Effects of Modified Outsole Patterns in Tennis Shoes on Frictional Force and Biomechanical Variables of Lower Extremity Joints

Abstract

1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Tennis Shoes

2.3. Experimental Process

2.4. Data Collection

2.5. Analysis Variables

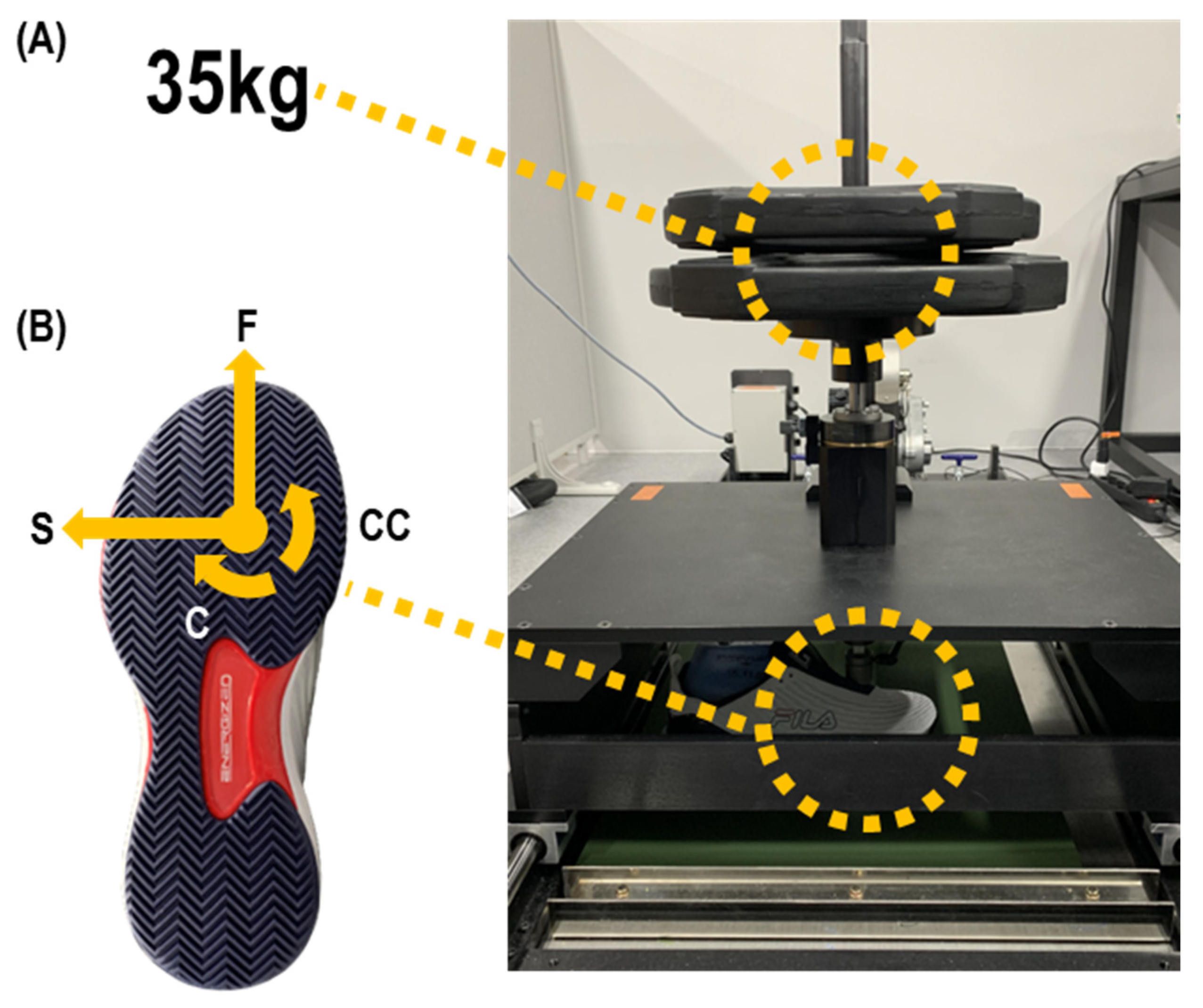

2.5.1. Frictional Force

2.5.2. Joint Angle

2.5.3. Joint Moment

2.6. Statistical Processing

3. Results

3.1. Mechanical Frictional Force

3.2. Frictional Force upon Braking Motion

3.3. Joint Angle and Joint Moment upon Forward Braking Motion

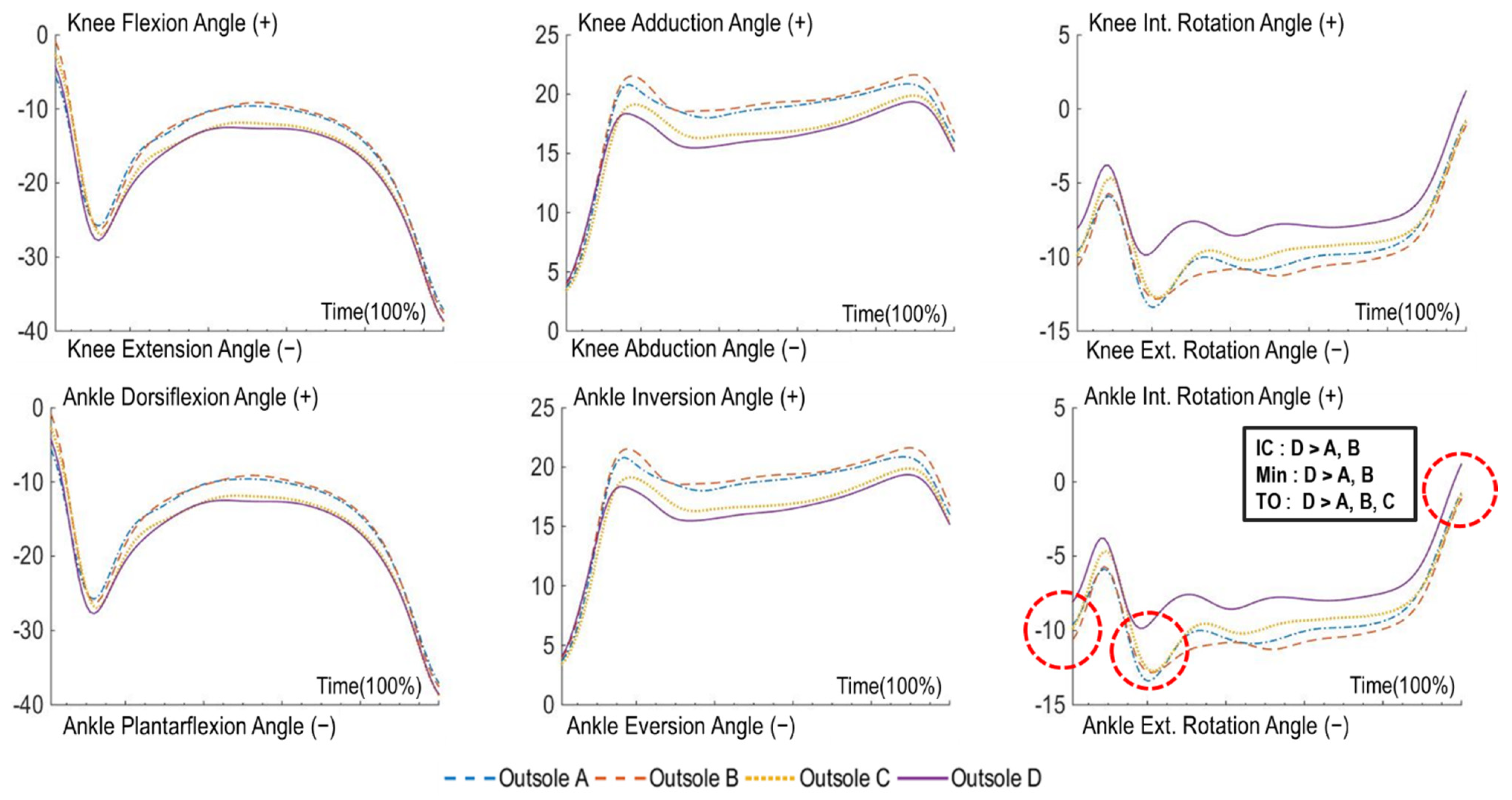

3.4. Joint Angle and Joint Moment upon Side Braking Motion

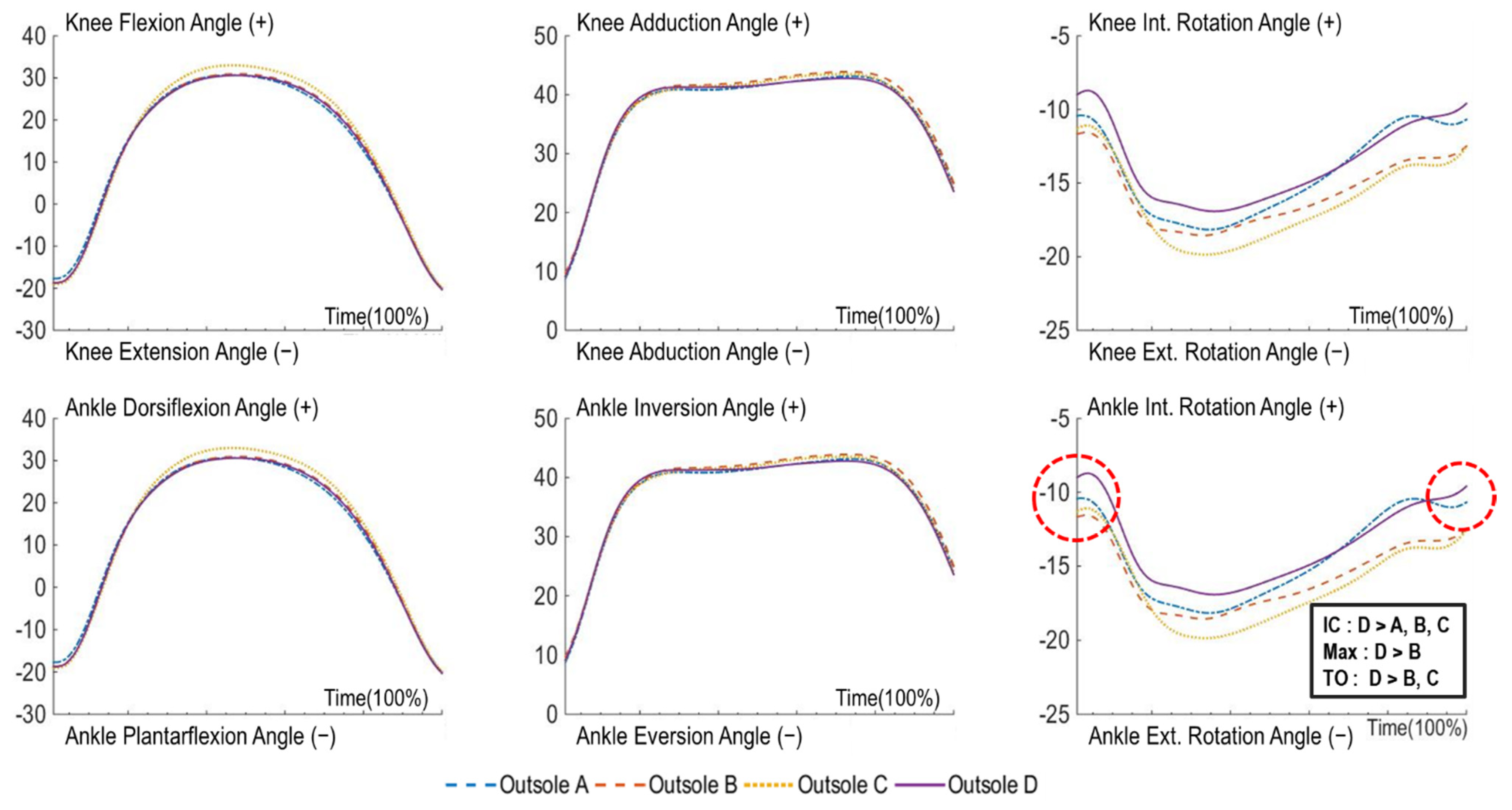

4. Discussion

4.1. Differences between Mechanical Frictional Force and Frictional Force upon Braking Motion between Outsole Patterns

4.2. Effects of Outsole Pattern on Forward and Side Braking Motions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Kinematic Variables (Degree) | Mean ± SD | F (p) | Post Hoc | Effect Size | Statistical Power | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | |||||||

