Abstract

High-temperature heat pumps consist of a promising choice for substituting conventional boilers and producing hot water with temperature levels in the range of 70–80 °C. The use of high-temperature heat pumps makes it possible to exploit the existing radiators in existing buildings to achieve effective heating of the indoor space and keep thermal comfort at high standards. The goal of this work is the detailed investigation of a high-temperature heat pump, with the R1234ze(E) as the working medium for producing heating at 80 °C for space-heating purposes, in Greek climate conditions. The analysis was conducted at two locations, one in the south (Athens—Zone B) and one in the north (Thessaloniki—Zone C), in order to examine the performance of the study’s technology in the most representative locations of Greece. The thermodynamic analysis of the heat pump was performed with a developed model in Engineering Equation Solver by exploiting real data from the compressor manufacturer and by practically using a gray box model. The heating thermal loads were calculated with a dynamic analysis using TRNSYS software. According to the final results, the high-temperature heat pump was beneficial when compared to a conventional oil boiler from energy, financial, and environmental points of view. The net savings were found at EUR 6448 for Athens and EUR 13,161 for Thessaloniki; the simple payback period resulted in 8.03 years for Athens and 6.11 years for Thessaloniki, while the CO2 emissions avoidance was found at 35% for Athens and 32% for Thessaloniki. Last but not least, the lifetime CO2 emissions reduction was calculated at 20,882 kgCO2 for Athens and 35,278 kgCO2 for Thessaloniki.

1. Introduction

Heat pumps are efficient energy systems that can provide heating and cooling in buildings while consuming reasonable amounts of energy [1]. Vapor compression heat pumps are very common in the building sector [2], while absorption heat pumps are not so widespread, mainly due to their high investment cost [3]. The efficiency of a heat pump is restricted by the Carnot refrigeration cycle limit [4], which enables their operation with high values of the coefficient of performance (COP), and this result also makes it possible to achieve high exergy efficiency. This advantage makes heat pumps more efficient, cost-effective, and environmentally friendly technologies when compared to conventional boiler systems [5].

In the last years, the advantages of heat pumps have led governments to create laws and guidelines for the substitution of conventional boilers with heat pumps with the aim to reduce primary energy consumption and CO2 emissions [6]. This situation has created the need for developing robust and efficient heat pumps for operation at relatively high temperatures (e.g., at 80 °C) that substitute the oil boiler while keeping the existing terminal units, which are usually radiators [7]. This need is an important one in order to avoid the high retrofitting cost of the heating systems by keeping the pipelines and the terminal units in the buildings. Moreover, heating with radiators presents some important advantages, which are associated with better indoor conditions, which lead to higher thermal comfort standards, due to quiet operation [8], a reduced vertical temperature gradient [9], and less dust transportation [10].

The literature includes some studies regarding the use of heat pumps with radiator terminal units. Wang et al. [11] examined the use of a heat pump coupled to radiators for a case study in China. The examined heat pump used CO2 as the working fluid and the system COP was calculated at 1.7. Shao et al. [12] examined a high-temperature heat pump coupled to a radiator and found a mean COP of 2.59. Also, the use of cast-iron radiators coupled with heat pumps was found to lead to a COP in the range of 1.7 to 2.2, according to Bin et al. [13]. Moreover, they stated that the use of the radiator led to high-quality thermal comfort conditions. A comparative study [14] between a ground source heat pump and a coal boiler in China proved that the heat pump had a better economic performance.

Shah et al. [15] compared a gas boiler with a heat pump system operating at 75 °C, and they found that a COP of around 2 led to 12% CO2 emission savings. Moreover, they stated that the use of a thermal energy storage system can lead to increased performance, and it can be examined as an interesting choice. Le et al. [16] studied the use of an air-source heat pump coupled to thermal energy storage for heating and domestic hot water production. The COP of the system was found to be around 2. Another interesting work conducted in Italy [17] proved that the substitution of existing energy systems with heat pumps by keeping the radiators led to primary energy savings in the range of 12% to 56%. According to the results of Ref. [18], the use of a high-temperature air-to-water heat pump could decrease the primary energy demand by up to 54% in Milan, Italy, and by up to 60% in Salerno, Italy when compared to a conventional boiler system. Shao et al. [19] examined the idea of using refrigerant in radiators for achieving higher performance. This design enabled the operation of the heat pump at a lower condensation temperature. According to their results, the COP was found in the range of 1.8 to 3.9, and it was stated that this system is a competitive one compared to other heating systems. Moreover, it is useful to add that the use of binary mixtures as working fluid in high-temperature heat pumps can be a promising choice for reducing the exergy reduction losses in the heat transfer process [20]. Another option for increasing the performance of high-temperature heat pumps is the use of transcritical cycles [21].

The previous literature presentation shows an interest in the use of heat pumps in heating systems with radiators. Some studies examine ideas with thermal storage systems, with CO2 as the working fluid, and include some comparative investigations. However, there is a lack of studies that makes a frank comparison of an air-to-water heat pump and an oil boiler under dynamic operating conditions. Thus, the present work comes to cover this gap by performing a detailed dynamic comparison in energy, economic, and environmental terms. A high-temperature heat pump was properly designed with the environmentally friendly working fluid R1234ze(E) [22], and it was examined thermodynamically with a developed model in Engineering Equation Solver [23]. The comparison of the heat pump with the oil boiler was conducted for the climate conditions of Greece by selecting the most representative cities of Athens (south Greece—Zone B) and Thessaloniki (north Greece—Zone C). The thermal heating loads of the examined building were calculated with a developed model in TRNSYS software [24]. The final results include the calculation of the primary energy demand, the payback period of the heat pump installation, the life cycle cost analysis, and the CO2 emissions avoidance.

