Application Characteristics of Bioethanol as an Oxygenated Fuel Additive in Diesel Engines

Abstract

1. Introduction

2. Experimental Details

2.1. Fuels

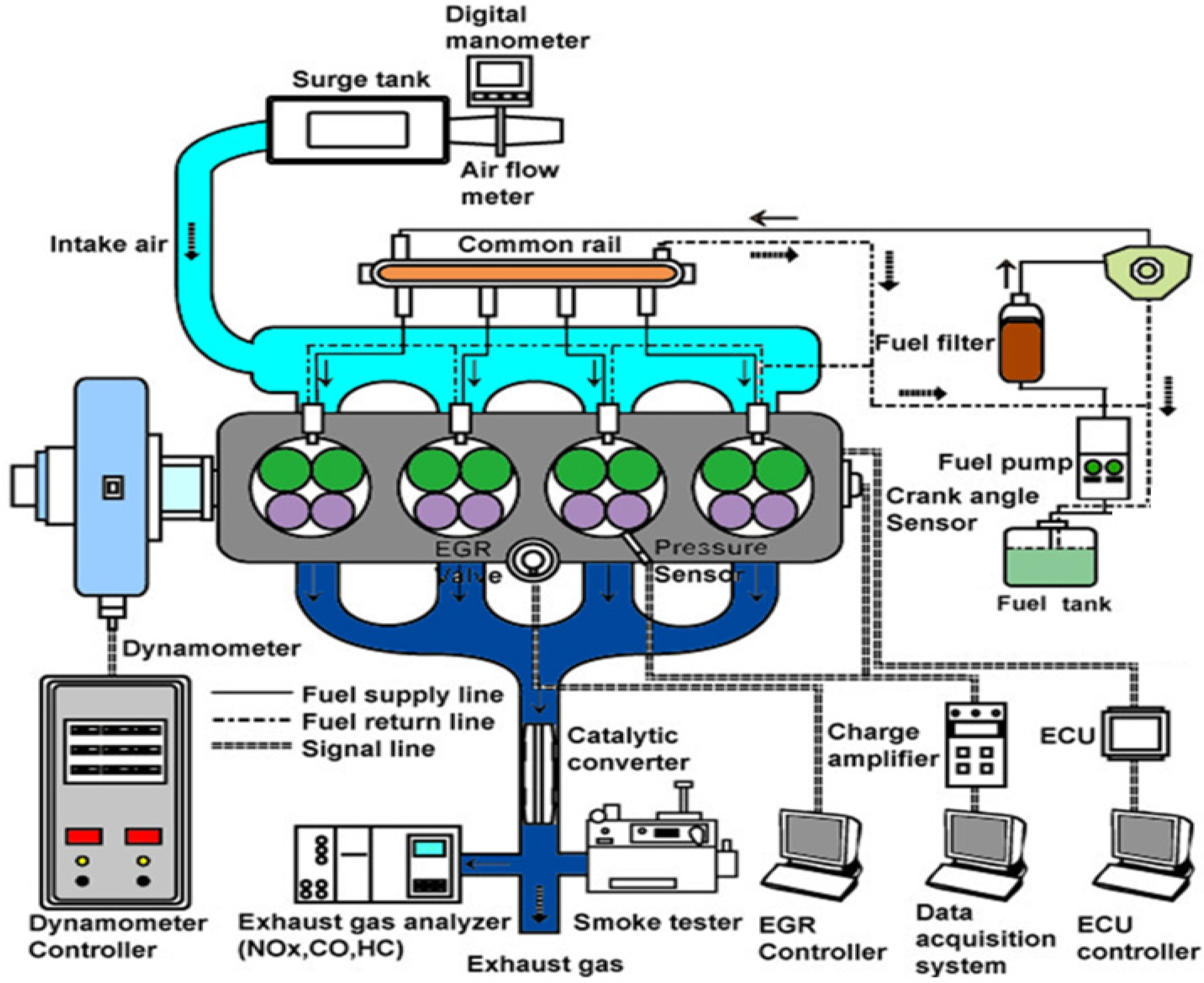

2.2. Experimental Apparatus

2.3. Experimental Conditions

3. Results and Discussion

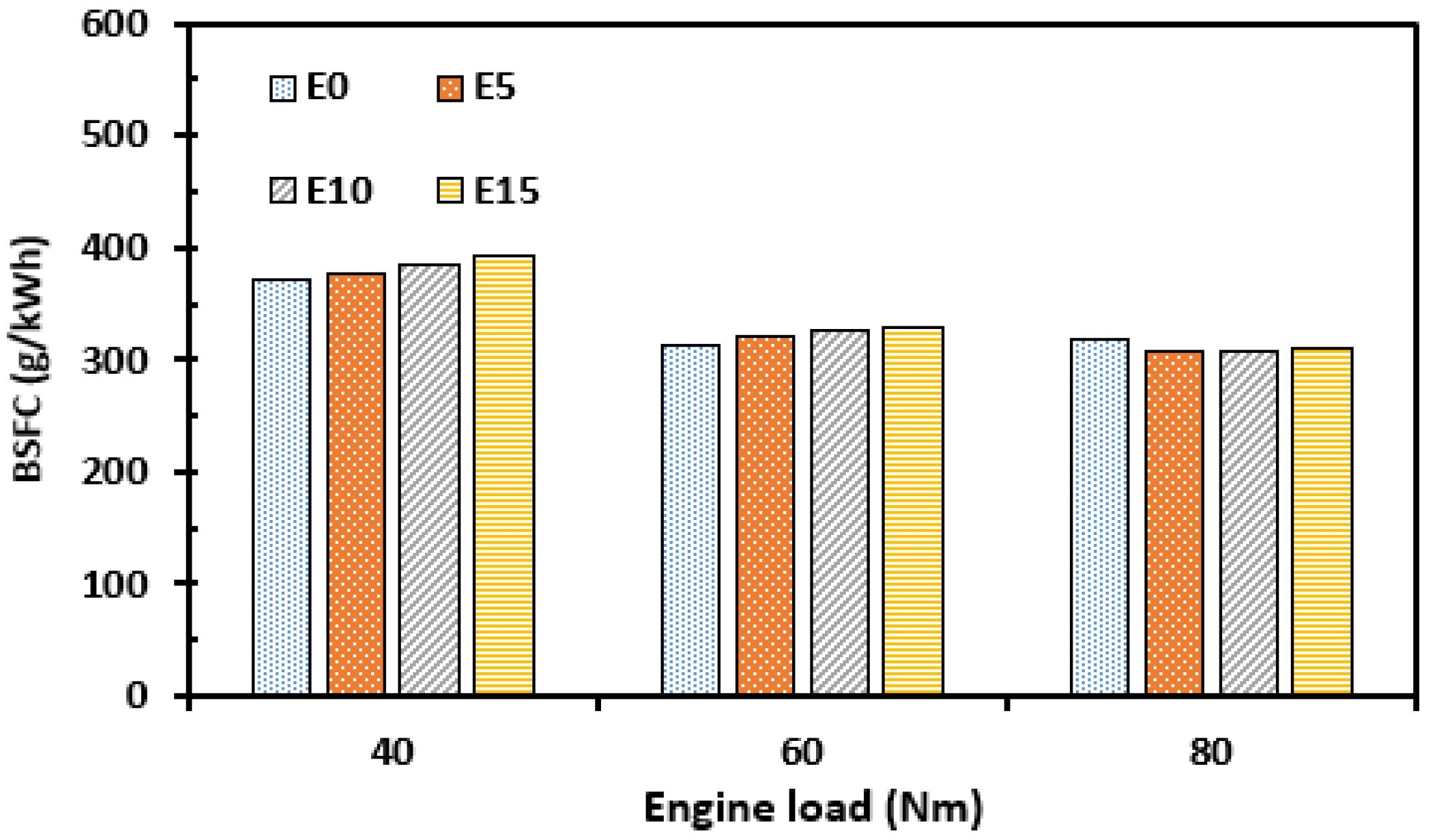

3.1. Engine Performance

3.2. Combustion

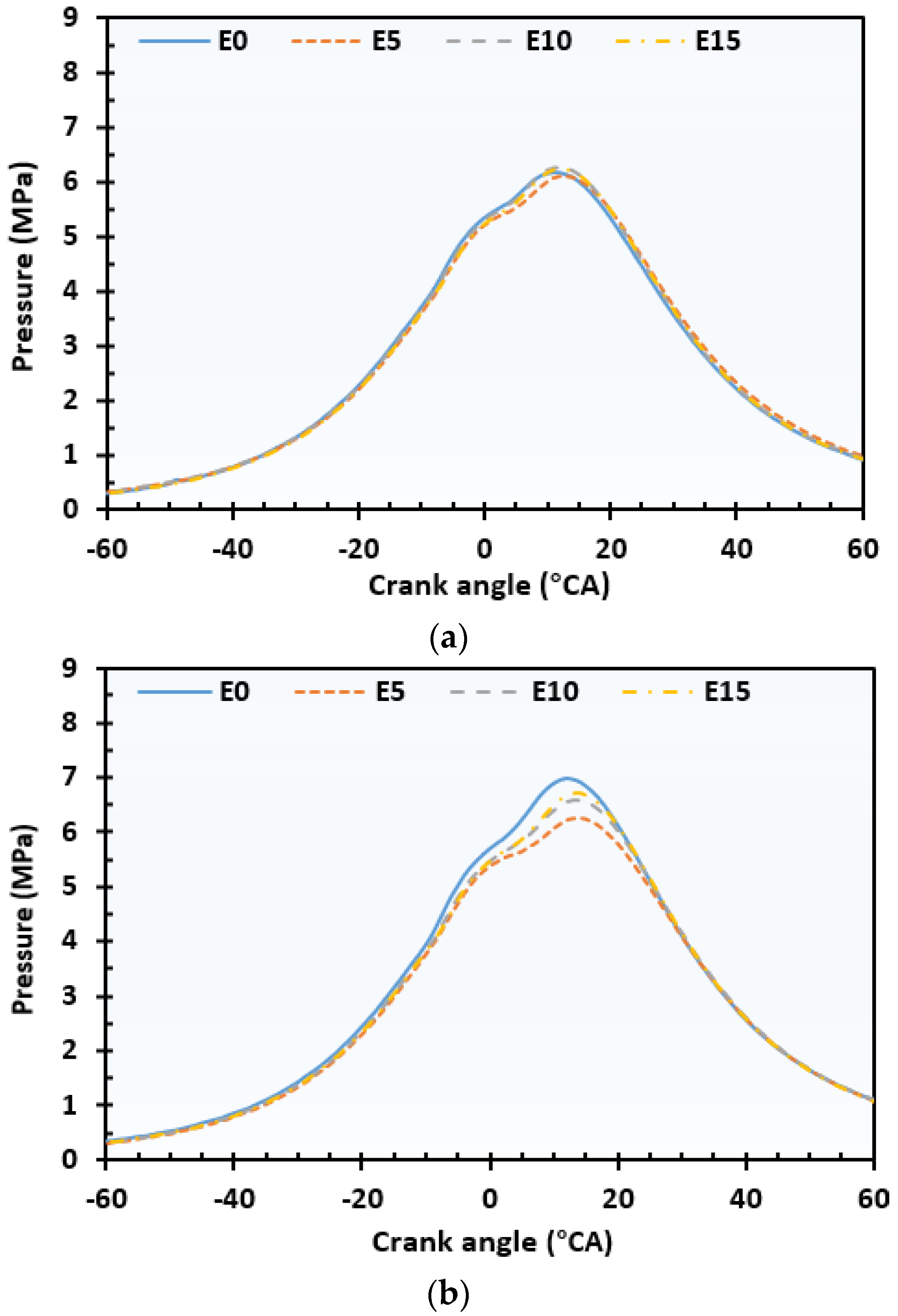

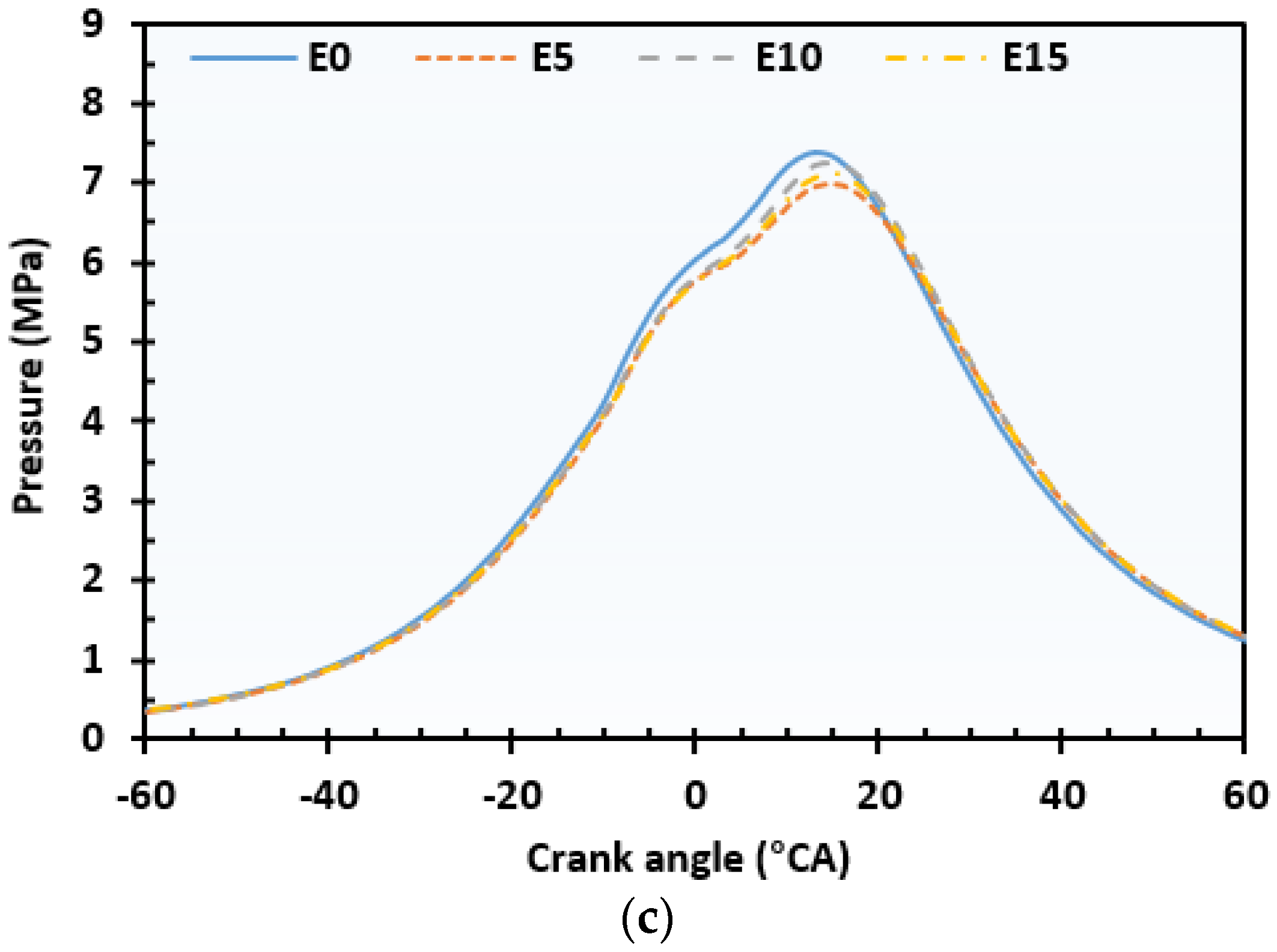

3.2.1. In-Cylinder Pressure

3.2.2. Peak Combustion Pressure

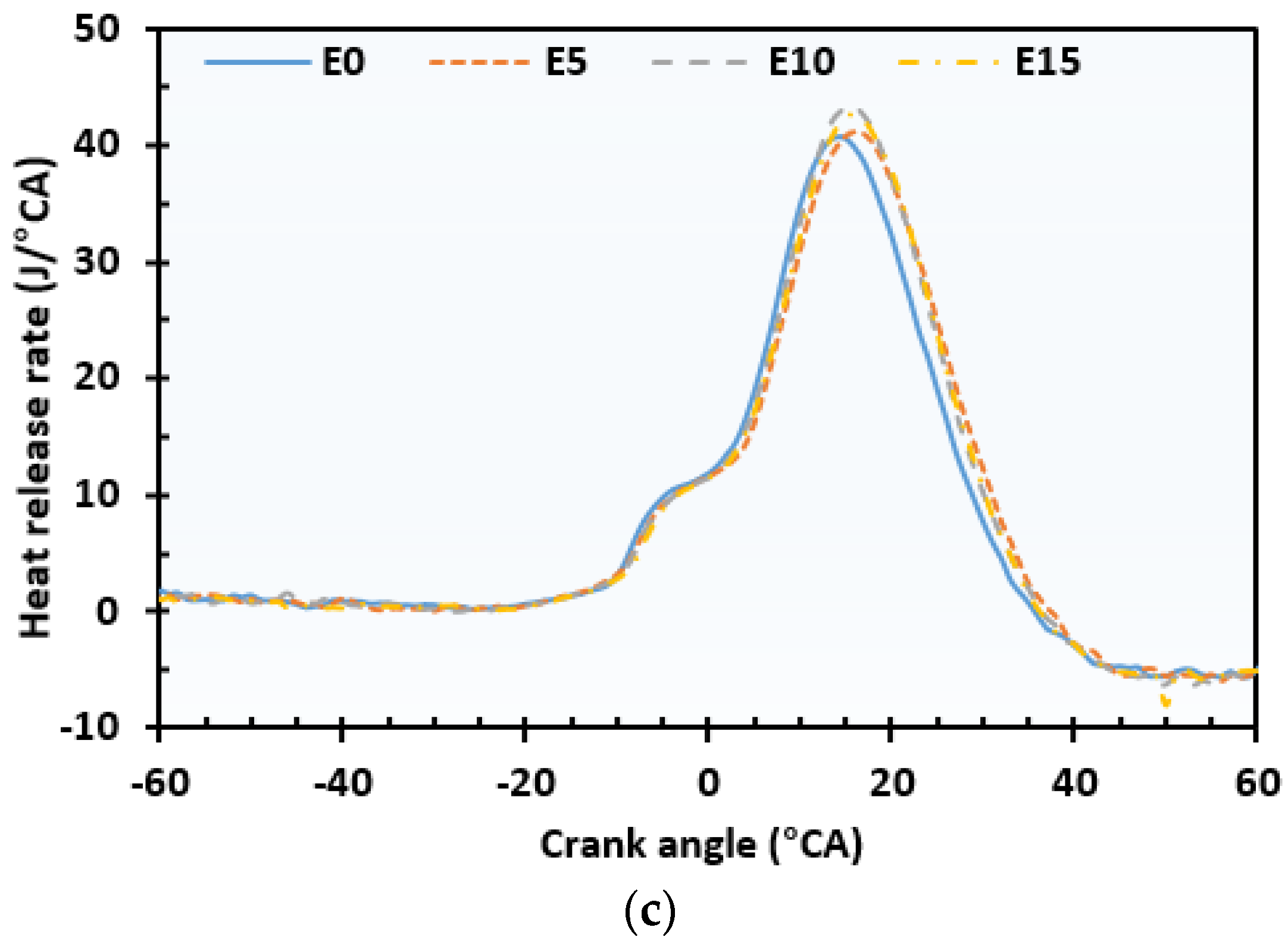

3.2.3. HRR

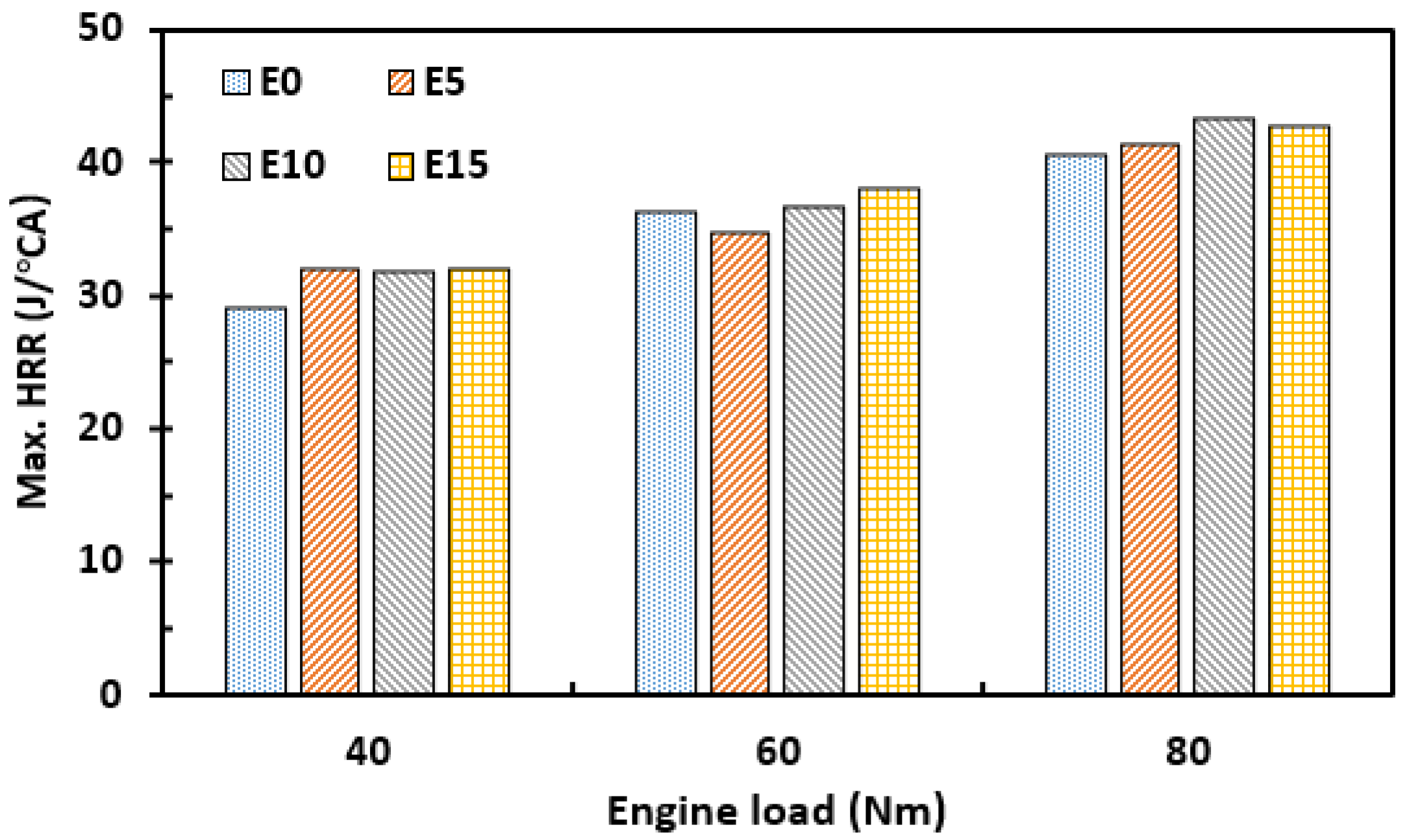

3.2.4. Maximum Heat Release Rate

3.3. Emissions

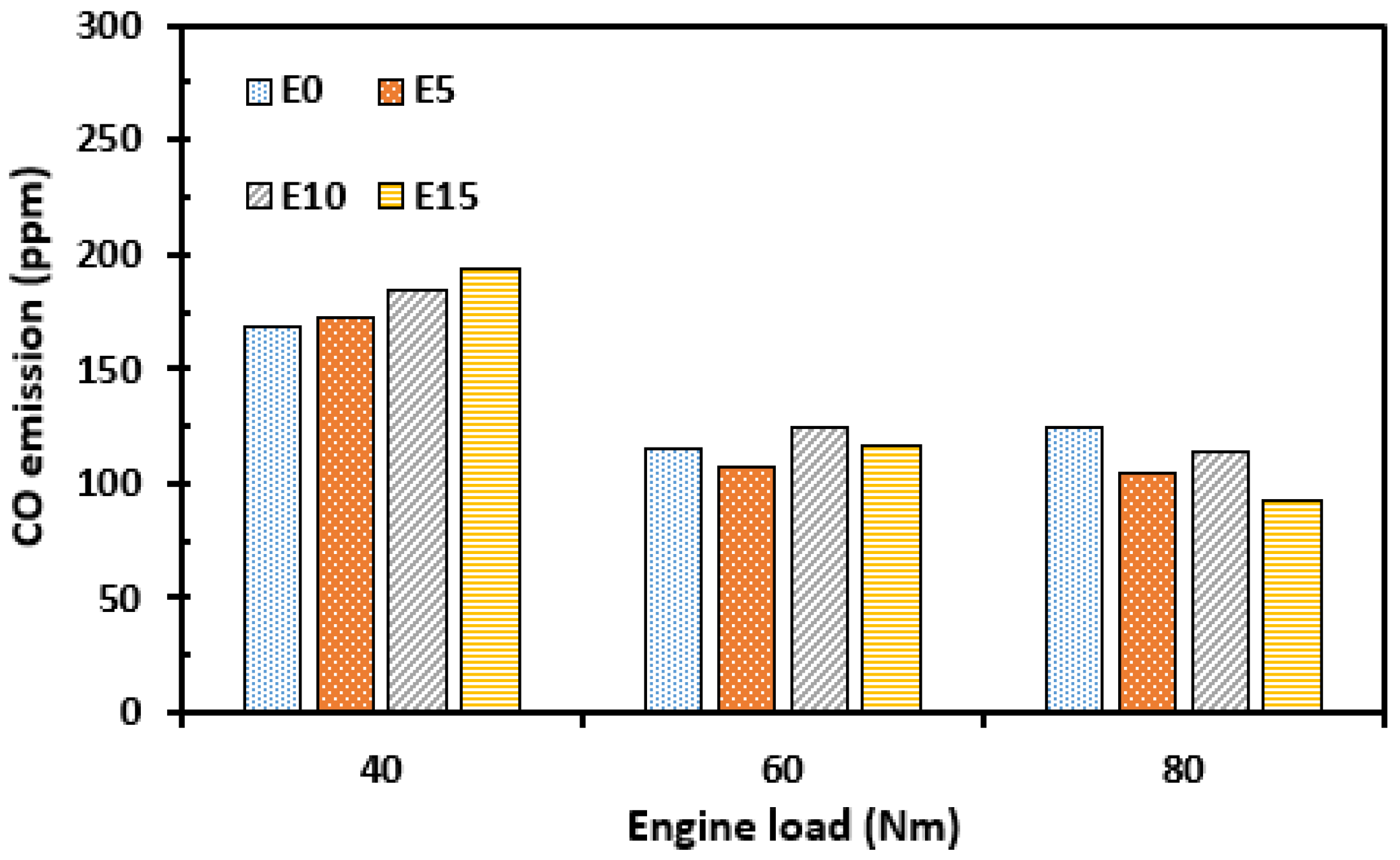

3.3.1. CO