| IC | Knee | Flexion | 15.93 ± 5.29 | 16.13 ± 6.02 | 16.87 ± 6.70 | 16.69 ± 7.98 | 0.31 (0.82) | 0.030 | 0.103 | |

| Adduction | 2.74 ± 4.16 | 3.02 ± 2.80 | 3.53 ± 3.38 | 3.49 ± 3.40 | 0.72 (0.55) | 0.067 | 0.184 | |||

| Int. Rot. | 0.12 ± 7.41 | −0.1 ± 6.70 | −1.15 ± 7.20 | −0.81 ± 5.06 | 0.48 (0.70) | 0.046 | 0.136 | |||

| Ankle | Dorsiflexion | −5.61 ± 13.83 | −0.85 ± 8.81 | −2.70 ± 9.60 | −4.27 ± 12.93 | 1.46 (0.25) | 0.128 | 0.347 | ||

| Inversion | 3.69 ± 3.63 | 3.92 ± 4.58 | 3.46 ± 4.59 | 4.08 ± 4.11 | 0.22 (0.88) | 0.022 | 0.087 | |||

| Int. Rot. | −9.61 ± 4.61 | −10.64 ± 4.27 | −9.84 ± 5.17 | −8.08 ± 5.02 | 3.44 (0.03) * | A,B>D | 0.256 | 0.714 | ||

| TO | Knee | Flexion | 9.36 ± 9.51 | 10.43 ± 6.33 | 9.12 ± 6.02 | 9.62 ± 6.77 | 0.17 (0.91) | 0.017 | 0.078 | |

| Adduction | 2.53 ± 4.11 | 2.66 ± 3.86 | 3.15 ± 4.25 | 2.77 ± 4.36 | 0.91 (0.45) | 0.084 | 0.225 | |||

| Int. Rot. | 1.07 ± 5.18 | 0.97 ± 4.22 | 1.14 ± 3.45 | −0.02 ± 4.90 | 0.32 (0.68) | 0.031 | 0.088 | |||

