Abstract

Brittle failure, also known as rockburst, is a violent phenomenon that occurs during the excavation of hard rock in areas with high geostress, particularly at great depths. The induced hazards have been a global concern since the first half of the 20th century, leading to extensive efforts to understand the mechanisms and develop effective approaches to predict and control such rock mass failures. To understand the current state of research and future prospects of rockburst, a comprehensive review of past developments has been conducted. Firstly, we briefly summarize different definitions and types of rockburst. Next, we delve into the various technologies and methods employed in rockburst research and analyze the current knowledge on the mechanisms, classifications, and prediction of rockbursts. Then, we examine the existing methods for preventing and controlling these events. Despite the advancements made, the relationship between the behavior of rock masses at different scales, both in the laboratory and real-world conditions, remains an area of challenge. Additionally, the absence of rock mass classifications under high in-situ stress and lack of accuracy in rockburst prediction methods remain persistent issues that need to be addressed. This study delves into cutting-edge rockburst research, illuminating potential ground support strategies and empowering the mining industry in order to unleash innovative solutions for controlling these explosive phenomena.

1. Introduction

Rockbursts are a dangerous and sudden phenomenon in underground mining caused by the release of stored energy in hard-brittle rock masses [1] and they can result in mechanical damage, project delays, and economic loss, making them difficult to mitigate and manage. Understanding the mechanisms behind rockbursts is important for effective preventative strategies [2]. They have been reported globally in mines and tunnels, including in South Africa [3], China [4], Chile [5], the US [6], Canada [7], Western Australia [8], and many other countries. Rockbursts are becoming more prevalent with increased excavation depths and have been referred to as a “cancer” in deep mining geomechanics [9]. China has experienced several major rockburst events in underground projects in the last 30 years, including at the Jinping II hydropower facility and in various tunnel and hydropower projects. In 2009, a severe rockburst resulted in seven deaths and the destruction of a tunnel-boring machine [10]. Understanding the factors that lead to rockburst is crucial for the safety of future deep underground building projects as they pose a threat to people, property, and engineering stability. Research on rockburst mechanisms and prediction has been conducted globally at institutions established in countries such as South Africa, the US, India, Poland, and China. China has launched comprehensive research on the topic as part of its ninth Five-Year Plan to address critical scientific and technical issues [11]. Accurate prediction of rockbursts is difficult due to the complexities of the phenomenon. Researchers have used various theories, including strength, stiffness, energy, fractal, fracture damage, and catastrophe theories, as well as numerical analysis, to study the mechanisms and prediction of rockbursts [12,13]. The stress–strength parameters for rockbursts were established in practical rock engineering by Hoek and Brown [14] and Russense [15]. Assessing rockburst potential is an important component of rockburst mechanism research and involves the study of mechanical characteristics of rock under specific conditions [16]. Due to the complexity of rockburst assessment systems, there is no universally accepted method for predicting rockburst timing, despite the use of various methods. Currently, the best that can be done is to identify areas of high rockburst potential using empirical criteria, numerical models, or personal observations.

The rockburst phenomenon is caused by various mechanisms. The primary sources are often associated with the local underground geometry, such as pillars and cavities, and the underlying geology [17,18]. Rockbursts are typically characterized as strain bursts, pillar bursts, or fault-slip bursts and can occur in large mining operations [19]. In civil works, the most common form is strain bursting, but buckling and face crushing can also occur. For less stressed and deformed rock formations created by blasting, caving, and adjacent tunneling, impact-induced rockburst should also be taken into consideration [20]. Rockburst failure is a dynamic and complicated phenomenon distinguished from other types of rock failure by its quick release of stored elastic energy, enormous spatial scale, various failure mechanisms, and unpredictability. Rockburst, in contrast to other types of rock failure, involves the fast ejection of rock fragments, which can result in significant injuries or fatalities. Rockburst is a concentrated failure mechanism because the enormous loads that induce it are usually localized in specific parts of the rock mass. The failure process is determined by the geological and structural features of the rock mass, the mining processes and equipment utilized, and the magnitude and direction of the applied loads. As a result, rockbursts are difficult to predict and pose a substantial risk to underground mining employees and equipment, necessitating careful monitoring and management.

The rest of this paper is structured as follows: Section 2 gives an overview of rockburst phenomena and their classifications. Section 3 covers works dealing with rockburst research technologies and methods, while Section 4 discusses the mechanics of the rockburst process. Section 5 focuses on the various rockburst prediction methods and Section 6 explores the prevention and control procedures for rockbursts on a project site, with a specific focus on rockburst support.

2. Rockburst Definition and Classification

2.1. Rockburst Description

The first recorded rockburst event happened in the gold mines of Witwatersrand, South Africa in the early 1900s [6]. Rockburst occurs when rocks fail suddenly and violently, and there is a clear connection between rockburst activity and mining depth, while stress concentration is also a factor that can lead to failure on the walls of shafts and boreholes after drilling [21]. As mining progresses deeper into the subsurface, the in-situ stress increases compared to rock strength, increasing the likelihood of rockburst. Rockbursts are related to hard rocks, geological structures like faults and dykes, and high extraction ratios and mining techniques that produce stress. Most practical rock engineering tasks predict stress versus strength relationships at subsurface apertures and failure causes [22]. Depending on the rock mass and loading circumstances, failure might happen quickly or slowly. Violent failure with fast ejection characterizes brittle failure or rockburst. Spalling (non-violent brittle failure) or ductile behavior (ability of the rock material to bear extensive, inelastic deformation post-failure without significant loss of strength, e.g., compressing ground) may characterize slow or non-violent failure.

Ortlepp defined rockbursts as seismic events causing significant damage to tunnels or mine excavations [23]. Rockbursts are typically associated with excavation damage or support failure. The term does not refer to seismic events that do not cause damage. Table 1 provides a review of historical definitions based on keywords such as violent failure, highly stressed, brittle rock, and strain energy. These definitions range from small rock pieces falling off to large seismic events displacing rock and being felt on the surface, such as a local earthquake.

Table 1.

Developmental timeline of rockburst definitions (1965–2021).

There is no universally accepted definition of rockburst, but several viewpoints on the failure phenomenon and mechanisms exist.

2.2. Classification of Rockbursts

Based on the nature of rockbursts, classification systems have been developed worldwide to record and report rockbursts. Colson [48] modified phrases for induced, residual, inherent, and combination bursts. Hoek [14] classified rockbursts into strain and fracture types based on slip and fracture. Ryder [49] categorized rockbursts into two classes based on mechanical properties and seismic signatures. Tan [50] classified rockbursts into three categories based on stress action patterns. dividing rockbursts into intrinsic, induced, and fault-slip bursts [34], but this classification has drawbacks as it does not thoroughly explore the geomechanical aspect of rockbursts and cannot characterize the process mechanism.

- Inherent burst occurs when the in-situ stresses are high enough to cause initial excavation failure.

- Induced burst occurs when the remaining stresses after excavation impact the pillar.

- Fault-slip burst occurs when there is an existing major geological structure.

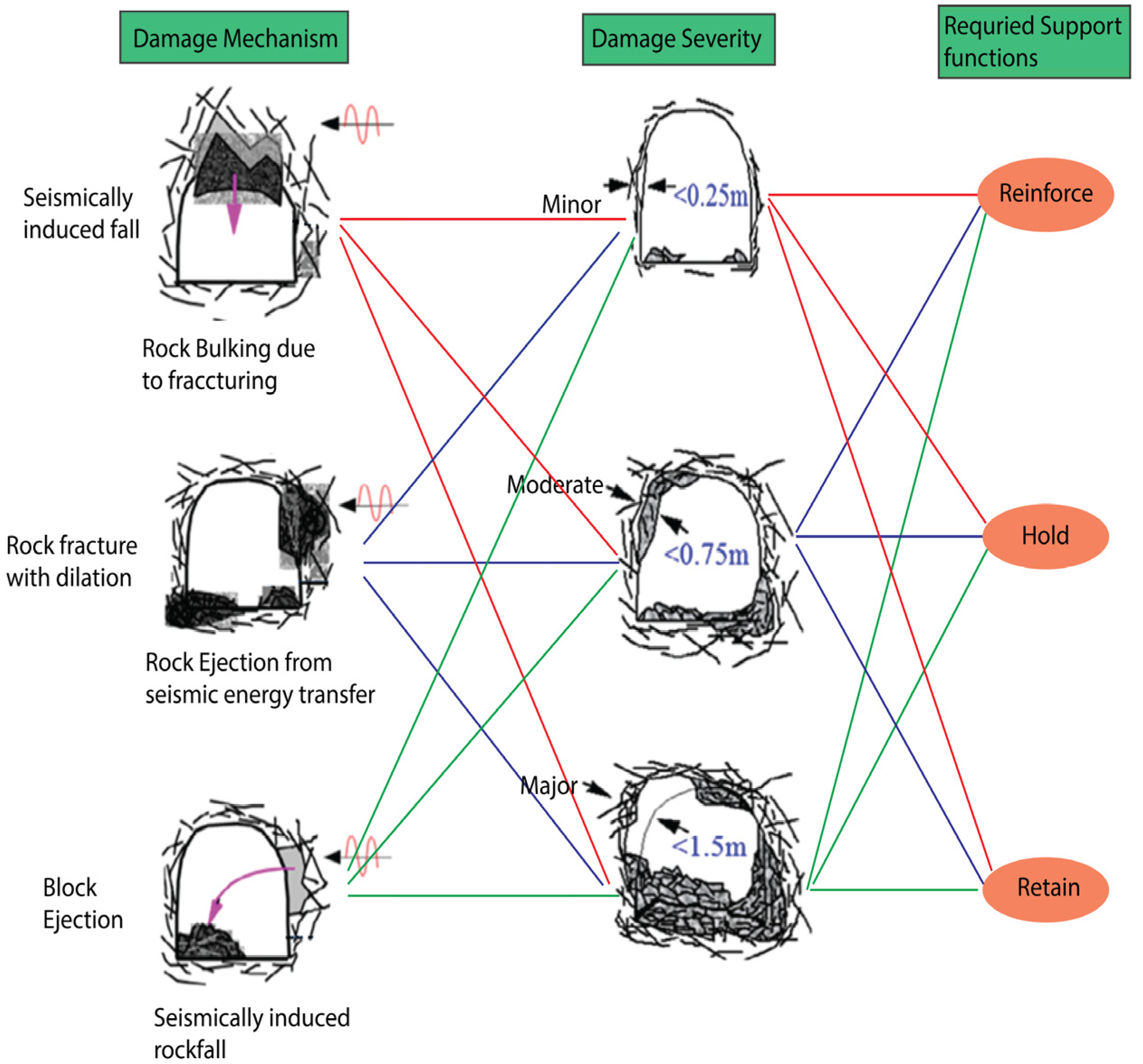

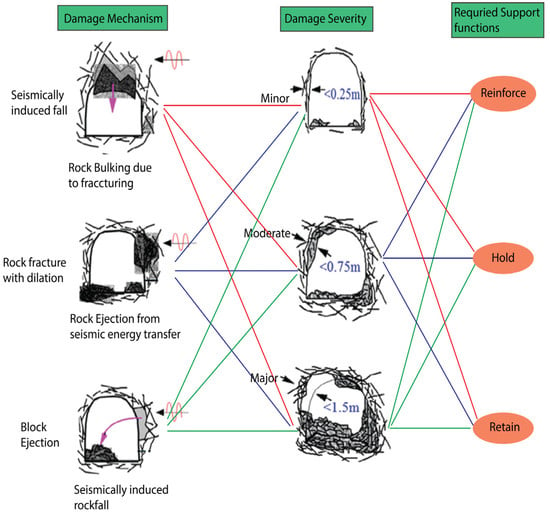

Rockbursts are classified as remote and self-initiated based on their triggering mechanism [7]. The definitions of rockburst mechanisms vary among authors, with Kaiser [51] referring to them as modes of failure. Rockbursts can also be further characterized as bulking, ejection, and seismically-induced collapse of ground based on the damage process [7] (See Figure 1).

Figure 1.

Types of rockburst damage mechanisms and damage severity (modified from ref. [7]).

Ortlepp and Stacey [17] classified rockbursts based on their seismic events and postulated source mechanisms. The classes are strain-bursting, buckling, face crush, shear failure, fault-slip, and shear failure, as shown in Table 2.

Table 2.

Classification of rockbursts [17].

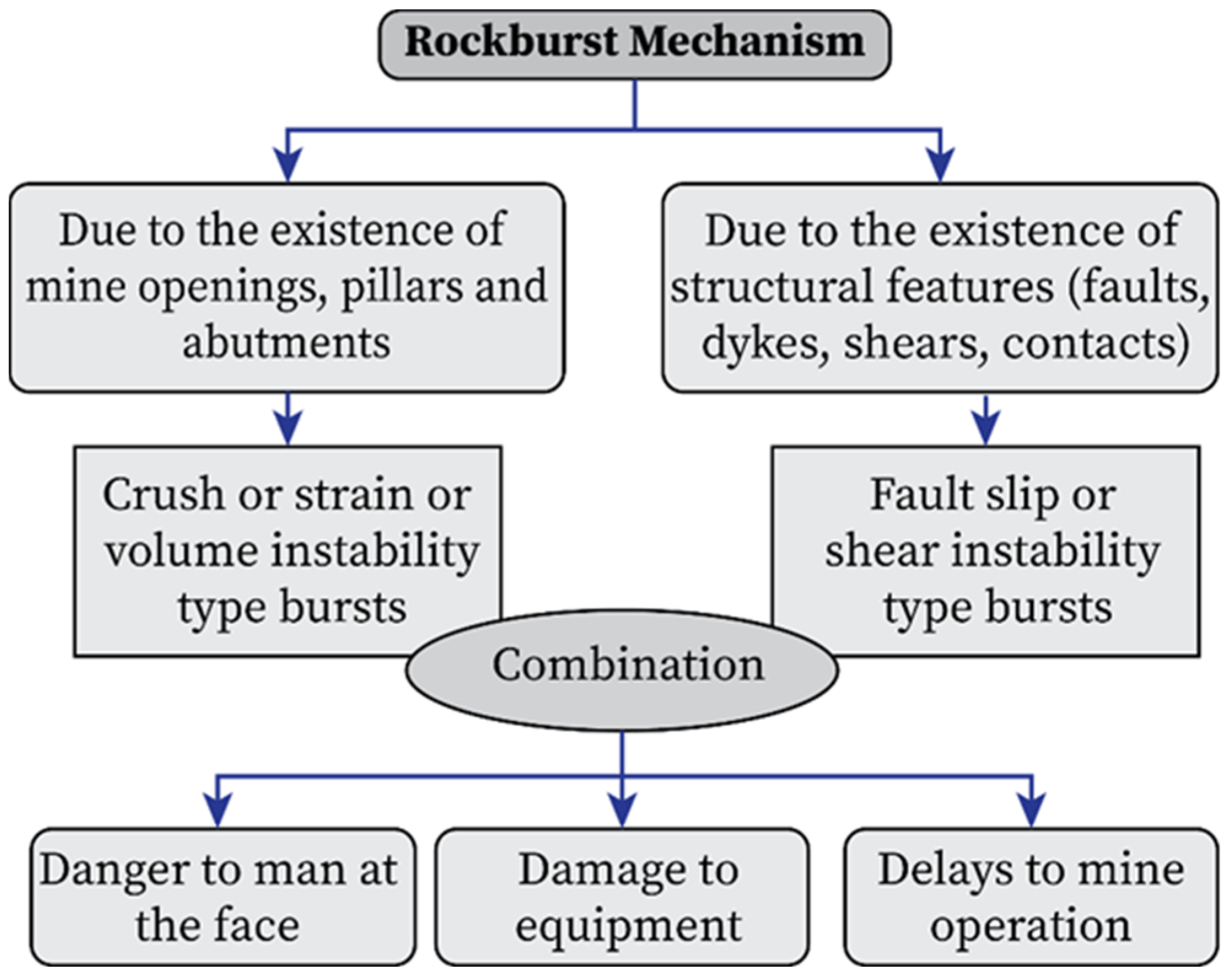

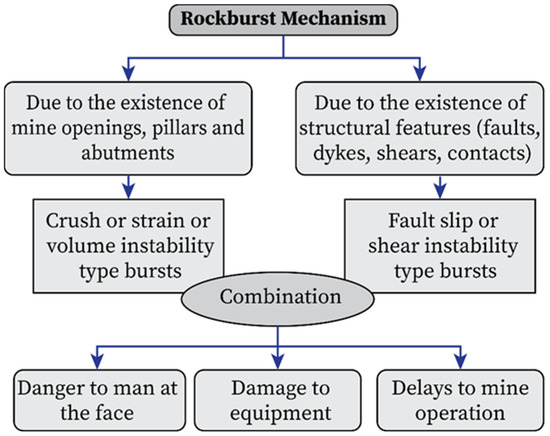

Tang [52] classified rockburst processes into three broad categories: strainbursts, fault-slip bursts, and mixed mechanisms (see Figure 2), and he stated that the bulk of rockbursts in deep hard rock mines are the strainburst type. Misich and Lang [53] investigated a more sophisticated rockburst categorization system that characterized rockbursts based on both the source and damage mechanisms at the excavation boundary.

