Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model

Abstract

1. Introduction

2. Materials and Methods

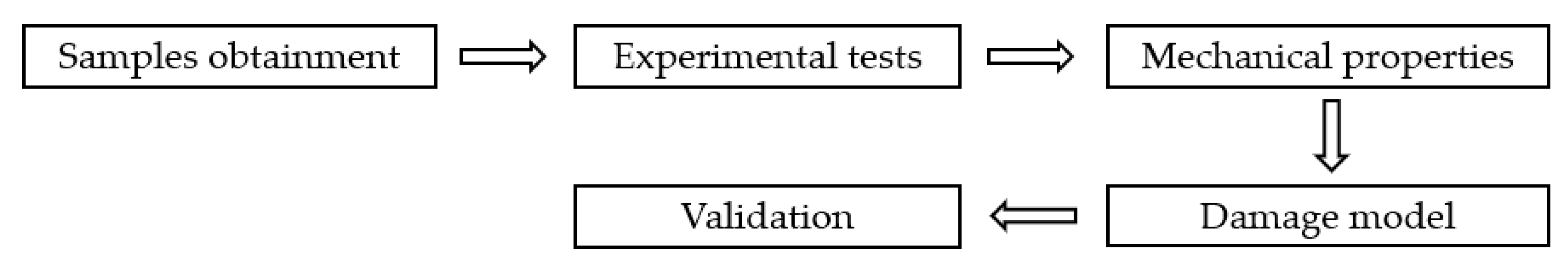

2.1. Simplified Outline of the Investigation

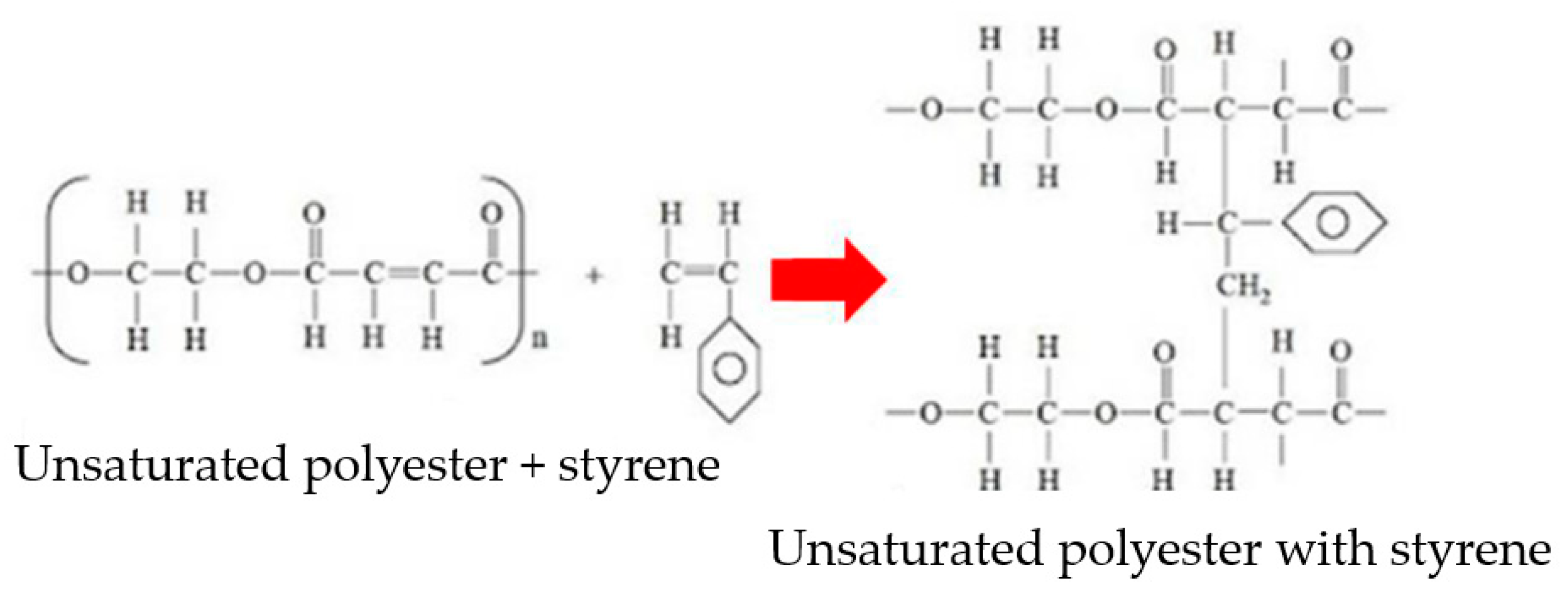

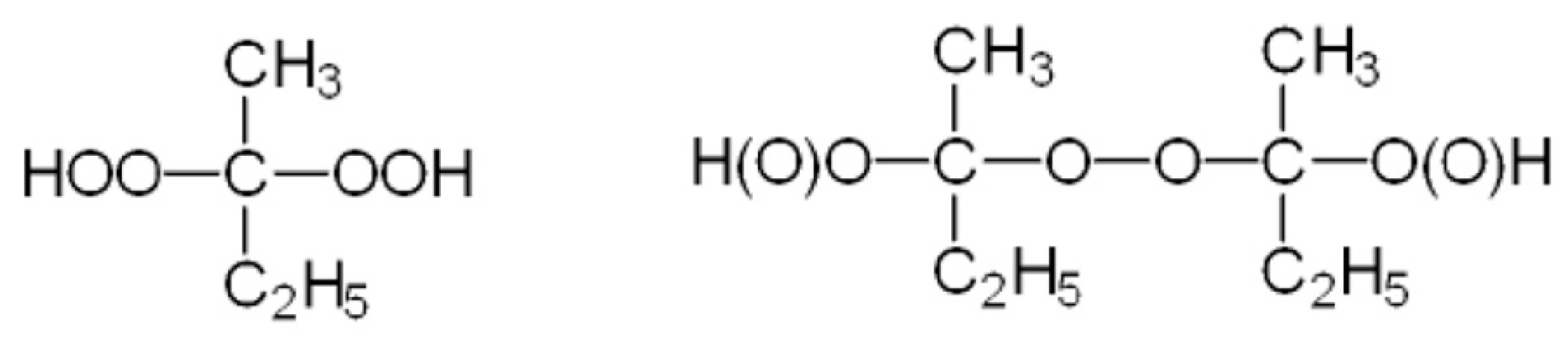

2.2. Materials

2.3. Characterization

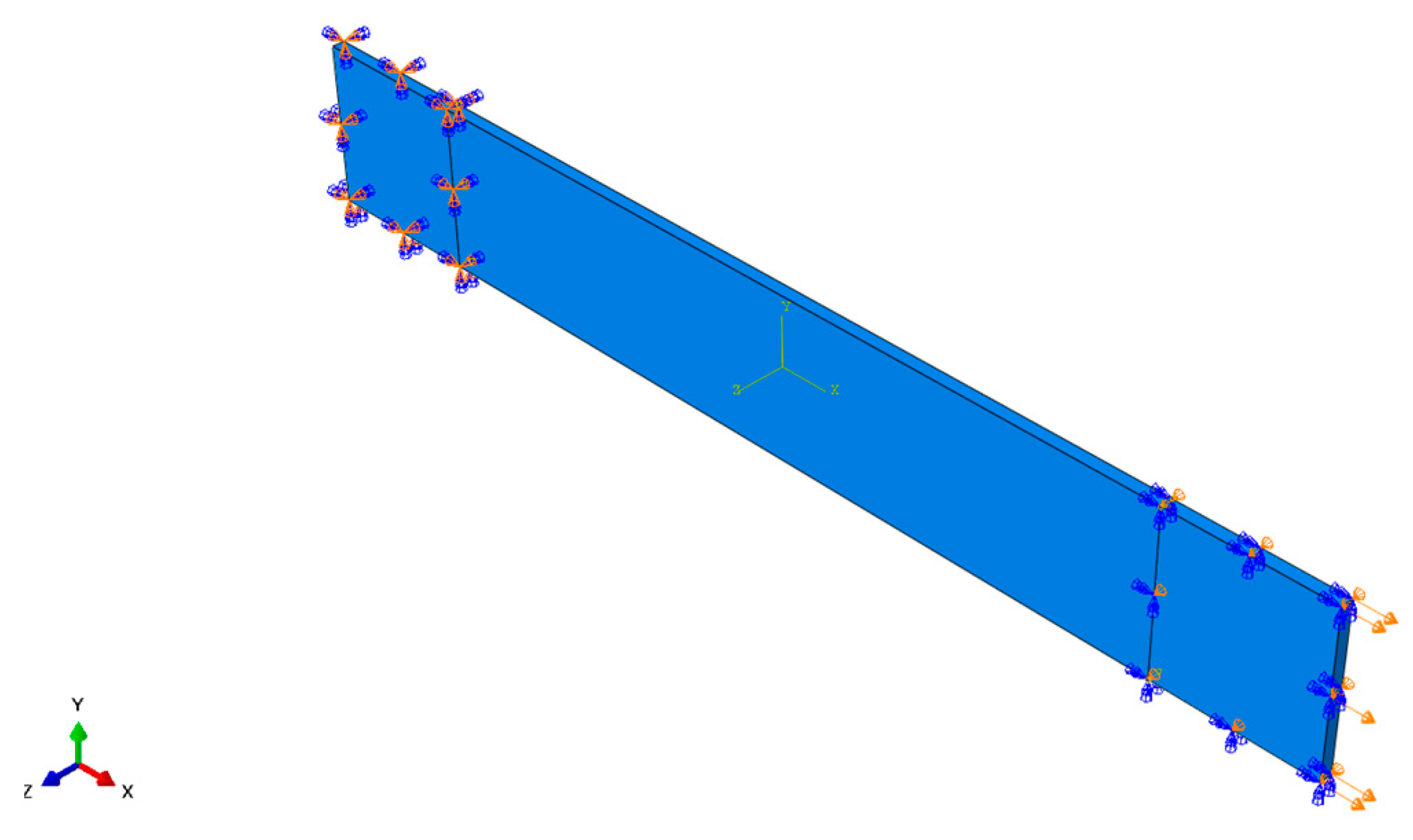

2.4. Computational Model

- 1.

- Abaqus returns, at the start of the increment, the incremental strain tensor, .

- 2.

- With the increase in strain, the algorithm calculates the strain tensor, and the effective stress tensor.

- 3.

- The damage variables, , and damage threshold, , are updated, respectively.

- 4.

- The effective effort is calculated.and the conjugate thermodynamic force of the damage variable

- 5.

- Verification of damage criteria.

- ■

- Damage evolution .

- ■

- Damage threshold update

- 6.

- Update of the tension tensor, to deliver them to Abaqus.

- 7.

- End of the process of explicit integration of the constitutive equation.