| Ankle | Dorsiflexion | −37.04 ± 6.52 | −37.52 ± 6.28 | −38.60 ± 4.46 | −38.57 ± 6.84 | 0.44 (0.73) | 0.042 | 0.127 | ||

| Inversion | 16.04 ± 7.81 | 16.76 ± 7.01 | 15.27 ± 6.01 | 15.19 ± 5.52 | 0.56 (0.65) | 0.053 | 0.151 | |||

| Int. Rot. | −0.74 ± 5.17 | −1.15 ± 4.25 | −0.81 ± 4.04 | −1.20 ± 3.69 | 3.67 (0.02) * | A,B,C>D | 0.268 | 0.745 | ||

| Max | Knee | Flexion | 57.23 ± 5.36 | 58.32 ± 6.76 | 58.02 ± 5.84 | 59.16 ± 4.88 | 1.30 (0.29) | 0.115 | 0.312 | |

| Adduction | 4.39 ± 4.05 | 5.02 ± 3.22 | 5.49 ± 2.75 | 5.20 ± 3.46 | 1.38 (0.27) | 0.121 | 0.329 | |||

| Int. Rot. | 16.11 ± 4.80 | 15.79 ± 5.18 | 15.76 ± 3.95 | 15.27 ± 5.31 | 0.27 (0.85) | 0.026 | 0.096 | |||

| Ankle | Dorsiflexion | 1.15 ± 5.12 | 1.94 ± 5.90 | −0.03 ± 5.53 | 0.52 ± 6.44 | 0.86 (0.47) | 0.079 | 0.214 | ||

| Inversion | 23.61 ± 11.93 | 24.56 ± 10.53 | 22.29 ± 7.43 | 21.76 ± 8.27 | 0.63 (0.55) | 0.059 | 0.140 | |||

| Int. Rot. | 0.31 ± 4.08 | −0.02 ± 3.39 | 0.61 ± 3.54 | 2.01 ± 3.11 | 2.20 (0.15) | 0.18 | 0.347 | |||

| Min | Knee | Flexion | 6.94 ± 4.82 | 8.59 ± 4.99 | 6.80 ± 2.85 | 6.58 ± 4.50 | 2.21 (0.11) | 0.181 | 0.505 | |