Figure 2.

Classification of rockburst mechanisms [52].

Blake [6] classified rockbursts into three types based on their potential causes: strain rockburst, pillar collapse rockburst, and fault-slip rockburst. He [38] classified rockbursts into five types based on the amount of time from unloading to occurrence: instant rockburst, standard rockburst, delayed rockburst, strainburst, and impact-induced rockburst, He [54] divided rockbursts into two major types based on stress routes and experimental procedures: strainbursts and impact-induced bursts. Based on in-situ observations of rockburst at the Jinping II hydropower facility, Feng [55] classified rockbursts into two types based on observations at the Jinping II hydropower facility: immediate rockburst and time-delayed rockburst. Wu [56] and Qian [57] classified rockbursts into two or three groups based on the control factors of surrounding rock collapse and stress release mode. Li [58] classified rockbursts into six primary geomechanical types based on geomechanical assessments in China. These classifications are summarized in Table 3.

Table 3.

Rockbursts and their properties [58].

Deng [59] classified rockbursts into three types based on the magnitude of the dynamic stimulation force: inherent rockburst, triggered rockburst, and induced rockburst. This categorization is commonly used by mining and geotechnical professionals to understand how rockbursts occur. However, different categorization systems may provide contradictory findings due to varying assessment indexes. Li [58] provided one of the most comprehensive rockburst classifications, characterizing six types based on the failure plane, cracking (tensile or shear), and energy released. The best categorization for a mining site may be obtained by combining this classification with field observations and recorded seismic data. Rockburst predictions can be divided into short-term and long-term predictions, with short-term predictions based on field monitoring and long-term predictions based on the potential for rockbursts and field circumstances. However, rockburst evaluation and classification also depend on engineers’ appraisals and the availability of data, and a comparable occurrence may result in different measurements depending on who made the classification. Future studies should strive for a unified rockburst categorization technique.

3. Technologies and Methods for Rockburst Research

Ground conditions in underground excavations can be managed more effectively with the help of advanced support systems, thanks to advancements in equipment and materials and increased understanding of ground failure modes. Underground operations in rock masses with high in-situ stress, such as rockburst-prone and squeezing ground, pose challenges. There is no universal standard for determining ground support needs, as each design must be tailored to the specific site, its ground conditions, excavation method, and regulations. The interplay of the tube, rock mass, and excavation is complex, making tunnel support design a challenging task [14,60,61]. Rockburst technologies and methodologies can be categorized into theoretical research, numerical modeling, physical model testing, and in-situ monitoring.

3.1. Theoretical Research

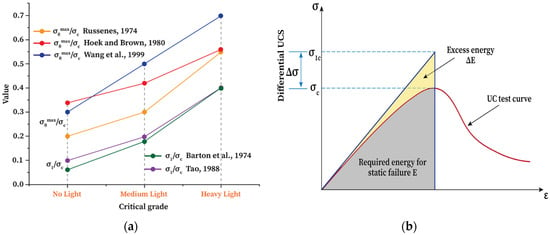

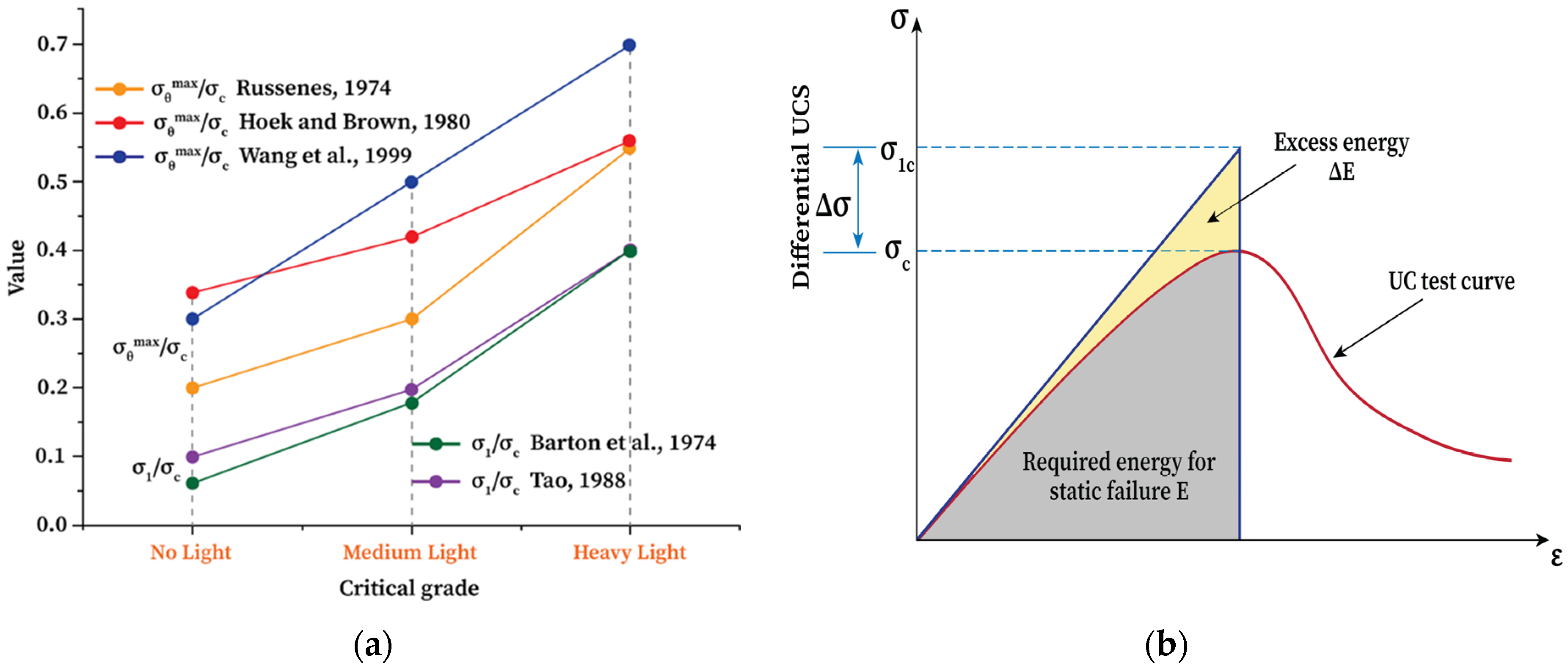

Many rockburst hypotheses have been suggested based on rockburst testing and field study, serving as the foundation for the development of prediction and preventive measures [62]. The current theoretical research focuses on analyzing the mechanisms and categories of rockburst through various aspects, such as strength, energy, defect, instability, and catastrophe theory. Bifurcation, dissipative structure, and chaos theory [24,63,64,65,66] are used to investigate the deformation and stability of rock mechanics systems. The most prevalent theories include strength, energy, stiffness, instability, and blasting reliability. The strength hypothesis is based on material strength in classical mechanics, but it does not specify how rockburst occurs. The energy hypothesis explains the rockburst failure process from an energy standpoint, but not the failure circumstances of an equilibrium state. The stiffness hypothesis states that the mine structure’s stiffness must be larger than the mine load for rockburst to occur, but it does not comprehensively understand the division and stiffness of the mine structure and load systems. The strength theory is a classic criterion for material failure, stating that when stress exceeds a material’s strength limit, it begins to fail. Obert and Duvall [25] first used this theory for rockburst prediction and it is commonly used in the form of stress-to-strength ratios, such as Turchaninov’s [67], Russenes’ [68], Barton’s [69], and Tao’s [32] criteria, based on which a series of rockburst strength criteria has been proposed, as summarized in Table 4. These standards can be divided into two categories: max tangential s to uniaxial strength and initial max primary stress to uniaxial strength. A comparison of the rockburst proneness grade divisions of these two groups is shown in Figure 3a. The concentrated local stress in the surrounding rock may exceed its long-term strength without causing rockburst. The strength theory can only show whether a rock mass has failed, but not whether the failure is stable or unstable [70].

Table 4.

Rockburst strength criteria [71].

Cook [76] proposed the energy hypothesis for rockburst in 1963, stating that it happened when the energy released by the surrounding rock system was higher than the energy used during mechanical equilibrium state failure [24]; it was seen as a violent energy release mechanism. Salamon [77,78] and Walsh [79] examined the balance between stored and dissipated energy during disturbances. He developed an analytical approach to assess the risk of rockburst caused by tunneling. The energy model of strainburst is shown in Figure 3b, with Δ and ΔE illustrated as the differential uniaxial compressive strength and excess energy, respectively. The ultimate stored energy of rock under the 3D stress state is much greater than the energy required for static failure under a biaxial or uniaxial state after unloading. Thus, once unloaded, the excess energy mainly transfers to the kinetic energy of the rock mass. Rock in a 3D stress state has more stored energy than necessary for static failure after unloading. Once unloaded, the surplus energy turns into the kinetic energy of the rock mass. The energy theory is widely accepted but difficult to use in practice due to difficulties in establishing and quantifying stress and strain fields. Numerical simulations and energy indices are often used to overcome this challenge. However, these indices have limited significance in evaluating a geological formation’s hazard amplification impacts [49].

Figure 3.

(a) Rockburst intensity divisions based on different strength criteria (modified from ref. [71]). (b) Energy model of strainburst (modified from ref. [54]).

Figure 3.

(a) Rockburst intensity divisions based on different strength criteria (modified from ref. [71]). (b) Energy model of strainburst (modified from ref. [54]).

The rockburst rigidity theory explains rockburst as a systematic stability problem [24,80] and considers the relationship between the stiffness of the testing machine and the post-peak deformation of the sample. The occurrence of rockbursts in mines can be identified by comparing the stiffness of the pillar and surrounding rock to that of the testing machine and sample [24,77,81,82,83,84]. The instability theory is more extensive than the strength and bursting liability theories, but its implementation is limited by difficulties in quantifying pillar and rock stiffness. Rockburst is a complex process that is difficult to describe with a single hypothesis, leading to a reliance on numerical simulations [85], physical model tests, and in-situ monitoring.

3.2. In-Situ Monitoring

In-situ monitoring can accurately measure rockburst parameters in real-time, allowing for quick evaluation and prediction of rockburst danger. The most common monitoring methods include microseismic monitoring [86], microgravity [87], infrared thermal imaging [88], electromagnetic radiation [89], acoustic emission (AE) [90], and the photoelastic method [91]. Acoustic emission and microseismic monitoring can detect failure in the early stages, before total collapse and damage. Table 5 summarizes four non-destructive methods used in rockburst trials, including high-speed photography, which records dynamic information on rock ejection. Each method has unique properties and data processing mechanisms.

Table 5.

Summary of monitoring technologies for rockburst tests [71].

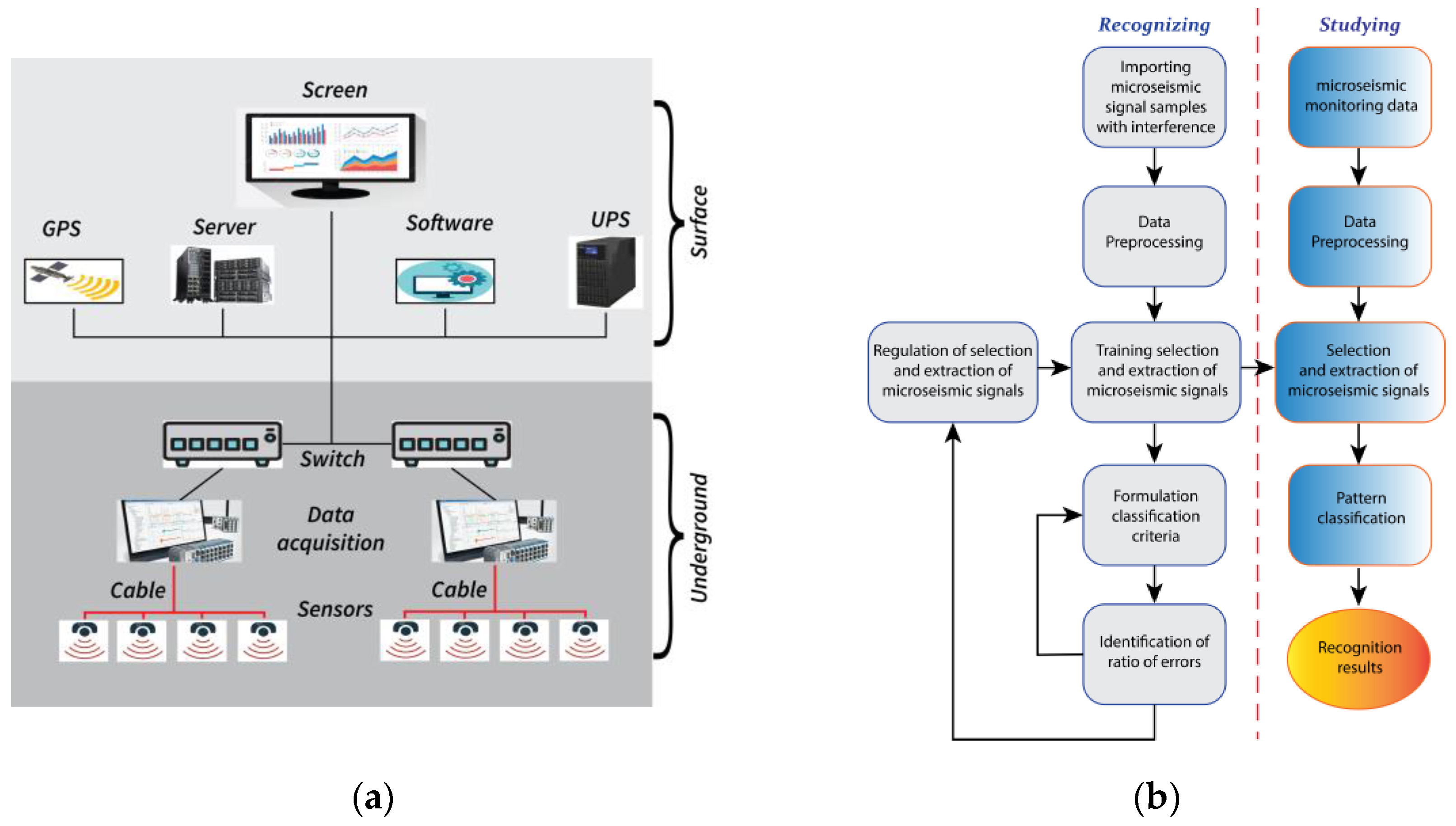

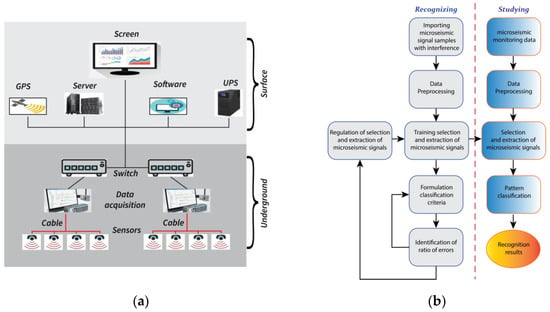

Considering its advantages, such as real-time monitoring, wide detection range, big data scale, and no harm to production, microseismic monitoring is best for rockburst event monitoring. Figure 4a shows a typical mine microseismic monitoring system. It is mainly used for rockburst early warning. The time and location of microseismic events are analyzed from microfracture signals, and then the number of events, energy, apparent volume, and apparent stress are determined for rockburst prediction (Figure 4b). The precision of microseismic location meets mine requirements, but obtaining usable rules from huge amounts of data remains a challenge in microseismic monitoring [92].

Figure 4.

(a) In-situ monitoring for rockbursts: (a) Structure of microseismic monitoring system in a mine (modified from ref. [93]); (b) pattern recognition for microseismic signals (modified from ref. [92]).

3.3. Physical Model Tests

Physical model tests are important for understanding rock mechanics and engineering challenges, as they provide key information about rock characteristics [94]. As rockbursts are a significant problem in rock mechanics and engineering, many physical tests have been created to address rockburst concerns. These tests have specific criteria for identical materials, theories, instruments, and equipment to simulate the abrupt and dynamic nature of rockbursts. However, few physical models have been designed specifically for rockbursts. To achieve accurate results, the rockburst strength of the materials used should not be too low and must have a similar brittle connection. Additionally, suitable materials with similar hard structure surfaces and structural planes with various geometric shapes and mechanical qualities must be explored.

Physical Modeling excavation has the following four major schemes:

- A cylinder core is pre-inserted and removed once the specimen dries, it is important to note that this method does not fully represent tunnel excavation and the stress related characteristics.

- After drying and beginning stress, multiple tiny pieces are pre-inserted and pushed out in sequence, simulating sectional excavation, but matching small pieces with the test specimen is difficult.

- Manual excavation of dried, loaded specimens is performed with a drilling rig or equipment, but difficulty arises with hidden excavations in restricted areas.

- High efficiency is desirable, but a gap between the basic rock-breaking mechanism and the in-situ machine leads to low test accuracy. Keys to accuracy include TBM excavation rate, cutter head thrust, torque, shoe pressure, shield pressure, explosive selection, and similarity index of blasting impact.