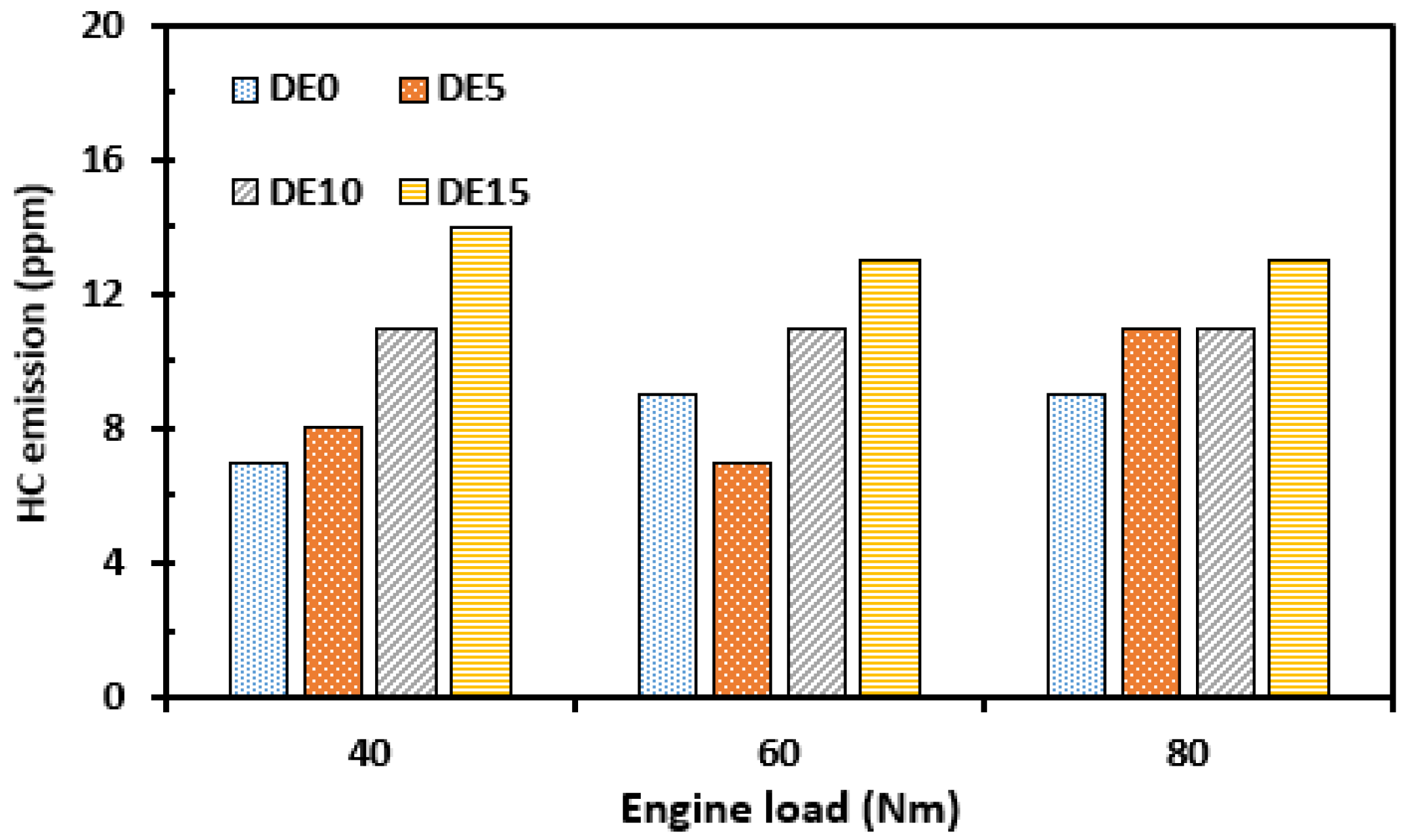

3.3.2. HC

3.3.3. NOx

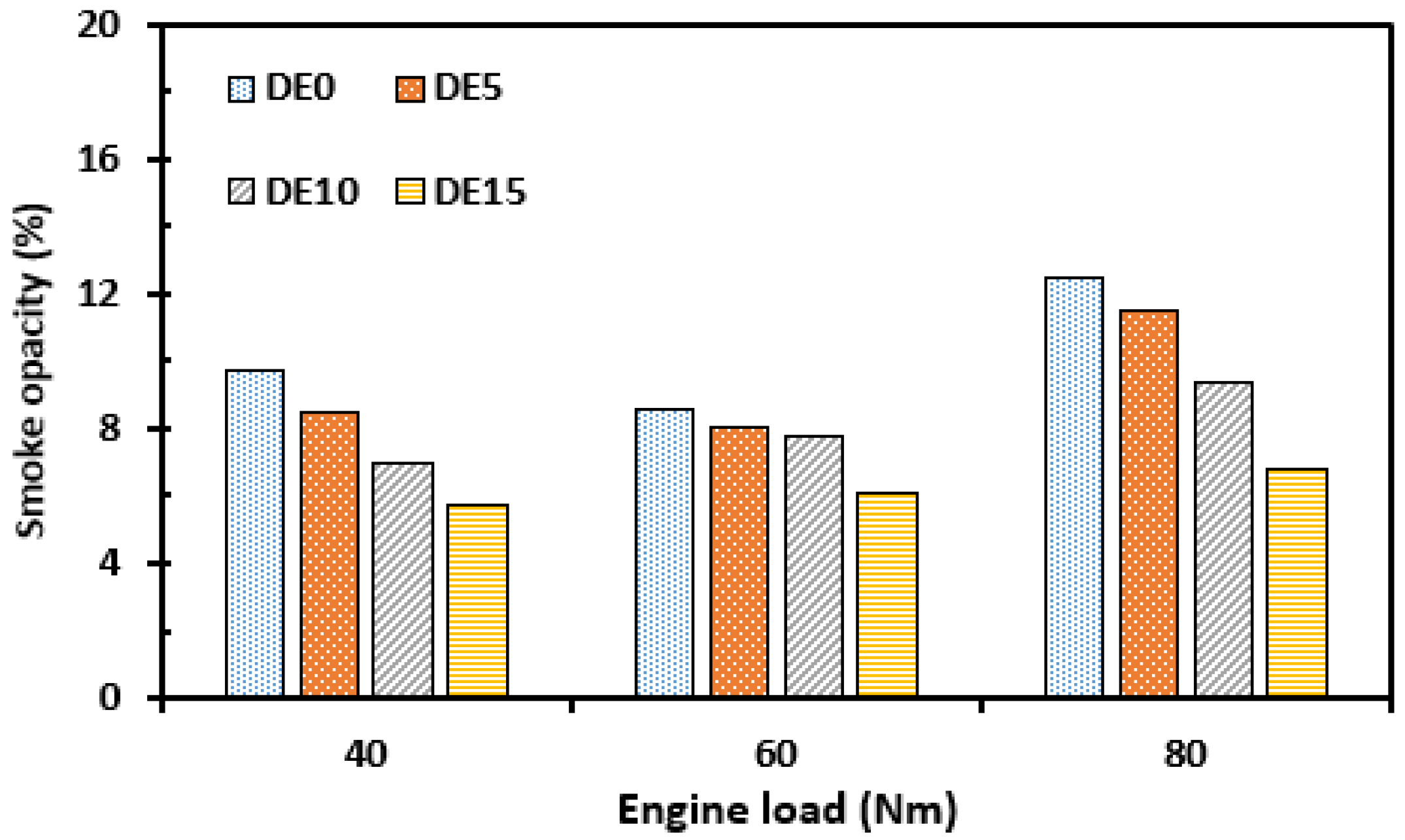

3.3.4. Smoke

4. Conclusions

- i.

- For the engine performance: Only under low (40 Nm) and medium (60 Nm) engine load conditions, the brake-specific fuel consumption (BSFC) of the CRDI engine was increased with the addition of ethanol. However, under the high load of 80 Nm, the BSFC was reduced with the addition of ethanol.

- ii.

- For the combustion characteristics: Under the low engine load of 40 Nm, the start of combustion (SOC) and maximum in-cylinder pressure of all test fuels were almost the same, while under the load of 60 Nm and 80 Nm, the maximum in-cylinder pressure gradually decreased with the