| Adduction | −7.56 ± 5.38 | −7.24 ± 5.74 | −6.79 ± 5.25 | −7.04 ± 5.17 | 0.32 (0.81) | 0.031 | 0.105 | |||

| Int. Rot. | −3.27 ± 6.20 | −3.69 ± 5.64 | −3.89 ± 5.35 | −4.24 ± 5.69 | 0.18 (0.91) | 0.017 | 0.079 | |||

| Ankle | Dorsiflexion | −39.17 ± 4.66 | −38.81 ± 4.84 | −39.78 ± 3.30 | −40.61 ± 3.29 | 1.75 (0.18) | 0.149 | 0.409 | ||

| Inversion | 2.90 ± 4.66 | 3.18 ± 5.27 | 2.88 ± 4.86 | 3.66 ± 3.96 | 0.34 (0.80) | 0.033 | 0.108 | |||

| Int. Rot. | −15.77 ± 7.39 | −15.71 ± 5.77 | −14.62 ± 6.66 | −12.96 ± 6.87 | 5.24 (0.01) * | A,B>D | 0.344 | 0.891 | ||

| RoM | Knee | Flexion | 50.29 ± 4.53 | 49.73 ± 4.87 | 51.22 ± 5.02 | 52.57 ± 3.88 | 2.63 (0.07) | 0.208 | 0.585 | |

| Adduction | 11.95 ± 5.21 | 12.26 ± 5.75 | 12.28 ± 5.45 | 12.24 ± 4.98 | 0.10 (0.96) | 0.010 | 0.066 | |||

| Int. Rot. | 19.37 ± 5.16 | 19.48 ± 4.56 | 19.64 ± 4.61 | 19.52 ± 5.01 | 0.02 (1.00) | 0.002 | 0.053 | |||

| Ankle | Dorsiflexion | 40.32 ± 5.00 | 40.74 ± 6.76 | 39.75 ± 7.02 | 41.13 ± 7.16 | 0.43 (0.73) | 0.041 | 0.126 | ||

| Inversion | 20.72 ± 8.78 | 21.38 ± 7.72 | 19.41 ± 5.24 | 18.10 ± 7.25 | 0.94 (0.39) | 0.085 | 0.172 | |||

| Int. Rot. | 16.09 ± 4.23 | 15.69 ± 3.08 | 15.23 ± 4.10 | 14.97 ± 4.34 | 0.79 (0.51) | 0.073 | 0.199 | |||

| Kinematic Variables (Degree) | Mean ± SD | F (p) | Post Hoc | Effect Size | Statistical Power | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | |||||||

| IC | Knee | Flexion | 24.00 ± 6.92 | 23.18 ± 7.22 | 22.88 ± 6.53 | 23.24 ± 6.97 | 0.44 (0.83) | 0.042 | 0.127 | |

| Adduction | −2.18 ± 3.55 | −1.83 ± 3.62 | −1.39 ± 3.76 | −1.61 ± 3.13 | 0.92 (0.44) | 0.084 | 0.227 | |||

| Int. Rot. | 1.16 ± 5.36 | 0.63 ± 4.29 | 0.54 ± 5.73 | 0.44 ± 5.76 | 0.23 (0.87) | 0.023 | 0.089 | |||

| Ankle | Dorsiflexion | −17.72 ± 6.15 | −18.67 ± 5.82 | −18.98 ± 4.50 | −18.73 ± 5.52 | 0.70 (0.56) | 0.066 | 0.181 | ||

| Inversion | 8.74 ± 3.29 | 9.68 ± 4.51 | 9.20 ± 3.74 | 9.17 ± 3.69 | 0.81 (0.50) | 0.075 | 0.204 | |||

| Int. Rot. | −10.43 ± 5.34 | −11.69 ± 4.91 | −11.28 ± 4.61 | −9.00 ± 5.05 | 3.61 (0.03) * | A,B,C>D | 0.265 | 0.737 | ||

| TO | Knee | Flexion | 8.19 ± 6.95 | 8.22 ± 6.16 | 9.47 ± 6.51 | 8.75 ± 5.72 | 0.96 (0.42) | 0.088 | 0.236 | |

| Adduction | 0.01± 3.15 | −0.55 ± 3.05 | −0.02 ± 2.81 | 0.17 ± 2.93 | 1.90 (0.15) | 0.160 | 0.441 | |||

| Int. Rot. | −5.06 ± 6.44 | −5.51 ± 5.61 | −4.87 ± 5.65 | −5.42 ± 5.58 | 0.40 (0.75) | 0.038 | 0.120 | |||

| Ankle | Dorsiflexion | −20.00 ± 8.65 | −20.09 ± 6.00 | −19.86 ± 7.17 | −20.09 ± 8.27 | 0.10 (0.96) | 0.010 | 0.066 | ||

| Inversion | 24.54 ± 4.64 | 25.05 ± 4.08 | 23.97 ± 5.57 | 23.61 ± 3.67 | 1.01 (0.40) | 0.092 | 0.247 | |||

| Int. Rot. | −10.68 ± 6.90 | −12.50 ± 5.94 | −12.55 ± 5.72 | −9.60 ± 6.55 | 5.10 (0.01) * | B,C>D | 0.338 | 0.882 | ||

| Max | Knee | Flexion | 45.40 ± 5.64 | 44.93 ± 5.42 | 45.08 ± 6.39 | 45.02 ± 6.01 | 0.06 (0.98) | 0.006 | 0.059 | |

| Adduction | 1.39 ± 3.29 | 0.91 ± 3.34 | 1.45 ± 3.52 | 1.85 ± 3.17 | 2.36 (0.09) | 0.191 | 0.533 | |||