Several researchers, including Vacek [95], Yang [96], Pan [97], Li [98], and Xu [99], have studied rockbursts in tunnels made of similar materials using both physical and mathematical modeling methodologies. Chen and Bai [100] used physical tests to analyze rockburst processes and mechanisms in circular caverns, while Li [101] recently conducted a physical simulation of rockburst in a typical tunnel cross-section. Although physical model testing has limitations, such as difficulty in simulating real-world conditions, limited monitoring methods, and resource consumption, it remains a valuable tool for investigating complex mining and geotechnical engineering issues.

3.4. Numerical Simulation Techniques

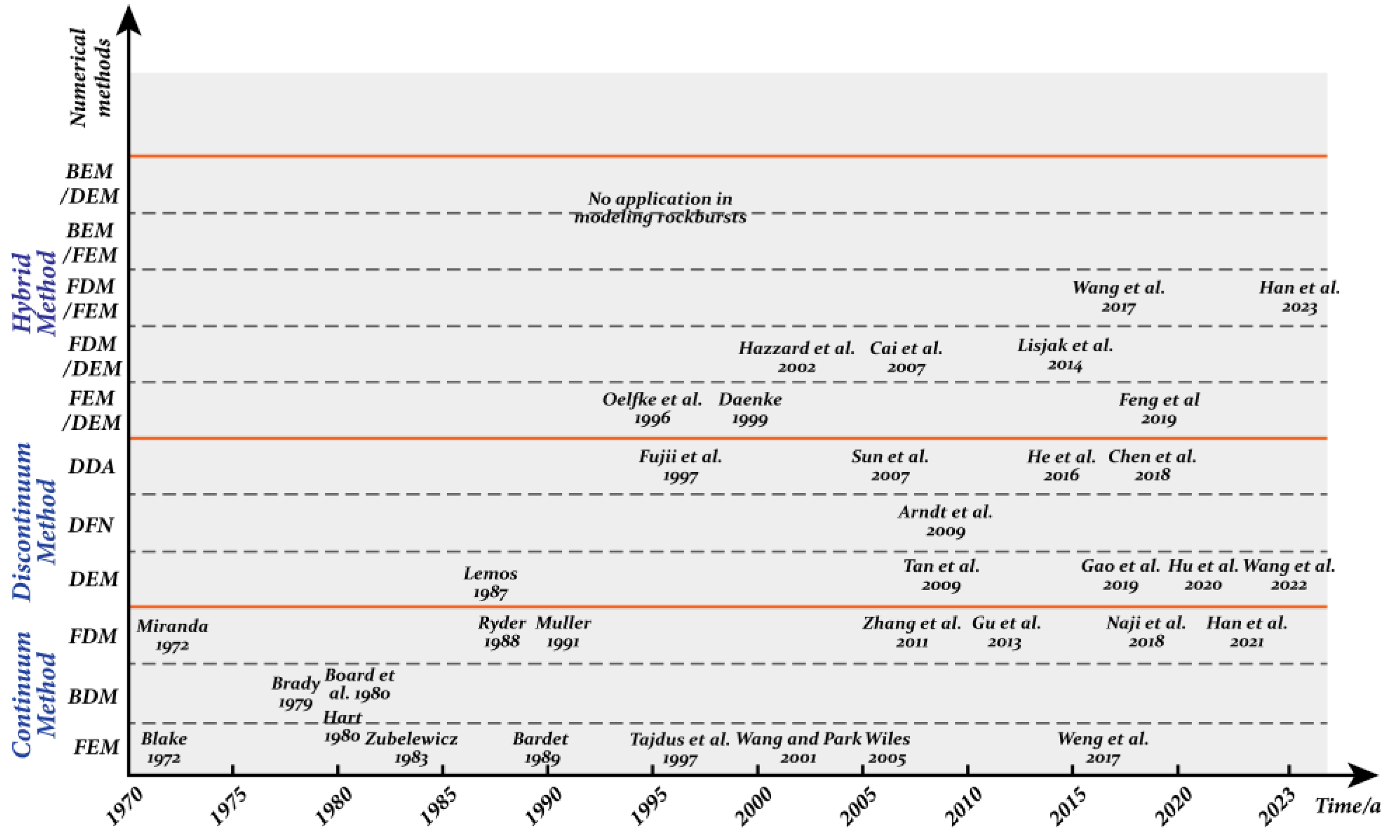

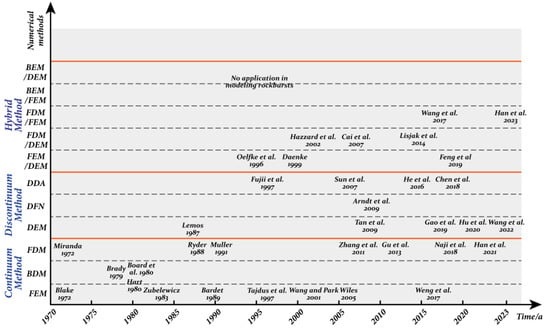

Numerical methods and computational techniques have become essential tools for engineers and researchers to tackle previously difficult technical and scientific challenges [94]. Much of the research on understanding and predicting rockbursts has been conducted using numerical modeling. According to Jing and Hudson [102,103], contemporary simulation methodologies in rock mechanics can be divided into three categories: continuum approaches, discontinuum approaches, and hybrid approaches. Spalling is a significant factor in rock faces subjected to dynamic loads from blasting or rockbursts. The use of numerical methods to study rock mechanics problems has been common since the 1960s and was employed in the 1970s to study rockburst difficulties. Numerical simulation is an effective technique for assessing rockburst hazards and improving mining design. The finite difference method (FDM) and the discrete element method (DEM) are commonly used for numerical modeling of rockbursts. The discontinuum approach represents large displacements and nonlinear constitutive behaviors in rock masses and joints [104,105,106,107,108,109]. The primary damage area of rockbursts is focused at the excavation face and linear material behavior is demonstrated in the far-field zone without cracks [103]. Cai [90] used the FLAC/PFC coupled numerical model to study excavation-induced acoustic emission in large-scale underground excavations, while Wang [110] suggested a coupled numerical technique for investigating the influence of excavation on ground motion. Figure 5 shows the evolution of various numerical approaches used in simulating rockbursts.

Figure 5.

History of numerical methods employed in modeling rockbursts.

Current numerical simulations for rockbursts can be divided into two groups based on their goal: understanding the mechanisms of rockbursts and engineering applications. Advanced simulation methods such as DEM, PEM, and PD are needed for understanding the mechanisms of rockbursts, but their higher calculation costs may limit their use for engineering purposes. Nominal techniques for modeling rockbursts often perform better on discontinuity difficulties, such as crack propagation and branching, but struggle to identify rock blocks created by fissures. The simulation should be able to estimate the kinetic energy of each block to evaluate the overall severity of the rockburst. Simulating structural rockbursts can be more challenging than strainburst simulation. FDEM has been used to study the interaction between existing discontinuities and new cracks during fault-slip rupture. A 3D simulation is necessary to achieve an accurate prediction of rock mass strength.

3.4.1. Continuum Approaches

Continuum approaches, which include the finite element method (FEM), boundary element method (BEM), and finite difference method, are based on classical continuum mechanics and thermodynamics theory (FDM). The stress–strain relationship of materials is introduced using the principle of conservation of energy, momentum, and mass based on the deformation and stress continuity in the object. The static or dynamic problems are transformed into partial differential equation (PDE) initial and boundary value problems, which are then discretized into linear, nonlinear, or time–history integral equations for numerical solutions. Muller claimed that FDM is better suited for rockburst simulation than FEM because FLAC can simulate local dynamic processes without causing the entire model to fail [111]. This is due to FLAC’s use of an iterative oscillating sequence that boosts out-of-balance forces within narrow grid boundaries. Cai reported similar results when comparing FLAC and Phase2 simulation results, pointing out that the difference in analysis results was due to explicit and implicit solvers, with one tool handling dynamic unloading by default while the other tool could not [112]. As a result, an explicit and dynamic solution scheme is better suited for rockburst simulation because the explicit numerical scheme is stable when the physical system is unstable [113].

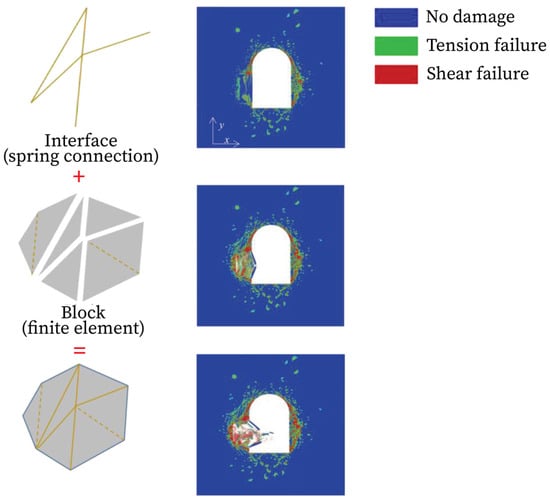

3.4.2. Hybrid Approaches

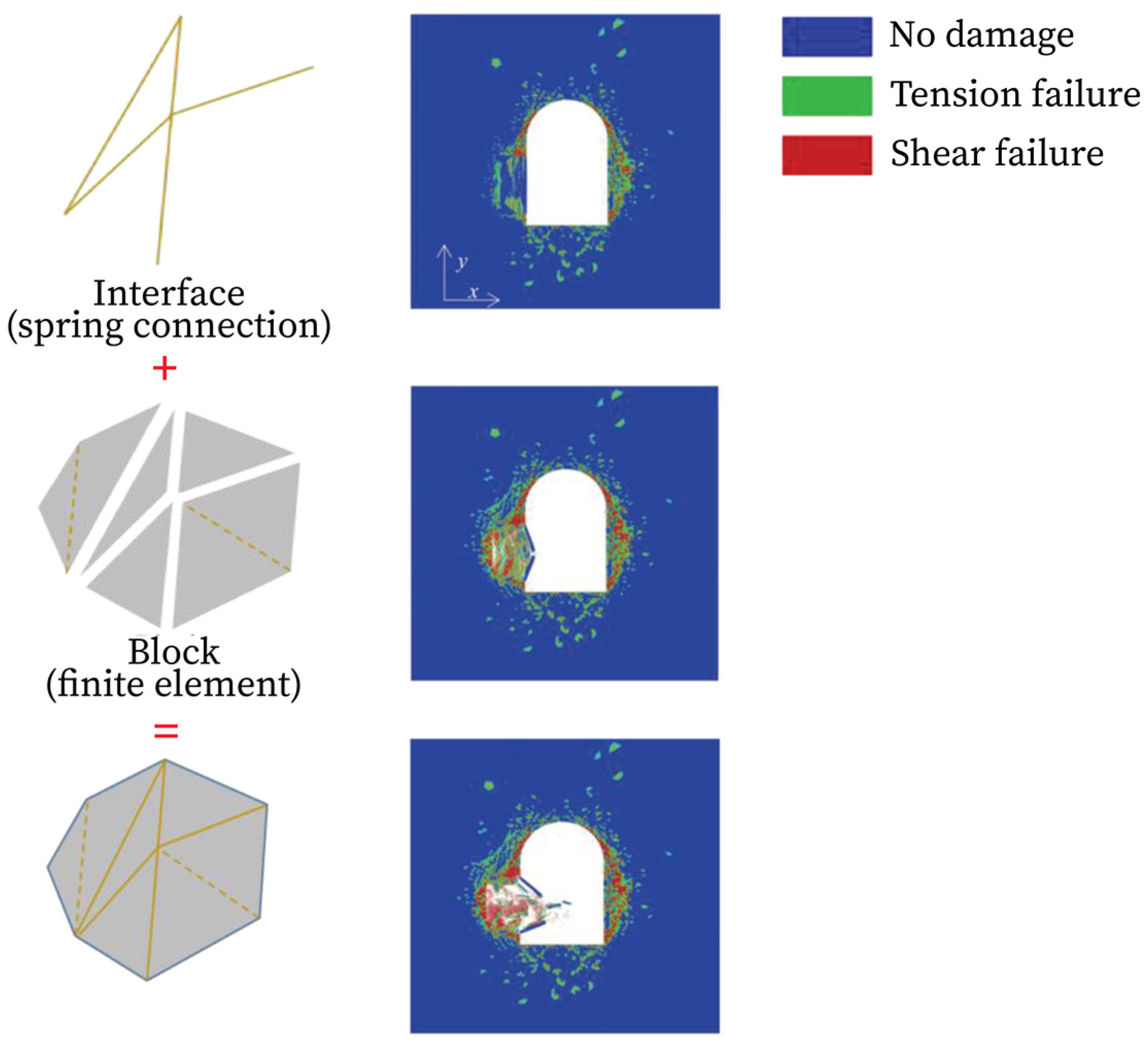

In general, the hybrid approach model describes continuous deformation and discontinuous fracture using finite elements and contact surfaces, respectively. The failure process of rockburst is characterized by a transition from a continuous to a discontinuous state as well as a transition from static to dynamic damage. As a result, the simulation should use an appropriate constitutive model to describe the material separation process as well as a suitable mechanism to calculate the interaction forces between elements that control particle motion. Explicitly modeling the continuous to discrete transformation yields a physically realistic representation using a number of testable parameters. The process and principle of GDEM are depicted schematically in Figure 6, where the block composed of one or more finite element elements is used to characterize the elastic, plastic, damage, and other continuous properties of materials, and the interface between them, using spring connectors, is used to characterize the fracture, slip, collision, and other discontinuous properties. The process of bending-bulging rockburst can be well captured by GDEM. In general, hybrid approaches can better describe the transition from continuous deformation to discontinuous fracture than continuum and discrete approaches, demonstrating their advantage in simulating rockbursts. The computational costs of hybrid approaches, on the other hand, are extremely high, thus limiting their applications.

Figure 6.

The principle schematic of GDEM numerical model (left) and the failure process of bending-bulging rockburst (right) [114].

4. Rockburst Mechanisms

4.1. Rockburst Instability Mechanisms

Rockburst mechanisms may be pretty sophisticated because of the complex physical and mechanical qualities of rock masses, the triggering effects of geomechanical circumstances, and construction factors. The rockburst mechanisms are yet unknown. As Brown [115] pointed out, it is not easy to agree on a definition of rockburst. Many research centers worldwide have looked at successful solutions to rockburst difficulties. These advancements represented a breakthrough in rock mechanics research and are of significant importance. Hoek and Brown [14] also said that this form of progressive failure mechanism is not well understood, posing a dilemma for rock mechanics researchers. Several ideas on the mechanisms of rockbursts have been offered to date, including the strength theory, the energy theory, the bursting liability theory, the rigidity theory, and the instability theory. Brauner initially offered the strength theory [116], on which Yao, Jia, and Romashov [117,118,119] proposed additional strength requirements for rockbursts. However, the strength theory is required rather than sufficient for rockbursts. It can show whether or not a rock mass has failed. It cannot, however, determine if the rock mass collapse is steady or unstable, i.e., whether rockburst will occur. Cook suggested the energy theory for rockbursts based on years of rockburst research in South Africa [24]. It was stated that rockburst happens when the mechanical equilibrium condition of the surrounding rock mass system is disrupted and the energy released exceeds the energy absorbed. Brauner suggested the energy rate hypothesis (Equation (1)) in the 1970s [120]:

