A Two-Dimensional Non-Destructive Beam Monitoring Detector for Ion Beams

Abstract

1. Introduction

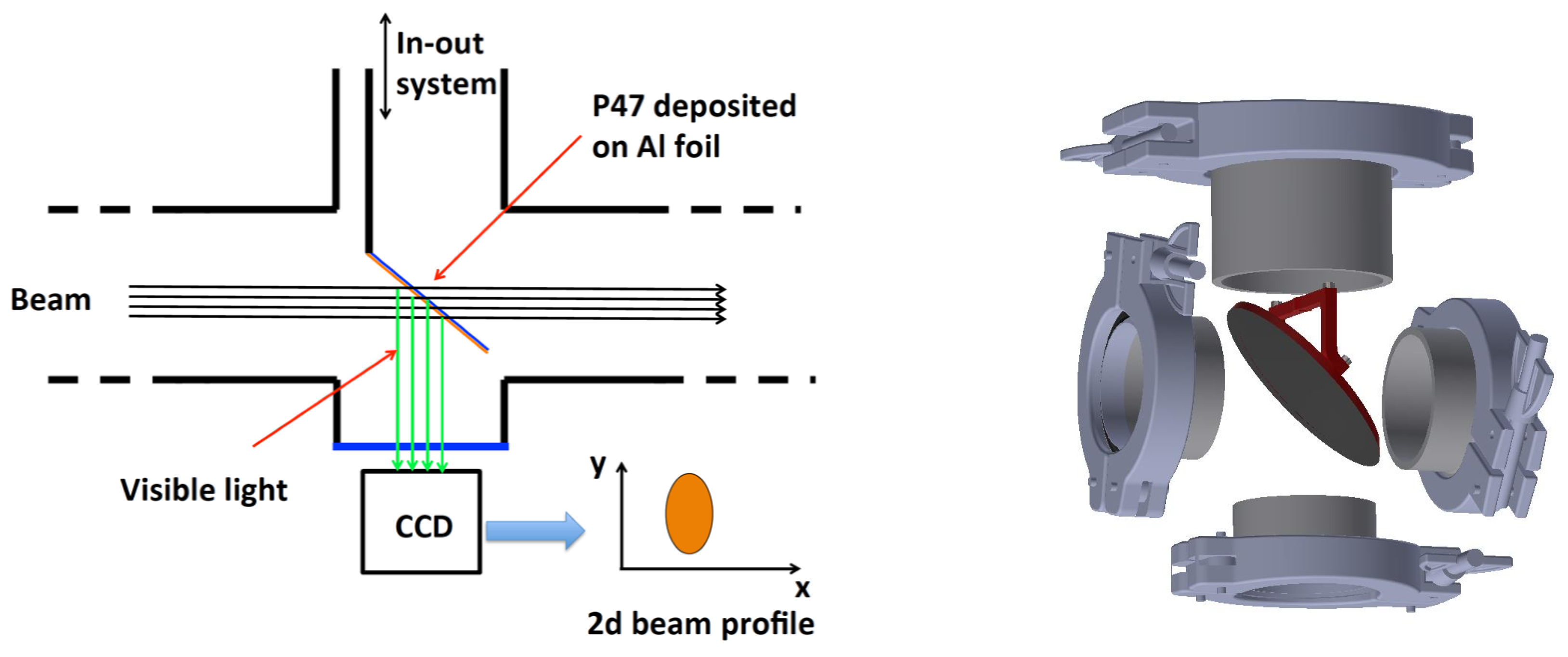

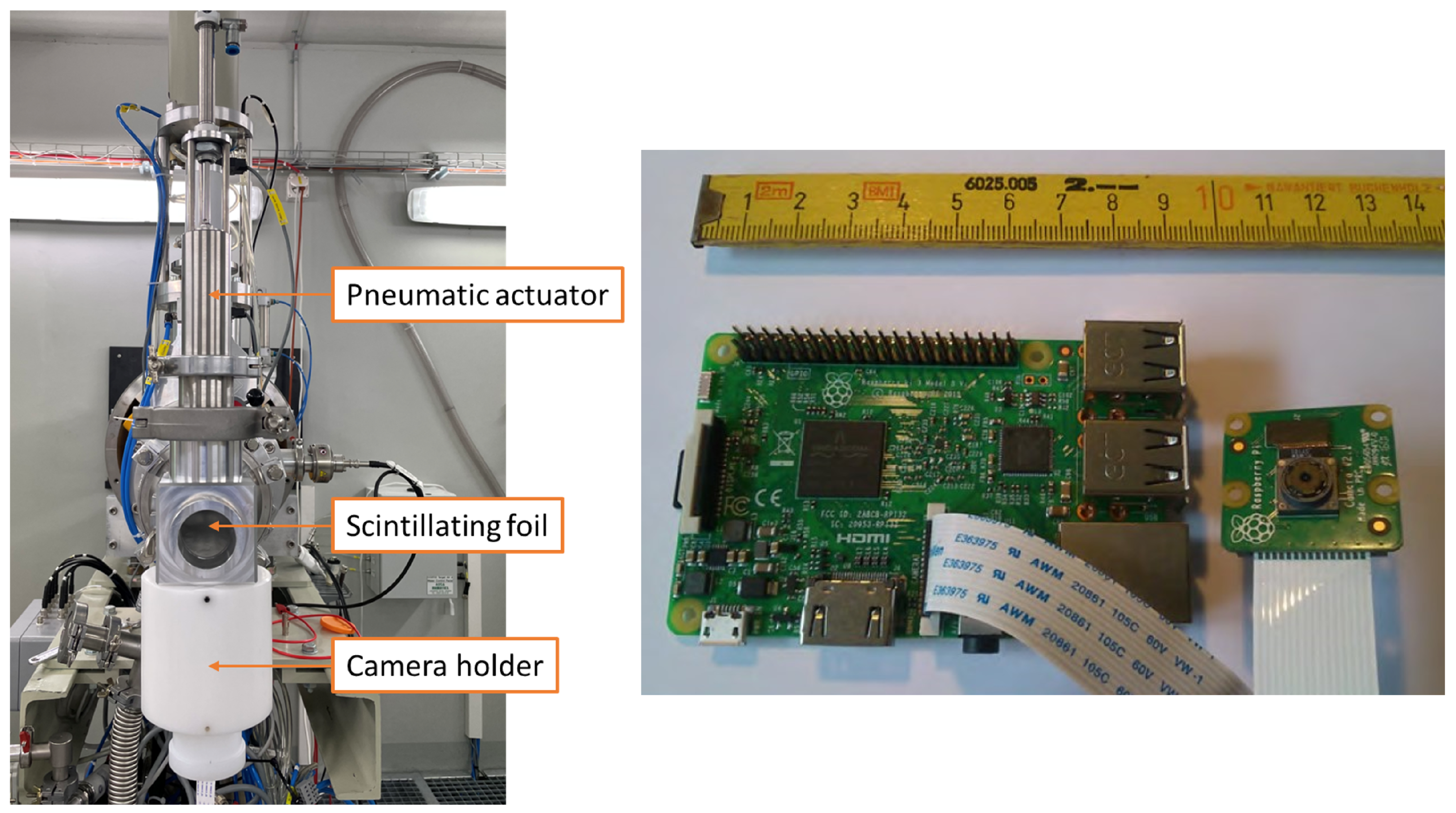

2. Materials and Methods

