Mixtures of Cationic Linear Polymer and Anionic Polymeric Microspheres for Stabilization of Sand: Physicochemical, Structural and Mechanical Study

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

3. Results and Discussion

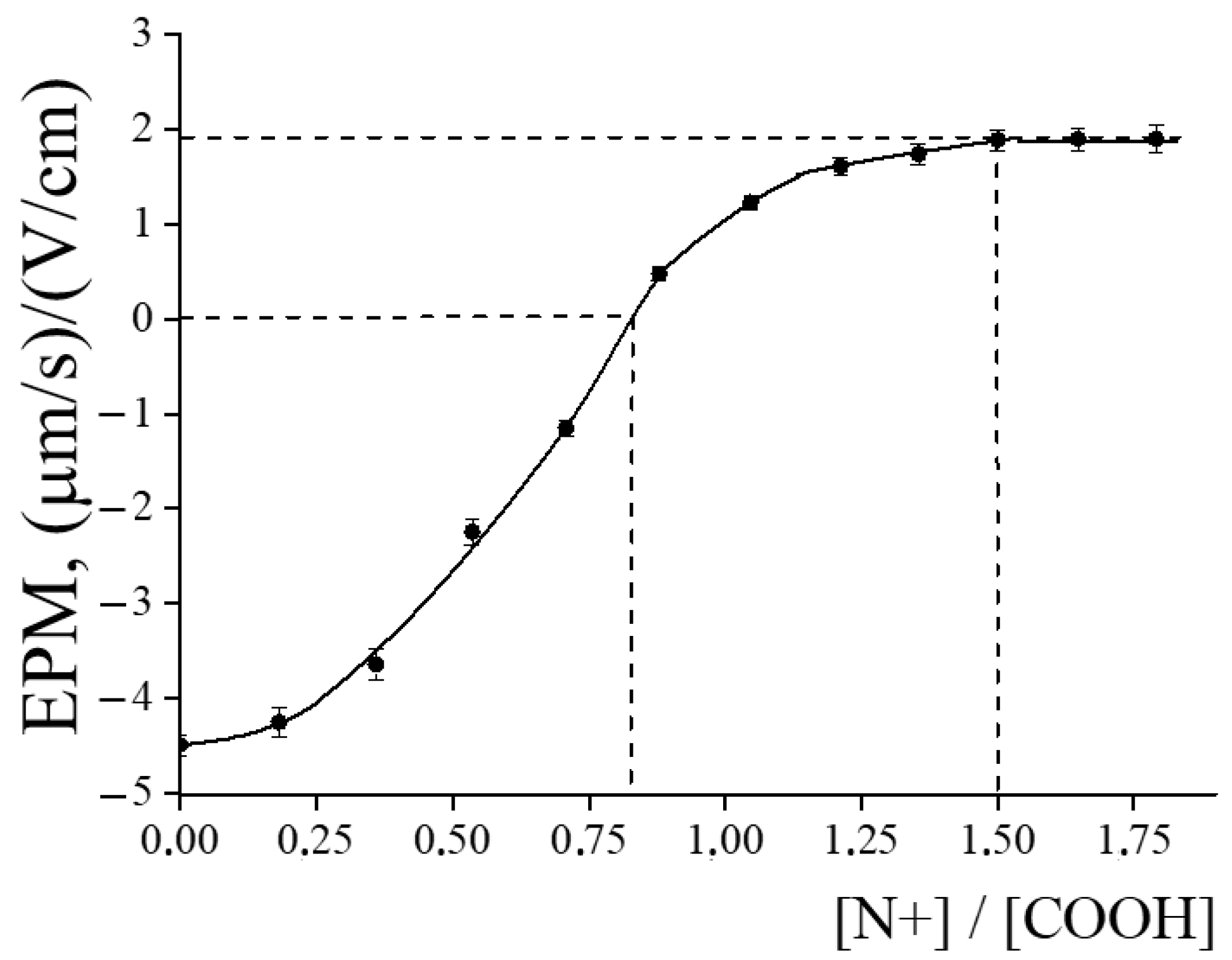

3.1. Formation of BSM–PDADCAC Binary Formulations

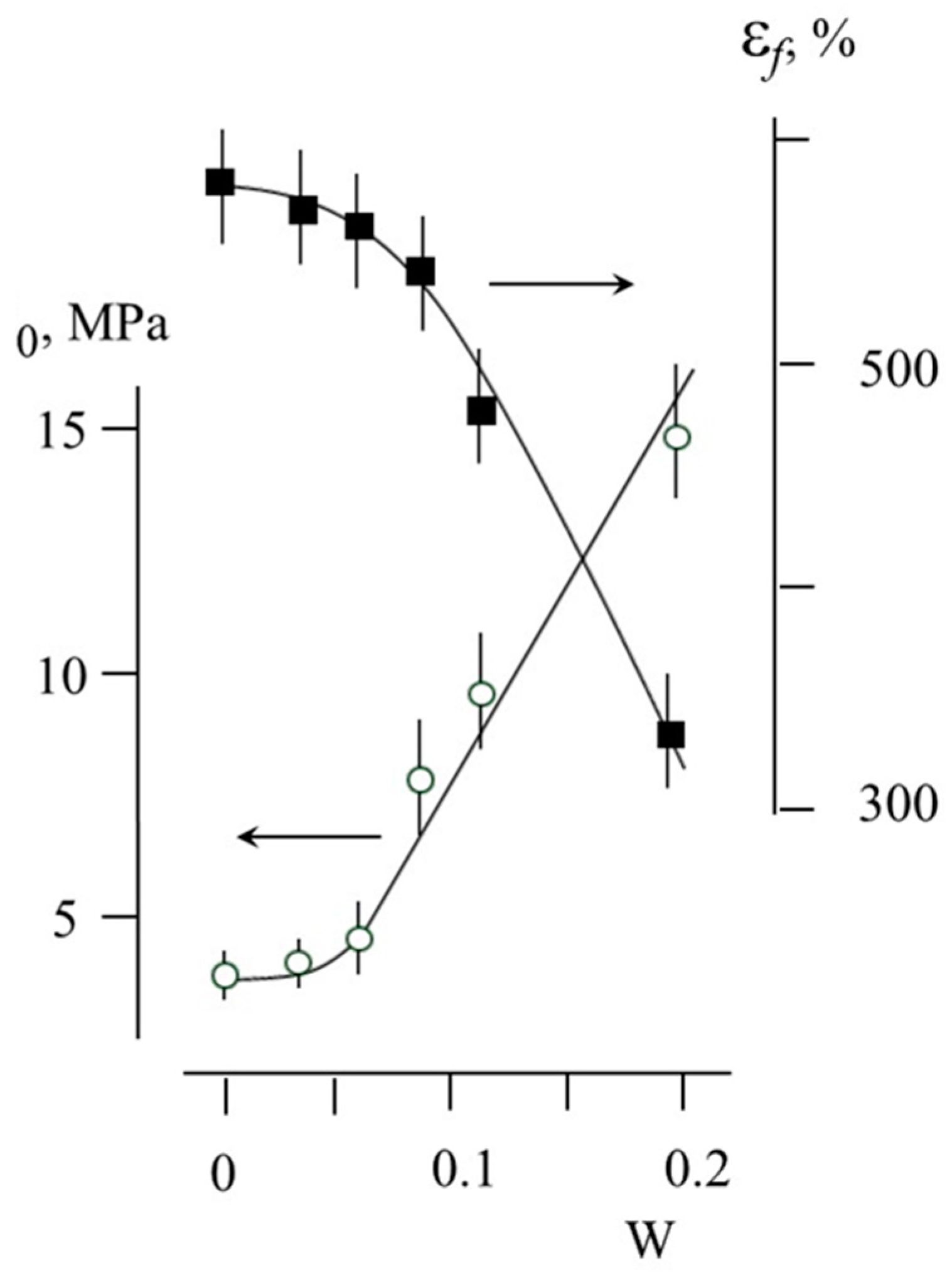

3.2. Mechanical Properties of BSMs–PDADMAC Films

