Flow Analysis of a Novel, Three-Way Cartridge Flow Control Valve

Abstract

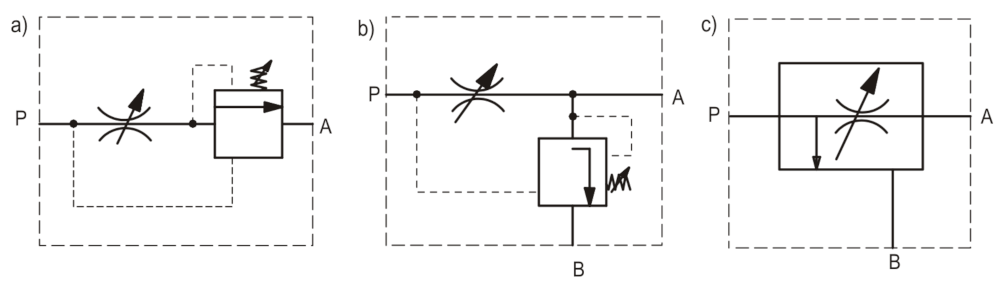

1. Introduction

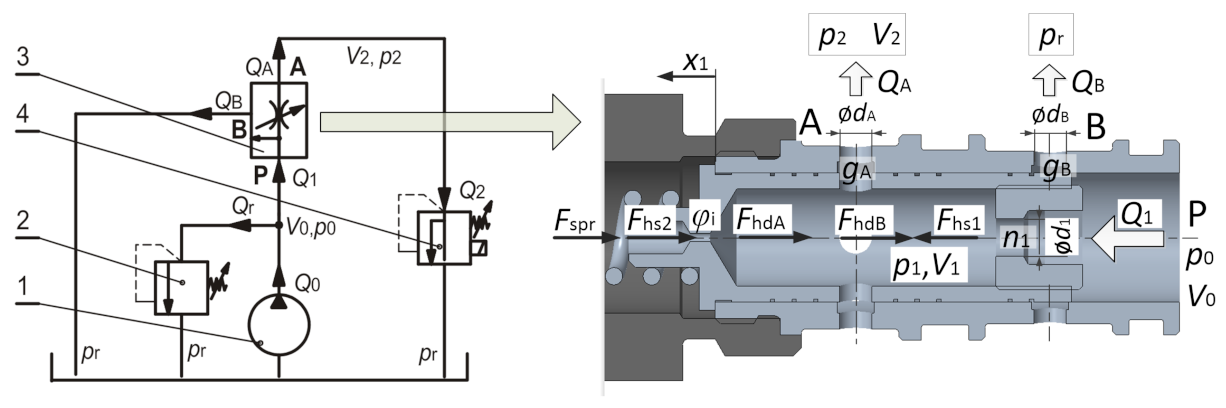

2. Case Study: Working Principle of a Cartridge Flow Control Valve

3. Methodology

3.1. Mathematical Model

3.2. Discrete Model and Mesh Quality Assessment

3.3. Physical Parameters and Boundary Conditions

- Inlet: average fluid velocity calculated based on the flow rate; velocity specification method: Magnitude, Normal to Boundary; inlet flow rate dm3 min−1;

- Outlet A: static pressure; outlet condition: Gauge Pressure; pressure value: various values in subsequent simulations in the range MPa;

- Outlet B: static pressure; outlet condition: Gauge Pressure; pressure value: various values in subsequent simulations in the range = 0.1–10MPa.