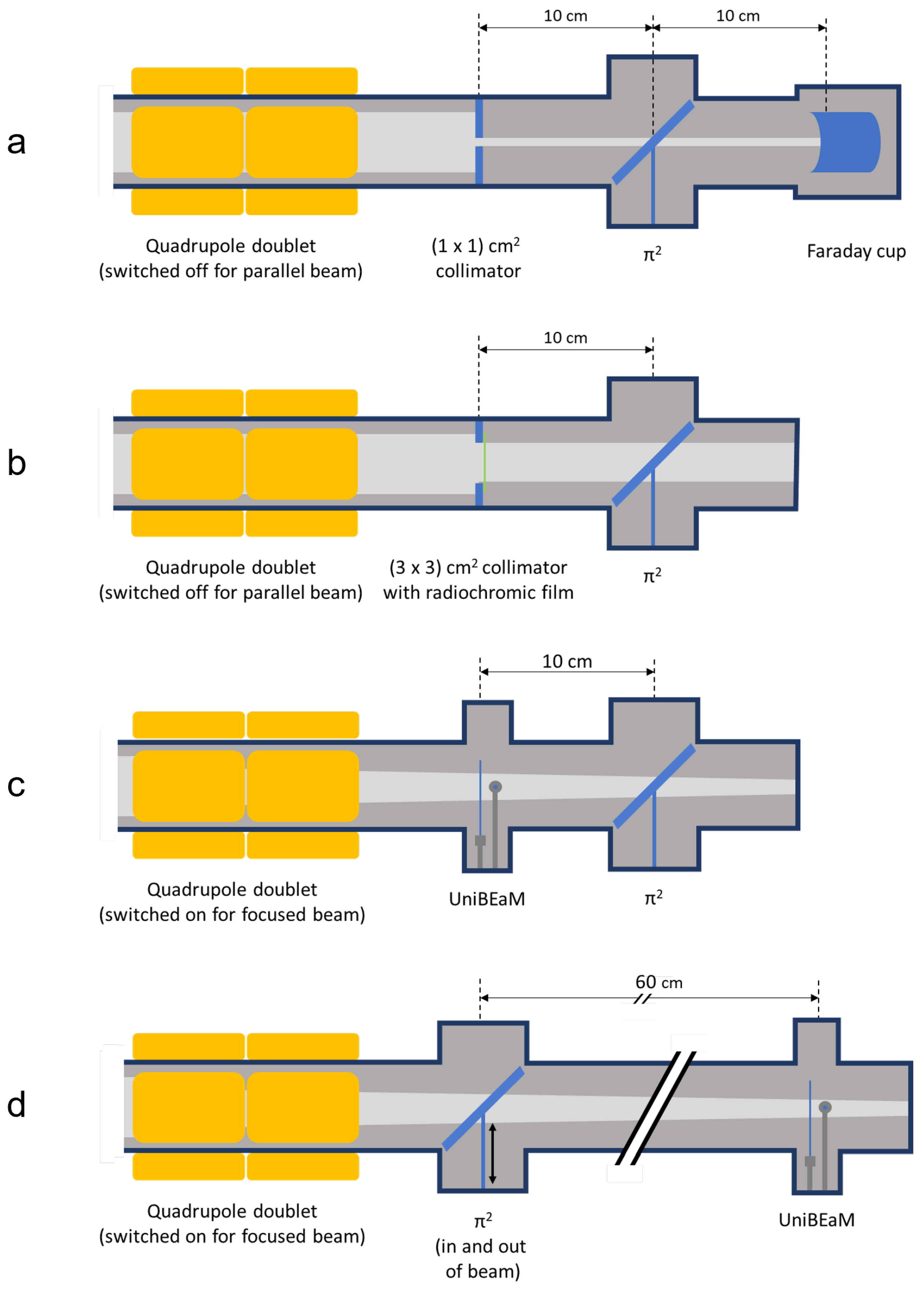

- The first experiment aimed at examining the response function of the apparatus with varying proton flux, and at establishing a calibration for displaying the beam footprint in terms of proton flux.

