A Study on the Material Composition and Traceability of the Wellhead Blockage in the Process of Oil and Gas Exploitation—A Case of the DH231 Well in the Tarim Basin, China

Abstract

1. Introduction

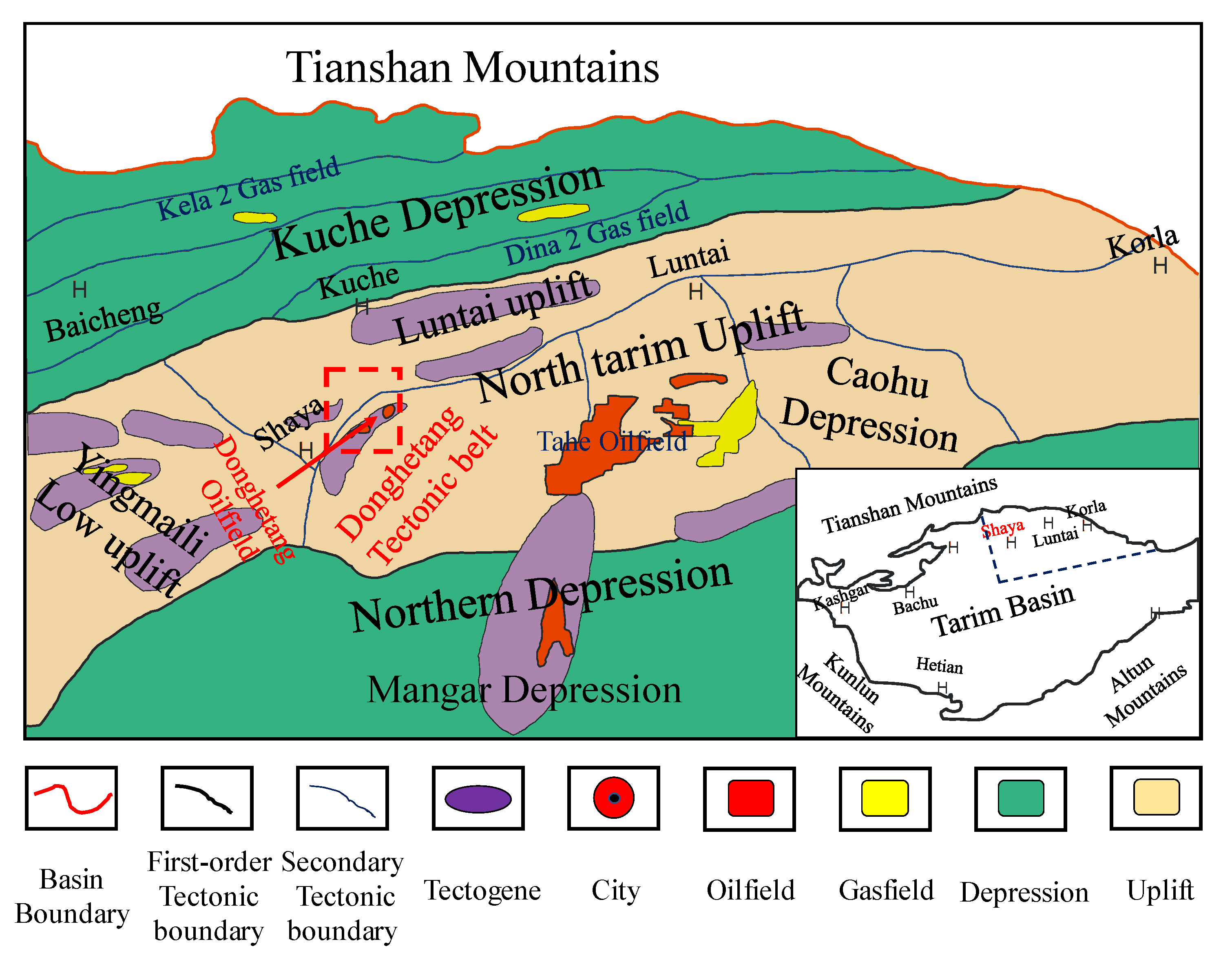

2. Geological Setting

3. Materials and Methods

3.1. Reagents and Materials

3.2. Samples’ Pre-Treatment Methods