3. Results

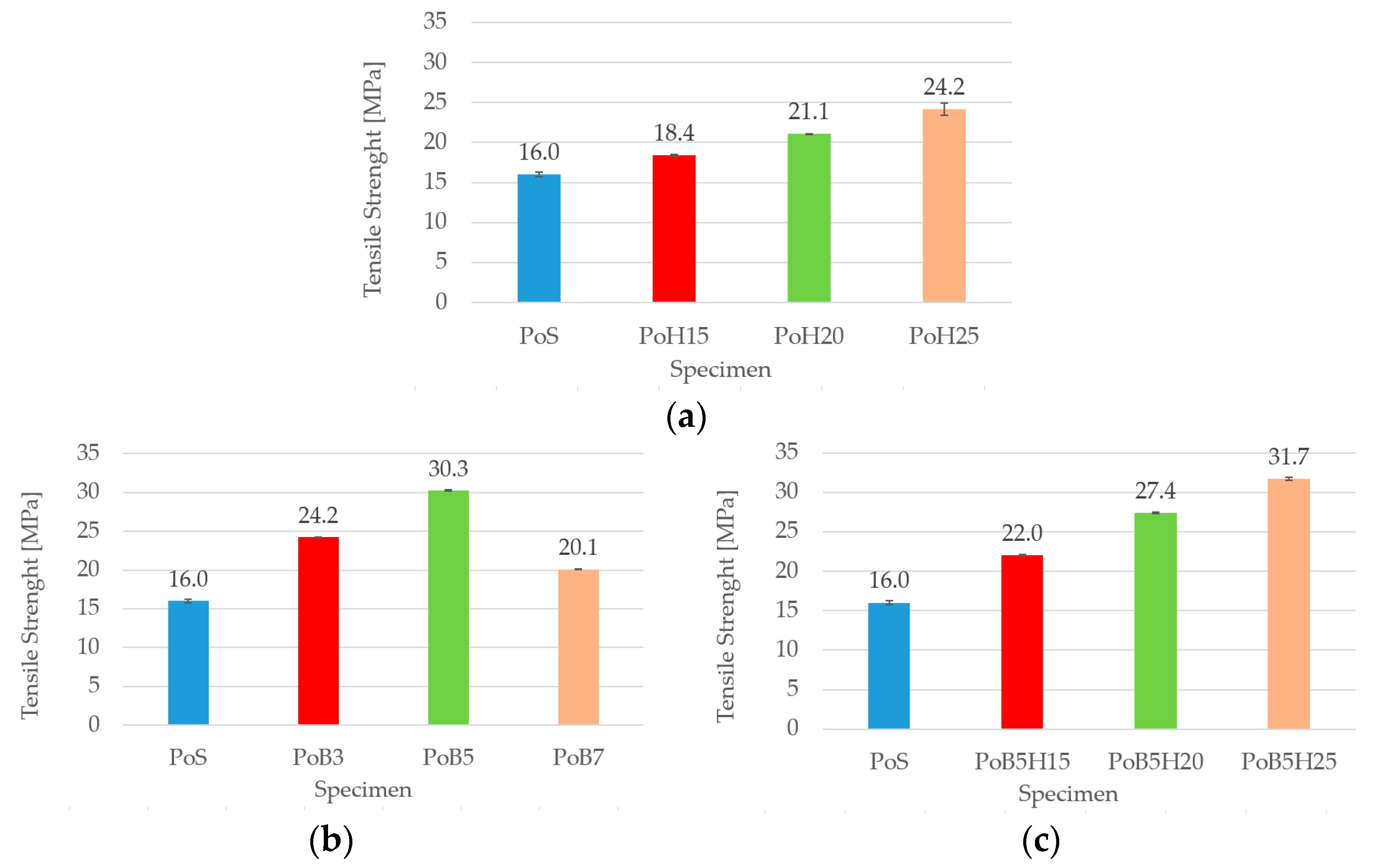

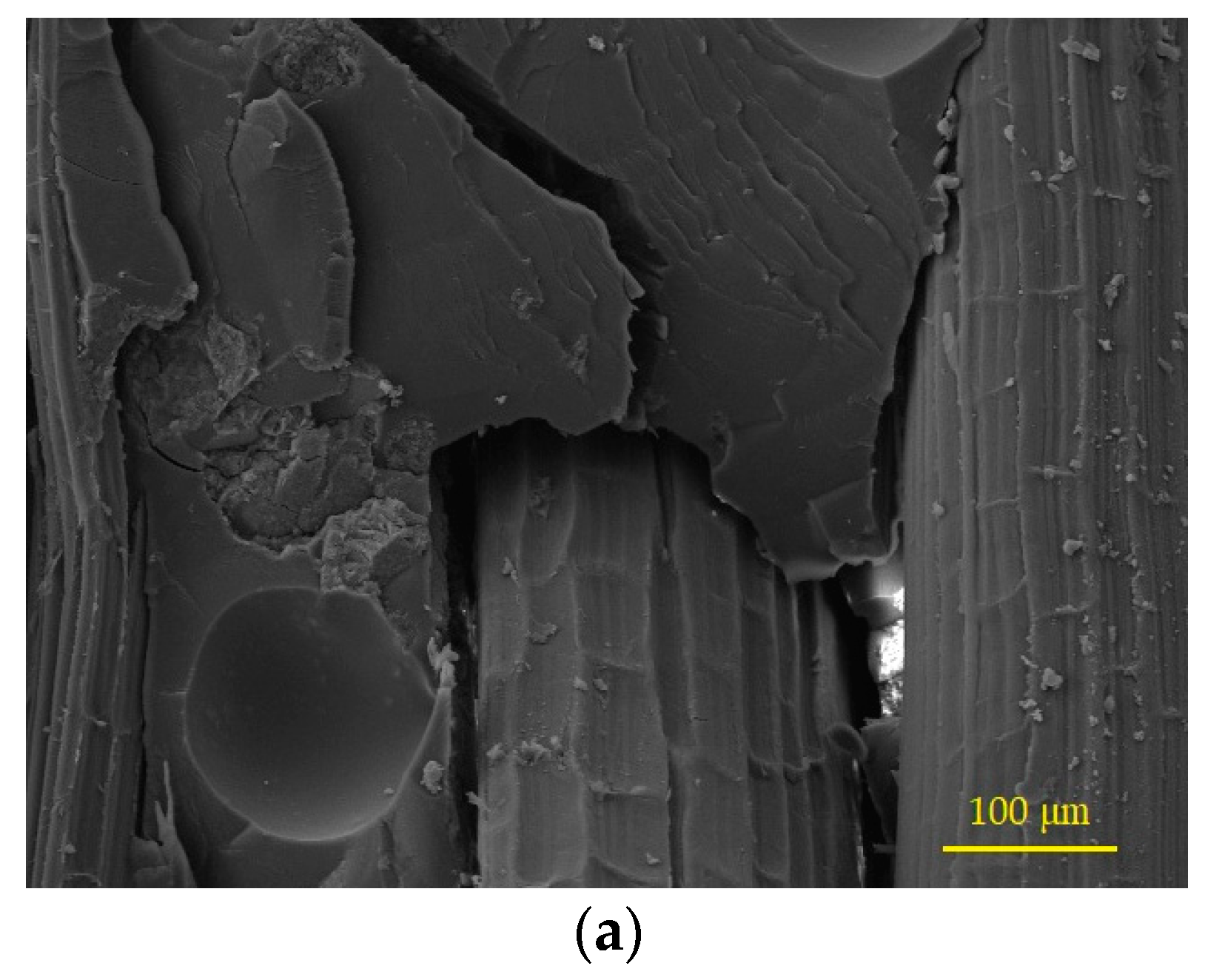

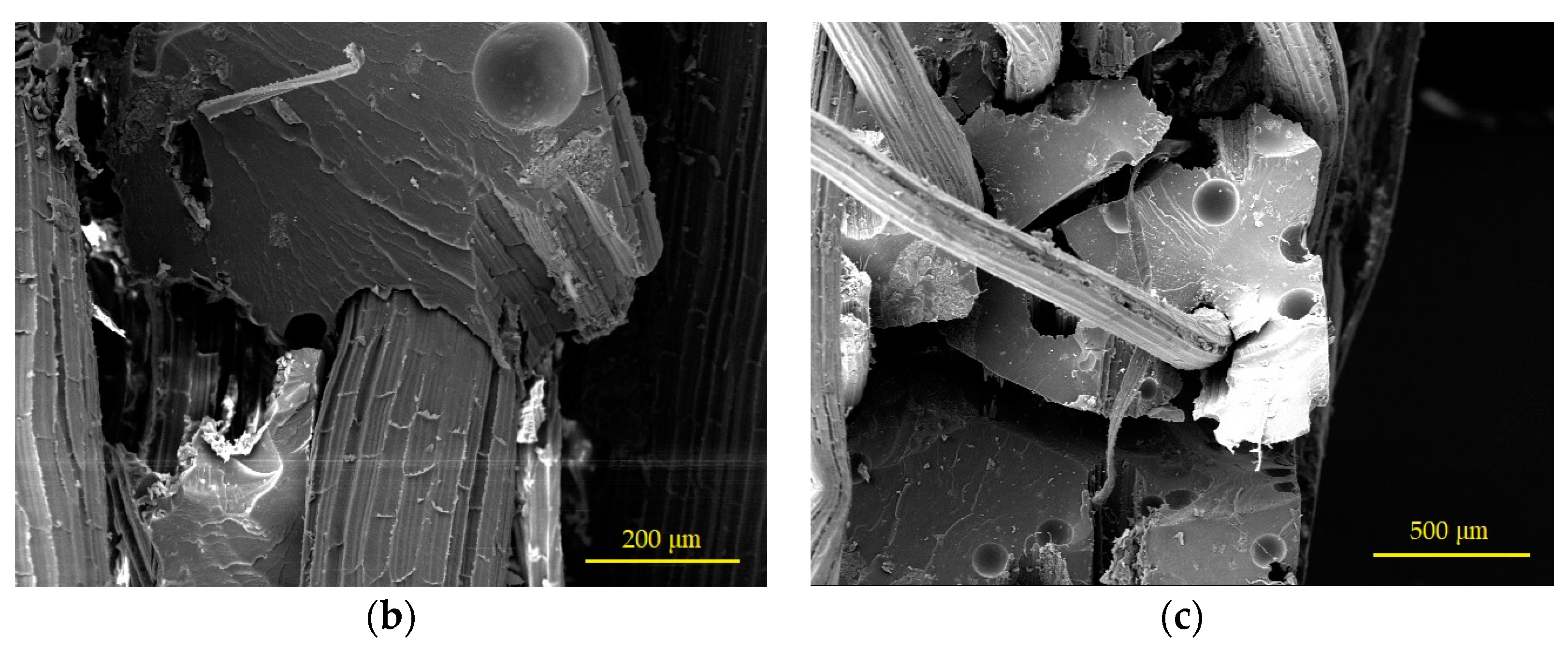

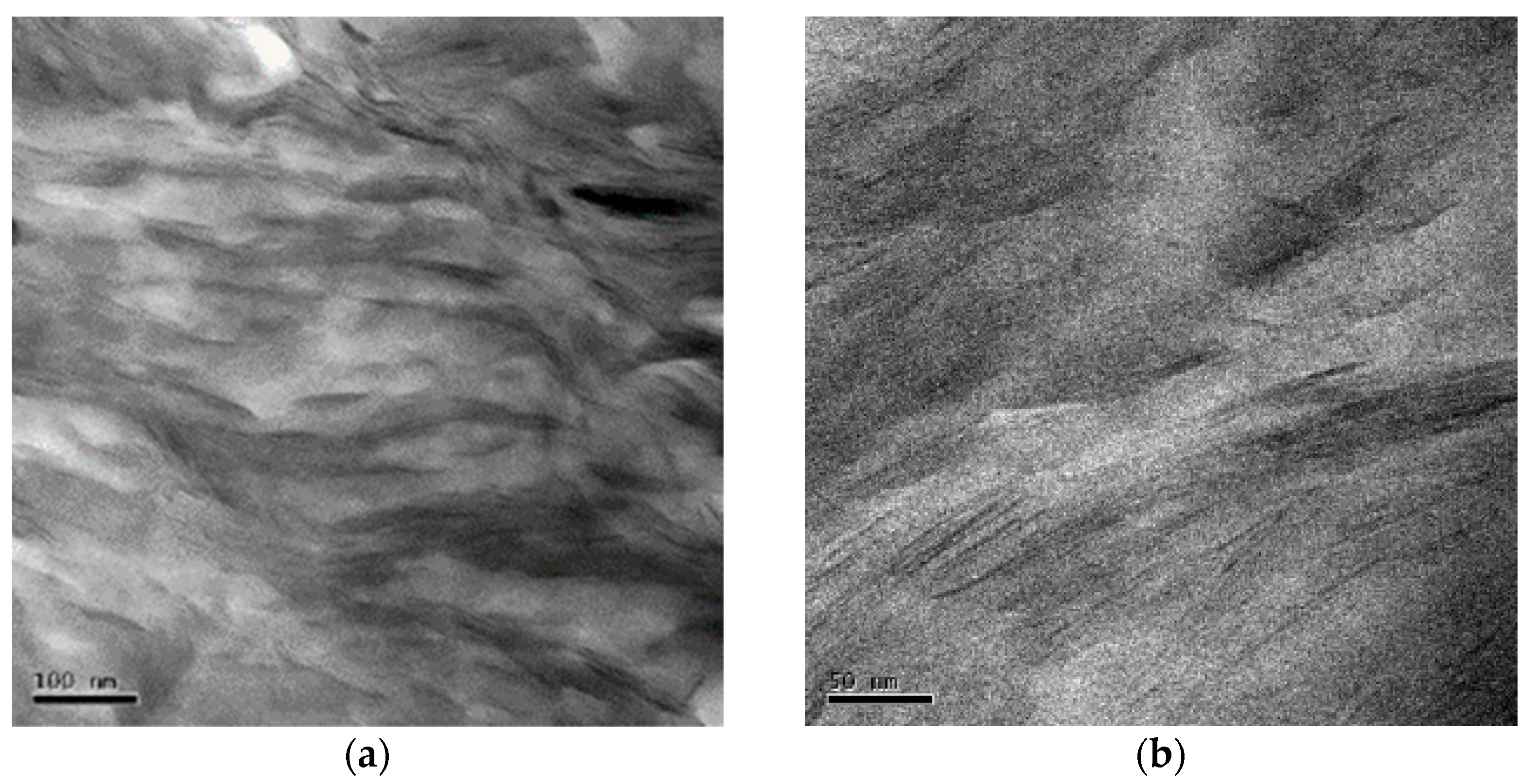

3.1. Characterization Results

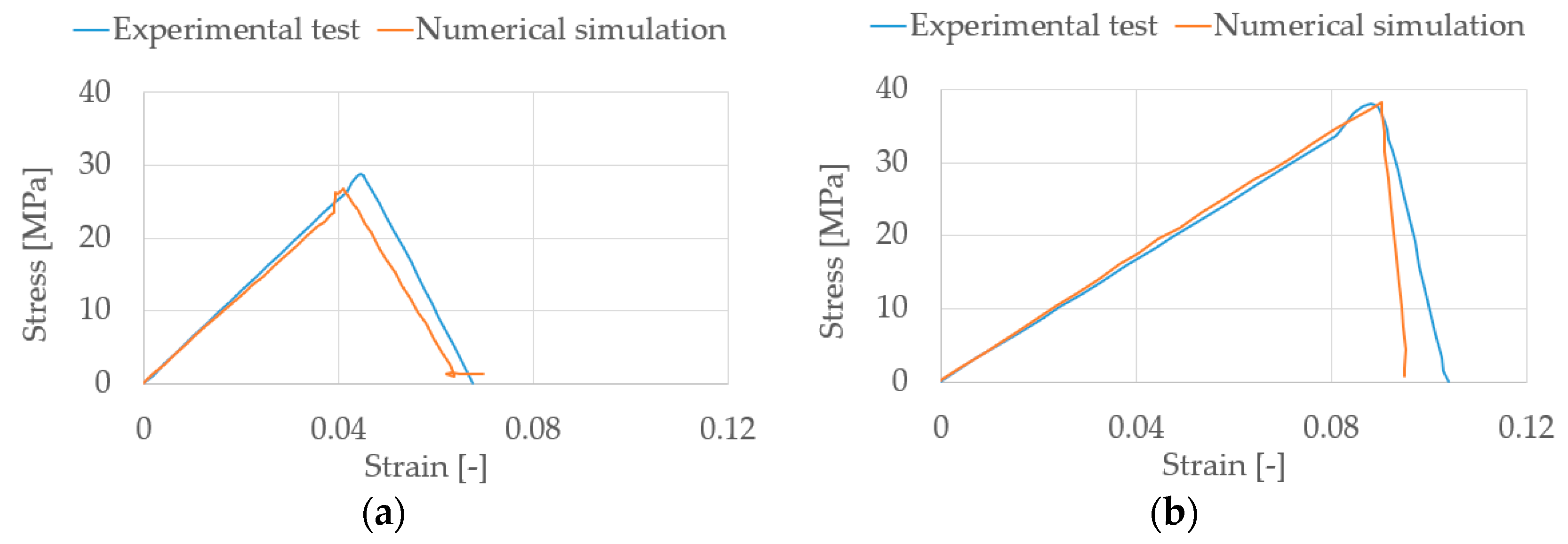

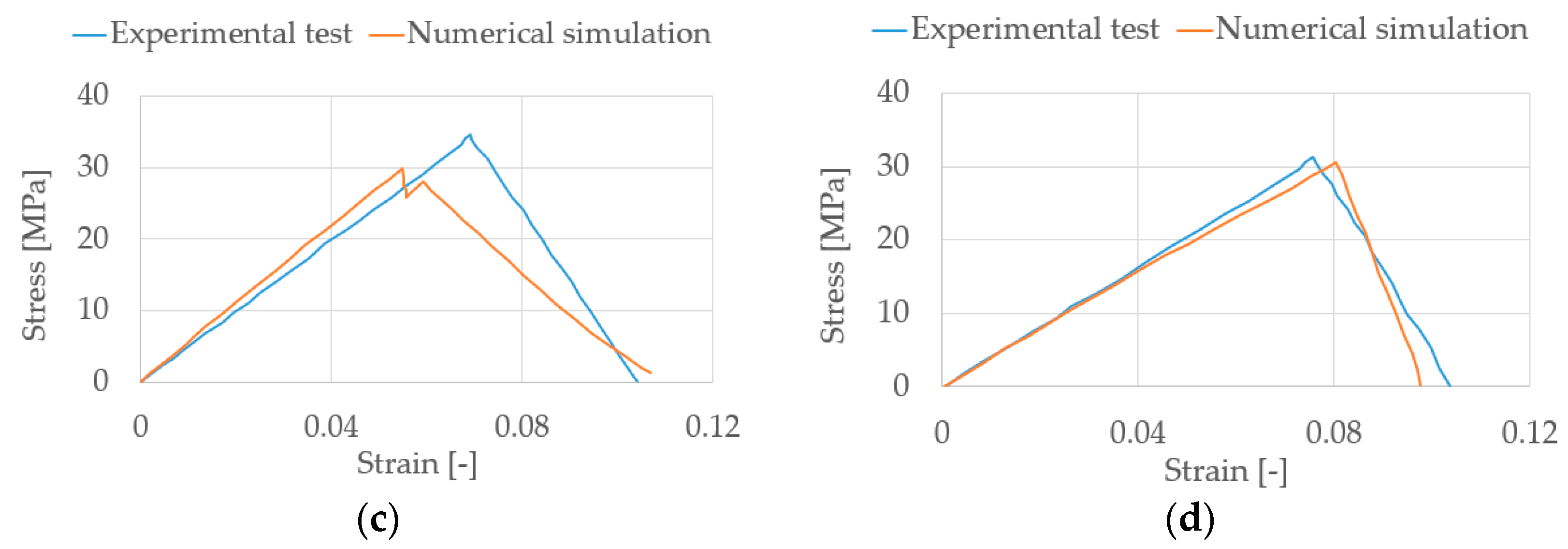

3.2. Computational Model Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdellaoui, H.; Bensalah, H.; Echaabi, J.; Bouhfid, R.; Qaiss, Y.A. Fabrication, characterization and modelling of laminated composites based on woven jute fibres reinforced epoxy resin. Mater. Des. 2015, 68, 104–113. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, Y.J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Kobayashi, S.; Goto, Y.K. Effects of surface treatment on mechanical and thermal properties of jute fabric-reinforced poly(butylene succinate) biodegradable composites. Adv. Compos. Mater. 2015, 24, 161–178. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, Y.A. Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos. Part Appl. Sci. Manuf. 2004, 35, 339–345. [Google Scholar] [CrossRef]

- Sanchez, E.M.S.; Cavani, C.S.; Leal, C.V.; Sanchez, Y.C.G. Unsaturated polyester resin composite with sugar cane bagasse: Influence of treatment on the fibers properties. Polímeros 2010, 20, 194–200. [Google Scholar] [CrossRef]

- Silva, R.; Haraguchi, S.K.; Muniz, E.C.; Rubira, Y.A.F. Aplicações de fibras lignocelulósicas na química de polímeros e em compósitos. Quím. Nova 2009, 32, 661–671. [Google Scholar] [CrossRef]

- Rodríguez-Soto, A.-A.; Valín-Rivera, J.-L.; Díaz, D.; Muniz-Fonseca, V.; Sanabio-Alves-Borges, Y.L.-M. Desarrollo de un material compuesto de fibras de henequén utilizando una matriz termofija. Ing. Mec. 2014, 17, 264–272. [Google Scholar]

- Hossen, M.F.; Hamdan, S.; Rahman, M.R.; Rahman, M.M.; Liew, F.K.; Lai, Y.J.C. Effect of fiber treatment and nanoclay on the tensile properties of jute fiber reinforced polyethylene/clay nanocomposites. Fibers Polym. 2015, 16, 479–485. [Google Scholar] [CrossRef]

- Wagh, J.; Madgule, M.; Awadhani, Y.L.V. Investigative studies on the mechanical behavior of Jute, Sisal, Hemp, and glass fiber-based composite material. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Hamou, K.B.; Kaddami, H.; Elisabete, F.; Erchiqui, Y.F. Synergistic association of wood /hemp fibers reinforcements on mechanical, physical and thermal properties of polypropylene-based hybrid composites. Ind. Crop. Prod. 2023, 192, 116052. [Google Scholar] [CrossRef]