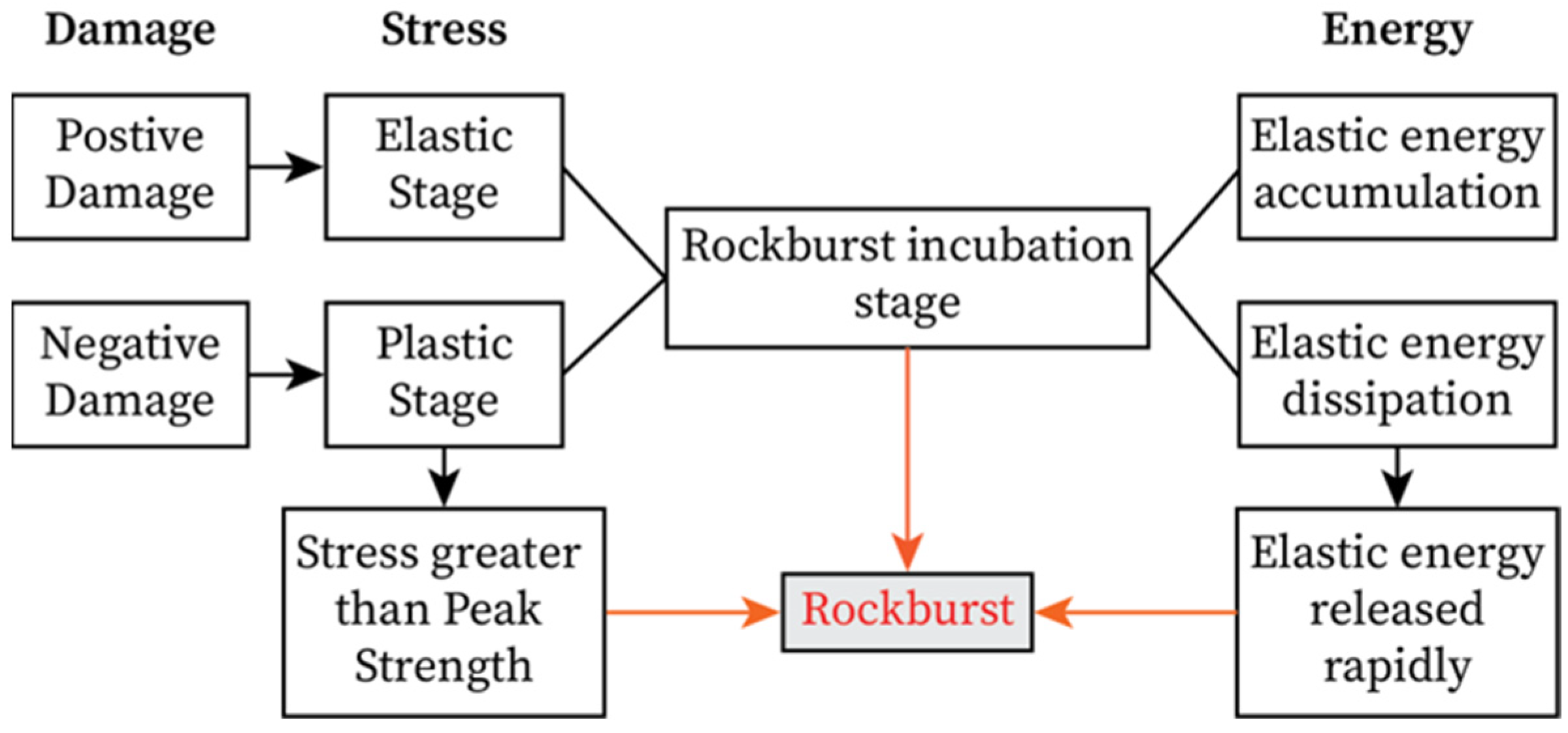

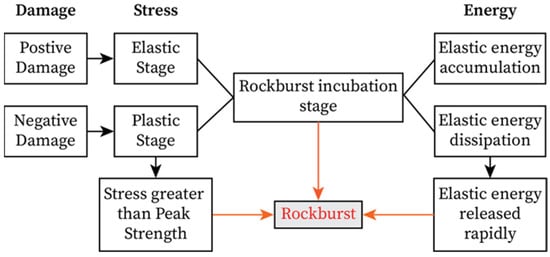

where is the effective coefficient of surrounding rockmass energy release, is the effective coefficient of energy release of the orebody, is the energy held by surrounding rockmass, is the energy stored by orebodies, and is the energy spent at the junction of orebodies and surrounding rock masses. The energy theory, based on the law of conservation of energy, overcomes the limits of conventional theory and provides a solution to the subject of the rockburst energy source. The energy hypothesis has a flaw in that it is impossible to identify the scope of surrounding rock masses relevant to fractured rock masses caused by rockburst, making it difficult to compute the energy involved in the rockburst event [121]. As illustrated in Figure 7, rockburst happens during the pre-peak period, whereas rockburst occurs during the post-peak stage. Furthermore, because energy is connected to the stress and strain fields of the surrounding rock masses, which are difficult to quantify, the energy theory can only give some qualitative information for rockburst occurrence and cannot be used in engineering procedures to anticipate rockbursts.

Figure 7.

Stress–energy mechanism of rockburst preparation and development (modified from ref. [122]).

The Kidybinski hypothesis on bursting liability posits that rockburst occurs when the inherent bursting liability of a rock mass exceeds a critical value [123]. The bursting liability can be indicated by various measures, such as energy, duration, deformation, and stiffness indexes [66]. However, it is important to note that the burst liability index is just one aspect of the rock mass and the occurrence of rockbursts is influenced by both the rock mass characteristics and the stress conditions in the system. Therefore, the bursting liability index should be used as a reference for support design rather than as a criterion for rockburst occurrence. Cook and Hodgeim were the first to obtain the complete stress–strain curve of marble using the rigidity theory by enhancing the test machine’s stiffness. This breakthrough in rock mechanics provided a better understanding of rock fracture mechanics [124] and revealed that the test machine’s lower rigidity caused a rock specimen to fail violently compared to its unloading stiffness. Cook utilized these findings to explain rockburst events in mines and shed some light on the phenomenon. The rigidity hypothesis provides insight into the cause of rockbursts and is useful in avoiding them in engineering projects. However, the hypothesis and its associated mechanism cannot fully describe the dynamic process of rockburst in the mechanical system. Additionally, the structural rigidity of mines included in the theory is unclear and lacks a suitable calculation method. Furthermore, it is challenging to determine the stiffness of mine construction after the peak strength is reached, which limits the applicability of the rigidity hypothesis.

More complex instability phenomena arise from the interaction of rock–rock interfaces. If the properties of the surrounding media are different for the same rock mass, the failure sequence and mode might vary. Previously, only the quality of the failed mass and energy generated were considered. However, recent studies [124,125] have shown that the energy released during rock mass fragmentation is much greater than that from the failed mass alone. The energy source for rock mass failure in events such as rockbursts comes from both the failed mass and the surrounding media’s elastic energy release. Further investigation into the interaction of rock–rock interfaces can provide important insight into the study of rockburst mechanisms.

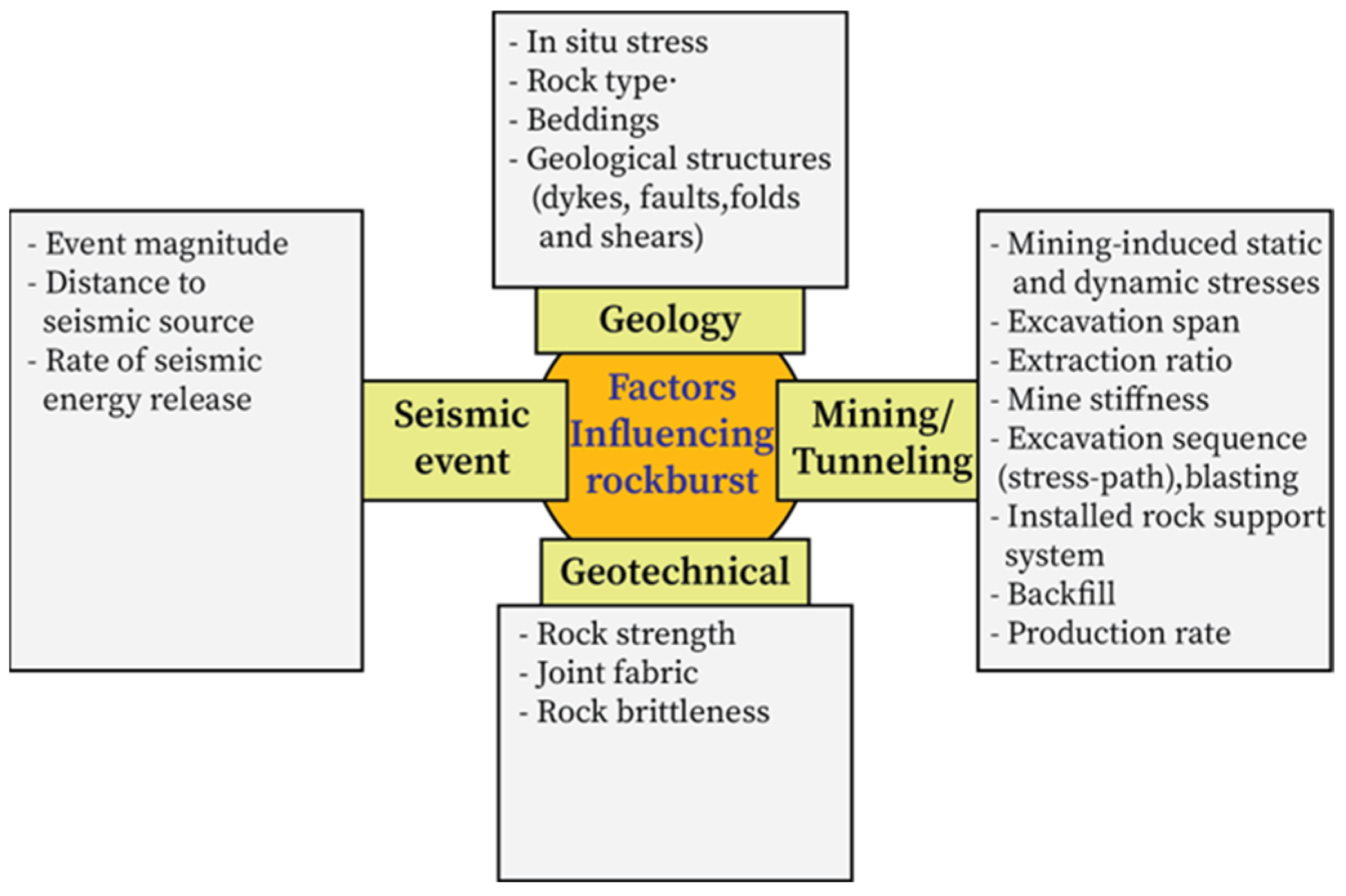

4.2. Factors Influencing Rockburst Instability

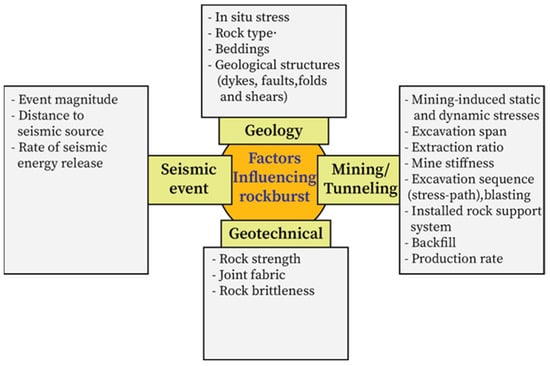

Identifying the primary elements that influence the incidence and severity of rockbursts is a key step in understanding this complex process. However, unifying the rockburst processes that occur under different geological contexts and excavation disturbances remains a challenge. Researchers use technical examples and physical model testing to gain insight into the formation circumstances and development processes of rockbursts [7,8,34,126,127]. The damage caused by rockbursts is influenced by a combination of seismic events, geology, geotechnical factors, and mining activities, according to Kaiser and Cai [2], as shown in Figure 8. Seismic events and geology determine the severity of dynamic loads at the damage areas, while geotechnical and mining factors dictate the site’s reaction to seismic impulses. By focusing on mining activities, such as the mining sequence, excavation span, and rock support system, it is possible to control the potential for rockburst harm. Modifying the mining process, changing the mining sequence, and changing drift sites are some ways to achieve this goal. A solid subterranean building technique will result in a safer work environment, but it is not enough on its own. A comprehensive rockburst support plan must also be in place. Numerous case studies have demonstrated the importance of appropriate rock support systems in preventing explosive ground.

Figure 8.

The main factors influencing rockburst damage and its severity (modified after ref. [2]).

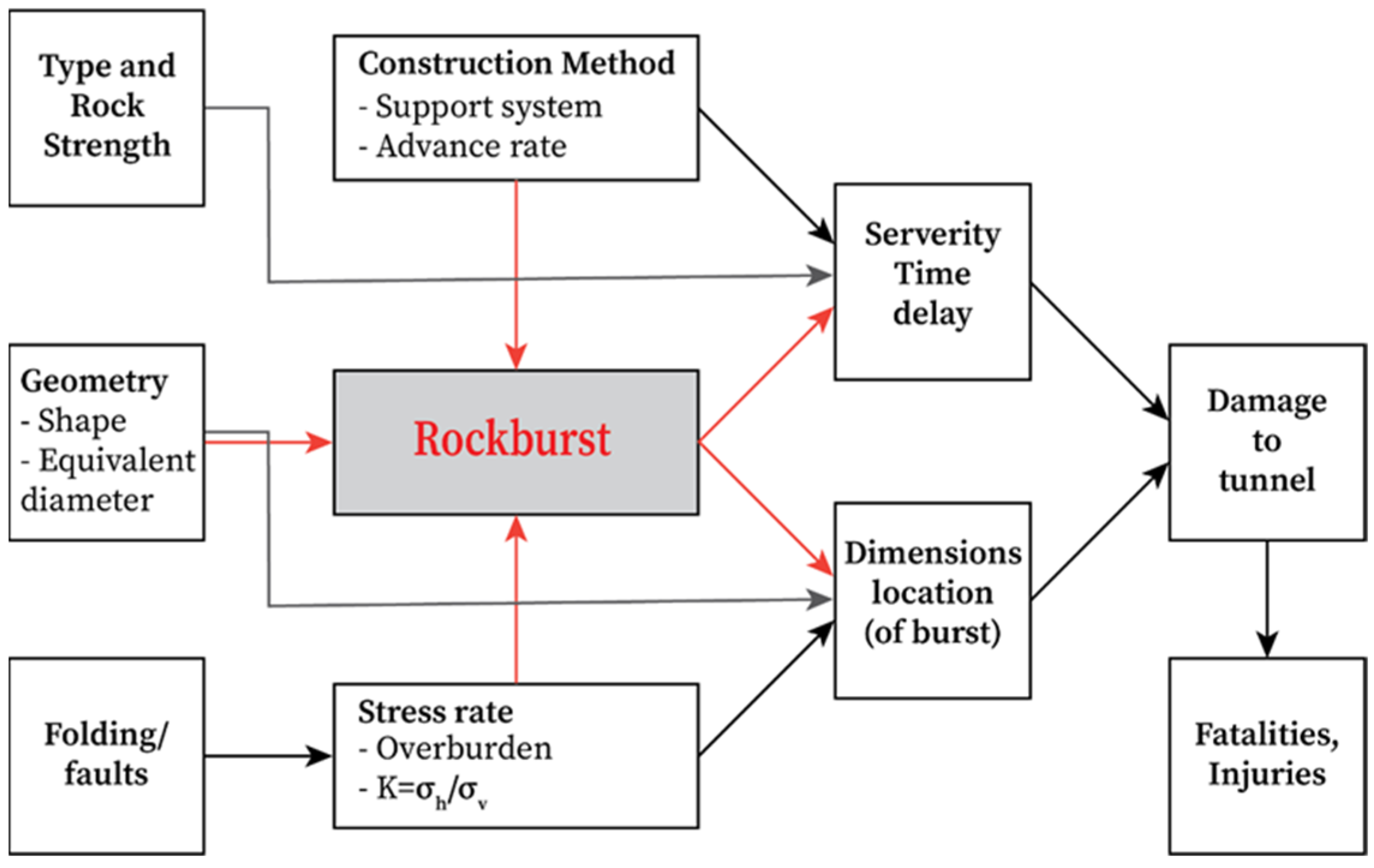

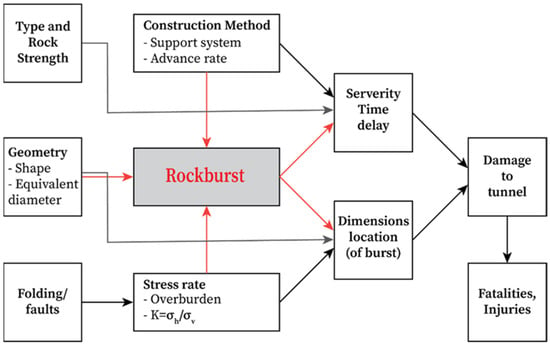

Meng et al. conducted physical model testing to study the elements that affect slide rockburst caused by a structural plane. The results showed that the average stress level had a significant impact on the failure mode of joints, which aligned with the conclusions drawn from in-situ microseismic monitoring analyses [128,129]. Sousa [130] conducted research on rockburst incidents in subsurface constructions and created an influence diagram, depicted in Figure 9, that showcased the parameters affecting the occurrence of rockbursts.

Figure 9.

Influence diagram for rockbursts (modified from ref. [130]).

Despite extensive research on the rockburst process, a unified hypothesis has yet to be established. This is due to the complexity of the numerous and diverse factors that influence the rockburst mechanisms and the nonlinear relationships between these factors. As a result, it is difficult to fully explain the mechanics of rockbursts in different situations and creating a general mechanical theory for rockbursts remains a challenge.

Influence of Rock Materials

Rockburst is generally more likely to occur in hard and brittle rock formations. An increase in coarse-grained columnar minerals and a decrease in fine-grained flake minerals can increase rock rigidity, thus increasing the likelihood of rockbursts [131]. Zhai investigated and compared the rockburst behavior of six types of intact hard and brittle rocks using a one-free-face true triaxial loading test [132]. The study discovered that tensile splitting near the free face accompanied granodiorite, granite, and marble strainbursts, resulting in higher rockburst intensity, whereas basalt, sandstone, and limestone primarily experienced shear rupture as the dominant failure mechanism. The primary factors that contribute to varying rockburst behavior in different rock types were identified as differences in inherent microstructures and fracture evolution under loading. The presence of structural planes influences rockburst phenomena in addition to inherent rock characteristics such as strength, stiffness, and fragmentation. The influence of structural planes on rockbursts can be divided into two categories. The first type is rockburst caused by local failure or sliding of structural planes, also known as fault- or structural-slip rockburst. The direct shear test is commonly used to investigate the mechanism of fault sliding and gain a better understanding of the occurrence of this type of rockburst [71].

