Deformation Characteristics and Grouting Control Technology of Reused Roadway in a Fully Mechanized Coalface with Large Mining Height

Abstract

1. Introduction

2. Engineering Background

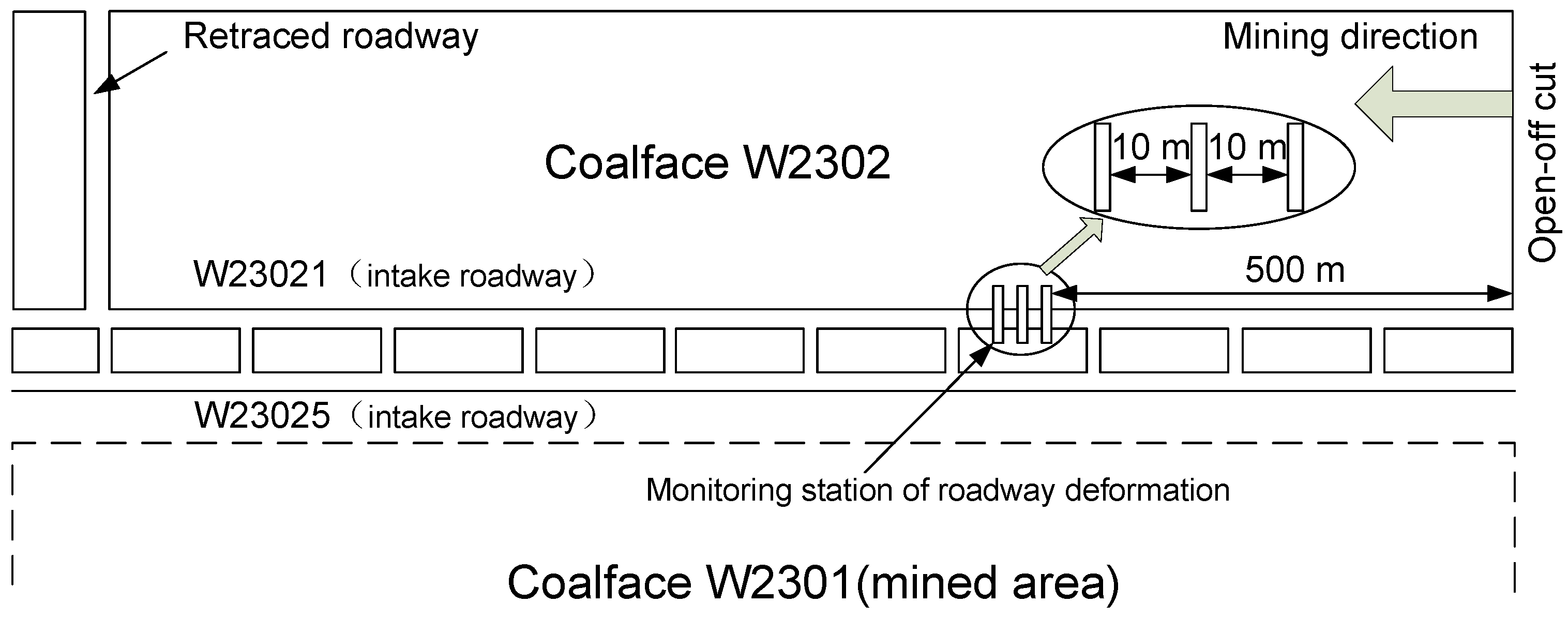

2.1. Basic Condition and Roadway Layout of Coalface W 2302

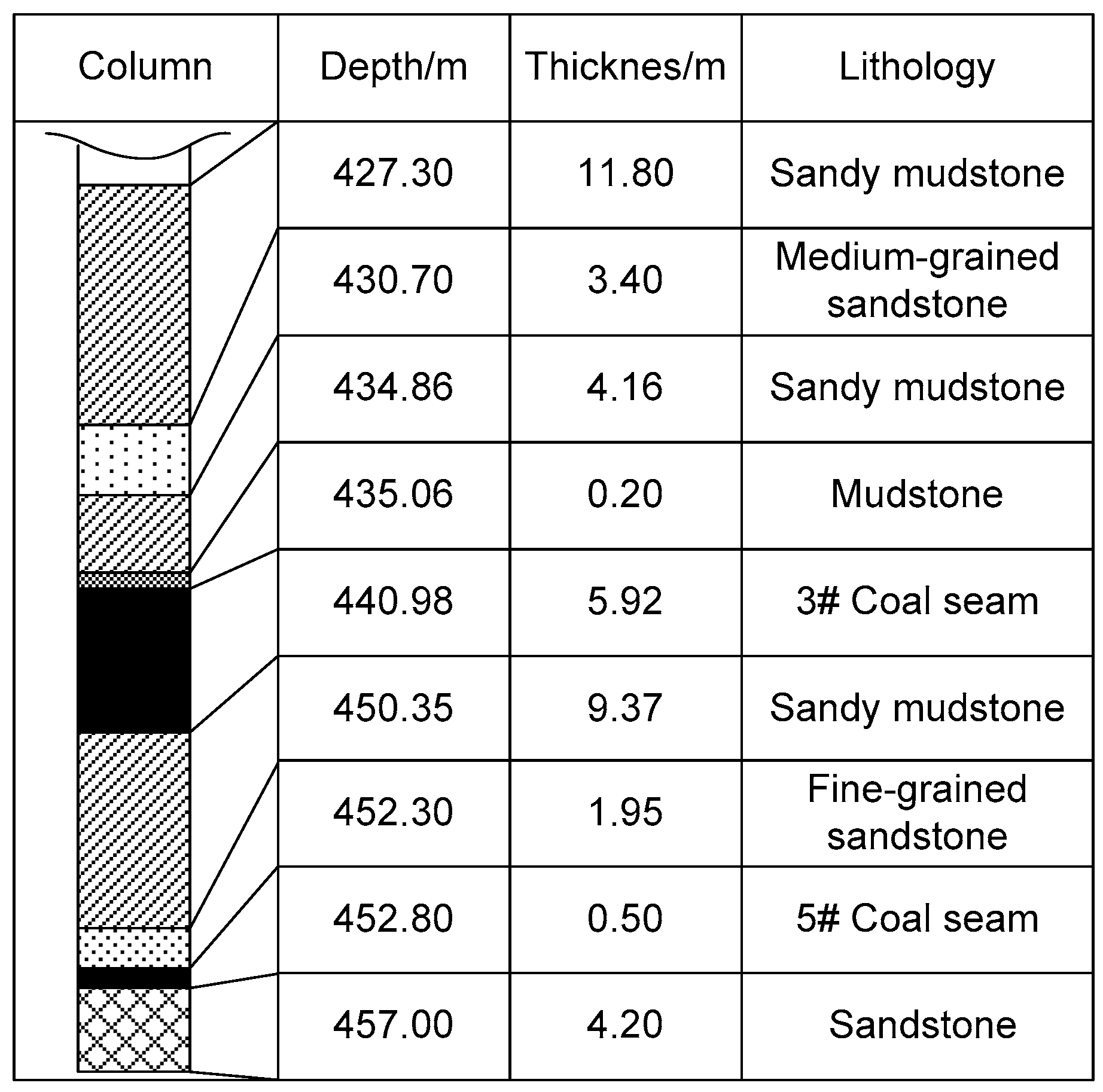

2.2. Lithology of the Roof and Floor

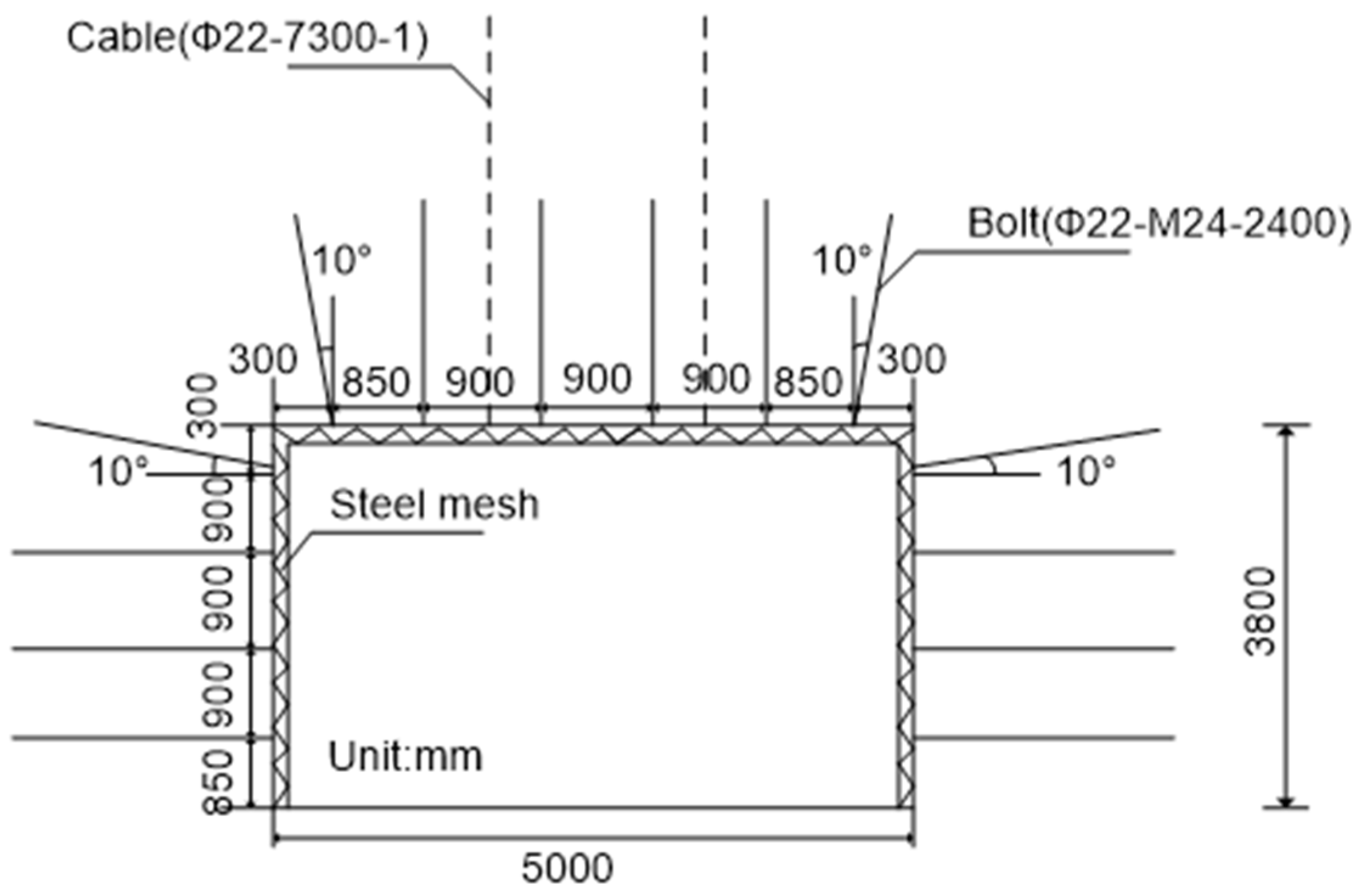

2.3. Support Situation of Roadway W 23021

- Roof support: There are six anchor bolts Φ 22-M 24-2400 in each row. The adjacent-spacing is 850 mm or 900 mm and the row-spacing is 1000 mm. The roof cable used was a Φ 22-7300-1 high-strength anchor cable, arranged two cables per row. The anchors were fixed along the entire length, and the diameter of the anchor holes was 32~38 mm. The adjacent-spacing is 1800 mm and the row-spacing is 2000 mm. The roof surface was covered by series of metal meshes. The size of each metal mesh is 6.0 × 1.1 m.

- Two sides support: There are four anchor bolts Φ 18-M 20-2000 in each side. The anchors were fixed along the entire length, and the diameter of the anchor holes was about 28 mm. The adjacent-spacing is 900 mm and the row-spacing is 1000 mm. The surface was covered by series of metal meshes, whose size is 3.5 × 1.1 m.