3.4. Turbulence Model

4. Results of Numerical Simulations

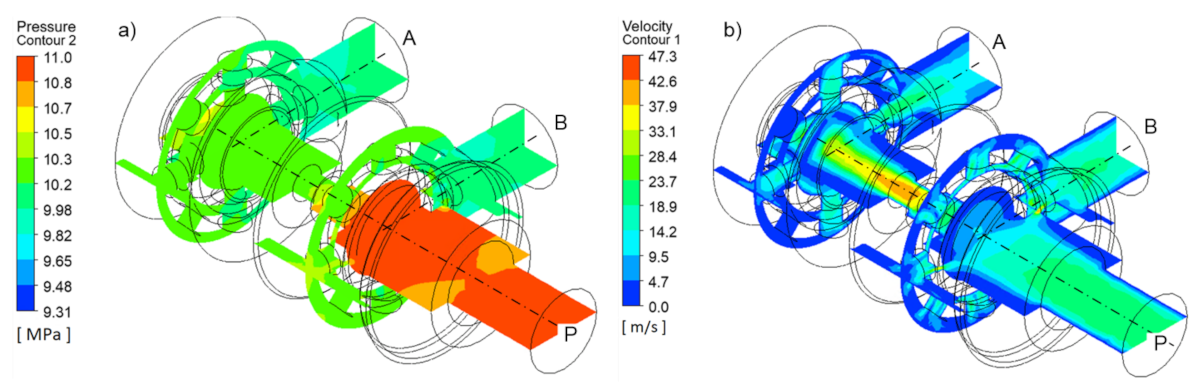

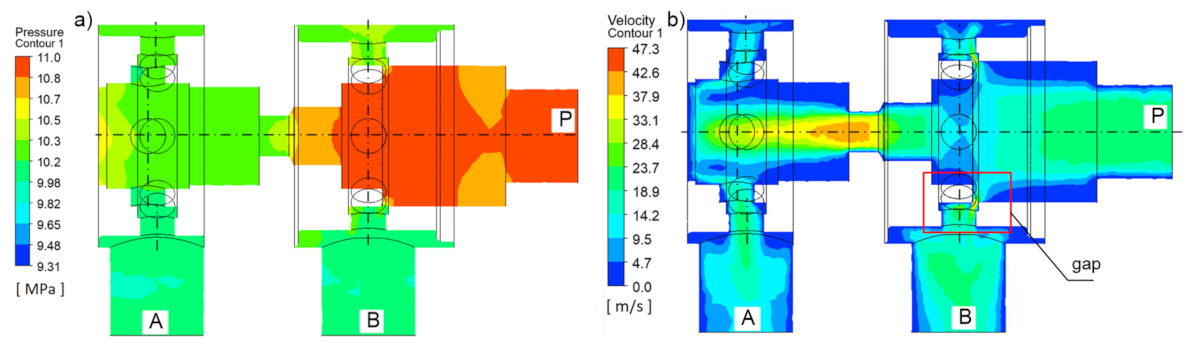

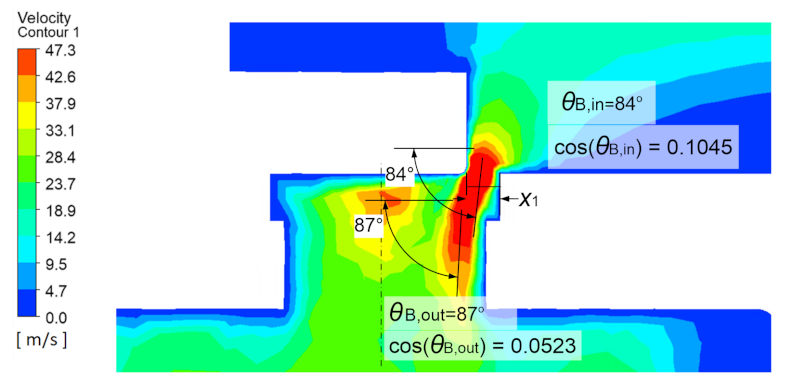

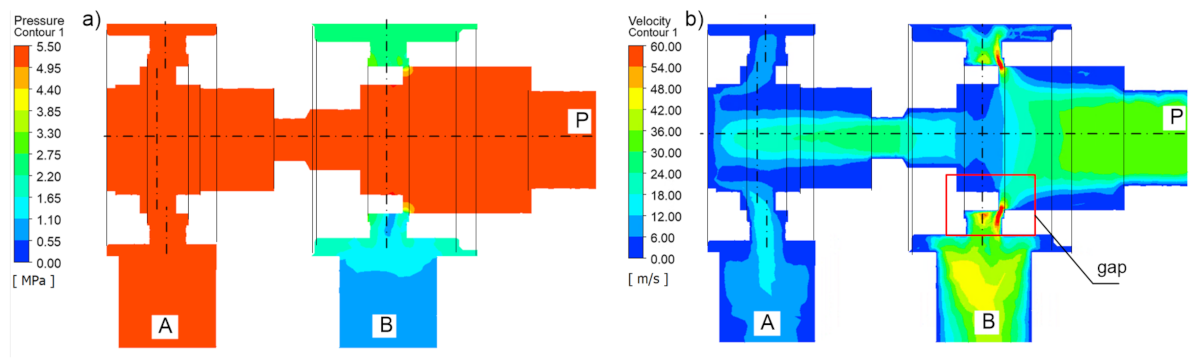

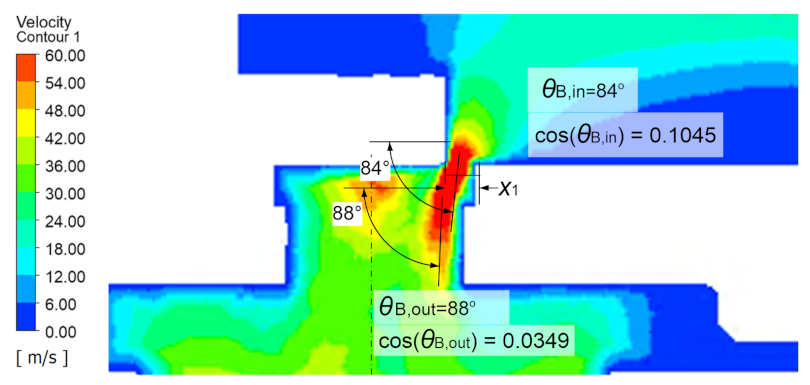

4.1. Results of CFD Simulations in Ansys

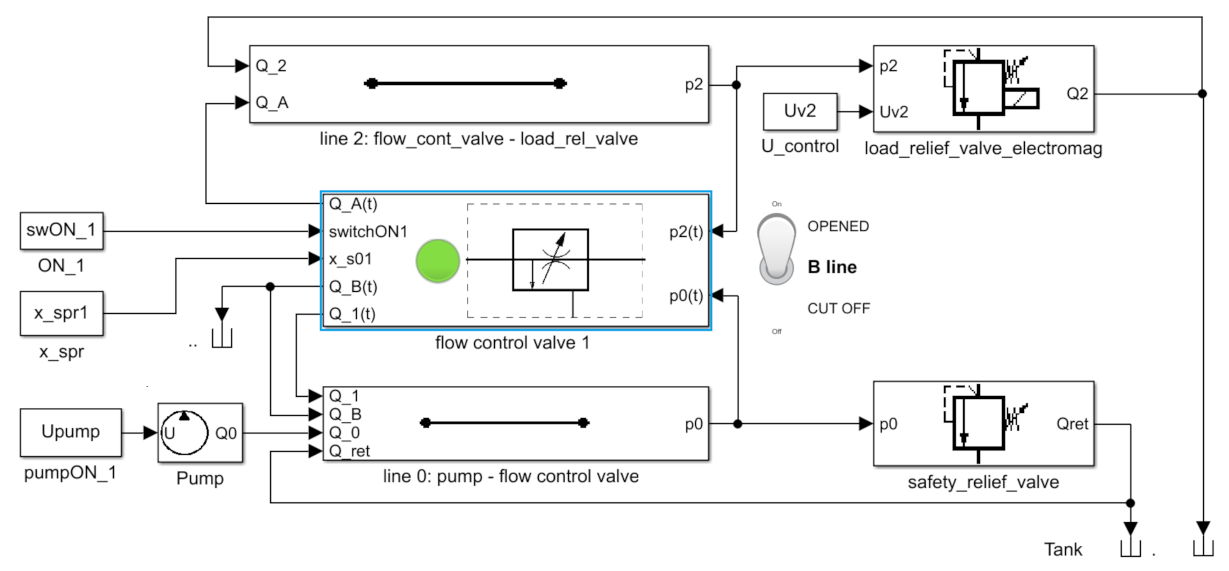

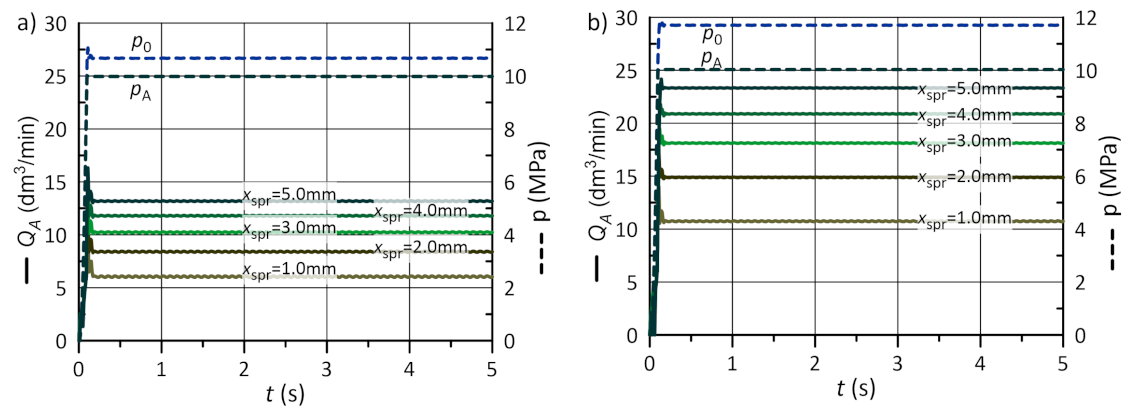