- Mylsamy, B.; Palaniappan, S.K.; Subramani, S.P.; Pal, S.K.; Sethuraman, Y.B. Innovative characterization and mechanical properties of natural cellulosic Coccinia Indica fiber and its composites. Mater. Test. 2020, 62, 61–67. [Google Scholar] [CrossRef]

- Gudapati, S.P.K.; Krishna, C.V.; Prasad, Y.A.V.R. Effect of nano clay on tensile and flexural properties of vakka fiber polyester composites. Mater. Today Proc. 2019, 18, 2032–2035. [Google Scholar] [CrossRef]

- Ranjith, C.B.; Vasudevan, Y.A. Enhancement on flexural strength of glass fiber composite addition of nano clay and (Mwcnt) using novel C shaped spiral tube position by vacuum bag molding process. Mater. Today Proc. 2022, 69, 1223–1228. [Google Scholar] [CrossRef]

- Alekseeva, O.V.; Noskov, A.V.; Agafonov, Y.A.V. Structure, physicochemical properties, and adsorption performance of the ethyl cellulose/bentonite composite films. Cellulose 2022, 29, 3947–3961. [Google Scholar] [CrossRef] [PubMed]

- Boem, I. Characterization of Textile-Reinforced Mortar: State of the Art and Detail-Level Modeling with a Free Open-Source Finite-Element Code. J. Compos. Constr. 2022, 26, 4022060. [Google Scholar] [CrossRef]

- Nayak, J.R.; Bochen, J.; Gołaszewska, Y.M. Experimental studies on the effect of natural and synthetic fibers on properties of fresh and hardened mortar. Constr. Build. Mater. 2022, 347, 128550. [Google Scholar] [CrossRef]

- Chun, B.; Oh, T.; Jang, Y.S.; Lee, S.K.; Lee, J.-H.; Yoo, Y.D.-Y. Strengthening effect of concrete beams using ultra-rapid-hardening fiber-reinforced mortar under flexure. Constr. Build. Mater. 2022, 352, 129064. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, Y.J. Natural fibers as reinforcement additives for geopolymers–A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Olivito, R.S.; Cevallos, O.A.; Carrozzini, Y.A. Development of durable cementitious composites using sisal and flax fabrics for reinforcement of masonry structures. Mater. Des. 2014, 57, 258–268. [Google Scholar] [CrossRef]

- de Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, Y.D.V. Experimental tests for the characterization of sisal fiber reinforced cementitious matrix for strengthening masonry structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef]

- Mercedes, L.; Gil, L.; Bernat-Maso, Y.E. Mechanical performance of vegetal fabric reinforced cementitious matrix (FRCM) composites. Constr. Build. Mater. 2018, 175, 161–173. [Google Scholar] [CrossRef]

- Rodríguez-González, J.A.; Renteria-Rodríguez, V.; Rubio-González, C.; Franco-Urquiza, Y.E.A. Spray-coating of graphene nanoplatelets on sisal fibers and its influence on electromechanical behavior of biocomposite laminates. J. Reinf. Plast. Compos. 2023, 07316844231152911. [Google Scholar] [CrossRef]

- Murali Mohan Rao, K.; Rao, K.M.; Prasad, Y.A.V.R. Fabrication and testing of natural fibre composites: Vakka, sisal, bamboo and banana. Mater. Des. 2010, 31, 508–513. [Google Scholar] [CrossRef]

- Gu, J.; Li, K.; Su, Y.L. A Continuum Damage Model for Intralaminar Progressive Failure Analysis of CFRP Laminates Based on the Modified Puck’s Theory. Materials 2019, 12, 3292. [Google Scholar] [CrossRef]

- Sun, L.; Wang, J.; Hu, H.; Ni, Y.A. A Simplified Computational Strategy Focused on Resin Damage to Study Matrix Cracking of The Cross-Ply Laminates Under Uniaxial Tension Load. Materials 2019, 12, 1984. [Google Scholar] [CrossRef]

- González Del Solar, G.; Martín, P.; Maldonado, Y.N. Formulación, implementación y validación de un modelo de daño escalar para materiales frágiles aplicado a elementos sólidos tridimensionales. Rev. Ing. Constr. 2018, 33, 111–122. [Google Scholar] [CrossRef]

- Rezasefat, M.; Mostafavi, Y.; Ma, D.; Manes, Y.A. A hybrid micro-macro mechanical damage model to consider the influence of resin-rich zones on the transverse tensile behaviour of unidirectional composites. Compos. Struct. 2023, 308, 116714. [Google Scholar] [CrossRef]

- Tijs, B.H.A.H.; Dávila, C.G.; Turon, A.; Bisagni, Y.C. The importance of accounting for large deformation in continuum damage models in predicting matrix failure of composites. Compos. Part Appl. Sci. Manuf. 2023, 164, 107263. [Google Scholar] [CrossRef]

- Fonseca, V.M. Desenvolvimento de Sistema Antichama Aplicado a Compósitos de Poliéster Insaturado Reforçados Com Fibras de Sisal. Tese de Doutorado, Universidade Federal do Rio Grande do Norte, Natal, Brasil, 2002. [Google Scholar]

- de Carvalho, L.H.; Cavalcanti, Y.W.S. Propriedades mecânicas de tração de compósitos poliéster/tecidos híbridos sisal/vidro. Polímeros 2006, 16, 33–37. [Google Scholar] [CrossRef]

- Kachanov, L.M. Rupture Time Under Creep Conditions. Int. J. Fract. 1999, 97, 11–18. [Google Scholar] [CrossRef]

- Cervera, M.; Manzoli, O.L.; Oliver, Y.J. A rate-dependent isotropic damage model for the seismic analysis of concrete dams. Eng. Comput. 1996, 25, 987–1010. [Google Scholar] [CrossRef]

- Lubliner, J. Plasticity Tehory; Pearson Education, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Lemaître, J.; Chaboche, J.Y. Aspect Phenomenologique de la Rupture Par Endommagement. 1978. [En Línea]. Available online: https://www.semanticscholar.org/paper/ASPECT-PHENOMENOLOGIQUE-DE-LA-RUPTURE-PAR-Lema%C3%AEtre-Chaboche/f55030466a796d43727d00769d56a67d9be37372 (accessed on 16 January 2023).

