Fiber Orientation Reconstruction from SEM Images of Fiber-Reinforced Composites

Abstract

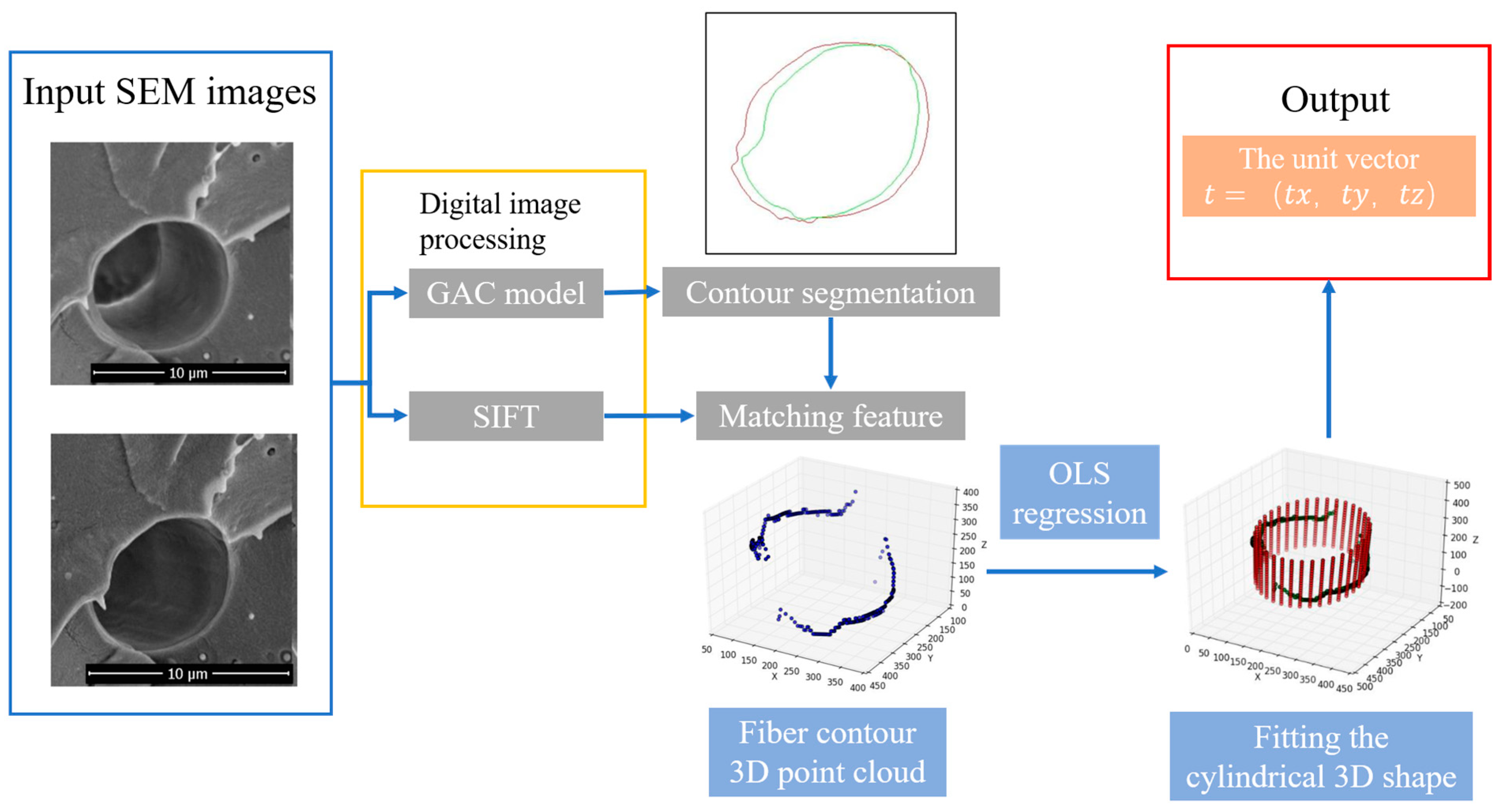

1. Introduction

2. Materials and Methods

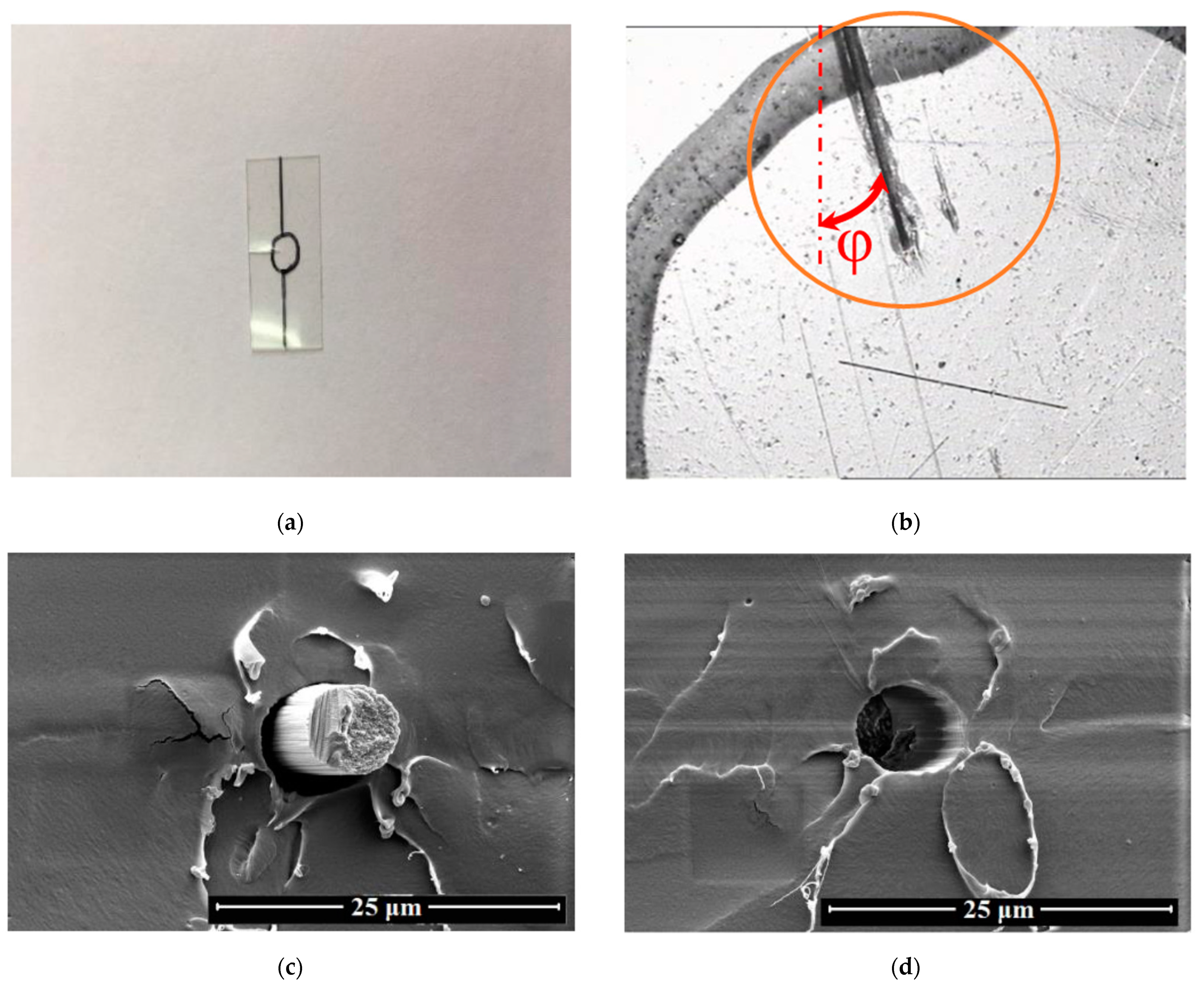

2.1. Experimental Material and Equipment

2.2. Image Processing Methods

2.2.1. Image Capture

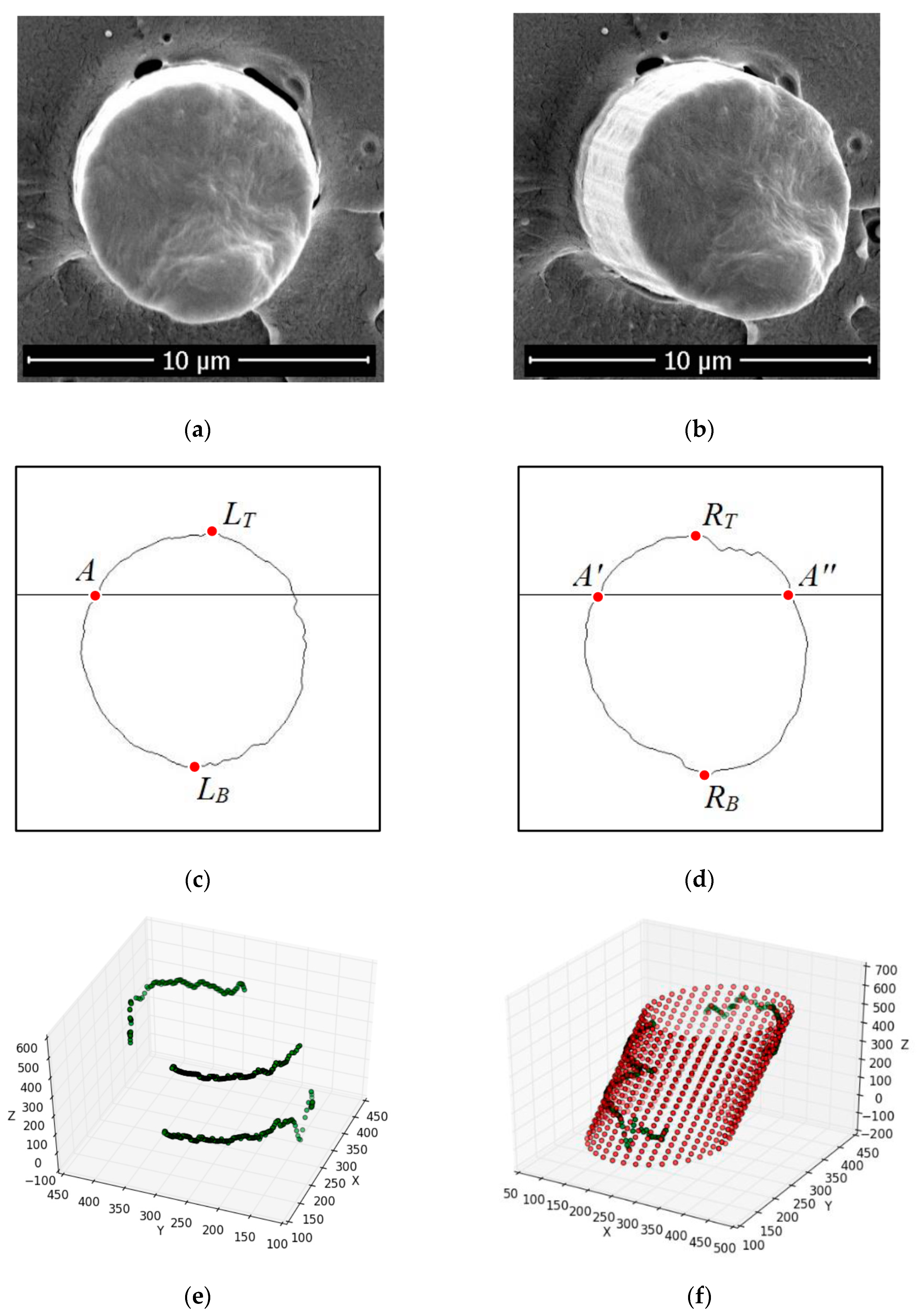

2.2.2. Image Segmentation

2.2.3. Scale Invariant Feature Transform

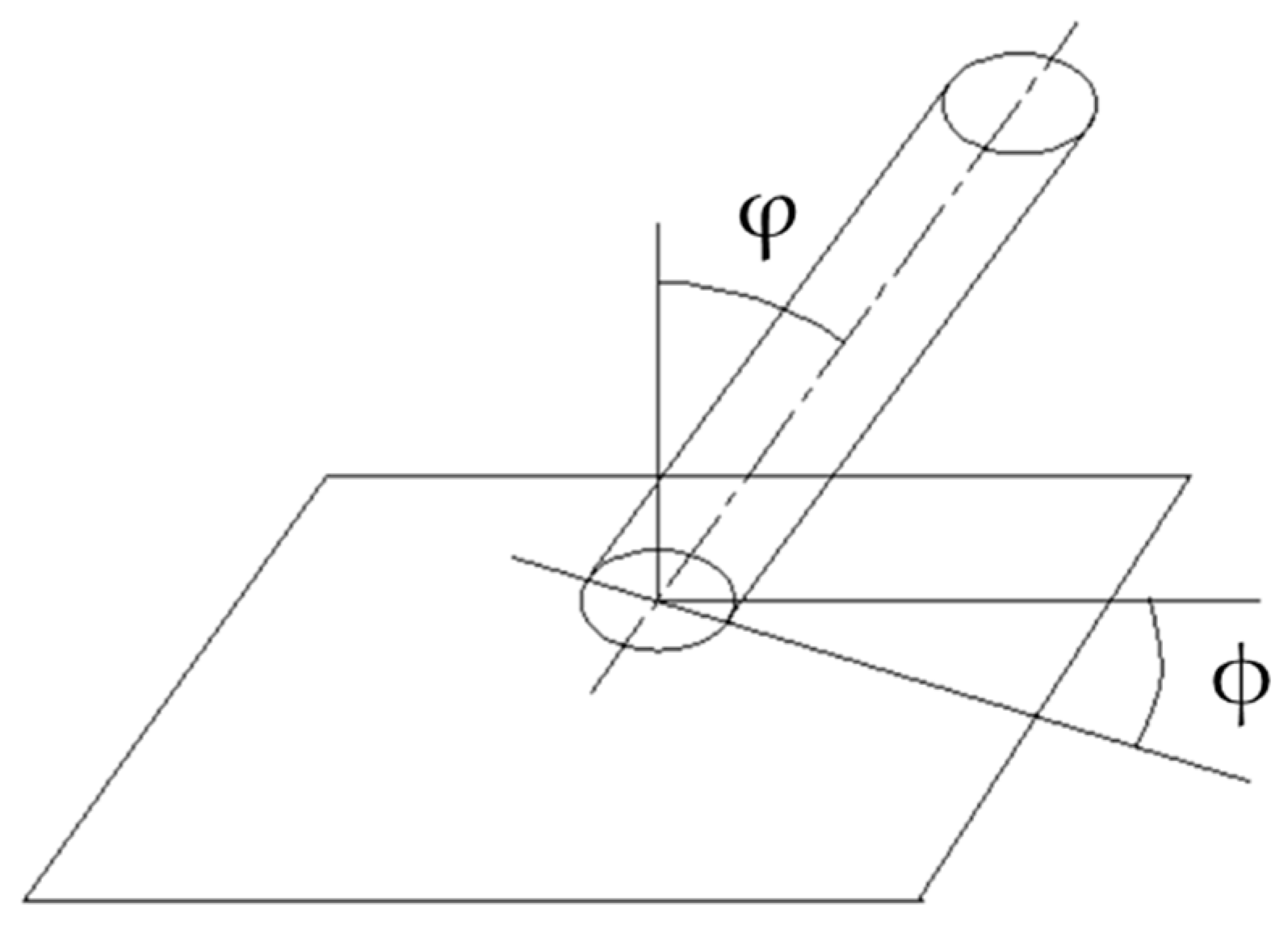

2.3. Methods for Describing Fiber Orientation

2.4. Cylindrical Fitting Method

2.5. Sample Preparation

3. Results and Discussion

3.1. Single-Fiber Deflection Angle Measurement Results

