Evaluation of the Effects of Different Packaging Materials on the Quality Attributes of the Tomato Fruit

Abstract

1. Introduction

2. Materials and Methods

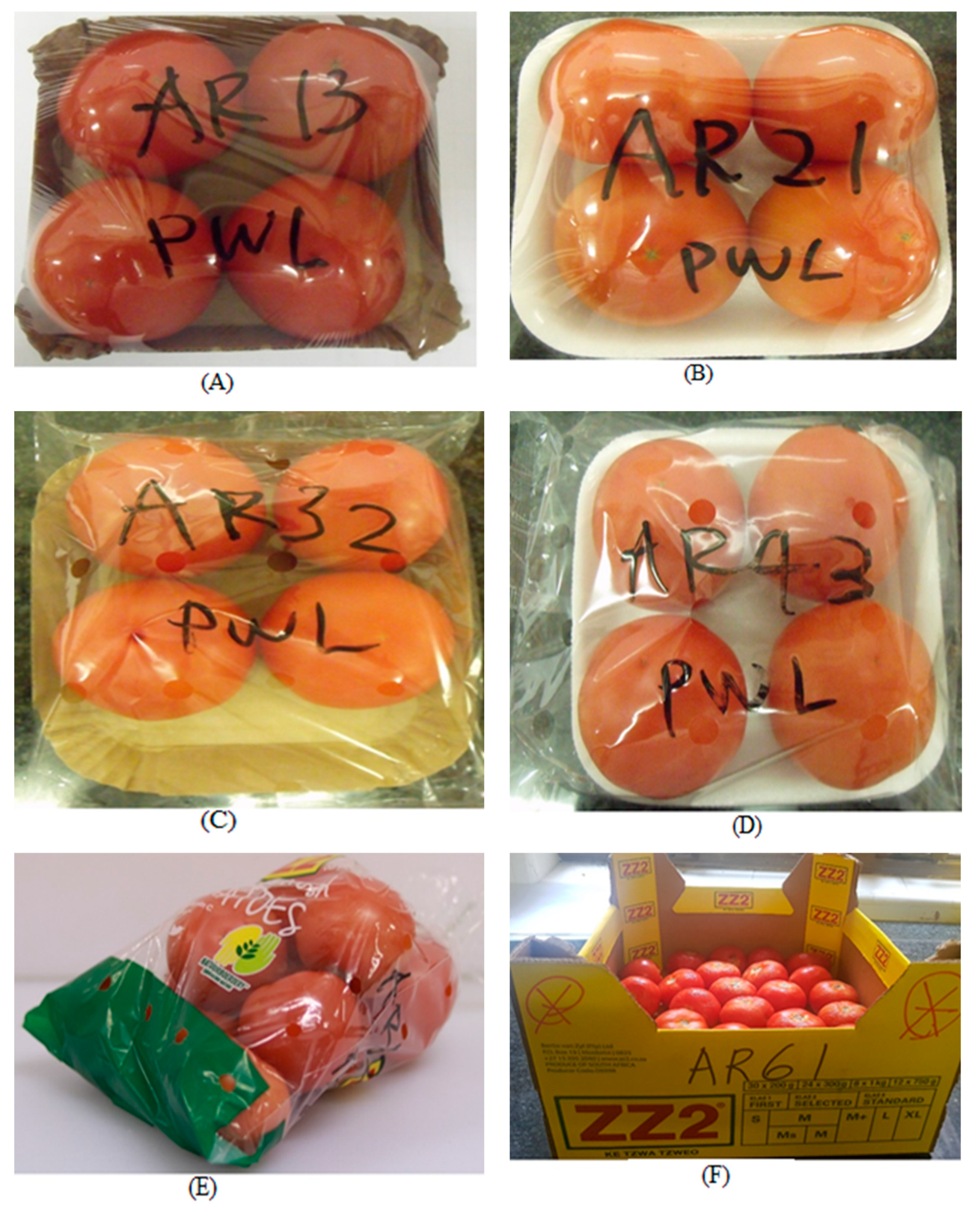

2.1. Packaging Materials

2.2. Storage Conditions

2.3. Firmness Analysis

2.4. Physiological Weight Loss

- the average weight of the tomato sample at Day 0

- the average weight tomato of the tomato sample on the final day

2.5. Titratable Acidity

2.6. pH Value

2.7. Total Sugars

2.8. Statistical Data Analysis

3. Results and Discussion

3.1. Physiological Weight Loss

3.2. Firmness

3.3. pH Value

3.4. Titratable Acidity

3.5. Total Sugars

4. Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nasir, M.U.; Hussain, S.; Jabbar, S. Tomato processing, lycopene and health benefits: A review. Sci. Lett. 2015, 3, 1–5. [Google Scholar]