Shear failure of faults or discontinuities and the resulting dynamic disturbance wave are major triggering mechanisms for rockbursts in mining engineering [2,17,133]. Small-scale structural planes around the tunnel may also contribute to rockbursts in tunnel engineering. Interlocked sawteeth and asperity rupture can cause tensile failure in the hanging wall or footwall, resulting in rockbursts [134,135]. Bedding is the second most studied group of structural planes. Through UC testing on coal samples with varying dip angles, rockburst proneness was found to be strongest at 90°, followed by 0°, and weakest at 45° [136]. Rockbursts were less likely to occur when the dip angle was small but they could be more intense, based on a series of strainburst tests on bedded sandstone [137,138].

5. Rockburst Prediction Methods

Predicting rockbursts is crucial for preventing and controlling rock failure in underground openings or tunnels [139]. There are two types of rockburst prediction: long-term, used during the design stage, and short-term, used during the life of the project [140]. Short-term prediction mainly uses field monitoring methods, such as micro-seismic, electromagnetic radiation, drilling cutting, micro-gravity, and infrared thermal imaging. High-frequency microseismic events have been successfully captured at mines using a high-frequency microseismic device [141]. Wang and colleagues observed that microcracking before rockbursts can be detected using microseismic monitoring [142]. Petukhov was the first to propose utilizing the volume of drilled coal debris to predict rockburst risk in coal mines [143]. The volume of drilled coal debris has been proposed to predict rockburst risk in coal mines.

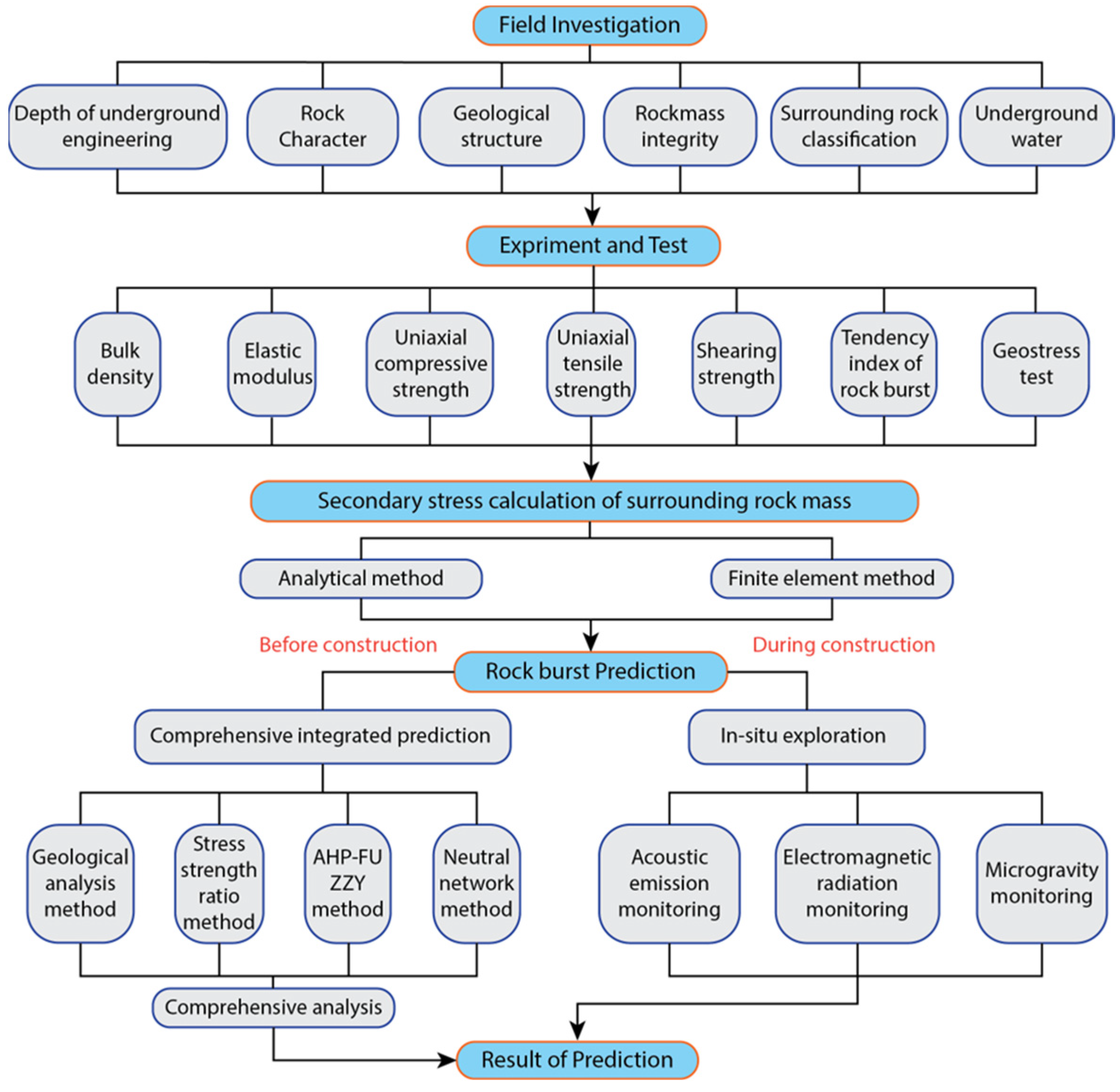

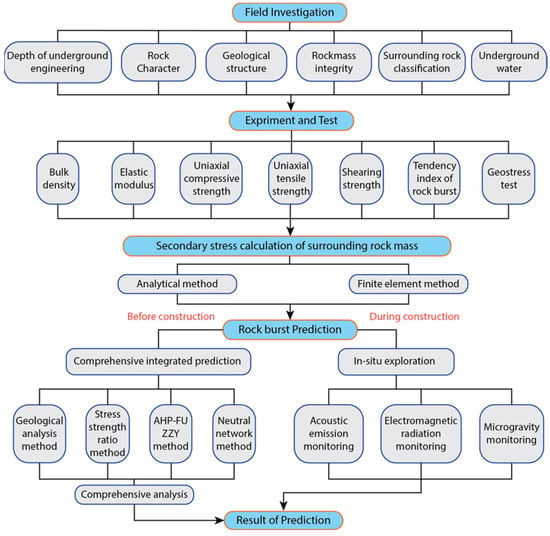

Long-term rockburst prediction assesses the likelihood of rockbursts and relevant field conditions using various markers. These markers include the strain energy storage index (WET) proposed by Kidybinski [123] and the elastic strain energy density used by Wattimena et al. [144]. Using this prediction method at the planning stage of future excavations helps to avoid rockburst hazards. However, the occurrence of rockbursts depends on various factors, such as ground stress, rock mass integrity, and strength, which have interrelated effects, leading to limitations in current engineering prediction systems. Figure 10 summarizes the comprehensive integrated method, after trials in Western China, using detailed in-situ investigations, rock mechanics experiments, and secondary stress calculation to predict rockbursts through qualitative and quantitative methods and single- and multi-factor predictions. This method will be discussed in detail in the following sections, along with the use and significance of stress and energy approaches in predicting rockbursts in underground excavations.

Figure 10.

Academic and scientific approaches of comprehensive rockburst prediction (modified after ref. [145]).

5.1. Stress Methods

The empirical stress estimate method is widely used for underground mining rockburst prediction and prevention. This method uses various indices and indicators to assess the rock mass, with geomechanical properties of undamaged rock and in-situ or produced stresses as crucial indicators of rockburst severity [146]. Observations such as drill core descriptions can provide valuable information on rock mass attributes and help to locate high-stress zones [147]. Brittleness, which refers to a decline in strength caused by the connection between grains, is used to assess rockburst intensity [32,148]. The rock brittleness coefficient is defined as the ratio of UCS to the tensile strength of undamaged rock based on experimental findings and site assessment [149], as expressed in Equation (2):

where is the uniaxial compressive strength of the rock and is the tensile strength of the rock. Both values are in MPa (Table 6). The mean stress index and strength index, ratios of rock strength to stress, are empirical approaches to rockburst prediction.

Table 6.

Rockburst intensity depending on the brittleness coefficient [149].

There is ongoing debate on how to accurately determine the in-situ rock strength, with different researchers proposing methods such as crack initiation stress or crack damage stress [150,151,152]. However, in-situ strength and stress remain poorly understood, partly due to the influence of excavation shape and boundary roughness on redistributed stress near the excavation boundary (σθmax) [153,154].

5.2. Energy Methods

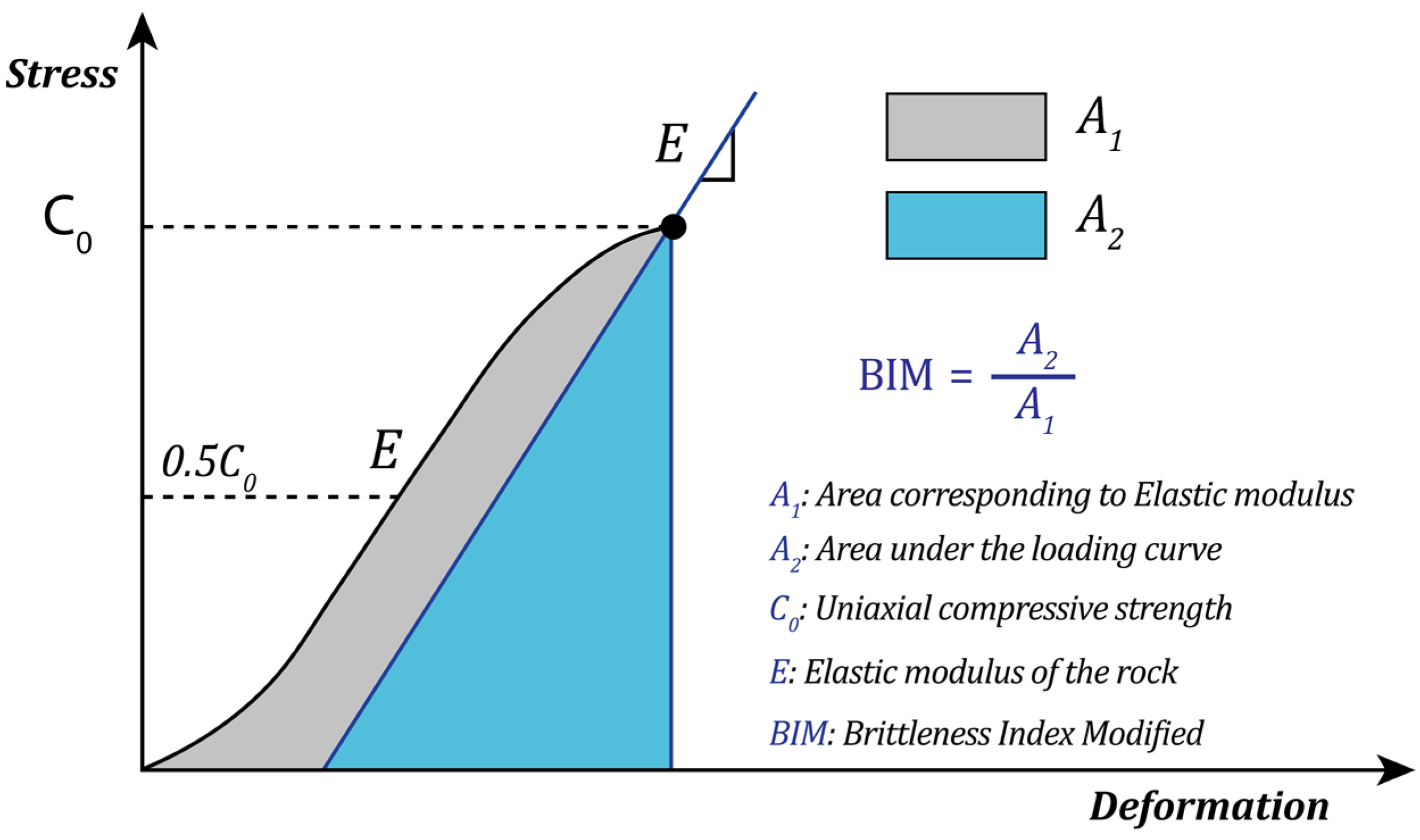

The stored strain energy in a rock mass fluctuates during excavation and its release during subsurface excavation can predict rockbursts. Rock mass energy analysis can determine the nature and severity of rockbursts. Cook’s study [76] was one of the first to show the relationship between energy changes in rock mass and rockburst mechanisms. The elastic energy stored in the rock is a major factor in calculating the intensity of rockburst. Kidybinski described the comprehensive stress–strain curve as the elastic strain energy index [123] in Equation (3):

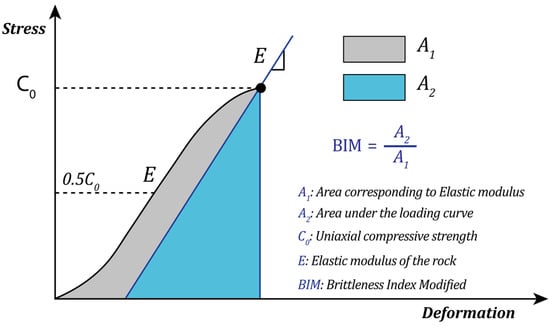

where is the elastic strain energy saved before rock failure and is the plastic strain energy consumed after rock failure. The elastic strain energy index () and brittleness index modified () are commonly used indices. is an equation that calculates the energy available for severe rupture, with a higher value indicating less energy (Figure 11). Aubertin [155] developed a risk rating for rockbursts based on the value, as illustrated in Table 7.

Figure 11.

BIM determination using uniaxial compression testing (Modified after ref. [155]).

Table 7.

BIM indicative values and risk of violent rupture [155].

The BIM equation is written in Equation (4), as follows:

where is the area under the loading curve and is the area under the line corresponding to the rock’s elastic modulus (E). When the increases, more energy is dissipated during loading, resulting in less energy available for severe rupture.

Spottiswoode [156] was the first to propose using the radiated energy of rockburst as a measurement tool. The relationship between the radiated energy and the intensity of rockbursts was explored, leading to radiated energy being recommended as an evaluation index for rockburst intensity classification. Chen [157] later analyzed seismic energy at a hydropower station in China to create a new seismic energy index. They studied the features, size, and laws of the radiated energy and their relationship to the intensity of rockburst. The energy-size-scaling (ESS) criterion was originally introduced by Ryder [49] as a measure of available energy during the transition from static resistance to dynamic resistance. However, not all positive ESS scenarios resulted in seismic occurrences, potentially due to data inaccuracies or stress involved, as noted by Gill [158] and Ryder [49].

5.3. Empirical Methods

In the early stages of a project, empirical methods are often used to evaluate the quality of the rock mass and assess the likelihood of rockbursts in underground apertures for feasibility and preliminary design purposes. Stille [159] noted that classification is a valuable tool in understanding rock engineering problems when object label information is provided. This allows for the application of techniques such as decision theory to select the best classification method for a specific rock engineering issue. Classification systems are commonly used in mining and geotechnical engineering to characterize the rock mass and provide empirical guidance for design and support [159,160]; rockburst prediction is an example of a classification problem. Lithology is the primary cause of rockbursts and both surrounding rock stress and lithology play a role in rockburst occurrence [161]. Empirical methods, such as , have been applied to estimate rockburst tendency. is defined as the ratio of the strain energy retained (, to the permanent strain energy [162]. is written in Equation (5), as follows:

Despite the advantage of the criterion, obtaining 80–90% of the rock strength with is difficult for two reasons: first, the strength can only be known probabilistically; second, the value of the index is determined by the relative value of the load attained. Furthermore, Heal [8] proposed the excavation vulnerability potential (EVP) as an empirical assessment tool for seismically active underground mines based on case histories and incidents of rockburst damage. Empirical models are often used in rock engineering to make predictions; however, they have limitations. They are obtained through curve interpolation and lack physical significance, which raises questions about their validity. Despite this, their ease of use in engineering applications is an advantage. However, a single evaluation indicator is not enough to fully consider all the factors affecting rockburst occurrence, making it challenging to accurately predict rockburst events. As rockbursts are complex and unpredictable, it is difficult to establish a universal criterion for rockburst prediction.

5.4. Simulation Methods

Currently, numerical methods and computational techniques are commonly used tools in engineering and research to solve complex problems [94]. A significant amount of work in understanding and predicting rockbursts has been performed using numerical modeling. The finite element method (FEM) and dynamic approach have been used to simulate the unstable breakdown of rock masses and the dynamic behavior of rockbursts [105]. The pre-existing numerical simulation work on rockburst assessment is summarized in Table 8.

Table 8.

Summary of pre-existing numerical simulation work.

