Analysis of Cleaner Production Performance in Manufacturing Companies Employing Artificial Neural Networks

Abstract

1. Introduction

2. Collected Data and Research Method

2.1. Data Collection and Dimensionality Reduction

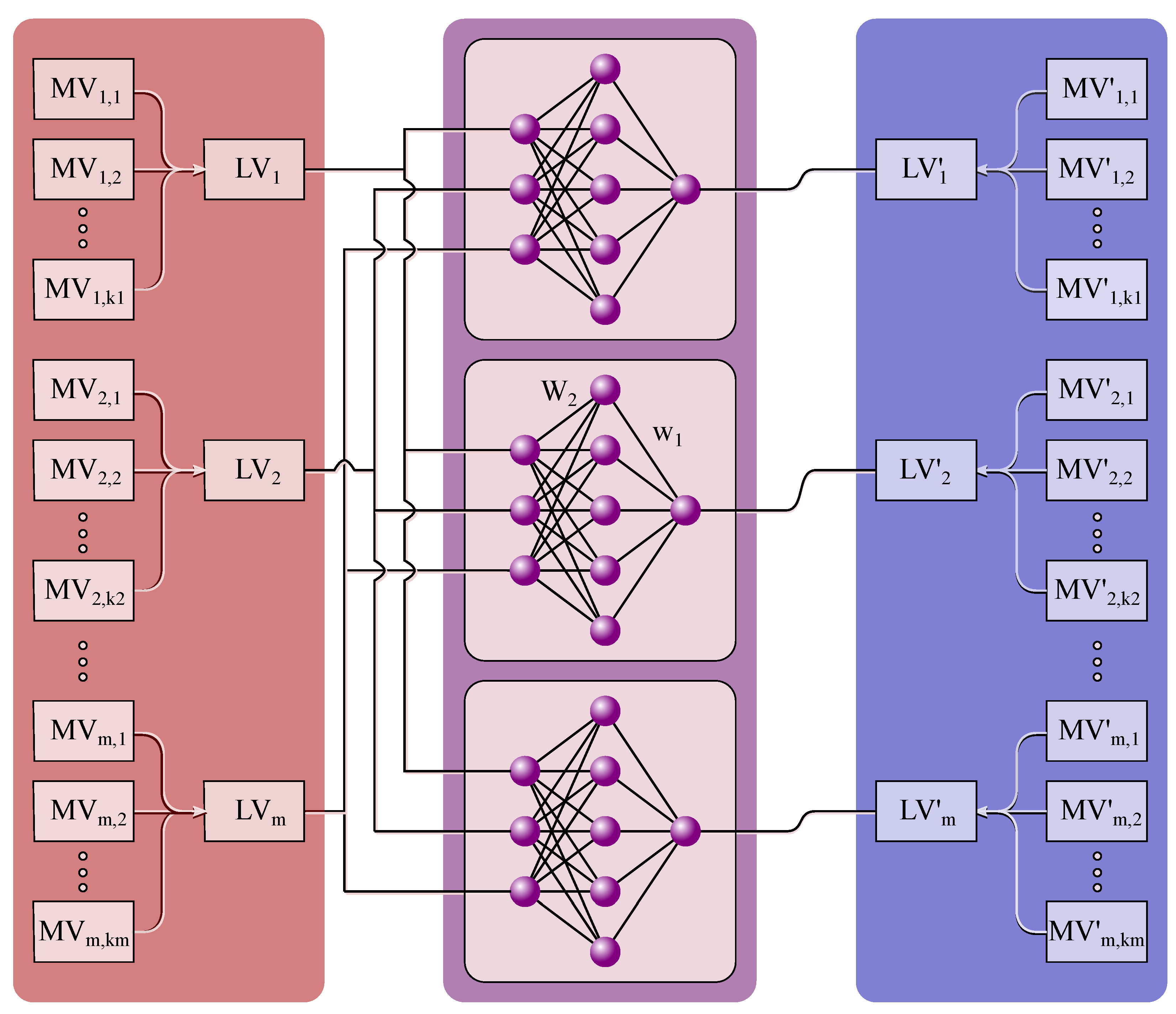

2.2. Modeling of Complex Systems Using Artificial Neural Networks

2.3. Sensitivity Analysis

3. Results

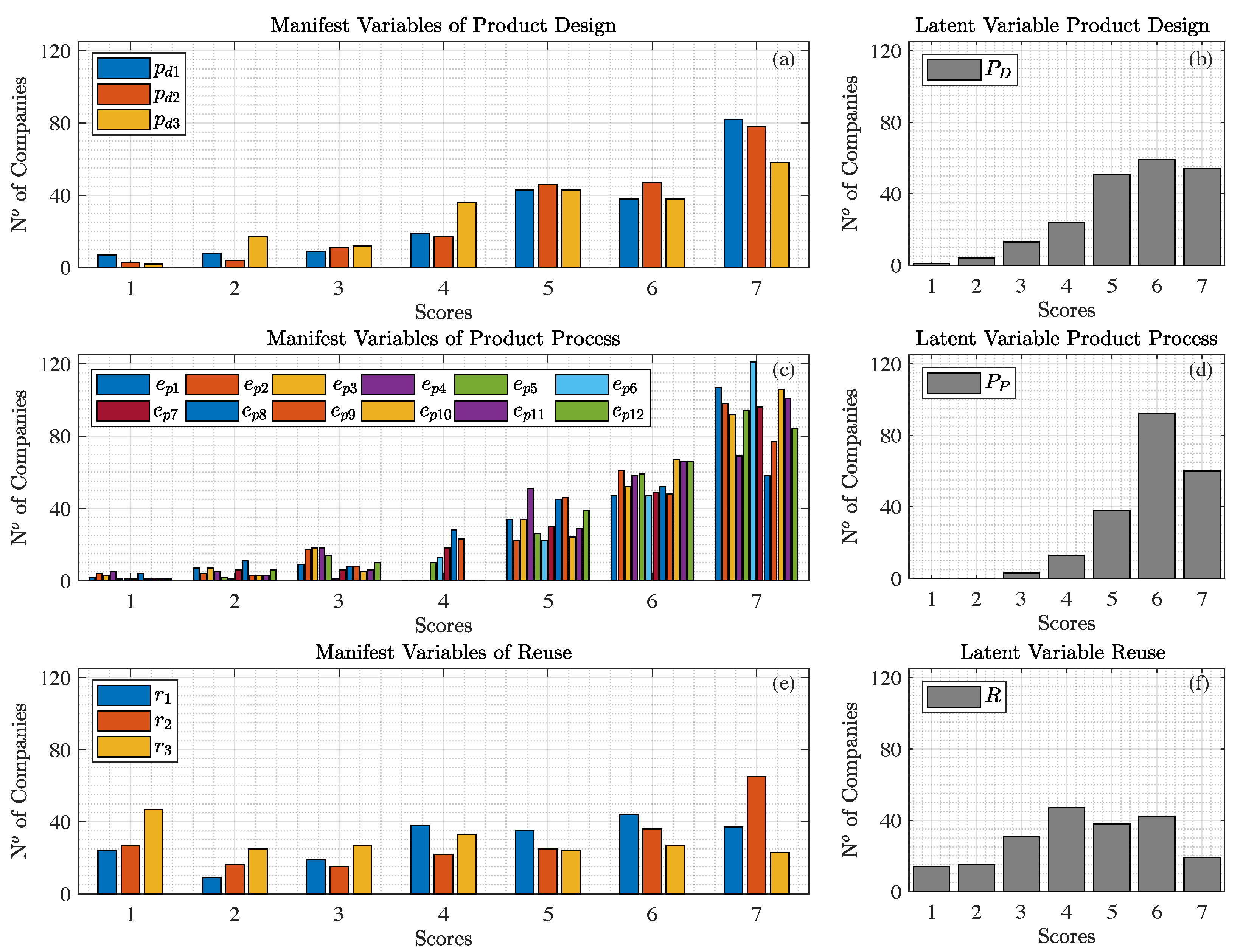

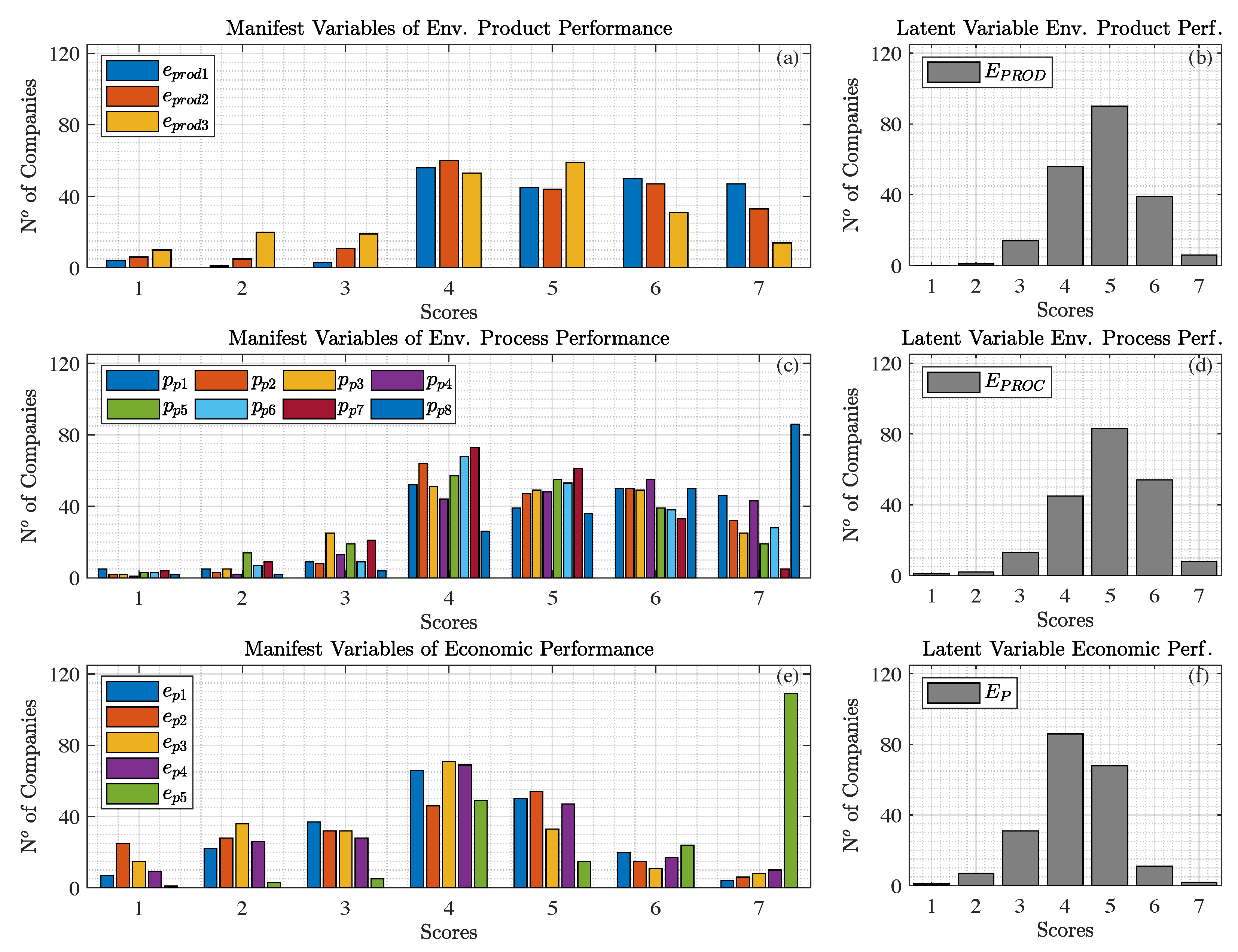

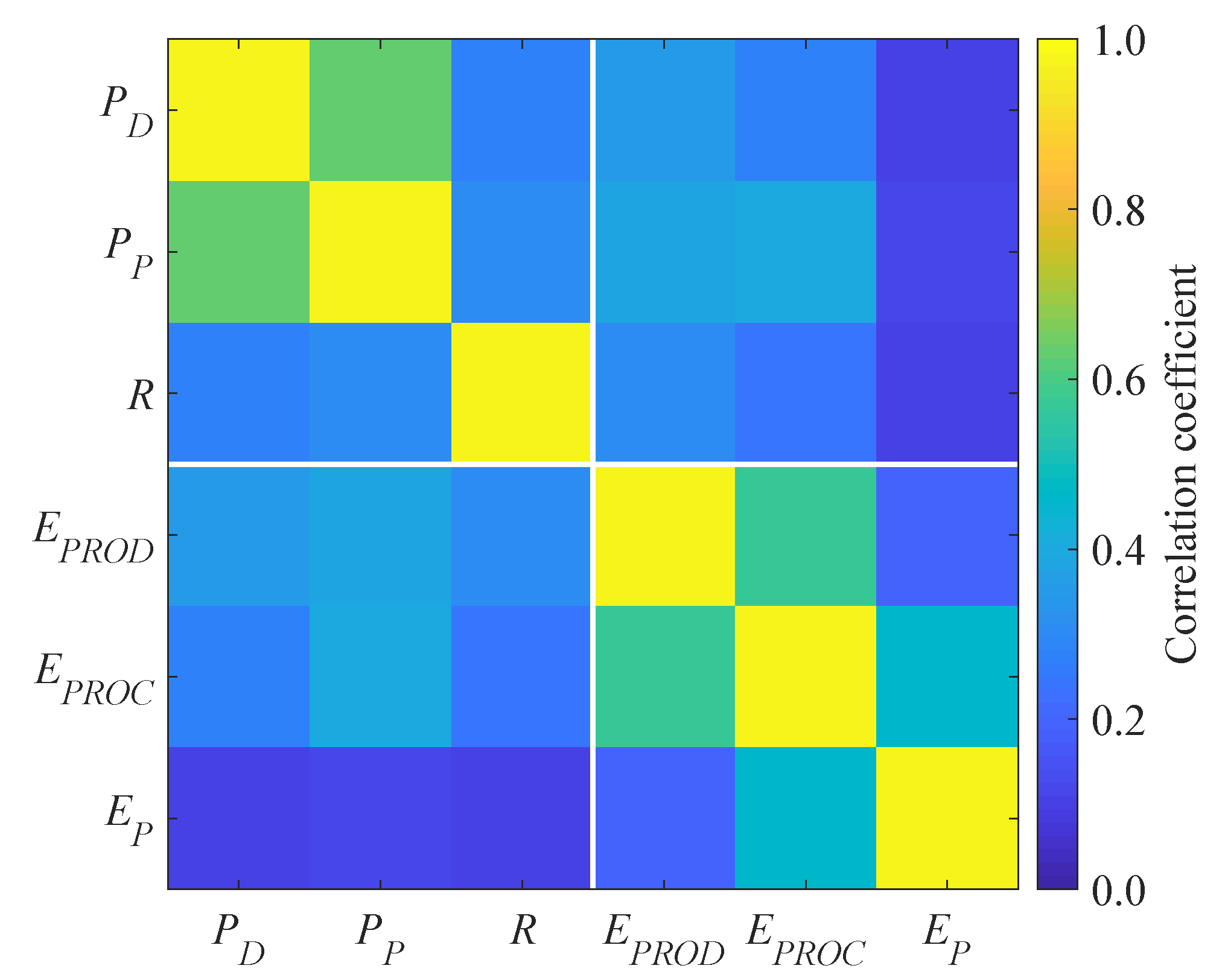

3.1. Data Analysis and Dimensionality Reduction

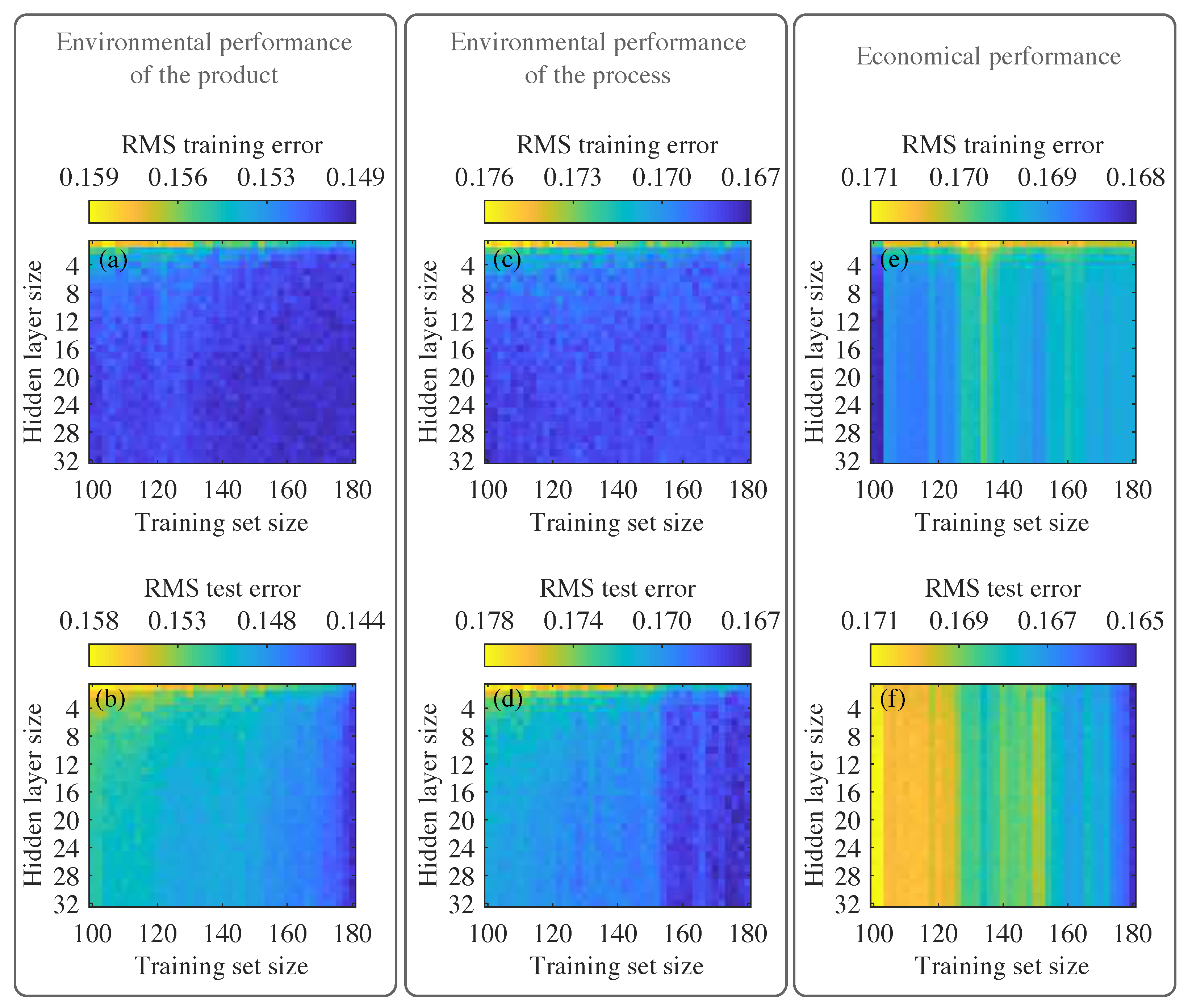

3.2. System Modeling

