Study of the Kinetics of Adhesive Bond Formation Using the Ultrasonic Method

Abstract

1. Introduction

2. Ultrasonic Testing of Materials

2.1. Research Plan

2.2. Characteristics of the Study Object

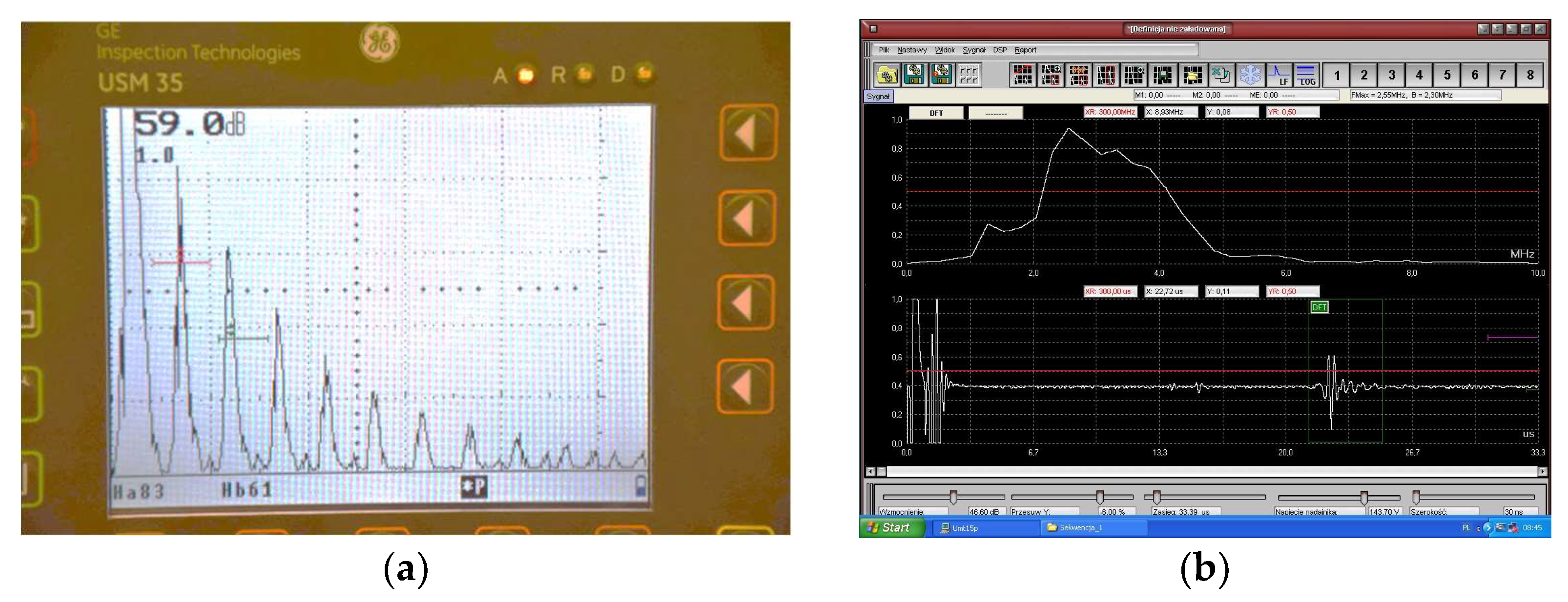

2.3. Ultrasonic Testing

2.4. Mechanical Testing

3. Results

3.1. Ultrasound Results

3.2. Mechanical Test Results

Results of the Adhesive Hardness Test

4. Discussion

5. Conclusions

- The kinetics of adhesive bond formation, determined non-destructively by both ultrasonic longitudinal and surface waves and confirmed by sample tear tests, has the character of an increasing curve in the initial stage of forming, in the adopted ultrasonic and mechanical measures of bond quality, with a tendency to stabilize after a certain period of time, marking the end of the bond formation.

- The kinetics of adhesive bond formation can be non-destructively determined using ultrasonic longitudinal and surface waves. The longitudinal wave allows for a better—in terms of inspection technology—assessment of the tested adhesive joint than the surface wave. Mechanical tests of the strength of the adhesive bond together with the adhesive hardness testing confirm the significant possibilities of the non-destructive method for determining the kinetics of the adhesive bond formation.

- The determination of the kinetics of adhesive bond formation allows for a more accurate determination of the time of formation of such a bond than before, which can be used in the planning of technological operations in the process of the construction of bodies of means of mass transport, the cyclicity of production, and the perfection of the technology for the manufacturing of these means, including non-destructive quality control of production.