However, creating a realistic simulation of rockburst dynamics is challenging using numerical methods. Various approaches have been proposed to predict rockburst hazard, including rock failure process analysis (RFPA) [169] and local energy release density (LERD) [166,170]. Simon [168] created the bursting potential ratio (BPR) and the out-of-balance index (OBI) has also been developed to assess rockburst potential in joints and discontinuities. To accurately estimate rockburst risk, it is important to use a combination of diverse indicators that consider different physical factors. Numerical models for rockburst are dependent on the inputs provided, some of which may not accurately reflect the real-life situation. Additionally, the lack of a widely accepted energy criteria means that the results obtained from FAI, ESS, LERD, LERR, and ERR indicators cannot definitively classify rockbursts. Further research involving a larger number of project cases is needed to validate these indicators.

5.5. Mathematical Model Approaches

The factors influencing rockbursts are partly defined and measurable, while others are random, qualitative, and fuzzy [16]. This makes it difficult to establish a suitable mathematical model for rockburst prediction. Data-driven models based on empirical criteria and previous engineering examples can be reliable, but the accuracy of the prediction depends on the amount and quality of data. Rockburst is a complex system influenced by many factors, including some that are uncertain. Research has compared the predicted performance of various data-driven techniques, including uncertainty theory (UT) algorithms, unsupervised learning (UL) algorithms, and supervised learning (SL) algorithms. However, challenges in applying these techniques include insufficient data and the uncertain nature of the rockburst system. As a result, recent theories, such as fuzzy mathematics, rough set theory, and others, have emerged to evaluate rockbursts.

Unsupervised learning algorithms aim to categorize data without predefined labels. They do this by finding similarities among data and grouping them into clusters. This family of machine learning approaches has been applied in the field of rockburst prediction, where accurate forecasting is crucial due to the catastrophic nature of rockbursts in deep subsurface engineering. Researchers such as Zhou [171] have used a fuzzy self-organization map approach in combination with a neural network-based geographical information system to assess rockburst tendency. Chen [157] used hierarchical clustering analysis and the complete linkage method to classify rockburst intensity based on energy as an evaluation index. With the advancement of scientific computing tools, the field of rockburst prediction has seen the integration of modern nonlinear science and artificial intelligence methodologies. Over the years, researchers have explored different supervised learning techniques to predict rockbursts.

5.6. Machine Learning Methods

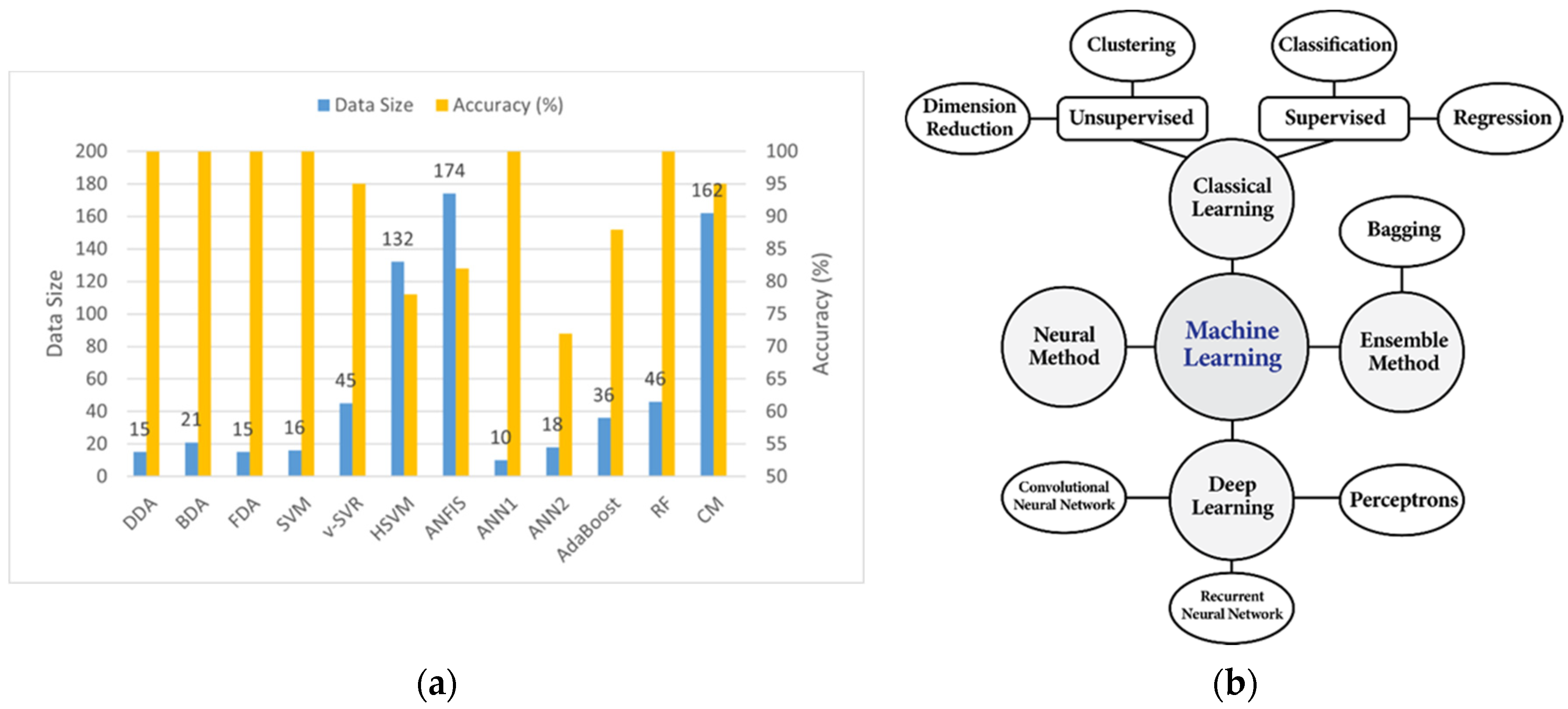

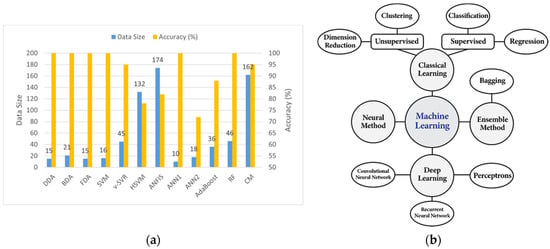

Machine learning methods are utilized in some studies for rockburst prediction, taking advantage of machine learning’s ability to handle nonlinear situations. Sun et al. applied fuzzy mathematics and neural networks to create a rockburst prediction model trained with enhanced BP algorithm using typical rockburst data [172]. Jia et al. proposed a method for predicting rockbursts based on a swarm optimization algorithm and general regression neural network (GRNN) [74]. To anticipate rockbursts, Zhang [173] utilized a radial basis function (RBF) neural network improved by a genetic algorithm. Zhou used a support vector machine (SVM) to classify long-term rockbursts for underground holes [4]. Cai employed principal component analysis and a fuzzy comprehensive evaluation model to evaluate the possibility of a coal burst [174]. Zhou compared the prediction accuracy of 12 machine learning algorithms, including artificial neural network (ANN), distance discriminant analysis (DDA), support vector machine (SVM), Bays discriminant analysis (BDA), and Fisher linear discriminant analysis (LDA), among others [175], in long-term rockburst prediction using different rockburst indicators as input features and varying training sample sizes. The accuracy of 12 machine learning algorithms is shown in Figure 12a.

Figure 12.

(a) Rockburst prediction accuracy from machine learning algorithms (modified from ref. [176]); (b) Machine learning approaches for rockburst prediction (Modified after ref. [11]).

Machine learning algorithms have been widely used in rockburst prediction, specifically for long-term prediction of potential bursts. This approach utilizes various algorithms, such as artificial neural networks, distance discriminant analysis, support vector machines, and more, to predict the occurrence of rockbursts based on rockburst indicators as input features. On the other hand, some researchers have employed machine learning in microseismic monitoring, a method that predicts rockbursts in the near future. The development of various machine learning algorithms for rockburst classification and prediction is illustrated in Figure 12b.

5.7. Microseismic Monitoring Techniques

The first seismic network for recording mining tremors in a coal mine was established in Upper Silesia, Poland, in the late 1920s and had four power stations [177]. Microseismic monitoring systems for mining tremors have been developed in various countries, including South Africa, Canada, the US, Australia, and China [178]. Microseismic monitoring of stress waves can determine the timing and location of a mine tremor and the energy released. Most research focuses on identifying suitable geophysics or mathematical/statistical factors to predict rockbursts based on microseismic monitoring data [178]. Estimating the stress field in a rock mass is a difficult task, but microseismic monitoring of naturally occurring mine tremors provides a more precise waveform due to the broad energy bandwidth in the tremors’ power spectrum.

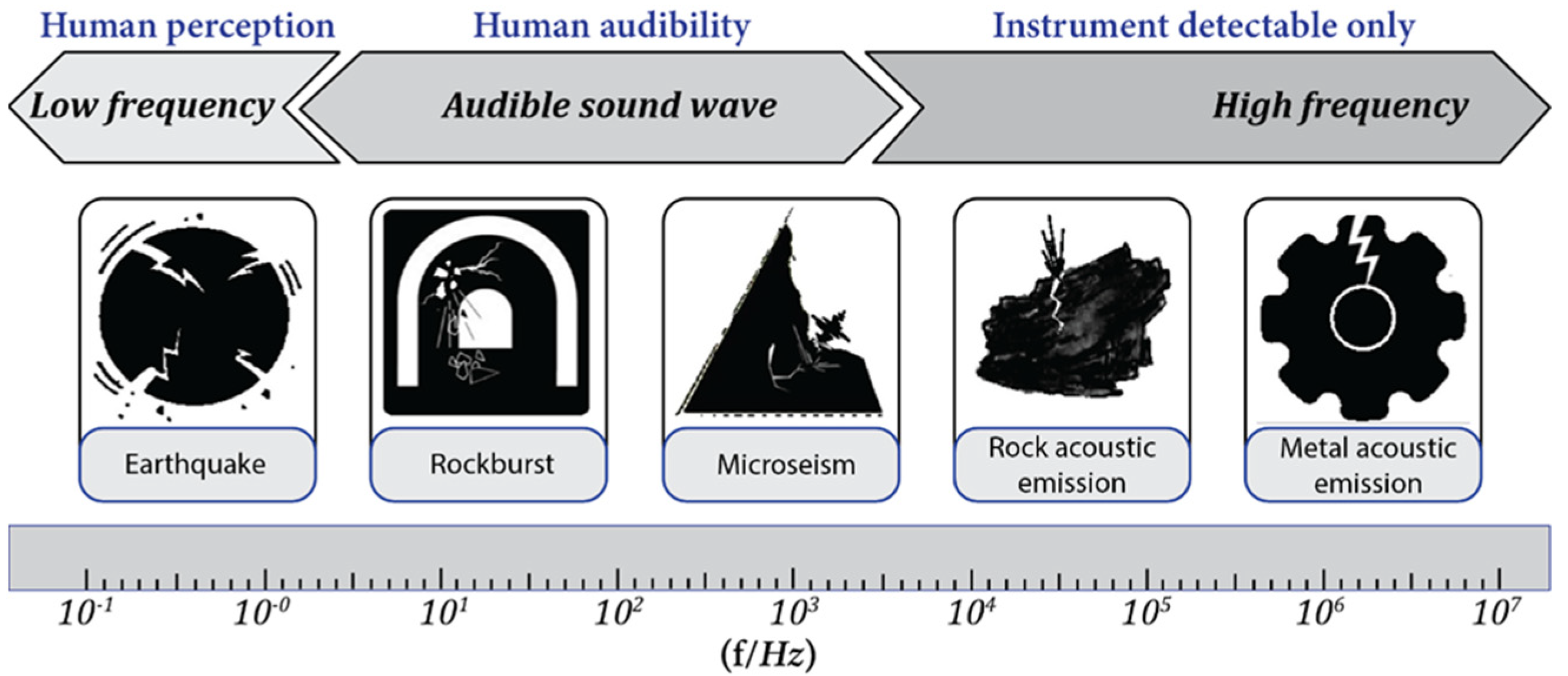

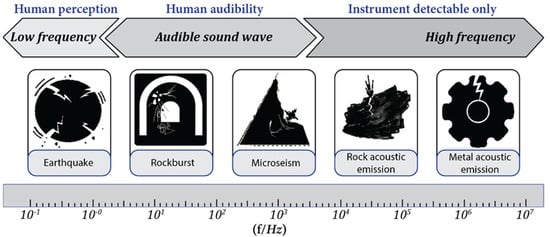

Cai [90] reported that emissions and microseismic events are low-energy seismic events caused by sudden inelastic deformation, such as movement of existing fractures, production of new fractures, or propagation of fractures. These events occur in a specific rock volume and emit detectable waves. The main difference between acoustic emissions and microseismic events is that acoustic emission signals have higher seismic motion frequencies, as illustrated in Figure 13. Seismic waves emitted by rock microcracks can be collected by sensors and processed to determine the source parameters of microseismic events, such as time, position, energy, magnitude, and apparent stress. By analyzing the source parameters of multiple microseismic events, the damage and stress variation of rocks can be evaluated, enabling the prediction of rockburst occurrence, location, and intensity through in-depth microseismic data analysis.

Figure 13.

Seismic wave frequency spectrum and application of microseismic techniques ([70]).