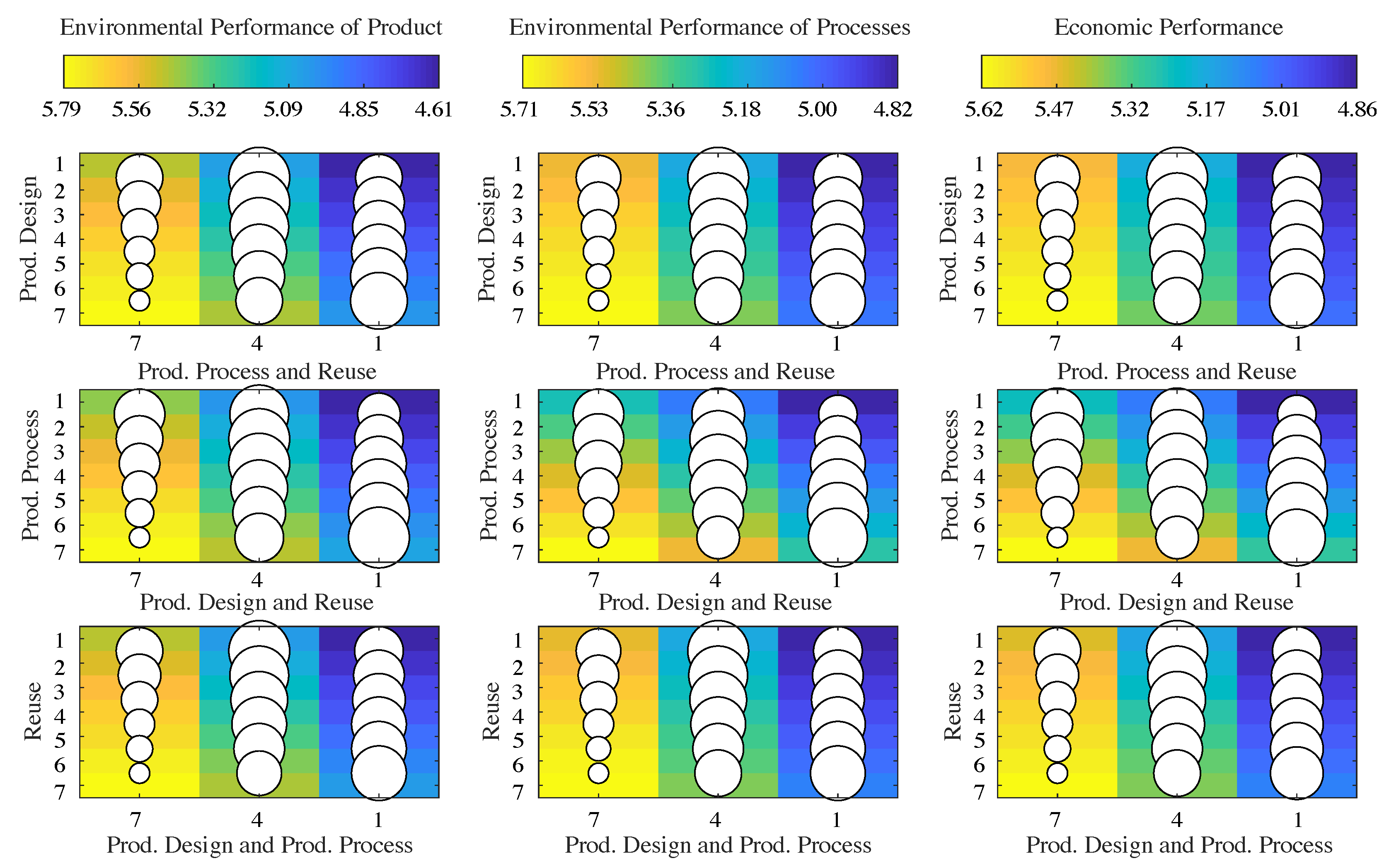

3.3. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Severo, E.A.; de Guimarães, J.C.F.; Dorion, E.C.H. Cleaner production and environmental management as sustainable product innovation antecedents: A survey in Brazilian industries. J. Clean. Prod. 2017, 142, 87–97. [Google Scholar] [CrossRef]

- Oliveira, J.A.; Lopes Silva, D.A.; Devós Ganga, G.M.; Filho, M.G.; Ferreira, A.A.; Esposto, K.F.; Ometto, A.R. Cleaner Production practices, motivators and performance in the Brazilian industrial companies. J. Clean. Prod. 2019, 231, 359–369. [Google Scholar] [CrossRef]