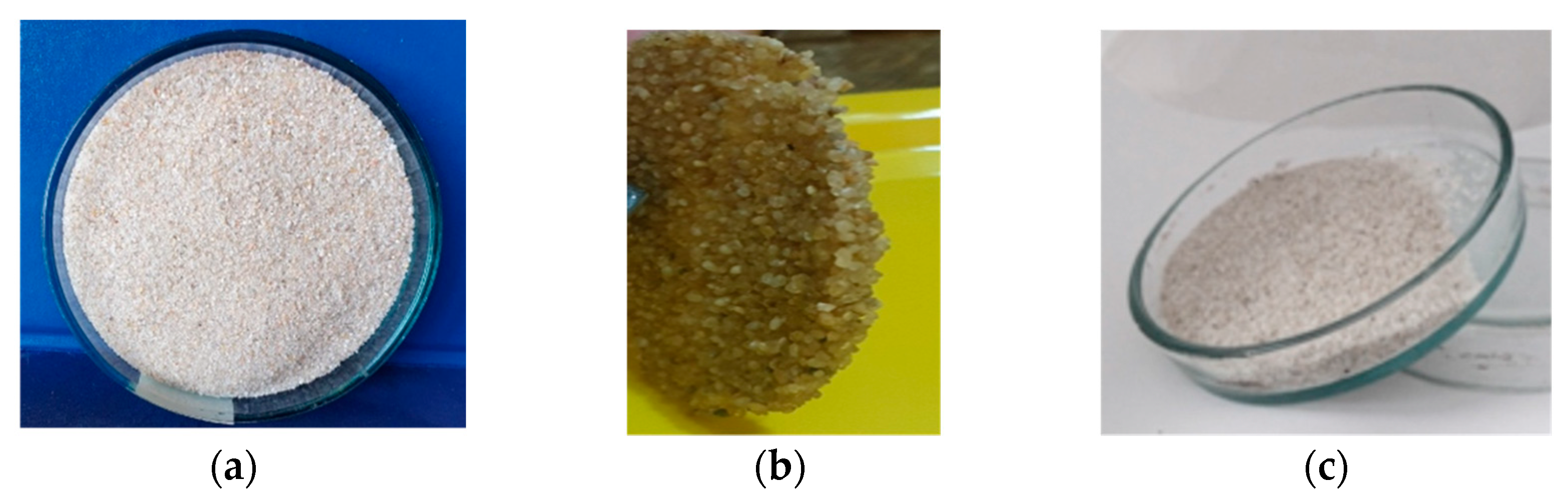

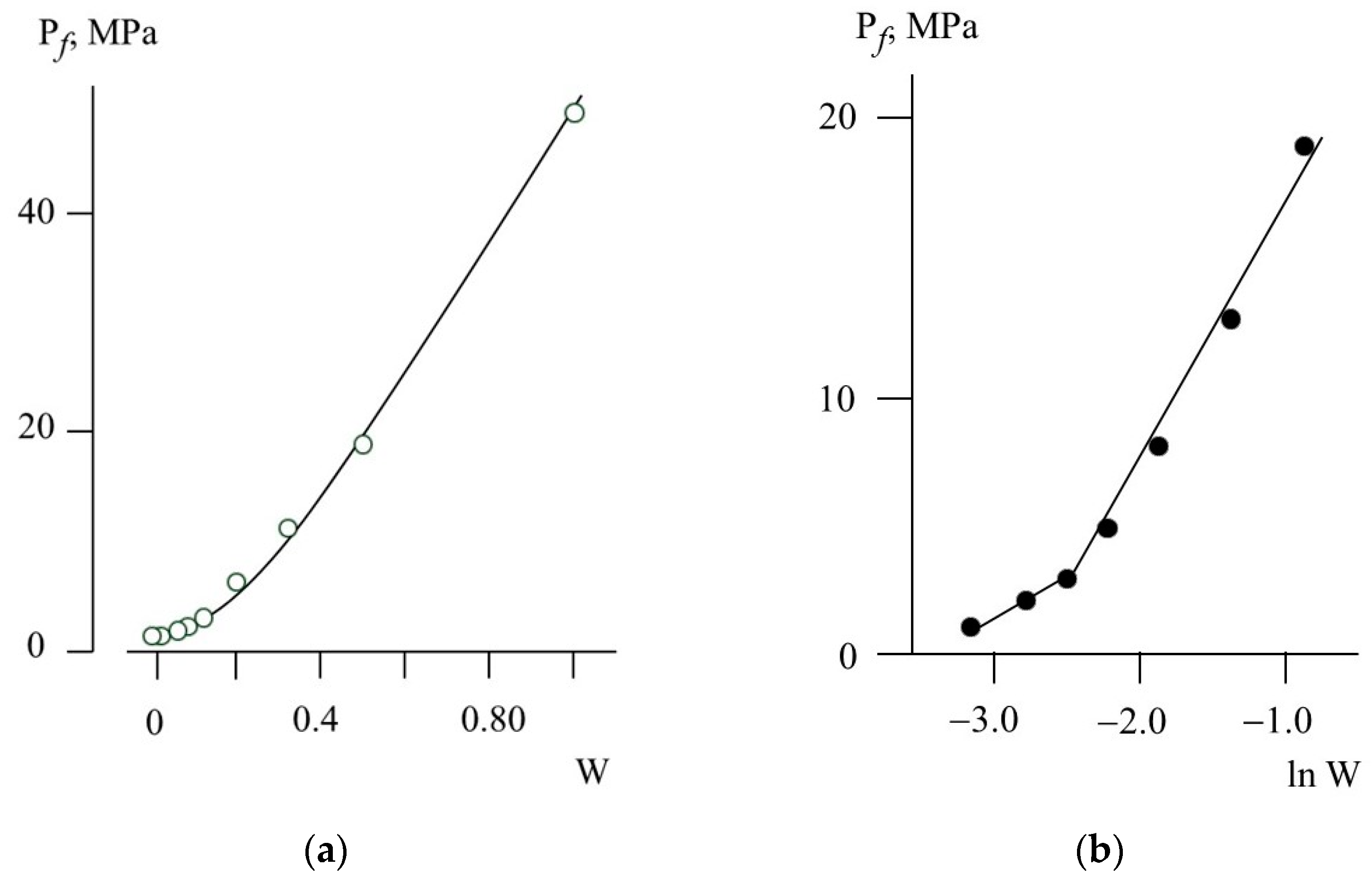

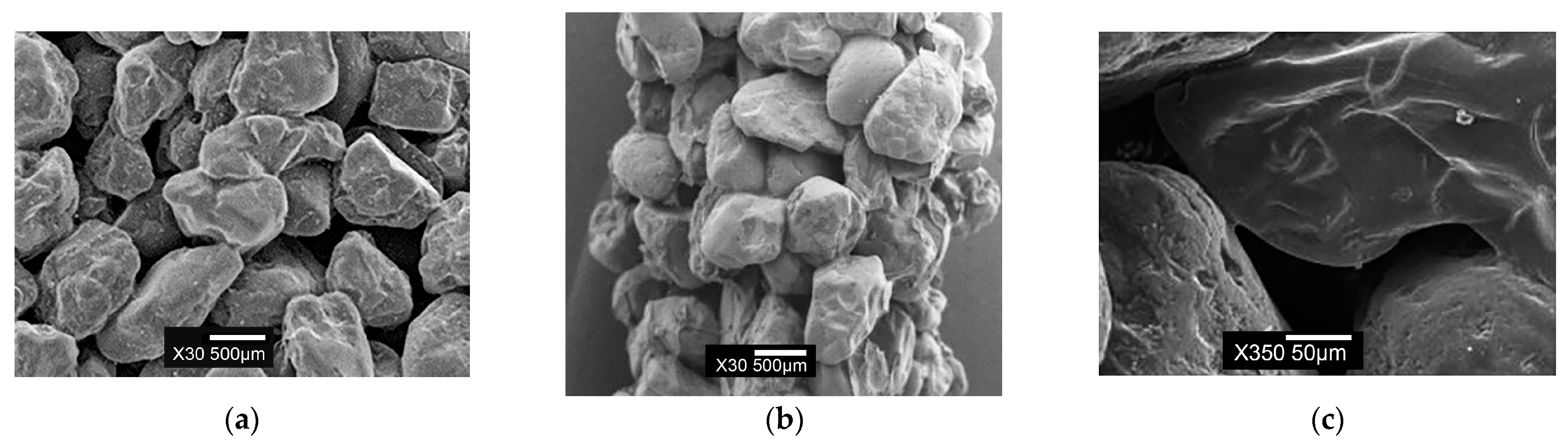

3.3. Structure and Properties of Polymer-Sand Protective Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Yang, Z. Recent progress in polymer-based building materials. Int. J. Polym. Sci. 2020, 2020, 8838160. [Google Scholar] [CrossRef]

