Dynamic Analysis and Parameter Optimization of the Cutting System for Castor Harvester Picking Devices

Abstract

:1. Introduction

2. Materials and Methods

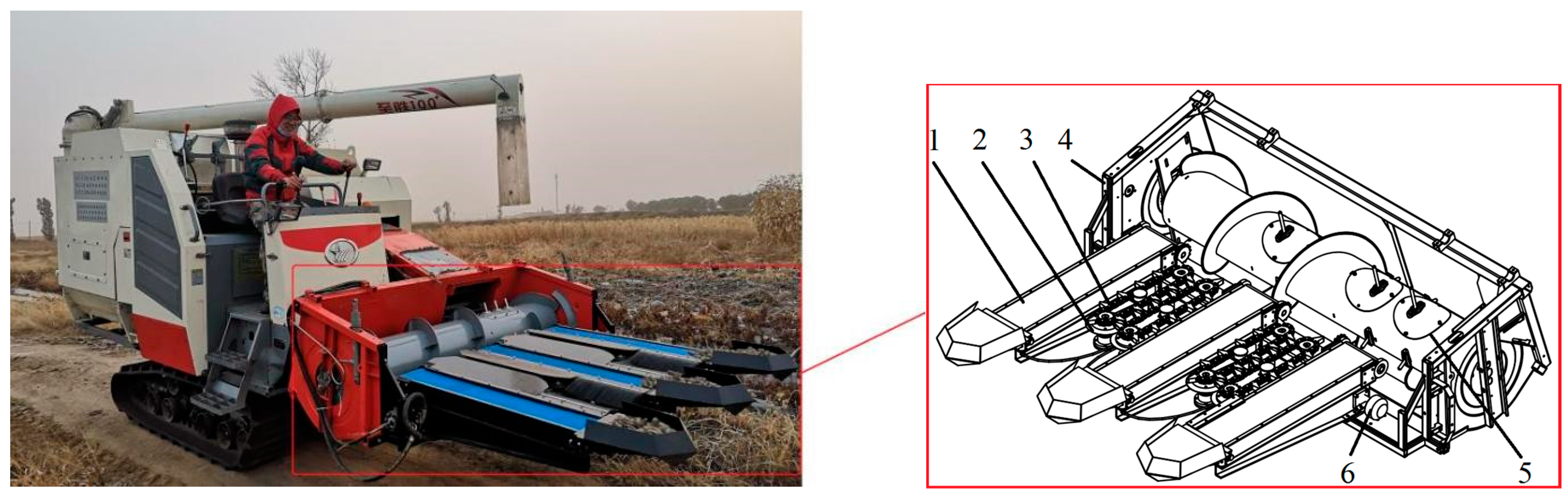

2.1. Machine Structure and Working Principles

2.1.1. Main Structure

2.1.2. Working Principles

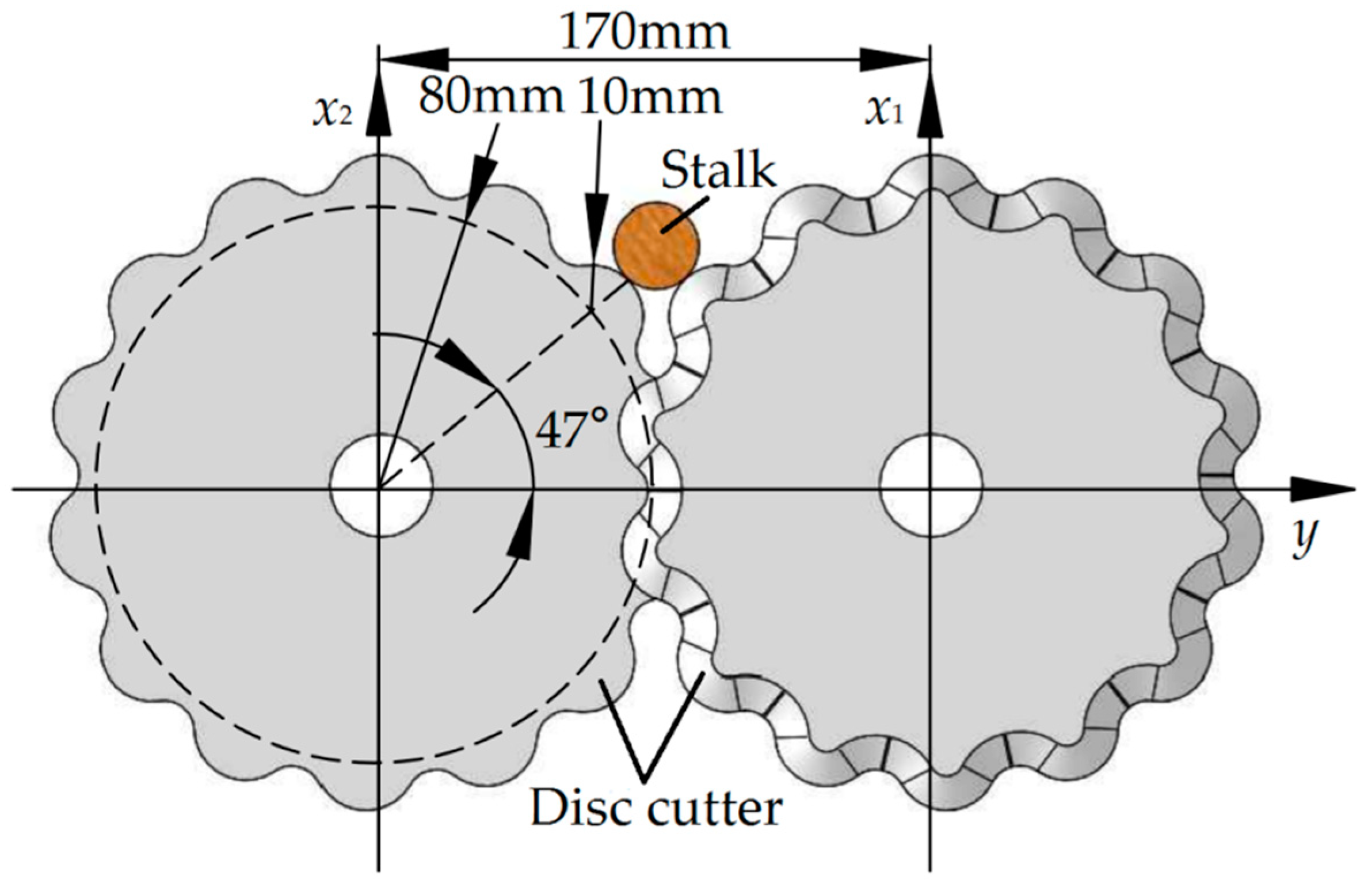

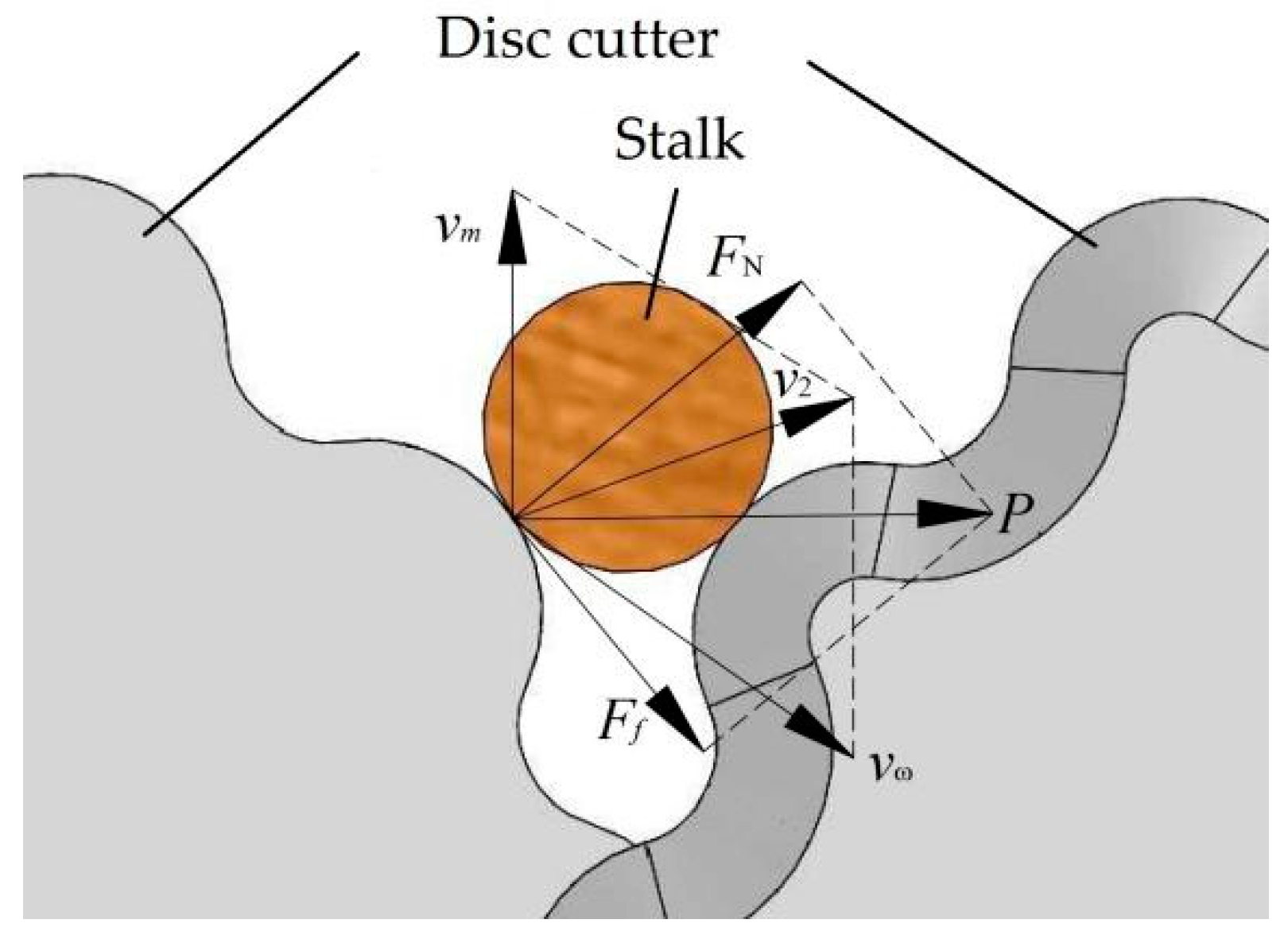

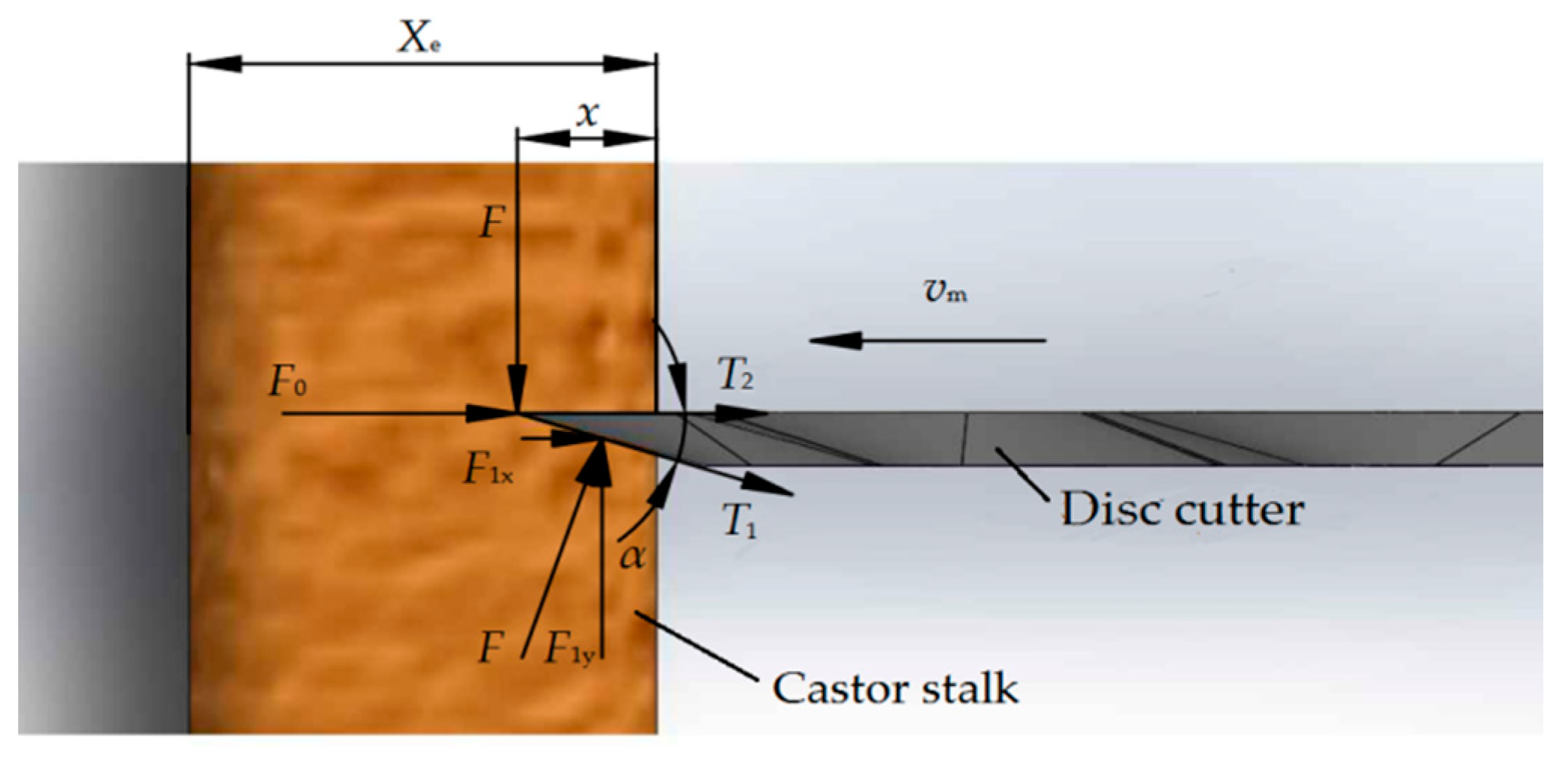

2.2. Mechanical Analysis

2.2.1. Contact Stage

2.2.2. Cutting Stage

2.3. Cutting Process Simulation Model

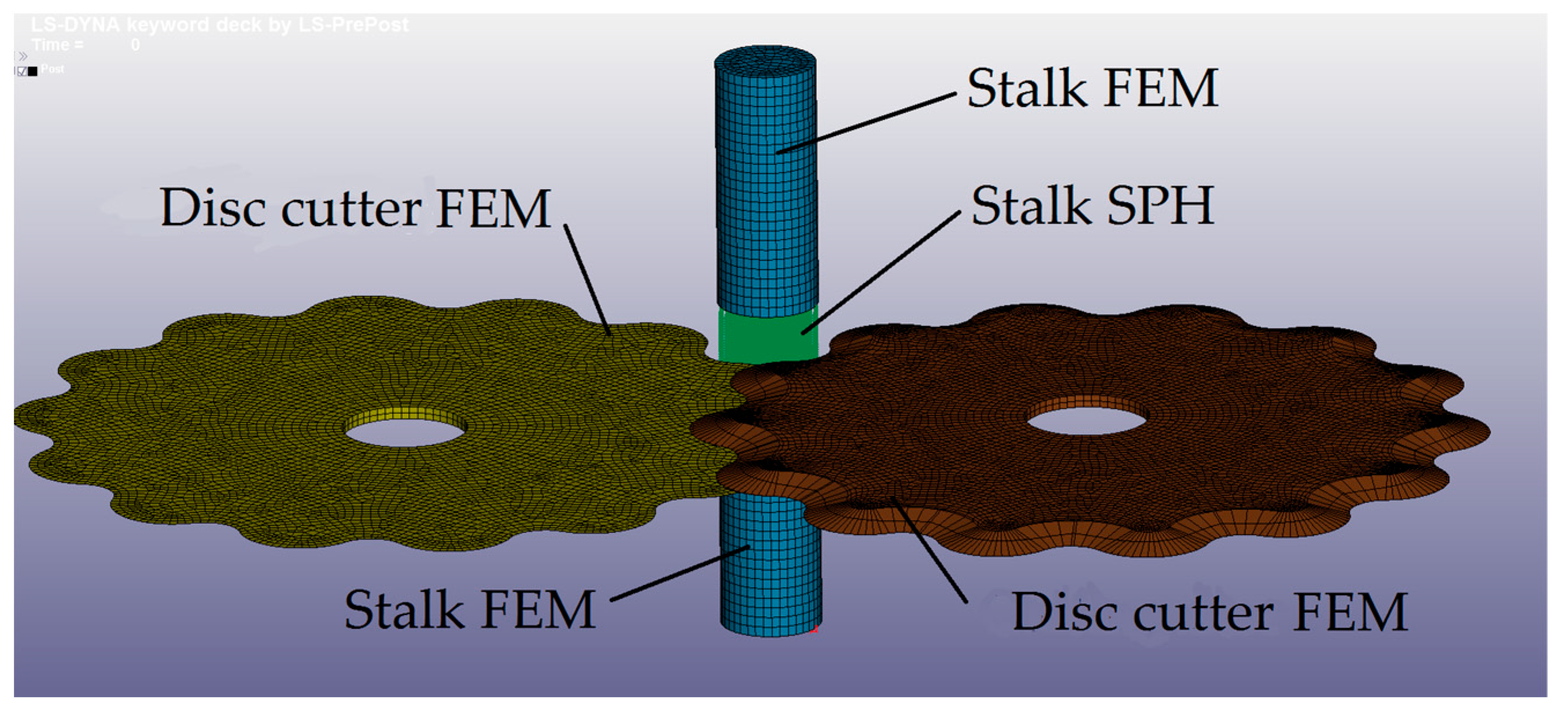