- UNEP. Guidance Manual: How to Establish and Operate Cleaner Production Centres; UNEP: Paris, France, 2004. [Google Scholar]

- Meza-Ruiz, I.D.; Rocha-Lona, L.; del Rocío Soto-Flores, M.; Garza-Reyes, J.A.; Kumar, V.; Lopez-Torres, G.C. Measuring Business Sustainability Maturity-levels and Best Practices. Procedia Manuf. 2017, 11, 751–759. [Google Scholar] [CrossRef]

- Zhang, P.; Duan, N.; Dan, Z.; Shi, F.; Wang, H. An understandable and practicable cleaner production assessment model. J. Clean. Prod. 2018, 187, 1094–1102. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Huisingh, D.; Mangla, S.K.; Narkhede, B.E.; Liu, Y. Development of a lean manufacturing framework to enhance its adoption within manufacturing companies in developing economies. J. Clean. Prod. 2020, 245, 118726. [Google Scholar] [CrossRef]

- Kuo, R.; Wang, Y.; Tien, F. Integration of artificial neural network and MADA methods for green supplier selection. J. Clean. Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Nasab, H.H.; Aliheidari bioki, T.; Khademi Zare, H. Finding a probabilistic approach to analyze lean manufacturing. J. Clean. Prod. 2012, 29-30, 73–81. [Google Scholar] [CrossRef]

- Pigosso, D.C.; Rozenfeld, H.; McAloone, T.C. Ecodesign maturity model: A management framework to