Personalised Production in the Age of Circular Additive Manufacturing

Abstract

1. Introduction

2. Methodology and Literature Review

- Customer Co-Creation of Products;

- Additive manufacturing—3D printing;

- Additive manufacturing—4D printing;

- Human Centric and Personalised Production;

- Environmentally Sustainable Personalised production.

2.1. Mass Customisation and Mass Personalisation

2.2. Customer Co-Creation of Products

2.3. Additive Manufacturing—3D Printing

2.4. Additive Manufacturing—4D Printing

2.5. Human Centric and Personalised Production

2.6. Environmentally Sustainable Personalised Production

2.7. Research Gaps Identified

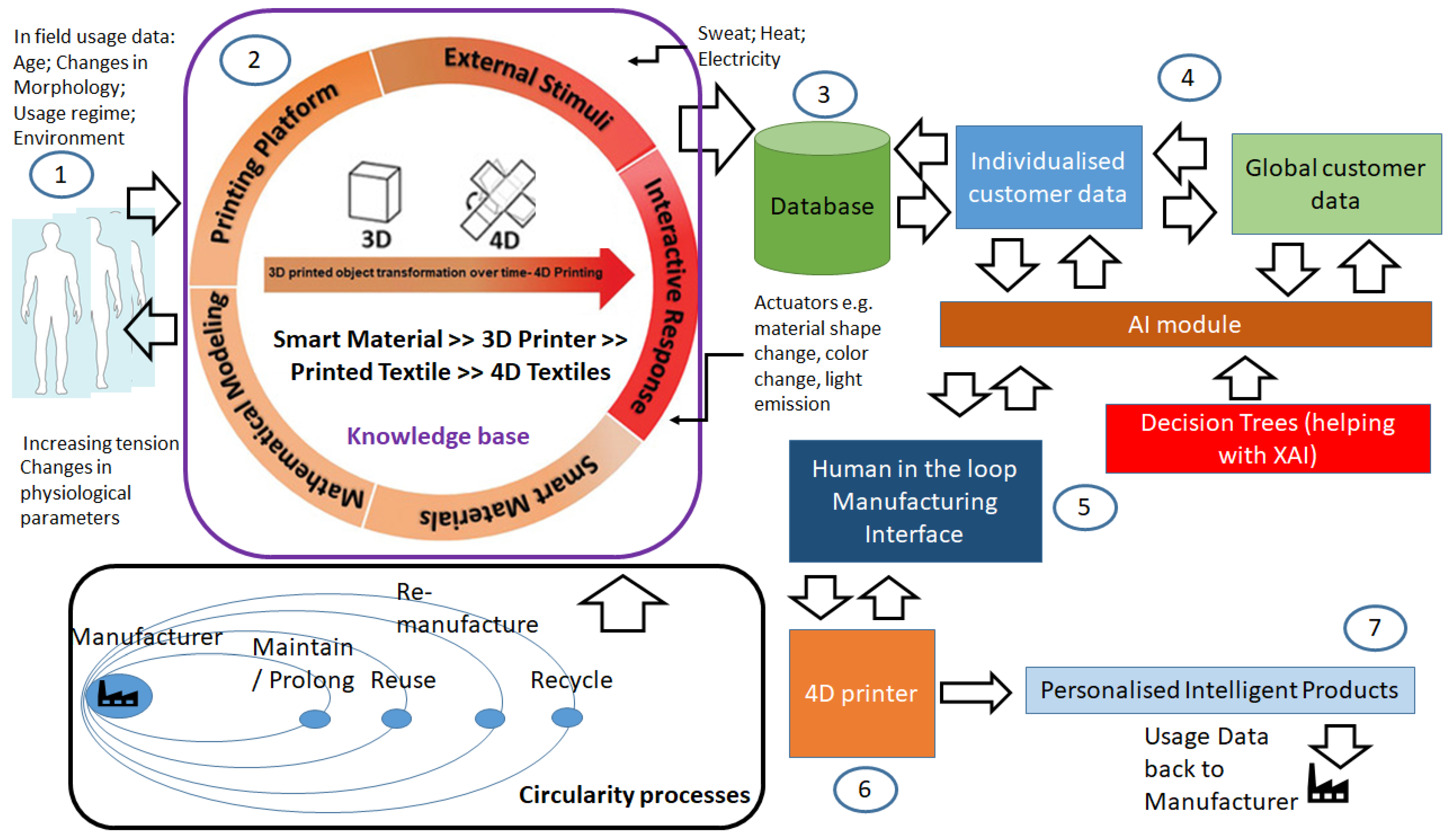

3. Framework for Circular Production of Additively Manufactured Personalised Products

- Core temperature;

- Pulse rate;

- Sweat;

- Walking pace and physical activity levels;

- Changes in morphology and strength due to age.