2. Material and Methods

2.1. The Examined Space Heating Systems

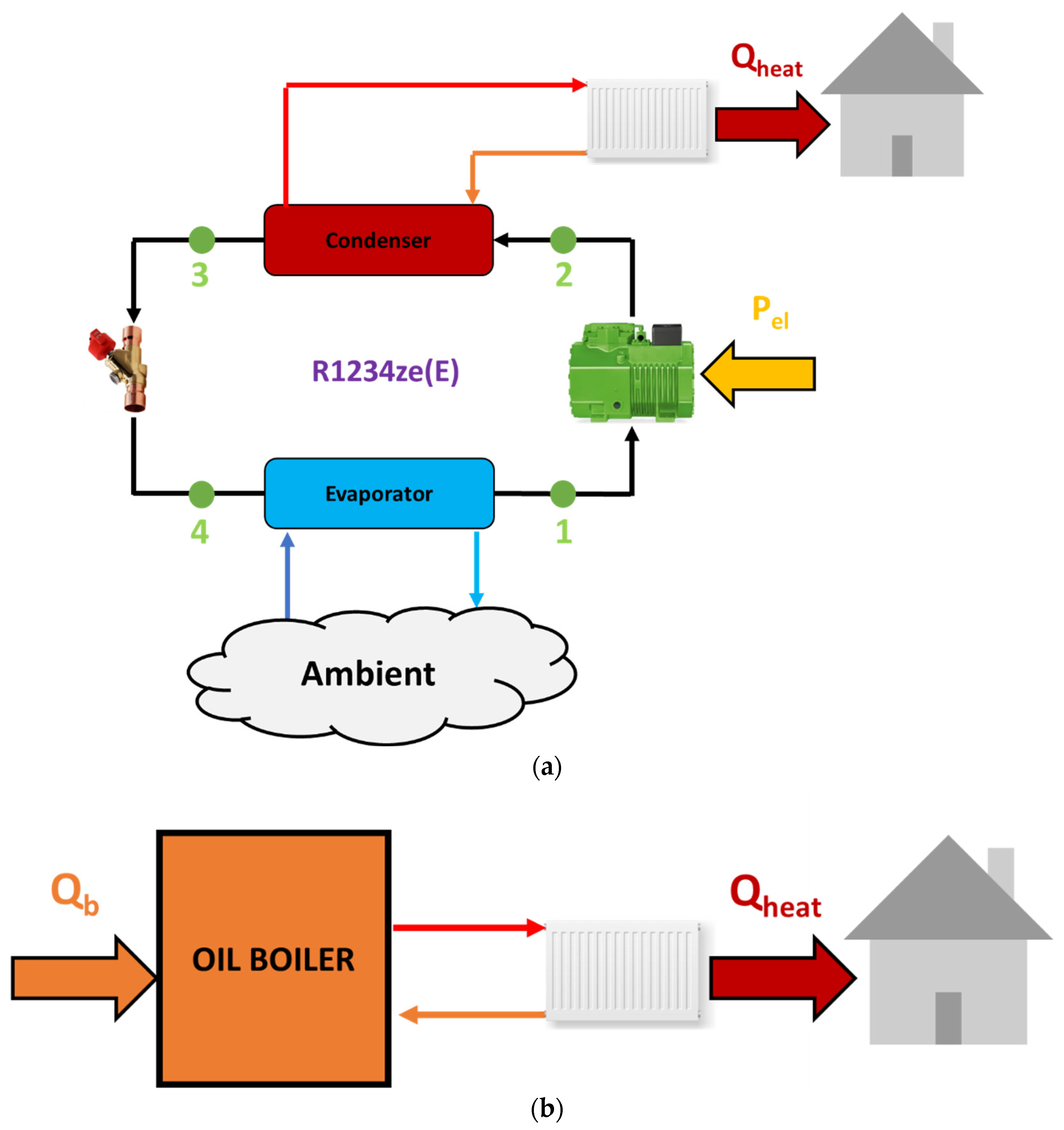

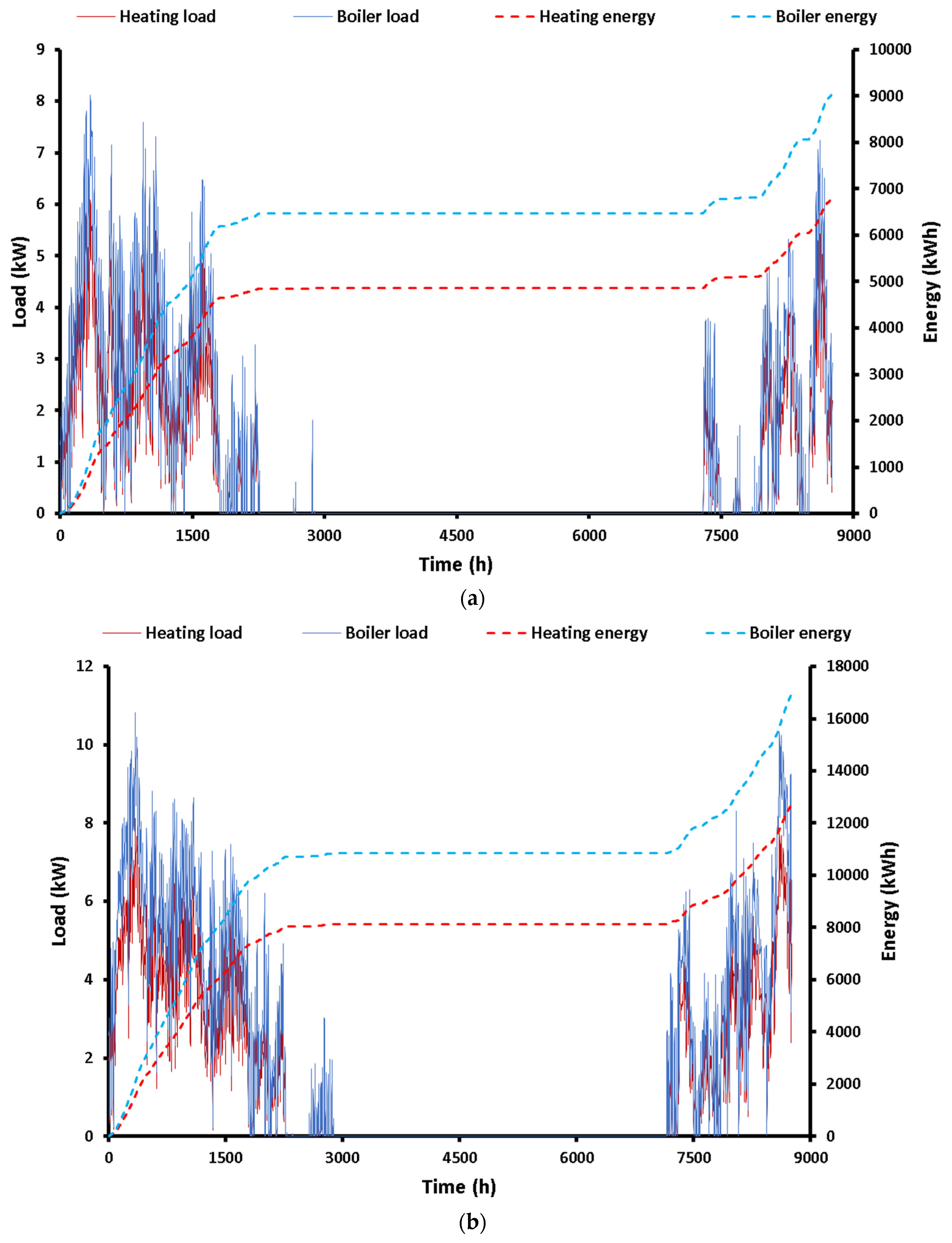

The examined space heating configuration includes a high-temperature air-to-water heat pump that produces hot water for feeding radiators, as Figure 1a shows. The competitive system is an oil boiler that produces hot water for feeding the same radiators, as Figure 1b depicts. The working medium in the heat pump was selected to be the R1234ze(E), which is a promising working fluid with various advantages. More specifically, this working fluid has zero ozone-depleting potential (ODP), has a low global warming potential (GWP) equal to 6, is non-toxic, and also presents restricted flammability (A2L—ASHRAE safety Classification) [22]. Practically, the GWP of R1234ze(E) is significantly lower when compared to other usual fluids, such as R404A, R134a, and R32, which are equal to 3922, 1300, and 677, respectively [25].

Figure 1.

The examined heating systems: (a) system with high-temperature heat pump, and (b) systems with oil boiler.

The heat pump cycle is a simple typical cycle with an evaporator, a compressor, a condenser, and a throttling valve, as Figure 1a illustrates. The superheating in the evaporator outlet was selected at 10 K, and there was no subcooling in the condenser outlet. The expansion in the throttling valve was assumed to be ideal, which means that there are no thermal losses to the environment. The compressor was selected to be a semi-hermetic reciprocating device, more specifically the model “2EES-3Y-40S” from the Bitzer manufacturer [26]. This compressor is able to produce high-temperature water for different ambient conditions, and, thus, it was selected. Data from the manufacturer software [27] were used in order to determine the isentropic efficiency of the compressor, and these values were inserted in the present developed thermodynamic model. The condensing temperature in the heat pump was selected at 80 °C in order to make it possible to operate the radiators close to the nominal conditions. The evaporator temperature was selected to be 7 K lower than the ambient temperature in order to achieve proper operation. Figure 1b shows the alternative system, which includes an oil boiler coupled to the radiator for providing heating in the building. The present work aims to examine the substitution of a relatively old system with a heat pump, and, thus, a boiler with a reduced overall efficiency of 75% [28] was selected to be studied. The lower heating value of the oil was chosen at 42,000 kJ/kg, and its density was chosen at 0.86 kg/m3 [29]. In the heating system of both subfigures, the red line indicates the hot water in the inlet of the radiator, and the orange line indicates the return of the water with a lower temperature level.

2.2. The Examined Buildings

The present study investigated two buildings, including one in the south of Greece (Athens—Climate Zone B) and one in the north of Greece (Thessaloniki—Climate Zone C). The examined buildings are similar, and the only differences are in the construction materials used to follow the Greek regulations (TOTEE—KENAK) [28]. Below, the descriptions of the buildings are given, and the different parameters between them are clearly highlighted. Moreover, it is important to state that the simulation regarding the thermal heating loads calculation was conducted with TRNSYS software [24].

Both buildings had the same dimensions (15 m × 15 m × 3 m), which included a floor area of 225 m2 and a volume of 675 m3. The walls were oriented in four directions, with the south wall including a double-glazed window of 8 m2. All the external walls, the roof, and the ground came in touch with the outdoor air, and there were no shadings. The buildings each had 4 occupants producing heat of 100 W according to ISO 7730 [30]. Also, the internal gains due to appliances and lighting were selected at 7 W/m2, which is a typical value for Greek buildings [28]. The infiltration rate and natural ventilation rate were chosen at 1.0 air change per hour, while there was no mechanical ventilation system in the buildings. The thermostat in the heating period was set at 20 °C. Table 1 includes the composition of the structural components for the building in Athens, while Table 2 gives the respective data for the building in Thessaloniki. The thermal properties of the materials, the U-values, and the thickness of the different materials are listed in Table 1 and Table 2. The window (including glazing and frame) in the building of Athens had a total U-value of 2.6 W/m2 K, and, in Thessaloniki, it was 2.4 W/m2 K. In both cases, the g-value of the windows was 75%. The heat convection coefficients for the indoor space and the outdoor space were chosen at hin = 7.69 W/m2 K and hout = 25 W/m2 K, respectively [28]. At this point, is important to state that the selected values in the present work were selected in order for the studied buildings to be in accordance with Greek legislation. Furthermore, Table 3 summarizes the data of this analysis for the examined buildings.

Table 1.

Structural elements for the building in Athens (Zone B).

Table 2.

Structural elements for the building in Thessaloniki (Zone C).

Table 3.

Information for the examined building.

2.3. Basic Mathematical Formulation Part

This section includes the basic mathematical equations for the modeling of the subsystems in the present study.

2.3.1. Heat Pump Modeling

The heat input in the system from the ambient (Qin) is given as:

State point (1) has low pressure and 10 K superheating, while state point (4) is a mixture of low pressure.

The heating production in the condenser (Qheat) is given as:

The state point (3) is a saturated liquid with high pressure.

The electricity demand in the compressor (Pel) is given as:

The isentropic efficiency in the compressor device (ηis) is defined as:

where the state point (2,is) has the same high pressure and specific entropy as the state point (1).

The expansion in the throttling valve is an ideal process, so the specific enthalpy of the state point (4) is the same as in the state point (3).

The heat pump coefficient of performance (COP) is defined below:

The isentropic efficiency of the examined compressor was calculated using the following formula:

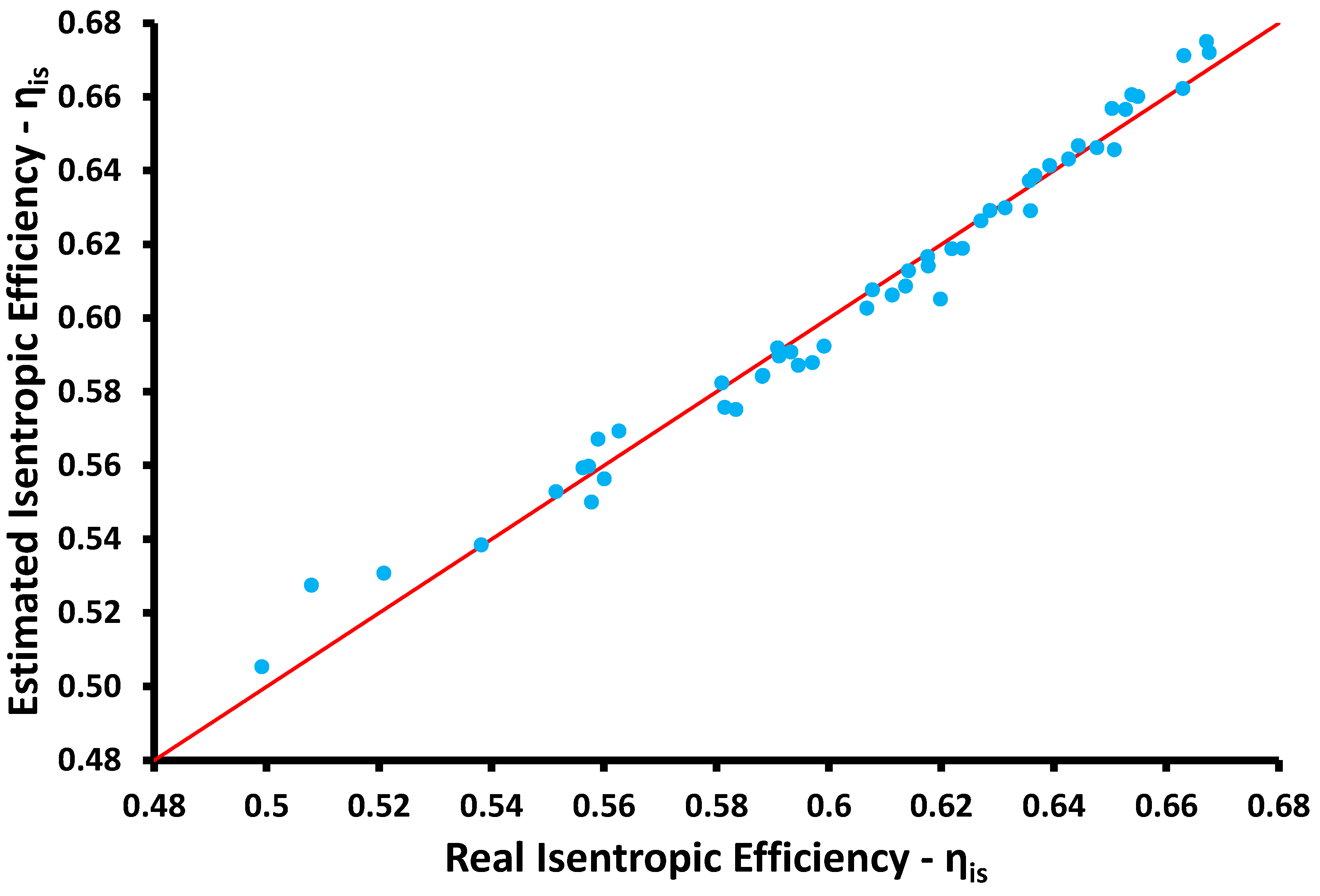

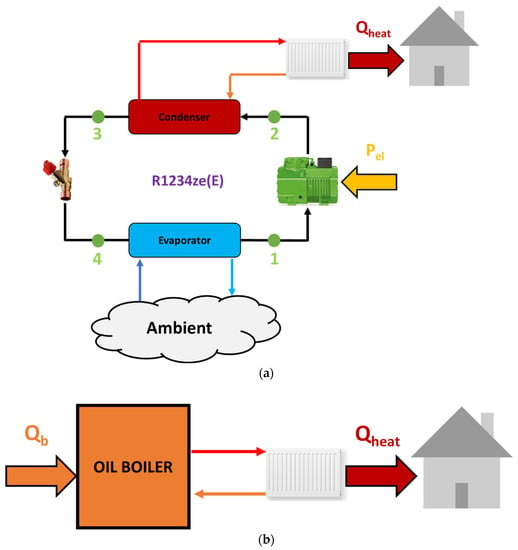

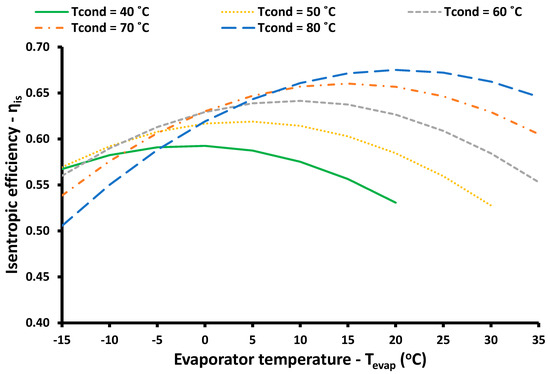

The previous formula was found after using the Bitzer software [27] and it has a mean deviation of 0.76%, while the maximum is 3.73%. This formula is valid for condenser temperatures in the range of [40 °C, 80 °C] and for evaporator temperatures in the range of [−15 °C, 35 °C]. It is also useful to state that the maximum evaporator temperature for Tcond = 50 °C is the Tevap = 30 °C, and for Tcond = 40 °C is the Tevap = 25 °C. Figure 2 shows the comparison of the calculated values with the aforementioned formula and the values that were found by processing the Bitzer data. It is obvious that there is high accuracy in the estimation of the isentropic efficiency using Equation (7) for all the examined cases.