2.3.1. Simulation Model

2.3.2. Contact Erosion Definition and Loading

2.4. Simulation Test Design

2.4.1. Test Evaluation Index

2.4.2. Test Factors and Levels

3. Results Analysis and Optimization

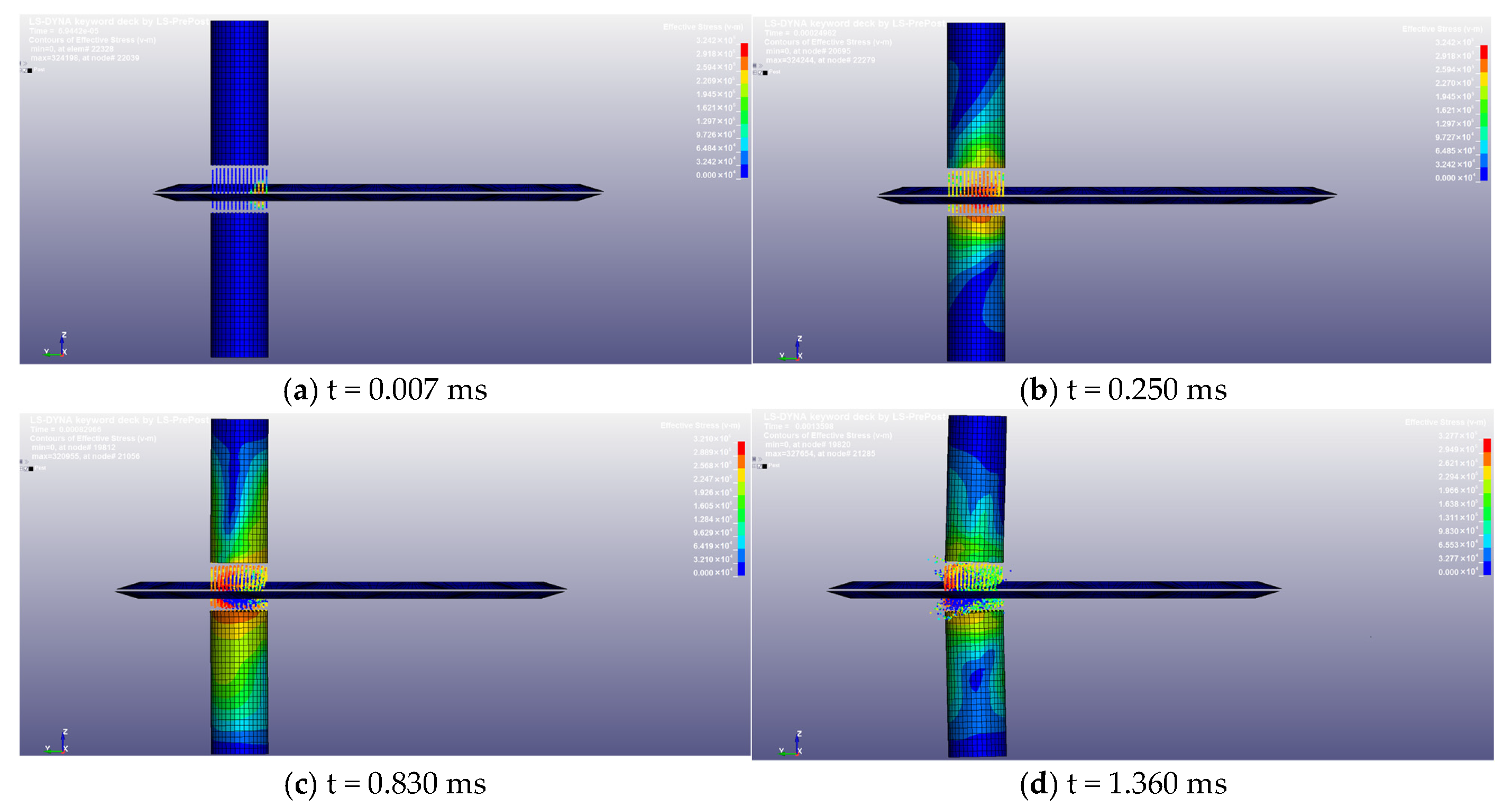

3.1. Simulation Results

3.2. Results and Analysis

3.3. Regression Equations

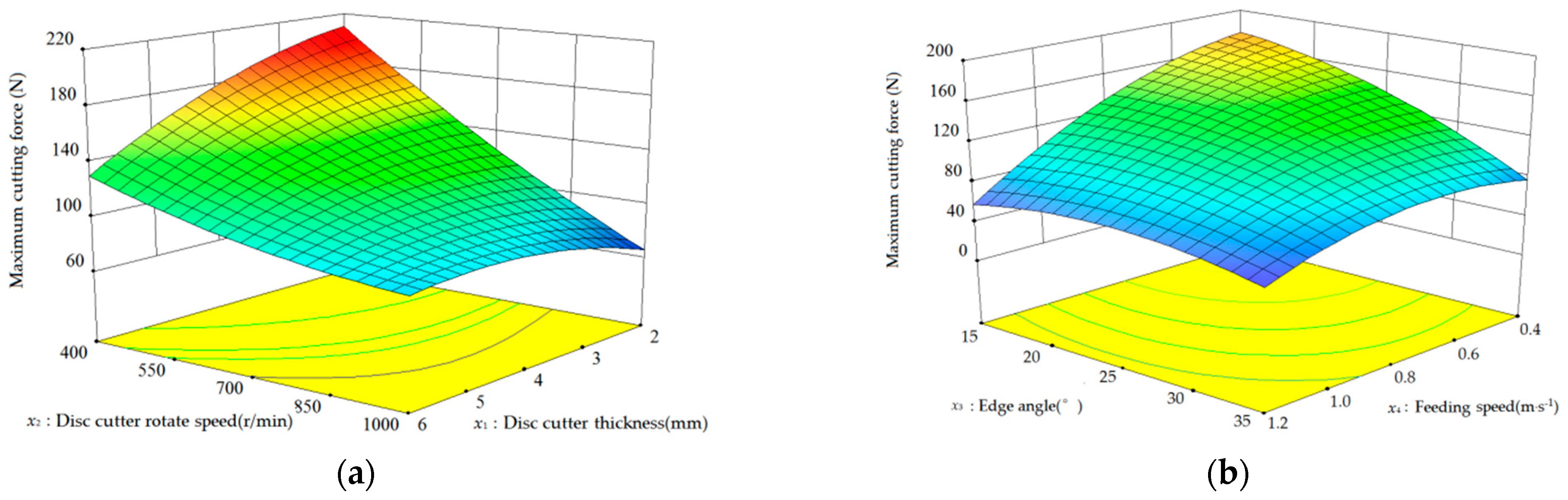

3.4. Analysis of the Response Surface

3.5. Parameter Optimization

4. Verification Test Results

4.1. Test Materials and Devices

4.2. Test Results

5. Conclusions

- (1)