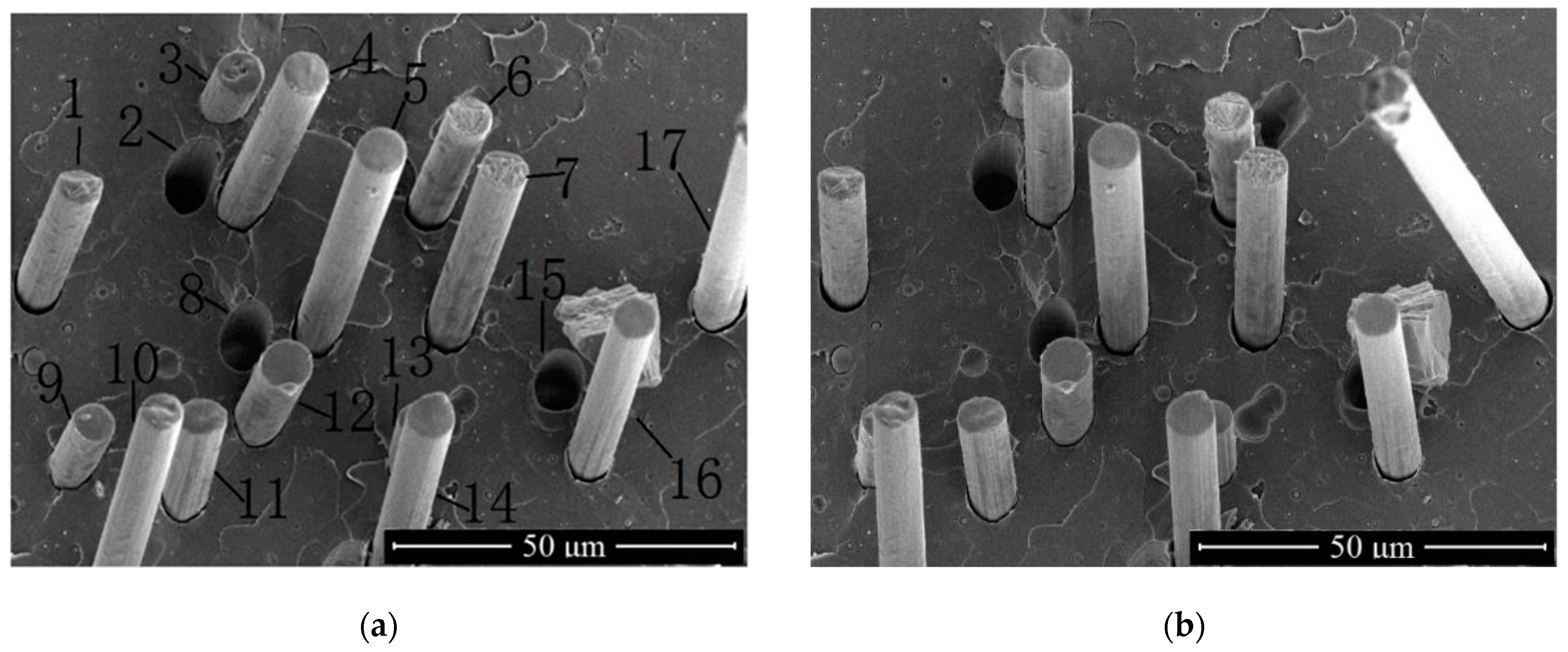

3.1.1. Prominent Fiber Orientation

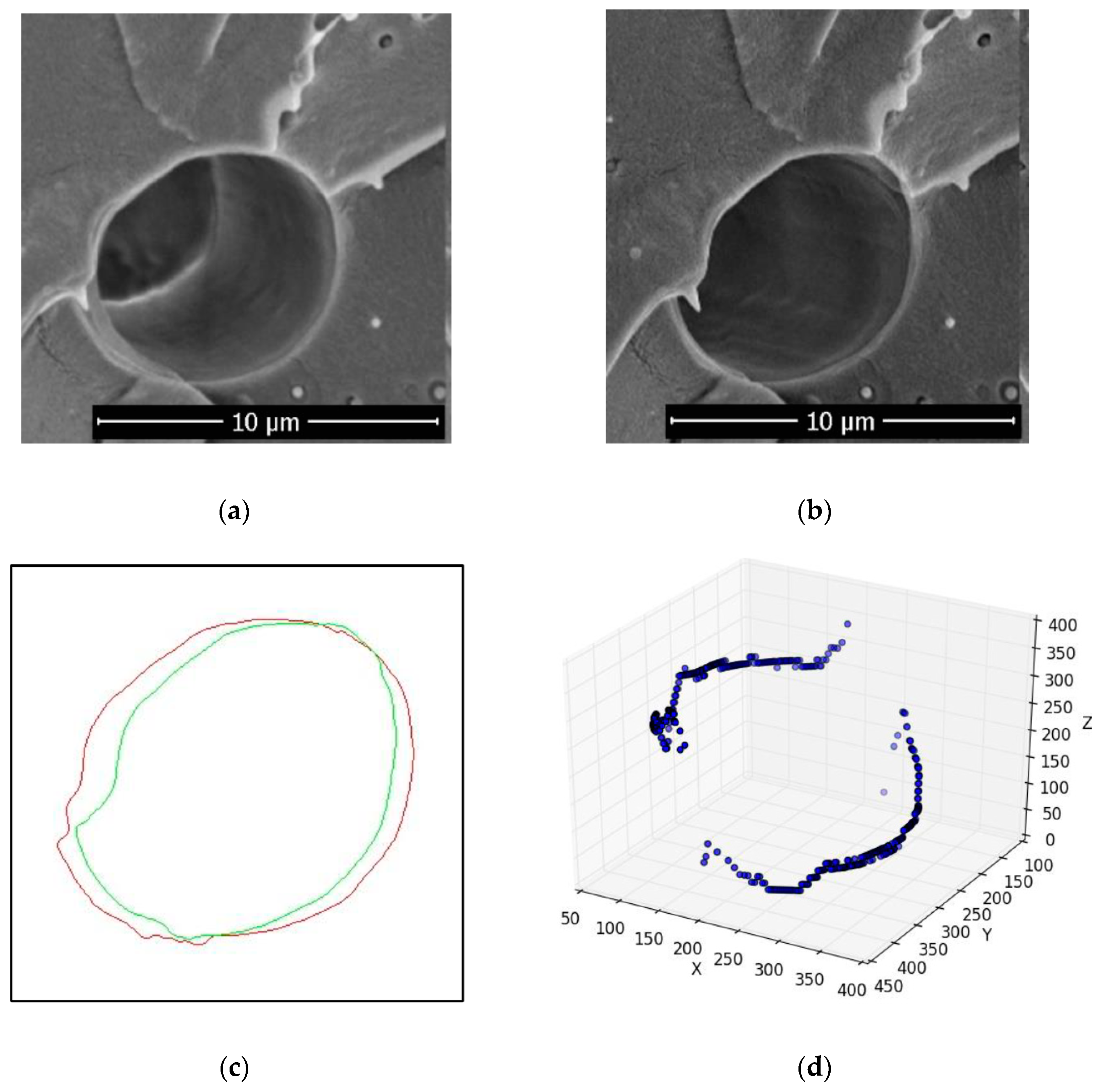

3.1.2. Fiber Pull-Out Cavity Orientation

3.1.3. Comparison with the Microscopic Measurement Method

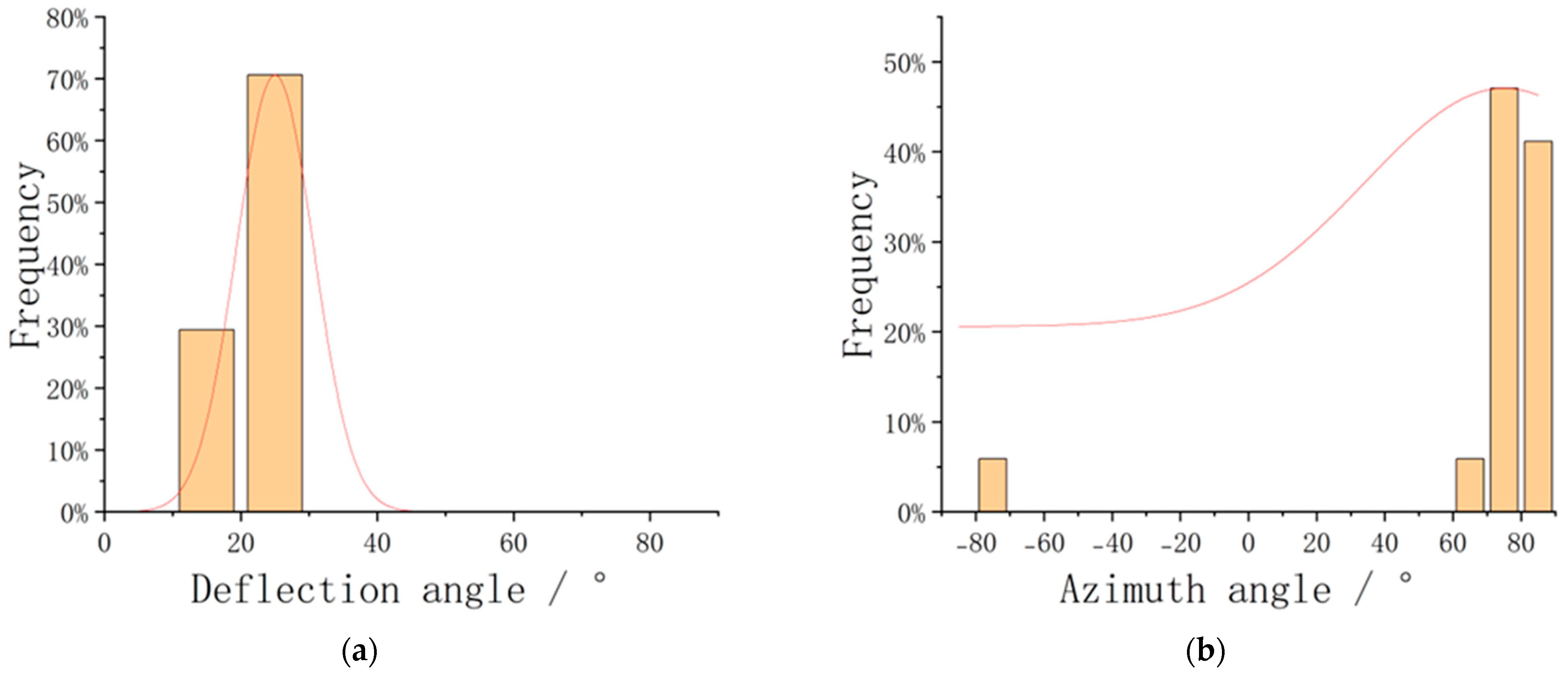

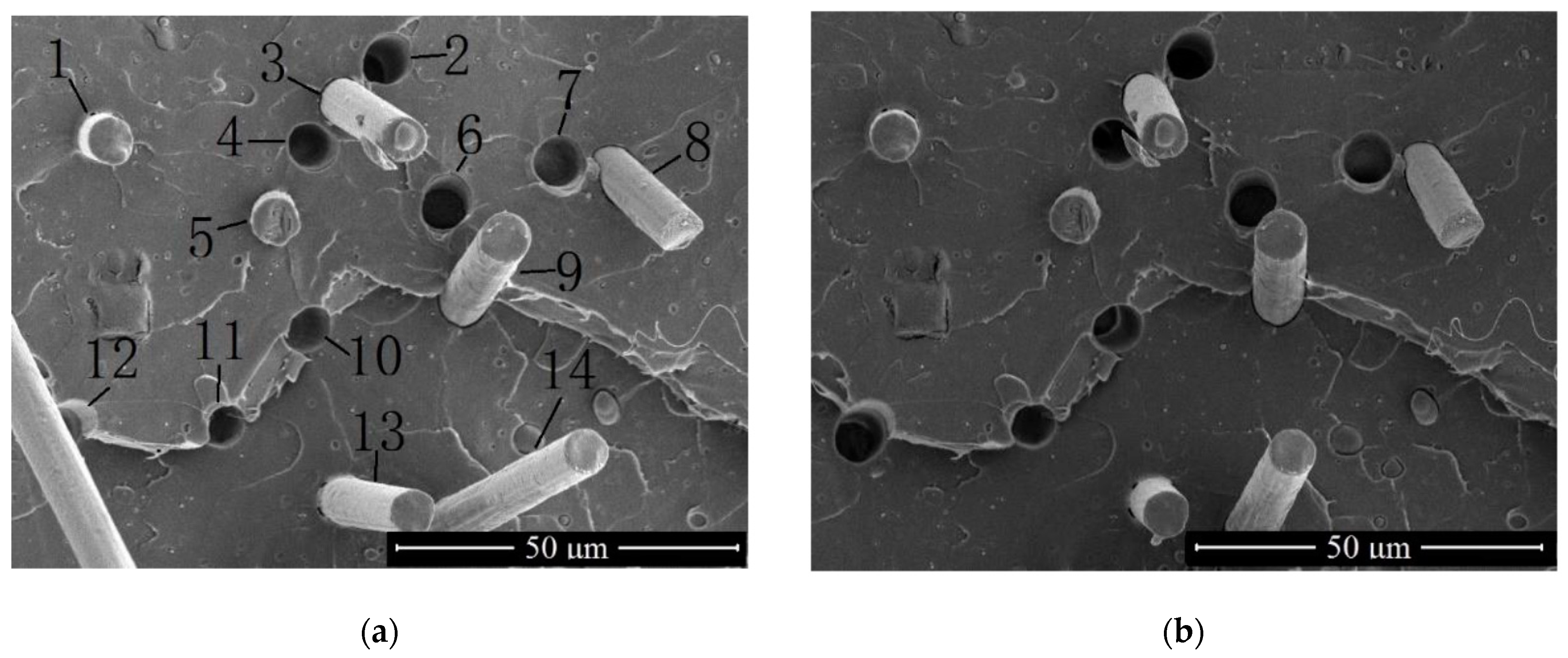

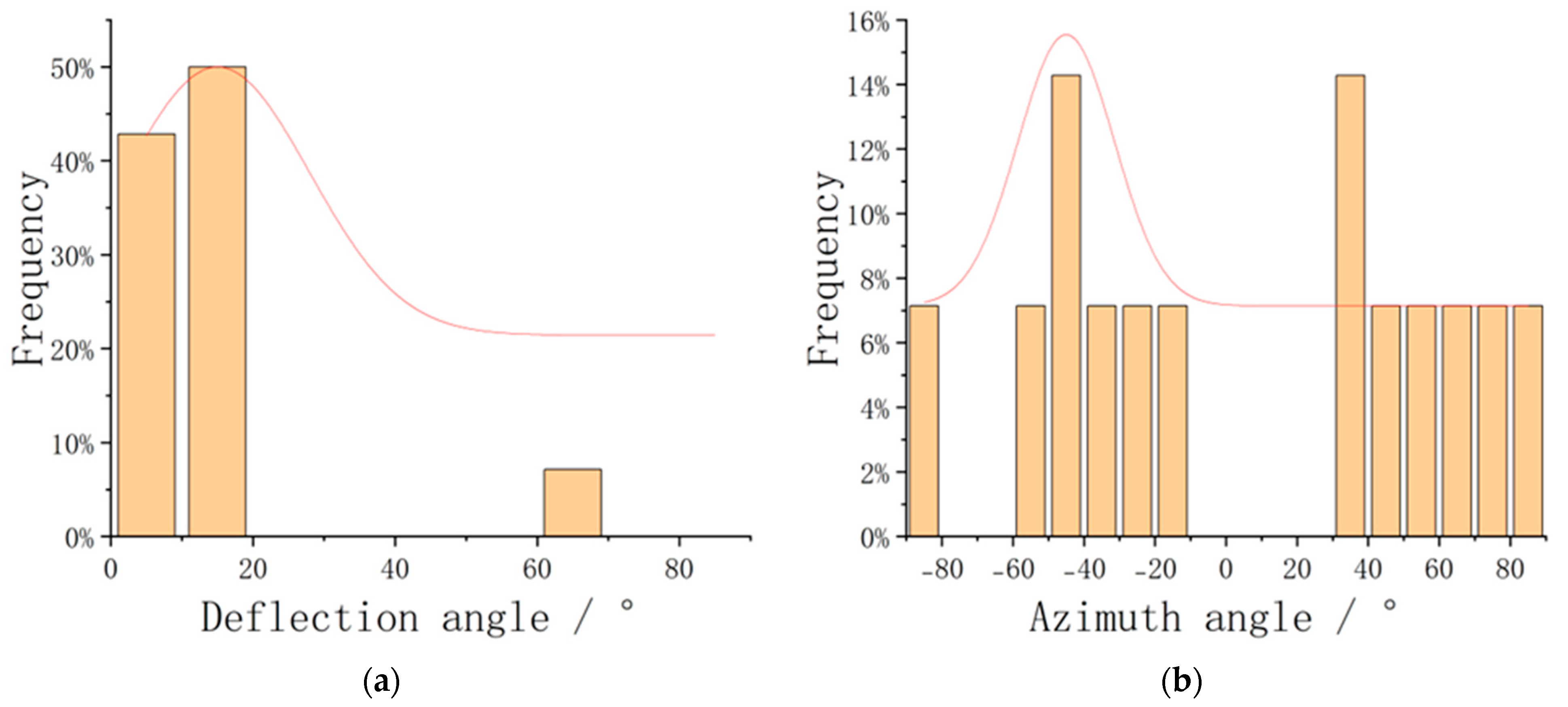

3.2. Multifiber Deflection Angle Measurement Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; Cambridge University Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Tsai, S.W.; Hahn, H.T. Introduction to Composite Materials; Routledge: Oxfordshire, UK, 2018. [Google Scholar]