support ecodesign implementation into manufacturing companies. J. Clean. Prod. 2013, 59, 160–173. [Google Scholar] [CrossRef]

- Introna, V.; Cesarotti, V.; Benedetti, M.; Biagiotti, S.; Rotunno, R. Energy Management Maturity Model: An organizational tool to foster the continuous reduction of energy consumption in companies. J. Clean. Prod. 2014, 83, 108–117. [Google Scholar] [CrossRef]

- Domingues, P.; Sampaio, P.; Arezes, P.M. Integrated management systems assessment: A maturity model proposal. J. Clean. Prod. 2016, 124, 164–174. [Google Scholar] [CrossRef]

- Oliveira, J.A.; Oliveira, O.J.; Ometto, A.R.; Ferraudo, A.S.; Salgado, M.H. Environmental Management System ISO 14001 factors for promoting the adoption of Cleaner Production practices. J. Clean. Prod. 2016, 133, 1384–1394. [Google Scholar] [CrossRef]

- Allais, R.; Roucoules, L.; Reyes, T. Governance maturity grid: A transition method for integrating sustainability into companies? J. Clean. Prod. 2017, 140, 213–226. [Google Scholar] [CrossRef]

- Rodrigues, V.P.; Pigosso, D.C.; McAloone, T.C. Measuring the implementation of ecodesign management practices: A and consolidation of process-oriented performance indicators. J. Clean. Prod. 2017, 156, 293–309. [Google Scholar] [CrossRef]