Figure 2.

Comparison of the isentropic efficiency between the estimated value with the approximation formula.

More specifically, the Bitzer software provides the discharge temperature (T2) for every operating scenario, and the use of this temperature makes it possible to calculate the isentropic efficiency. More specifically, since (T2) is known, it is possible to find the (h2), because the state point (2) has the system’s high pressure. The knowledge of the (h2) makes it possible to calculate the (ηis) as below:

2.3.2. Building and Boiler Modeling

The U-value of the structural elements (U) can be found below:

In the previous equations, it is assumed that the examined structural element (e.g., wall) has (M) layers, and every layer has (Li) thickness and (ki) thermal conductivity, while the indoor heat convective coefficient is hin = 7.69 W/m2 K, and the outdoor heat convective coefficient is hout = 25 W/m2 K.

The total boiler efficiency (ηb) is defined below:

The fuel energy can be expressed using the lower heating value (Hu) and the oil consumption rate (mb):

2.3.3. Evaluation Metrics

The primary energy demand in the heat pump case is found below [28]:

The primary energy demand in the boiler case is found below [28]:

The yearly CO2 emissions in the heat pump case are calculated below [31]:

The yearly CO2 emissions in the boiler case are calculated below [28]:

The initial cost for the heat pump investment (C0) was estimated at EUR 4500 for Athens and EUR 6000 for Thessaloniki, which took into consideration a specific cost of about EUR 750 /kWth [32]. The electricity cost was estimated at kel = EUR 0.22/kWh which is a reasonable value for the present situation in Greece. The lifetime of the project was estimated at (N = 25 years), and the discount factor was estimated at (r = 2%). The life cycle cost of the heat pump system can be calculated below:

The cost of the oil was chosen at (EUR 1.4 /L), the oil’s density at 0.86 kg/m3, and the oil’s lower heating value at 42,000 kJ/kg. Thus, the oil cost per energy (koil) was calculated at EUR 0.1395 /kWh. The life cycle cost of the oil boiler system can be calculated below:

The net savings on the present time (NS) are calculated as below:

The simple payback period (SPP) of the investment of the heat pump system can be calculated as below:

The mean yearly COP or seasonal COP of the heat pumps system (SCOP) is calculated below:

2.4. Summary of the Followed Methodology

In this work, a high-temperature heat pump was examined as an alternative choice for substituting an oil boiler while keeping the radiators in the building. The thermodynamic analysis of the heat pump was performed with a developed model in Engineering Equation Solver [23] by using data from the Bitzer manufacturer [26] for the modeling of the compressor. The high-temperature heat pump system operates with R1234ze(E) working fluid, which is an environmentally friendly fluid.

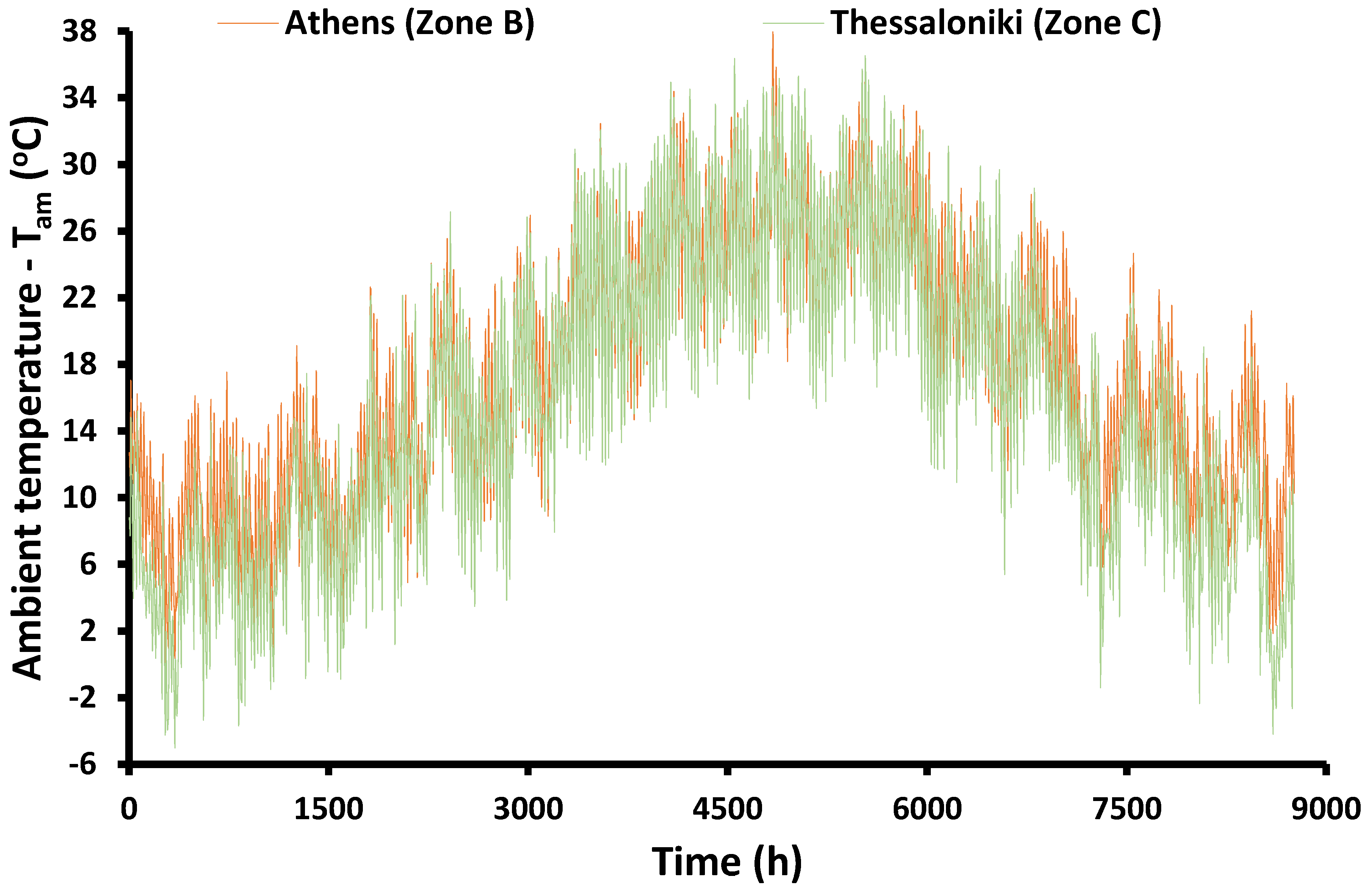

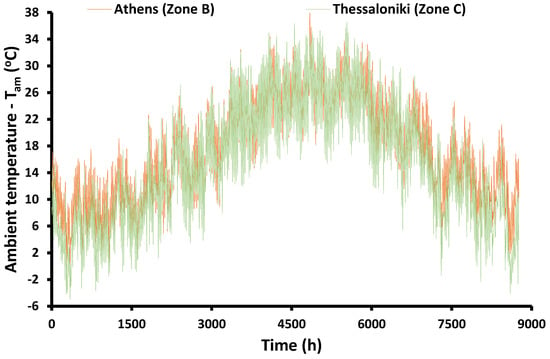

The building thermal loads were calculated with a developed dynamic model in the TRNSYS tool [24]. Two locations were examined in Greece, including one in the south (Athens—Climate Zone B—37°59′ N, 23°43′ E) and one in the north (Thessaloniki—Climate Zone C—40°37′ N, 22°56′ E). The ambient temperature of the locations is depicted in Figure 3. It is clear that during the winter, there are lower temperature levels in Thessaloniki compared to Athens.

Figure 3.

Yearly deviation of the ambient temperature for the examined locations in Greece.

The heat pump system was compared with the oil boiler system in terms of energy, economic, and environmental figures. Specifically, the energy comparison was conducted by using the primary energy consumption, and the economic analysis was conducted using the simple payback period, the life cycle cost, and the net savings indexes, while the environmental analysis was conducted by calculating the CO2 avoidance for the system lifetime.

3. Results and Discussion

This section includes the results of this study, and it is separated into three subsections. Section 3.1 is devoted to the thermodynamic presentation of the examined high-temperature heat pump, while Section 3.2 includes the results of the heating system analysis on a yearly basis for the two examined locations. Finally, Section 3.3 is devoted to presenting the comparison of the heat pump system with the oil boiler case.