addition of ethanol. Additionally, the maximum heat release rate (HRR) of most blended fuels was higher than that of diesel.

- iii.

- For the emission characteristics: The addition of ethanol was beneficial to the reduction in carbon monoxide (CO) only under the medium and high loads of 60 Nm and 80 Nm, but under most test conditions, the addition of ethanol led to the increase in hydrocarbons (HCs) in varying degrees compared with diesel only. It is relevant to mention that nitrogen oxides (NOx) and smoke emissions were simultaneously reduced with the addition of ethanol.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahlia, T.; Syazmi, Z.; Mofijur, M.; Abas, A.P.; Bilad, M.; Ong, H.C.; Silitonga, A.S. Patent landscape review on biodiesel production: Technology updates. Renew. Sustain. Energy Rev. 2020, 118, 109526. [Google Scholar] [CrossRef]

- Ge, J.C.; Yoon, S.K.; Choi, N.J. Using canola oil biodiesel as an alternative fuel in diesel engines: A review. Appl. Sci. 2017, 7, 881. [Google Scholar] [CrossRef]

- Ge, J.C.; Yoon, S.K.; Song, J.H. Combustion and emission characteristics of a diesel engine fueled with crude palm oil blends at various idling speeds. Appl. Sci. 2022, 12, 6294. [Google Scholar] [CrossRef]

- Meher, L.C.; Sagar, D.V.; Naik, S. Technical aspects of biodiesel production by transesterification—A review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Mathiyazhagan, M.; Ganapathi, A. Factors affecting biodiesel production. Res. Plant Biol. 2011, 1, 1–5. [Google Scholar]