- Darwish, M.S.; Mostafa, M.H.; Al-Harbi, L.M. Polymeric Nanocomposites for Environmental and Industrial Applications. Int. J. Mol. Sci. 2022, 23, 1023. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Halliwell, S.M. Polymers in Building and Construction; Rapra Technology: Shrewsbury, UK, 2003. [Google Scholar]

- Lu, Y.; Shah, K.W.; Xu, J. Synthesis, morphologies and building applications of nanostructured polymers. Polymers 2017, 9, 506. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Li, X.; Liu, R.; Li, S.; Zhang, C.; Li, J.; Cheng, B.; Liu, Y.; Ma, C.; Yan, J. Effect of SBR and XSBRL on water demand, mechanical strength and microstructure of cement paste. Constr. Build. Mater. 2022, 332, 127309. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 2020, 21, 686–702. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Kanashiki, N.; Ishizaki, H.; Kobayashi, M.; Osawa, K. Relationship between soil erodibility by concentrated flow and shear strength of a Haplic Acrisol with a cationic polyelectrolyte. Catena 2022, 217, 106506. [Google Scholar] [CrossRef]

- Panova, I.G.; Ilyasov, L.O.; Yaroslavov, A.A. Polycomplex formulations for the protection of soils against degradation. Polym. Sci. Ser. C 2021, 63, 237–248. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer—An environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, W.; Yuan, W.; Liu, Y.; Sui, Z. Research on the Ecological Protection of Coal Gangue Slope Based on a Polymer Curing Agent. Adv. Mater. Sci. Eng. 2021, 2021, 8181688. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, Z.; Dong, X.; Lu, T.; Chen, Y.; Wang, W. Experimental study on the mechanical properties of polymer-treated tailings. Arab. J. Geosci. 2021, 14, 2653–2666. [Google Scholar] [CrossRef]

- Li, F.; Wang, C.; Xia, Y.; Hao, Y.; Zhao, P.; Shi, M. Strength and Solidification Mechanism of Silt Solidified by Polyurethane. Adv. Civ. Eng. 2020, 2020, 8824524. [Google Scholar] [CrossRef]

- Li, R.; Zhang, B.; Wang, Y.; Zhao, Y.; Li, F. Leaching potential of stabilized fly ash from the incineration of municipal solid waste with a new polymer. J. Environ. Manag. 2019, 232, 286–294. [Google Scholar] [CrossRef]

- Yang, Q.W.; Pei, X.J.; Huang, R.Q. Impact of polymer mixtures on the stabilization and erosion control of silty sand slope. J. Mt. Sci. 2019, 16, 470–485. [Google Scholar] [CrossRef]

- Li, T.; Dai, F.; He, Y.; Xu, D.; Wang, R. An Eco-Friendly Polymer Composite Fertilizer for Soil Fixation, Slope Stability, and Erosion Control. Polymers 2022, 14, 1461. [Google Scholar] [CrossRef]

- Liang, Y.; Yeh, T.-C.J.; Ma, C.; Zhang, J.; Xu, W.; Yang, D.; Hao, Y. Experimental investigation on hole erosion behaviors of chemical stabilizer treated soil. J. Hydrol. 2020, 594, 125647. [Google Scholar] [CrossRef]

- Zang, Y.X.; Gong, W.; Xie, H.; Liu, B.L.; Chen, H.L. Chemical sand stabilization: A review of material, mechanism, and problems. Environ. Technol. Rev. 2015, 4, 119–132. [Google Scholar] [CrossRef]

- Zinchenko, A.; Sakai, T.; Morikawa, K.; Nakano, M. Efficient stabilization of soil, sand, and clay by a polymer network of biomass-derived chitosan and carboxymethyl cellulose. J. Environ. Chem. Eng. 2022, 10, 107084. [Google Scholar] [CrossRef]