- Azmai, W.N.S.M.; Latif, N.S.A.; Zain, N.M. Efficiency of edible coating chitosan and cinnamic acid to prolong the shelf life of tomatoes. J. Trop. Resour. Sustain. Sci. (JTRSS) 2019, 7, 47–52. [Google Scholar] [CrossRef]

- Hövelmann, Y.; Jagels, A.; Schmid, R.; Hübner, F.; Humpf, H.-U. Identification of potential human urinary biomarkers for tomato juice intake by mass spectrometry-based metabolomics. Eur. J. Nutr. 2020, 59, 685–697. [Google Scholar] [CrossRef] [PubMed]

- Bertin, N.; Génard, M. Tomato quality as influenced by preharvest factors. Sci. Hortic. 2018, 233, 264–276. [Google Scholar] [CrossRef]

- Osorio, S.; Carneiro, R.T.; Lytovchenko, A.; McQuinn, R.; Sørensen, I.; Vallarino, J.G.; Giovannoni, J.J.; Fernie, A.R.; Rose, J.K.C. Genetic and metabolic effects of ripening mutations and vine detachment on tomato fruit quality. Plant Biotechnol. J. 2020, 18, 106–118. [Google Scholar] [CrossRef]

- Wang, D.; Yeats, T.H.; Uluisik, S.; Rose, J.K.; Seymour, G.B. Fruit Softening: Revisiting the Role of Pectin. Trends Plant Sci. 2018, 23, 302–310. [Google Scholar] [CrossRef]

- Paolo, D.; Bianchi, G.; Scalzo, R.L.; Morelli, C.F.; Rabuffetti, M.; Speranza, G. The Chemistry behind Tomato Quality. Nat. Prod. Commun. 2018, 13, 1225–1232. [Google Scholar] [CrossRef]

- Dobrin, A.; Nedelus, A.; Bujor, O.; Mot, A.; Zugravu, M.; Badulescu, L. Nutritional Quality Parameters of the Fresh Red Tomato Varieties Cultivated in Organic System. Sci. Papers. Ser. B Hortic. 2019, 63, 439–443. [Google Scholar]

- Garuba, T.; Mustapha, O.; Oyeyiola, G. Shelf life and proximate composition of tomato (Solanum lycopersicum L.) fruits as influenced by storage methods. Ceylon J. Sci. 2018, 47, 387. [Google Scholar] [CrossRef]

- Abera, G.; Ibrahim, A.M.; Forsido, S.F.; Kuyu, C.G. Assessment on post-harvest losses of tomato (Lycopersicon esculentem Mill.) in selected districts of East Shewa Zone of Ethiopia using a commodity system analysis methodology. Heliyon 2020, 6, e03749. [Google Scholar] [CrossRef]

- Oboulbiga, E.B.; Parkouda, C.; Sawadogo-Lingani, H.; Compaoré, E.W.R.; Sakira, A.K.; Traoré, A.S. Nutritional Composition, Physical Characteristics and Sanitary Quality of the Tomato Variety Mongol F1 from Burkina Faso. Food Nutr. Sci. 2017, 8, 444–455. [Google Scholar] [CrossRef]

- Margeirsson, B.; Gospavic, R.; Pálsson, H.; Arason, S.; Popov, V. Experimental and numerical modelling comparison of thermal performance of expanded polystyrene and corrugated plastic packaging for fresh fish. Int. J. Refrig. 2011, 34, 573–585. [Google Scholar] [CrossRef]

- Song, X.-C.; Wrona, M.; Nerin, C.; Lin, Q.-B.; Zhong, H.-N. Volatile non-intentionally added substances (NIAS) identified in recycled expanded polystyrene containers and their migration into food simulants. Food Packag. Shelf Life 2019, 20, 100318. [Google Scholar] [CrossRef]