- Smart materials—3D printed material that are able to change over time [37] and contain sensors and miniaturised (Edge) processing functionality;

- Interactive response—smart materials that are capable of measuring physiological changes such as the temperature of a human wearer of a garment, for example;

- Mathematical modelling—the degree and nature of the shape change of 4D printed smart materials may be predicted using such techniques [37], along with sensor outputs from the materials (when integrated in the materials);

- Printing platform—the type of printer used to produce the materials and its control by software based systems, whether it is 3D or 4D capable [37];

- External stimuli—exemplified by advances such as soft robotics, where smart materials aid the robot in working safely alongside a human worker [37].

3.1. Potential Information Flows Possible in the Framework—With Uses

- Sensor data:

- o

- Produced by Wearable sensors.

- Human in the loop:

- o

- Customer interactions—personalisation and product co-creation.

- Reuse, remanufacture, recycling:

- o

- Inclusion of new processes for reuse, remanufacture, and recycling;

- o

- Product ‘in use’ health data (product maintenance purposes);

- o

- Inclusion of new materials and their relationship with Reuse, remanufacture and recycling decisions.

- 4D printer:

- o

- Optimisation potential of design and printing process used to form product based on real time manufacturing status feedback from the printer;

- o

- Monitoring of materials and energy use in real-time.