- Xu, G.; Ding, X.; Kuruppu, M.; Zhou, W.; Biswas, W. Research and application of non-traditional chemical stabilizers on bauxite residue (red sand) dust control, a review. Sci. Total Environ. 2018, 616, 1552–1565. [Google Scholar] [CrossRef]

- Alakbari, F.S.; Mohyaldinn, M.E.; Muhsan, A.S.; Hasan, N.; Ganat, T. Chemical sand consolidation: From polymers to nanoparticles. Polymers 2020, 12, 1069. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Darezereshki, E.; Yilmaz, E. Geopolymerization of soil by sodium silicate as an approach to control wind erosion. Int. J. Environ. Sci. Technol. 2021, 18, 1837–1848. [Google Scholar] [CrossRef]

- Porter, H.; Dhami, N.K.; Mukherjee, A. Synergistic chemical and microbial cementation for stabilization of aggregates. Cem. Concr. Compos. 2017, 83, 160–170. [Google Scholar] [CrossRef]

- James, J.; Vijayasimhan, S.; Eyo, E. Stress-Strain Characteristics and Mineralogy of an Expansive Soil Stabilized Using Lime and Phosphogypsum. Appl. Sci. 2023, 13, 123. [Google Scholar] [CrossRef]

- Yi, H.; Oh, K.; Kou, R.; Qiao, Y. Sand-filler structural material with a low content of polyethylene binder. Sustain. Mater. Technol. 2020, 25, e00194. [Google Scholar] [CrossRef]

- Song, Z.; Liu, J.; Bai, Y.; Wei, J.; Li, D.; Wang, Q.; Qian, W. Laboratory and field experiments on the effect of vinyl acetate polymer-reinforced soil. Appl. Sci. 2019, 9, 208. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Soltani, A.; Khayat, N. Stabilization of soft clay using short fibers and polyvinyl alcohol. Geotext. Geomembr. 2018, 46, 646–655. [Google Scholar] [CrossRef]

- Sojka, R.E.; Bjorneberg, D.L.; Entry, J.A.; Lentz, R.D.; Orts, W.J. Polyacrylamide in agriculture and environmental land management. Adv. Agron. 2007, 92, 75–162. [Google Scholar]

- Saleh, S.; Yunus, N.Z.M.; Ahmad, K.; Ali, N. Improving the strength of weak soil using polyurethane grouts: A review. Constr. Build. Mater. 2019, 202, 738–752. [Google Scholar] [CrossRef]

- Albalasmeh, A.A.; Hamdan, E.H.; Gharaibeh, M.A.; El Hanandeh, A. Improving aggregate stability and hydraulic properties of Sandy loam soil by applying polyacrylamide polymer. Soil Tillage Res. 2021, 206, 104821. [Google Scholar] [CrossRef]

- Kumar, P.; Puppala, A.J.; Tingle, J.S.; Chakraborty, S.; Sarat Chandra Congress, S. Resilient Characteristics of Polymer Emulsion-Treated Sandy Soil. Transp. Res. Rec. 2022, 2676, 526–538. [Google Scholar] [CrossRef]

- Baghini, M.S.; Ismail, A.; Naseralavi, S.S.; Firoozi, A.A. Performance evaluation of road base stabilized with styrene–butadiene copolymer latex and Portland cement. Int. J. Pavement Res. Technol. 2016, 9, 321–336. [Google Scholar] [CrossRef]

- Lu, S.; Wang, Z.; Hu, Y.; Liu, B.; Liu, J.E. Effectiveness and durability of polyacrylamide (PAM) and polysaccharide (Jag C 162) in reducing soil erosion under simulated rainfalls. Water 2018, 10, 257. [Google Scholar] [CrossRef]

- Lentz, R.D. Polyacrylamide and biopolymer effects on flocculation, aggregate stability, and water seepage in a silt loam. Geoderma 2015, 241–242, 289–294. [Google Scholar] [CrossRef]

- Ahbab, A.; Sardroud, S.N.E.; Katebi, H.; Avci, E. Prevention of Wind Erosion in Salty Lands of Urmia Lake with Butadiene Carboxylic Latex and Cement Grout. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 47, 447–455. [Google Scholar] [CrossRef]