3.2.1. Acidification of the Blockage

3.2.2. Soxhlet Extraction and Group Components’ Separation

3.3. Analysis of Thin Section, SEM, and X-ray Energy Spectroscopy

3.4. Analysis of GC-MS

4. Results and Discussion

4.1. Component Identification of Wellhead Blockage

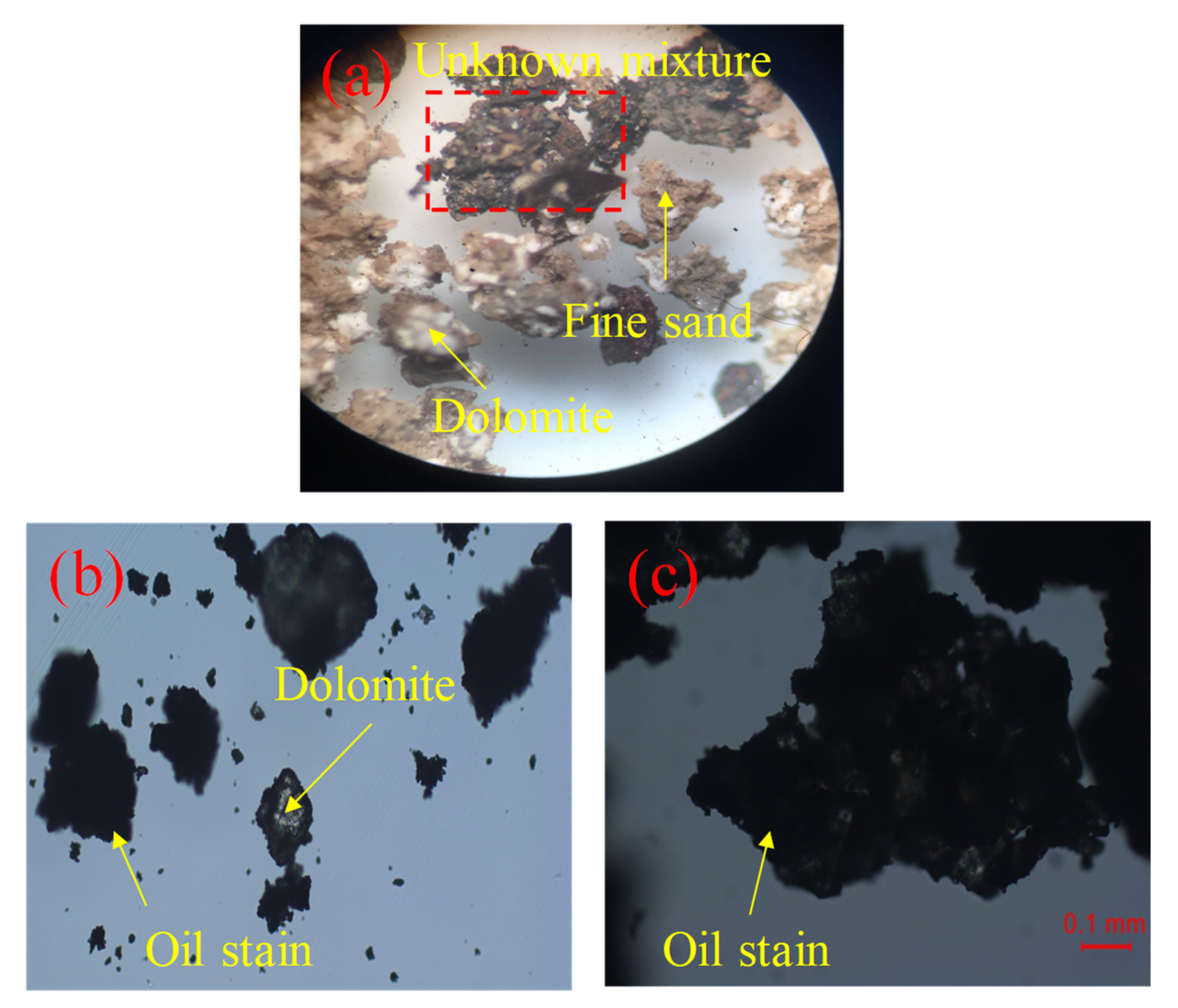

4.1.1. Identification of Inorganic Phases