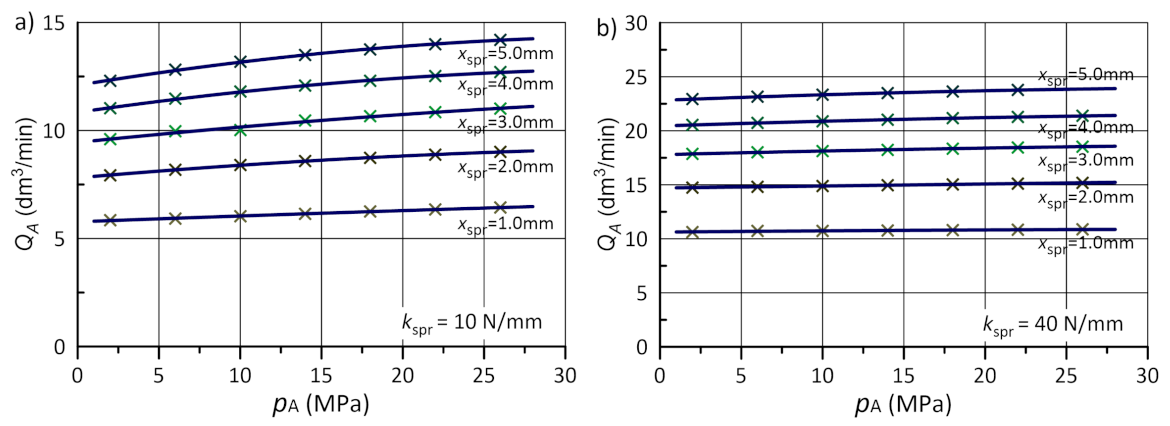

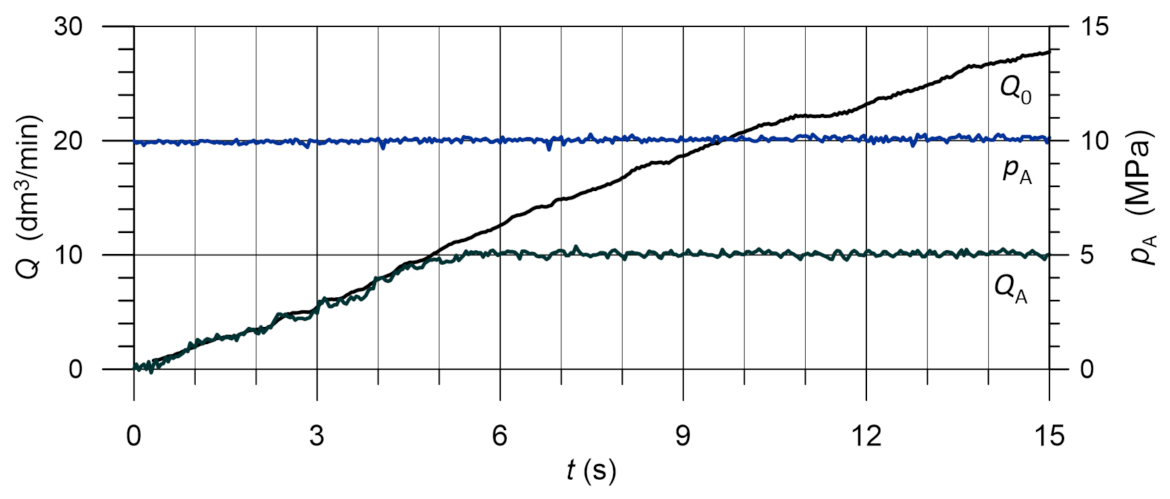

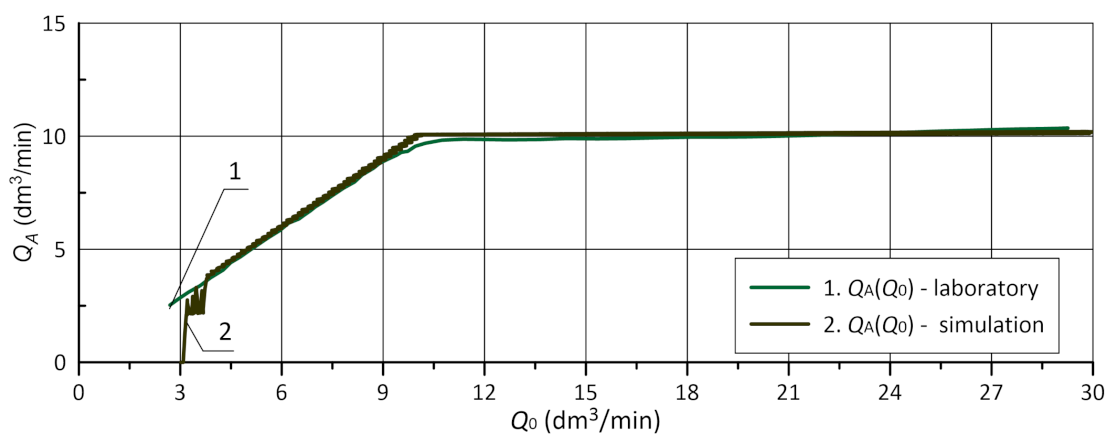

4.2. Simulink Model and Results of Simulations

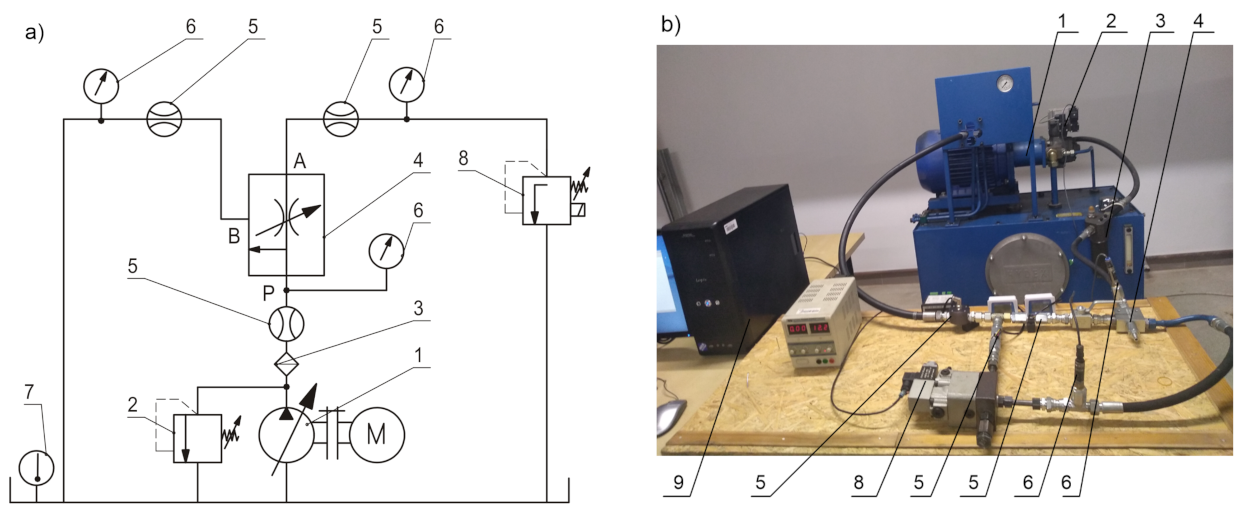

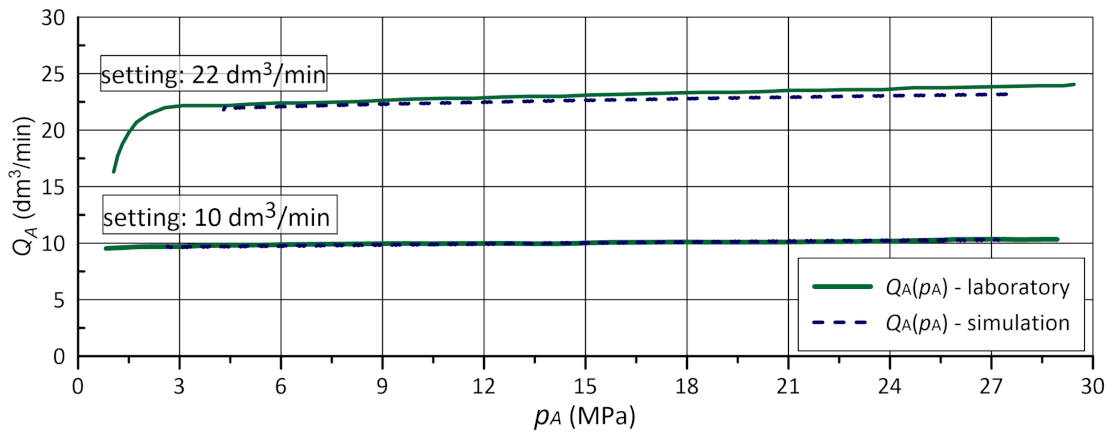

5. Laboratory Test Bench and Experimental Results

6. Discussion

7. Conclusions

- The proposed valve can be used in practice in all power hydraulic systems where a specific fixed value of the minimum flow rate must be ensured regardless of the load.

- There are operational limitations: under conditions of variable load, the possibility of increasing the flow by 10% compared to the required value should be taken into account, especially for low regulated flow (setting 6 dm3 min −1 results in accuracy up to 10%, while for 22 dm3 min −1 the maximum change does not exceed 4%.

- Compared to a typical two-way flow control valve, the proposed solution is more advantageous in terms of energy demand, especially in systems of many valves connected in parallel, since the presence of a relief line prevents the need for higher pressure in the supply line.