- Chawla, K.K. Composite Materials: Science and Engineering; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Van Hattum, F.W.J.; Bernardo, C.A. A Model to Predict the Strength of Short Fiber Composites. Polym. Compos. 1999, 20, 524–533. [Google Scholar] [CrossRef]

- Gupta, M.; Wang, K.K. Fiber Orientation and Mechanical Properties of Short-Fiber-Reinforced Injection-Molded Composites: Simulated and Experimental Results. Polym. Compos. 1993, 14, 367–382. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B.; Mäder, E.; Yue, C.-Y.; Hu, X. Tensile Properties of Short-Glass-Fiber- and Short-Carbon-Fiber-Reinforced Polypropylene Composites. Compos. Part Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Yoo, Y.; Spencer, M.W.; Paul, D.R. Morphology and Mechanical Properties of Glass Fiber Reinforced Nylon 6 Nanocomposites. Polymer 2011, 52, 180–190. [Google Scholar] [CrossRef]

- Denton, D.L.; Munson-McGee, S.H. Use of X-Radiographic Tracers to Measure Fiber Orientation in Short Fiber Composites; ASTM International: West Conshohocken, PA, USA, 1985. [Google Scholar]

- Bernasconi, A.; Cosmi, F.; Hine, P.J. Analysis of Fibre Orientation Distribution in Short Fibre Reinforced Polymers: A Comparison between Optical and Tomographic Methods. Compos. Sci. Technol. 2012, 72, 2002–2008. [Google Scholar] [CrossRef]