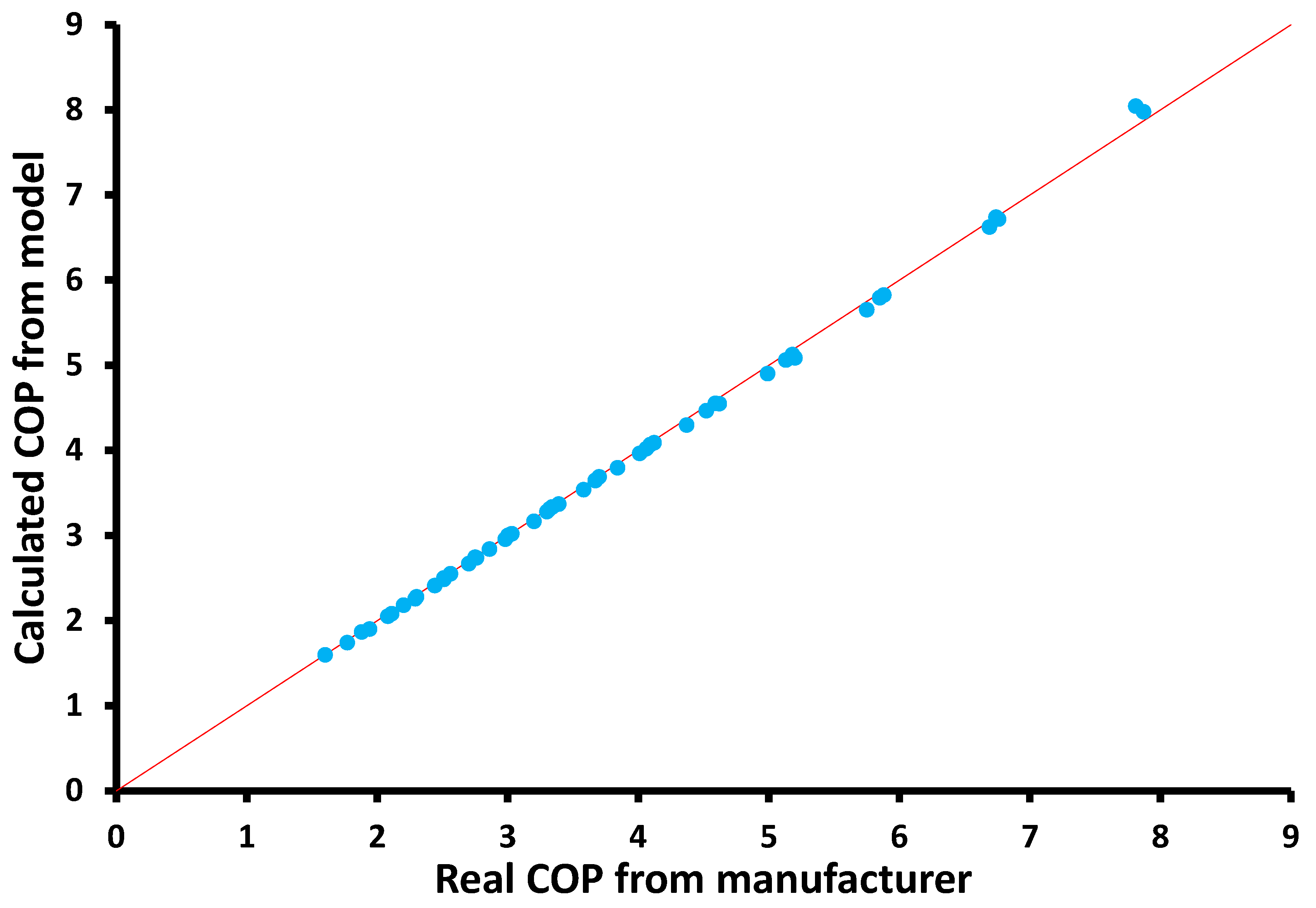

3.1. Thermodynamic Analysis of the Heat Pump

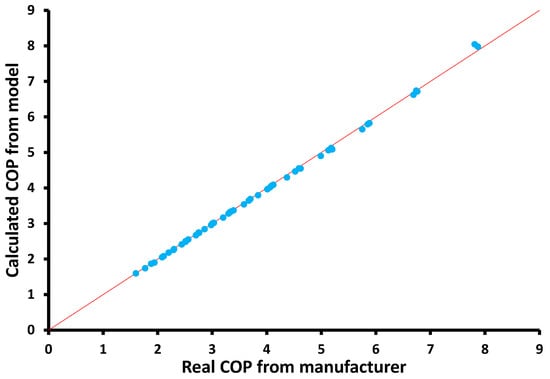

The examined heat pump was investigated with a created model in Engineering Equation Solver. The developed model was validated by using data from the Bitzer software [27]. The validation was performed for different combinations of evaporator and condenser temperature levels. Figure 4 depicts that the points are close to the “y = x” line, which is a fact that proves the high accuracy of the developed model. Moreover, the mean COP deviation was calculated at 0.94%, while the maximum deviation was calculated at 3.01%. The aforementioned deviation values were relatively low, and, thus, the created thermodynamic model is an accurate one.

Figure 4.

Comparison of the calculated COP with the developed model of the COP by Bitzer.

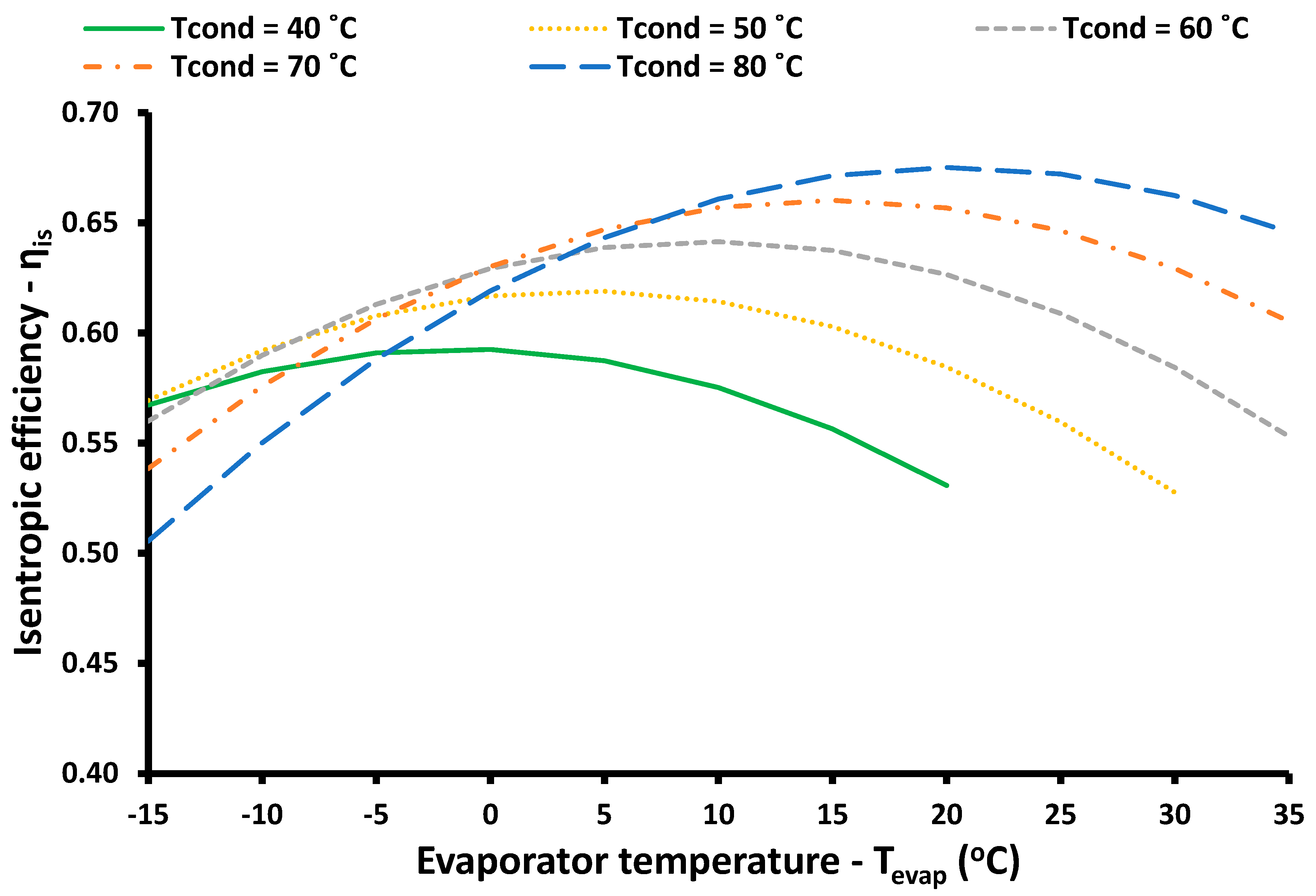

The next step in the thermodynamic analysis was the presentation of the isentropic efficiency for different operating conditions. Figure 5 illustrates that the isentropic efficiency was found in the range of 50.6% to 67.5%. For every condenser temperature, there is a specific evaporator temperature that makes the compressor operate with maximum isentropic efficiency. The global maximum isentropic efficiency was found for [Tcond = 80 °C, Tevap = 20 °C] and it had the value ηis = 67.5%. For low evaporator temperatures, the isentropic efficiency had higher values for lower condenser temperatures. On the other hand, for higher evaporator temperatures, the isentropic efficiency was maximized for higher condenser temperatures. These results indicate that the system presented optimum compressor operation for a temperature lift of around 60 K, which is a characteristic of the examined compressor.

Figure 5.

Variation in the compressor isentropic efficiency for different evaporator and condenser temperature levels.

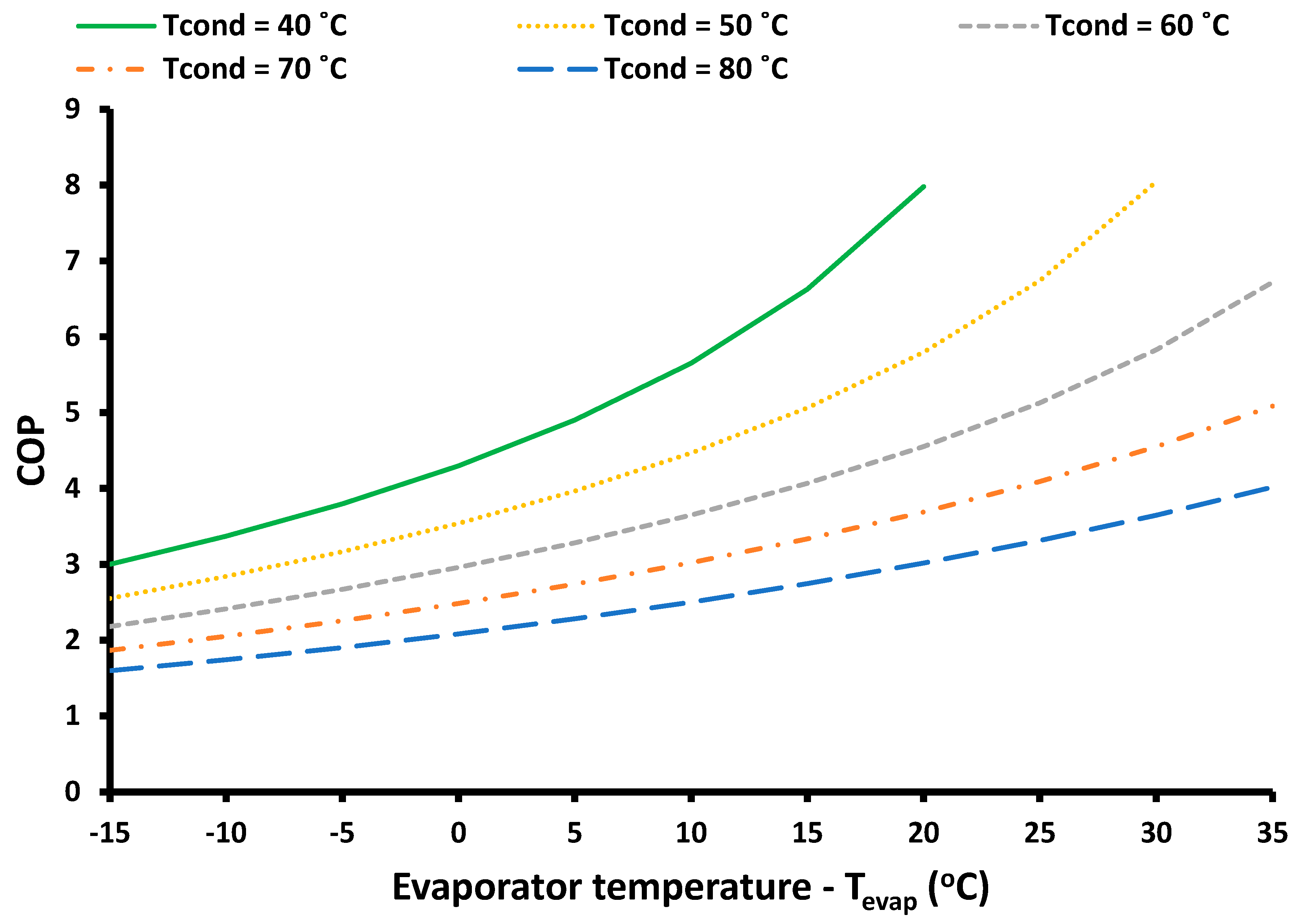

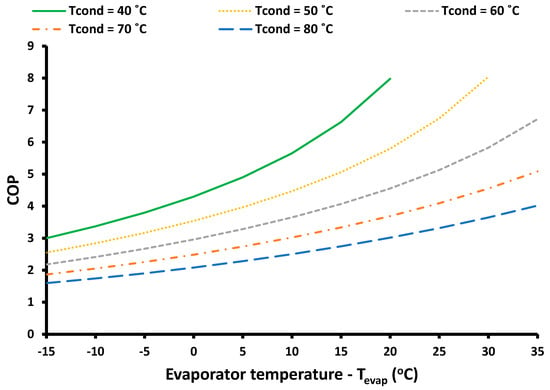

Figure 6 illustrates the COP variation for different combinations of evaporator and condenser temperatures. It is clear that higher evaporator temperature increases the COP, while lower condenser temperatures increased the COP. These are reasonable results because the COP needs a small temperature lift in order to have higher values. According to the results, the COP range was found to be from 1.6 to 8.0 for all the examined cases. It is remarkable that, in Figure 5 and Figure 6, the lines did not have the same range, which is something that was justified by constraints in the compressor operation. More specifically, for Tcond = 40 °C, the evaporator temperature can be up to 20 °C, while for Tcond = 50 °C the evaporator temperature can be up to 30 °C. This fact indicates that a minimum 20 K lift can be achieved with the present heat pump.

Figure 6.

Variation in the heat pump COP for different evaporator and condenser temperature levels.

