1.1. The Essence of Constructing Pallet Load Units

Forming palletized load units—PLU is an issue closely related to the functioning of distribution networks and supply chains. It concerns the proper placement of products on the smallest possible number of carriers. In practice, there are two basic types of palletized load units, i.e., homogeneous and heterogeneous. In the first case, products of one type are loaded on a pallet, which is mostly performed by product manufacturers. In the other case, the loaded products differ in basic characteristics such as weight, length, width and height, and product type, and this case mainly occurs at distributors and dealers.

The arrangement of products in PLUs has a number of practical consequences. Firstly, it affects the stability of the pallet units, which, on the one hand, may involve the risk of product damage during basic logistics operations such as transportation, storage, and handling. Product safety depends on their placement on the pallet as they need to be layered to prevent crushing the ones located on lower and intermediate layers. Secondly, product arrangement affects the cost of logistics operations. The smaller the number of PLUs, the less space necessary for transportation and storage, the less energy required, and the lower the cost of performing these operations. The comprehensive research on the distribution network structure and its effectiveness related to the type of packages, including PLUs and parcels are presented in the previous work of the authors; see Sawicki and Sawicka [

1].

In general, the essence of the problem of forming palletized load units involves the proper arrangement of products on the pallet to ensure its stability and compliance with basic constraints such as the limited weight and height of the load unit. An overview of the current state-of-the-art in this area, including the categories of decision-making problems, the way these problems are modeled, the procedures for solving them as well as the results obtained, are presented in the following subsection.

Based on the results of the literature review and the authors’ empirical experience, this publication focuses on the issue of forming a specific type of load unit, which is a stacked pallet load unit—SPLU, commonly referred to as a sandwich-pallet. This issue involves creating a single load unit composed of several elementary PLUs previously arranged on separate pallets. The need to build this type of unit is a direct result of the increasingly noticeable phenomenon within the distribution network of the formation of PLUs whose weight and/or height significantly deviate from the limit values, i.e., the available space on the pallets is not fully utilized. This results from the requirements of purchasers, mainly large retail chains, who order large volumes of goods versus a variety of products and expect that the PLUs will be prepared in such a way that the goods reaching their transshipment warehouses will not require any additional operations, except for the redirection of dedicated PLUs for shipment to the final receivers. Thus, creating a few collective units instead of many smaller PLUs is becoming a necessity. In practice, such operations are undertaken on an ongoing basis, i.e., whilst loading, the forklift operator subjectively assesses whether it is feasible to combine the available PLUs into SPLUs. The FLT operator uses his own experience and intuition, yet whether such an operation is correct, both in terms of the durability of product packaging on individual PLUs and the created weight and height of the SPLU, cannot be guaranteed. The work undertaken in this area by the authors of this article provides a proposal to solve this problem by developing and verifying a procedure to optimize the process of creating SPLUs.

1.2. The State-of-the-Art Design of Palletized Load Units

In the literature, the problem of planning pallet load units is called

bin packing problem—BPP. To solve the problem, one needs to define which items of different sizes need to be packed into a finite number of bins or containers, each of a given and fixed capacity so as to minimize the number of bins used. In the literature, the same problem, depending on the authors, is referred to as pallet loading problem—PLP, e.g., Dell’Amico and Magnani [

2], Morabito et al. [

3], pallet building problem—PBP, e.g., Alonso et al. [

4], container loading problem—CLP, e.g., Lim and Zhang [

5], or packing problem—PP, e.g., Ali et al. [

6].

Since the packing problem is an NP-hard decision problem, it can also be analyzed, with the exception of its principal constraint, i.e., the weight of the product, as a soft version of two dimensions (2D), i.e., width x length of the products to be packed, e.g., G and Kang [

7], or a more complex problem of three dimensions (3D), i.e., width x length x height, e.g., Dell’Amico and Magnani [

1], Morabito et al. [

3], or Ali et al. [

6].

From the perspective of the location, the packing problem is analyzed and planned with respect to homogenous items by some of the researchers who refer to it as manufacturer’s pallet loading—MPL, e.g., Marabito et al. [

3]. When packaging involves heterogeneous items, it is called distributor’s pallet loading—DPL; see Akkaya et al. [

8].