- Lee, K.S.; Lee, S.W.; Youn, J.R.; Kang, T.J.; Chung, K. Confocal Microscopy Measurement of the Fiber Orientation in Short Fiber Reinforced Plastics. Fibers Polym. 2001, 2, 41–50. [Google Scholar] [CrossRef]

- Kwon, S.-W.; Bosche, F.; Kim, C.; Haas, C.T.; Liapi, K.A. Fitting Range Data to Primitives for Rapid Local 3D Modeling Using Sparse Range Point Clouds. Autom. Constr. 2004, 13, 67–81. [Google Scholar] [CrossRef]

- Nurunnabi, A.; Sadahiro, Y.; Lindenbergh, R. Robust Cylinder Fitting in Three-Dimensional Point Cloud Data. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 63–70. [Google Scholar] [CrossRef]

- Watanabe, R.; Sugahara, A.; Hagihara, H.; Mizukado, J.; Shinzawa, H. Insight into Interfacial Compatibilization of Glass-Fiber-Reinforced Polypropylene (PP) Using Maleic-Anhydride Modified PP Employing Infrared Spectroscopic Imaging. Compos. Sci. Technol. 2020, 199, 108379. [Google Scholar] [CrossRef]

- Feliciani, C.; Takai, Y. Measurement and Numerical Prediction of Fiber-Reinforced Thermoplastics’ Thermal Conductivity in Injection Molded Parts. J. Appl. Polym. Sci. 2014, 131, 39811. [Google Scholar] [CrossRef]

- Mazahir, S.M.; Vélez-García, G.M.; Wapperom, P.; Baird, D. Fiber Orientation in the Frontal Region of a Center-Gated Disk: Experiments and Simulation. J. Non-Newton. Fluid Mech. 2015, 216, 31–44. [Google Scholar] [CrossRef]

- Vélez-García, G.M.; Wapperom, P.; Baird, D.G.; Aning, A.O.; Kunc, V. Unambiguous Orientation in Short Fiber Composites over Small Sampling Area in a Center-Gated Disk. Compos. Part Appl. Sci. Manuf. 2012, 43, 104–113. [Google Scholar] [CrossRef]

- Koutsoudis, A.; Vidmar, B.; Ioannakis, G.; Arnaoutoglou, F.; Pavlidis, G.; Chamzas, C. Multi-Image 3D Reconstruction Data Evaluation. J. Cult. Herit. 2014, 15, 73–79. [Google Scholar] [CrossRef]

- Shen, H.; Nutt, S.; Hull, D. Direct Observation and Measurement of Fiber Architecture in Short Fiber-Polymer Composite Foam through Micro-CT Imaging. Compos. Sci. Technol. 2004, 64, 2113–2120. [Google Scholar] [CrossRef]