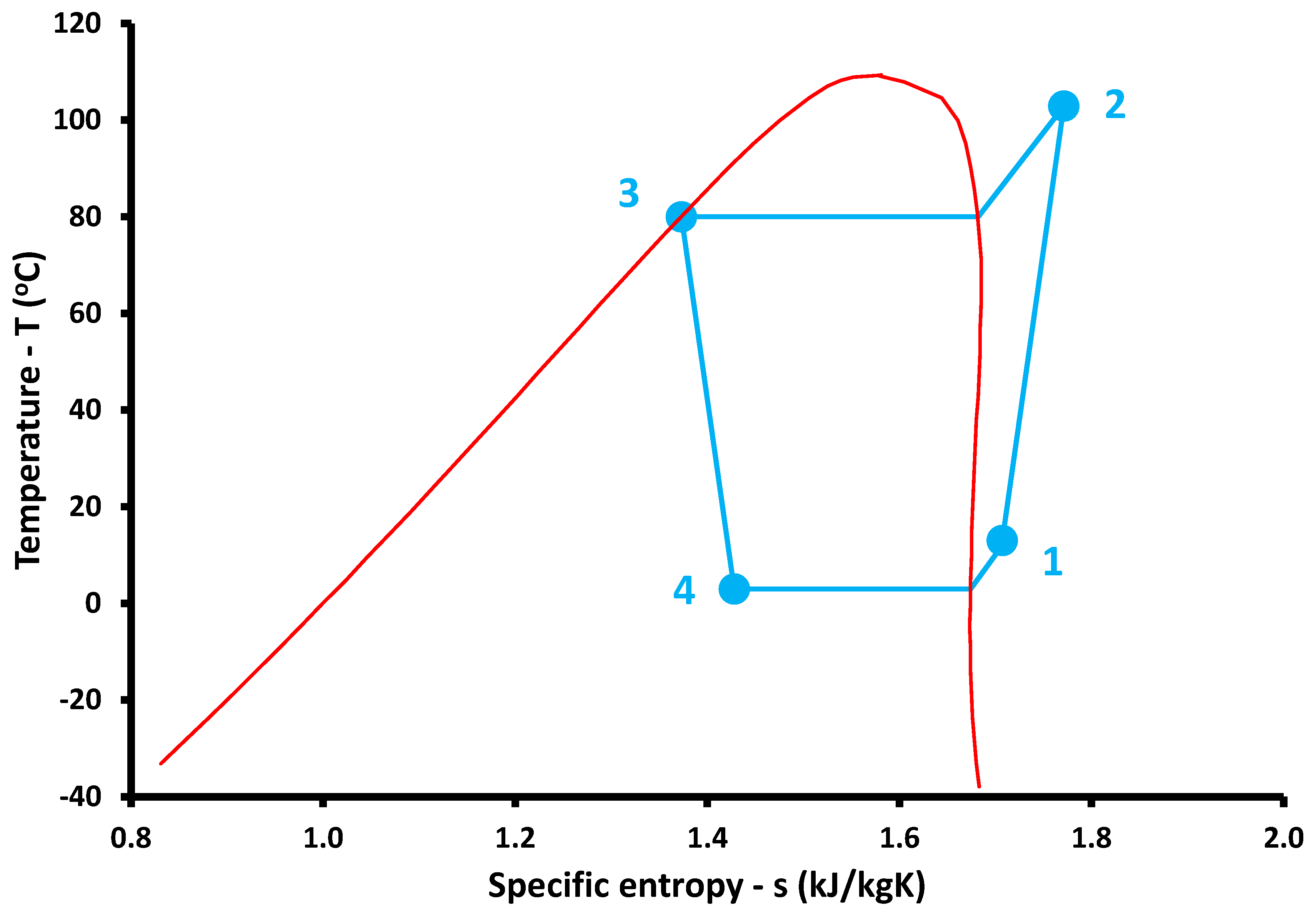

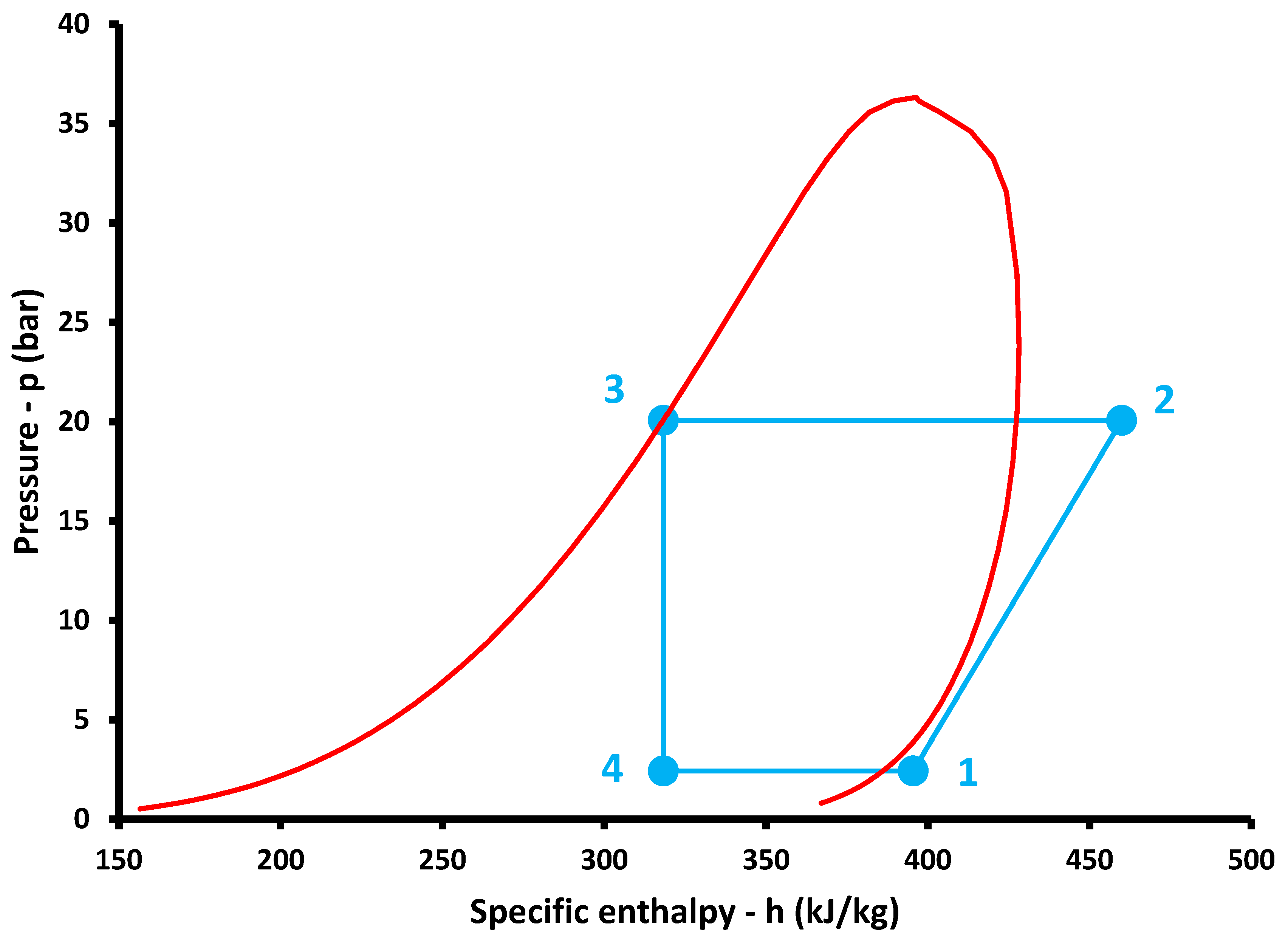

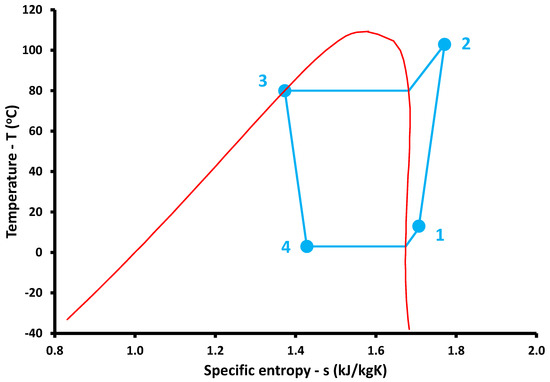

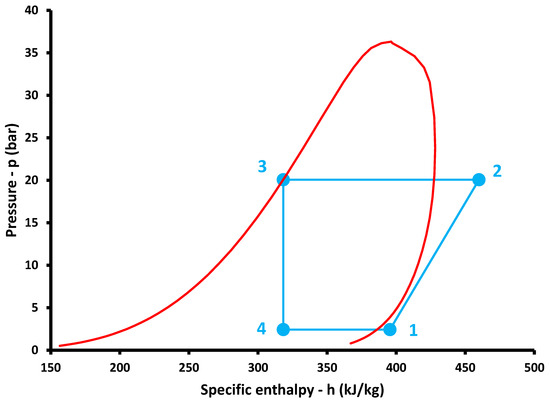

At the end of this section, the heat pump thermodynamic charts are presented for a typical case with ambient temperature at Tam = 10 °C, which means that the evaporator temperature is set at Tevap = 3 °C, while Tcond = 80 °C. Figure 7 depicts the temperature–specific entropy (T–s) depiction, while Figure 8 shows the pressure–specific enthalpy (p–h) depiction. Process 1 → 2 is the compression in the compressor, process 2 → 3 is the heat rejection under constant pressure from the condenser to the building, process 3 → 4 is the isenthalpic expansion in the throttling valve, and process 4 → 1 is the heat absorption from the ambient environment under constant pressure.

Figure 7.

Temperature–specific entropy depiction (T–s) of the heat pump cycle for the case with ambient temperature at 10 °C.

Figure 8.

Pressure–specific enthalpy depiction (p–h) of the heat pump cycle for the case with ambient temperature at 10 °C.