- Lee, J.-S.; Lee, Y.-S. Effect of Packaging Methods on Postharvest Quality of Tah Tasai Chinese Cabbage (Brassica campestris var. narinosa) Baby Leaf Vegetable. Korean J. Food Preserv. 2012, 19, 1–6. [Google Scholar] [CrossRef]

- Sirisomboon, P.; Tanaka, M.; Kojima, T. Evaluation of tomato textural mechanical properties. J. Food Eng. 2012, 111, 618–624. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 14th ed.; Association of Official Analytical: Chemists, VA, USA, 1984; pp. 414–420. [Google Scholar]

- Domínguez, I.; Ferreres, F.; del Riquelme, F.P.; Font, R.; Gil, M.I. Influence of preharvest application of fungicides on the postharvest quality of tomato (Solanum lycopersicum L.). Postharvest Biol. Technol. 2012, 72, 1–10. [Google Scholar] [CrossRef]

- Tigist, M.; Workneh, T.S.; Woldetsadik, K. Effects of variety on the quality of tomato stored under ambient conditions. J. Food Sci. Technol. 2013, 50, 477–486. [Google Scholar] [CrossRef]

- Pinela, J.; Barros, L.; Carvalho, A.M.; Ferreira, I.C.F.R. Nutritional composition and antioxidant activity of four tomato (Lycopersicon esculentum L.) farmer’ varieties in Northeastern Portugal homegardens. Food Chem. Toxicol. 2012, 50, 829–834. [Google Scholar] [CrossRef]

- Fawuyini, J.; Patrick, O.A.; Sedar, A. Effect of maturity stage on quality and shelf life of tomato (Lycopersicon esculentum mill.) using the refrigerator storage system. Eurasian J. Agric. Res. 2020, 4, 23–44. [Google Scholar]

- Sammi, S.; Masud, T. Effect of different packaging systems on the quality of tomato (Lycopersicon esculentum var. Rio Grande) fruits during storage. Int. J. Food Sci. Technol. 2009, 44, 918–926. [Google Scholar] [CrossRef]

- Asem, A.; Arisha, H.; Bardisi, A.; Ibraheim, S.K.A. Effect of some packaging materials on quality attributes of tomato fruits (Solanum lycopersicum L.) during cold storage and after shelf life period. Middle East J. Agric. Res. 2016, 5, 687–700. [Google Scholar]

- Gebeyehu, A.S. The Effects of Packaging Materials on Post Harvest Quality of Tomato (Solanum lycopersicum). J. Nat. Sci. Res. 2018, 8, 97–103. [Google Scholar]

- Tilahun, S.; Park, D.S.; Taye, A.M.; Jeong, C.S. Effects of Storage Duration on Physicochemical and Antioxidant Properties of Tomato (Lycopersicon esculentum Mill.). Korean J. Hortic. Sci. 2017, 35, 89–97. [Google Scholar] [CrossRef]

- Albaloushi, N.; Azam, M.; Amer Eissa, A. Mechanical Properties of Tomato Fruits Under Storage Conditions. J. Appl. Sci. Res. 2012, 8, 3053–3064. [Google Scholar]

- Tilahun, S. Feasibility and economic evaluation of low-cost evaporative cooling system in fruit and vegetables storage. Afr. J. Food Agric. Nutr. Dev. 2010, 10, 2984–2997. [Google Scholar] [CrossRef]

- Barrett, D.M.; Garcia, E.; Wayne, J.E. Textural Modification of Processing Tomatoes. Crit. Rev. Food Sci. Nutr. 1998, 38, 173–258. [Google Scholar] [CrossRef]

- Olveira-Bouzas, V.; Pita-Calvo, C.; Vázquez-Odériz, M.L.; Romero-Rodríguez, M. Evaluation of a modified atmosphere packaging system in pallets to extend the shelf-life of the stored tomato at cooling temperature. Food Chem. 2021, 364, 130309. [Google Scholar] [CrossRef]

- Azene, M.; Workneh, T.S.; Woldetsadik, K. Effect of packaging materials and storage environment on postharvest quality of papaya fruit. J. Food Sci. Technol. 2014, 51, 1041–1055. [Google Scholar] [CrossRef]

- Anthon, G.E.; LeStrange, M.; Barrett, D.M. Changes in pH, acids, sugars and other quality parameters during extended vine holding of ripe processing tomatoes. J. Sci. Food Agric. 2011, 91, 1175–1181. [Google Scholar] [CrossRef]