- Simulation tests showed that the disc cutter rotation speed, feeding speed, disc cutter thickness, and edge angle had a highly significant influence on the maximum cutting force. The influence of each factor on the maximum cutting force was in the order of disc cutter rotation speed > feeding speed > edge angle > disc cutter thickness. The following optimal parameters were obtained: disc cutter thickness of 2.71–3.15 mm, disc cutter rotation speed of 844.2–942.1 r·min−1, feeding speed of 0.89–1.01 m·s−1, and edge angle of 29.2–33.9°, where the maximum cutting force was less than 50 N;

- (2)

- The operating parameters were set as follows: disc cutter thickness at 3 mm, disc cutter rotation speed at 942 r/min, feeding speed at 1.0 m/s, and edge angle at 30°, with a predicted maximum cutting force of 42.64 N. The verification test indicated that the maximum cutting force obtained by the SPH–FEM coupling simulation method was generally consistent with the castor-cutting bench test using the optimized combination of parameters and that there was no significant difference in the data obtained using the two methods. The simulation method can, therefore, be used to study castor harvester disc cutters and provides an effective method for further parameter optimization of castor disc cutters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alexopoulou, E.; Papatheohari, Y.; Zanetti, F.; Tsiotas, K.; Papamichael, I.; Christou, M.; Namatov, I.; Monti, A. Comparative studies on several castor (Ricinus communis L.) hybrids: Growth, yields, seed oil and biomass characterization. Ind. Crops Prod. 2015, 75, 8–13. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and Economic Assessment of Castor Oil Supply Chain:A Case Study. Sustainability 2020, 12, 6339. [Google Scholar] [CrossRef]

