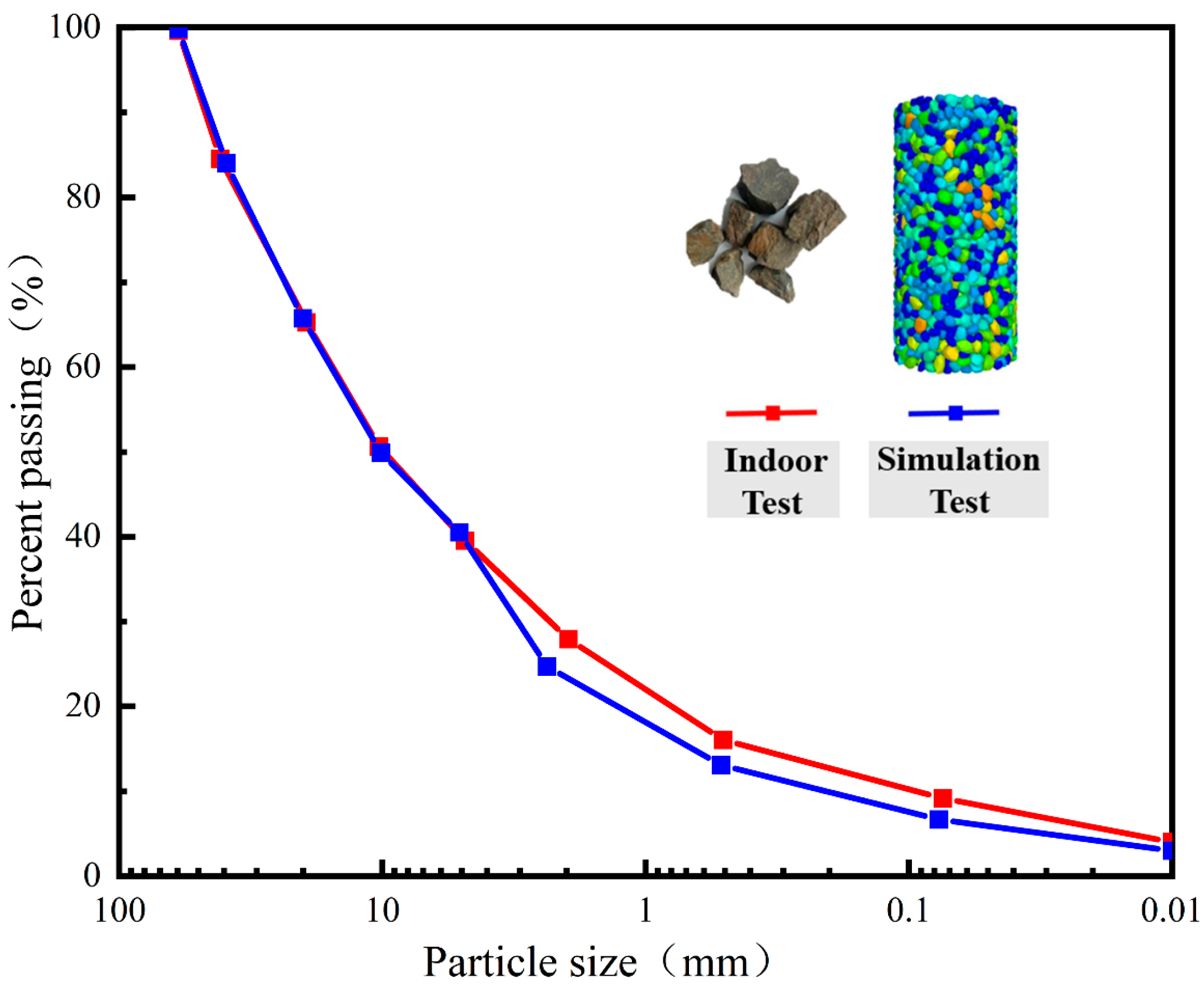

2.5. Microscopic Parameter Calibration

3. Test Results and Analysis

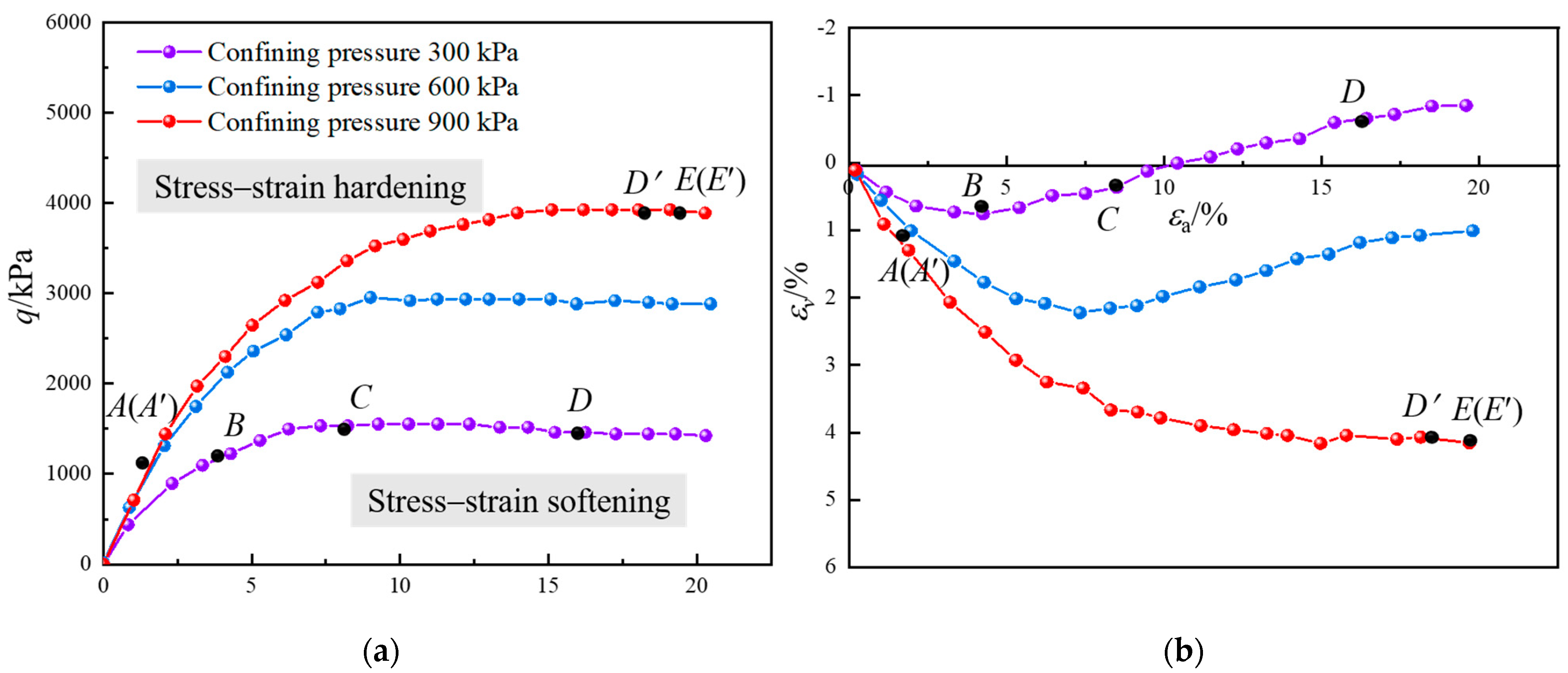

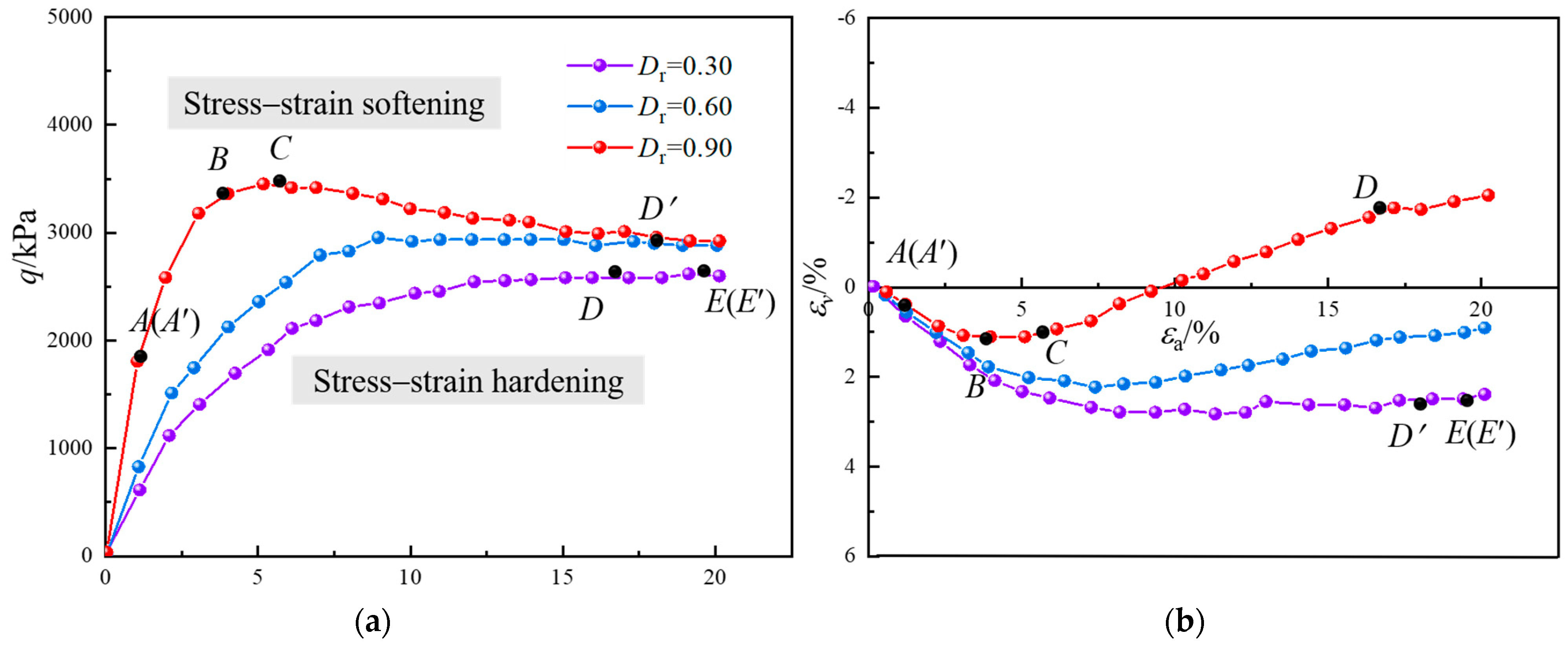

3.1. Deformation Characteristics of Rockfill Materials Considering the Effect of Density

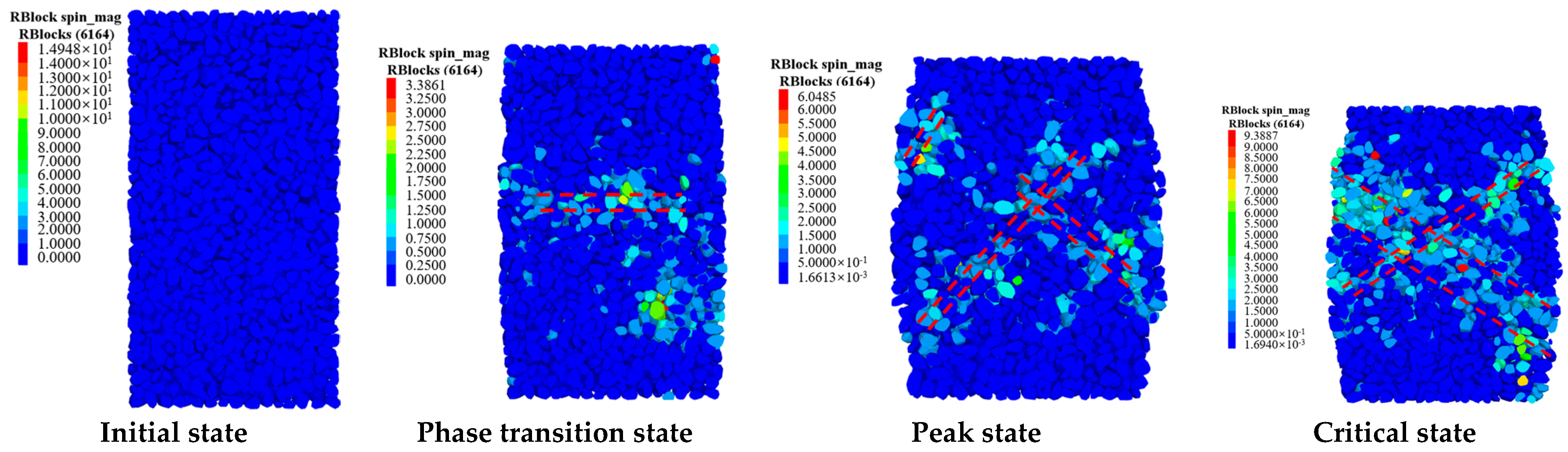

3.2. Analysis of the Microscopic-Scale Evolution of Stress-Strain Softening Type Curves