In general, the bin packing problem can be analyzed as a stand-alone packing problem or as a part of a more complex problem, i.e., in combination with vehicle loading. As far as the stand-alone approach is concerned, it has been extensively analyzed as a decision problem for around 50 years. In recent years several papers have been published to review or compare different approaches to this problem [

6,

9]. Silva et al. [

9] reviewed the papers with respect to the methods proposed for the solution of the problem. In conclusion, a group of the most challenging methods was identified. Ali et al. [

6] analyzed different approaches to the decision-making problem concerning packing. They differentiated 3D off-line vs. on-line streams of packing problems. Off-line packing problems can happen when full knowledge about items is available beforehand. The on-line problem, i.e., real-time problem, is when items arrive one by one, and the packing decision should be made immediately without prior knowledge about the items. According to Ali et al., most of the packing problems described in the literature are of the off-line type. Contemporary examples of the on-line bin packing problem can be found in Lin et al. [

10], where a pattern-based adaptive heuristics for the on-line bin packing problem is proposed. The distribution of items may be predicted based on the packed items, and the pattern is next applied in the packing of the items that arrive later.

Some new research into the bin packing problem was published in the last few years. Gzara et al. [

11] analyzed a wide spectrum of practical constraints, including vertical support, load bearing, planogram sequencing, and weight limits. The authors performed extensive numerical tests to prove the ability of the approach to find high-quality solutions for industrial-size instances within a short computational time. There are also some recent papers on the application of more efficient computational procedures whose aim is to achieve computation results in the shortest time possible. Tresca et al. [

12] published a paper on the 3D bin packing problem (3D-BPP) where they proposed a model oriented on pallets configurations to satisfy the practical requirements of item grouping by logistic features such as load bearing, stability, height homogeneity, overhang as well as weight limits, and robotized layer picking. The complex problem is solved with metaheuristics, which combines MILP formulation and layer-building heuristics. Moreover, 3D-BPP is analyzed in the work of Zuo et al. [

13]. The authors addressed a novel 3D-BPP variant in which the shape-changing factor of non-rectangular and deformable items was incorporated into the model. In the research of Elhedhli et al. [

14], another practical variant of 3D-BPP is addressed. The authors analyzed the mixed-case palletization problem, where item support with the presence of different sizes of items is considered. Elhedhli et al. proposed a novel problem formulation as well as a column-generation solution approach. El-Ashmawi and Elminaam [

15] concentrated on the design of an approximate algorithm of BPP applicable to solve large-scale instances within a reasonable time. They proposed a modified version of the squirrel search algorithm (SSA) for solving the 1D bin packing problem. In the experiments, hard class instances of up to 200 items were tested, and the obtained result was compared against other approximate algorithms such as particle swarm optimization (PSO), African buffalo optimization (ABO), and crow search algorithm (CSA).

A typical complex decision problem is usually a combination of packing and vehicle loading problems [

3,

4,

15]. In the work of Morabito et al. [

3], the optimal solution to the problem is presented. However, the mathematical model is not presented in detail. This concept is applied to solve the combined problem of pallet and vehicle loading, and the size of unit packages and the size of pallets and vehicles are also discussed. A two-phase approach with a packing problem is also considered by Moura and Bortfeld [

16]. In this approach, however, the main objective is to guarantee sufficient utilization of the truck loading space. Alonso et al. [

4] considered the problem of building and placing pallets on the truck at the same time, i.e., pallet loading as the first phase and truck loading as the second phase. The authors implemented several extended constraints, including the total weight of the load, the maximum weight supported by each vehicle’s axle, and the distribution of the load inside the vehicle. During the truck loading phase, it was allowed to stack one pallet on top of another. The model was constructed and solved with the GRASP algorithm, and the experiments were performed in the domain of the number of instances, vehicles, and computation time. Dell’Amico and Magnani [

2] have also proposed a two-phase procedure. In the first phase, 2D layers were defined, while in the second phase, the layers were combined on the minimum number of pallets. The authors constructed a specialized metaheuristic with a MILP model of a 3D problem, which was subsequently solved by the Gurobi solver. The experiments were performed in the domain of the number of instances and computation time. Contrary to the previous research on BPP and vehicle loading problems, Moura Santos et al. [

17] proposed the research on BPP with compatible categories, i.e., products that cannot be transported together. In this approach, the bin is the fleet of vehicles, and the problem is to allocate products with respect to the product categories. Moura Santos et al. concentrated on large instances of 200–1000 items, and they solved them with a variable neighborhood search (VNS) procedure. The experiments were also compared with alternative procedures.