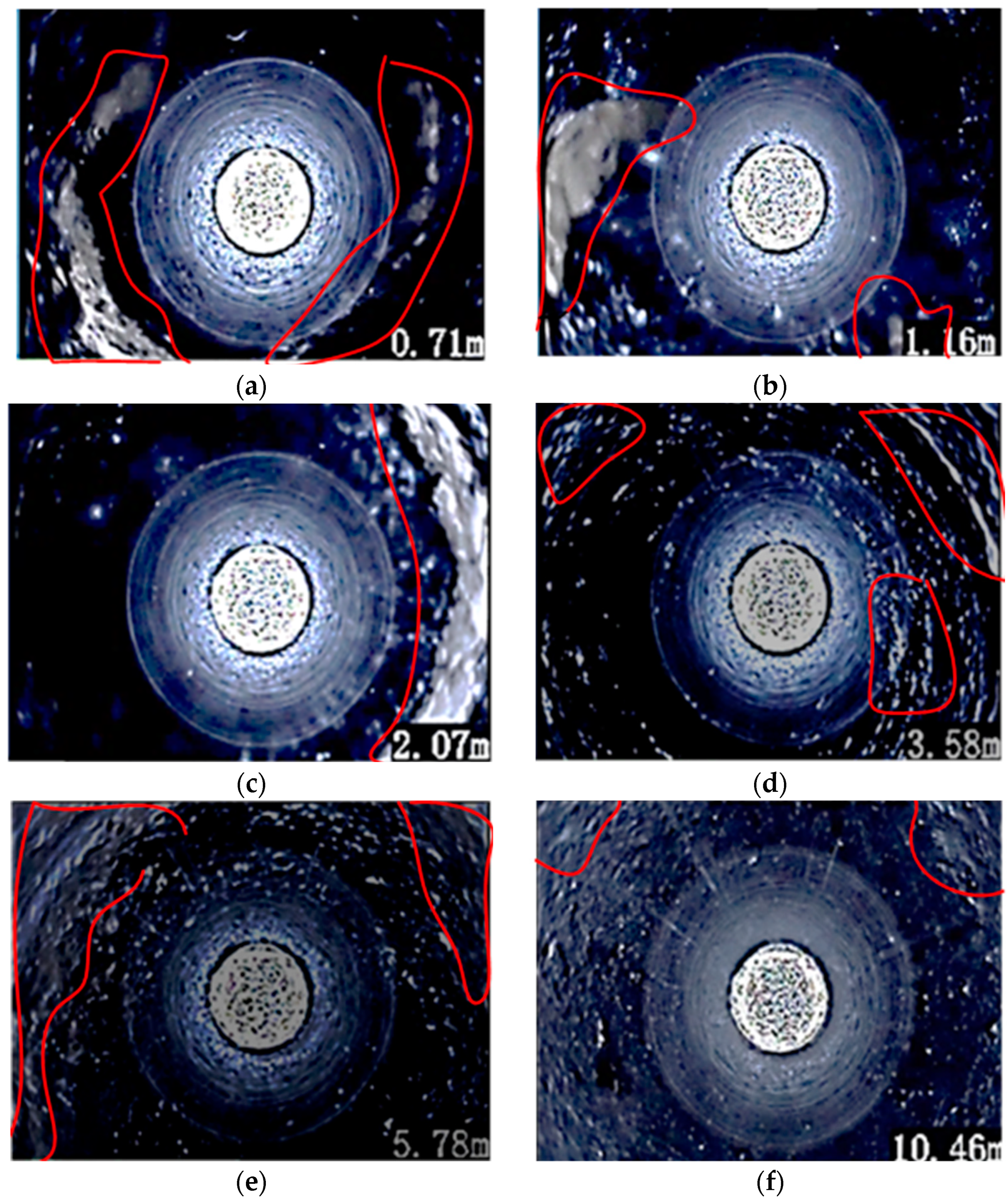

3. Deformation Characteristics and Forced Mechanism of Roadway W 23021

3.1. Field Monitoring

3.1.1. Monitoring Scheme

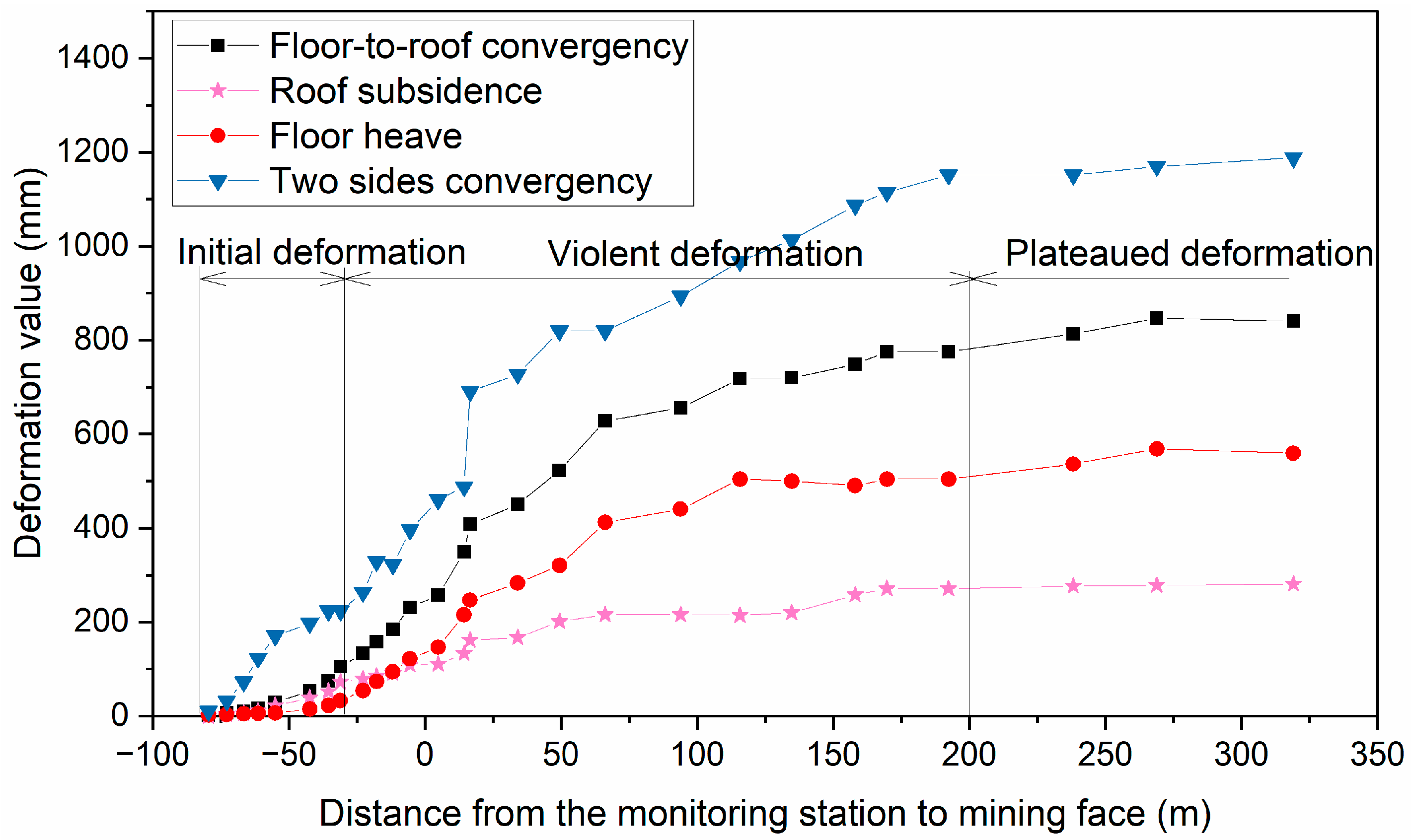

3.1.2. Roadway Deformation during the First Mining

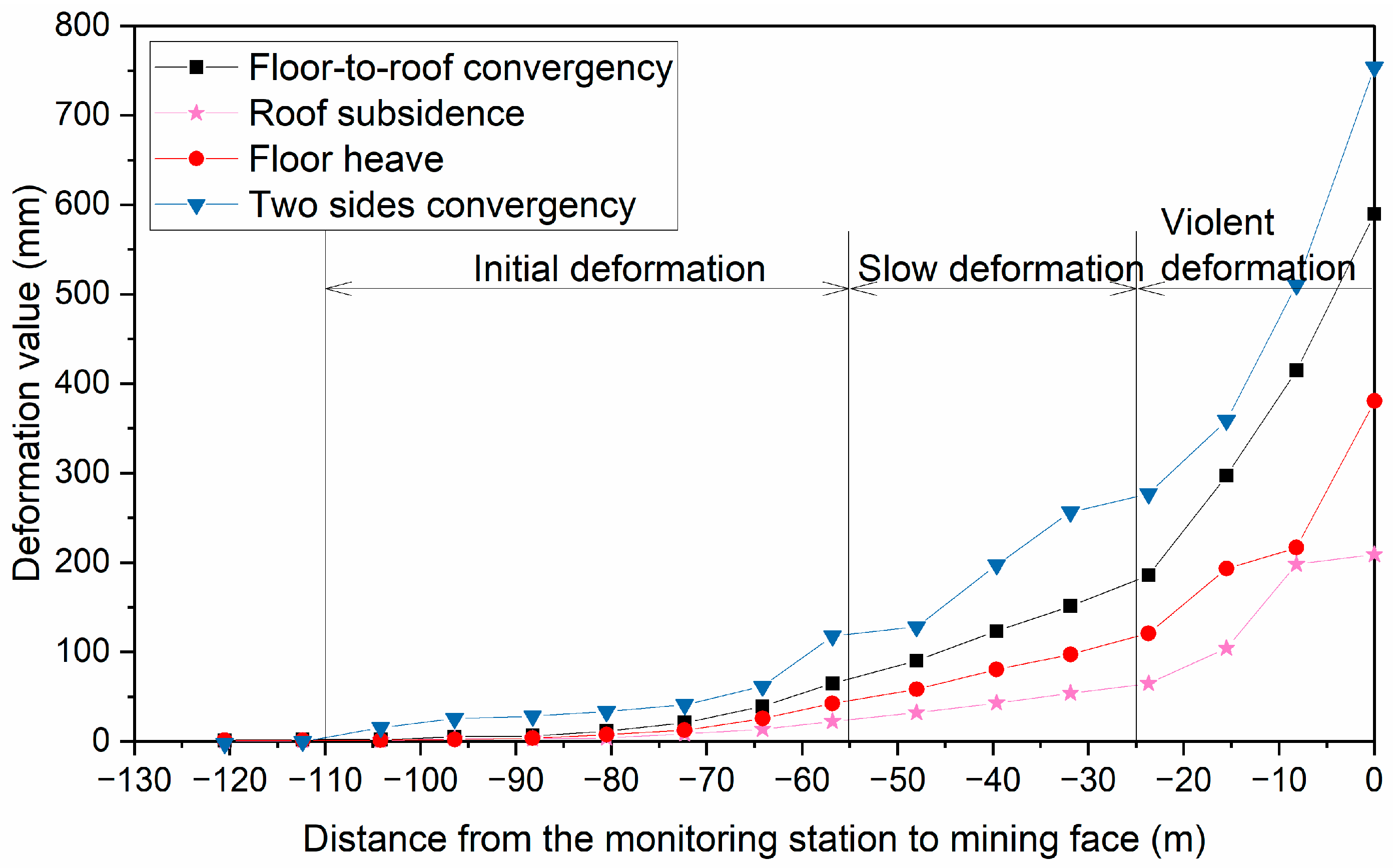

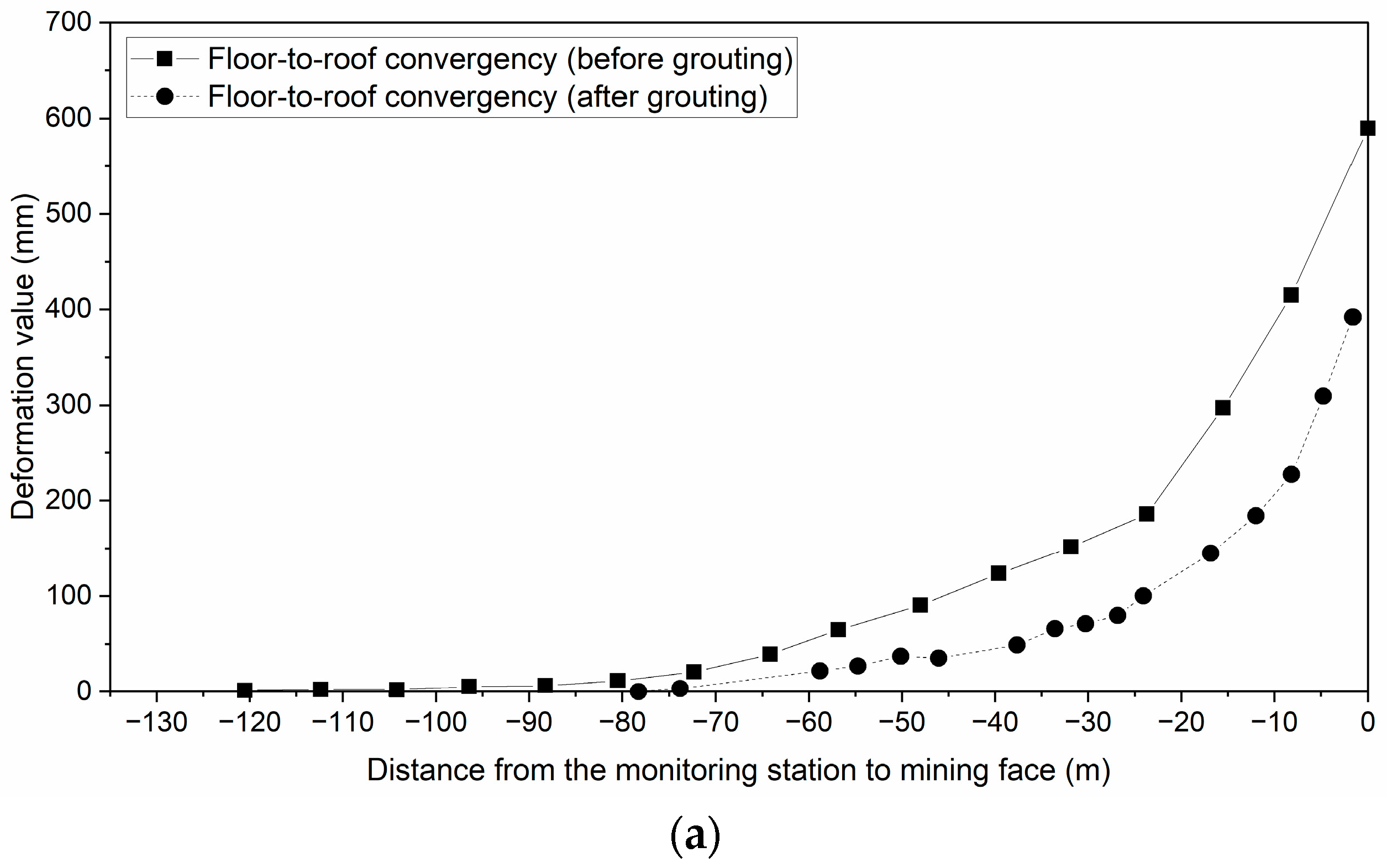

3.1.3. Roadway Deformation during the Second Mining

3.2. Numerical Simulation

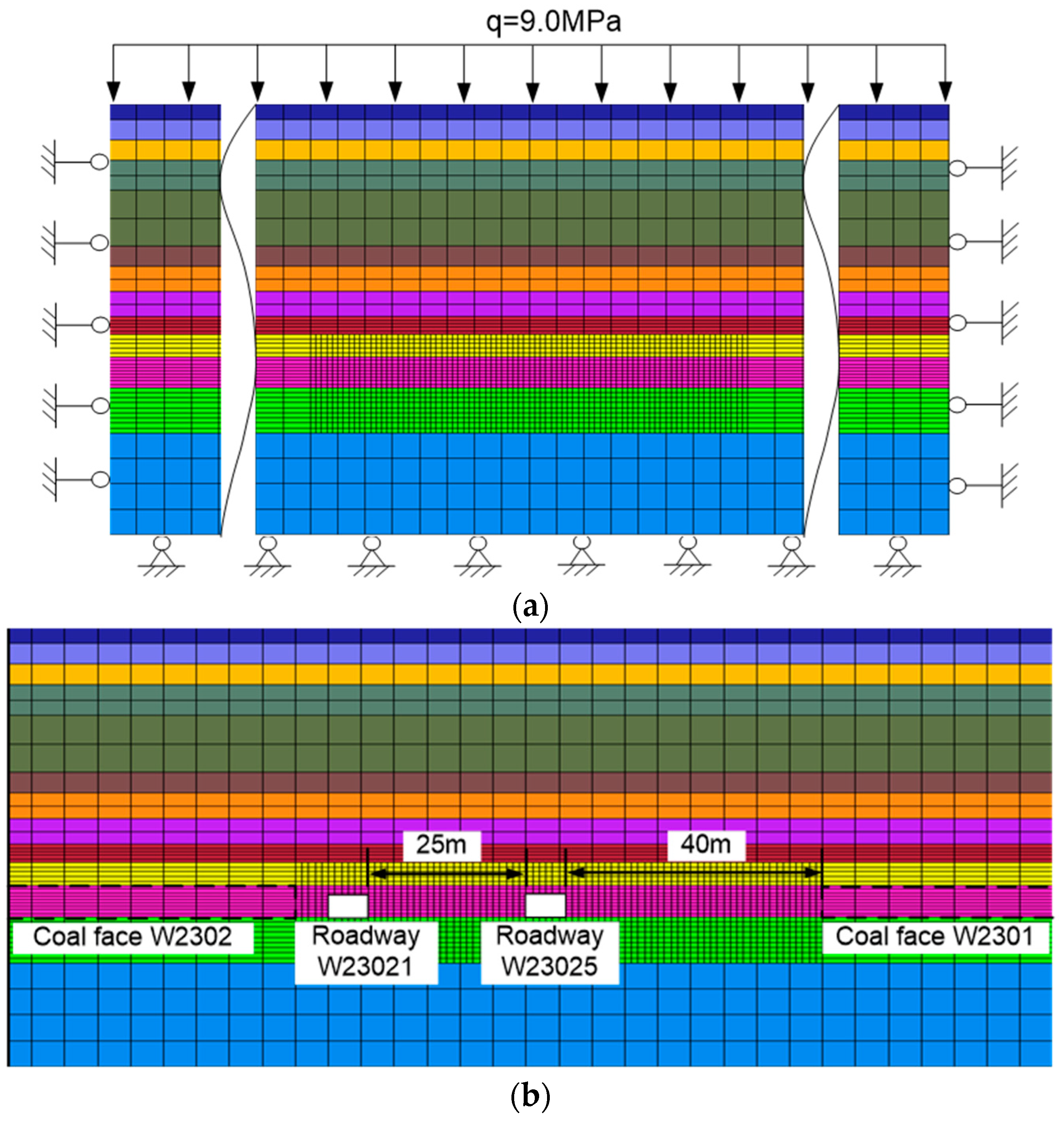

3.2.1. Numerical Model

3.2.2. Constitutive Model and Model Parameters

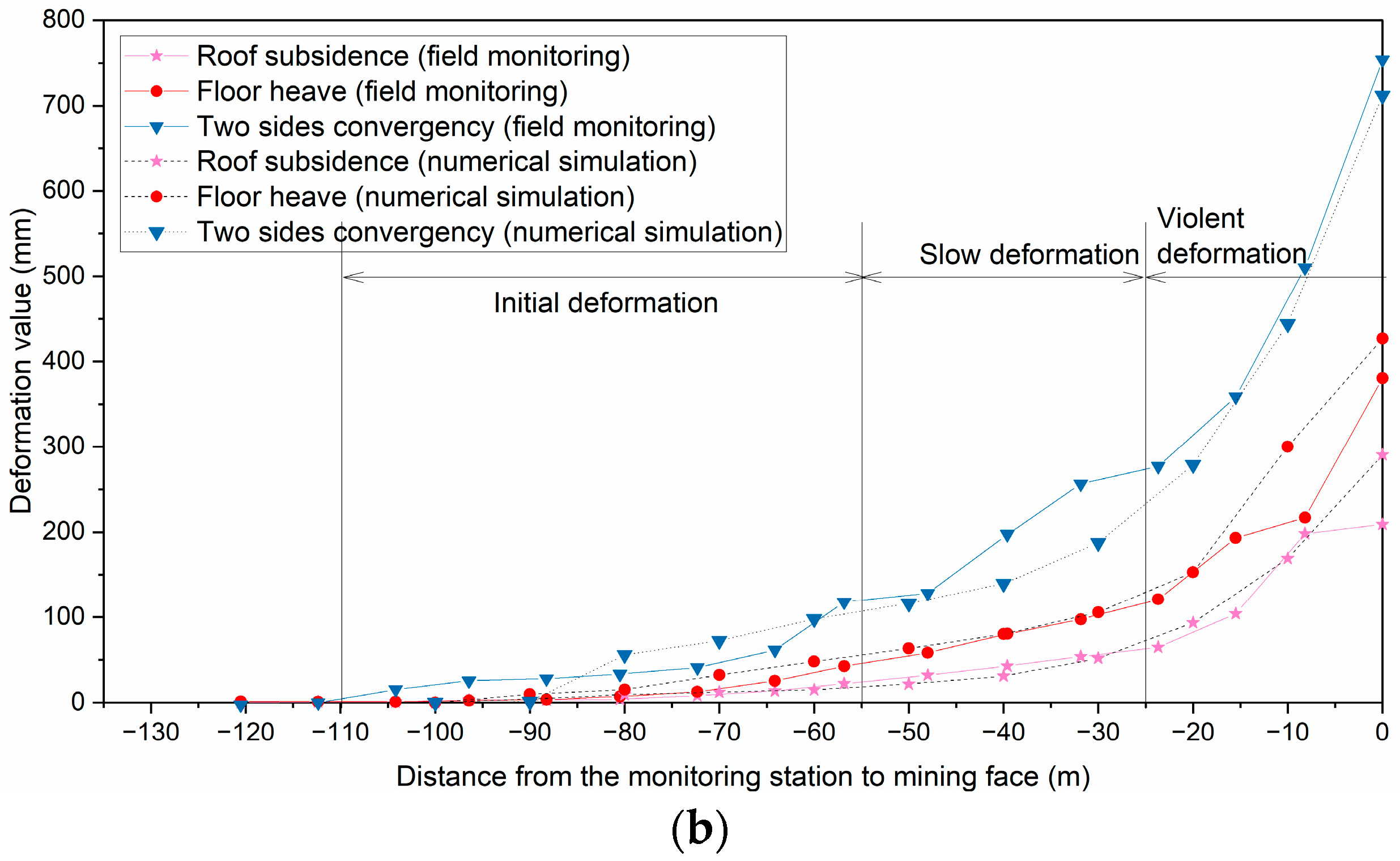

3.2.3. Roadway Deformation Simulation Results

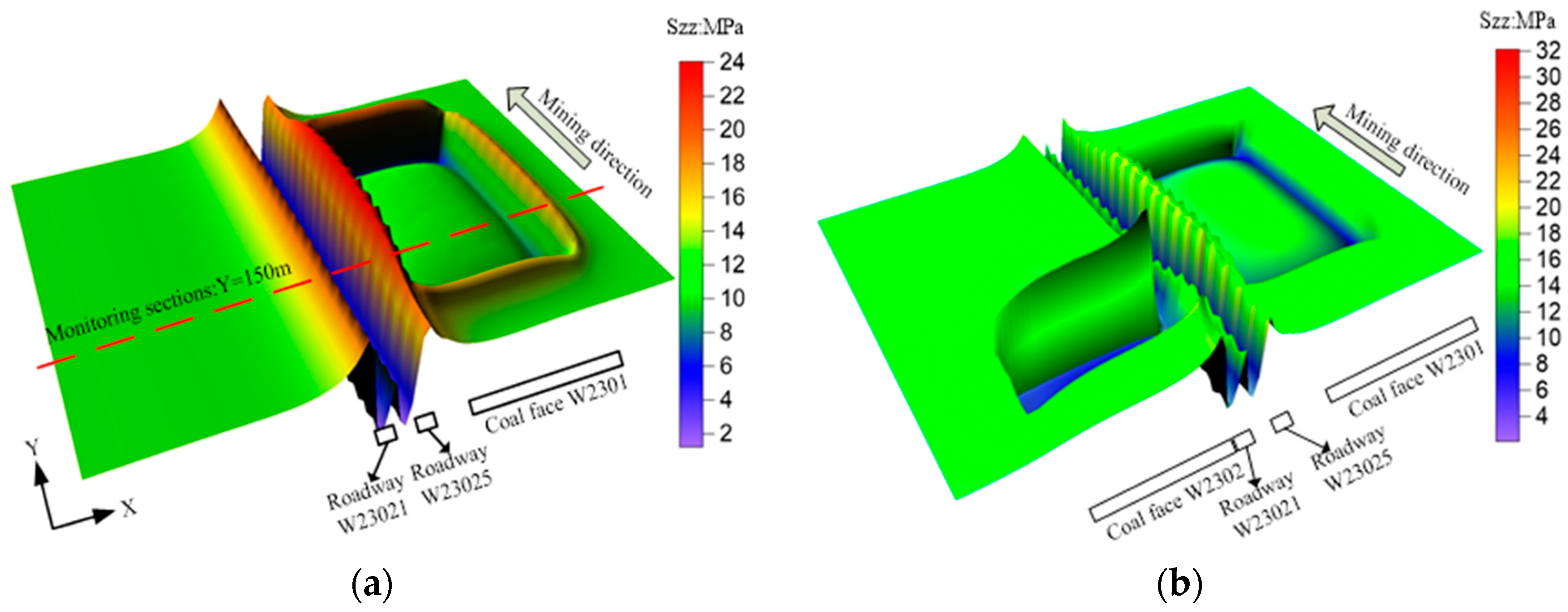

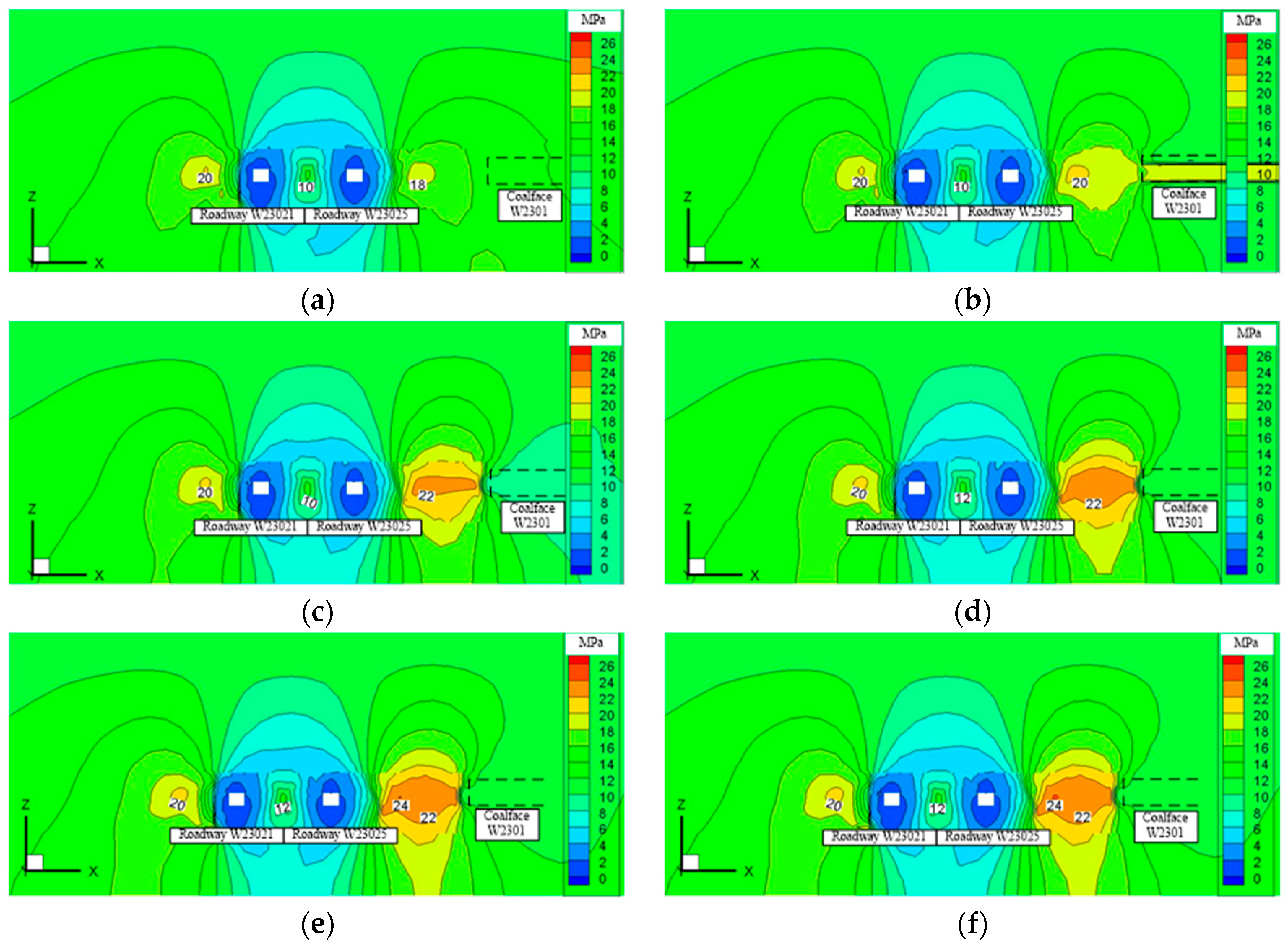

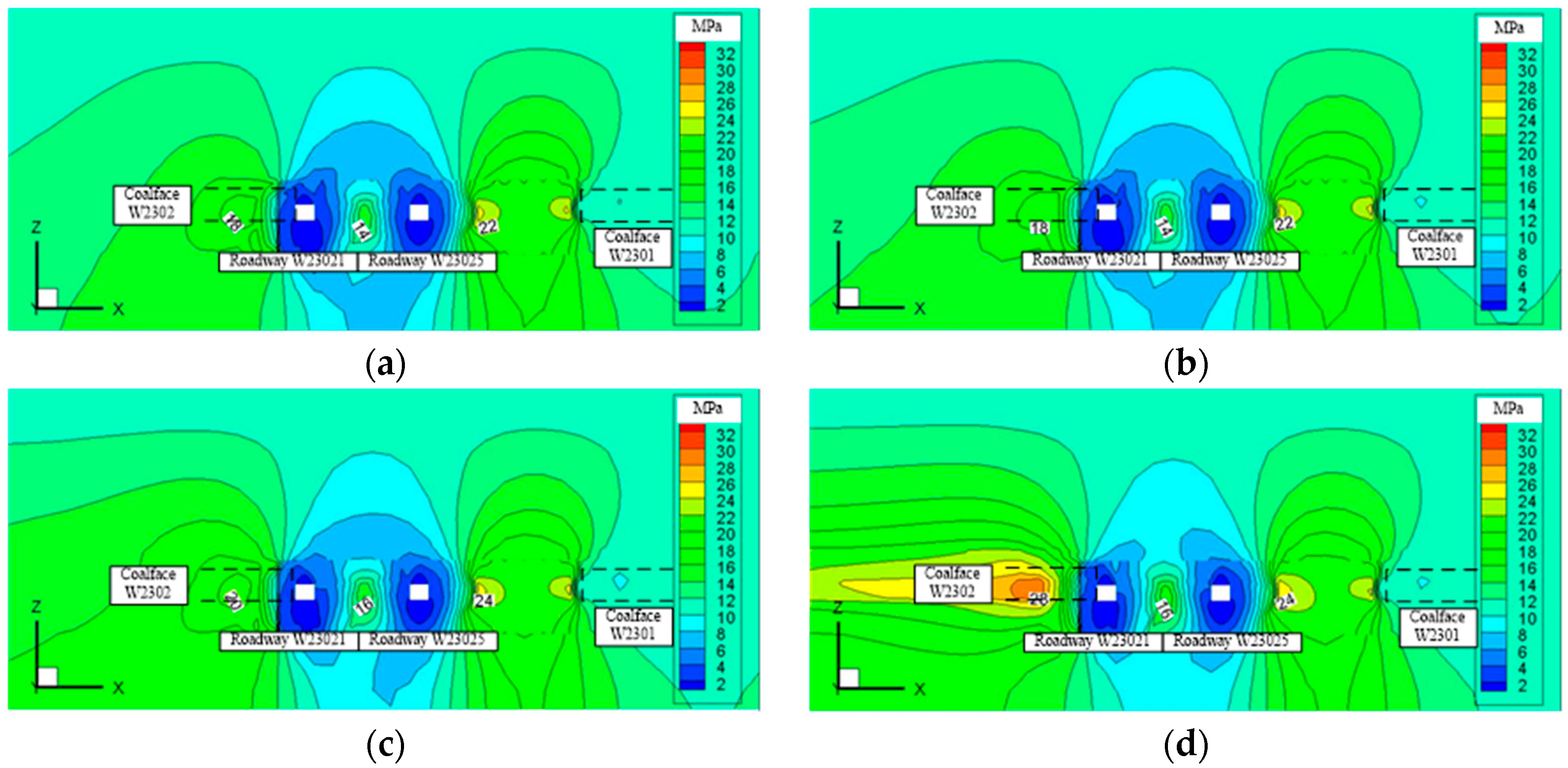

3.2.4. Stress Distribution Simulation Results

4. Grouting Control Technology

4.1. Grouting Material

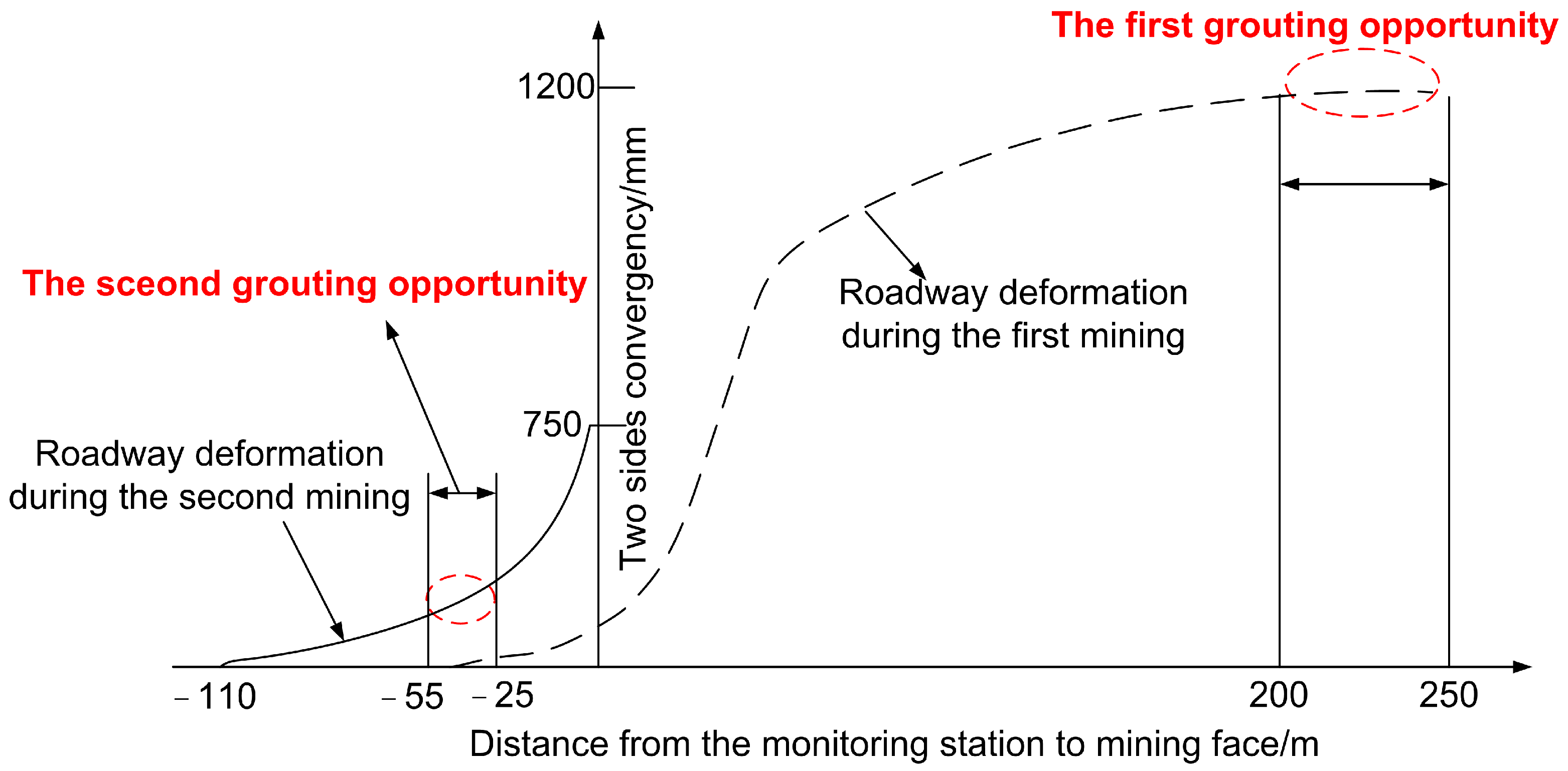

4.2. Grouting Opportunity

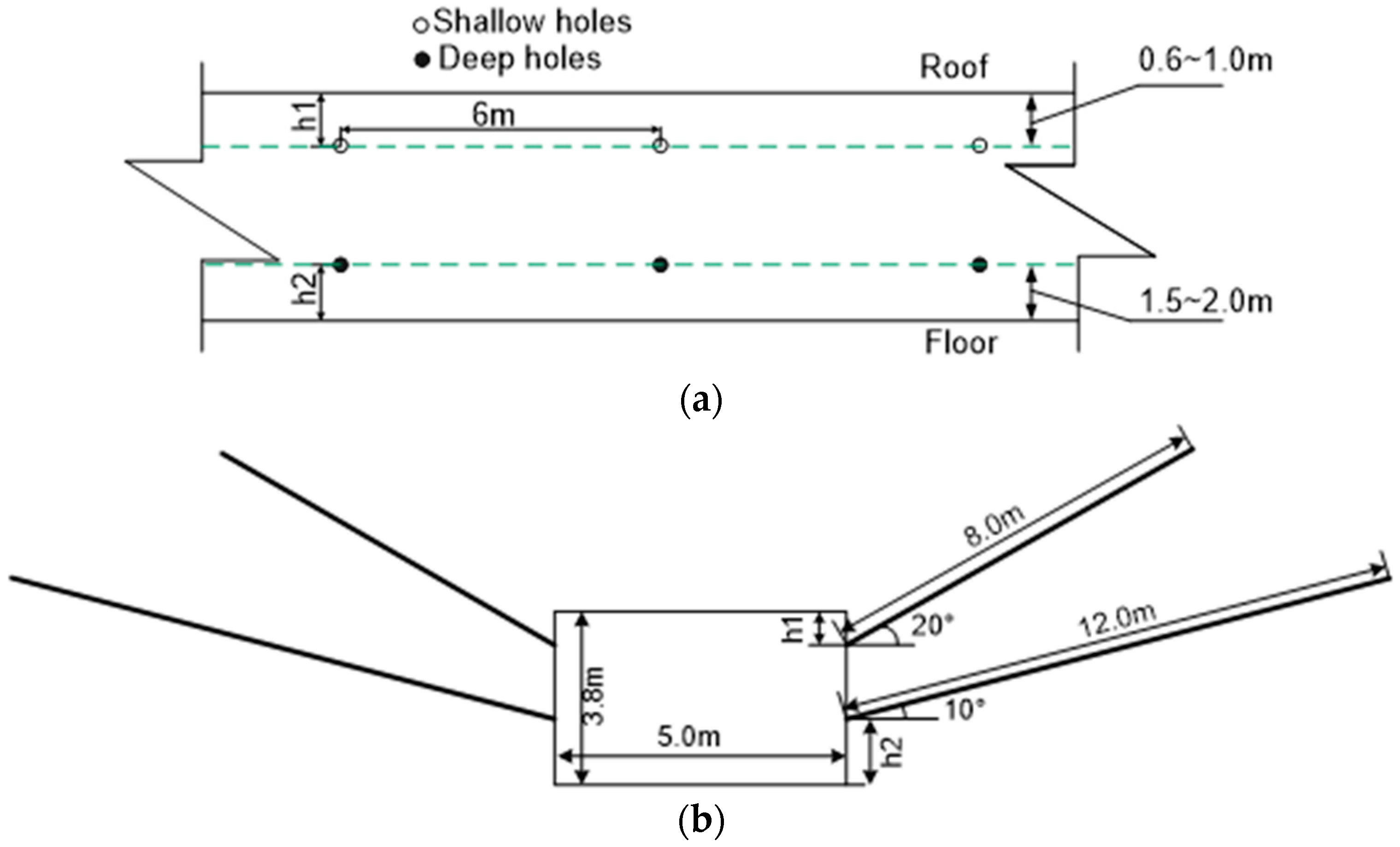

4.3. Grouting Drilling Arrangement and Technological Parameters

4.4. Application Effect

4.5. Future Work

5. Conclusions

- The roadway deformation was significantly affected by the lateral abutment pressure of the coalface during the first mining operation, which is characterized by lagging stable deformation and means a permanent