- Demirbas, A.H. Biofuels for future transportation necessity. Energy Educ. Sci. Technol. Part A 2010, 26, 13–23. [Google Scholar]

- Brunet, R.; Boer, D.; Guillén-Gosálbez, G.; Jiménez, L. Reducing the cost, environmental impact and energy consumption of biofuel processes through heat integration. Chem. Eng. Res. Des. 2015, 93, 203–212. [Google Scholar] [CrossRef]

- Botshekan, M.; Moheb, A.; Vatankhah, F.; Karimi, K.; Shafiei, M. Energy saving alternatives for renewable ethanol production with the focus on separation/purification units: A techno-economic analysis. Energy 2022, 239, 122363. [Google Scholar] [CrossRef]

- Kurre, S.K.; Pandey, S.; Garg, R.; Saxena, M. Experimental study of the performance and emission of diesel engine fueled with blends of diesel–ethanol as an alternative fuel. Biofuels 2015, 6, 209–216. [Google Scholar] [CrossRef]

- Ge, J.C.; Wu, G.; Choi, N.J. Comparative study of pilot–main injection timings and diesel/ethanol binary blends on combustion, emission and microstructure of particles emitted from diesel engines. Fuel 2022, 313, 122658. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Alabdulkarem, A.; Rashed, M.M.; Teoh, Y.H.; How, H.G. Higher alcohol–biodiesel–diesel blends: An approach for improving the performance, emission, and combustion of a light-duty diesel engine. Energy Convers. Manag. 2016, 111, 174–185. [Google Scholar] [CrossRef]

- Qi, D.; Ma, L.; Chen, R.; Jin, X.; Xie, M. Effects of EGR rate on the combustion and emission characteristics of diesel-palm oil-ethanol ternary blends used in a CRDI diesel engine with double injection strategy. Appl. Therm. Eng. 2021, 199, 117530. [Google Scholar] [CrossRef]

- Prakash, T.; Geo, V.E.; Martin, L.J.; Nagalingam, B. Effect of ternary blends of bio-ethanol, diesel and castor oil on performance, emission and combustion in a CI engine. Renew. Energy 2018, 122, 301–309. [Google Scholar] [CrossRef]

- Hansen, A.C.; Zhang, Q.; Lyne, P.W. Ethanol–diesel fuel blends––a review. Bioresour. Technol. 2005, 96, 277–285. [Google Scholar] [CrossRef] [PubMed]