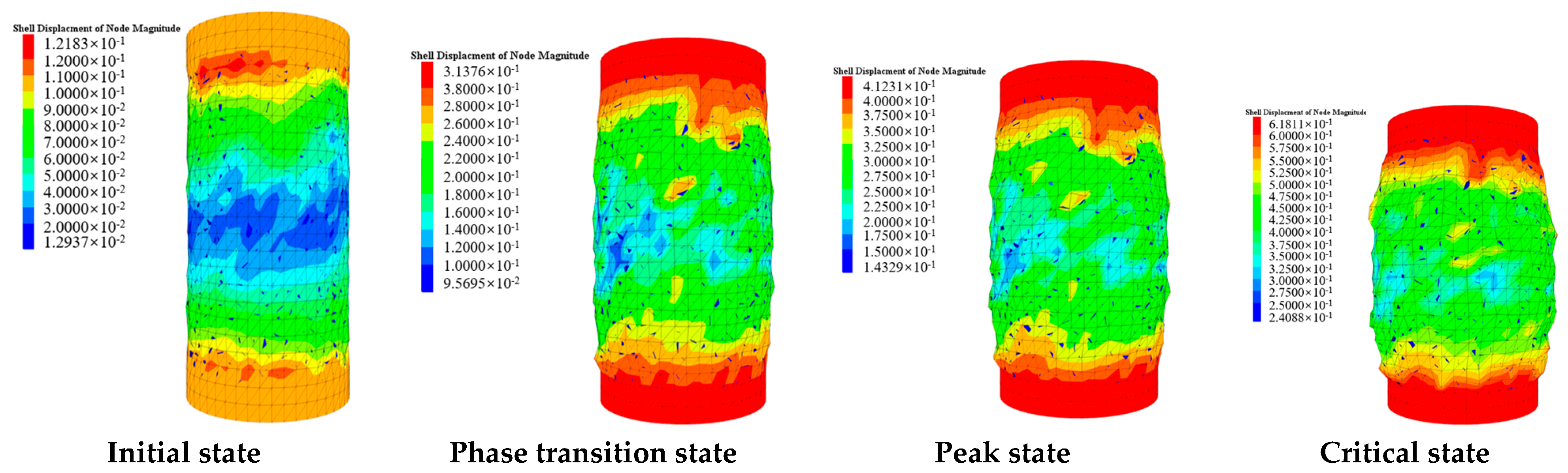

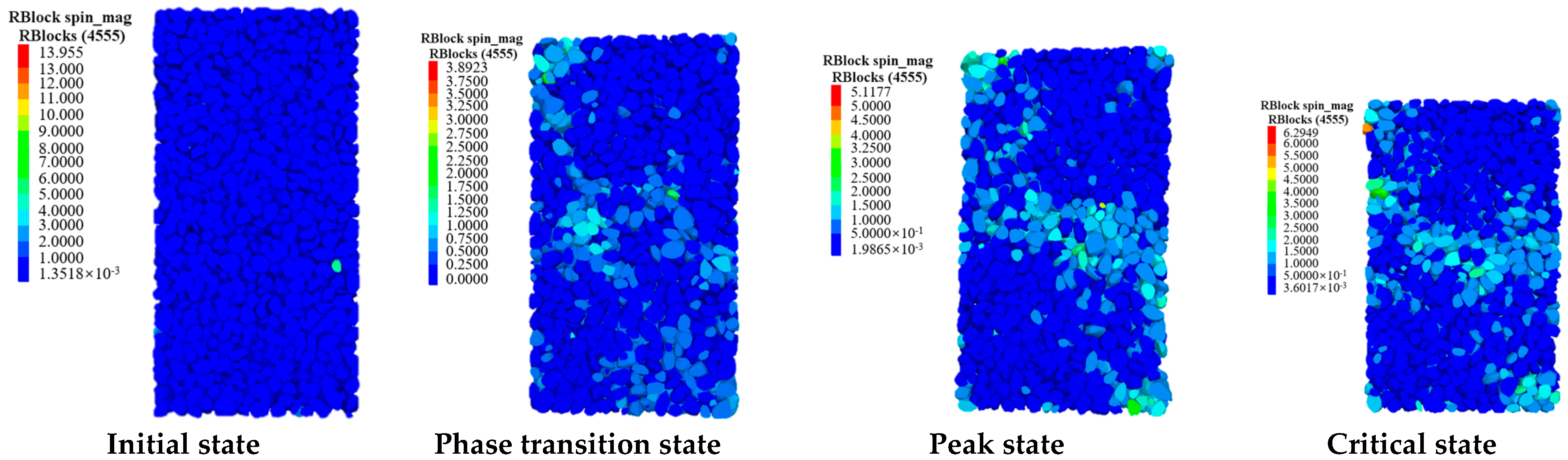

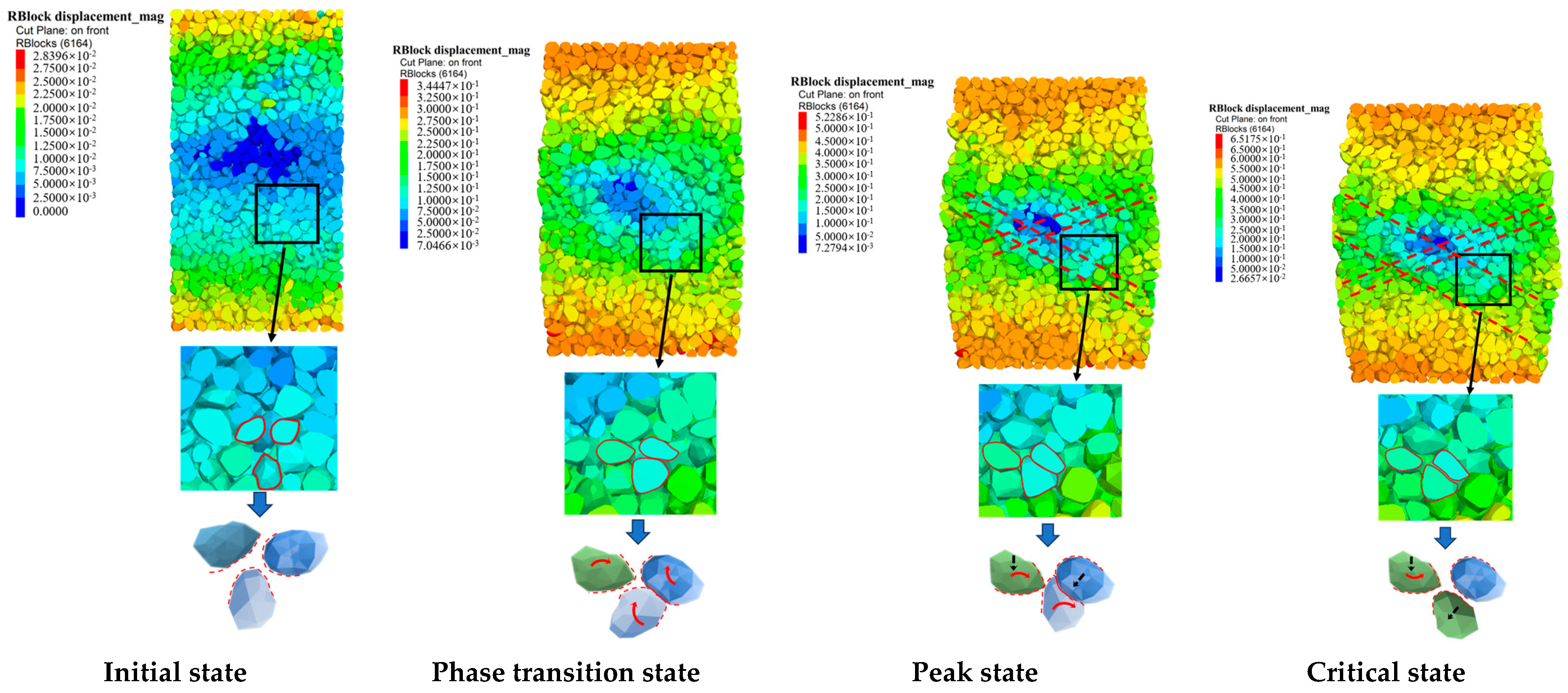

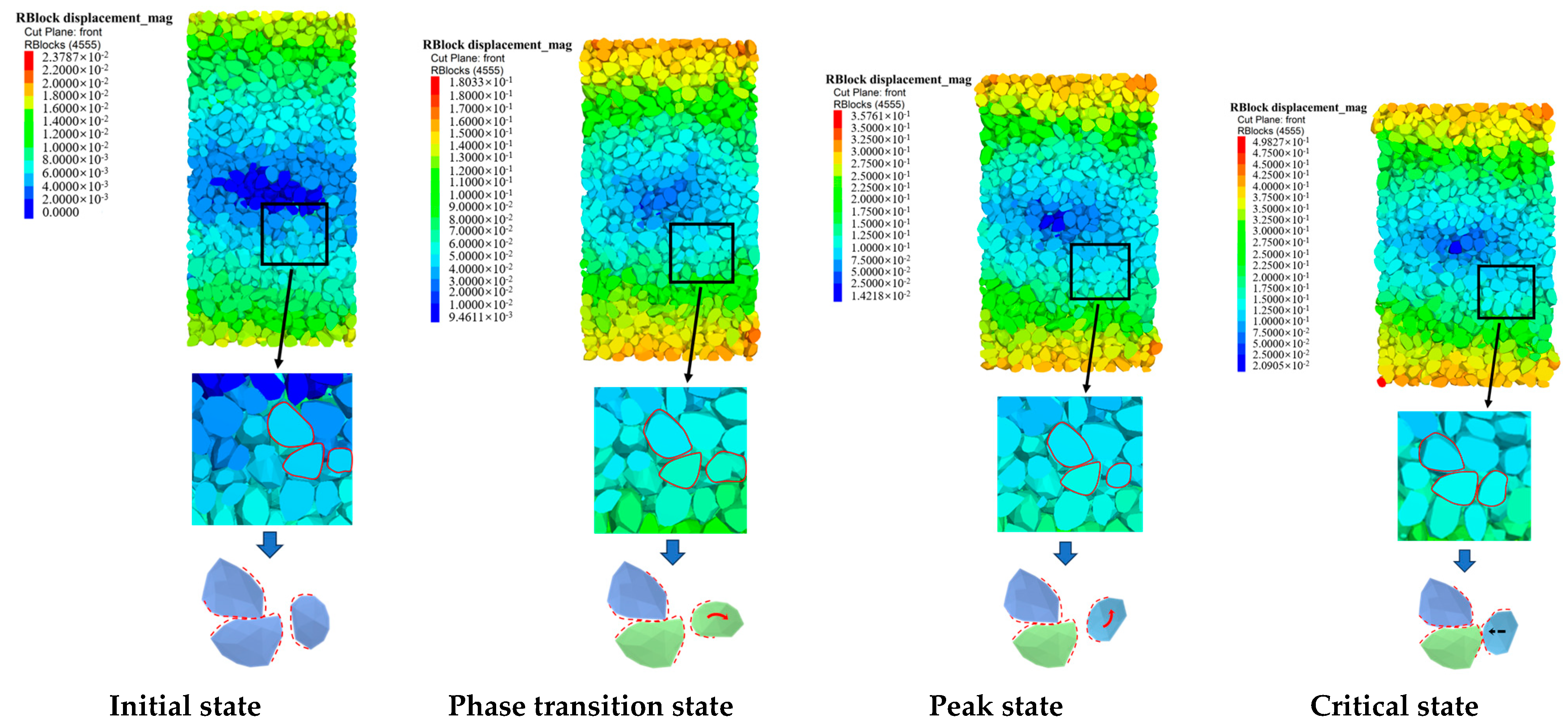

3.2.1. Flexible Boundary Displacement Shear Zone

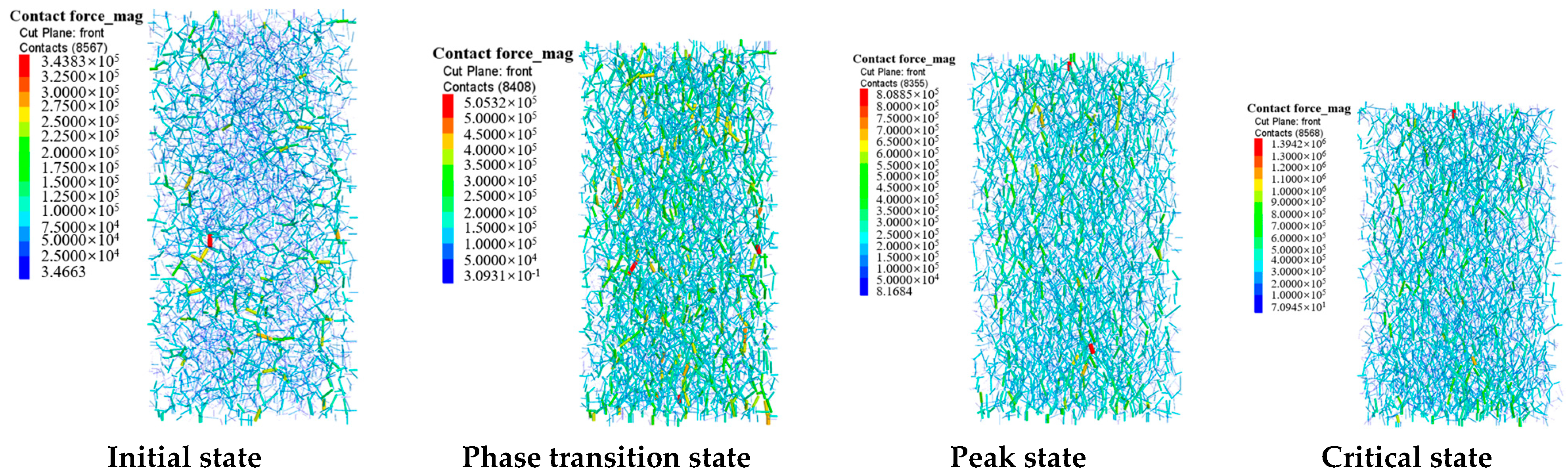

3.2.2. Contact Force Chain

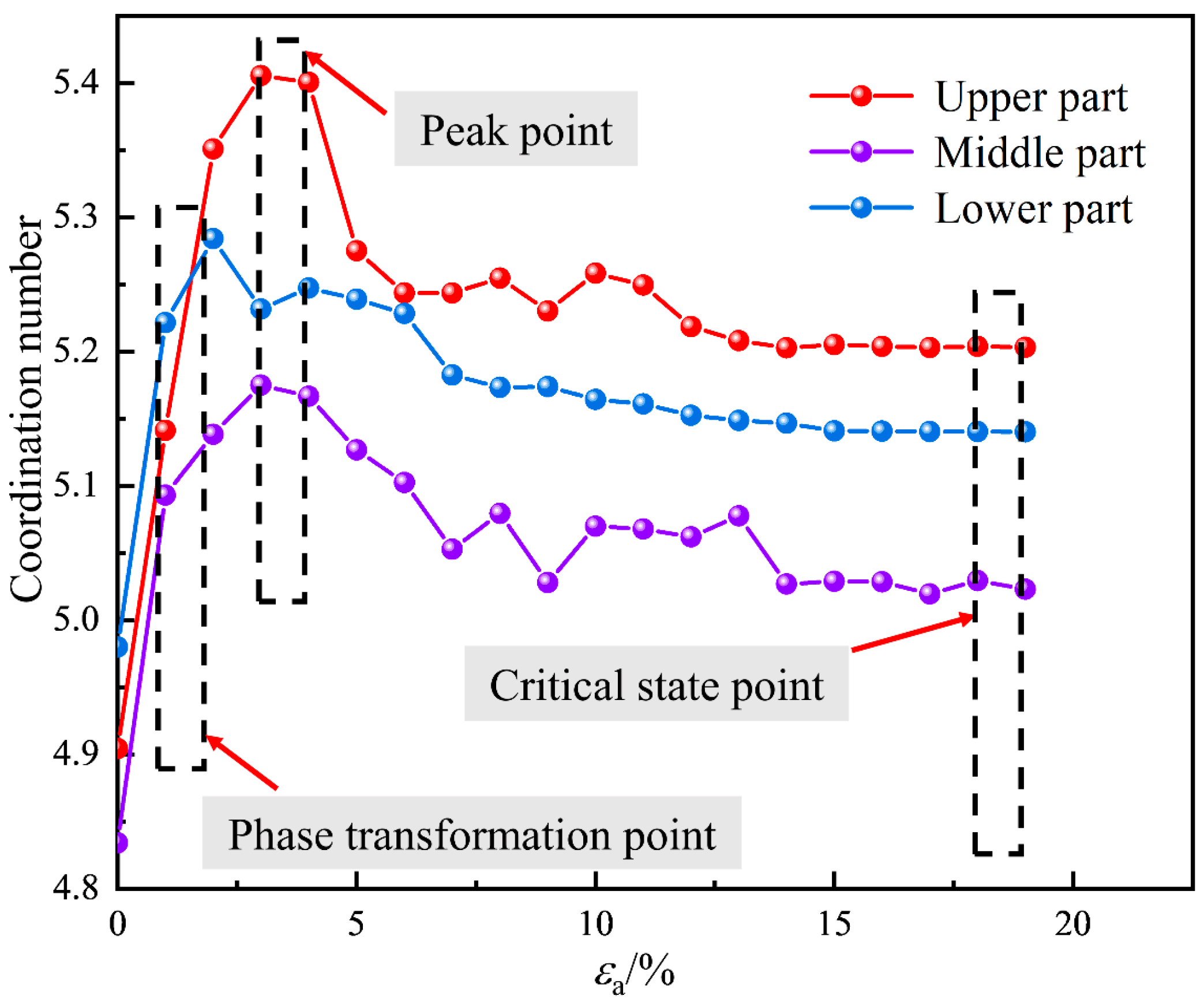

3.2.3. Coordination Number

3.3. Analysis of the Microscopic-Scale Evolution of Stress-Strain Hardening Type Curves

3.3.1. Flexible Boundary Displacement Shear Zone

3.3.2. Contact Force Chain

3.3.3. Coordination Number

4. Discussion

5. Conclusions

- (1)

- The stress-strain curve characteristics of rockfill materials can be divided into softening and hardening types. The softening type curve shows different mechanical properties in the initial, phase transition, peak, and critical states, resulting in significant shear deformation. The hardening type curve in the loading process of deviatoric stress continues to increase, and there is no obvious distinction between the phase transition, peak, and critical states; at the same time, more significant shear shrinkage deformation is produced.

- (2)

- The softening curve in the fine view shows that the displacement of the upper and lower ends of the shell unit on the flexible boundary increases with increasing loading, and the displacement of the middle ends decreases; however, the rotational deformation of the particles in the middle part of the specimen increases, and there is an “X”-type shear band. The strength of the force chain tends to increase and subsequently decrease. The coordination number is closely related to the deformation of the specimen, and it tends to increase first and subsequently decrease. The coordination number is closely related to the deformation of the specimen, showing a tendency to increase and then decrease, which corresponds to the macroscopic deformation of the specimen of shear shrinkage and then shear expansion.