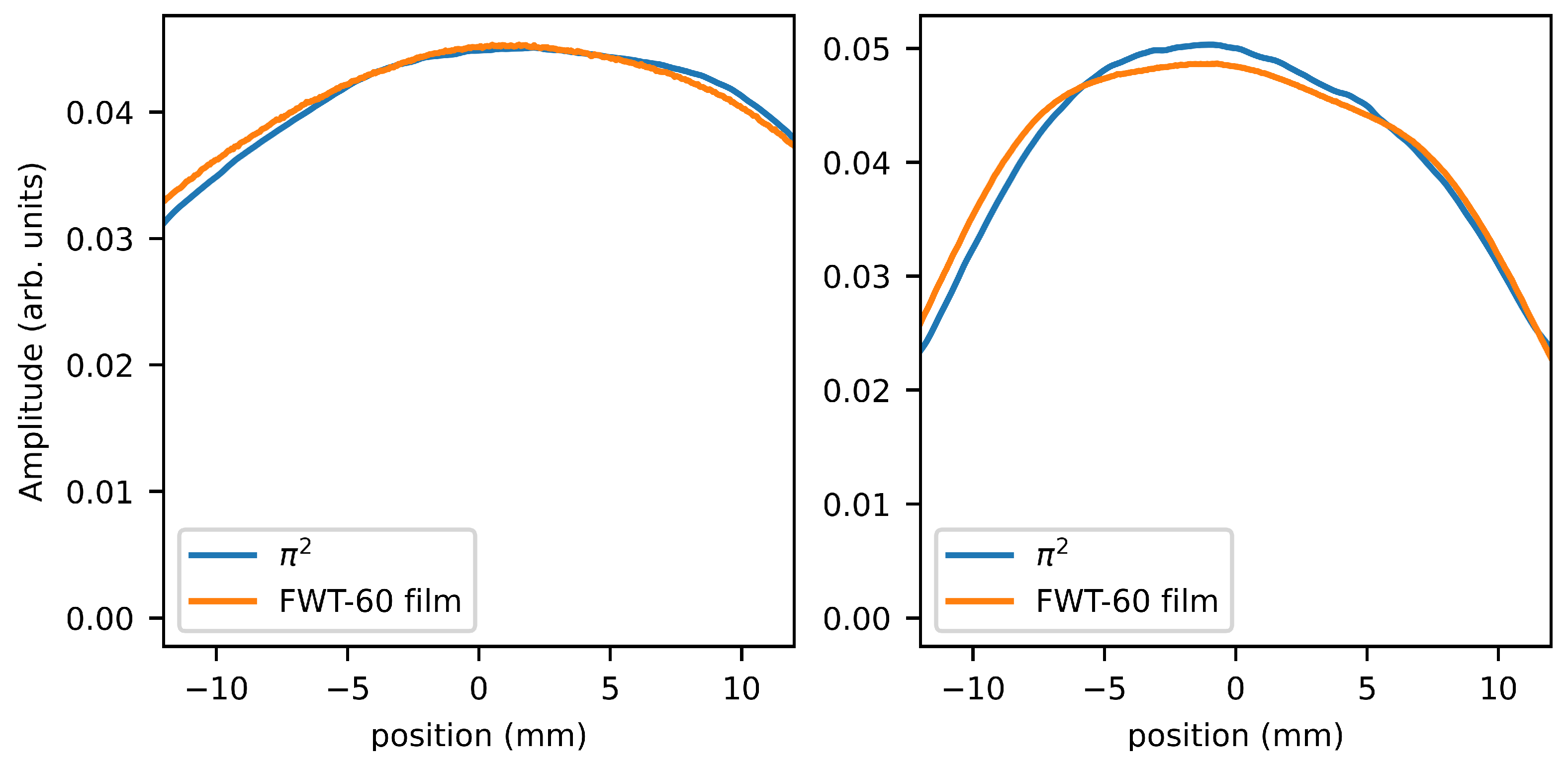

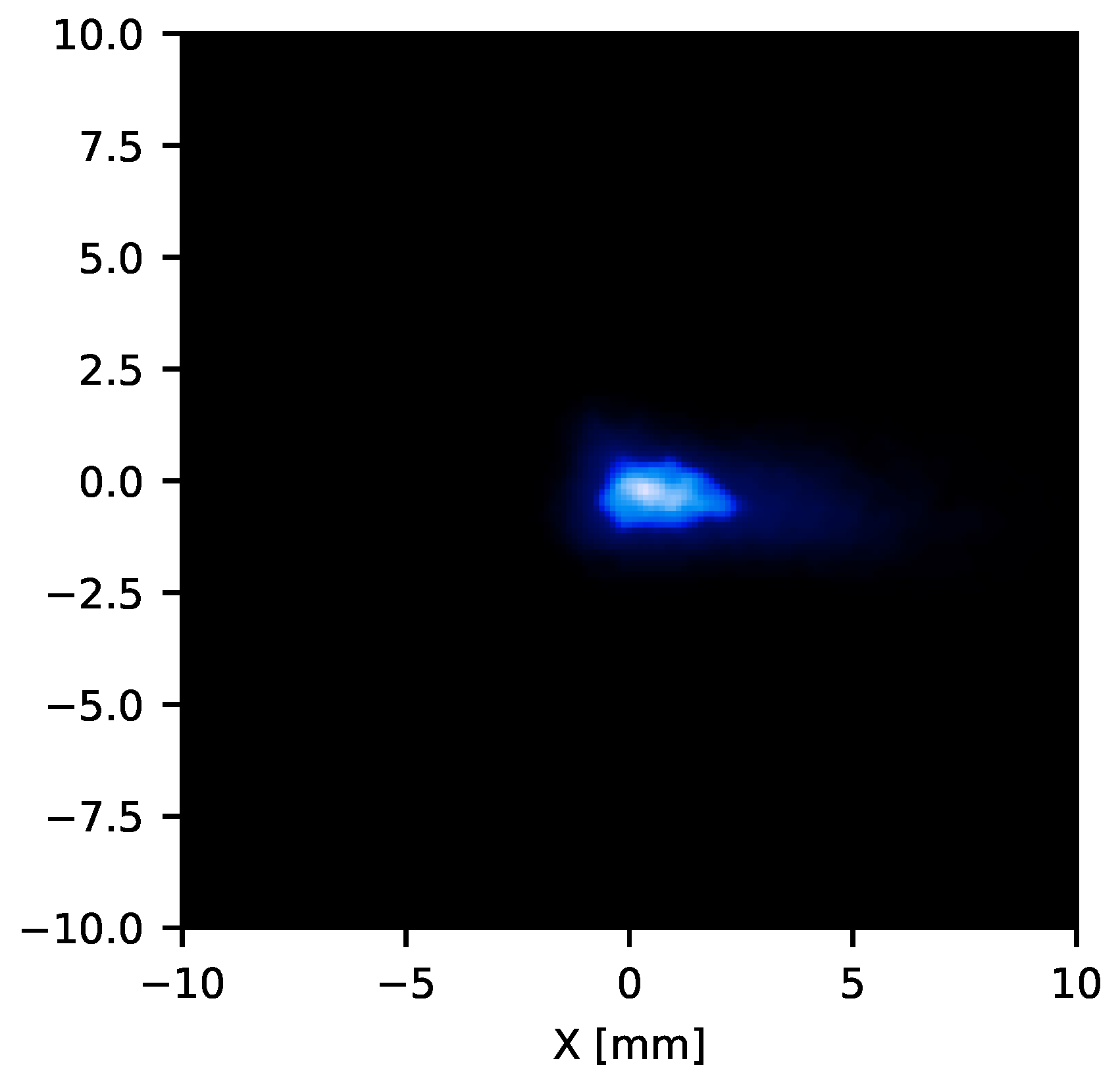

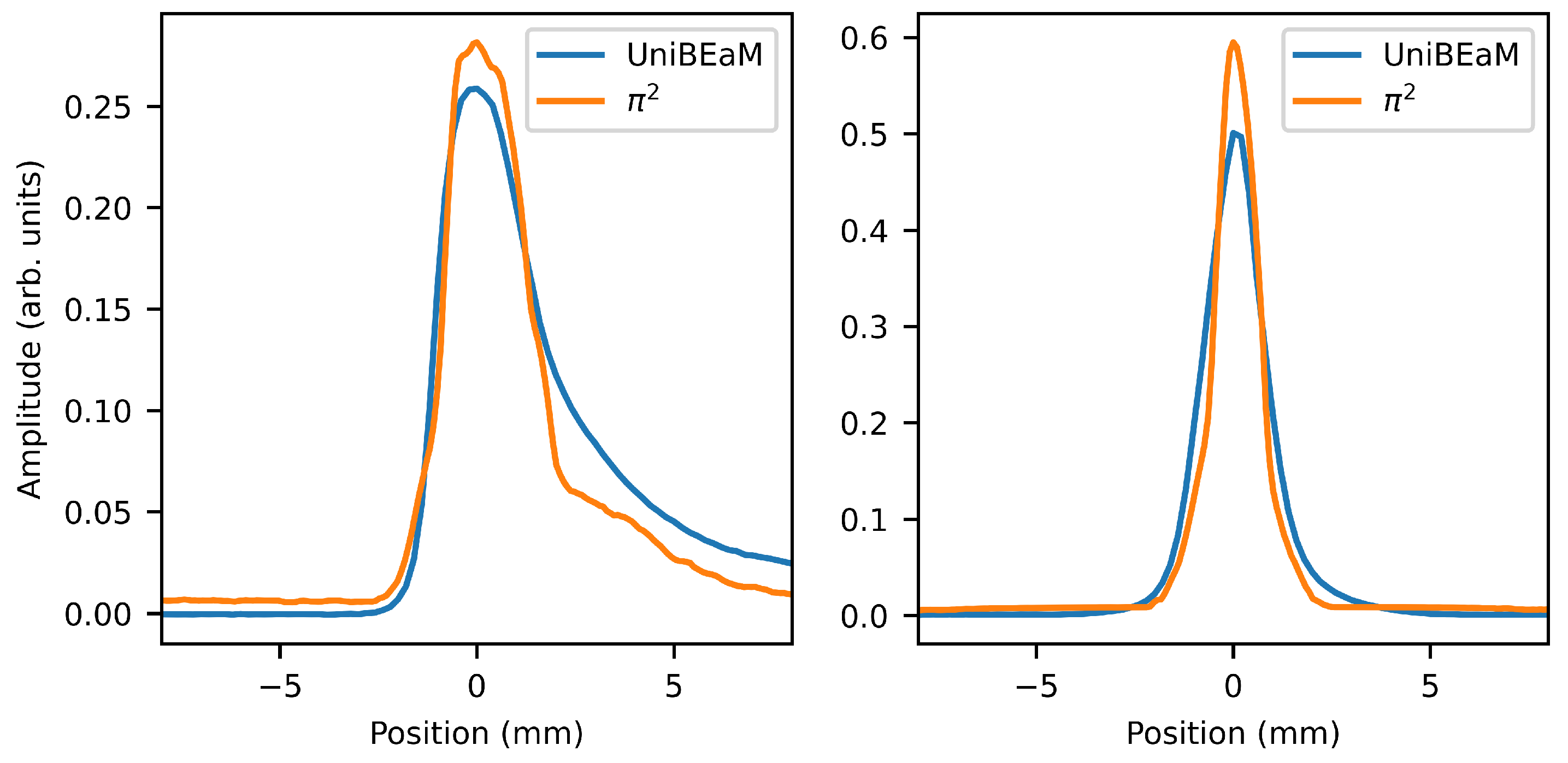

- The second experiment aimed at validating the beam profile measurements by the and involved a comparison between the measured beam profile and those obtained from radiochromic films and the UniBEaM detector. The comparison was carried out for parallel beams and focused beams, respectively.