- The sensitivity of ultrasonic waves (longitudinal and surface) to changes in the adhesive bond, found during our research, reveals the potential possibility of using these waves also for the study of the degradation of such bonds and—as a consequence—for the diagnosis of this type of permanent bond.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lucas, F.M.; da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology, 2nd ed.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Fay, P.A. A history of adhesive bonding. In Adhesive Bonding; Adams, R.D., Ed.; Woodhead Publishing: Sawston, UK, 2021; pp. 3–40. [Google Scholar] [CrossRef]

- Ayesha, K. Rubber toughened epoxy-based nanocomposite: A promising pathway toward advanced materials. J. Macromol. Sci. Part A 2020, 57, 499–511. [Google Scholar] [CrossRef]

- Bagheri, R.; Marouf, B.T.; Pearson, R.A. Rubber-Toughened Epoxies: A Critical Review. Polym. Rev. 2009, 49, 201–225. [Google Scholar] [CrossRef]

- Allen, J.C.P.; Ng, C.T. Debonding detection at adhesive joints using nonlinear Lamb waves mixing. NDT&E Int. 2022, 125, 102552. [Google Scholar]

- Kowalczyk, J.; Ulbrich, D.; Nowak, M.; Sędłak, K.; Gruber, K.; Kurzynowski, T.; Jósko, M. Acoustic Properties Comparison of Ti6Al4V Produced by Conventional Method and AM Technology in the Aspect of Ultrasonic Structural Health Monitoring of Adhesive Joints. Appl. Sci. 2023, 13, 371. [Google Scholar] [CrossRef]

- da Costa, P.R.; Sardinha, M.; Reis, L.; Freitas, M.; Fonte, M. Ultrasonic fatigue testing in as-built and polished Ti6Al4V alloy manufactured by SLM. Forces Mech. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Kim, C.; Yin, H.; Shmatok, A.; Prorok, B.C.; Lou, X.; Matlack, K.H. Ultrasonic nondestructive evaluation of laser powder bed fusion 316L stainless steel. Addit. Manuf. 2021, 38, 101800. [Google Scholar] [CrossRef]

- Hsia, S.Y.; Chou, Y.T. Assessing the Hardness of Quenched Medium Steel Using and Ultrasonic Nondestructive Method. Adv. Mater. Sci. Eng. 2015, 2015, 684836. [Google Scholar] [CrossRef]

- Kowalczyk, J.; Jósko, M.; Wieczorek, D.; Sędłak, K.; Nowak, M. The Influence of the Hardness of the Tested Material and the Surface Preparation Method on the Results of Ultrasonic Testing. Appl. Sci. 2023, 13, 9904. [Google Scholar] [CrossRef]

- Dey, B.K.; Sarkar, B.; Seok, H. Cost-effective smart autonomation policy for a hybrid manufacturing-remanufacturing. Comput. Ind. Eng. 2021, 162, 107758. [Google Scholar] [CrossRef]

- Yang, C.-M.; Chen, K.-S. An integrated contract manufacturer selection and product quality optimization methodology for the mechanical manufacturing industry. Expert Syst. Appl. 2021, 183, 115336. [Google Scholar] [CrossRef]

- Omair, M.; Alkahtani, M.; Ayaz, K.; Hussain, G.; Buhl, J. Supply Chain Modelling of the Automobile Multi-Stage Production Considering Circular Economy by Waste Management Using Recycling and Reworking Operations. Sustainability 2022, 14, 15428. [Google Scholar] [CrossRef]

- Hayashi, A.; Sekiguchi, Y.; Sato, C. AFM observation of sea-island structure formed by second generation acrylic adhesive. J. Adhes. 2021, 97, 155–171. [Google Scholar] [CrossRef]

- Kowalczyk, J.; Matysiak, W.; Sawczuk, W.; Wieczorek, D.; Sędłak, K.; Nowak, M. Quality Tests of Hybrid Joint–Clinching and Adhesive—Case Study. Appl. Sci. 2022, 12, 11782. [Google Scholar] [CrossRef]

- Ulbrich, D.; Psuj, G.; Wypych, A.; Bartkowski, D.; Bartkowska, A.; Stachowiak, A.; Kowalczyk, J. Inspection of Spot Welded Joints with the Use of the Ultrasonic Surface Wave. Materials 2023, 16, 7029-1–7029-16. [Google Scholar] [CrossRef] [PubMed]

- Ulbrich, D.; Kańczurzewska, M. Correlation Tests of Ultrasonic Wave and Mechanical Parameters of Spot-Welded Joints. Materials 2022, 15, 1701-1–1701-21. [Google Scholar] [CrossRef]

- Borges, C.S.; Akhavan-Safar, A.; Tsokanas, P.; Carbas, R.J.; Marques, E.A.; da Silva, L.F. From fundamental concepts to recent developments in the adhesive bonding technology: A general view. Discov Mech. Eng. 2023, 2, 8. [Google Scholar] [CrossRef]

- Sharma, R.; Gupta, A. A critical review on influencing parameters for adhesively bonded joints in composite laminates for structural applications. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Adams, R.D.; Comyn, J.; Wake, W.C. Structural Adhesive Joints in Engineering; Chapman & Hall: London, UK, 1997; p. 359. [Google Scholar]