6. Rockburst Prevention and Control

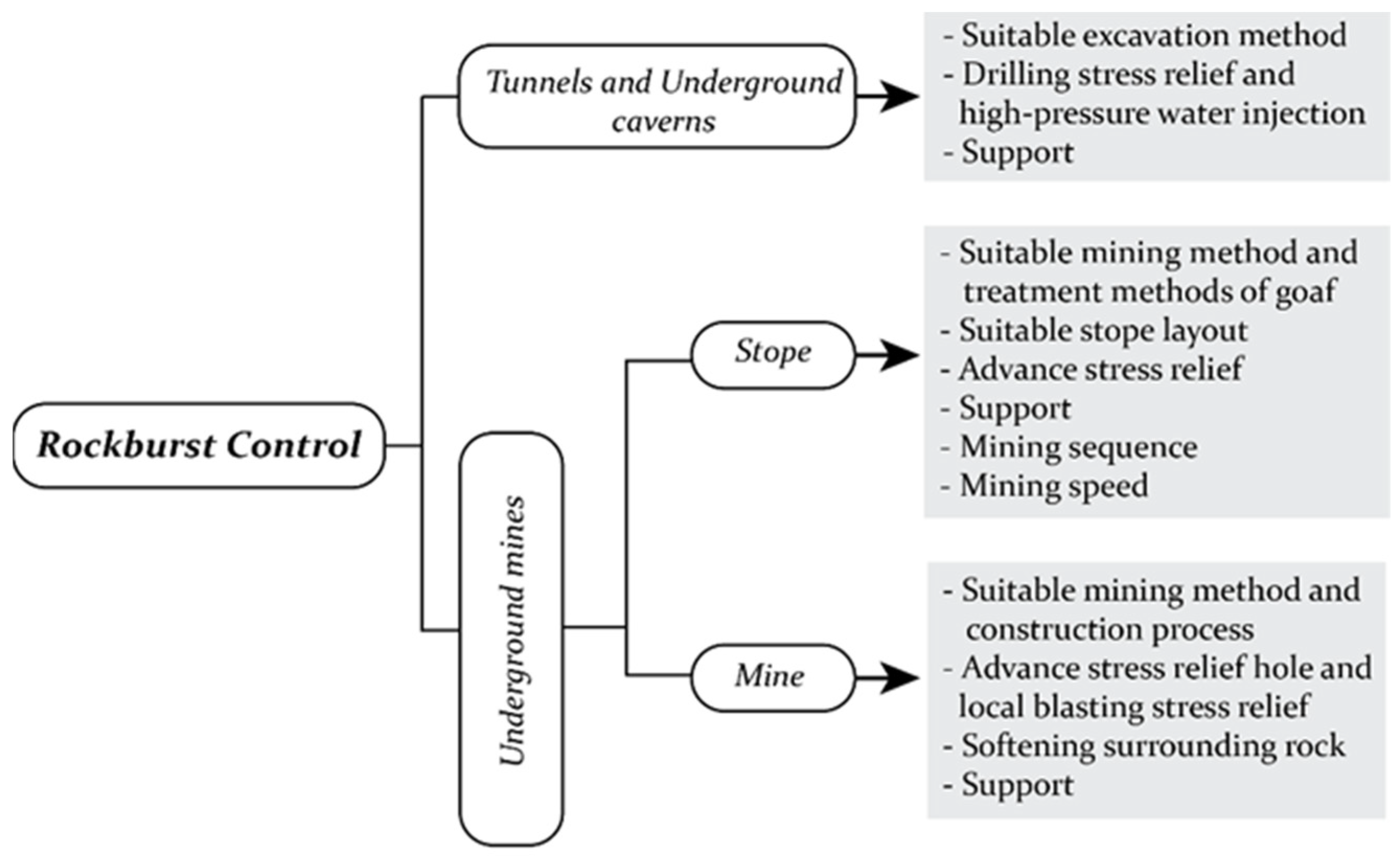

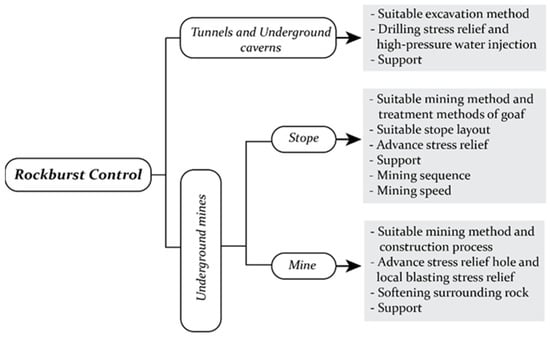

The significance of rockburst incidents has led engineers and academics to focus on rockburst prevention and control strategies. Yan detailed the procedures for rockburst prevention at the Jinping II Hydropower Station, which effectively prevented rockbursts by reducing the surrounding rock stress and weakening excavation disturbance [179]. The presence of foliations in the rock mass at Big Bell, Australia, influences both the magnitude of high stress and deviatoric stress. Mining is concentrated in a central slot in the orebody that spans a larger 350 m section. This, however, can cause strain and pillar bursts. Destress blasting, which involves developing the footwall and decline, is used to mitigate this hazard. This is accomplished by drilling two 4.2 m holes at 45° angles from the top corners and filling each with 700 mm packaged emulsion [180,181,182]. Another rockburst event occurred at Australia’s Long Shaft, which is located in a high horizontal stress field. The rock mass here is made up of a complex of varying strength units. The orebody has a strength of 140 MPa, while the footwall has a strength of 275 MPa. The hanging wall, on the other hand, has a pressure range of 75 to 250 MPa. A variety of events, such as fault-slip, strain, and pillar bursts, can occur as a result of these opposing strengths. Effective dynamic support is used to mitigate these risks. Mesh-reinforced shotcrete, yielding tendon bolts, fiber (steel)-reinforced shotcrete, friction bolts, mesh, and mesh straps are examples of such measures [183]. According to Yang, the primary cause of rockbursts in an uneven working face is the combined dynamic and static strain, which led to the development of a suitable control method to reduce dynamic load through directional hydraulic fracture and improve the surrounding rock through a support system [184]. Simser highlighted several solutions used in Canada to reduce the risk of rockbursts in deep mines, arguing that with increasing mine depth, widespread construction of a support system with dynamic load-bearing capability may become necessary [185]. Li outlined rockburst pretreatment methods such as blasting, decompression drilling, and hydraulic fracturing and presented rockburst support experience from Australia, Canada, and South Africa [186]. Figure 14 summarizes the main rockburst prevention and control strategies used in several mines and tunnels.

Figure 14.

Control measures for rockbursts [11].

To prevent rockbursts, researchers and engineers have long focused on excavation support techniques. Laurentian University’s Rock Mechanics Research Center conducted a five-year research project on rockburst control, resulting in the creation of the Canadian Rockburst Support Handbook. The handbook outlines the causes and features of rockburst failure and provides support system design approaches [7]. Kaiser emphasized the importance of continuously evaluating and adjusting support selection in burst-prone areas based on four crucial functions of a viable support system [187]. Moganedi evaluated various rockburst support systems for their economic usefulness in deep tunnels and mines, providing guidelines for support system selection [188].

6.1. Rock Support in Burst-Prone Ground

Stress-induced rock failure and fracturing are inevitable as mining and underground structures move deeper, and in rare cases, they can cause rockbursts. Rockbursts can occur in hard rock mines and civil tunnels worldwide and are linked to stress changes after excavation. The occurrence of rockbursts is categorized as either a strainburst or a fault-slip burst depending on the triggering mechanism. The typical damage from rockbursts in underground excavations includes stress-induced rock fracturing, roof and sidewall bulging, floor heaving, rock shearing, block ejection, and seismically induced ground fall. Designing ground support for dynamic conditions involves considering uncertainties in loading circumstances, rock mass variations, rock mass behavior, and ground support performance [189]. There are various methods for selecting adequate dynamic ground support, including deterministic methods such as in the Canadian Rockburst Support Handbook and the kinetic and potential energy calculation method [7,30,190,191,192], which are based on the assessment of energy absorption capacity and make assumptions about dynamic mechanisms. Table 9 lists the principal rockburst prevention and control strategies used in several mines and tunnels.

Table 9.

Rockburst prevention and control in different locations and rock types.

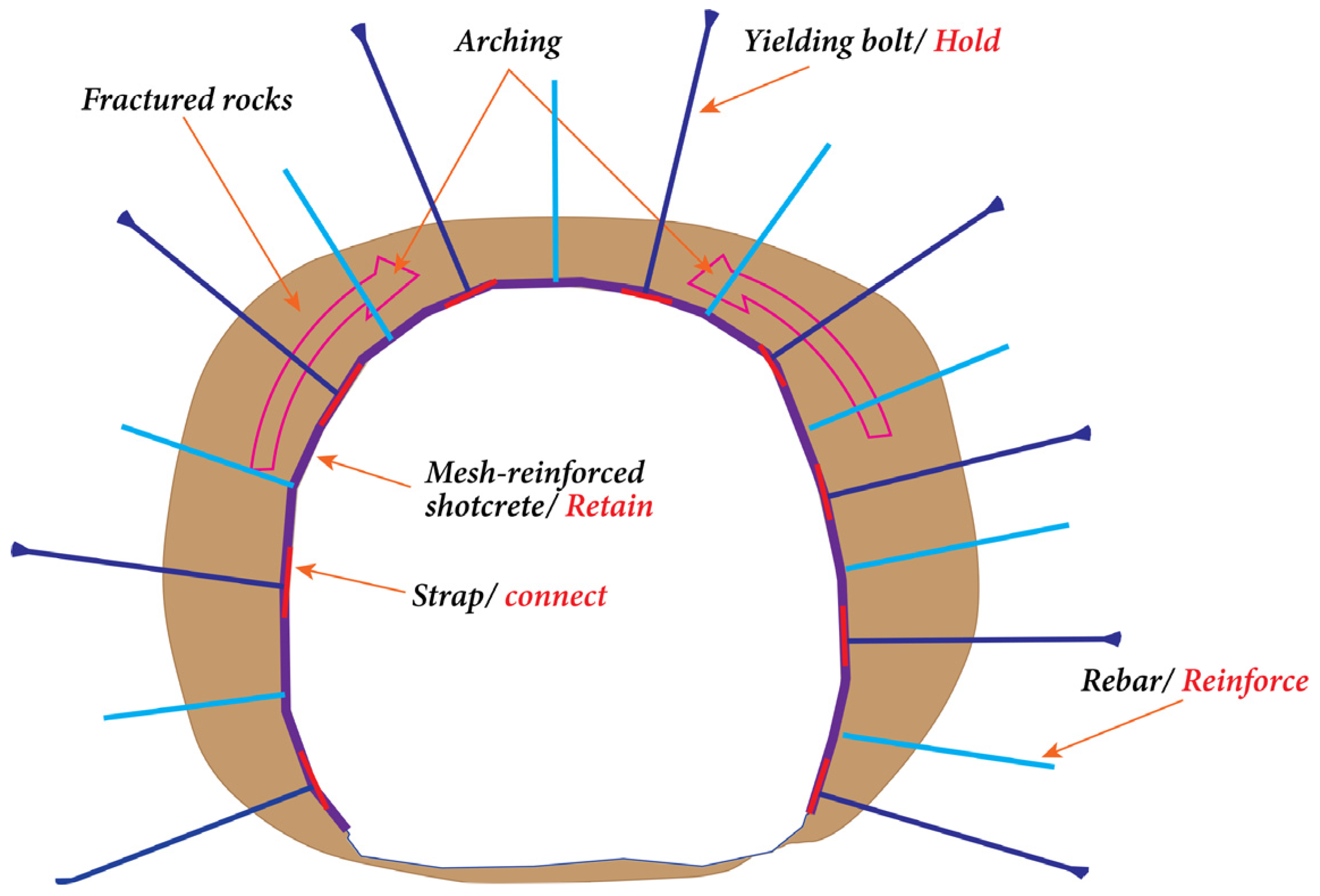

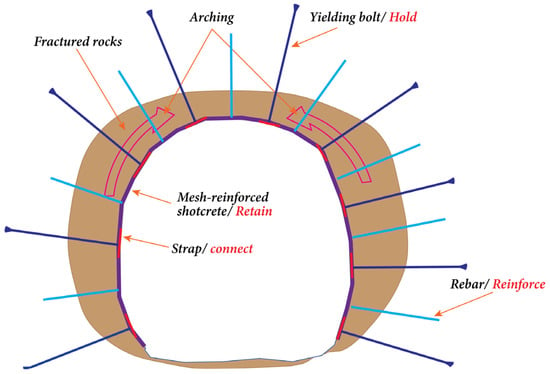

Manouchehrian [201] conducted numerical studies to examine the impact of neighboring weak geological formations on rockbursts in tunnels subjected to static and dynamic loads. The presence of discontinuities around tunnels led to increased velocity and kinetic energy released during rock failure, making it more violent. Rock support in rockburst-prone areas should ideally balance the stiffness and yielding properties of support elements to provide stiffness when necessary and yielding when required [202]. As shown in Figure 15, Kaiser [203] outlined four crucial elements to provide a reliable support system in burst-prone areas:

Figure 15.

Required support functions in burst-prone ground (modified after ref. [202]).

- To control the bulking process and prevent crack spreading, reinforce the marginally stable rock mass to strengthen it.

- To prevent critical block failure and unraveling, maintain damaged and fractured rock.

- By using deformation-compliant support components, return the reinforced rock and retaining system to a stable state.

- To ensure system stability, connect holding and retaining components.

To build an effective support system in rockburst-prone areas, understanding the four key functions of each support component is essential. Though some components may play multiple roles, it is crucial to identify their strengths and weaknesses [204]. The weakest link in a support system under dynamic loading is often the surface support or the connection between the surface support and reinforcement. The ideal surface support should have high initial stiffness to reduce rock fracturing and bulking, and then shift to yielding as deformation progresses. Fiber-reinforced shotcrete (FRS) has been shown to have this capability under static conditions in high-stress environments.

6.2. Rockburst Support Design Principles

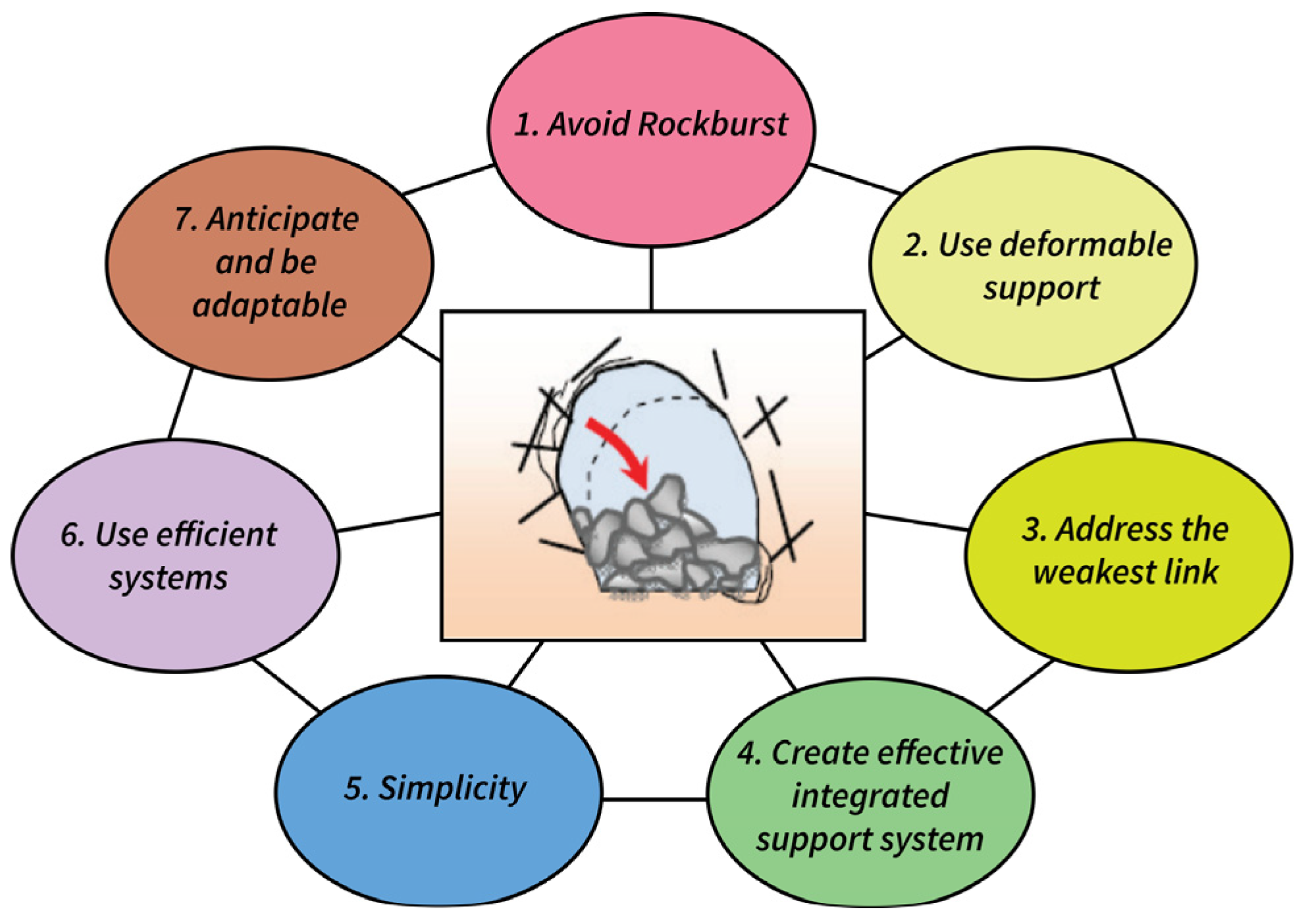

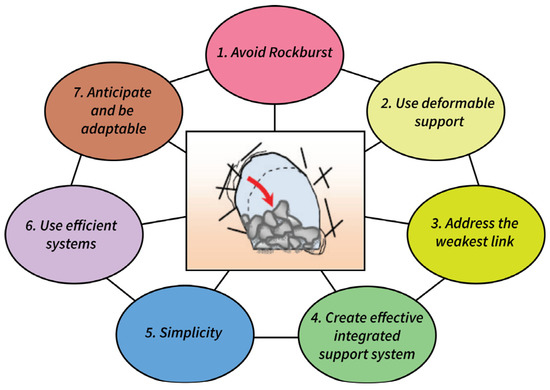

Strategy encompasses the overall management of underground construction operations, while tactics focus on the effective use of tools and problem-solving in the field. Many engineers tend to focus on tactics, as their day-to-day work demands quick solutions to pressing challenges. Strategic thinking, however, requires long-term planning and a proactive approach to mitigating rockburst damage. Cai [127] distilled practical field experiences into clear, easy-to-understand principles for designing rockburst support, as outlined in Figure 16.

Figure 16.

Seven principles of rockburst mitigation and support selection principles [2].

The first principle is to minimize rockburst risk through methods such as changing the tunnel location, using alternative excavation methods, adjusting stope size and shape, modifying the mining sequence, or changing technologies. The second principle supports the use of yielding support in hazardous conditions, where the support must be flexible and able to withstand convergence without self-destruction while absorbing energy to ensure tunnel safety [2]. A yielding support system works with the surrounding rock mass, but the weakest link in conventional systems is often the connection between bolts and screens. Rock support design often overlooks the impact of the rock mass between bolts on the support system. To establish an effective system, holding components must be paired with reinforcing elements and surface support, forming an integrated approach. The fifth principle is simplicity; rock support should be easy to fabricate, install, and maintain to be accepted by mine operators and miners. Mining businesses must prioritize safety over cost savings, as rockbursts can lead to damage, equipment loss, decreased output, injuries, and fatalities [2]. The final principle highlights the importance of adaptability to a wide range of ground conditions to prevent and control damage, reduce investment risk, and protect workers. Understanding these seven principles (Figure 16) improves rockburst mitigation. Rockbursts can occur as a result of a variety of circumstances, including geological conditions, stress levels, and mining operations. As a result, prevention and control strategies must be tailored to the unique rockburst type and mechanism at hand. Mining industries, for example, can install seismic monitoring systems and rock strengthening techniques, such as rock bolting, to prevent seismic rockbursts caused by unexpected energy release in the rock mass. Pre-excavation analyses and controlled blasting techniques can help to reduce dynamic rockbursts induced by excavation disturbances in the rock mass. Gravity-induced rockbursts can be avoided by reinforcing the rock mass and uniformly distributing the load with support systems such as rock bolting or shotcreting. Hybrid rockbursts, which are a combination of several kinds of rockburst, can be difficult to prevent and control; hence, mining companies can employ a combination of the approaches listed above, depending on the unique mechanism involved.