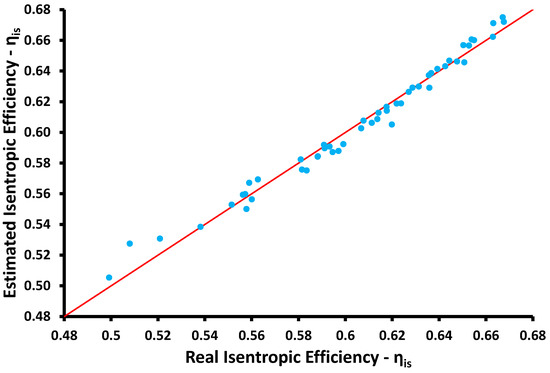

3.2. System Performance Comparison for Both Climate Zones

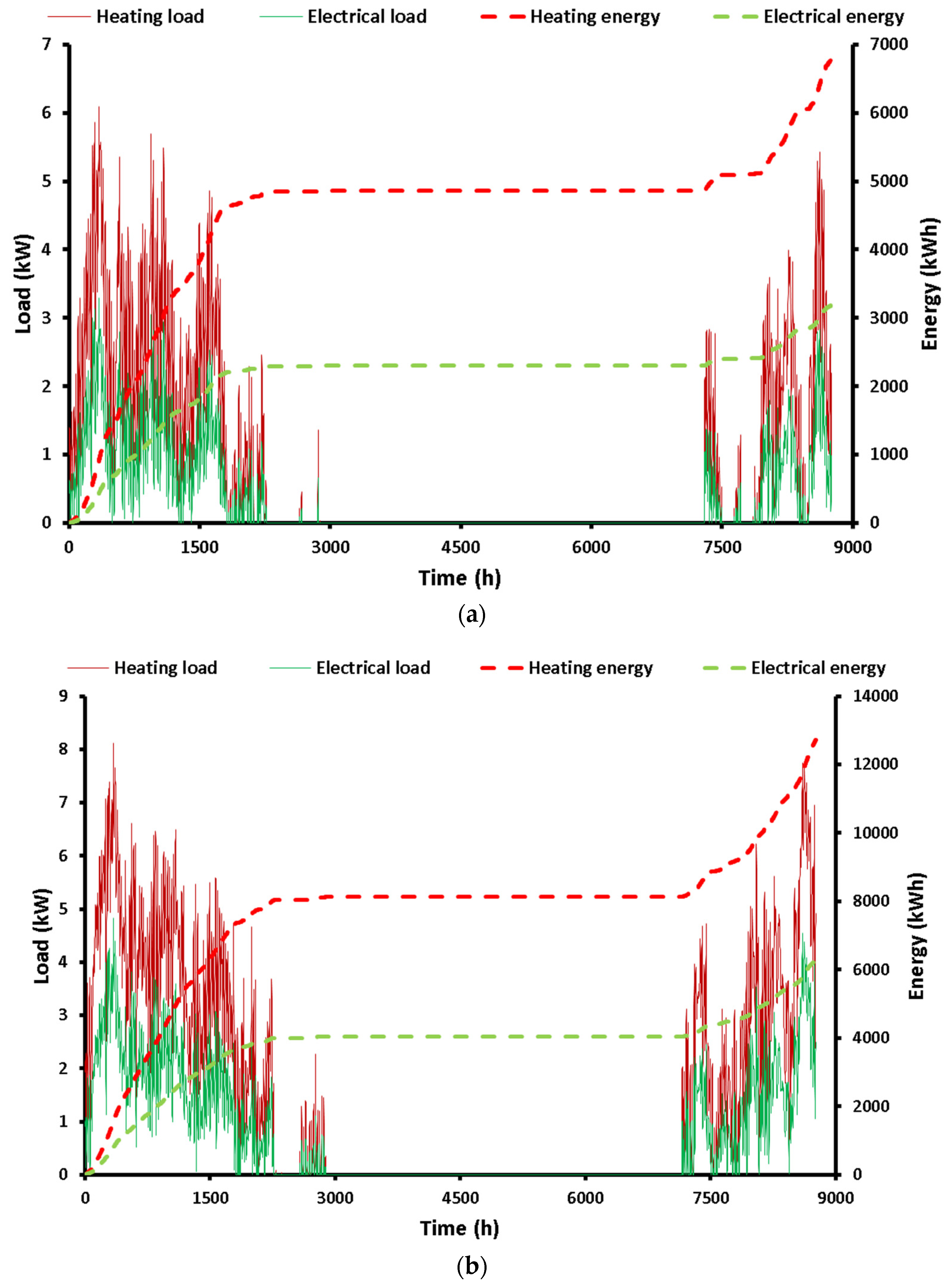

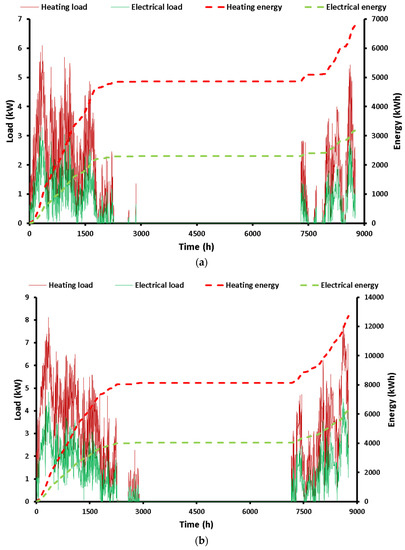

After the thermodynamic investigation, the next step regards the analysis of the total heating system and its comparison with the oil boiler case. The analysis was done for two representative locations in Greece: Athens and Thessaloniki. Figure 9 shows the results of the heating loads, the electrical demand from the heat pump, and the respective cumulative energy quantities. Figure 9a illustrates the results of the simulation for Athens, and Figure 9b illustrates the results of the simulation for Thessaloniki. The maximum heating load in Athens was found at 6 kW, while in Thessaloniki, it was found at 8 kW. Moreover, it is obvious that the heating period was a bit greater in Thessaloniki compared to Athens. More specifically, the heating period in Athens was 3009 h, while in Thessaloniki it was 3847 h. The yearly heating demand in Athens was found at 6785 kWh and the respective electricity consumption was found at 3189 kWh. The yearly heating demand in Thessaloniki was found at 12,591 kWh and the respective electricity consumption was found at 6236 kWh. It is clear that Thessaloniki had approximately the double thermal loads compared to the Athens case.

Figure 9.

Heat pump system: loads in [W] and cumulative energy in [kWh] for heating for (a) Athens (Zone B) and (b) Thessaloniki (Zone C).