- The valve can be used in systems and environmental conditions that exclude direct access to the electrical power supply.

- To obtain a wide range of adjustable flow rates, springs of different stiffness can be used, with a stiffer spring allowing for higher values. At the same time, the exact setting is achieved by manually adjusting the initial tension of the spring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Indices | |

| 0 | supply line |

| 1 | flow control valve |

| 2 | load line |

| r | return line |

| Parameters | |

| , , | flow control valve areas: nozzle, and gaps, s spool (m2) |

| fluid bulk modulus (MPa) | |

| turbulence model constants (-) | |

| hydrodynamic forces in A and B gaps acting on spool (N) | |

| forces acting on spool: hydrostatic, spring, viscous friction (N) | |

| turbulence model factors: intensity, length scale (-, m) | |

| , , | flow rate: pump, load line, return line (dm3 min−1) |

| , , | flow control valve flow rate: inlet, A port, B port (dm3 min−1) |

| , | nominal flow rate through , relief valve (dm3 min−1) |

| , | volume: supply line, load line (m3) |

| pump design geometrical parameters (mm) | |

| , | flow diameter of nozzle, spool diameter (m2) |

| pump eccentricity (mm) | |

| valve spring stiffness (N m−1) | |

| valve spool mass (kg) | |

| pressure: supply line, load line, return line (MPa) | |

| , , | pressure: inside valve, at the A port, at the B port (MPa) |

| turbulence model constants (-) | |

| time, start-up time (s) | |

| average fluid velocity in the P, A, B port (m s−1) | |

| valve spool position (m) | |

| initial tension of valve spring (m) | |

| pump rotational angle (rad) | |

| , | readjustment of , relief valve at nominal flow (MPa) |

| fluid dynamic viscosity (Pa s) | |

| fluid jet angle (rad) | |

| fluid kinematic viscosity (m2 s−1) | |

| , , | discharge coefficient of flow control valve nozzle and gaps (-) |

| turbulent viscosity (m2 s−1) | |

| fluid density (kg m−3) | |

| valve spool damping coefficient (N s m−1) | |

| pump rotational speed, pump nominal speed (rev s−1) |

References

- Huang, J.; Wang, X.; Wang, H.; Hao, H. Development of a flow control valve with digital flow compensator. Flow Meas. Instrum. 2019, 66, 157–169. [Google Scholar] [CrossRef]

- Okhotnikov, I.; Noroozi, S.; Sewell, P.; Godfrey, P. Evaluation of steady flow torques and pressure losses in a rotary flow control valve by means of computational fluid dynamics. Int. J. Heat Fluid Flow 2017, 64, 89–102. [Google Scholar] [CrossRef]

- Lisowski, E.; Filo, G. CFD analysis of the characteristics of a proportional flow control valve with an innovative opening shape. Energy Convers. Manag. 2016, 123, 15–28. [Google Scholar] [CrossRef]

- Filo, G.; Lisowski, E. Numerical Analysis of Fluid Stream Division to Supply Multiple Hydraulic Receivers. Appl. Sci. 2022, 12, 10327. [Google Scholar] [CrossRef]

- Liu, J.; Li, R.; Ding, X.; Liu, Q. Flow force research and structure improvement of cartridge valve core based on CFD method. Heliyon 2022, 8, e11700. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, J. Simulation research on dynamic performance of cartridge two position four way directional valve. Mach. Tool Hydraul. 2021, 49, 135–190. [Google Scholar]

- Kumar, S.; Tewari, V.K.; Bharti, C.K.; Ranjan, A. Modeling, simulation and experimental validation of flow rate of electro-hydraulic hitch control valve of agricultural tractor. Flow Meas. Instrum. 2021, 82, 102070. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Do, T.C.; Ahn, K.K. A Study on a New Independent Metering Valve for Hydraulic Boom Excavator. Appl. Sci. 2022, 12, 605. [Google Scholar] [CrossRef]

- Li, D.; Hang, J.; Li, Y.; Dong, S. Fuel Flowrate Control for Aeroengine and Fuel Thermal Management for Airborne System of Aircraft; An Overview. Appl. Sci. 2022, 12, 279. [Google Scholar] [CrossRef]

- Adeoye, A.; Aderoba, A.; Oladapo, B. Simulated Design of a Flow Control Valve for Stroke Speed Adjustment of Hydraulic Power of Robotic Lifting Device. Procedia Eng. 2017, 173, 1499–1506. [Google Scholar] [CrossRef]

- Han, J.; Wang, F.; Wang, Y. A Control Method for the Differential Steering of Tracked Vehicles Driven Independently by a Dual Hydraulic Motor. Appl. Sci. 2022, 12, 6355. [Google Scholar] [CrossRef]