- (3)

- According to the fine view of the hardening curve, with the loading of the flexible boundary on the shell unit, the softening type curve is similar to the performance of the upper and lower ends of the displacement and is large in the middle of the displacement, but the overall displacement is small. Similarly, for the specimens in the middle of the rotational deformation and the emergence of more cleavage zones rather than shear zones, the strength of the force chain continues to increase, and the coordination number of the first increases and then tends to stabilize, corresponding to macroscopic shear shrinkage deformation of the specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Göncü, F.; Luding, S. Effect of particle friction and polydispersity on the macroscopic stress—Strain relations of granular materials. Acta Geotech. 2013, 8, 629–643. [Google Scholar] [CrossRef]

- Pietruszczak, S.; Guo, P. Description of deformation process in inherently anisotropic granular materials. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 478–490. [Google Scholar] [CrossRef]

- Wan, R.G.; Guo, P.J. A simple constitutive model for granular soils: Modified stress-dilatancy approach. Comput. Geotech. 1998, 22, 109–133. [Google Scholar] [CrossRef]

- Ishihara, K.; Tatsuoka, F.; Yasuda, S. Undrained deformation and liquefaction of sand under cyclic stresses. Soils Found. 1975, 15, 29–44. [Google Scholar] [CrossRef]

- Liu, J.M.; Zou, D.G.; Kong, X.J.; Liu, H.B. Stress-dilatancy of Zipingpu gravel in triaxial compression tests. Sci. China Technol. Sci. 2016, 59, 214–224. [Google Scholar] [CrossRef]

- Kong, X.; Liu, J.; Zou, D.; Liu, H.B. Stress-dilatancy relationship of Zipingpu gravel under cyclic loading in triaxial stress states. Int. J. Geomech. 2016, 16, 04016001. [Google Scholar] [CrossRef]

- Luong, M.P. Stress-strain aspects of cohesionless soils under cyclic and transient loading. In Proceedings of the International Symposium on Soils under Cyclic and Transient Loading, Rotterdam, The Netherlands, 7–11 January 1980; Volume 1, pp. 315–324. [Google Scholar]

- Xiao, Y.; Liu, H.; Liu, H.; Chen, Y.M.; Zhang, W.G. Strength and dilatancy behaviors of dense modeled rockfill material in general stress space. Int. J. Geomech. 2016, 16, 04016015. [Google Scholar] [CrossRef]

- Roscoe, K.H.; Schofield, A.N.; Wroth, C.P. On the yielding of soils. Geotechnique 1958, 8, 22–53. [Google Scholar] [CrossRef]

- Yang, G.; Jiang, Y.; Nimbalkar, S. Influence of particle size distribution on the critical state of rockfill. Adv. Civ. Eng. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Ning, F.; Liu, J.; Kong, X. Critical state and grading evolution of rockfill material under different triaxial compression tests. Int. J. Geomech. 2020, 20, 04019154. [Google Scholar]

- Xiao, Y.; Liu, H.; Chen, Y. State-dependent constitutive model for rockfill materials. Int. J. Geomech. 2015, 15, 04014075. [Google Scholar]

- Yang, Z.X.; Wu, Y. Critical state for anisotropic granular materials: A discrete element perspective. Int. J. Geomech. 2017, 17, 04016054. [Google Scholar] [CrossRef]

- Cheng, J.; Ma, G.; Zhang, G. Deterioration of Mechanical Properties of Rockfill Materials Subjected to Cyclic Wetting–Drying and Wetting. Rock Mech. Rock Eng. 2023, 56, 2633–2647. [Google Scholar] [CrossRef]

- Chang, W.J.; Phantachang, T. Effects of gravel content on shear resistance of gravelly soils. Eng. Geol. 2016, 207, 78–90. [Google Scholar] [CrossRef]

- Liu, M.; Gao, Y.; Liu, H. An elastoplastic constitutive model for rockfills incorporating energy dissipation of nonlinear friction and particle breakage. Int. J. Numer. Anal. Methods Geomech. 2014, 38, 935–960. [Google Scholar] [CrossRef]

- Mahinroosta, R.; Alizadeh, A.; Gatmiri, B. Simulation of collapse settlement of first filling in a high rockfill dam. Eng. Geol. 2015, 187, 32–44. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Zhang, J.H.; Sun, G.L. Deformation and shear strength of rockfill materials composed of soft siltstones subjected to stress, cyclical drying/wetting and temperature variations. Eng. Geol. 2015, 190, 87–97. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Han, H.; Chen, W.; Huang, B. Numerical simulation of the influence of particle shape on the mechanical properties of rockfill materials. Eng. Comput. 2017, 34, 2228–2241. [Google Scholar] [CrossRef]

- Zhou, W.; Ma, G.; Chang, X.L. Discrete modeling of rockfill materials considering the irregular shaped particles and their crushability. Eng. Comput. 2015, 32, 1104–1120. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, L.; Shi, C. Microscopic mechanical properties of rockfill materials under different stress paths. Granul. Matter 2024, 26, 41. [Google Scholar] [CrossRef]

- Xu, M.; Hong, J.; Song, E. DEM study on the effect of particle breakage on the macro-and micro-behavior of rockfill sheared along different stress paths. Comput. Geotech. 2017, 89, 113–127. [Google Scholar] [CrossRef]