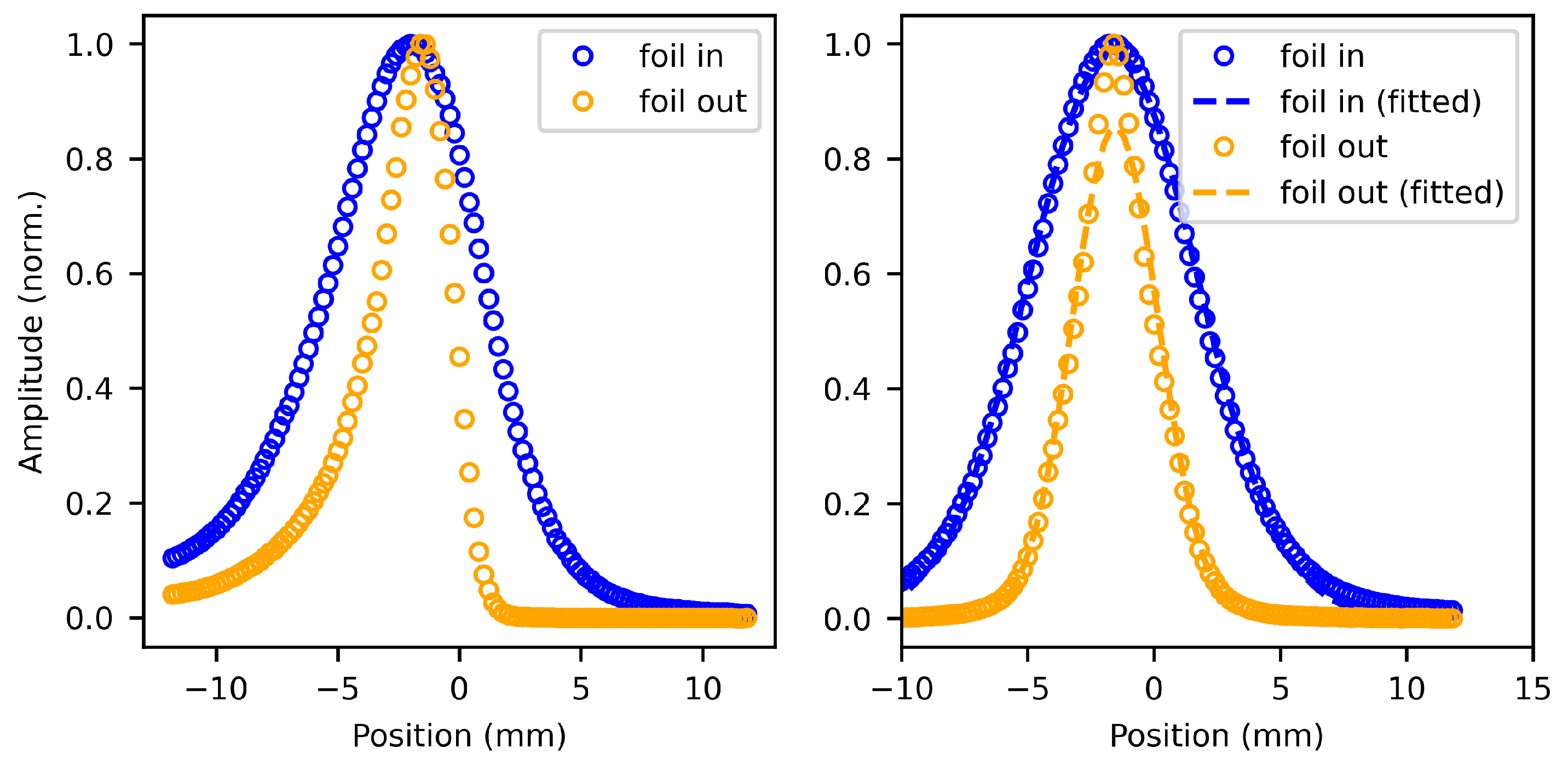

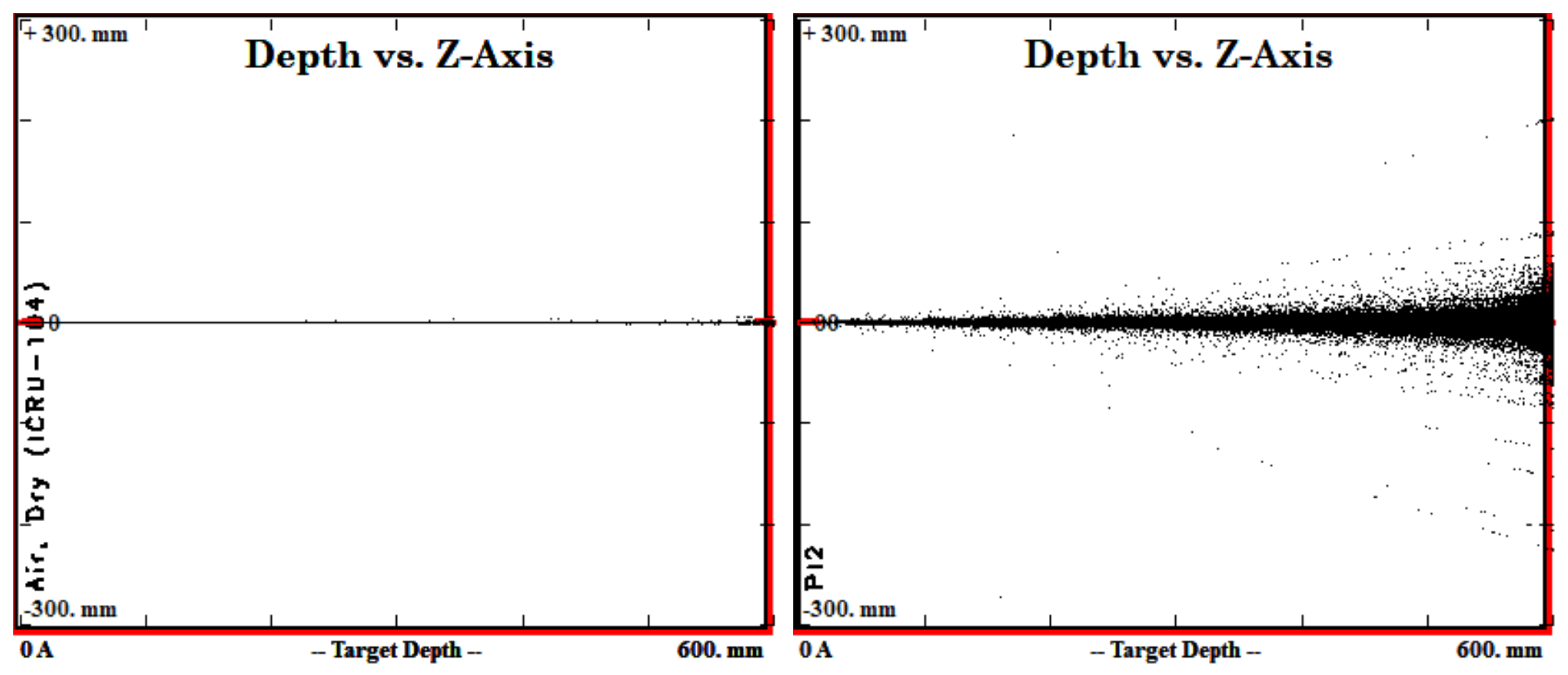

- Beam Scattering Analysis: The third experiment focused on characterising the amount of beam scattering introduced by the foil. The goal was to evaluate the impact of the foil on the beam profile downstream of the detector.

- Radiation Tolerance Study: The final experiment aimed at investigating the radiation tolerance of the scintillator material used in the detector. The goal was to determine if the light yield of the scintillator is affected by exposure to radiation and to assess the long-term stability of the detector.