deformation is achieved only after the coalface has advanced and passed a long distance. The deformation range during the first mining can be divided into initial deformation, violent deformation and plateaued deformation stages.

- The roadway deformation is significantly affected by the leading abutment pressure of the coalface during the second mining operation, which is characterized by ceaselessly increasing deformation and means that the deformation becomes more and more severe with the advancing of the coalface. The deformation range during the second mining can be divided into initial deformation, slow deformation and violent deformation stages.

- The grouting operation of the reused roadway ought to be conducted twice. The first grouting opportunity was suggested to be in the front part of the plateaued deformation stage during the first mining operation because the roadway damage had become stable basically at this stage. The second grouting opportunity was suggested in the slow deformation stage during the second mining operation because the gradually developed damage cracks provide the possibility for large-area grouting.

- The grouting operation has greatly improved the broken surrounding rock of the reused roadway and reduced its deformation dramatically. However, the grouting is difficult to be conducted in several seriously damaged areas, in which the chemical materials could be used to form a surface-integrity layer that can seal the surface crack channels quickly. Some additional roadway repairs and reinforcements such as bolt or cable supports and so on are still be necessary for parts of severely damaged roads.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, Y.; Liu, Q.; Xi, H. Numerical analysis of THM coupling of a deeply buried roadway passing through composite strata and dense faults in a coal mine. Bull. Eng. Geol. Environ. 2014, 73, 77–86. [Google Scholar] [CrossRef]

- Singh, R.; Singh, T. Investigation into the Behaviour of a Support System and Roof Strata during Sublevel Caving of a Thick Coal Seam. Geotech. Geol. Eng. 1999, 17, 21–35. [Google Scholar] [CrossRef]

- Unver, B.; Yasitli, N. Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 2006, 66, 227–252. [Google Scholar] [CrossRef]

- Ju, J.; Xu, J. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar] [CrossRef]

- Kong, D.-Z.; Cheng, Z.-B.; Zheng, S.-S. Study on the failure mechanism and stability control measures in a large-cutting-height coal mining face with a deep-buried seam. Bull. Eng. Geol. Environ. 2019, 78, 6143–6157. [Google Scholar] [CrossRef]