- Wu, K.; Sun, W.; Liu, S.; Zhang, X. Study of shear behavior of granular materials by 3D DEM simulation of the triaxial test in the membrane boundary condition. Adv. Powder Technol. 2021, 32, 1145–1156. [Google Scholar] [CrossRef]

- Qu, T.; Feng, Y.T.; Wang, Y. Discrete element modelling of flexible membrane boundaries for triaxial tests. Comput. Geotech. 2019, 115, 103154. [Google Scholar] [CrossRef]

- Cil, M.B.; Alshibli, K.A. 3D analysis of kinematic behavior of granular materials in triaxial testing using DEM with flexible membrane boundary. Acta Geotech. 2014, 9, 287–298. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, J.; Ma, G. Three-dimensional DEM investigation of critical state and dilatancy behaviors of granular materials. Acta Geotech. 2017, 12, 527–540. [Google Scholar] [CrossRef]

- Cai, G.; Li, J.; Liu, S. Simulation of Triaxial Tests for Unsaturated Soils under a Tension–Shear State by the Discrete Element Method. Sustainability 2022, 14, 9122. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, C.; Zhang, X. A three-dimensional discrete element model of triaxial tests based on a new flexible membrane boundary. Sci. Rep. 2021, 11, 4753. [Google Scholar] [CrossRef] [PubMed]

- Xiao, G.; Liu, S.; Zhang, Y.; Wu, Y.; Chen, B.; Song, S. A measurement method of the belt grinding allowance of hollow blades based on blue light scanning. Int. J. Adv. Manuf. Technol. 2021, 116, 3295–3303. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, X.; Zhou, X.; Zhang, Y. Experimental simulation and a reliable calibration method of rockfill microscopic parameters by considering flexible boundary. Powder Technol. 2022, 396, 279–290. [Google Scholar] [CrossRef]

- Li, J.; Konietzky, H.; Frühwirt, T. Voronoi-based DEM simulation approach for sandstone considering grain structure and pore size. Rock Mech Rock Eng. 2017, 50, 2749–2761. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, C.; Wang, S.; Zhang, Y. Vibratory compaction properties of off-shore gravity quays rubble bed based on rigid blocks. Mar. Georesources Geotechnol. 2023, 41, 1–16. [Google Scholar] [CrossRef]

- Shi, C.; Xu, W. Techniques and Practices for Numerical Simulation of Particle Flows; China Architecture & Building Press: Beijing, China, 2015; pp. 380–403. [Google Scholar]

- Shi, C.; Li, W.; Meng, Q. A dynamic strain-rate-dependent contact model and its application in Hongshiyan landslide. Geofluids 2021, 2021, 1–23. [Google Scholar] [CrossRef]

- Bu, P.; Li, Y.; Zhang, X. A calibration method of discrete element contact model parameters for bulk materials based on experimental design method. Powder Technol. 2023, 425, 118596. [Google Scholar] [CrossRef]

- Ma, C.; Yang, J.; Zenz, G. Calibration of the microparameters of the discrete element method using a relevance vector machine and its application to rockfill materials. Adv. Eng. Soft. 2020, 147, 102833. [Google Scholar] [CrossRef]

- Guo, W.L.; Cai, Z.Y.; Wu, Y.L.; Zhang, C. Dilatancy behavior of rockfill materials and its description. Eur. J. Environ. 2022, 26, 1883–1896. [Google Scholar] [CrossRef]

- Xu, M.; Hong, J.; Song, E. DEM study on the macro-and micro-responses of granular materials subjected to creep and stress relaxation. Comput. Geotech. 2018, 102, 111–124. [Google Scholar] [CrossRef]

- Pan, J.; Jiang, J.; Cheng, Z. Large-scale true triaxial test on stress-strain and strength properties of rockfill. Int. J. Geomech. 2020, 20, 04019146. [Google Scholar]

- Wang, Y.; Cui, F. Energy evolution mechanism in process of Sandstone failure and energy strength criterion. Appl. Geophys. 2018, 154, 21–28. [Google Scholar] [CrossRef]

| Materials | E/Pa | kn/(N·m–1) | ks/(N·m–1) | μ | ν | Film Thickness/(mm) |

|---|---|---|---|---|---|---|

| Particles | 55 × 109 | 7.85 × 108 | 6.28 × 108 | 0.6 | ||

| Boundary | 7.86 × 106 | — | — | 0 | 0.47 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Zhang, L.; Shi, C.; Zhang, R. Research on the Characteristic State of Rockfill Materials and the Evolution Mechanism at the Microscopic Scale. Appl. Sci. 2024, 14, 4353. https://doi.org/10.3390/app14114353

Cui Y, Zhang L, Shi C, Zhang R. Research on the Characteristic State of Rockfill Materials and the Evolution Mechanism at the Microscopic Scale. Applied Sciences. 2024; 14(11):4353. https://doi.org/10.3390/app14114353

Chicago/Turabian StyleCui, Yunchao, Lingkai Zhang, Chong Shi, and Runhan Zhang. 2024. "Research on the Characteristic State of Rockfill Materials and the Evolution Mechanism at the Microscopic Scale" Applied Sciences 14, no. 11: 4353. https://doi.org/10.3390/app14114353

APA StyleCui, Y., Zhang, L., Shi, C., & Zhang, R. (2024). Research on the Characteristic State of Rockfill Materials and the Evolution Mechanism at the Microscopic Scale. Applied Sciences, 14(11), 4353. https://doi.org/10.3390/app14114353