3. Experimental Results

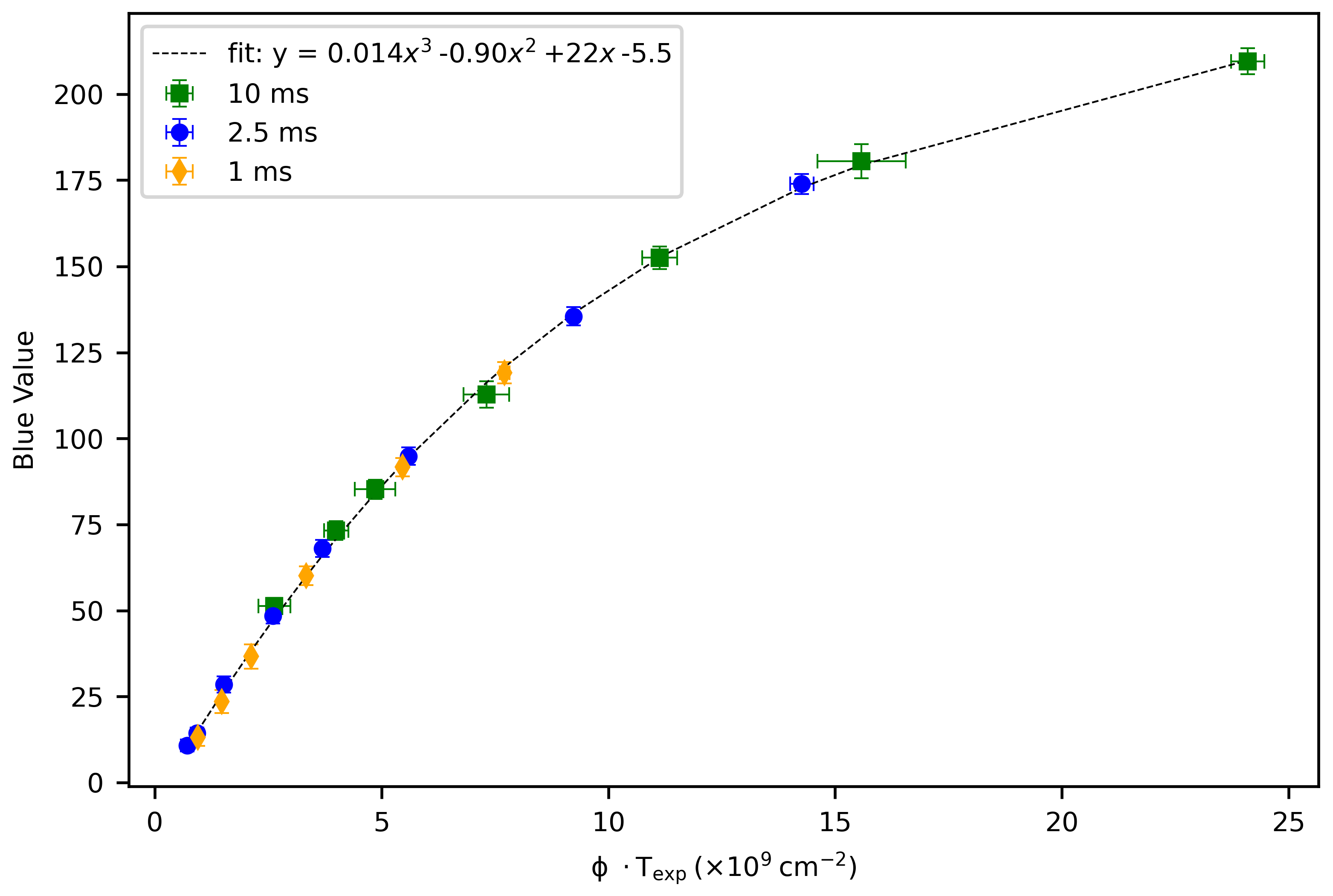

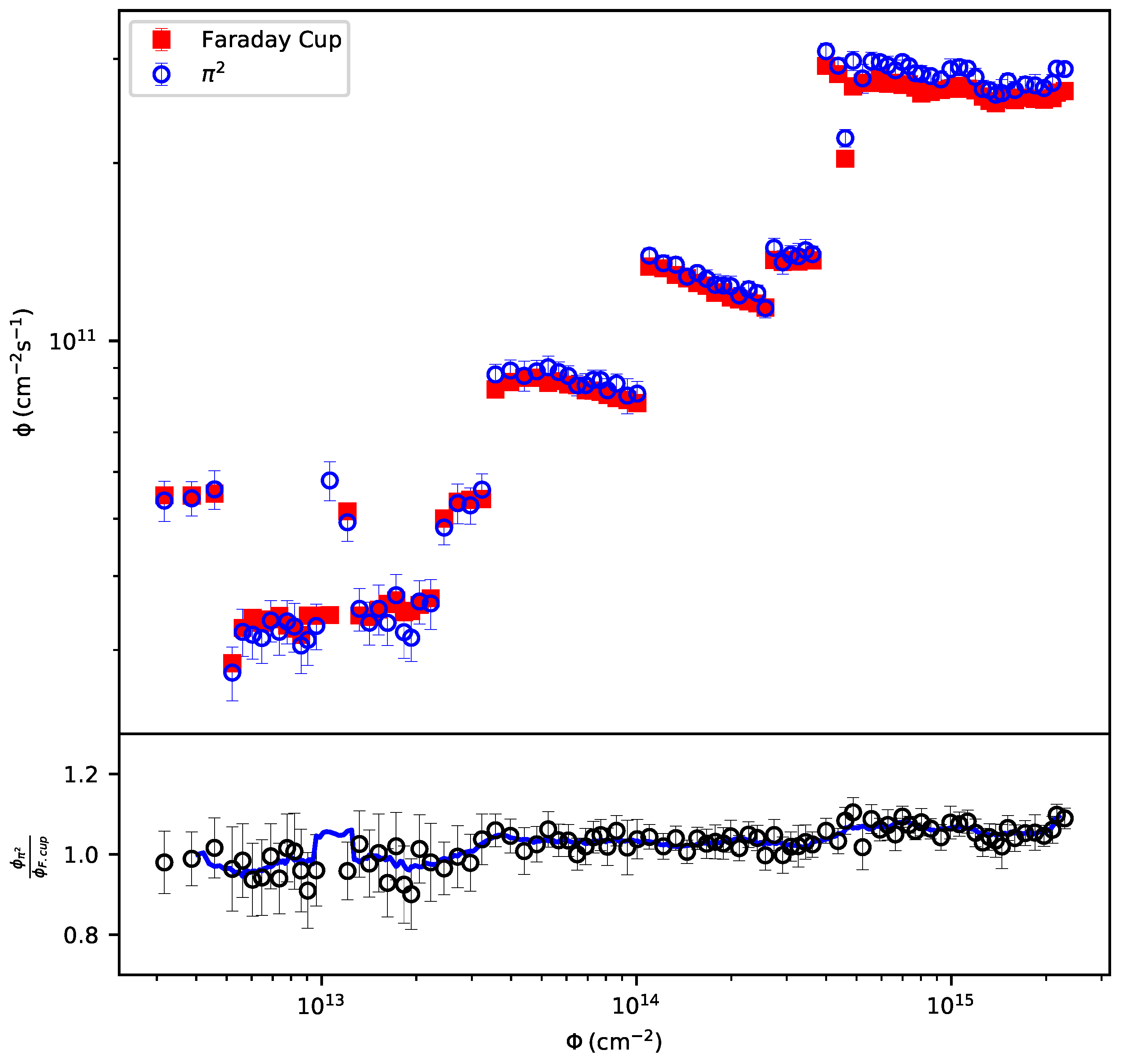

3.1. Linearity with Respect to Beam Current

- A saturation of the scintillator light yield at high incident proton flux.

- A saturation of the camera sensor or front-end electronics at high photon count rates.

- A non-linear encoding of the photon count into pixel value.

3.2. Comparison with Reference Beam Profile Measurements

3.3. Scattering Effects

3.4. Radiation Tolerance Study

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jacobson, O.; Chen, X. PET designated flouride-18 production and chemistry. Curr. Top. Med. Chem. 2010, 10, 1048–1059. [Google Scholar] [CrossRef] [PubMed]

- Hoehr, C.; Bénard, F.; Buckley, K.; Crawford, J.; Gottberg, A.; Hanemaayer, V.; Kunz, P.; Ladouceur, K.; Radchenko, V.; Ramogida, C.; et al. Medical Isotope Production at TRIUMF—From Imaging to Treatment. Phys. Procedia 2017, 90, 200–208. [Google Scholar] [CrossRef]

- Synowiecki, M.A.; Perk, L.R.; Nijsen, J.F.W. Production of novel diagnostic radionuclides in small medical cyclotrons. EJNMMI Radiopharm. Chem. 2018, 3, 3. [Google Scholar] [CrossRef] [PubMed]