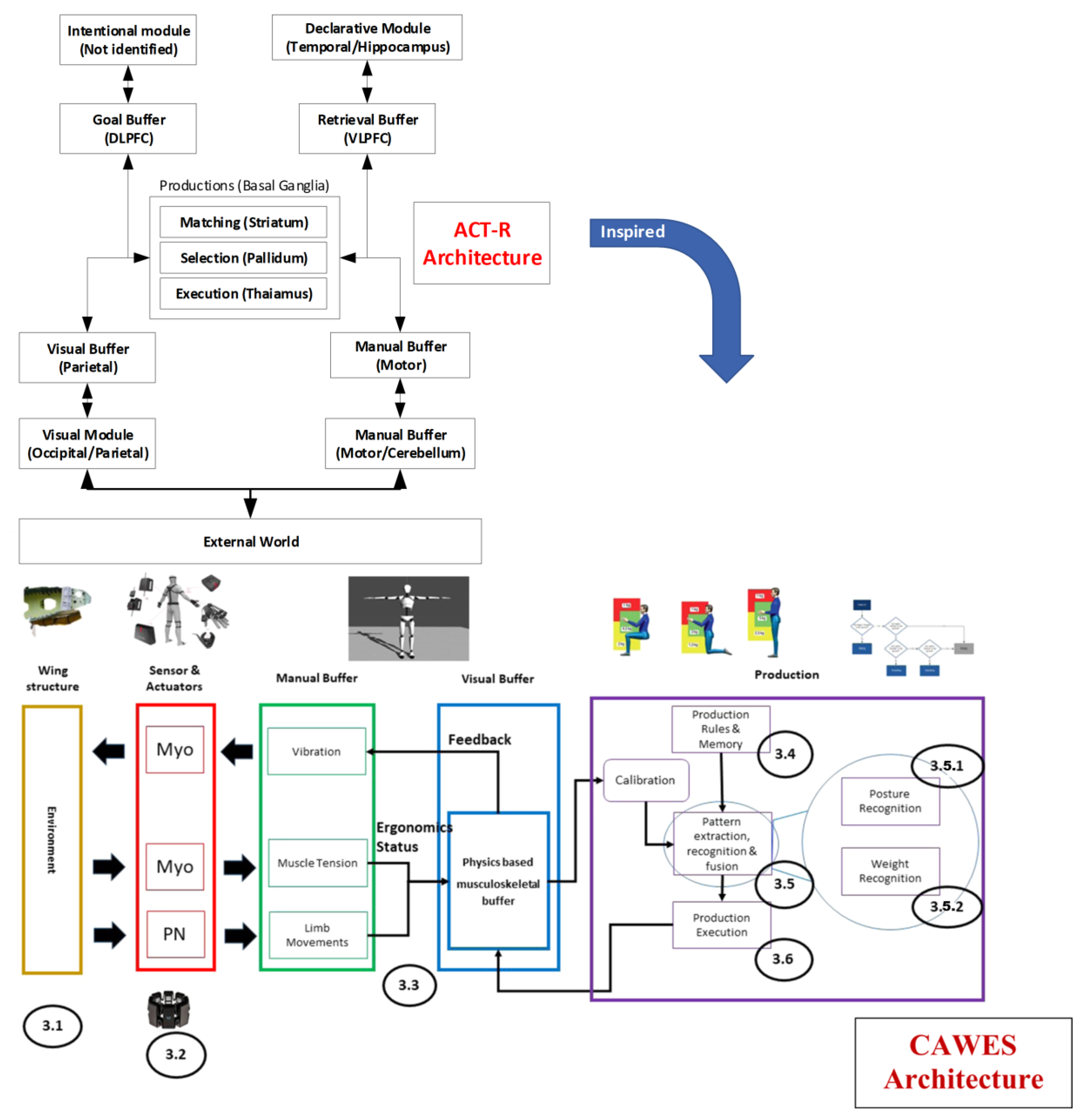

3.2. Data from Wearable Sensors for Use in the Redesign of Manufacturing Activities

3.3. Human in the Loop

- Brain—machine interface;

- Speech and gesture recognition;

- Artificial intelligence that enhances human creativity, analytical and decision making skills;

- Digital twin and simulation;

- Causality based AI.