- Liu, J.; Bai, Y.; Song, Z.; Lu, Y.; Qian, W.; Kanungo, D.P. Evaluation of strength properties of sand modified with organic polymers. Polymers 2018, 10, 287. [Google Scholar] [CrossRef]

- Arias-Trujillo, J.; Matías-Sanchez, A.; Cantero, B.; López-Querol, S. Effect of polymer emulsion on the bearing capacity of aeolian sand under extreme confinement conditions. Constr. Build. Mater. 2020, 236, 117473. [Google Scholar] [CrossRef]

- Izumrudov, V.A.; Mussabayeva, B.K.; Kassymova, Z.S.; Klivenko, A.N.; Orazzhanova, L.K. Interpolyelectrolyte complexes: Advances and prospects of application. Russ. Chem. Rev. 2019, 88, 1046. [Google Scholar] [CrossRef]

- Kabanov, V.A. Polyelectrolyte complexes in solution and in bulk. Russ. Chem. Rev. 2005, 74, 3–20. [Google Scholar] [CrossRef]

- Klivenko, A.; Orazzhanova, L.; Mussabayeva, B.; Yelemessova, G.; Kassymova, Z. Soil structuring using interpolyelectrolyte complexes of water-soluble polysaccharides. Polym. Adv. Technol. 2020, 31, 3292–3301. [Google Scholar] [CrossRef]

- Novoskoltseva, O.A.; Loiko, N.G.; Nikolaev, Y.A.; Lisin, A.O.; Panova, I.G.; Yaroslavov, A.A. Interpolyelectrolyte complexes based on hydrolyzed polyacrylonitrile for anti-erosion stabilization of soils and ground. Polym. Int. 2022, 71, 697–705. [Google Scholar] [CrossRef]

- Yakimenko, O.; Ziganshina, A.; Terekhova, V.; Panova, I.; Gladkova, M.; Timofeev, M.; Yaroslavov, A. Ecotoxicity of polyelectrolyte formulations in water and soil matrices. Environ. Sci. Pollut. Res. 2022, 29, 65489–65499. [Google Scholar] [CrossRef]

- George, S.C.; Ninan, K.N.; Groeninckx, G.; Thomas, S. Styrene–butadiene rubber/natural rubber blends: Morphology, transport behavior, and dynamic mechanical and mechanical properties. J. Appl. Polym. Sci. 2000, 78, 1280–1303. [Google Scholar] [CrossRef]

- Alimardani, M.; Abbassi-Sourki, F. New and emerging applications of carboxylated styrene butadiene rubber latex in polymer composites and blends: Review from structure to future prospective. J. Compos. Mater. 2015, 49, 1267–1282. [Google Scholar] [CrossRef]

- Khaidapova, D.D.; Pestonova, E.A. Strength of interparticle bonds in soil pastes and aggregates. Eurasian J. Soil Sci. 2007, 40, 1187–1192. [Google Scholar] [CrossRef]

- Sukhishvili, S.A.; Chechik, O.S.; Yaroslavov, A.A. Adsorption of poly-N-ethyl-4-vinylpyridinium bromide on the surface of carboxylated latex particles: Composition and structure of interfacial complex. J. Colloid Interface Sci. 1996, 178, 42–46. [Google Scholar] [CrossRef]

- Bauer, D.; Buchhammer, H.; Fuchs, A.; Jaeger, W.; Killmann, E.; Lunkwitz, K.; Rehmet, R.; Schwarz, S. Stability of colloidal silica, sikron and polystyrene latex influenced by the adsorption of polycations of different charge density. Colloids Surf. A Physicochem. Eng. Asp. 1999, 156, 291–305. [Google Scholar] [CrossRef]

- Choi, J.; Rubner, M.F. Influence of the degree of ionization on weak polyelectrolyte multilayer assembly. Macromolecules 2005, 38, 116–124. [Google Scholar] [CrossRef]

- Szilagyi, I.; Trefalt, G.; Tiraferri, A.; Maroni, P.; Borkovec, M. Polyelectrolyte adsorption, interparticle forces, and colloidal aggregation. Soft Matter 2014, 10, 2479–2502. [Google Scholar] [CrossRef]