- Braccini, S.; Ereditato, A.; Scampoli, P.; Bremen, K.V. The new Bern cyclotron laboratory for radioisotope production and research. In Proceedings of the IPAC2011, San Sebastian, Spain, 4–9 September 2011; p. 3618, THPS080. Available online: www.jacow.org (accessed on 20 February 2023).

- Raich, U. Beam Diagnostics; CER-2006-012; CERN Accelerator School (CAS): Geneva, Switzerland, 2006; p. 297. [Google Scholar]

- Gasior, M.; Jones, R.; Lefevre, T.; Schmickler, H.; Wittenburg, K. Introduction to Beam Instrumentation and Diagnostics; CERN-2014-009; CERN Accelerator School (CAS): Geneva, Switzerland, 2016; p. 23. [Google Scholar]

- Brown, K.L.; Tautfest, G.W. Faraday-Cup Monitors for High-Energy Electron Beams. Rev. Sci. Instruments 1956, 27, 696–702. [Google Scholar] [CrossRef]

- Peyser, T.A.; Antoniades, J.A.; Myers, M.C.; Lampe, M.; Pechacek, R.E.; Murphy, D.P.; Meger, R.A. A segmented concentric Faraday cup for measurement of time-dependent relativistic electron beam profiles. Rev. Sci. Instruments 1991, 62, 2895–2903. [Google Scholar] [CrossRef]

- Noh, S.Y.; Chang, S.D.; Yang, T.-K.; Hahn, G.R.; Hwang, J.-G. The development of scintillating screen detector for beam monitoring at the Khima project. In Proceedings of the International Particle Accelerator Conference (IPAC), Busan, Republic of Korea, 8–13 May 2016. MOPMR010. [Google Scholar]