3.4. Product and Materials Reuse, Remanufacture and Recycling

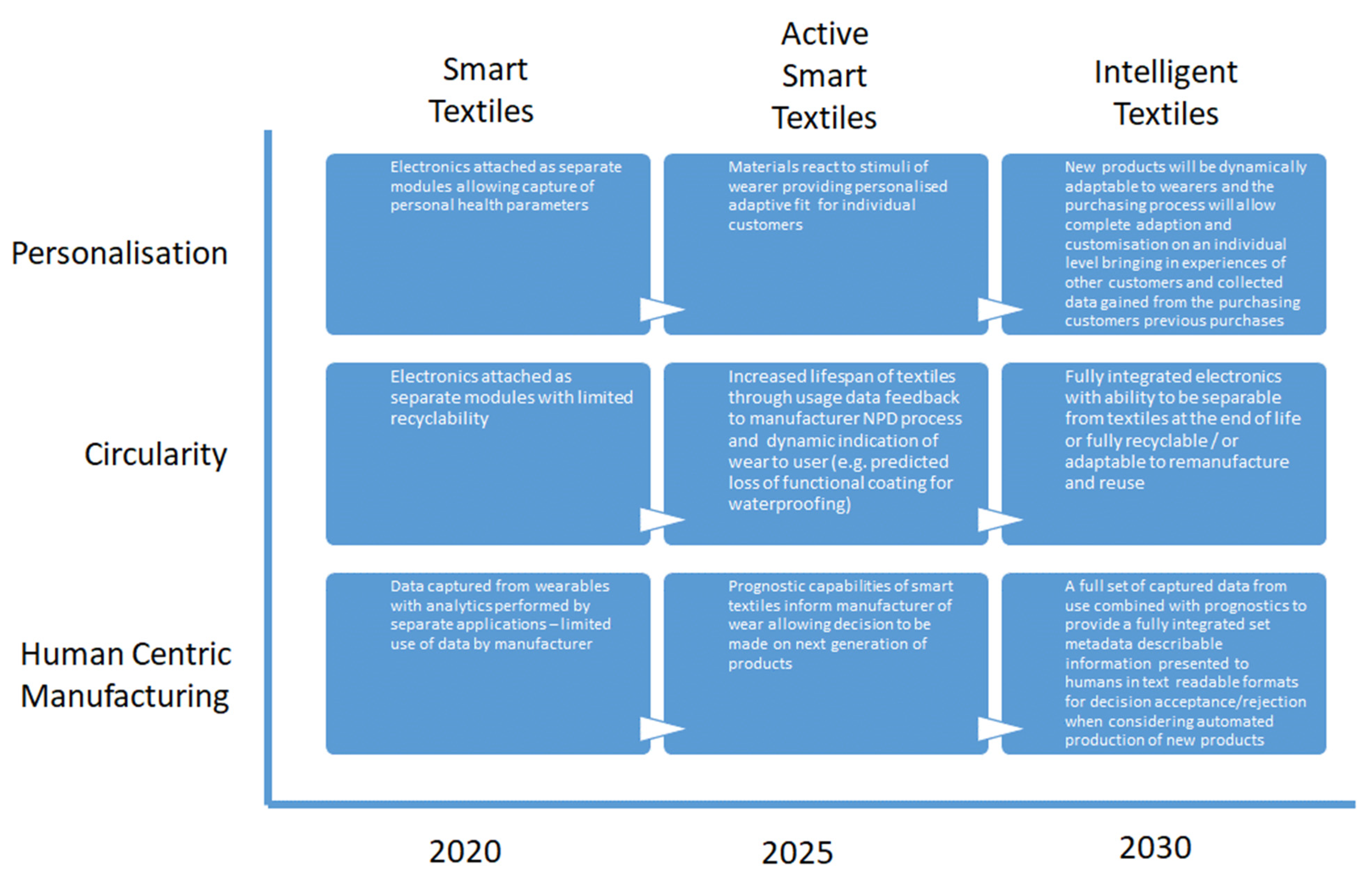

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef]

- Pollard, D.; Chuo, S.; Lee, B. Strategies For Mass Customization. J. Bus. Econ. Res. (JBER) 2008, 6. [Google Scholar] [CrossRef]

- Lee, H.-H.; Chang, E. Consumer Attitudes Toward Online Mass Customization: An Application of Extended Technology Acceptance Model. J. Comput. Commun. 2011, 16, 171–200. [Google Scholar] [CrossRef]

- Kumar, A. From mass customization to mass personalization: A strategic transformation. Int. J. Flex. Manuf. Syst. 2007, 19, 533–547. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef]

- Zhou, F.; Ji, Y.; Jiao, R.J. Affective and cognitive design for mass personalization: Status and prospect. J. Intell. Manuf. 2013, 24, 1047–1069. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M. Design and planning of manufacturing networks for mass customisation and personalisation: Challenges and Outlook. In Proceedings of the 2nd Cirp Robust Manufacturing Conference (Romac 2014), Bremen, Germany, 7–9 July 2014; Volume 19, pp. 1–13. [Google Scholar]

- Koren, Y.; Shpitalni, M.; Gu, P.; Hu, S. Product Design for Mass-Individualization. Procedia CIRP 2015, 36, 64–71. [Google Scholar] [CrossRef]

- Guo, D.; Ling, S.; Li, H.; Ao, D.; Zhang, T.; Rong, Y.; Huang, G.Q. A framework for personalized production based on digital twin, blockchain and additive manufacturing in the context of Industry 4.0. In Proceedings of the 2020 IEEE 16th International Conference on Automation Science and Engineering (CASE), Hong Kong, China, 20–21 August 2020; pp. 1181–1186. [Google Scholar] [CrossRef]

- Berry, C.; Wang, H.; Hu, S.J. Product architecting for personalization. J. Manuf. Syst. 2013, 32, 404–411. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, L.; Zhao, X.; Zhou, W. Modularity in building mass customization capability: The mediating effects of customization knowledge utilization and business process improvement. Technovation 2014, 34, 678–687. [Google Scholar] [CrossRef]

- Mourtzis, D. Challenges and future perspectives for the life cycle of manufacturing networks in the mass customisation era. Logist. Res. 2016, 9, 1–20. [Google Scholar] [CrossRef]

- Aheleroff, S.; Philip, R.; Zhong, R.Y.; Xu, X. The Degree of Mass Personalisation under Industry 4.0. Procedia CIRP 2019, 81, 1394–1399. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Hsiao, W.P.; Chiu, M.C. A mass personalization methodology based on co-creation. In Moving Integrated Product Development to Service Clouds in the Global Economy; Ios Press: Amsterdam, The Netherlands, 2014; pp. 698–705. [Google Scholar] [CrossRef]