There are several conclusions resulting from the state-of-the-art of the bin packing problem that should be highlighted, i.e.,

Numerous papers on BPP focus on the analysis of a wide spectrum of constraints that are either theoretical or practical. There is hardly any research on small-size pallets, i.e., substantially below the maximum height or weight of the PLU. It is a typical situation in contemporary logistics.

The BPP is an NP-hard decision problem, which is why a substantial number of studies have been carried out on the effectiveness of the optimization procedures.

The case when PLUs can be stacked one on top of another is referred to as a combined problem of pallet and vehicle loading. It is not, however, a widely discussed topic in the literature.

One specific way of formulating the BPP problem can be regarded as the inspiration for the formulation of the problem of stacking pallet load units, i.e., every single PLU can be treated as equivalent to a single layer considered in the PLU packing planning process.

1.3. Formulation of the Decision Problem

The article considers the problem of building stacked pallet load units (SPLUs) composed of elementary pallet load units (PLUs) whose height and gross weight parameters are significantly below the permissible values. Therefore, a mechanism is sought to plan the stacking of a set of PLUs in a way that will reduce the amount of space required on the load bed or in racking slots, while the parameters of the SPLUs built in this way should be within the permissible values of weight and height. It is assumed that the elementary PLUs are created in advance as a result of the adaptation to the specific requirements of the ordering party and may not be subject to content modification. It is also assumed that individual PLUs may contain homogeneous or mixed products, and the ordering party agrees to stack PLUs to form SPLUs.

The basic characteristics parameterizing the susceptibility of elementary PLUs to the formation of SPLUs include such parameters as gross weight and gross height, i.e., including the pallet itself, the fragility class of the stacked products, and the status of the PLUs resulting from the filling of its upper layers.

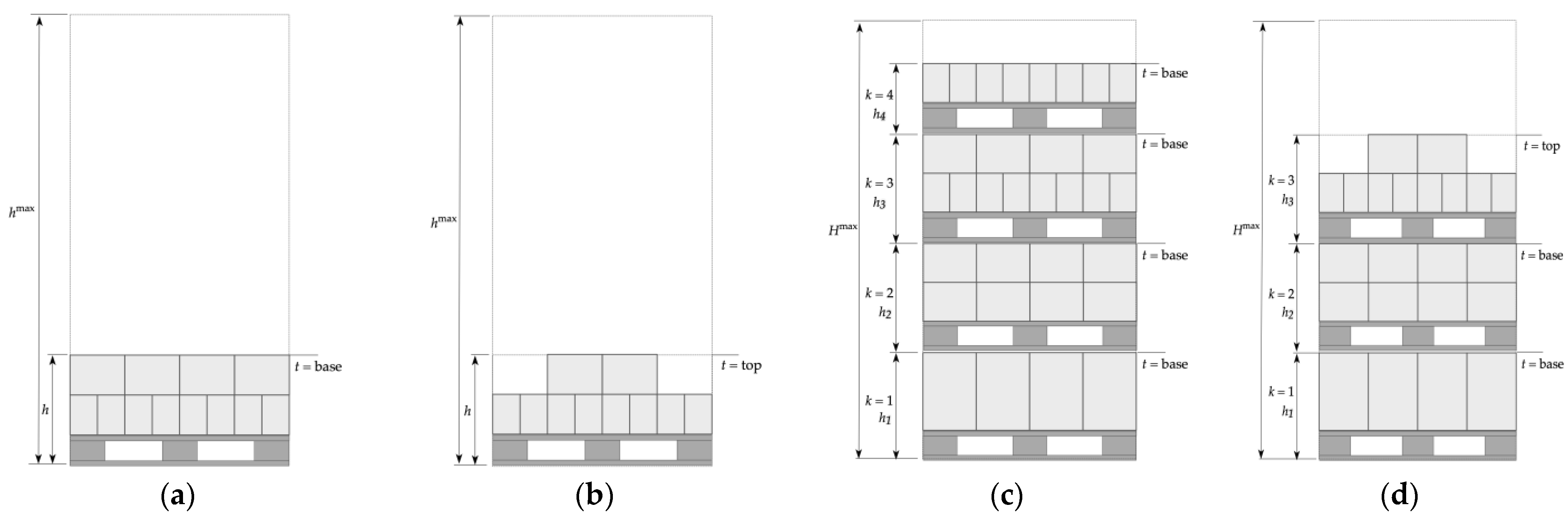

Figure 1a,b show elementary PLUs with a total height well below the limit value; the PLUs in

Figure 1a have a base status on which it is possible to stack more PLUs, and in

Figure 1b, a

top status: on this type of unit it is impossible to stack more PLUs.