| Int. Rot. | 16.28 ± 4.08 | 15.84 ± 3.92 | 16.06 ± 4.10 | 15.07 ± 3.65 | 1.06 (0.38) | 0.095 | 0.257 | |||

| Ankle | Dorsiflexion | 31.71 ± 9.03 | 31.75 ± 8.21 | 33.53 ± 8.62 | 31.33 ± 9.28 | 2.70 (0.06) | 0.213 | 0.597 | ||

| Inversion | 44.00 ± 3.45 | 44.81 ± 4.01 | 44.59 ± 6.14 | 43.76 ± 5.29 | 0.41 (0.75) | 0.040 | 0.122 | |||

| Int. Rot. | −6.70 ± 6.71 | −8.56 ± 6.43 | −8.48 ± 5.60 | −6.03 ± 6.60 | 3.58 (0.03) * | B>D | 0.264 | 0.734 | ||

| Min | Knee | Flexion | 7.73 ± 6.72 | 8.09 ± 6.10 | 9.09 ± 6.32 | 8.33 ± 5.47 | 0.95 (0.43) | 0.086 | 0.233 | |

| Adduction | −7.96 ± 3.36 | −8.35 ± 4.73 | −6.98 ± 3.56 | −7.08 ± 3.45 | 1.87 (0.16) | 0.158 | 0.436 | |||

| Int. Rot. | −5.63 ± 6.09 | −5.72 ± 5.40 | −5.34 ± 5.63 | −5.85 ± 5.49 | 0.18 (0.91) | 0.017 | 0.079 | |||

| Ankle | Dorsiflexion | −22.46 ± 6.00 | −21.52 ± 5.67 | −21.94 ± 5.11 | −23.00 ± 5.71 | 1.95 (0.14) | 0.163 | 0.451 | ||

| Inversion | 8.74 ± 3.29 | 9.68 ± 4.51 | 9.20 ± 3.74 | 9.17 ± 3.69 | 0.81 (0.50) | 0.075 | 0.204 | |||

| Int. Rot. | −21.09 ± 6.00 | −21.54 ± 5.53 | −22.20 ± 5.63 | −19.56 ± 6.32 | 3.48 (0.08) | 0.258 | 0.458 | |||

| RoM | Knee | Flexion | 37.67 ± 6.67 | 36.84 ± 4.51 | 35.99 ± 6.55 | 36.69 ± 5.66 | 0.59 (0.63) | 0.055 | 0.156 | |

| Adduction | 9.36 ± 4.26 | 9.26 ± 3.53 | 8.42 ± 3.06 | 8.93 ± 3.48 | 0.95 (0.43) | 0.087 | 0.234 | |||

| Int. Rot. | 21.92 ± 5.50 | 21.56 ± 5.16 | 21.40 ± 4.29 | 20.92 ± 4.19 | 0.52 (0.67) | 0.050 | 0.144 | |||

| Ankle | Dorsiflexion | 51.03 ± 6.26 | 51.37 ± 5.78 | 52.84 ± 6.85 | 51.13 ± 5.64 | 1.56 (0.24) | 0.135 | 0.267 | ||

| Inversion | 19.16 ± 5.31 | 19.43 ± 4.86 | 20.40 ± 5.21 | 19.80 ± 5.85 | 0.84 (0.48) | 0.078 | 0.210 | |||

| Int. Rot. | 10.20 ± 3.45 | 9.14 ± 2.83 | 9.73 ± 3.54 | 9.75 ± 3.83 | 1.02 (0.40) | 0.093 | 0.250 | |||

References

- Reinschmidt, C.; Nigg, B.M. Current Issues in the Design of Running and Court Shoes. Sportverletz. Sportschaden 2000, 14, 72–81. [Google Scholar] [CrossRef]

- Lake, M.J. Determining the protective function of sports footwear. Ergonomics 2000, 43, 1610–1621. [Google Scholar] [CrossRef]

- Frederick, E. Physiological and ergonomics factors in running shoe design. Appl. Ergon. 1984, 15, 281–287. [Google Scholar] [CrossRef]

- Fales, C.W.; Stone, R.T.; Van Groningen, D.; Westby, B. Tread Patterns and the Effect on Basketball Player Slippage. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, 5–9 October 2020; Volume 64, pp. 1328–1332. [Google Scholar] [CrossRef]

- Werd, M.B.; Knight, E.L.; Langer, P.R. Athletic Footwear and Orthoses in Sports Medicine; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Valiant, G.A. Friction—Slipping—Traction. Sportverletz. Sportschaden 1993, 7, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Worobets, J.T.; Panizzolo, F.; Hung, S.; Wannop, J.W.; Stefanyshyn, D.J. Increasing Running Shoe Traction Can Enhance Performance. Res. J. Text. Appar. 2014, 18, 17–22. [Google Scholar] [CrossRef]

- Shorten, M.; Hudson, B.; Himmelsbach, J. Shoe-surface traction of conventional and in-filled synthetic turf football surfaces. In Proceedings of the XIX International Congress on Biomechanics, Dunedin, New Zealand, 21–25 August 2003. [Google Scholar]

- Luo, G.; Stefanyshyn, D. Identification of critical traction values for maximum athletic performance. Footwear Sci. 2011, 3, 127–138. [Google Scholar] [CrossRef]

- Severn, K.A.; Fleming, P.R.; Dixon, N. Science of synthetic turf surfaces: Player–surface interactions. Sports Technol. 2010, 3, 13–25. [Google Scholar] [CrossRef]

- Strandberg, L.; Lanshammar, H. The dynamics of slipping accidents. J. Occup. Accid. 1981, 3, 153–162. [Google Scholar] [CrossRef]