- Thi, T.B.N.; Morioka, M.; Yokoyama, A.; Hamanaka, S.; Yamashita, K.; Nonomura, C. Measurement of Fiber Orientation Distribution in Injection-Molded Short-Glass-Fiber Composites Using X-Ray Computed Tomography. J. Mater. Process. Technol. 2015, 219, 1–9. [Google Scholar] [CrossRef]

- Fang, H.; Lafarge, F. Connect-and-Slice: An Hybrid Approach for Reconstructing 3D Objects. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 13–19 June 2020; pp. 13490–13498. [Google Scholar]

- Paluch, B. Analysis of Geometric Imperfections in Unidirectionally Reinforced Composites. In Proceedings of the 6th European Conference on Composite Materials(ECCM 6), Bordeaux, France, 20–24 September 1993; pp. 305–310. [Google Scholar]

- Pinter, P.; Dietrich, S.; Bertram, B.; Kehrer, L.; Elsner, P.; Weidenmann, K.A. Comparison and Error Estimation of 3D Fibre Orientation Analysis of Computed Tomography Image Data for Fibre Reinforced Composites. NDT E Int. 2018, 95, 26–35. [Google Scholar] [CrossRef]

- Samak, D.; Fischer, A.; Rittel, D. 3D Reconstruction and Visualization of Microstructure Surfaces from 2D Images. CIRP Ann. 2007, 56, 149–152. [Google Scholar] [CrossRef]

- de Azevedo, C.R.F.; Marques, E.R. Three-Dimensional Analysis of Fracture, Corrosion and Wear Surfaces. Eng. Fail. Anal. 2010, 17, 286–300. [Google Scholar] [CrossRef]

- Caselles, V.; Kimmel, R.; Sapiro, G. Geodesic Active Contours. Int. J. Comput. Vis. 1997, 22, 61. [Google Scholar] [CrossRef]

- Osher, S.; Sethian, J.A. Fronts Propagating with Curvature-Dependent Speed: Algorithms Based on Hamilton-Jacobi Formulations. J. Comput. Phys. 1988, 79, 12–49. [Google Scholar] [CrossRef]

- Lowe, D.G. Distinctive Image Features from Scale-Invariant Keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Clarke, A.R.; Archenhold, G.; Davidson, N.C. A Novel Technique for Determining the 3D Spatial Distribution of Glass Fibres in Polymer Composites. Compos. Sci. Technol. 1995, 55, 75–91. [Google Scholar] [CrossRef]

| No. | The Method Used in This Paper | Image Measurement Results | |

|---|---|---|---|

| Prominent Fiber | Pull-Out Cavity | ||

| 1 | 16.508 | 19.638 | 17.027 |

| 2 | 33.491 | 35.275 | 32.519 |

| 3 | 19.746 | 19.917 | 19.642 |

| 4 | 9.468 | 8.013 | 9.735 |

| 5 | 24.955 | 23.481 | 21.128 |

| No. | Deflection Angle/° | Azimuth Angle/° |

|---|---|---|

| 1 | 21.381 | 78.694 |

| 2 | 29.457 | 74.249 |

| 3 | 29.098 | 69.986 |

| 4 | 19.075 | 76.891 |

| 5 | 22.353 | 81.301 |

| 6 | 17.431 | 81.63 |

| 7 | 27.589 | 78.824 |

| 8 | 28.139 | 77.121 |

| 9 | 23.202 | 71.189 |

| 10 | 28.304 | 82.292 |

| 11 | 23.035 | 87.383 |

| 12 | 17.295 | 76.298 |

| 13 | 28.43 | 84.86 |

| 14 | 27.165 | 83.763 |

| 15 | 20.683 | 79.546 |

| 16 | 19.692 | 84.716 |

| 17 | 10.936 | −78.599 |

| No. | Deflection Angle/° | Azimuth Angle/° |

|---|---|---|

| 1 | 8.61 | −56.77 |

| 2 | 9.37 | 47.64 |

| 3 | 13.53 | −44.89 |

| 4 | 7.69 | −49.15 |

| 5 | 2.66 | −85.39 |

| 6 | 10.95 | 76.42 |

| 7 | 8.87 | 83.56 |

| 8 | 66.53 | 50.54 |

| 9 | 15.42 | 69.78 |

| 10 | 19.3 | −33.13 |

| 11 | 17.36 | −28.17 |

| 12 | 10.79 | 38.11 |

| 13 | 7.09 | −14.54 |

| 14 | 11.43 | 38.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Wu, H.; Zhang, M.; Fu, S.; Zhu, K. Fiber Orientation Reconstruction from SEM Images of Fiber-Reinforced Composites. Appl. Sci. 2023, 13, 3700. https://doi.org/10.3390/app13063700

Zhao Z, Wu H, Zhang M, Fu S, Zhu K. Fiber Orientation Reconstruction from SEM Images of Fiber-Reinforced Composites. Applied Sciences. 2023; 13(6):3700. https://doi.org/10.3390/app13063700

Chicago/Turabian StyleZhao, Zhouxiang, Hongwu Wu, Meng Zhang, Shiqiang Fu, and Kang Zhu. 2023. "Fiber Orientation Reconstruction from SEM Images of Fiber-Reinforced Composites" Applied Sciences 13, no. 6: 3700. https://doi.org/10.3390/app13063700

APA StyleZhao, Z., Wu, H., Zhang, M., Fu, S., & Zhu, K. (2023). Fiber Orientation Reconstruction from SEM Images of Fiber-Reinforced Composites. Applied Sciences, 13(6), 3700. https://doi.org/10.3390/app13063700