Figure 1c,d show SPLUs built from elementary PLUs. In the case of (c), all PLUs have

base status, and in the case of (d), the highest layer is a

top-type PLU, which makes it impossible to build further layers on it.

1.4. Purpose and Scope of the Research

Based on the conclusions resulting from the state-of-the-art, see

Section 1.2, and based on the formulation of the research problem, see

Section 1.3, the purpose of the work was defined. The objective of the study is to develop a procedure to optimize the construction process of stacked pallet load units (SPLUs) built from elementary PLUs, taking into account, in addition to the classical limitations of the weight and height of the unit, the susceptibility of PLUs to the construction of successive layers, including the fragility of products, the flatness of the top layer of products contained on the PLU, and the filling of the top layer.

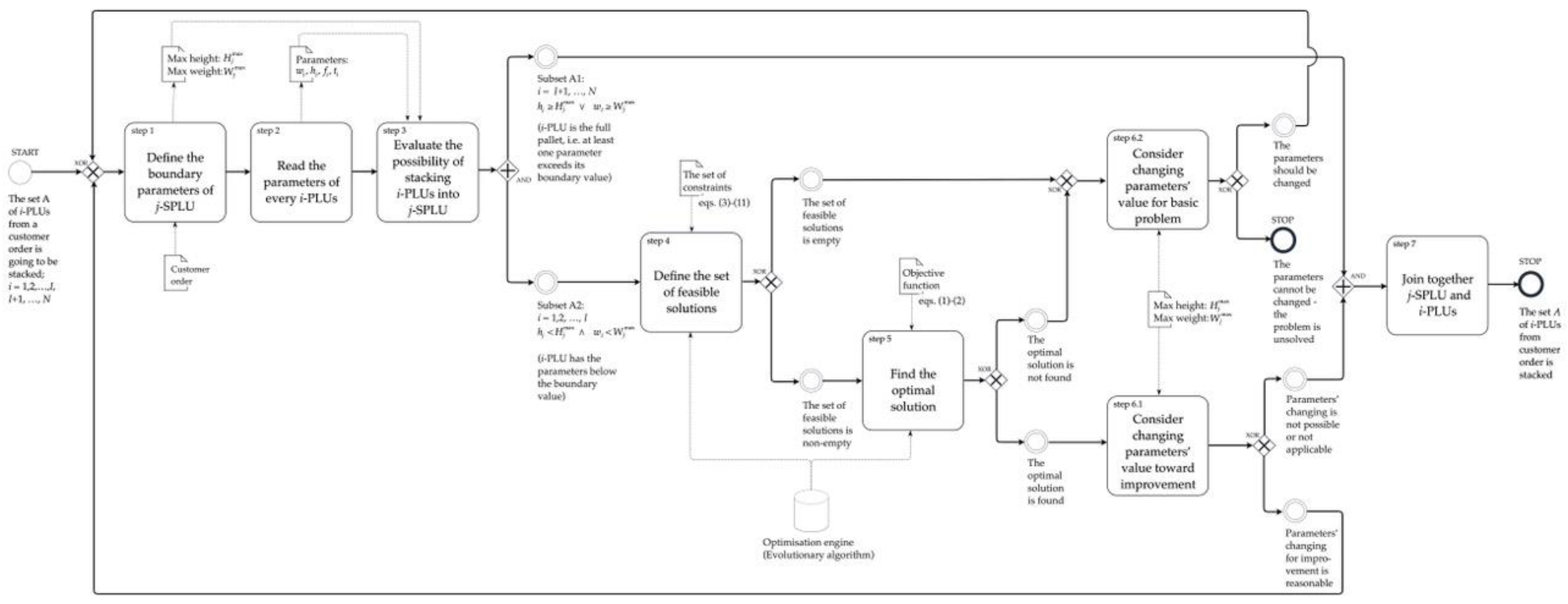

The article contains four key sections. In

Section 1, the need for PLU formation as a cost driver in transportation and warehousing processes is discussed, the decision problem is defined, and the research objective is formulated.

Section 2 presents the research methodology, including the definition of the objective function and a set of constraints; it also presents the assumptions for the proposed methodology, i.e., its applicability limits.

Section 3 presents the results of computational experiments; the methodology is verified based on a test dataset.

Section 4 is a summary of the article, where the obtained results are described with reference to the formulated purpose of the work, and the directions for further work are defined. Finally, a list of the literature used is presented.