- Suurbaar, J.; Mosobil, R.; Donkor, A.M. Antibacterial and antifungal activities and phytochemical profle of leaf extract from diferent extractants of Ricinus communis against selected pathogens. BMC Res. Notes 2017, 10, 660. [Google Scholar] [CrossRef]

- Severino, L.S.; Auld, D.L. A framework for the study of the growth and development of castor plant. Ind. Crops Prod. 2013, 46, 25–38. [Google Scholar] [CrossRef]

- Baldanzi, M.; Fambrini, M.; Pugliesi, C. Redesign of the castorbean plant body plan for optimal combine harvesting. Ann. Appl. Biol. 2003, 142, 299–306. [Google Scholar] [CrossRef]

- Wu, C.F.; Chen, W.C.; Sheng, C.T. Study on the harvester development of ricinus communis. J. Agric. Fore. 2013, 62, 33–44. [Google Scholar]

- Liu, L.; Wu, T.; Kong, F.T.; Sun, Y.F.; Chen, C.L.; Xie, Q.; Shi, L. Optimized design and experiment of the picking mechanism for brush-roller castor harvesters. Trans. Chin. Soc. Agric. Eng. 2021, 37, 19–29. [Google Scholar]

- Stefanoni, W.; Latterini, F.; Malkogiannidis, V.; Salpiggidis, V.; Alexopoulou, E.; Pari, L. Mechanical Harvesting of Castor Bean (Ricinus communis L.)with a Combine Harvester Equipped with Two Different Headers: A Comparison of Working Performance. Energies 2022, 15, 2999. [Google Scholar] [CrossRef]

- Rostek, T.; Homberg, W. Locally graded steel materials for self-sharpening cutting blades. Procedia Eng. 2017, 207, 2185–2190. [Google Scholar] [CrossRef]

- Song, Y.P.; Wu, K.; Wang, W. Fabrication of self-sharpening blades via vacuum-rolling composite technology and its interfacial material microstruature and properties. Trans. Chin. Soc. Agric. Eng. 2020, 51 (Suppl. 2), 586–592. [Google Scholar]

- Momin, M.A.; Wempe, P.A.; Grift, T.E. Effects of four base cutter blade designs on sugarcane stem cut quality. Trans. ASABE 2017, 60, 1551–1560. [Google Scholar] [CrossRef]

- Wu, K.; Song, Y.P. Research progress analysis of crop stalk cutting theory and method. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–20. [Google Scholar] [CrossRef]

- Hang, H.D.; Wang, Y.X.; Tang, Y.Q.; Zhao, F.; Kong, X.F. Finite element simulation of sugarcane cutting. Trans. Chin. Soc. Agric. Eng. 2011, 27, 161–166. [Google Scholar] [CrossRef]

- Meng, Y.M.; Wei, J.D.; Wet, J.; Chen, H.; Cui, Y.S. An ANSYS/LS-DYNA simulation and experimental study of circular saw blade cutting system of mulberry cutting machine. Comput. Electron. Agric. 2019, 157, 38–48. [Google Scholar] [CrossRef]

- Xie, L.X.; Wang, J.; Cheng, S.M.; Zeng, B.S.; Yang, Z.Z. Optimisation and finite element simulation of the chopping process for chopper sugarcane harvesting. Biosyst. Eng. 2018, 175, 16–26. [Google Scholar] [CrossRef]

- Cao, W.B.; Sun, W.L.; Niu, C.; Jiao, H.B.; Chen, B.B. Combed Safflower Picking Device Based on ANSYS/LS DYNA. Trans. Chin. Soc. Agric. Mach. 2018, 49, 123–131. [Google Scholar]

- Souza, V.H.S.; Dias, G.L.; Santos, A.A.R.; Costa, A.L.G.; Santos, F.L.; Magalhães, R.R. Evaluation of the interaction between a harvester rod and a coffee branch based on finite element analysis. Comput. Electron. Agric. 2018, 150, 476–483. [Google Scholar] [CrossRef]

- Ibrahmi, A.; Bentaher, H.; Hbaieb, M.; Maalej, A.; Mouazen, A.M. Study the effect of tool geometry and operational conditions on mouldboard plough forces and energy requirement: Part 1. Finite element simulation. Comput. Electron. Agric. 2015, 117, 258–267. [Google Scholar] [CrossRef]

- Ahmadi, E.; Barikloo, H.; Kashfi, M. Viscoelastic finite element analysis of the dynamic behavior of apple under impact loading with regard to its different layers. Comput. Electron. Agric. 2016, 121, 1–11. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Kulasegaram, S.; Chen, P.; Chen, Y.Q. An efficient SPH methodology for modelling mechanical characteristics of particulate composites. Def. Technol. 2021, 17, 135–146. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Klippel, H.; Röthlin, M.; Wegener, K. An improved thermal model for SPH metal cutting simulations on GPU. Appl. Math. Model. 2021, 100, 728–750. [Google Scholar] [CrossRef]