- Finnerty, N.; Sterling, R.; Coakley, D.; Keane, M.M. An energy management maturity model for multi-site industrial organisations with a global presence. J. Clean. Prod. 2017, 167, 1232–1250. [Google Scholar] [CrossRef]

- Poltronieri, C.F.; Ganga, G.M.D.; Gerolamo, M.C. Maturity in management system integration and its relationship with sustainable performance. J. Clean. Prod. 2019, 207, 236–247. [Google Scholar] [CrossRef]

- Xavier, A.F.; Naveiro, R.M.; Aoussat, A.; Reyes, T. Systematic literature review of eco-innovation models: Opportunities and recommendations for future research. J. Clean. Prod. 2017, 149, 1278–1302. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Magalhães, L.; Zancul, E.; Campos, L.M.; Cauchick-Miguel, P.A. Cleaner production as an antecedent for circular economy paradigm shift at the micro-level: Evidence from a home appliance manufacturer. J. Clean. Prod. 2018, 185, 740–748. [Google Scholar] [CrossRef]

- Teixeira, G.F.G.; Canciglieri Junior, O. How to make strategic planning for corporate sustainability? J. Clean. Prod. 2019, 230, 1421–1431. [Google Scholar] [CrossRef]

- Maier, A.M.; Moultrie, J.; Clarkson, P.J. Assessing Organizational Capabilities: Reviewing and Guiding the Development of Maturity Grids. IEEE Trans. Eng. Manag. 2012, 59, 138–159. [Google Scholar] [CrossRef]

- Prashar, A. Energy efficiency maturity (EEM) assessment framework for energy-intensive SMEs: Proposal and evaluation. J. Clean. Prod. 2017, 166, 1187–1201. [Google Scholar] [CrossRef]

- Sun, R.; Liu, T.; Chen, X.; Yao, L. A biomass-coal co-firing based bi-level optimal approach for carbon emission reduction in China. J. Clean. Prod. 2021, 278, 123318. [Google Scholar] [CrossRef]

- Saaty, T. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Alpaydin, E. Introduction to MACHINE Learning. The MIT Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Karpatne, A.; Ebert-Uphoff, I.; Ravela, S.; Babaie, H.A.; Kumar, V. Machine learning for the geosciences: Challenges and opportunities. IEEE Trans. Knowl. Data Eng. 2018, 31, 1544–1554. [Google Scholar] [CrossRef]

- Lary, D.J.; Alavi, A.H.; Gandomi, A.H.; Walker, A.L. Machine learning in geosciences and remote sensing. Geosci. Front. 2016, 7, 3–10. [Google Scholar] [CrossRef]

- Zibar, D.; Piels, M.; Jones, R.; Schäeffer, C.G. Machine learning techniques in optical communication. J. Light. Technol. 2015, 34, 1442–1452. [Google Scholar] [CrossRef]

- El Misilmani, H.M.; Naous, T.; Al Khatib, S.K. A review on the design and optimization of antennas using machine learning algorithms and techniques. Int. J. Microw.-Comput.-Aided Eng. 2020, 30, e22356. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, H.; Ren, Y.; Han, Z.; Chen, K.C.; Hanzo, L. Machine learning paradigms for next-generation wireless networks. IEEE Wirel. Commun. 2016, 24, 98–105. [Google Scholar] [CrossRef]

- Rajkomar, A.; Dean, J.; Kohane, I. Machine learning in medicine. N. Engl. J. Med. 2019, 380, 1347–1358. [Google Scholar] [CrossRef]

- Sidey-Gibbons, J.A.; Sidey-Gibbons, C.J. Machine learning in medicine: A practical introduction. BMC Med. Res. Methodol. 2019, 19, 1–18. [Google Scholar] [CrossRef]

- Shobana, G.; Umamaheswari, K. Forecasting by machine learning techniques and econometrics: A review. In Proceedings of the 2021 6th International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 20–22 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1010–1016. [Google Scholar]

- Mullainathan, S.; Spiess, J. Machine learning: An applied econometric approach. J. Econ. Perspect. 2017, 31, 87–106. [Google Scholar] [CrossRef]

- Oleśków-Szłapka, J.; Wojciechowski, H.; Domański, R.; Pawłowski, G. Logistics 4.0 Maturity Levels Assessed Based on GDM (Grey Decision Model) and Artificial Intelligence in Logistics 4.0-Trends and Future Perspective. Procedia Manuf. 2019, 39, 1734–1742. [Google Scholar] [CrossRef]