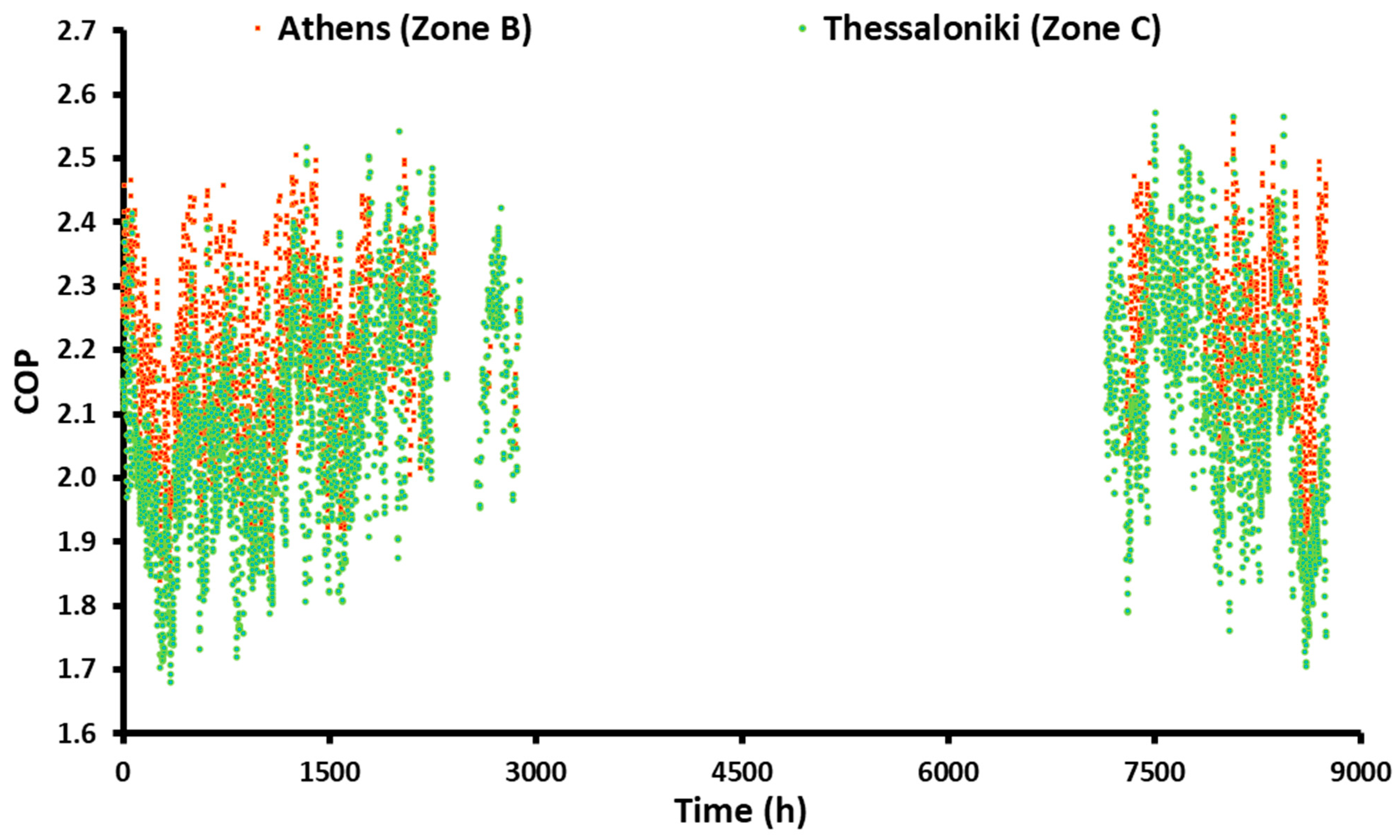

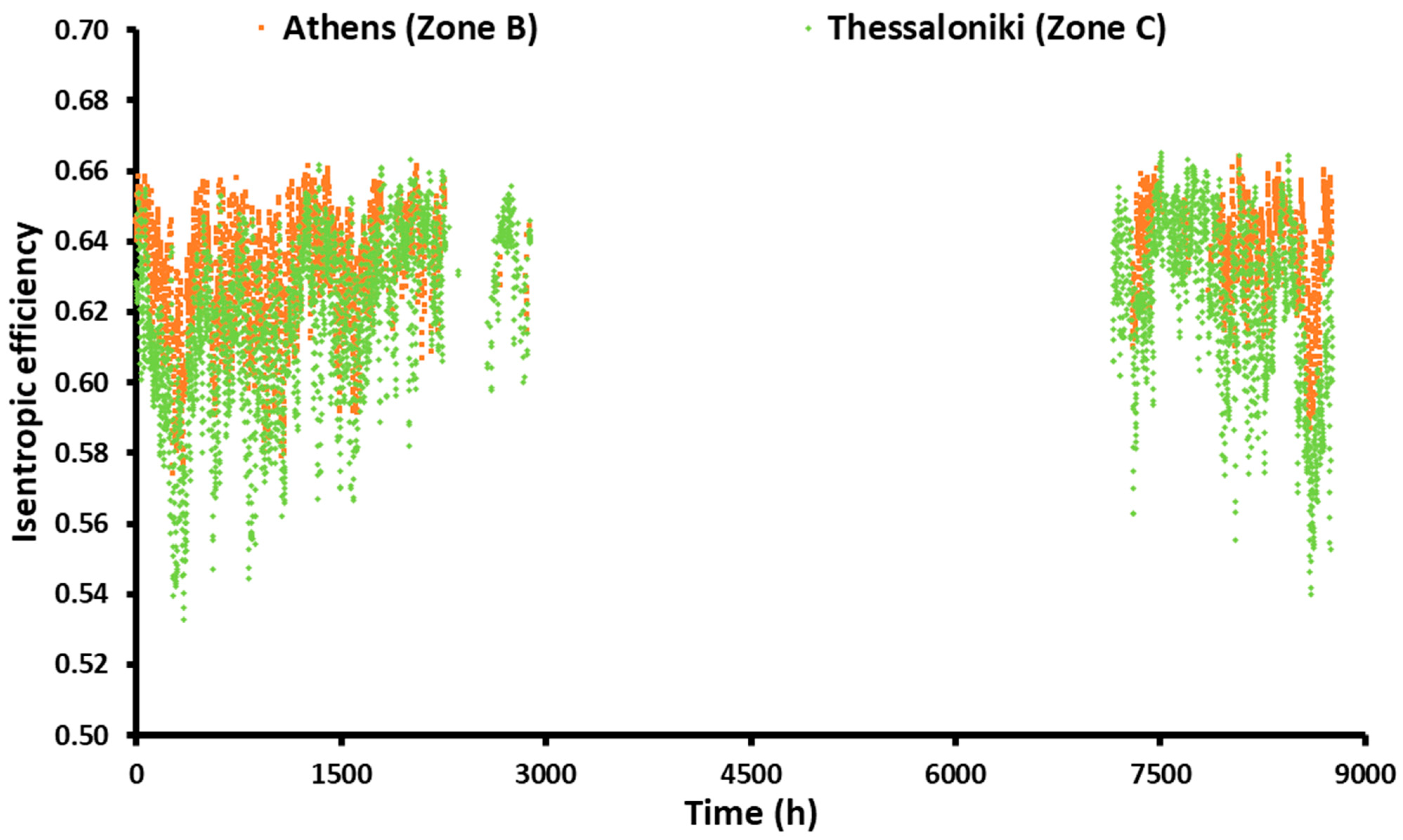

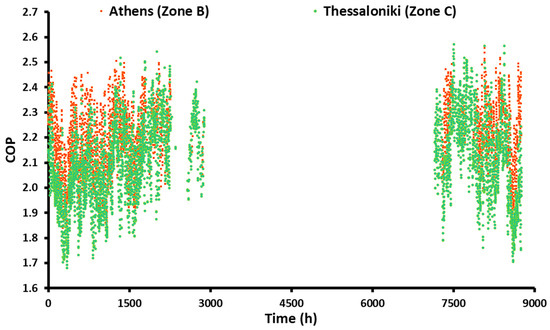

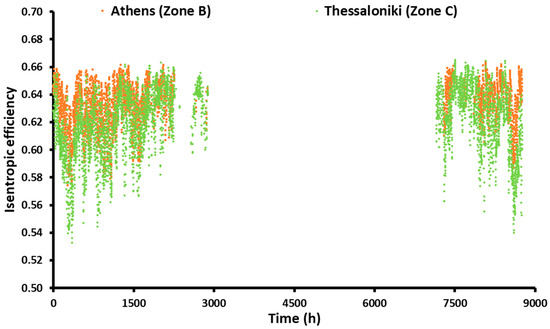

The mean yearly COP or seasonal COP (SCOP) in Athens was calculated at 2.128, while in Thessaloniki it was calculated at 2.019. The lower value in Thessaloniki is reasonable due to the lower ambient temperatures in Thessaloniki compared to Athens, as has been presented in Figure 3. Also, it has to be added that the reduction of the COP with the reduction of the ambient temperature is clear by checking Figure 6. Practically, the lower ambient temperature reduced the evaporator temperature, and consequently, the COP was getting to lower values according to Figure 6. Additionally, Figure 10 depicts the hourly COP variation for both locations during the year. It is clear that the COP values were generally smaller in Thessaloniki compared to the respective values in Athens; the fact verifies the lower mean yearly COP in Thessaloniki. Moreover, Figure 11 shows the variation in the compressor’s isentropic efficiency during the year for both locations. Again, it can be said that the isentropic efficiency in Thessaloniki takes lower values compared to the efficiency in Athens. The mean yearly isentropic efficiency in Athens was found at 63.3%, while in Thessaloniki, it was found at 61.9%.

Figure 10.

Heat pump system: variation in the COP during the year of operation for the examined locations.

Figure 11.

Heat pump system: variation in the compressor isentropic efficiency during the year of operation for the examined locations.

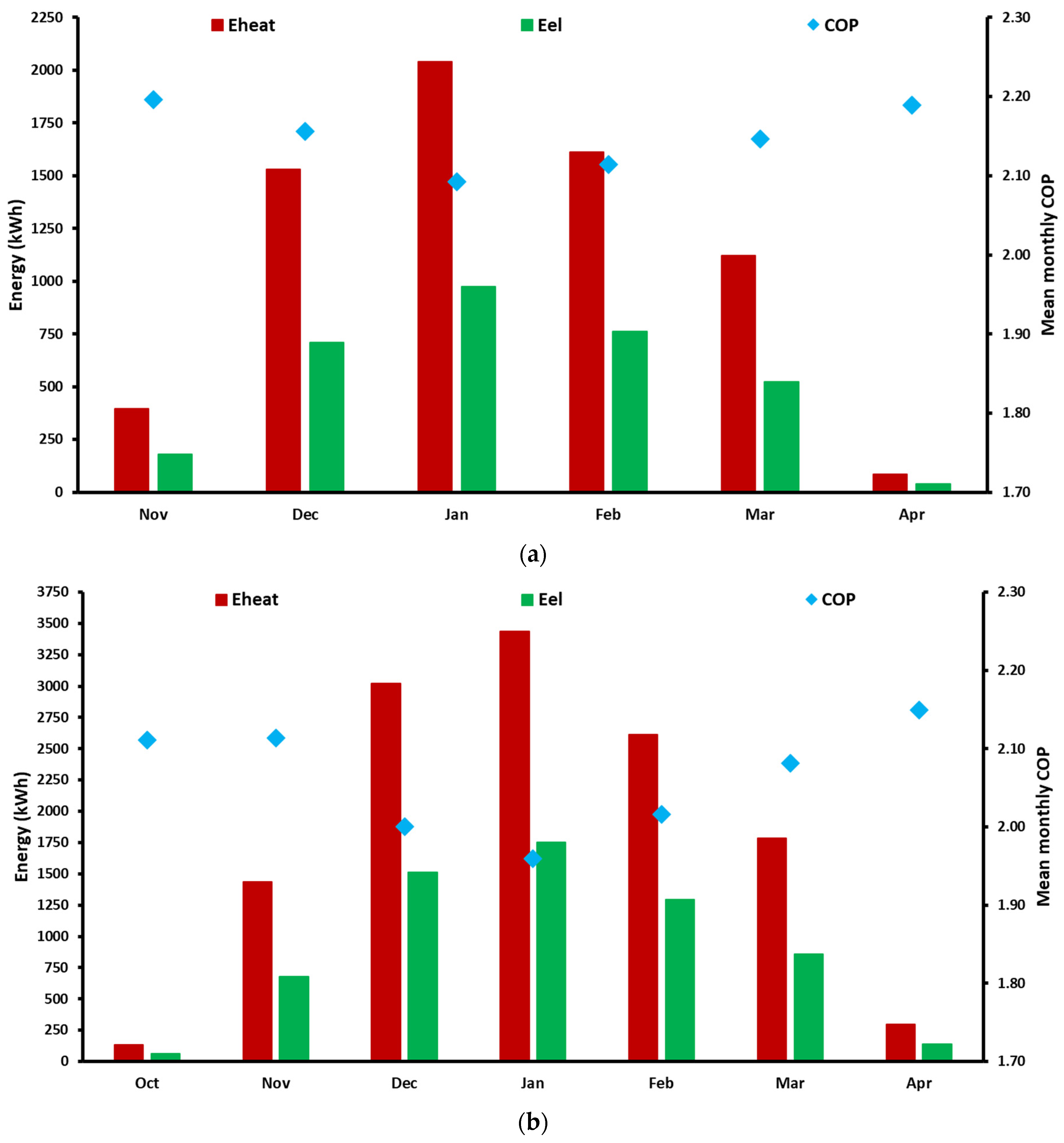

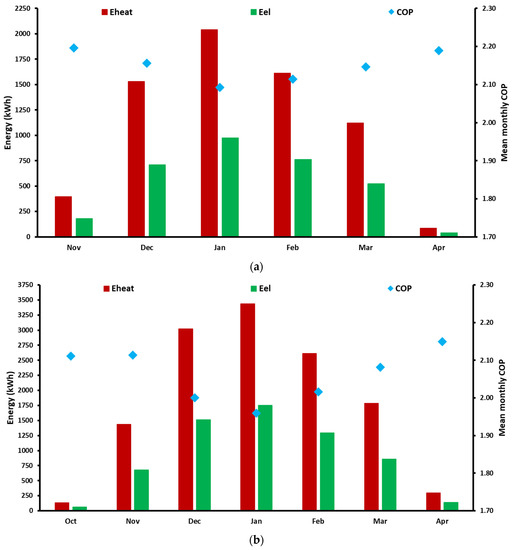

Figure 12 shows the monthly results in energy and efficiency terms for both locations. The heating period for Athens starts in November and stops in April, while for Thessaloniki, it starts in October and stops in April. The maximum heating energy demand was found for both locations in January, and, more specifically, it was 2039 kWh for Athens and 3435 kWh for Thessaloniki. The minimum COP was found in January for both locations due to the lower ambient temperature during this month compared to the others. More specifically, the mean monthly COP for January was calculated at 2.093 for Athens and 1.959 for Thessaloniki.

Figure 12.

Heat pump system: monthly energy quantities [kWh] and mean COP for (a) Athens (Zone B), and (b) Thessaloniki (Zone C).

3.3. Comparison with the Oil Boiler System

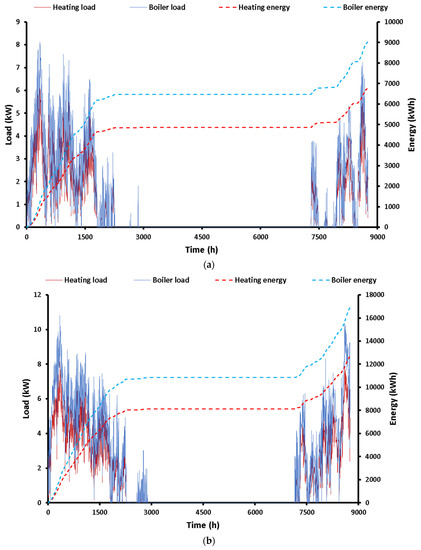

The last step in the present analysis regards the comparison of the air-source high-temperature heat pump system with the oil boiler case (baseline scenario). Figure 13 displays the heating and boiler loads for the oil boiler case in Athens and Thessaloniki. The cumulative consumption in fuel energy input was found at 9046 kWh for Athens and 16,965 kWh for Thessaloniki. Table 4 includes the data of the energy, financial, and environmental analysis of the examined scenarios in this study, while Table 5 summarizes the most valuable comparative indexes.

Figure 13.

Boiler system: loads in [W] and cumulative energy in [kWh] for heating for (a) Athens (Zone B) and (b) Thessaloniki (Zone C).

Table 4.

Comparison of the performance of the two heating systems for both locations.

Table 5.

Final assessment of both technologies.

The primary energy consumption with the heat pump decreased from 9951 kWh to 9247 kWh per year in Athens, leading to a reduction of 7.1%. For Thessaloniki, the primary energy demand was reduced from 18,861 kWh to 18,267 kWh, which presented a reduction of 3.1%. The lower primary energy gain in Thessaloniki can be explained by the reduced mean yearly COP in this city when compared to Athens. The lifetime primary energy savings were found to be 17,588 kWh in Athens and 9857 kWh in Thessaloniki.

The financial analysis shows the important benefits of the use of heat pumps, which proves the need for expanding the use of this technology. The simple payback period for the case in Athens was 8.03 years, while in Thessaloniki, it was 6.11 years. Both values encourage the SPP in Thessaloniki to be lower due to the greater yearly economic gain in this city. Practically, the higher demand in Thessaloniki makes the profit greater in this city, while the investment cost for the heat pump is greater in Thessaloniki due to the higher capacity of the system compared to the capacity in Athens. The life cycle cost analysis indicates that the present net savings in Athens were EUR 5956, and in Thessaloniki, the net savings were EUR 7286. Thus, it is clear that the investment leads to satisfying gain, which was higher in Thessaloniki.

The environmental analysis indicates that the CO2 emissions for Athens were reduced by 35% with the heat pump, while the respective reduction in Thessaloniki was 32%. The lifetime CO2 emissions reduction was calculated at 20,882 kgCO2 for Athens and 35,278 kgCO2 for Thessaloniki. Although the reduction percentage was higher for Athens, the total CO2 avoidance was greater in Thessaloniki due to the greater energy demands in this location. Moreover, the present heat pump uses an environmentally friendly working fluid, and this fact adds an extra environmental benefit to the suggested configuration.

It is remarkable to state that the examined high-temperature heat pump is an ideal solution for both examined locations. While the performance of the heat pump in Athens was a bit higher than in the case of Thessaloniki, the benefits in Thessaloniki seemed to be greater. This result is explained by the higher heating demand in Thessaloniki, which makes it possible to achieve higher enhancements margins by retrofitting the heating system in Thessaloniki. In every case, it has to be highlighted that, in both locations, there are important advantages that indicate the utilization of high-temperature heat pumps both in the southern and northern Greek regions.

Finally, it is obvious that all the energy, economic, and environmental indexes showed that the substitution of the oil boiler with the heat pump is a viable and feasible choice. The relatively low mean COP of around 2 is enough for overcoming the oil boiler performance. Thus, it is strongly recommended to install high-temperature heat pumps for heating purposes due to the multiple advantages compared to conventional systems. Moreover, the use of advanced heat pump cycles with internal heat exchangers, ejectors, etc. can improve the COP and lead to greater benefits. Also, the incorporation of solar thermal systems and/or geothermal energy into the system can make it more efficient, and this fact has to be examined with the aim to achieve higher performance.