- Prendeville, S.; Bocken, N. Sustainable Business Models through Service Design. Procedia Manuf. 2017, 8, 292–299. [Google Scholar] [CrossRef]

- Tseng, M.M.; Wang, Y.; Jiao, R.J. Mass Customization. In CIRP Encyclopedia of Production Engineering; Laperrière, L., Reinhart, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Mandolfo, M.; Chen, S.; Noci, G. Co-creation in new product development: Which drivers of consumer participation? Int. J. Eng. Bus. Manag. 2020, 12. [Google Scholar] [CrossRef]

- Rathore, A.K.; Ilavarasan, P.V.; Dwivedi, Y.K. Social media content and product co-creation: An emerging paradigm. J. Enterp. Inf. Manag. 2016, 29, 7–18. [Google Scholar] [CrossRef]

- Zheng, P.; Lin, Y.; Chen, C.-H.; Xu, X. Smart, connected open architecture product: An IT-driven co-creation paradigm with lifecycle personalization concerns. Int. J. Prod. Res. 2019, 57, 2571–2584. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, J.; Gou, H.; Tan, J. A Research Review on the Key Technologies of Intelligent Design for Customized Products. Engineering 2017, 3, 631–640. [Google Scholar] [CrossRef]

- Liu, Z.; Ming, X.; Song, W.; Qiu, S.; Qu, Y. A perspective on value co-creation-oriented framework for smart product-service system. Procedia CIRP 2018, 73, 155–160. [Google Scholar] [CrossRef]

- Chang, C.-H. Do green motives influence green product innovation? The mediating role of green value co-creation. Corp. Soc. Responsib. Environ. Manag. 2018, 26, 330–340. [Google Scholar] [CrossRef]

- Roberts, D.L.; Palmer, R.; Hughes, M. Innovating the product innovation process to enable co-creation. RD Manag. 2022, 52, 484–497. [Google Scholar] [CrossRef]

- Sjödin, D.R.; Parida, V.; Lindström, J. Barriers and conditions of open operation: A customer perspective on value co-creation for integrated product-service solutions. Int. J. Technol. Mark. 2017, 12, 90. [Google Scholar] [CrossRef]

- Leclercq, T.; Poncin, I.; Hammedi, W. The Engagement Process During Value Co-Creation: Gamification in New Product-Development Platforms. Int. J. Electron. Commer. 2017, 21, 454–488. [Google Scholar] [CrossRef]

- Alimamy, S.; Deans, K.R.; Gnoth, J. The Role of Augmented Reality in the Interactivity of Co-Creation: A critical review. Int. J. Technol. Hum. Interact. 2018, 14, 88–104. [Google Scholar] [CrossRef]

- Cowan, K.; Ketron, S. A dual model of product involvement for effective virtual reality: The roles of imagination, co-creation, telepresence, and interactivity. J. Bus. Res. 2019, 100, 483–492. [Google Scholar] [CrossRef]

- Despeisse, M.; Ford, S. The role of additive manufacturing in improving resource efficiency and sustainability. In Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth: APMS 2015. IFIP Advances in Information and Communication Technology; Umeda, S., Nakano, M., Mizuyama, H., Hibino, H., Kiritsis, D., von Cieminski, G., Eds.; Springer: Cham, Switzerland, 2015; Volume 460. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Cui, J.; Ren, L.; Mai, J.; Zheng, P.; Zhang, L. 3D Printing in the Context of Cloud Manufacturing. Robot. Comput.-Integr. Manuf. 2022, 74, 102256. [Google Scholar] [CrossRef]

- Kang, H.S.; Noh, S.D.; Son, J.Y.; Kim, H.; Park, J.H.; Lee, J.Y. The FaaS system using additive manufacturing for personalized production. Rapid Prototyp. J. 2018, 24, 1486–1499. [Google Scholar] [CrossRef]

- Seoane-Viaño, I.; Januskaite, P.; Alvarez-Lorenzo, C.; Basit, A.W.; Goyanes, A. Semi-solid extrusion 3D printing in drug delivery and biomedicine: Personalised solutions for healthcare challenges. J. Control. Release 2021, 332, 367–389. [Google Scholar] [CrossRef]