- Song, H.; Pan, P.; Ren, G.; Yang, Z.; Xu, J. SPH/FEM modeling for laser-assisted machining of fused silica. Int. J. Adv. Manuf. Technol. 2020, 106, 5–6. [Google Scholar] [CrossRef]

- Hasanpour, A.; Istrati, D.; Buckle, I. Coupled SPH-FEM Modeling of Tsunami-Borne Large Debris Flow and Impact on Coastal Structures. J. Mar. Sci. Eng. 2021, 9, 1068. [Google Scholar] [CrossRef]

- Du, M.; Wang, H.; Dong, H.; Guo, Y.; Ke, Y. Numerical research on kerf characteristics of abrasive waterjet machining based on the SPH-DEM-FEM approach. Int. J. Adv. Manuf. Technol. 2020, 111, 3519–3533. [Google Scholar] [CrossRef]

- Liu, Q.T.; Qiu, Y.G.; Qing, S.L.; Wang, W.Z. Cutting Force Calculation of Sugarcane Stalk. Trans. Chin. Soc. Agric. Mach. 2006, 37, 89–92. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H.S.; Wang, Q.C.; Chen, Z.J. Influencing Factors of Cutting Force for Apple Tree Branch Pruning. Agriculture 2022, 12, 312. [Google Scholar] [CrossRef]

- Wang, T.; Liu, Z.; Yan, X.; Mi, G.; Liu, S.; Chen, K.; Zhang, S.; Wang, X.; Zhang, S.; Wu, X. Finite Element Model Construction and Cutting Parameter Calibration of Wild Chrysanthemum Stem. Agriculture 2022, 12, 894. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, X.; Ma, L.; Zong, W.; Zhan, G.; Lin, Z. Design and Test of Static Sliding Cut Angle Constant Cutting Machine for Chain Oil Sunflower Harvester Header. Trans. Chin. Soc. Agric. Mach. 2021, 52, 99–108. [Google Scholar] [CrossRef]

- Xun, X.L.; You, Y.; Wang, D.C.; Li, S.B.; Zhu, L.; Liao, L.L. Design and Experiment of Rotary Cutter Disc Type Flat Stubble Cutting Device for King Grass Harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 112–124. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, D.; Li, W.; Huang, Y.; Zhu, R. Design and experiment of two-disc rotary mower of alfalfa. Trans. Chin. Soc. Agric. Mach. 2018, 49, 214–220. [Google Scholar] [CrossRef]

- Liu, F.J.; Yang, X.J.; Fang, X.F. Design and experiment of chopper divice in sugarcane harvester. Trans. Chin. Soc. Agric. Mach. 2018, 49, 90–94. [Google Scholar] [CrossRef]

- Kong, F.T.; Wang, D.F.; Shi, L.; Wu, T.; Chen, C.L.; Sun, Y.F.; Xie, Q. Design and experiment of disc-cutting picking device of castor. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–9. [Google Scholar] [CrossRef]

- Wang, M.W.; Xue, Z.; Song, D.Q.; Zhang, L.F.; Zhang, J. Model analysis of cassavastalk cutter based on ANSYS. J. Chin. Agric. Mech. 2016, 37, 102–105+117. [Google Scholar] [CrossRef]

- Hou, J.M.; Bai, J.B.; He, T.; Yang, Y.; Li, J.P.; Yao, E.C. Design and Experiment of Castor Dehulling and Cleaning Device with Double Curved Table. Trans. Chin. Soc. Agric. Mach. 2018, 49, 132–140. [Google Scholar] [CrossRef]

- Ugwu, K.C.; Egwuagu, O.M.; Omoruyi, A. Determination of some mechanical and aerodynamic properties of castor fruits and seeds. Int. J. Sci. Eng. Res. 2015, 6, 659–666. [Google Scholar]

- Lorestani, A.N.; Jaliliantabar, F.; Gholami, R. Physical and mechanical properties of castor seed. Qual. Assur. Saf. Crops Foods 2013, 4, e29–e32. [Google Scholar] [CrossRef]

- Hou, J.M.; Bai, J.G.; Yao, E.C.; Zhu, H.J. Design and Parameter Optimization of Disc Type Cutting Device for Castor Stem. ACCESS 2020, 8, 191152–191162. [Google Scholar] [CrossRef]

| Item | Values | Item | Values |

|---|---|---|---|

| Boundary dimension/(mm × mm × mm) | 2360 × 2262 × 567 | Working width/(mm) | 1500 |

| Working speed/(m·s−1) | 0~1.58 | Rows picked/row | 2 |

| Stalk | Density (kg·m−3) | Elasticity Modulus (MPa) | Poisson’s Ratio | Shear Modulus (MPa) | Yield Strength (MPa) |

|---|---|---|---|---|---|

| Value | 1080 | 13.3 | 0.252 | 4.37 | 110 |

| level | Disc Cutter Thickness (mm) | Disc Cutter Rotation Speed (r∙min−1) | Feeding Speed (m∙s−1) | Edge Angle (°) |