- Xing-cai, L.; Jian-guang, Y.; Wu-gao, Z.; Zhen, H. Effect of cetane number improver on heat release rate and emissions of high speed diesel engine fueled with ethanol–diesel blend fuel. Fuel 2004, 83, 2013–2020. [Google Scholar] [CrossRef]

- Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol–diesel blends. Fuel 2010, 89, 3410–3415. [Google Scholar] [CrossRef]

- Rajasekar, E.; Selvi, S. Review of combustion characteristics of CI engines fueled with biodiesel. Renew. Sustain. Energy Rev. 2014, 35, 390–399. [Google Scholar] [CrossRef]

- Ghadikolaei, M.A.; Cheung, C.S.; Yung, K.-F. Comparison between blended mode and fumigation mode on combustion, performance and emissions of a diesel engine fueled with ternary fuel (diesel-biodiesel-ethanol) based on engine speed. J. Energy Inst. 2019, 92, 1233–1250. [Google Scholar] [CrossRef]

- Gawale, G.R.; Naga Srinivasulu, G. Experimental investigation of ethanol/diesel and ethanol/biodiesel on dual fuel mode HCCI engine for different engine load conditions. Fuel 2020, 263, 116725. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Lv, J.; Wang, S.; Zhong, Y.; Dong, R.; Gao, S.; Cao, C.; Tian, D. Investigation on combustion, performance and emission characteristics of a diesel engine fueled with diesel/alcohol/n-butanol blended fuels. Fuel 2022, 320, 123975. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.; Shao, K.; Liu, Y.; Chen, X.; Qian, Y. Analyzing the combustion and emissions of a DI diesel engine powered by primary alcohol (methanol, ethanol, n-butanol)/diesel blend with aluminum nano-additives. Fuel 2022, 328, 125222. [Google Scholar] [CrossRef]

- Doppalapudi, A.T.; Azad, A.K.; Khan, M.M.K. Combustion chamber modifications to improve diesel engine performance and reduce emissions: A review. Renew. Sustain. Energy Rev. 2021, 152, 111683. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Robbins, C. Review of the effects of biodiesel on NOx emissions. Fuel Process. Technol. 2012, 96, 237–249. [Google Scholar] [CrossRef]

- Ge, J.C.; Wu, G.; Yoo, B.-O.; Choi, N.J. Effect of injection timing on combustion, emission and particle morphology of an old diesel engine fueled with ternary blends at low idling operations. Energy 2022, 253, 124150. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Du Jun, Y.; Lee, K.B. Performance and emission study of preheated Jatropha oil on medium capacity diesel engine. Energy 2010, 35, 2484–2492. [Google Scholar] [CrossRef]

- Sayin, C.; Ilhan, M.; Canakci, M.; Gumus, M. Effect of injection timing on the exhaust emissions of a diesel engine using diesel–methanol blends. Renew. Energy 2009, 34, 1261–1269. [Google Scholar] [CrossRef]

| Properties (Units) | Diesel | Ethanol | Test Standard |

|---|---|---|---|

| Density (kg/m3 at 15 °C) | 836.8 | 800 | ASTM D941 |

| Kinematic viscosity (mm2/s at 40 °C) | 2.719 | 1.1 | ASTM D445 |

| Low calorific value (MJ/kg) | 43.96 | 28.18 | ASTM D4809 |

| Cetane index | 55.8 | 8 | ASTM D4737 |

| Flash point (°C) | 55 | 13 | ASTM D93 |

| Oxygen content (%) | 0 | 35 | - |

| Item | Units | Specifications |

|---|---|---|

| Type | - | In-line 4-cylinder |

| Number of cylinders | - | 4 |

| Bore × stroke | mm | 83 × 92 |

| Injector hole diameter | mm | 0.17 |

| Injector nozzle holes | - | 5 |

| Injection pump type | - | Bosch in-line type |

| Compression ratio | - | 17.7:1 |

| Max. power | kW/rpm | 82/4000 |

| Item | Unit | Conditions |

|---|---|---|

| Fuel | - | E0, E5, E10, E15 |

| Load | Nm | 40, 60, 80 |

| Speed | rpm | 1600 |

| Fuel injection pressure | MPa | 35 |

| Pilot injection timing | °CA BTDC | 17 |

| Main injection timing | °CA BTDC | 7 |

| Intake air temperature | °C | 25 ± 3 |

| Cooling water temperature | °C | 85 ± 2 |

| Item | Range | Resolution | Accuracy |

|---|---|---|---|

| Electrochemical O2 (%) | 0–30 | 0.1% | ±0.57% |

| Electrochemical CO (ppm) | 0–4000 | 1 ppm | ±0.62% |

| Pellistor HC (ppm) | 0–10,000 | 1 ppm | ±5% |

| Electrochemical NOx (ppm) | 0–6000 | 1 ppm | ±0.25% |

| Smoke opacity (%) | 0–100 | 0.1% | ±1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, S.K. Application Characteristics of Bioethanol as an Oxygenated Fuel Additive in Diesel Engines. Appl. Sci. 2023, 13, 1813. https://doi.org/10.3390/app13031813

Yoon SK. Application Characteristics of Bioethanol as an Oxygenated Fuel Additive in Diesel Engines. Applied Sciences. 2023; 13(3):1813. https://doi.org/10.3390/app13031813

Chicago/Turabian StyleYoon, Sam Ki. 2023. "Application Characteristics of Bioethanol as an Oxygenated Fuel Additive in Diesel Engines" Applied Sciences 13, no. 3: 1813. https://doi.org/10.3390/app13031813

APA StyleYoon, S. K. (2023). Application Characteristics of Bioethanol as an Oxygenated Fuel Additive in Diesel Engines. Applied Sciences, 13(3), 1813. https://doi.org/10.3390/app13031813