- Trenfield, S.J.; Awad, A.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D Printing Pharmaceuticals: Drug Development to Frontline Care. Trends Pharmacol. Sci. 2018, 39, 440–451. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. Opportunities and challenges in IoT-enabled circular business model implementation—A case study. Resour. Conserv. Recycl. 2020, 162, 105047. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Chen, A.Y.; Pegg, E.; Chen, A.; Jin, Z.; Gu, G.X. 4D Printing of Electroactive Materials. Adv. Intell. Syst. 2021, 3, 2100019. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Kouzani, A. Closed-loop 4D-printed soft robots. Mater. Des. 2020, 188, 108411. [Google Scholar] [CrossRef]

- Huang, J.; Xia, S.; Li, Z.; Wu, X.; Ren, J. Applications of four-dimensional printing in emerging directions: Review and prospects. J. Mater. Sci. Technol. 2021, 91, 105–120. [Google Scholar] [CrossRef]

- Subeshan, B.; Baddam, Y.; Asmatulu, E. Current progress of 4D-printing technology. Prog. Addit. Manuf. 2021, 6, 495–516. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2019, 29, 1805290. [Google Scholar] [CrossRef]

- Anas, S.; Khan, M.Y.; Rafey, M.; Faheem, K. Concept of 5D printing technology and its applicability in the healthcare industry. Mater. Today: Proc. 2022, 56, 1726–1732. [Google Scholar] [CrossRef]

- Aheleroff, S.; Zhong, R.Y.; Xu, X. A Digital Twin Reference for Mass Personalization in Industry 4.0. Procedia CIRP 2020, 93, 228–233. [Google Scholar] [CrossRef]

- Park, K.T.; Lee, J.; Kim, H.-J.; Noh, S.D. Digital twin-based cyber physical production system architectural framework for personalized production. Int. J. Adv. Manuf. Technol. 2020, 106, 1787–1810. [Google Scholar] [CrossRef]

- Ramesh, A.; Qin, Z.; Lu, Y. Digital Thread Enabled Manufacturing Automation Towards Mass Personalization. In Proceedings of the International Manufacturing Science and Engineering Conference, Virtual, 3 September 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84263, p. V002T07A008. [Google Scholar] [CrossRef]

- Sakowski, A.; Dangelmaier, M.; Hertwig, M.; Spath, D. Bidirectional Interoperability of Product Engineering and Manufacturing Enhancing Mass Customization. Procedia Manuf. 2019, 39, 81–89. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Zhang, R.; Shafiee, S.; Li, C. A “User-Knowledge-Product” Co-Creation Cyberspace Model for Product Innovation. Complexity 2020, 2020, 7190169. [Google Scholar] [CrossRef]

- Mladineo, M.; Zizic, M.C.; Aljinovic, A.; Gjeldum, N. Towards a knowledge-based cognitive system for industrial application: Case of personalized products. J. Ind. Inf. Integr. 2021, 27, 100284. [Google Scholar] [CrossRef]

- Ogunsakin, R.; Marin, C.A.; Mehandjiev, N. Towards engineering manufacturing systems for mass personalisation: A stigmergic approach. Int. J. Comput. Integr. Manuf. 2021, 34, 341–369. [Google Scholar] [CrossRef]

- Suginouchi, S.; Kokuryo, D.; Kaihara, T. Value Co-creative Manufacturing System for Mass Customization: Concept of Smart Factory and Operation Method Using Autonomous Negotiation Mechanism. Procedia CIRP 2017, 63, 727–732. [Google Scholar] [CrossRef]

- Xia, M.; He, Y. Research on the Construction of Smart Factory for Mass Personalization Production. In Proceedings of the 2020 IEEE Conference on Telecommunications, Optics and Computer Science (TOCS), Shenyang, China, 11–13 December 2020; pp. 247–251. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0. towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Hirica, A. Industry 5.0—Are Designers Leading the Way? Des. Manag. Rev. 2021, 32, 12–17. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Tiihonen, J.; Felfernig, A. An introduction to personalization and mass customization. J. Intell. Inf. Syst. 2017, 49, 1–7. [Google Scholar] [CrossRef]

- Gembarski, P.C.; Schoormann, T.; Schreiber, D.; Knackstedt, R.; Lachmayer, R. Effects of Mass Customization on Sustainability: A Literature-Based Analysis. In Customization 4.0; Springer: Cham, Switzerland, 2018; pp. 285–300. [Google Scholar] [CrossRef]