- Cherono, K.; Sibomana, M.; Workneh, T.S. Effect of infield handling conditions and time to pre-cooling on the shelf-life and quality of tomatoes. Braz. J. Food Technol. 2018, 21, e2017016. [Google Scholar] [CrossRef]

- Adhikari, P.; Dhakal, A.; Pahadi, K.; Adhikari, S.; Ghimire, P.; Subedi, S.; Ghimire, D. Effect of different plastic packaging on postharvest quality of tomato (Lycopersicon esculentum Mill.). Trop. Agroecosys. 2020, 1, 15–18. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R. Chemical and nutritional quality changes of tomato during postharvest transportation and storage. J. Saudi Soc. Agric. Sci. 2021, 20, 401–408. [Google Scholar] [CrossRef]

- Tolasa, M.; Gedamu, F.; Woldetsadik, K. Impacts of harvesting stages and pre-storage treatments on shelf life and quality of tomato (Solanum lycopersicum L.). Cogent Food Agric. 2021, 7, 1863620. [Google Scholar] [CrossRef]

- Shehata, S.A.; Abdelrahman, S.Z.; Megahed, M.M.A.; Abdeldaym, E.A.; El-Mogy, M.M.; Abdelgawad, K.F. Extending Shelf Life and Maintaining Quality of Tomato Fruit by Calcium Chloride, Hydrogen Peroxide, Chitosan, and Ozonated Water. Horticulturae 2021, 7, 309. [Google Scholar] [CrossRef]

- Tolesa, G.N.; Workneh, T.S. Influence of storage environment, maturity stage and pre-storage disinfection treatments on tomato fruit quality during winter in KwaZulu-Natal, South Africa. J. Food Sci. Technol. 2017, 54, 3230–3242. [Google Scholar] [CrossRef] [PubMed]

- Giannakourou, M.; Tsironi, T. Application of Processing and Packaging Hurdles for Fresh-Cut Fruits and Vegetables Preservation. Foods 2021, 10, 830. [Google Scholar] [CrossRef]

- Ivonkovic, A.; Zeljko, K.; Talic, S.; Lasic, M. Biodegradable packaging in the food industry. J. Food Saf. Food Qual. 2017, 68, 26–38. [Google Scholar] [CrossRef]

- Cantwell, M.; Nie, X.; Hong, G. Impact of storage conditions on grape tomato quality. In Proceedings of the 6th ISHS Postharvest Symposium, Antalya, Turkey, 8–12 April 2009. [Google Scholar]

- Farooq, S.; Rather, S.A.; Gull, A.; Ganai, S.A.; Masoodi, F.; Wani, S.M.; Ganaie, T.A. Physicochemical and nutraceutical properties of tomato powder as affected by pretreatments, drying methods, and storage period. Int. J. Food Prop. 2020, 23, 797–808. [Google Scholar] [CrossRef]

- Charles, M.T.; Arul, J.; Charlebois, D.; Yaganza, E.-S.; Rolland, D.; Roussel, D.; Merisier, M.J. Postharvest UV-C treatment of tomato fruits: Changes in simple sugars and organic acids contents during storage. LWT 2016, 65, 557–564. [Google Scholar] [CrossRef]

- Oms-Oliu, G.; Hertog, M.L.A.T.M.; Van de Poel, B.; Ampofo-Asiama, J.; Geeraerd, A.H.; Nicolai, B.M. Metabolic characterization of tomato fruit during preharvest development, ripening, and postharvest shelf-life. Postharvest Biol. Technol. 2011, 62, 7–16. [Google Scholar] [CrossRef]

| Package Treatment | Storage Conditions | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| SP Tray + PVC wrap | Cold | 0.00 a | 2.42 ± 0.36 b–k | 3.23 ± 0.14 f–m | 4.22 ± 0.20 j–q | 5.45 ± 0.60 n–r |

| Ambient | 0.00 a | 3.44 ± 0.13 g–m | 4.80 ± 0.24 l–r | 5.67 ± 1.49 o–s | 8.64 ± 0.07 tu | |

| EPS Tray + PVC wrap | Cold | 0.00 a | 0.23 ± 0.03 a | 0.77 ± 0.04 a–d | 1.28 ± 0.08 a–g | 1.78 ± 0.11 a–i |