- Hair, J.F.; Tatham, R.L.; Anderson, R.E.; Black, W. Multivariate Data Analysis, 7th ed.; Prentice Hall: Hoboken, NJ, USA, 2009. [Google Scholar]

- Zurada, J.M. Introduction to Artificial Neural Systems. West Group: Eagan, MN, USA, 1992. [Google Scholar]

- Yegnanarayana, B. Artificial Neural Networks; Prentice-Hall: Hoboken, NJ, USA, 2009. [Google Scholar]

| Latent Variable | Manifest Variable | Survey Statement |

|---|---|---|

| Product Design () | Our company replaces toxic and/or polluting materials in product design | |

| Our company makes modifications to the product design in order to improve/adapt the environment | ||

| Our company empowers employees to develop cleaner products | ||

| Production Processes () | Our company cleans and organizes the production/shop floor environments | |

| Our company systematically manages stocks (raw materials/inputs/final products) | ||

| Our company performs equipment maintenance periodically | ||

| Our company improves and standardizes the equipment of the production process | ||

| Our company standardizes work instructions in the production processes | ||

| Our company separates waste and waste from production processes | ||

| Our company has mechanisms for collecting all types of tailings (including spills and burrs) | ||

| Our company empowers employees to carry out cleaner production processes | ||

| Our company replaces toxic and/or polluting materials in production processes | ||

| Our company controls the production processes | ||

| Our company makes changes in the production processes | ||

| Our company makes technological changes in production processes | ||

| Reuse (R) | Our company reuses waste and residues from a production process as by-products for the same production process | |

| Our company reuses water used in a production process as a resource for the same production process | ||

| Our company uses energy from a production process as a resource for the same production process |

| Latent Variable | Manifest Variable | Survey Statement |

|---|---|---|

| Environmental Performance of Product () | The durability of our products | |

| The recycling capacity (recyclability) of our products | ||

| The energy consumption of our products | ||

| The use of toxic and/or polluting materials in our products | ||

| Environmental Performance of Processes () | Air emissions from our production processes | |

| The generation of industrial wastewater from our production processes | ||

| The generation of solid waste from our production processes | ||

| The consumption of toxic and/or polluting materials and/or substances from our production processes | ||

| The consumption of electricity by our production processes | ||

| Water consumption by our production processes | ||

| The consumption of raw materials by our production processes | ||

| The frequency of environmental accidents in our production processes | ||

| Economic Performance () | The cost of purchasing materials from our company | |

| Our company’s energy consumption cost | ||

| Our company’s waste treatment rates | ||

| Our company’s waste disposal rates | ||

| Fines for environmental accidents in our company |

| Latent Variable | CA | CR | AVE |

|---|---|---|---|

| Product Design () | 0.79 | 0.88 | 0.71 |

| Production Processes () | 0.93 | 0.94 | 0.81 |

| Reuse (R) | 0.81 | 0.89 | 0.73 |

| Environmental Performance of Product () | 0.45 | 0.69 | 0.34 |

| Environmental Performance of Processes () | 0.90 | 0.92 | 0.63 |

| Economic Performance () | 0.75 | 0.85 | 0.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Penchel, R.A.; Aldaya, I.; Marim, L.; dos Santos, M.P.; Cardozo-Filho, L.; Jegatheesan, V.; de Oliveira, J.A. Analysis of Cleaner Production Performance in Manufacturing Companies Employing Artificial Neural Networks. Appl. Sci. 2023, 13, 4029. https://doi.org/10.3390/app13064029

Penchel RA, Aldaya I, Marim L, dos Santos MP, Cardozo-Filho L, Jegatheesan V, de Oliveira JA. Analysis of Cleaner Production Performance in Manufacturing Companies Employing Artificial Neural Networks. Applied Sciences. 2023; 13(6):4029. https://doi.org/10.3390/app13064029

Chicago/Turabian StylePenchel, Rafael Abrantes, Ivan Aldaya, Lucas Marim, Mirian Paula dos Santos, Lucio Cardozo-Filho, Veeriah Jegatheesan, and José Augusto de Oliveira. 2023. "Analysis of Cleaner Production Performance in Manufacturing Companies Employing Artificial Neural Networks" Applied Sciences 13, no. 6: 4029. https://doi.org/10.3390/app13064029

APA StylePenchel, R. A., Aldaya, I., Marim, L., dos Santos, M. P., Cardozo-Filho, L., Jegatheesan, V., & de Oliveira, J. A. (2023). Analysis of Cleaner Production Performance in Manufacturing Companies Employing Artificial Neural Networks. Applied Sciences, 13(6), 4029. https://doi.org/10.3390/app13064029