- Arenas, J.M.; Alía, C.; Narbón, J.J.; Ocaña, R.; González, C. Considerations for the industrial application of structural adhesive joints in the aluminium–composite material bonding. Compos. Part B Eng. 2013, 44, 417–423. [Google Scholar] [CrossRef]

- Seong, M.S.; Kim, T.H.; Nguyen, K.H.; Kweon, J.H.; Choi, J.H. A parametric study on the failure of bonded single-lap joints of carbon composite and aluminum. Compos. Struct. 2008, 86, 135–145. [Google Scholar] [CrossRef]

- Arenas, J.M.; Alía, C.; Ocaña, R.; Narbón, J.J. Degradation of Adhesive Joints for Joining Composite Material with Aluminum under Immersion in Water and Motor Oil. Procedia Eng. 2013, 63, 287–294. [Google Scholar] [CrossRef][Green Version]

- Banea, M.D.; da Silva, L.F.M.; Carbas, R.J.C. Debonding on command of adhesive joints for the automotive industry, International. J. Adhes. Adhes. 2015, 59, 14–20. [Google Scholar] [CrossRef]

- Rudawska, A.; Haniecka, I.; Jaszek, M.; Stefaniuk, D. The Influence of Adhesive Compounds Biochemical Modification on the Mechanical Properties of Adhesive Joints. Polymers 2018, 10, 344. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Shi, J. Effectiveness of Surface Treatment on Bonding Performance of Starch-Based Aqueous Polymer Isocyanate Wood Adhesive. Polymers 2023, 15, 988. [Google Scholar] [CrossRef] [PubMed]

- Ulbrich, D. Monitoring the boundary of an adhesive coating to a steel substrate with an ultrasonic Rayleigh wave. Open Eng. 2022, 12, 933–945. [Google Scholar] [CrossRef]

- Takeda, T.; Yasuoka, T.; Hoshi, H.; Sugimoto, S.; Iwahori, Y. Effectiveness of flame-based surface treatment for adhesive bonding of carbon fiber reinforced epoxy matrix composites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 30–37. [Google Scholar] [CrossRef]

- Kalnins, M.; Avotins, J. Kinetics of Adhesion Interaction of Polyolefins with Metals Under Conditions of Contact Thermooxidation. J. Adhes. 1998, 68, 163–182. [Google Scholar] [CrossRef]

- Comyna, J.; de Buyl, F.; Shephardc, N.E.; Subramaniam, C. Kinetics of cure, cross link density and adhesion of water-reactive alkoxysilicone sealants. J. Adhes. Sci. Technol. 2002, 16, 1055–1071. [Google Scholar] [CrossRef]

| Transducer Name/Parameters | KD1-6 | GE20 | S6WB10WM |

|---|---|---|---|

| Number of ultrasonic transducer | 1 | 2 | 3 |

| Frequency MHz | 2.4 | 20 | 10 |

| Transducer diameter mm | 12 | 3.15 | 6 |

| Effective diameter of the beam mm | 11.64 | 3.05 | 5.82 |

| Mean wave velocity in tested material m/s | 5940 | 5940 | 5940 |

| Wavelength mm | 2.475 | 0.297 | 0.594 |

| Near field mm | 13.1 | 7.8 | 14.1 |

| Decibel drop ratio K | 0.87 | 0.87 | - |

| Sin beam divergence angle ° | 0.11 | 0.08 | - |

| Divergence angle ° | 6.1 | 4.85 | - |

| The width of the ultrasonic wave beam mm | 6.4 | 3.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalczyk, J.; Jósko, M.; Wieczorek, D.; Sędłak, K.; Nowak, M. Study of the Kinetics of Adhesive Bond Formation Using the Ultrasonic Method. Appl. Sci. 2024, 14, 163. https://doi.org/10.3390/app14010163

Kowalczyk J, Jósko M, Wieczorek D, Sędłak K, Nowak M. Study of the Kinetics of Adhesive Bond Formation Using the Ultrasonic Method. Applied Sciences. 2024; 14(1):163. https://doi.org/10.3390/app14010163

Chicago/Turabian StyleKowalczyk, Jakub, Marian Jósko, Daniel Wieczorek, Kamil Sędłak, and Michał Nowak. 2024. "Study of the Kinetics of Adhesive Bond Formation Using the Ultrasonic Method" Applied Sciences 14, no. 1: 163. https://doi.org/10.3390/app14010163

APA StyleKowalczyk, J., Jósko, M., Wieczorek, D., Sędłak, K., & Nowak, M. (2024). Study of the Kinetics of Adhesive Bond Formation Using the Ultrasonic Method. Applied Sciences, 14(1), 163. https://doi.org/10.3390/app14010163