- Huang, Q.; He, Y.; Li, F. Research on the Roof Advanced Breaking Position and Influences of Large Mining Height Working Face in Shallow Coal Seam. Energies 2020, 13, 1685. [Google Scholar] [CrossRef]

- Yuan, Y.; Tu, S.H.; Zhang, X.G.; Li, B. Dynamic effect and control of key strata break of immediate roof in fully mechanized mining with large mining height. Shock Vib. 2015, 2015, 657818. [Google Scholar]

- Li, C.; Zuo, J.; Wei, C.; Xu, X.; Zhou, Z.; Li, Y.; Zhang, Y. Fracture Development at Laminated Floor Layers under Longwall Face in Deep Coal Mining. Nat. Resour. Res. 2020, 29, 3857–3871. [Google Scholar] [CrossRef]

- Chen, J.; Wu, H.; Zhang, X.; Gao, X.; Ling, T.; Zhang, Z. Experimental Study of the Plastic Zone and Stress Asymmetric Distribution in Roadway Layered Surrounding Rocks. Appl. Sci. 2022, 12, 6108. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Guo, J.; Zhao, H. Deformation Characteristics and Control Method of Kilometer-Depth Roadways in a Nickel Mine: A Case Study. Appl. Sci. 2020, 10, 3937. [Google Scholar] [CrossRef]

- Islam, M.R.; Shinjo, R. Numerical simulation of stress distributions and displacements around an entry roadway with igneous intrusion and potential sources of seam gas emission of the Barapukuria coal mine, NW Bangladesh. Int. J. Coal Geol. 2009, 78, 249–262. [Google Scholar] [CrossRef]