- Pedroza, A.; Fernandez, S.; Heidt, R., Jr.; Kaeding, C. Evaluation of the Shoe-Surface Interaction Using an Agility Maneuver. Med. Sci. Sports Exerc. 2010, 42, 1754–1759. [Google Scholar] [CrossRef]

- Andreasson, G.; Lindenberger, U.; Renström, P.; Peterson, L. Torque developed at simulated sliding between sport shoes and an artificial turf. Am. J. Sports Med. 1986, 14, 225–230. [Google Scholar] [CrossRef] [PubMed]

- Damm, L.C.; Low, D.; Richardson, A.; Clarke, J.; Carré, M.; Dixon, S. The effects of surface traction characteristics on frictional demand and kinematics in tennis. Sports Biomech. 2013, 12, 389–402. [Google Scholar] [CrossRef] [PubMed]

- Nigg, B.M.; Stefanyshyn, D.J.; Rozitis, A.I.; Mündermann, A.; Muendermann, A. Resultant knee joint moments for lateral movement tasks on sliding and non-sliding sport surfaces. J. Sports Sci. 2009, 27, 427–435. [Google Scholar] [CrossRef]

- Nigg, B.M.; Yeadon, M.R. Biomechanical aspects of playing surfaces. J. Sports Sci. 1987, 5, 117–145. [Google Scholar] [CrossRef]

- Worobets, J.; Wannop, J.W. Influence of basketball shoe mass, outsole traction, and forefoot bending stiffness on three athletic movements. Sports Biomech. 2015, 14, 351–360. [Google Scholar] [CrossRef]

- Ismail, S.I.; Nunome, H.; Tamura, Y. Does visual representation of futsal shoes outsole tread groove design resemblance its mechanical traction, dynamic human traction performance, and perceived traction during change of direction and straight sprint tasks? Footwear Sci. 2021, 13, 79–89. [Google Scholar] [CrossRef]

- Wannop, J.W.; Worobets, J.T.; Stefanyshyn, D.J. Footwear Traction and Lower Extremity Joint Loading. Am. J. Sports Med. 2010, 38, 1221–1228. [Google Scholar] [CrossRef]

- Müller, C.; Sterzing, T.; Lange, J.; Milani, T.L. Comprehensive evaluation of player-surface interaction on artificial soccer turf. Sports Biomech. 2010, 9, 193–205. [Google Scholar] [CrossRef]

- Sterzing, T.; Müller, C.; Schwanitz, S.; Odenwald, S.; Milani, T.L. Discrepancies between mechanical and biomechanical measurements of soccer shoe traction on artificial turf. In Proceedings of the ISBS-Conference Proceedings Archive, Seoul, Republic of Korea, 14–18 July 2008. [Google Scholar]

- Driscoll, H.; Kirk, B.; Koerger, H.; Haake, S. Influence of outsole design on centre of rotation during turning movements. Procedia Eng. 2012, 34, 301–306. [Google Scholar] [CrossRef]

- Girard, O.; Eicher, F.; Fourchet, F.; Micallef, J.P.; Millet, G.P. Effects of the playing surface on plantar pressures and potential injuries in tennis. Br. J. Sports Med. 2007, 41, 733–738. [Google Scholar] [CrossRef]

- Pavailler, S.; Horvais, N. Sliding Allows Faster Repositioning during Tennis Specific Movements on Hard Court. Procedia Eng. 2014, 72, 859–864. [Google Scholar] [CrossRef]

- Starbuck, C.; Damm, L.; Clarke, J.; Carré, M.; Capel-Davis, J.; Miller, S.; Stiles, V.; Dixon, S. The influence of tennis court surfaces on player perceptions and biomechanical response. J. Sports Sci. 2016, 34, 1627–1636. [Google Scholar] [CrossRef] [PubMed]

- ITF. Surface Types. Available online: https://www.itftennis.com/media/2169/surfaces-surface-types.pdf (accessed on 6 November 2022).

- Damm, L.; Starbuck, C.; Stocker, N.; Clarke, J.; Carré, M.; Dixon, S. Shoe-surface friction in tennis: Influence on plantar pressure and implications for injury. Footwear Sci. 2014, 6, 155–164. [Google Scholar] [CrossRef]

- Clarke, J.; Dixon, S.J.; Damm, L.; Carré, M.J. The effect of normal load force and roughness on the dynamic traction developed at the shoe–surface interface in tennis. Sports Eng. 2013, 16, 165–171. [Google Scholar] [CrossRef]

- Miller, S. Modern tennis rackets, balls, and surfaces. Br. J. Sports Med. 2006, 40, 401–405. [Google Scholar] [CrossRef]

- Goff, J.E.; Boswell, L.; Ura, D.; Kozy, M.; Carré, M.J. Critical shoe contact area ratio for sliding on a tennis hard court. Proc. Inst. Mech. Eng. Part P: J. Sports Eng. Technol. 2017, 232, 112–121. [Google Scholar] [CrossRef]

- Ura, D.; Clarke, J.; Carre, M. Effect of shoe orientation on shoe-surface traction in tennis. Footwear Sci. 2013, 5, S86–S87. [Google Scholar] [CrossRef]

- Monnet, T.; Domalain, M.; Decatoire, A.; Horvais, N.; Lacouture, P. Sliding on hardcourt surface with specific shoes, prelim-inary results. In Proceedings of the ISBS-Conference Proceedings Archive, Johnson City, TN, USA, 12–16 July 2014. [Google Scholar]

- Kovacs, M.S. Movement for Tennis: The Importance of Lateral Training. Strength Cond. J. 2009, 31, 77–85. [Google Scholar] [CrossRef]