- Jackson, M.; Zaman, A. Factory-in-a-box–mobile production capacity on demand. Int. J. Mod. Eng. 2007, 8, 12–26. [Google Scholar]

- Prendeville, S.; Hartung, G.; Purvis, E.; Brass, C.; Hall, A. Makespaces: From Redistributed Manufacturing to a Circular Economy. In International Conference on Sustainable Design and Manufacturing; Springer: Cham, Switzerland, 2016; pp. 577–588. [Google Scholar]

- Torn, I.; Vaneker, T. Mass Personalization with Industry 4.0 by SMEs: A concept for collaborative networks. Procedia Manuf. 2019, 28, 135–141. [Google Scholar] [CrossRef]

- Kreiger, M.; Pearce, J.M. Environmental Life Cycle Analysis of Distributed Three-Dimensional Printing and Conventional Manufacturing of Polymer Products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Garn, W.; Duggan, C.; Abdou, K. Human Centric Manufacturing in the Circular Economy: A new Agenda for Intelligent Products in Industry 5.0. Sustainability 2022, 14, 14847. [Google Scholar] [CrossRef]

- Lancos, L.; Thronickle, W.; Ristol, S. Smart Fabrics White Paper. Atos: France, 2017; pp. 1–20. Available online: https://atos.net/wp-content/uploads/2018/01/atos-smartfabric-white-paper-1.pdf (accessed on 23 August 2022).

- Oyekan, J.; Chen, Y.; Turner, C.; Tiwari, A. Applying a fusion of wearable sensors and a cognitive inspired architecture to real-time ergonomics analysis of manual assembly tasks. J. Manuf. Syst. 2021, 61, 391–405. [Google Scholar] [CrossRef]

- Lebiere, C.; Archer, R.; Warwick, W.; Schunk, D. Integrating modelling and simulation into a general-purpose tool. In Proceedings of the 11th International Conference on Human-Computer Interaction, Las Vegas, NV, USA, 22–27 July 2005; pp. 22–27. [Google Scholar]

- Turner, C.J.; Ma, R.; Chen, J.; Oyekan, J. Human in the Loop: Industry 4.0 technologies and scenarios for worker mediation of automated manufacturing. IEEE Access 2021, 9, 103950–103966. [Google Scholar] [CrossRef]

- Müller, J. Enabling technologies for industry 5.0, results of a workshop with europe’s technology leaders. In EU Directorate-General for Research and Innovation; Publications Office: Luxembourg, 2020. [Google Scholar]

- Turner, C.; Okorie, O.; Emmanouilidis, C.; Oyekan, J. XAI Sustainable Human in the Loop Maintenance. In Proceedings of the Advanced Maintenance Engineering, Services and Technology (AMEST), Bogota, Columbia, 26–29 July 2022. [Google Scholar] [CrossRef]

- Nonaka, I.; von Krogh, G. Perspective—Tacit Knowledge and Knowledge Conversion: Controversy and Advancement in Organizational Knowledge Creation Theory. Organ. Sci. 2009, 20, 635–652. [Google Scholar] [CrossRef]

- Turner, C.; Okorie, O.; Emmanouilidis, C.; Oyekan, J. Circular production and maintenance of automotive parts: An Internet of Things (IoT) data framework and practice review. Comput. Ind. 2022, 136, 103593. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turner, C.; Oyekan, J. Personalised Production in the Age of Circular Additive Manufacturing. Appl. Sci. 2023, 13, 4912. https://doi.org/10.3390/app13084912

Turner C, Oyekan J. Personalised Production in the Age of Circular Additive Manufacturing. Applied Sciences. 2023; 13(8):4912. https://doi.org/10.3390/app13084912

Chicago/Turabian StyleTurner, Chris, and John Oyekan. 2023. "Personalised Production in the Age of Circular Additive Manufacturing" Applied Sciences 13, no. 8: 4912. https://doi.org/10.3390/app13084912

APA StyleTurner, C., & Oyekan, J. (2023). Personalised Production in the Age of Circular Additive Manufacturing. Applied Sciences, 13(8), 4912. https://doi.org/10.3390/app13084912