- Liu, X.; Yang, S.; Ding, X.; Zhang, C.; Wang, X.; Zhou, B.; Ding, X. Physical Simulation and Monitoring the Deformation and Fracture of Roadway in Coal Mining. Adv. Civ. Eng. 2018, 2018, 2607957. [Google Scholar] [CrossRef]

- Mandal, P.K.; Das, A.J.; Kumar, N.; Bhattacharjee, R.; Tewari, S.; Kushwaha, A. Assessment of roof convergence during driving roadways in underground coal mines by continuous miner. Int. J. Rock Mech. Min. Sci. 2018, 108, 169–178. [Google Scholar] [CrossRef]

- Wang, H.; Xue, S.; Jiang, Y.; Deng, D.; Shi, S.; Zhang, D. Field Investigation of a Roof Fall Accident and Large Roadway Deformation under Geologically Complex Conditions in an Underground Coal Mine. Rock Mech. Rock Eng. 2018, 51, 1863–1883. [Google Scholar] [CrossRef]

- Zang, C.; Chen, M.; Zhang, G.; Wang, K.; Gu, D. Research on the failure process and stability control technology in a deep roadway: Numerical simulation and field test. Energy Sci. Eng. 2020, 8, 2297–2310. [Google Scholar] [CrossRef]

- Chen, D.; Ji, C.; Xie, S.; Wang, E.; He, F.; Cheng, Q.; Zhang, Q. Deviatoric Stress Evolution Laws and Control in Surrounding Rock of Soft Coal and Soft Roof Roadway under Intense Mining Conditions. Adv. Mater. Sci. Eng. 2020, 2020, 5036092. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, W.; Li, X.; Wang, Y.; Qin, Q.; Lu, X.; Xue, T. Abutment Pressure Distribution Law and Support Analysis of Super Large Mining Height Face. Int. J. Environ. Res. Public Health 2023, 20, 227. [Google Scholar] [CrossRef]

- Sun, Y.; Bi, R.; Chang, Q.; Taherdangkoo, R.; Zhang, J.; Sun, J.; Huang, J.; Li, G. Stability Analysis of Roadway Groups under Multi-Mining Disturbances. Appl. Sci. 2021, 11, 7953. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, H.; Li, G. Study on Size Optimization of a Protective Coal Pillar under a Double-Key Stratum Structure. Appl. Sci. 2022, 12, 11868. [Google Scholar] [CrossRef]

- Basarir, H.; Sun, Y.; Li, G. Gateway stability analysis by global-local modeling approach. Int. J. Rock Mech. Min. 2019, 113, 31–40. [Google Scholar] [CrossRef]

- Kang, H.; Wu, L.; Gao, F.; Lv, H.; Li, J. Field study on the load transfer mechanics associated with longwall coal retreat mining. Int. J. Rock Mech. Min. Sci. 2019, 124, 104141. [Google Scholar] [CrossRef]

- Yang, X.J.; Yang, G.; Huang, R.F.; Wang, Y.J.; Liu, J.N.; Zhang, J.; Hou, S.L. Comprehensive study on surrounding rock failure characteristics of longwall roadway and control rechniques. Appl. Sci. 2021, 11, 9795. [Google Scholar] [CrossRef]