- Wannop, J.W.; Stefanyshyn, D.J. The effect of translational and rotational traction on lower extremity joint loading. J. Sports Sci. 2016, 34, 613–620. [Google Scholar] [CrossRef]

- Hamill, J. Evaluating sport shoes using ground reaction force data. In Proceedings of the ISBS-Conference Proceedings Archive, Madeira, Portugal, 25–29 July 1996. [Google Scholar]

- Frederick, E.C. Optimal frictional properties for sport shoes and sport surfaces. In Proceedings of the ISBS-Conference Proceedings Archive, Amherst, MA, USA, 23–26 June 1993. [Google Scholar]

- Frederick, E. Kinematically mediated effects of sport shoe design: A review. J. Sports Sci. 1986, 4, 169–184. [Google Scholar] [CrossRef]

- Hamill, J.; Ryu, J. Experiment in Sport Biomechanics; Daehanmedia: Seoul, Republic of Korea, 2003. [Google Scholar]

- Winter, D.A. Chapter 9: Kinesiological Electromyography. In Biomechanics and Motor Control of Human Movement, 4th ed.; Winter, D.A., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Lindsey, C. Tennis Shoe Traction-Developing a Test Rig to Measure Shoe Traction on Tennis Courts. Available online: https://twu.tennis-warehouse.com/learning_center/traction.php (accessed on 6 November 2022).

- Nigg, B.M. The validity and relevance of tests used for the assessment of sports surfaces. Med. Sci. Sports Exerc. 1990, 22, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Bonstingl, R.W.; Morehouse, C.A.; Niebel, B.W. Torques developed by different types of shoes on various playing surfaces. Med. Sci. Sports 1975, 7, 127–131. [Google Scholar] [CrossRef] [PubMed]

- Kibler, W.B.; Safran, M. Tennis Injuries. Med. Sport Sci. 2005, 48, 120–137. [Google Scholar] [CrossRef] [PubMed]

| Mechanical Friction | Mean ± SD | F (p) | Post-Hoc | Effect Size | Statistical Power | |||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | |||||

| Forward CoF (μ) | 0.77 ± 0.01 | 0.78 ± 0.01 | 0.73 ± 0.01 | 0.74 ± 0.01 | 158.55 (0.01) * | B>A>D>C | 0.946 | 1.000 |

| Sideward CoF (μ) | 0.84 ± 0.01 | 0.82 ± 0.01 | 0.83 ± 0.01 | 0.82 ± 0.01 | 24.48 (0.01) * | A,C>D>B | 0.731 | 1.000 |

| C-RF (Nm) | 29.18 ± 1.37 | 29.84 ± 1.21 | 29.58 ± 0.94 | 30.76 ± 1.09 | 4.10 (0.02) * | D>A,C | 0.313 | 0.789 |

| CC-RF (Nm) | 27.92 ± 2.19 | 27.31 ± 1.79 | 28.51 ± 2.54 | 29.62 ± 2.84 | 1.84 (0.16) | 0.170 | 0.423 | |

| Biomechanical Friction | Mean ± SD | F (p) | Post Hoc | Effect Size | Statistical Power | ||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | ||||||

| Forward Braking | Max CoF (μ) | 0.91 ± 0.07 | 0.90 ± 0.08 | 0.90 ± 0.11 | 0.92 ± 0.10 | 0.92 (0.45) | 0.084 | 0.226 | |

| Max RF (Nm) | 3.66 ± 2.49 | 2.81 ± 1.68 | 3.57 ± 1.98 | 4.21 ± 3.65 | 0.76 (0.40) | 0.071 | 0.124 | ||

| Min RF (Nm) | −28.49 ± 6.74 | −28.12 ± 7.34 | −27.27 ± 6.40 | −29.46 ± 8.15 | 0.40 (0.75) | 0.039 | 0.120 | ||

| Side Braking | Max CoF (μ) | 0.94 ± 0.03 | 0.92 ± 0.05 | 0.93 ± 0.06 | 0.92 ± 0.06 | 0.94 (0.43) | 0.086 | 0.232 | |

| Max RF (Nm) | 12.35 ± 5.72 | 13.27 ± 7.55 | 12.37 ± 7.21 | 12.55 ± 4.78 | 0.10 (0.96) | 0.010 | 0.066 | ||

| Min RF(Nm) | −14.28 ± 5.41 | −13.40 ± 5.84 | −13.78 ± 7.43 | −14.82 ± 4.90 | 0.32 (0.68) | 0.031 | 0.089 | ||

| Maximum Moment (Nm/kg) | Mean ± SD | F (p) | Post Hoc | Effect Size | Statistical Power | ||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | ||||||

| Knee | Flexion Moment | 1.79 ± 0.73 | 1.92 ± 0.63 | 1.84 ± 0.64 | 1.94 ± 0.88 | 0.31 (0.82) | 0.030 | 0.103 | |

| Extension Moment | 1.71 ± 0.28 | 1.65 ± 0.37 | 1.70 ± 0.37 | −1.65 ± 0.34 | 0.22 (0.76) | 0.022 | 0.077 | ||

| Adduction Moment | 1.59 ± 0.85 | 1.62 ± 0.80 | 1.49 ± 0.62 | 1.56 ± 0.82 | 0.31 (0.71) | 0.030 | 0.091 | ||

| Abduction Moment | 0.37 ± 0.31 | 0.34 ± 0.19 | 0.33 ± 0.28 | −0.33 ± 0.30 | 0.55 (0.65) | 0.052 | 0.150 | ||

| Int. Rot. Moment | 0.40 ± 0.28 | 0.41 ± 0.27 | 0.42 ± 0.28 | 0.39 ± 0.28 | 0.21 (0.89) | 0.020 | 0.084 | ||