- Kleimann, J.; Gehin-Delval, C.; Auweter, H.; Borkovec, M. Super-stoichiometric charge neutralization in particle− polyelectrolyte systems. Langmuir 2005, 21, 3688–3698. [Google Scholar] [CrossRef]

- Li, H.; Cui, C.; Temitope, A.A.; Feng, Z.; Zhao, G.; Guo, P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J. Traffic Transp. Eng. 2022, 9, 836–863. [Google Scholar] [CrossRef]

- Borthakur, A.; Das, T.K.; Zhang, Y.; Libbert, S.; Prehn, S.; Ramos, P.; Dooley, G.; Blotevogel, J.; Mahendra, S.; Mohanty, S.K. Rechargeable stormwater biofilters: In situ regeneration of PFAS removal capacity by using a cationic polymer, polydiallyldimethylammonium chloride. J. Clean. Prod. 2022, 375, 134244. [Google Scholar] [CrossRef]

| No. | W | PDADMAC-BSM Films | Strength of Polymer-Sand Crust Pf, MPa | ||

|---|---|---|---|---|---|

| Elastic Modulus (E0), mPa | Strength (σf), mPa | Ultimate Strain (εf), % | |||

| 1 | 2 | 3 | 4 | 5 | 6 |

| 1 | 0 | 4.5 ± 0.4 | 3.5 ± 0.3 | 580 ± 60 | 0.8 |

| 2 | 0.036 | 5.0 ± 0.4 | 3.8 ± 0.3 | 570 ± 55 | 1.1 |

| 3 | 0.059 | 5.5 ± 0.45 | 4.0 ± 0.3 | 560 ± 55 | 1.9 |

| 4 | 0.077 | 9.0 ± 0.65 | 5.05 ± 0.25 | 550 ± 55 | 2.7 |

| 5 | 0.111 | 11.0 ± 0.8 | 5.5 ± 0.15 | 480 ± 50 | 3.5 |

| 6 | 0.2 | 15.0 ± 1.0 | 5.7 ± 0.2 | 330 ± 45 | 8.0 |

| 7 | 0.33 | 17.0 ± 2.0 | 6.6 ± 0.25 | 300 ± 40 | 13.0 |

| 8 | 0.5 | 90.0 ± 8.0 | 7.2 ± 0.4 | 270 ± 20 | 18.0 |

| 9 | 1 | - | - | - | 45.0 |

| Deposited Formulation | Water (Control) | PDADMAC–BSM Formulation, W | ||||

|---|---|---|---|---|---|---|

| 0 | 0.036–0.2 | 0.333 | 0.5 | 1 | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Loss of sand, S, % | 30 ± 3 | 0 | 0 | 11 ± 2 | 19 ± 3 | 39 ± 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Panova, I.; Shevaleva, E.; Gritskova, I.; Arzhakov, M.; Yaroslavov, A. Mixtures of Cationic Linear Polymer and Anionic Polymeric Microspheres for Stabilization of Sand: Physicochemical, Structural and Mechanical Study. Appl. Sci. 2023, 13, 4311. https://doi.org/10.3390/app13074311

Panova I, Shevaleva E, Gritskova I, Arzhakov M, Yaroslavov A. Mixtures of Cationic Linear Polymer and Anionic Polymeric Microspheres for Stabilization of Sand: Physicochemical, Structural and Mechanical Study. Applied Sciences. 2023; 13(7):4311. https://doi.org/10.3390/app13074311

Chicago/Turabian StylePanova, Irina, Evgeniya Shevaleva, Inessa Gritskova, Maxim Arzhakov, and Alexander Yaroslavov. 2023. "Mixtures of Cationic Linear Polymer and Anionic Polymeric Microspheres for Stabilization of Sand: Physicochemical, Structural and Mechanical Study" Applied Sciences 13, no. 7: 4311. https://doi.org/10.3390/app13074311

APA StylePanova, I., Shevaleva, E., Gritskova, I., Arzhakov, M., & Yaroslavov, A. (2023). Mixtures of Cationic Linear Polymer and Anionic Polymeric Microspheres for Stabilization of Sand: Physicochemical, Structural and Mechanical Study. Applied Sciences, 13(7), 4311. https://doi.org/10.3390/app13074311