- Lei, T.; Wang, J.; Yao, Z. Modelling and Stability Analysis of Articulated Vehicles. Appl. Sci. 2021, 11, 3663. [Google Scholar] [CrossRef]

- Leephakpreeda, T. Flow-sensorless control valve: Neural computing approach. Flow Meas. Instrum. 2003, 14, 261–266. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.; Xu, B.; Su, Q.; Lu, Z.; Wang, W. Flow control of a proportional directional valve without the flow meter. Flow Meas. Instrum. 2019, 67, 131–141. [Google Scholar] [CrossRef]

- Feng, H.; Song, Q.; Ma, S.; Ma, W.; Yin, C.; Cao, D.; Yu, H. A new adaptive sliding mode controller based on the RBF neural network for an electro-hydraulic servo system. ISA Trans. 2022, 129, 472–484. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Y.; Zhang, J.; Lei, F.; Zhao, D.; Hong, H. Multi-Objective Optimization Design of Key Parameters of a Stepless Flow Control System with Multi-System Coupling Characteristics. Appl. Sci. 2022, 12, 1301. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Chen, J.; Chen, W.; Li, C.; Huo, D. Design and control performance optimization of dual-mode hydraulic steering system for wheel loader. Autom. Constr. 2022, 143, 104539. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, L.; Liu, T.; Guo, Z.; Golnary, F. Dynamic mode decomposition analysis of the two-dimensional flow past two transversely in-phase oscillating cylinders in a tandem arrangement. Phys. Fluids 2022, 34, 033602. [Google Scholar] [CrossRef]

- Bao, M.; Xie, Y.; Zhang, X.; Ju, J.; Wang, Y. Performance improvement of a control valve with energy harvesting. Energy 2023, 263, 125862. [Google Scholar] [CrossRef]

- Ding, X.; Li, R.; Xu, J.; Liu, Q.; Cheng, Y.; Liu, J. Study on flow force compensation characteristics and optimization design of jet guiding groove. Flow Meas. Instrum. 2022, 86, 102194. [Google Scholar] [CrossRef]

- Liu, F.; Cao, S.; Zhou, W.; Zhao, D.; Zheng, L.; Shao, M. Transient flow analysis on opening process of pneumatic gas proportional valve with two-solenoid valve. Flow Meas. Instrum. 2023, 89, 102291. [Google Scholar] [CrossRef]

- Ye, J.; Zhao, Z.; Cui, J.; Hua, Z.; Peng, W.; Jiang, P. Transient flow behaviors of the check valve with different spool-head angle in high-pressure hydrogen storage systems. J. Energy Storage 2022, 46, 103761. [Google Scholar] [CrossRef]

- Filo, G.; Lisowski, E.; Kwiatkowski, D.; Rajda, J. Numerical and Experimental Study of a Novel Valve Using the Return Stream Energy to Adjust the Speed of a Hydraulic Actuator. Stroj. Vestn.-J. Mech. Eng. 2019, 65, 103–112. [Google Scholar] [CrossRef]

- Valdés, J.R.; Miana, M.J.; Núñez, J.L.; Pütz, T. Reduced order model for estimation of fluid flow and flow forces in hydraulic proportional valves. Energy Convers. Manag. 2008, 49, 1517–1529. [Google Scholar] [CrossRef]

- Anh, P.N.; Bae, J.S.; Hwang, J.H. Computational Fluid Dynamic Analysis of Flow Rate Performance of a Small Piezoelectric-Hydraulic Pump. Appl. Sci. 2021, 11, 4888. [Google Scholar] [CrossRef]

- Yang, L.J.; Waikhom, R.; Wang, W.C.; Jabaraj Joseph, V.; Esakki, B.; Kumar Unnam, N.; Li, X.H.; Lee, C.Y. Check-Valve Design in Enhancing Aerodynamic Performance of Flapping Wings. Appl. Sci. 2021, 11, 3416. [Google Scholar] [CrossRef]

- Jin-yuan, Q.; Lin, W.; Zhi-jiang, J.; Jian-kai, W.; Han, Z.; An-le, L. CFD analysis on the dynamic flow characteristics of the pilot-control globe valve. Energy Convers. Manag. 2014, 87, 220–226. [Google Scholar] [CrossRef]

- Nishad, K.; Ries, F.; Li, Y.; Sadiki, A. Numerical Investigation of Flow through a Valve during Charge Intake in a DISI -Engine Using Large Eddy Simulation. Energies 2019, 12, 2620. [Google Scholar] [CrossRef]

- Wen, Q.; Liu, Y.; Chen, Z.; Wang, W. Numerical simulation and experimental validation of flow characteristics for a butterfly check valve in small modular reactor. Nucl. Eng. Des. 2022, 391, 111732. [Google Scholar] [CrossRef]