- Maugin, G.A. The Thermomechanics of Plasticity and Fracture; Cambridge University Press: Singapore, 1992. [Google Scholar]

- Coleman, B.D.; Gurtin, Y.M.E. Thermodynamics with Internal State Variables. J. Chem. Phys. 1967, 47, 597–613. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Bammann, Y.D.J. Historical review of internal state variable theory for inelasticity. Int. J. Plast. 2010, 26, 1310–1334. [Google Scholar] [CrossRef]

- Luo, S.; Netravali, Y.A.N. Characterization of henequen fibers and the henequen fiber/poly(hydroxybutyrate-co-hydroxyvalerate) interface. J. Adhes. Sci. Technol. 2001, 15, 423–437. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, Y.M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Mahadeva Raju, G.K.; Dakshayini, B.S.; Madhu, G.M.; Khan, M.A.; Reddy, Y.P.D.S. Characterizing and Modeling of Mechanical Properties of Epoxy Polymer Composites Reinforced with Bentonite Clay. Mater. Today Proc. 2018, 5 Pt 2, 28098–28107. [Google Scholar] [CrossRef]

| Properties | Test Methods | Typical Values |

|---|---|---|

| Color | RS13F | light yellow |

| Odor | - | styrene |

| Acid number | RS02 | 24–31 mg KOH/g |

| Stability at 20 °C in the dark | RS07G | six months |

| Apparent density | ISO 2811 | 1.1–1.15 g/cm3 |

| RVF viscosity, s 2 rpm | GM025 | 580–700 mPa.s |

| Styrene monomer content | RS06C | 31–35% |

| Reactivity | 0.3%Co6% + 0.8%MEKP | |

| Gel time | RS13G | 20–26 min. |

| Hardening time | RS13G | 31–43 min. |

| Exothermic peak | RS13G | 140–170 °C |

| Flashpoint | EN 22719 | 31 °C |

| Properties | Typical Values |

|---|---|

| Physical state and color | liquid and colorless |

| CAS number | 1338-23-4 |

| Formula | C4H10O4 |

| Flashpoint | 56°C, Method: ISO 3679, Seta–Flash. |

| Melting point/range | −10 to −5.5 °C |

| Vapor pressure | 0.184 Pa at 25 °C |

| Density | 1.02 g/cm3 at 20 °C |

| Water solubility | Approximately 6.5 g/L at 20 °C |

| Dynamic viscosity | 13 mPa.s at 20 °C |

| Refractive index | 1.43 at 20 °C |

| Sample | Fiber [%] | Bentonite [%] |

|---|---|---|

| PoS | - | - |

| PoH15 | 15 | - |

| PoH20 | 20 | - |

| PoH25 | 25 | - |

| PoB3 | - | 3 |

| PoB5 | - | 5 |

| PoB7 | - | 7 |

| PoB5H15 | 15 | 5 |

| PoB5H20 | 20 | 5 |

| PoB5H25 | 25 | 5 |

| Sample | Endurance (MPa) | Elongation (%) | Elastic Module (MPa) | Increase (%) |

|---|---|---|---|---|

| PoH15 | 18.37 | 9.60 | 191.35 | |

| PoB5H15 | 18.34 | 6.60 | 277.88 | 45.22 |

| PoH20 | 21.06 | 10.1 | 208.51 | |

| PoB5H20 | 20.37 | 7.70 | 264.55 | 26.87 |

| PoH25 | 24.16 | 4.50 | 536.89 | |

| PoB5H25 | 21.34 | 5.40 | 395.19 | −26.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, M.V.; Rivera, J.L.V.; Rodríguez, F.P.; Losada, H.F.; Abreu, M.E.F.; Diaz, F.R.V.; Soto, A.R.; Alvarez, A.A.; Quinteros, R.; Ketterer, C.G.; et al. Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model. Appl. Sci. 2023, 13, 2677. https://doi.org/10.3390/app13042677

Fernández MV, Rivera JLV, Rodríguez FP, Losada HF, Abreu MEF, Diaz FRV, Soto AR, Alvarez AA, Quinteros R, Ketterer CG, et al. Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model. Applied Sciences. 2023; 13(4):2677. https://doi.org/10.3390/app13042677

Chicago/Turabian StyleFernández, Meylí Valin, José Luis Valin Rivera, Frank Pérez Rodríguez, Henry Figueredo Losada, María Elena Fernández Abreu, Francisco Rolando Valenzuela Diaz, Angel Rodríguez Soto, Alexander Alfonso Alvarez, Roberto Quinteros, Cristobal Galleguillos Ketterer, and et al. 2023. "Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model" Applied Sciences 13, no. 4: 2677. https://doi.org/10.3390/app13042677

APA StyleFernández, M. V., Rivera, J. L. V., Rodríguez, F. P., Losada, H. F., Abreu, M. E. F., Diaz, F. R. V., Soto, A. R., Alvarez, A. A., Quinteros, R., Ketterer, C. G., & García del Pino, G. (2023). Mechanical Characterization of a Polymer/Natural Fibers/Bentonite Composite Material with Implementation of a Continuous Damage Model. Applied Sciences, 13(4), 2677. https://doi.org/10.3390/app13042677