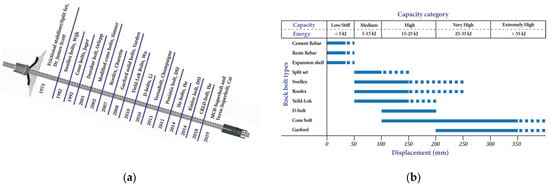

6.3. Performance of Rockbolts in High-Stress Ground Conditions

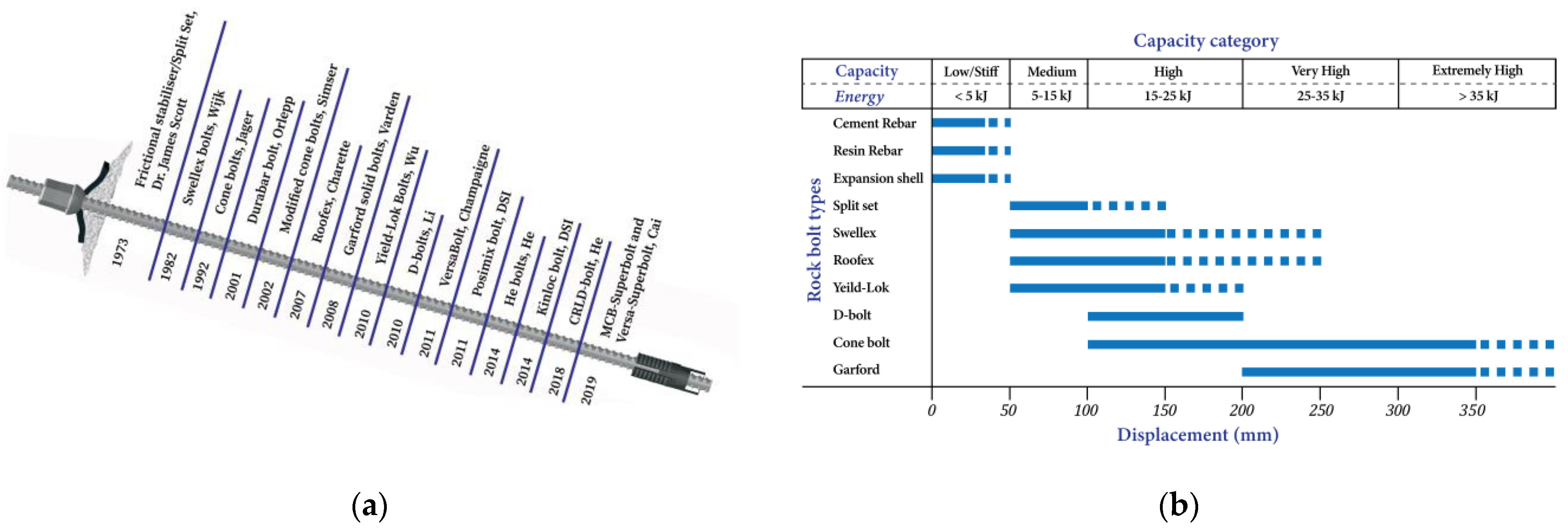

The key difference between deep and shallow rock is the increase in in-situ rock stresses, leading to large deformations in soft rocks and rockbursts in hard rocks in deep excavations [204]. A bolt is an essential component in a support system, but a standard bolt is not effective under high-stress conditions. An energy-absorbing bolt, on the other hand, has a higher bearing and deformation capacity and can absorb more energy generated during dynamic rock collapse [205]. Figure 17a depicts some acceptable energy-absorbing bolts. A good rockburst support system should consist of high-strength energy-absorbing bolts and appropriate surface support components [206]. Masoudi’s large-scale dynamic testbed study offers guidance on selecting the appropriate bolt type based on the surrounding rock energy demands and deformation capacity [207].

Figure 17.

(a) Typical energy-absorbing bolts [184,208,209,210,211,212,213,214,215], (b). Energy dissipation capacity categories of different types of reinforcement (Modified from [204]).

Rockbolts are categorized into five types based on their load and deformation capacity: stiff, medium yielding, high yielding, very high yielding, and extremely high yielding. The behavior of high-yielding rockbolts is influenced by loading conditions and environmental factors such as loading velocity and installation quality. Figure 17b shows the energy dissipation capacity of different forms of reinforcement. It depicts the energy dissipation and deformation capacity of each category for a specific type of rock reinforcement. In rockburst-prone and squeezing ground conditions, both internal and external support devices should be able to absorb a significant amount of the released strain energy to prevent sudden failure of the support network, rather than only balancing the ground load. Rockbolts with high-loading capacities that absorb energy are beneficial for rock support, especially in high-stress rock masses.

7. Conclusions

The failure of rock masses is a major concern in underground excavation. As the depth of excavation increases, so does the likelihood of rock mass failure. Excavation increases tangential stress and decreases radial stress, leading to rockbursts as a common failure process in brittle and hard rock. In underground excavations, spalling and slabbing forms of rockburst are frequently encountered. There have been extensive efforts to understand the causes of rockbursts and how to control them under high in-situ stress. A comprehensive review of research conducted between 1965 and 2021 on the use of various methods to predict rockbursts in underground engineering has been conducted. This review covers elaborate and simplified engineering empirical criteria or graph methods, numerical simulation and physics model tests, mathematical algorithms models, artificial intelligence and support vector machines, and is organized based on the approach type, source of data sets and variables used, and the comparative performance of strategies in terms of prediction accuracy.

The failure of rock masses during underground excavation is a major concern and becomes more prevalent as the depth of the excavation increases. The increased tangential stress and decreased radial stress resulting from excavation can lead to rockbursts as a primary failure process in brittle and hard rock. Research has been conducted to understand the causes and develop control methods for rockbursts under high in situ stress, and various approaches have been used, such as empirical criteria, numerical simulations, physical model tests, and artificial intelligence algorithms. Although these approaches have been widely accepted and used, there are still limitations due to the complexity of rockburst behavior. In-situ monitoring is an effective method for acquiring real-time parameters to evaluate and predict rockburst danger, using techniques such as microseismic monitoring, microgravity, infrared thermal imaging, and more. Numerical simulations and physical model tests are also effective, but the choice of the ideal model depends on the level of accuracy and data availability. Further research is necessary to develop a complete and unified understanding of rockburst mechanisms.

The mechanisms of rockburst are a topic of numerous theories, yet there is no agreement on what constitutes rockburst. Its occurrence is affected by rock mass qualities and the overall stress condition of the system. The rigidity theory is limited in accurately describing the dynamic process and mechanisms of rockburst. The intensity and damage caused by rockbursts are influenced by factors such as seismic events, geology, geotechnical issues, and the type of mining activity, including the sequence, span, and rock support system used. The significance of effective rock support systems in preventing rockbursts is widely acknowledged. Despite extensive research, a unified hypothesis for rockburst mechanisms remains elusive.

The intensity of rockbursts can vary greatly depending on the prediction model used. Empirical approaches rely on one or two stress indices, each with its own unique formula. Energy and stress approaches have shown to be effective in predicting rockbursts. The ideal model for rockburst prediction is determined by the available data and level of accuracy. Numerical and intelligent procedures can help solve many technical and scientific problems. To forecast rockbursts, researchers often use fuzzy mathematics, rough set theory, mathematical attribute theory, cloud theory, and grey systems theory. Some even employ machine learning techniques. For example, a fuzzy mathematics and neural network model with an improved BP algorithm has been developed for potential assessment. Seismic events can also provide insight into rockbursts and be used for prediction. The burst support design tool considers seismic events, ground motion, rock mass quality, and mining-induced pressures to enhance rockburst risk management. Energy-absorbing rockbolts can be used for rock support, either installed internally within the rock mass or externally for surface support.

Further research and exploration into the following topics will be needed in the future:

- The quest to accurately predict rockbursts is ongoing, with many techniques developed to determine rockburst intensity and location. However, the elusive challenge remains—predicting the occurrence time of rockburst. Further investigation and exploration are needed, and the microseismic monitoring method may hold the key to unraveling the regularities of rock rupture signals over time.

- Despite numerous efforts to predict and prevent rockbursts, the prediction accuracy remains wanting and rockburst accidents persist. The complexity of anisotropic and inhomogeneous rock masses and the unpredictable external environment call for more focused research into rockburst prediction and prevention methods in uncertain situations.

- Current rockburst stress and energy methods rely heavily on curve interpolation, lacking adequate validation from actual data. To establish more accurate predictions, a comprehensive database of rockburst events from all sources should be created, and empirical methods should be applied for verification against real-life rockburst occurrences.

- Experiments and numerical models, such as virtual hybrid simulations, hold great potential to enhance our understanding of rockbursts. The need of the hour is to develop a multi-parameter evaluation model that is effective, reliable, robust, and efficient to make accurate predictions and provide effective mitigation strategies.

If these challenges are tackled, the practical use of these techniques for rockburst prediction will be streamlined and bring numerous benefits.

Author Contributions

Conceptualization, S.G. and S.Q.; methodology, M.F.W.; investigation, S.G. and S.Q.; writing—original draft preparation, M.F.W.; writing—review and editing, S.G.; supervision, S.G. and S.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Second Tibetan Plateau Scientific Expedition and Research Program (STEP) under Grant No. 2019QZKK0904, the National Natural Science Foundation of China under Grants Nos. 42077266, 41825018, 42141009, and 42090051, and the Youth Innovation Promotion Association of the Chinese Academy of Sciences under grant No. 2022062. A special acknowledgement should also be expressed to the China–Pakistan Joint Research Centre on Earth Sciences that supported the implementation of this study.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, T.B.; Meng, L.B.; Zheng, J.G.; Xiao, X.P. The Features of Rockburst and Its Geomechanical Patterns in a Hydroelectric Power Station in West China. In Proceedings of the Geologically Active: 11th IAEG Congress, Auckland, New Zealand, 5–10 September 2010; pp. 3203–3211. [Google Scholar]

- Kaiser, P.K.; Cai, M. Design of Rock Support System under Rockburst Condition. J. Rock Mech. Geotech. Eng. 2012, 4, 215–227. [Google Scholar] [CrossRef]

- Leger, J.-P. Trends and Causes of Fatalities in South African Mines. Saf. Sci. 1991, 14, 169–185. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Shi, X. Long-Term Prediction Model of Rockburst in Underground Openings Using Heuristic Algorithms and Support Vector Machines. Saf. Sci. 2012, 50, 629–644. [Google Scholar] [CrossRef]

- Ortlepp, W.D. RaSiM Comes of Age—A Review of the Contribution to the Understanding and Control of Mine Rockbursts. In Proceedings of the RaSiM6: Sixth International Symposium on Rockburst and Seismicity in Mines Proceedings, Perth, Australia, 9–11 March 2005; Australian Centre for Geomechanics: Perth, Australia, 2005. [Google Scholar]

- Blake, W.; Hedley, D.G.F. Rockbursts: Case Studies from North American Hard-Rock Mines; SME: Littleton, CO, USA, 2003; ISBN 0873352327. [Google Scholar]

- Kaiser, P.K.; McCreath, D.R.; Tannant, D.D. Canadian Rockburst Support Handbook; Geomechanics Research Center: Sudbury, ON, Canada, 1996. [Google Scholar]

- Heal, D.; Hudyma, M.; Potvin, Y. Evaluating Rockburst Damage Potential in Underground Mining. In Proceedings of the Golden Rocks 2006, the 41st US Symposium on Rock Mechanics (USRMS), Golden, CO, USA, 17 June 2006; OnePetro: Richardson, TX, USA, 2006. [Google Scholar]

- Suorineni, F.T.; Hebblewhite, B.; Saydam, S. Geomechanics Challenges of Contemporary Deep Mining: A Suggested Model for Increasing Future Mining Safety and Productivity. J. S. Afr. Inst. Min. Metall. 2014, 114, 1023–1032. [Google Scholar]

- Xiao, Y.X.; Feng, X.T.; Li, S.J.; Feng, G.L.; Yu, Y. Rock Mass Failure Mechanisms during the Evolution Process of Rockbursts in Tunnels. Int. J. Rock Mech. Min. Sci. 2016, 83, 174–181. [Google Scholar] [CrossRef]

- Wu, M.; Ye, Y.; Wang, Q.; Hu, N. Development of Rockburst Research: A Comprehensive Review. Appl. Sci. 2022, 12, 974. [Google Scholar] [CrossRef]

- Ma, C.-C.; Li, T.-B.; Xing, H.-L.; Zhang, H.; Wang, M.-J.; Liu, T.-Y.; Chen, G.-Q.; Chen, Z.-Q. Brittle Rock Modeling Approach and Its Validation Using Excavation-Induced Micro-Seismicity. Rock Mech. Rock Eng. 2016, 49, 3175–3188. [Google Scholar] [CrossRef]

- Ma, C.C.; Li, T.B.; Chen, G.Q.; Chen, Z.Q. A Micro Particle Model for Hard Brittle Rock and the Effect of Unloading Rock Burst. Chin. J. Rock Mech. Eng. 2015, 34, 1–11. [Google Scholar]

- Brown, E.T. Underground Excavations in Rock; CRC Press: Boca Raton, FL, USA, 1980; ISBN 0429178123. [Google Scholar]

- Russenes, B.F. Analyses of Rockburst in Tunnels in Valley Sides; Norwegian Institute of Technology: Trondheim, Norway, 1974. [Google Scholar]

- Zhou, J.; Li, X.; Mitri, H.S. Evaluation Method of Rockburst: State-of-the-Art Literature Review. Tunn. Undergr. Sp. Technol. 2018, 81, 632–659. [Google Scholar] [CrossRef]

- Ortlepp, W.D.; Stacey, T.R. Rockburst Mechanisms in Tunnels and Shafts. Tunn. Undergr. Sp. Technol. 1994, 9, 59–65. [Google Scholar] [CrossRef]

- Camiro Mining Division. Rockburst Research Handbook; CAMIRO Mining Division: Sudbury, ON, Canada, 1995. [Google Scholar]

- Castro, L.A.M.; Bewick, R.P.; Carter, T.G. An Overview of Numerical Modelling Applied to Deep Mining. Innov. Numer. Model. Geomech. 2012, 393–414. [Google Scholar]

- He, M.C.; Sousa, L.R.; Farmarzi, L. Rockburst Process Evaluation Using Experimental and Artificial Intelligence Techniques. In Proceedings of the 1st Iranian Congress of Mining, Yazd, Iran, 5 September 2012; p. 24. [Google Scholar]

- Jolfaei, S.; Lakirouhani, A. Sensitivity Analysis of Effective Parameters in Borehole Failure, Using Neural Network. Adv. Civ. Eng. 2022, 2022, 4958004. [Google Scholar] [CrossRef]

- Martin, C.D.; Kaiser, P.K.; Tannant, D.D.; Yazici, S. Stress Path and Instability around Mine Openings. In Proceedings of the 9th ISRM Congress, Paris, France, 25–28 August 1999; OnePetro: Richardson, TX, USA, 1999. [Google Scholar]

- Ortlepp, W.D. Rock Fracture and Rockbursts: An Illustrative Study. S. Afr. Inst. Min. Metall. 1997, 9. [Google Scholar]

- Cook, N.G.W. A Note on Rockbursts Considered as a Problem of Stability. J. S. Afr. Inst. Min. Metall. 1965, 65, 437–446. [Google Scholar]

- Obert, L.; Duvall, W.I. Rock Mechanics and the Design of Structures in Rock; Wiley: New York, NY, USA, 1967; Volume 650. [Google Scholar]

- Thrush, P.W. A Dictionary of Mining, Mineral, and Related Terms; US Bureau of Mines: Washington, DC, USA, 1968.

- Blake, W. Rock-Burst Mechanics. Q. Colo. Sch. Mines 1972, 67. [Google Scholar]

- Larocque, G. Review of Rockburst Phenomena. Canada Cent. Miner. Energy Technol. Canmet. Min. Res. Lab. Rep. ERP-MRL 1980, 80–94. [Google Scholar]

- Labour, O.M. Occupational Health and Safety Act and Regulations for Mines and Mining Plants. Hearing on Proposed Standards for Ground Control Metal/Nonmetal Mines 1984, 694, 48. [Google Scholar]

- Mine Safety and Health Administration. Hearing on Proposed Standards for Ground Control Metal/Nonmetal Mines; Mine Safety and Health Administration: Spokane, WA, USA, 1984.

- Tan, Y.A. Mechanism Research and Comprehensive Evaluation of Rockburst. Ph.D. Thesis, Xi’an College of Geology, Xi’an, China, 1988. [Google Scholar]

- Zhen-Yu, T. Support Design of Tunnels Subjected to Rockbursting. In Proceedings of the ISRM International Symposium, Madrid, Spain, 12 September 1988; OnePetro: Richardson, TX, USA, 1988. [Google Scholar]

- Zhang, J. Some Rock Mechanics Problems in Construction of Hydro-Power Station. Chin. J. Rock. Mech. Eng. 1991, 2, 169–177. [Google Scholar]

- Hedley, D.G.F. Rockburst Handbook for Ontario Hardrock Mines; Canmet: Hamilton, ON, Canada, 1992; Volume 92, ISBN 0660145499. [Google Scholar]