- Gasior, M. An inductive pick-up for beam position and current measurements. In Proceedings of the European Workshop on Beam Diagnostics and Instrumentation for Particle Accelerators (DIPAC), Mainz, Germany, 5–7 May 2003. [Google Scholar]

- Bernier, K.; de Rijk, G.; Ferioli, G.; Hatziangeli, E.; Marchionni, A.; Palladino, V.; Stevenson, G.R.; Fatis, T.T.d.; Tsesmelis, E. Calibration of Secondary Electron Emission Monitors of Absolute Proton Beam Intensity in the CERN SPS North Area; CERN Yellow Report 97-07 1997; European Organization for Nuclear Research: Geneva, Switzerland, 1997. [Google Scholar]

- Bosser, J.; Camas, J.; Evans, L.; Ferioli, G.; Hopkins, R.; Mann, J.; Olsen, O. Transverse emittance measurement with a rapid wire scanner at the CERN SPS. Nucl. Instrum. Methods Phys. Res. A: Accel. Spectrom. Detect. Assoc. Equip. 1985, 235, 475–480. [Google Scholar] [CrossRef]

- Badano, L.; Ferrando, O.; Klatka, T.; Koziel, M.; Molinari, G.; Abbas, K.; Braccini, S.; Bulgheroni, A.; Caccia, M.; Gibson, P.N.; et al. Laboratory and in-beam tests of a novel real-time beam monitor for hadrontherapy. IEEE Trans. Nucl. Sci. 2005, 52, 4. [Google Scholar] [CrossRef]

- Kirillova, E. Study and Test of a Beam Monitor Detector for the Bern Medical Cyclotron. Master’s Thesis, University of Bern, Bern, Switzerland, 2014. [Google Scholar]

- Braccini, S.; Bergesio, D.; Ereditato, A.; Kirillova, E.; Molinari, G.; Nesteruk, K.P.; Scampoli, P.; Amaldi, U. An innovative on-line beam-monitoring detector based on the emission of secondary electrons. Radiother. Oncol. 2014, 110, S14. [Google Scholar] [CrossRef]

- Belver-Aguilar, C.; Carzaniga, T.S.; Gsponer, A.; Häffner, P.; Molinari, G.; Scampoli, P.; Schmid, M.; Braccini, S. Development of novel non-destructive 2D and 3D beam monitoring detectors at the Bern medical Cyclotron. In Proceedings of the IBIC 2020—9th International Beam Instrumentation Conference, TUPP32, JACoW, Santos, Brazil, 14–18 September 2020; Available online: https://indico.jacow.org/event/34/ (accessed on 20 February 2023).

- Belver-Aguilar, C.; Braccini, S.; Carzaniga, T.S.; Gsponer, A.; Häffner, P.D.; Scampoli, P.; Schmid, M. A novel three-dimensional non-destructive beam-monitoring detector. Appl. Sci. 2020, 10, 8217. [Google Scholar] [CrossRef]

- Auger, M.; Braccini, S.; Carzaniga, T.S.; Ereditato, A.; Nesteruk, K.P.; Scampoli, P. A detector based on silica fibers for ion beam monitoring in a wide current range. J. Instrum. 2016, 11, P03027. [Google Scholar] [CrossRef]

- Potkins, D.E.; Braccini, S.; Nesteruk, K.P.; Carzaniga, T.S.; Vedda, A.; Chiodini, N.; Timmermans, J.; Melanson, S.; Dehnel, M.P. A low-cost beam profiler based On cerium-doped silica fibres. Phys. Procedia 2017, 90, 215–222. [Google Scholar] [CrossRef]

- Braccini, S. The new Bern PET cyclotron, its research beam line, and the development of an innovative beam monitor detector. AIP Conf. Proc. 2013, 1525, 144–150. [Google Scholar] [CrossRef]

- Auger, M.; Braccini, S.; Ereditato, A.; Nesteruk, K.P.; Scampoli, P. Low current performance of the Bern medical cyclotron down to the pA range. Meas. Sci. Technol. 2015, 26, 094006. [Google Scholar] [CrossRef]

- FWT-60 Radiochromic Film. Available online: https://www.fwt.com/racm/fwt60ds.htm (accessed on 20 February 2023).

- ITU Recommendation, BT. 709-6 (06/2015). Available online: https://www.itu.int/rec/R-REC-BT.709-6-201506-I/en (accessed on 20 February 2023).

- SRIM and TRIM Software. Available online: http://www.srim.org/ (accessed on 20 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Braccini, S.; Carzaniga, T.S.; Casolaro, P.; Dellepiane, G.; Franconi, L.; Mateu, I.; Scampoli, P.; Schmid, M. A Two-Dimensional Non-Destructive Beam Monitoring Detector for Ion Beams. Appl. Sci. 2023, 13, 3657. https://doi.org/10.3390/app13063657

Braccini S, Carzaniga TS, Casolaro P, Dellepiane G, Franconi L, Mateu I, Scampoli P, Schmid M. A Two-Dimensional Non-Destructive Beam Monitoring Detector for Ion Beams. Applied Sciences. 2023; 13(6):3657. https://doi.org/10.3390/app13063657

Chicago/Turabian StyleBraccini, Saverio, Tommaso Stefano Carzaniga, Pierluigi Casolaro, Gaia Dellepiane, Laura Franconi, Isidre Mateu, Paola Scampoli, and Matthias Schmid. 2023. "A Two-Dimensional Non-Destructive Beam Monitoring Detector for Ion Beams" Applied Sciences 13, no. 6: 3657. https://doi.org/10.3390/app13063657

APA StyleBraccini, S., Carzaniga, T. S., Casolaro, P., Dellepiane, G., Franconi, L., Mateu, I., Scampoli, P., & Schmid, M. (2023). A Two-Dimensional Non-Destructive Beam Monitoring Detector for Ion Beams. Applied Sciences, 13(6), 3657. https://doi.org/10.3390/app13063657