4. Conclusions

Heat pumps are efficient devices for producing space heating and substituting conventional systems with boilers. The present work came to examine the use of an air-to-water high-temperature heat pump with R1234ze (E) working medium as an alternative choice to substitute an oil boiler system by keeping the radiators and the piping system of the building. The analysis was performed for two locations in Greece, including one in the south (Athens—Climate Zone B) and one in the north (Thessaloniki—Climate Zone C). The most valuable conclusions of the present work are summarized below:

- -

- The mean yearly COP was found at 2.128 for Athens, while it was found at 2.013 for Thessaloniki. This difference is justified by the lower ambient temperatures in Thessaloniki. The primary energy savings for Athens was found at 17,588 kWh, and, for Thessaloniki, it was found at 9857 kWh. The reduction of the primary energy demand with the heat pump compared to the oil boiler case was found at 7.1% for Athens and 3.1% for Thessaloniki.

- -

- The economic analysis showed that the use of a heat pump is a feasible choice that presented a simple payback period of 8.03 years in Athens and 6.11 years in Thessaloniki. The lifecycle analysis indicated net present savings of EUR 6448 in Athens and EUR 13,161 in Thessaloniki. The higher profit in Thessaloniki is justified by the higher heating demand in Thessaloniki.

- -

- The environmental analysis proved significant benefits with the use of the air-to-water heat pump, which led to a CO2 emissions reduction of 35% in Athens and 32% in Thessaloniki. The lifetime CO2 emissions avoidance was found at 20,882 kgCO2 for Athens and 35,278 kgCO2 for Thessaloniki.

To conclude, the substitution of an oil boiler with a high-temperature heat pump is a beneficial choice according to energy, economic, and environmental criteria. Thus, it is strongly recommended to expand the use of high-temperature heat pumps in buildings for heating purposes. However, there is a need for extra studies with regard to enhancing the performance of the heat pumps, and it is also an interesting idea to consider its hybridization with renewables (e.g., solar thermal collectors).

Author Contributions

E.B.: Conceptualization, methodology, software, investigation, writing—original draft preparation; D.T.: Conceptualization, software, investigation, writing—original draft preparation; P.L.: Methodology, software, writing—original draft preparation; A.K.: Methodology, investigation, writing—original draft preparation; D.N.K.: Methodology, writing—original draft preparation; M.G.V.: Conceptualization, supervision, writing—original draft preparation; C.T.: Conceptualization, supervision, writing—original draft preparation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Available after request.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| cp | Specific heat capacity, kJ/kgK |

| C0 | Investment cost, EUR |

| h | Specific enthalpy, kJ/kg |

| hin | Convection coefficient inside the building, W/m2 K |

| hout | Heat convection coefficient with outdoor air, W/m2 K |

| Hu | Lower heating value of the oil, kJ/kg |

| k | Thermal conductivity, W/mK |

| kel | Electricity cost, EUR/kWhel |

| koil | Oil cost, EUR/kWhth |

| L | Thickness of material in a structural element, m |

| LCC | Life cycle cost, EUR |

| m | Mass flow rate, kg/s |

| Μ | Number of layers in every structural element |

| N | Lifetime of the project, years |

| NS | Net savings, EUR |

| p | Pressure, bar |

| Pel | Electricity demand on the compressor, kW |

| PE | Primary energy, kWh |

| Qb | Boiler energy demand, kW |

| Qheat | Heating demand, kW |

| Qin | Heat input in the heat pump from the ambient, kW |

| r | Discount factor, % |

| s | Specific entropy, kJ/kgK |

| SPP | Simple payback period, years |

| T | Temperature, °C |

| U | Thermal transmittance, W/m2 K |

| YCO2 | Yearly CO2 emissions, kgCO2/year |

| Greek Symbols | |

| ηb | Boiler efficiency |

| ηis | Isentropic efficiency |

| ρ | Density, kg/m3 |

| Subscripts | |

| am | Ambient |

| b | Boiler |

| Bitzer | Data from the Bitzer manufacturer |

| cond | Condenser |

| evap | Evaporator |

| HP | Heat pump |

| is | Isentropic |

| Abbreviations | |

| ACH | Air changes per hour |

| COP | Coefficient of performance |

| GWP | Global warming potential |

| ODP | Ozone depleting potential |

| SCOP | Seasonal coefficient of performance |

References

- Wu, D.; Hu, B.; Wang, R.Z. Vapor compression heat pumps with pure Low-GWP refrigerants. Renew. Sustain. Energy Rev. 2021, 138, 110571. [Google Scholar] [CrossRef]

- Cui, M.; Cheng, Z.; Wang, B.; Wei, F.; Shi, W. Experimental investigation on an auto-cascade quasi two-stage compression heat pump system. Appl. Therm. Eng. 2023, 219, 119498. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Z.; Qin, C.; Gu, Y. Economic analysis of gas heat pump in different building applications: A case study in Shanghai. Case Stud. Therm. Eng. 2022, 38, 102303. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Sadatsakkak, S.A. Thermodynamic analysis and performance optimization of irreversible Carnot refrigerator by using multi-objective evolutionary algorithms (MOEAs). Renew. Sustain. Energy Rev. 2015, 51, 1055–1070. [Google Scholar] [CrossRef]

- Naumann, G.; Schropp, E.; Gaderer, M. Life Cycle Assessment of an Air-Source Heat Pump and a Condensing Gas Boiler Using an Attributional and a Consequential Approach. Procedia CIRP 2022, 105, 351–356. [Google Scholar] [CrossRef]

- Parrish, B.; Hielscher, S.; Foxon, T.J. Consumers or users? The impact of user learning about smart hybrid heat pumps on policy trajectories for heat decarbonisation. Energy Policy 2021, 148, 112006. [Google Scholar] [CrossRef]

- Lämmle, M.; Bongs, C.; Wapler, J.; Günther, D.; Hess, S.; Kropp, M.; Herkel, S. Performance of air and ground source heat pumps retrofitted to radiator heating systems and measures to reduce space heating temperatures in existing buildings. Energy 2022, 242, 122952. [Google Scholar] [CrossRef]

- Hao, X.; Zhang, G.; Chen, Y.; Zou, S.; Moschandreas Demetrios, J. A combined system of chilled ceiling, displacement ventilation and desiccant dehumidification. Build. Environ. 2007, 42, 3298–3308. [Google Scholar] [CrossRef]

- Imanari, T.; Omori, T.; Bogaki, K. Thermal comfort and energy consumption of the radiant ceiling panel system: Comparison with the conventional all-air system. Energy Build. 1999, 30, 167–175. [Google Scholar] [CrossRef]

- Catalina, T.; Virgone, J.; Kuznik, F. Evaluation of thermal comfort using combined CFD and experimentation study in a test room equipped with a cooling ceiling. Build. Environ. 2009, 44, 1740–1750. [Google Scholar] [CrossRef]

- Wang, Z.; Li, G.; Wang, F.; Zhang, Y. Performance investigation of a transcritical CO2 heat pump combined with the terminal of radiator and floor radiant coil for space heating in different climates, China. J. Build. Eng. 2021, 44, 102927. [Google Scholar] [CrossRef]

- Shao, S.; Zhang, H.; You, S.; Zheng, W.; Jiang, L. Thermal performance analysis of a new refrigerant-heated radiator coupled with air-source heat pump heating system. Appl. Energy 2019, 247, 78–88. [Google Scholar] [CrossRef]

- Hu, B.; Wang, R.Z.; Xiao, B.; He, L.; Zhang, W.; Zhang, S. Performance evaluation of different heating terminals used in air source heat pump system. Int. J. Refrig. 2019, 98, 274–282. [Google Scholar] [CrossRef]

- Luo, J.; Xue, W.; Shao, H. Thermo-economic comparison of coal-fired boiler-based and groundwater-heat-pump based heating and cooling solution—A case study on a greenhouse in Hubei, China. Energy Build. 2020, 223, 110214. [Google Scholar] [CrossRef]

- Shah, N.N.; Wilson, C.; Huang, M.J.; Hewitt, N.J. Analysis on field trial of high temperature heat pump integrated with thermal energy storage in domestic retrofit installation. Appl. Therm. Eng. 2018, 143, 650–659. [Google Scholar] [CrossRef]

- Le, K.X.; Huang, M.J.; Shah, N.; Wilson, C.; Mac Artain, P.; Byrne, R.; Hewitt, N.J. High Temperature Air Source Heat Pump Coupled with Thermal Energy Storage: Comparative Performances and Retrofit Analysis. Energy Procedia 2019, 158, 3878–3885. [Google Scholar] [CrossRef]

- Carella, A.; D’Orazio, A. The heat pumps for better urban air quality. Sustain. Cities Soc. 2021, 75, 103314. [Google Scholar] [CrossRef]

- Carella, A.; Del Ferraro, L.; D’Orazio, A. Air/Water Heat Pumps in Existing Heating and Hot Water Systems for Better Urban Air Quality and Primary Energy Savings: Scenarios of Two Italian Cities. Energies 2023, 16, 377. [Google Scholar] [CrossRef]

- Shao, S.; Zhang, H.; Zheng, W.; You, S.; Wang, Y. Numerical and experimental investigations on heat transfer performance of the refrigerant-heated radiator. Appl. Therm. Eng. 2020, 179, 115748. [Google Scholar] [CrossRef]

- Abedini, H.; Vieren, E.; Demeester, T.; Beyne, W.; Lecompte, S.; Quoilin, S.; Arteconi, A. A comprehensive analysis of binary mixtures as working fluid in high temperature heat pumps. Energy Convers. Manag. 2023, 277, 116652. [Google Scholar] [CrossRef]

- Adamson, K.M.; Walmsley, T.G.; Carson, J.K.; Chen, Q.; Schlosser, F.; Kong, L.; Cleland, D.J. High-temperature and transcritical heat pump cycles and advancements: A review. Renew. Sustain. Energy Rev. 2022, 167, 112798. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Navarro-Esbrí, J.; Molés, F.; Cervera, Á.B.; Peris, B.; Verdú, G. A review of refrigerant R1234ze(E) recent investigations. Appl. Therm. Eng. 2016, 95, 211–222. [Google Scholar] [CrossRef]

- EES: Engineering Equation Solver|F-Chart Software: Engineering Software. n.d. Available online: https://fchartsoftware.com/ees/ (accessed on 17 December 2022).

- Welcome|TRNSYS: Transient System Simulation Tool. n.d. Available online: https://www.trnsys.com/ (accessed on 17 December 2022).

- List of Refrigerants. Wikipedia 2023. Available online: https://en.wikipedia.org/wiki/List_of_refrigerants (accessed on 17 December 2022).

- Welcome to BITZER. n.d. Available online: https://www.bitzer.de/gr/en/ (accessed on 17 December 2022).

- BITZER Software. n.d. Available online: https://www.bitzer.de/websoftware/Default.aspx (accessed on 17 December 2022).

- Greek Technical Chamber. Available online: http://portal.tee.gr/portal/page/portal/SCIENTIFIC_WORK/GR_ENERGEIAS/kenak/files/TOTEE_20701-1_2017_TEE_1st_Edition.pdf (accessed on 17 December 2022).

- Bellos, E.; Lykas, P.; Tzivanidis, C. Theoretical Analysis of a Biomass-Driven Single-Effect Absorption Heat Pump for Heating and Cooling Purposes. Appl. Syst. Innov. 2022, 5, 99. [Google Scholar] [CrossRef]

- ISO 7730, 2005. ISO. n.d. Available online: https://www.iso.org/standard/39155.html (accessed on 17 December 2022).

- DAPEEP. n.d. Available online: https://www.dapeep.gr/ (accessed on 17 December 2022).

- Heat Pumps YDOR. n.d. Available online: https://www.ydor.com.gr/antlies-thermotitas/?gclid=CjwKCAiAp7GcBhA0EiwA9U0mtkyRiiUfH5m8RsWav7hpm85YOuhnNqXMx851rw63fKlo_KWaUNVcxRoCgzwQAvD_BwE&f2--=6-kw&page=2 (accessed on 17 December 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).