| Ambient | 0.00 a | 1.17 ± 0.67 a–f | 3.20 ± 1.13 f–m | 3.58 ± 0.32 h–o | 6.11 ± 1.19 qrs | |

| SP Tray + Flow wrap | Cold | 0.00 a | 0.57 ± 0.06 ab | 1.79 ± 0.20 a–i | 2.84 ± 0.39 c–m | 3.92 ± 0.50 i–p |

| Ambient | 0.00 a | 0.88 ± 0.08 a–e | 2.90 ± 0.20 d–m | 4.56 ± 0.28 k–q | 6.74 ± 0.38 rst | |

| EPS Tray + Flow wrap | Cold | 0.00 a | 0.58 ± 0.11 ab | 1.83 ± 0.43 a–i | 3.03 ± 0.64 e–m | 4.29 ± 0.91 j–q |

| Ambient | 0.00 a | 1.44 ± 0.95 a–h | 3.11 ± 0.31 f–m | 4.97 ± 0.44 m–r | 7.48 ± 0.89 stu | |

| 1 kg PP bag | Cold | 0.00 a | 0.62 ± 0.12 ab | 1.91 ± 0.26 a–i | 3.21 ± 0.49 f–m | 4.46 ± 0.59 k–q |

| Ambient | 0.00 a | 2.64 ± 3.46 b–l | 3.13 ± 1.09 f–m | 8.70 ± 3.26 tu | 9.34 ± 3.37 u | |

| Unpackaged (Control) | Cold | 0.00 a | 0.69 ± 0.12 abc | 2.19 ± 0.37 a–j | 4.14 ± 0.80 j–q | 6.00 ± 1.14 p–s |

| Ambient | 0.00 a | 1.91 ± 0.46 a–i | 4.86 ± 1.75 m–r | 8.51 ± 2.80 tu | 11.93 ± 3.70 v | |

| Packaging Treatment | Storage Conditions | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| SP Tray + PVC wrap | Cold | 155.5 v | 133.6 ± 0.01 n–t | 123.7 ± 0.01 j–q | 116.8 ± 16.83 f–n | 107.3 ± 2.63 c–i |

| Ambient | 155.5 v | 129.5 ± 0.01 m–t | 116.0 ± 0.06 f–m | 105.8 ± 1.72 c–h | 101.1 ± 0.01 c–g | |

| EPS Tray + PVC wrap | Cold | 155.5 v | 143.9 ± 5.64 s–v | 128.1 ± 0.01 m–t | 119.0 ± 0.01 g–p | 112.0 ± 0.01 e–l |

| Ambient | 155.5 | 126.3 ± 24.83 k–r | 115.4 ± 0.01 f–m | 113.4 ± 9.92 e–m | 103.4 ± 1.60 c–g | |

| SP Tray + Flow wrap | Cold | 155.5 v | 135.6 ± 0.010–t | 127.0 ± 0.01 l–s | 124.2 ± 0.01 i–q | 106.6 ± 0.01 c–h |

| Ambient | 155.5 uv | 129.5 ± 27.00 m–t | 123.6 ± 12.28 j–q | 96.2 ± 19.25 b–e | 92.8 ± 2.52 bcd | |

| EPS Tray + Flow wrap | Cold | 155.5 v | 145.9 ± 0.01 tuv | 133.8 ± 0.01 n–t | 128.6 ± 1.73 l–s | 99.8 ± 19.60 c–f |

| Ambient | 155.5 uv | 136.1 ± 0.01 p–t | 126.1 ± 0.01 k–r | 116.6 ± 0.01 f–m | 103.4 ± 12.61 c–g | |

| 1 kg PP bag | Cold | 155.5 uv | 129.9 ± 8.87 m–t | 129.5 ± 0.01 m–t | 112.9 ± 4.41 e–m | 108.6 ± 0.01 d–j |

| Ambient | 155.5 uv | 116.2 ± 0.01 f–m | 113.9 ± 15.00 f–m | 81.6 ± 13.75 ab | 93.7 ± 0.64 bcd | |

| Unpackaged (Control) | Cold | 155.5 uv | 138.8 ± 3.46 q–u | 124.7 ± 6.01 j–q | 110.9 ± 5.06 e–l | 105.5 ± 13.20 c–g |

| Ambient | 155.5 uv | 134.8 ± 0.010–t | 107.5 ± 0.01 c–j | 90.5 ± 22.04 bc | 72.8 ± 21.53 a | |