- Domagała, M.; Momeni, H.; Fabiś-Domagała, J. The Influence of Oil Contamination on Flow Control Valve Operation. Mater. Res. Proc. 2022, 24, 001008. [Google Scholar] [CrossRef]

- Chen, F.; Qian, J.; Chen, M.; Zhang, M.; Chen, L.; Jin, Z. Turbulent compressible flow analysis on multi-stage high pressure reducing valve. Flow Meas. Instrum. 2018, 61, 26–37. [Google Scholar] [CrossRef]

- Scuro, N.; Angelo, E.; Angelo, G.; Andrade, D. A CFD analysis of the flow dynamics of a directly-operated safety relief valve. Nucl. Eng. Des. 2018, 328, 321–332. [Google Scholar] [CrossRef]

- Filo, G.; Lisowski, E.; Rajda, J. Design and Flow Analysis of an Adjustable Check Valve by Means of CFD Method. Energies 2021, 14, 2237. [Google Scholar] [CrossRef]

- ANSYS Fluent in ANSYS Workbench User’s Guide, 2020th ed.; ANSYS Inc.: Canonsburg, PA, USA. 2020. Available online: http://www.ansys.com (accessed on 4 February 2023).

- Lisowski, E.; Filo, G.; Rajda, J. Pressure compensation using flow forces in a multi-section proportional directional control valve. Energy Convers. Manag. 2015, 103, 1052–1064. [Google Scholar] [CrossRef]

| Case (-) | Nodes (-) | Elements (-) | Time (min) | Calculated Flow (dm min) | Experimental Flow (dm min ) |

|---|---|---|---|---|---|

| 131124 | 681846 | 111 | |||

| 165697 | 881507 | 160 | |||

| 215124 | 1196093 | 210 | |||

| 235848 | 1311315 | 240 |

| Oil Kinematic Viscosity | Oil Density | Oil Temperature | Inlet Flow Rate | Load Line Pressure | Reynolds Number |

|---|---|---|---|---|---|

| T | |||||

| m2 s−1 | kg m−3 | °C | dm3 min−1 | MPa | - |

| 850 | 50 | 30 | 1–30 | 2000–28,000 |

| Turbulence Intensity | Turbulence Length Scale | Turb. Viscosity Constant | Kinetic Energy Constant | Kinetic Energy Dissipation Constants | ||

|---|---|---|---|---|---|---|

| I (%) | ℓ (mm) | (-) | (-) | (-) | (-) | (-) |

| 4.3–6.3 | 0.12–0.51 | 0.09 | 1.0 | 1.3 | 1.44 | 1.92 |

| Spool and Nozzle Mass | Spool Diameter | Spool Damping Coefficient | Nozzle Diameter | Spring Rate | Spring Init. Tension |

|---|---|---|---|---|---|

| kg | mm | Ns mm−1 | mm | N mm | mm |

| 12 |

| Pressure | Flow Rate | Temperature | DAQ Card | |

|---|---|---|---|---|

| Name | Trafag NAT | KEM HM | Introl FH0 | Advantech 4704 |

| Range Unit | 0–25 MPa | 0.3–33 dm3 min−1 | 0–100 C | 12 bit AI, AO |

| Accuracy | % | % | C | n.a. |

| Mean Error | Mean % Error | Max. Error | Std. Deviation | Std. Error | |

|---|---|---|---|---|---|

| dm3/min | % | dm3/min | dm3/min | dm3/min | |

| dm3/min | % | dm3/min | dm3/min | dm3/min | |

| MPa | % | MPa | MPa | MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisowski, E.; Filo, G.; Pluskowski, P.; Rajda, J. Flow Analysis of a Novel, Three-Way Cartridge Flow Control Valve. Appl. Sci. 2023, 13, 3719. https://doi.org/10.3390/app13063719

Lisowski E, Filo G, Pluskowski P, Rajda J. Flow Analysis of a Novel, Three-Way Cartridge Flow Control Valve. Applied Sciences. 2023; 13(6):3719. https://doi.org/10.3390/app13063719

Chicago/Turabian StyleLisowski, Edward, Grzegorz Filo, Piotr Pluskowski, and Janusz Rajda. 2023. "Flow Analysis of a Novel, Three-Way Cartridge Flow Control Valve" Applied Sciences 13, no. 6: 3719. https://doi.org/10.3390/app13063719

APA StyleLisowski, E., Filo, G., Pluskowski, P., & Rajda, J. (2023). Flow Analysis of a Novel, Three-Way Cartridge Flow Control Valve. Applied Sciences, 13(6), 3719. https://doi.org/10.3390/app13063719