- Wu, X.Y.; Liu, H.T.; Li, J.W.; Guo, X.F.; Lv, K.; Wang, J.Y. Temporal-spatial evolutionary law of plastic zone and stability control in repetitive mining roadway. J. China Coal Soc. 2020, 45, 3389–3400. (In Chinese) [Google Scholar]

- Wu, X.Y.; Wang, J.Y.; Chen, S.J.; Zhang, Y.J.; Bu, Q.W. Regulation principle and stability control of plastic zone in repeated mining roadway. Rock Soil Mech. 2022, 43, 205–217. (In Chinese) [Google Scholar]

- Gao, Y.; Liu, R.; Jing, H.; Chen, W.; Yin, Q. Hydraulic properties of single fractures grouted by different types of carbon nanomaterial-based cement composites. Bull. Eng. Geol. Environ. 2020, 79, 2411–2421. [Google Scholar] [CrossRef]

- Jones, B.R.; Van Rooy, J.L.; Mouton, D.J. Verifying the ground treatment as proposed by the Secondary Permeability Index during dam foundation grouting. Bull. Eng. Geol. Environ. 2019, 78, 1305–1326. [Google Scholar] [CrossRef]

- Song, B.; Zhang, S.; Zhang, D.; Fan, G.; Yu, W.; Zhao, Q.; Liang, S. Inorganic Cement Grouting for Reinforcing Triangular Zone of Highly Gassy Coal Face with Large Mining Height. Energies 2018, 11, 2549. [Google Scholar] [CrossRef]

- Stromsvik, H.; Gammelsaeter, B. Investigation and assessment of pre-grouted rock mass. B Eng. Geol. Env. 2020, 79, 2543–2560. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.; Liu, R.; Li, Z.; Zhang, Q. Experimental study on performance of cement-based grouts admixed with fly ash, bentonite, superplasticizer and water glass. Constr. Build. Mater. 2018, 161, 282–291. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Y. Experimental and Mechanism Study of a Polymer Foaming Grouting Material for Reinforcing Broken Coal Mass. KSCE J. Civ. Eng. 2019, 23, 346–355. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B. Research on the preparation and properties of a novel grouting material based on magnesium phosphate cement. Constr. Build. Mater. 2019, 214, 516–526. [Google Scholar] [CrossRef]

- Sun, X.; Wang, L.; Lu, Y.; Jiang, B.; Li, Z.; Zhang, J. A yielding bolt-grouting support design for a soft-rock roadway under high stress: A case study of the Yuandian No. 2 coal mine in China. J. South. Afr. Inst. Min. Met. 2018, 118, 71–82. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Wei, J.; Zhang, Q.; Liu, R.; Zhang, X.; Yin, H. Grouting rock fractures with cement and sodium silicate grout. Carbonate Evaporite 2017, 33, 211–222. [Google Scholar] [CrossRef]

- Sun, Y.; Li, G.; Zhang, J. Investigation on jet grouting support strategy for controlling time-dependent deformation in the roadway. Energy Sci. Eng. 2020, 8, 2151–2158. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, N.; Feng, X.; Liang, D.; Wei, Q.; Weng, M. Investigation on the evolution and control of surrounding rock fracture under different supporting conditions in deep roadway during excavation period. Int. J. Rock Mech. Min. Sci. 2019, 123, 104122. [Google Scholar] [CrossRef]

- Chang, Q.; Yao, X.; Leng, Q.; Cheng, H.; Wu, F.; Zhou, H.; Sun, Y. Strata Movement of the Thick Loose Layer under Strip-Filling Mining Method: A Case Study. Appl. Sci. 2021, 11, 11717. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Apel, D.B.; Wang, J.; Xu, H.; Guo, L. Choice of the Arch Yielding Support for the Preparatory Roadway Located near the Fault. Energies 2022, 15, 3774. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, L.; Zhu, Y.; Zhou, Z.; Chen, S. Stress Field Distribution and Deformation Law of Large Deformation Tunnel Excavation in Soft Rock Mass. Appl. Sci. 2019, 9, 865. [Google Scholar] [CrossRef]

- Han, Y.; Liu, X.; Li, D.; Tu, Y.; Deng, Z.; Liu, D.; Wu, X. Model test on the bearing behaviors of the tunnel-type anchorage in soft rock with underlying weak interlayers. Bull. Eng. Geol. Environ. 2020, 79, 1023–1040. [Google Scholar] [CrossRef]

- Zhou, J.W.; Xu, W.Y.; Li, M.W.; Zhou, X.Q.; Chong, S.H.I. Application of rock strain softening model to numerical analysis of deep tunnel. Chin. J. Rock Mech. Eng. 2009, 28, 1116–1127. (In Chinese) [Google Scholar]

- Cheng, Z.; Liu, B.; Zou, Q.; Wang, X.; Feng, J.; Zhao, Z.; Sun, F. Analysis of Spatial–Temporal Evolution of Mining-Induced Fracture Field: A Case Study Using Image Processing in the Shaqu Coal Mine, China. Nat. Resour. Res. 2020, 29, 1601–1615. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J.S.; Fu, J.Y.; Ou, X.F.; Xie, Y.P.; Liang, X. Performance evaluation of modified cement-sodium silicate grouting material for pre-reinforcing loose deposit tunnels. J. Mater. Civ. Eng. 2019, 31, 06019003. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, P.; Wang, Y. Hydration Behaviors of Portland Cement with Different Lithologic Stone Powders. Int. J. Concr. Struct. Mater. 2015, 9, 55–60. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Li, T.; Xiong, Z.; Sun, Y. Effects of lithium carbonate on performances of sulphoaluminate cement-based dual liquid high water material and its mechanisms. Constr. Build. Mater. 2018, 161, 374–380. [Google Scholar] [CrossRef]

- Ju, Y.; Wang, Y.; Su, C.; Zhang, D.; Ren, Z. Numerical analysis of the dynamic evolution of mining-induced stresses and fractures in multilayered rock strata using continuum-based discrete element methods. Int. J. Rock Mech. Min. Sci. 2019, 113, 191–210. [Google Scholar] [CrossRef]

- Liu, H.; Deng, K.; Zhu, X.; Jiang, C. Effects of mining speed on the developmental features of mining-induced ground fissures. Bull. Eng. Geol. Environ. 2019, 78, 6297–6309. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, Y.; Xue, S.; Shen, B.; Wang, C.; Lv, J.; Yang, T. Assessment of excavation damaged zone around roadways under dynamic pressure induced by an active mining process. Int. J. Rock Mech. Min. Sci. 2015, 77, 265–277. [Google Scholar] [CrossRef]

- Yu, W.; Wang, W.; Chen, X.; Du, S. Field investigations of high stress soft surrounding rocks and deformation control. J. Rock Mech. Geotech. 2015, 7, 421–433. [Google Scholar] [CrossRef]

| Lithology | Tensile Strength/MPa | Elastic Modulus/GPa | Cohesion/MPa | Internal Friction Angle/º | Poisson’s Ratio | Density/kg/m3 |

|---|---|---|---|---|---|---|

| Mudstone | 1.1 | 3.95 | 3.0 | 28 | 0.24 | 2500 |

| Sandy mudstone | 0.9 | 5.19 | 4.0 | 30 | 0.30 | 2500 |

| Fine-grained sandstone | 2.67 | 8.26 | 6.0 | 32 | 0.29 | 2500 |

| Medium-grained sandstone | 1.7 | 6.31 | 3.6 | 32 | 0.26 | 2500 |

| Coal | 0.56 | 3.66 | 2.5 | 26 | 0.22 | 1400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Cui, Z.; Peng, R.; Wei, T.; Wang, L.; Liu, D. Deformation Characteristics and Grouting Control Technology of Reused Roadway in a Fully Mechanized Coalface with Large Mining Height. Appl. Sci. 2023, 13, 1951. https://doi.org/10.3390/app13031951

Zhao L, Cui Z, Peng R, Wei T, Wang L, Liu D. Deformation Characteristics and Grouting Control Technology of Reused Roadway in a Fully Mechanized Coalface with Large Mining Height. Applied Sciences. 2023; 13(3):1951. https://doi.org/10.3390/app13031951

Chicago/Turabian StyleZhao, Leilei, Zhendong Cui, Ruidong Peng, Tao Wei, Longcan Wang, and Dongxu Liu. 2023. "Deformation Characteristics and Grouting Control Technology of Reused Roadway in a Fully Mechanized Coalface with Large Mining Height" Applied Sciences 13, no. 3: 1951. https://doi.org/10.3390/app13031951

APA StyleZhao, L., Cui, Z., Peng, R., Wei, T., Wang, L., & Liu, D. (2023). Deformation Characteristics and Grouting Control Technology of Reused Roadway in a Fully Mechanized Coalface with Large Mining Height. Applied Sciences, 13(3), 1951. https://doi.org/10.3390/app13031951