| Packaging Treatment | Storage Conditions | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| SP Tray + PVC wrap | Cold | 4.20 a | 4.51 ± 0.02 d–j | 4.42 ± 0.06 b–f | 4.48 ± 0.01 d–j | 4.47 ± 0.03 c–j |

| Ambient | 4.20 a | 4.55 ± 0.01 f–k | 4.45 ± 0.05 b–i | 4.54 ± 0.05 e–k | 4.58 ± 0.02 i–k | |

| EPS tray + PVC wrap | Cold | 4.20 a | 4.47 ± 0.23 c–i | 4.34 ± 0.01 b | 4.44 ± 0.07 b–g | 4.44 ± 0.03 b–f |

| Ambient | 4.20 a | 4.53 ± 0.03 e–j | 4.47 ± 0.03 c–j | 4.57 ± 0.06 g–k | 4.54 ± 0.01 e–k | |

| SP Tray + Flow wrap | Cold | 4.20 a | 4.42 ± 0.02 b–f | 4.34 ± 0.01 b | 4.35 ± 0.05 bc | 4.50 ± 0.01 d–j |

| Ambient | 4.20 a | 4.46 ± 0.05 b–i | 4.46 ± 0.05 b–i | 4.48 ± 0.02 d–j | 4.48 ± 0.04 d–j | |

| EPS Tray + Flow wrap | Cold | 4.20 a | 4.48 ± 0.16 d–j | 4.43 ± 0.02 b–f | 4.44 ± 0.01 b–g | 4.49 ± 0.06 d–j |

| Ambient | 4.20 a | 4.57 ± 0.11 h–k | 4.46 ± 0.03 b–i | 4.57 ± 0.03 g–k | 4.52 ± 0.06 e–j | |

| 1 kg PP bag | Cold | 4.20 a | 4.44 ± 0.06 b–h | 4.44 ± 0.04 b–f | 4.50 ± 0.02 d–j | 4.49 ± 0.04 d–j |

| Ambient | 4.20 a | 4.53 ± 0.03 e–j | 4.46 ± 0.05 b–i | 4.53 ± 0.09 e–j | 4.55 ± 0.03 f–k | |

| Unpackaged (control) | Cold | 4.20 a | 4.50 ± 0.06 d–j | 4.47 ± 0.18 c–j | 4.53 ± 0.01 e–j | 4.58 ± 0.02 i–k |

| Ambient | 4.20 a | 4.60 ± 0.01 jk | 4.50 ± 0.03 d–j | 4.66 ± 0.19 k | 4.60 ± 0.06 jk | |

| Packaging Treatment | Storage Condition | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| SP Tray + PVC wrap | Cold | 0.51 r | 0.50 ± 0.08 r | 0.43 ± 0.03 k–n | 0.38 ± 0.01 g–j | 0.26 ± 0.11 a–c |

| Ambient | 0.51 r | 0.46 ± 0.01 n–q | 0.39 ± 0.02 h–k | 0.35 ± 0.04 e–g | 0.24 ± 0.05 a | |

| EPS Tray + PVC wrap | Cold | 0.51 r | 0.45 ± 0.02 m–p | 0.40 ± 0.01 i–l | 0.36 ± 0.01 e–i | 0.38 ± 0.02 g–j |

| Ambient | 0.51 r | 0.43 ± 0.01 k–n | 0.35 ± 0.02 e–h | 0.30 ± 0.02 cd | 0.25 ± 0.02 ab | |

| SP Tray + Flow wrap | Cold | 0.51 r | 0.49 ± 0.01 p–r | 0.48 ± 0.01 o–r | 0.37 ± 0.01 e–i | 0.35 ± 0.03 e–g |

| Ambient | 0.51 r | 0.47 ± 0.01 n–r | 0.36 ± 0.02 e–i | 0.30 ± 0.02 cd | 0.24 ± 0.00 a | |

| EPS Tray + Flow wrap | Cold | 0.51 r | 0.46 ± 0.01 n–q | 0.43 ± 0.01 k–n | 0.38 ± 0.01 g–j | 0.33 ± 0.02 de |

| Ambient | 0.51 r | 0.41 ± 0.03 j–m | 0.37 ± 0.01 f–j | 0.29 ± 0.01 cd | 0.27 ± 0.02 a–c | |