| Ext. Rot. Moment | 0.43 ± 0.36 | 0.42 ± 0.31 | 0.43 ± 0.25 | −0.43 ± 0.37 | 0.01 (1.00) | 0.001 | 0.050 | ||

| Ankle | Dorsiflexion Moment | 0.41 ± 0.25 | 0.48 ± 0.14 | 0.48 ± 0.13 | 0.41 ± 0.20 | 1.58 (0.22) | 0.136 | 0.372 | |

| Plantarflexion Moment | 1.60 ± 0.38 | 1.55 ± 0.23 | 1.55 ± 0.20 | 1.58 ± 0.27 | 0.35 (0.66) | 0.034 | 0.092 | ||

| Inversion Moment | 0.18 ± 0.14 | 0.13 ± 0.12 | 0.15 ± 0.15 | 0.17 ± 0.15 | 1.07 (0.38) | 0.097 | 0.260 | ||

| Eversion Moment | 0.51 ± 0.31 | 0.54 ± 0.30 | 0.54 ± 0.31 | 0.55 ± 0.29 | 0.64 (0.60) | 0.060 | 0.167 | ||

| Int. Rot. Moment | 0.34 ± 0.11 | 0.37 ± 0.10 | 0.31 ± 0.09 | 0.36 ± 0.13 | 3.04 (0.04) * | B>C | 0.233 | 0.654 | |

| Ext. Rot. Moment | 0.11 ± 0.10 | 0.10 ± 0.06 | 0.10 ± 0.07 | 0.09 ± 0.06 | 0.58 (0.52) | 0.055 | 0.119 | ||

| Maximum Moment (Nm/kg) | Mean ± SD | F (p) | Post Hoc | Effect Size | Statistical Power | ||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | ||||||

| Knee | Flexion Moment | 0.83 ± 0.23 | 0.79 ± 0.23 | 0.81 ± 0.18 | 0.80 ± 0.23 | 0.25 (0.86) | 0.024 | 0.092 | |

| Extension Moment | 2.49 ± 0.56 | 2.47 ± 0.75 | 2.54 ± 0.79 | 2.50 ± 0.73 | 0.20 (0.90) | 0.020 | 0.083 | ||

| Adduction Moment | 1.73 ± 0.46 | 1.78 ± 0.42 | 1.76 ± 0.46 | 1.77 ± 0.39 | 0.17 (0.91) | 0.017 | 0.078 | ||

| Abduction Moment | 0.23 ± 0.07 | 0.20 ± 0.06 | 0.22 ± 0.08 | 0.21 ± 0.06 | 1.26 (0.31) | 0.112 | 0.302 | ||

| Int. Rot. Moment | 0.09 ± 0.10 | 0.09 ± 0.11 | 0.10 ± 0.08 | 0.09 ± 0.09 | 0.15 (0.83) | 0.014 | 0.068 | ||

| Ext. Rot. Moment | 0.56 ± 0.20 | 0.60 ± 0.20 | 0.56 ± 0.13 | 0.59 ± 0.15 | 0.62 (0.61) | 0.058 | 0.164 | ||

| Ankle | Dorsiflexion Moment | 0.01 ± 0.01 | 0.00 ± 0.01 | 0.01 ± 0.03 | 0.01 ± 0.01 | 1.81 (0.21) | 0.153 | 0.259 | |

| Plantarflexion Moment | 3.47 ± 1.01 | 3.57 ± 1.01 | 3.62 ± 0.99 | 3.48 ± 0.90 | 1.34 (0.28) | 0.118 | 0.319 | ||

| Inversion Moment | 0.20 ± 0.19 | 0.21 ± 0.19 | 0.21 ± 0.17 | 0.18 ± 0.15 | 1.09 (0.37) | 0.098 | 0.264 | ||

| Eversion Moment | 0.30 ± 0.15 | 0.34 ± 0.21 | 0.31 ± 0.16 | 0.35 ± 0.24 | 0.80 (0.51) | 0.074 | 0.201 | ||

| Int. Rot. Moment | 0.19 ± 0.05 | 0.19 ± 0.06 | 0.20 ± 0.07 | 0.19 ± 0.05 | 0.16 (0.92) | 0.016 | 0.077 | ||

| Ext. Rot. Moment | 0.21 ± 0.17 | 0.22 ± 0.18 | 0.20 ± 0.15 | 0.18 ± 0.11 | 0.68 (0.57) | 0.064 | 0.177 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, J.; Ryu, S.; Gil, H.-J.; Park, S.-K. Effects of Modified Outsole Patterns in Tennis Shoes on Frictional Force and Biomechanical Variables of Lower Extremity Joints. Appl. Sci. 2023, 13, 2342. https://doi.org/10.3390/app13042342

Kang J, Ryu S, Gil H-J, Park S-K. Effects of Modified Outsole Patterns in Tennis Shoes on Frictional Force and Biomechanical Variables of Lower Extremity Joints. Applied Sciences. 2023; 13(4):2342. https://doi.org/10.3390/app13042342

Chicago/Turabian StyleKang, Jaewon, Sihyun Ryu, Ho-Jong Gil, and Sang-Kyoon Park. 2023. "Effects of Modified Outsole Patterns in Tennis Shoes on Frictional Force and Biomechanical Variables of Lower Extremity Joints" Applied Sciences 13, no. 4: 2342. https://doi.org/10.3390/app13042342

APA StyleKang, J., Ryu, S., Gil, H.-J., & Park, S.-K. (2023). Effects of Modified Outsole Patterns in Tennis Shoes on Frictional Force and Biomechanical Variables of Lower Extremity Joints. Applied Sciences, 13(4), 2342. https://doi.org/10.3390/app13042342