|---|---|---|---|---|

| −2 | 2 | 400 | 0.4 | 15 |

| −1 | 3 | 550 | 0.6 | 20 |

| 0 | 4 | 700 | 0.8 | 25 |

| 1 | 5 | 850 | 1.0 | 30 |

| 2 | 6 | 1000 | 1.2 | 35 |

| Serial Number | Disc Cutter Thickness (mm) | Disc Cutter Rotation Speed (r∙min−1) | Feeding Speed (m∙s−1) | Edge Angle (°) | Maximum Cutting Force Y1 (N) |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 | 134.7 |

| 2 | −1 | 1 | −1 | 1 | 86.3 |

| 3 | 1 | −1 | −1 | 1 | 143.9 |

| 4 | 0 | 0 | 0 | 0 | 128.7 |

| 5 | 1 | 1 | 1 | −1 | 71.2 |

| 6 | −1 | 1 | 1 | 1 | 56.4 |

| 7 | 0 | 0 | 2 | 0 | 74.4 |

| 8 | 0 | 0 | 0 | −2 | 144.2 |

| 9 | 0 | 0 | 0 | 0 | 124.7 |

| 10 | 1 | −1 | −1 | −1 | 146.3 |

| 11 | −2 | 0 | 0 | 0 | 133.8 |

| 12 | −1 | −1 | −1 | −1 | 198.1 |

| 13 | 2 | 0 | 0 | 0 | 107.2 |

| 14 | 0 | −2 | 0 | 0 | 181.6 |

| 15 | 0 | 0 | 0 | 0 | 113.7 |

| 16 | 1 | −1 | 1 | −1 | 100.1 |

| 17 | 0 | 0 | 0 | 0 | 124.7 |

| 18 | −1 | −1 | 1 | 1 | 120.6 |

| 19 | −1 | −1 | −1 | 1 | 126.3 |

| 20 | 0 | 0 | 0 | 2 | 88.6 |

| 21 | 1 | 1 | 1 | 1 | 73.9 |

| 22 | 1 | 1 | −1 | 1 | 97.8 |

| 23 | 1 | −1 | 1 | 1 | 111.2 |

| 24 | 1 | 1 | −1 | −1 | 110.8 |

| 25 | −1 | −1 | 1 | −1 | 168.6 |

| 26 | −1 | 1 | 1 | −1 | 76.2 |

| 27 | 0 | 2 | 0 | 0 | 97.3 |

| 28 | −1 | 1 | −1 | −1 | 146.7 |

| 29 | 0 | 0 | 0 | 0 | 136.7 |

| 30 | 0 | 0 | −2 | 0 | 149.3 |

| Serials | Maximum Cutting Force Y1 (%) | |||

|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | F Value | p Value | |

| Model | 31,473.42 | 14 | 23 | <0.0001 |

| A | 1308.33 | 1 | 13.38 | 0.0023 |

| B | 13,272.81 | 1 | 135.78 | <0.0001 |

| C | 7625.54 | 1 | 78.01 | <0.0001 |

| D | 4076.83 | 1 | 41.71 | <0.0001 |

| AB | 627.5 | 1 | 6.42 | 0.0229 |

| AC | 2.89 | 1 | 0.03 | 0.8658 |

| AD | 2460.16 | 1 | 25.17 | 0.0002 |

| BC | 155 | 1 | 1.59 | 0.2272 |

| BD | 26.52 | 1 | 0.27 | 0.61 |

| CD | 547.56 | 1 | 5.6 | 0.0318 |

| A2 | 232 | 1 | 2.37 | 0.1442 |

| B2 | 91.77 | 1 | 0.94 | 0.3479 |

| C2 | 705.28 | 1 | 7.22 | 0.0169 |

| D2 | 424.35 | 1 | 4.34 | 0.0547 |

| Residual | 1466.25 | 15 | ||

| Lack of fit | 1122.75 | 10 | 1.63 | 0.3062 |

| Pure error | 343.5 | 5 | ||

| Total | 32,939.67 | 29 | ||

| Item | Optimization Value | Verification Test | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Maximum cutting force (N) | 42.64 | 43.5 | 45.8 | 46.1 | 41.5 | 46.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, F.; Wang, D.; Shi, L.; Huang, H.; Xie, Q.; Wu, T.; Sun, Y.; Chen, C. Dynamic Analysis and Parameter Optimization of the Cutting System for Castor Harvester Picking Devices. Appl. Sci. 2023, 13, 2116. https://doi.org/10.3390/app13042116

Kong F, Wang D, Shi L, Huang H, Xie Q, Wu T, Sun Y, Chen C. Dynamic Analysis and Parameter Optimization of the Cutting System for Castor Harvester Picking Devices. Applied Sciences. 2023; 13(4):2116. https://doi.org/10.3390/app13042116

Chicago/Turabian StyleKong, Fanting, Defu Wang, Lei Shi, Huinan Huang, Qing Xie, Teng Wu, Yongfei Sun, and Changlin Chen. 2023. "Dynamic Analysis and Parameter Optimization of the Cutting System for Castor Harvester Picking Devices" Applied Sciences 13, no. 4: 2116. https://doi.org/10.3390/app13042116

APA StyleKong, F., Wang, D., Shi, L., Huang, H., Xie, Q., Wu, T., Sun, Y., & Chen, C. (2023). Dynamic Analysis and Parameter Optimization of the Cutting System for Castor Harvester Picking Devices. Applied Sciences, 13(4), 2116. https://doi.org/10.3390/app13042116