| 1 kg PP bag | Cold | 0.51 r | 0.45 ± 0.00 n–p | 0.37 ± 0.01 e–i | 0.35 ± 0.01 e–g | 0.33 ± 0.03 d–f |

| Ambient | 0.51 r | 0.45 ± 0.01 m–p | 0.38 ± 0.00 g–j | 0.28 ± 0.01 bc | 0.28 ± 0.02 a–c | |

| Unpackaged (Control) | Cold | 0.51 r | 0.47 ± 0.03 o–r | 0.43 ± 0.01 l–n | 0.40 ± 0.02 i–l | 0.34 ± 0.02 e–g |

| Ambient | 0.51 r | 0.44 ± 0.00 m–o | 0.40 ± 0.04 i–l | 0.28 ± 0.02 a–c | 0.25 ±0.02 ab | |

| Packaging Treatment | Storage Condition | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| SP Tray + PVC wrap | Cold | 8.95 v | 7.69 ± 0.09 u | 6.58 ± 0.30 o–r | 5.96 ± 0.06 k–n | 5.06 ± 0.16 gh |

| Ambient | 8.95 v | 6.22 ± 0.05 m–p | 6.02 ± 0.44 k–n | 5.19 ± 0.03 g–j | 5.00 ± 0.05 gh | |

| EPS Tray + PVC wrap | Cold | 8.95 v | 7.564 ± 0.08 u | 6.67 ± 0.19 pqr | 6.57 ± 0.06 o–r | 6.11 ± 0.06 l–o |

| Ambient | 8.95 v | 6.40 ± 0.06 n–q | 6.01 ± 0.35 k–m | 6.04 ± 0.18 lmn | 5.76 ± 0.28 klm | |

| SP Tray + Flow wrap | Cold | 8.95 v | 6.02 ± 0.44 k–n | 5.88 ± 0.35 klm | 5.79 ± 0.53 klm | 5.64 ± 0.01 i–l |

| Ambient | 8.95 v | 5.64 ± 0.23 i–l | 5.63 ± 0.29 jkl | 5.52 ± 0.32 h–k | 4.43 ± 0.33 cde | |

| EPS Tray + Flow wrap | Cold | 8.95 v | 7.33 ± 0.07 tu | 6.95 ± 0.26 rst | 6.87 ± 0.39 q–t | 5.22 ± 0.58 g–j |

| Ambient | 8.95 v | 6.05 ± 0.13 lmn | 4.98 ± 0.06 fg | 4.41 ± 0.04 cde | 4.26 ± 0.32 bcd | |

| 1 kg PP bag | Cold | 8.95 v | 6.94 ± 0.21 rst | 6.19 ± 0.03 m–p | 5.16 ± 0.13 ghi | 3.96 ± 0.07 bc |

| Ambient | 8.95 v | 4.86 ± 0.69 efg | 4.79 ± 0.05 efg | 4.38 ± 0.02 cde | 3.87 ± 0.11 b | |

| Unpackaged (Control) | Cold | 8.95 v | 7.26 ± 0.22 stu | 6.82 ± 0.30 qrs | 5.07 ± 0.11 gh | 4.56 ± 0.00 def |

| Ambient | 8.95 v | 6.26 ± 0.72 m–p | 6.01 ± 0.08 k–n | 4.55 ± 0.79 def | 3.43 ± 0.13 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dladla, S.S.; Workneh, T.S. Evaluation of the Effects of Different Packaging Materials on the Quality Attributes of the Tomato Fruit. Appl. Sci. 2023, 13, 2100. https://doi.org/10.3390/app13042100

Dladla SS, Workneh TS. Evaluation of the Effects of Different Packaging Materials on the Quality Attributes of the Tomato Fruit. Applied Sciences. 2023; 13(4):2100. https://doi.org/10.3390/app13042100

Chicago/Turabian StyleDladla, Sandile Sifiso, and Tilahun Seyoum Workneh. 2023. "Evaluation of the Effects of Different Packaging Materials on the Quality Attributes of the Tomato Fruit" Applied Sciences 13, no. 4: 2100. https://doi.org/10.3390/app13042100

APA StyleDladla, S. S., & Workneh, T. S. (2023). Evaluation of the Effects of Different Packaging Materials on the Quality Attributes of the Tomato Fruit. Applied Sciences, 13(4), 2100. https://doi.org/10.3390/app13042100