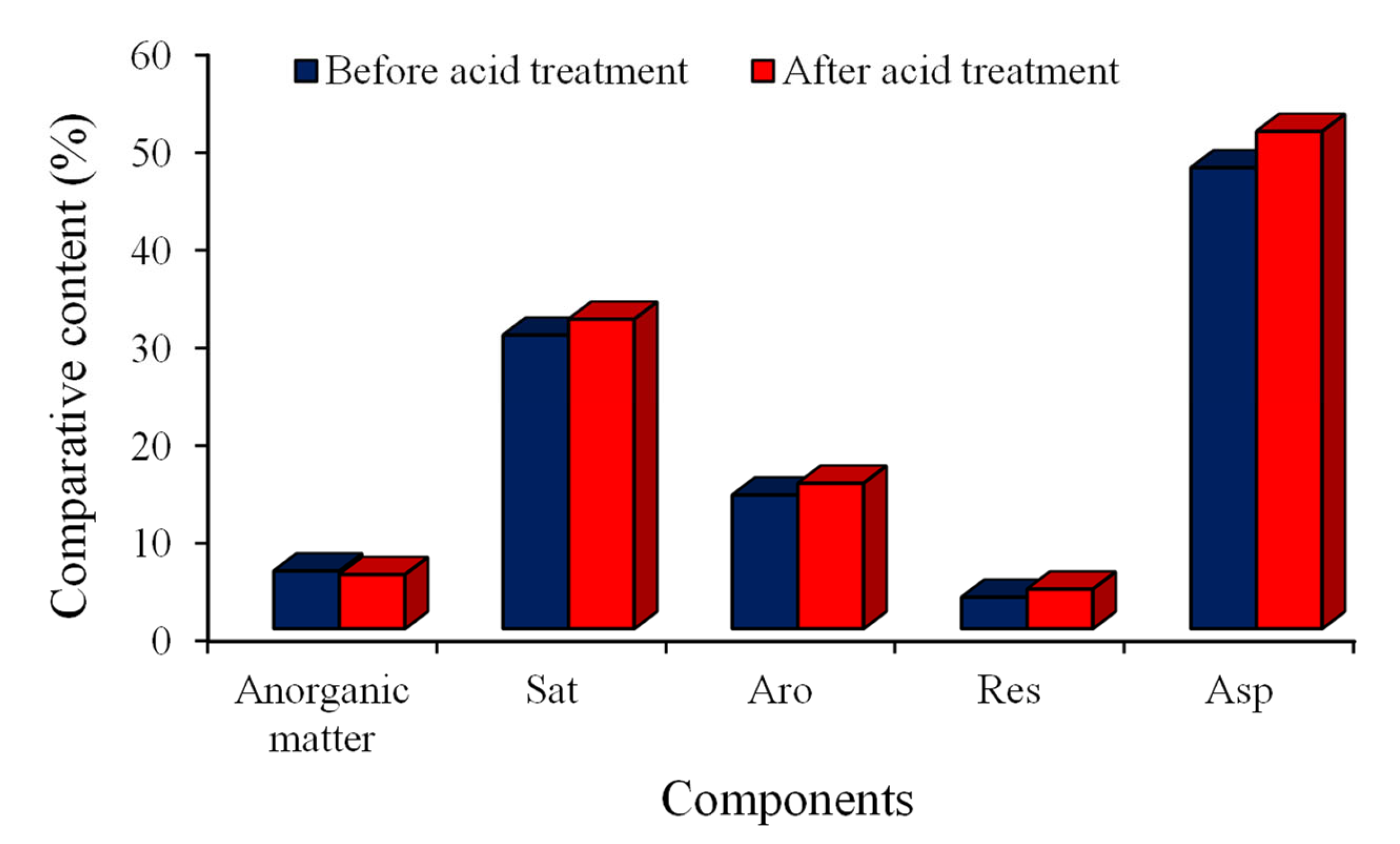

4.1.2. Component Analysis of Oil Stains

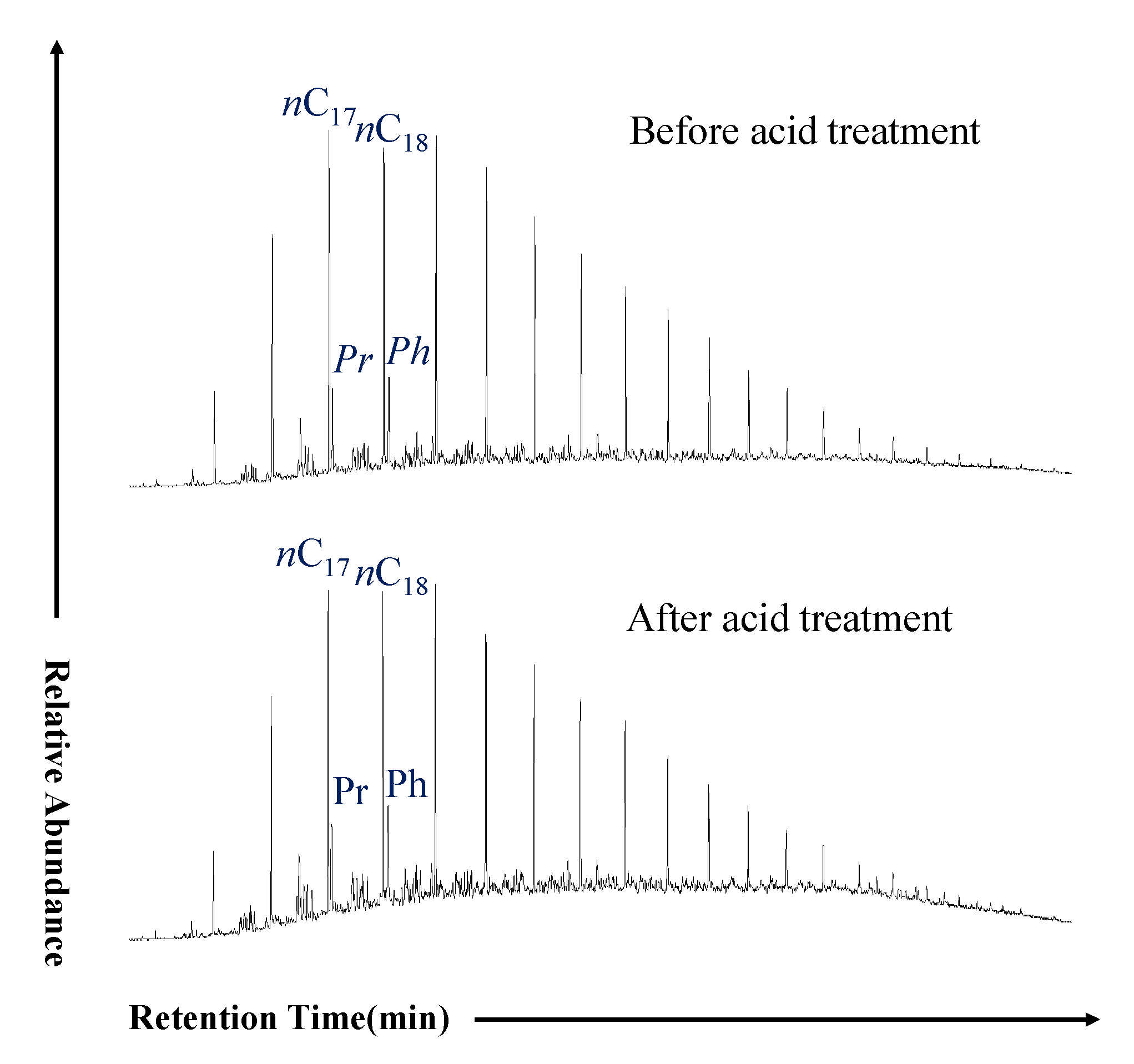

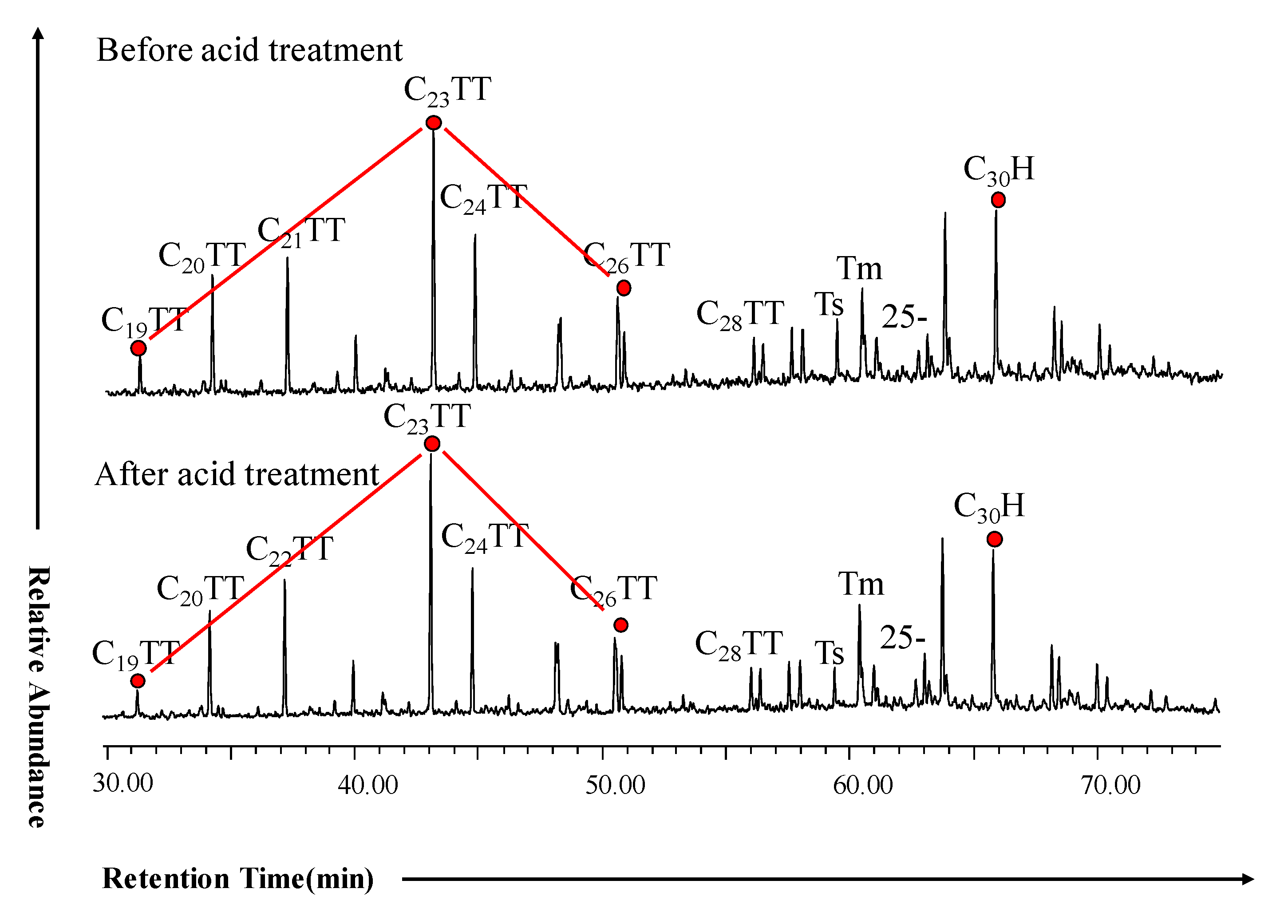

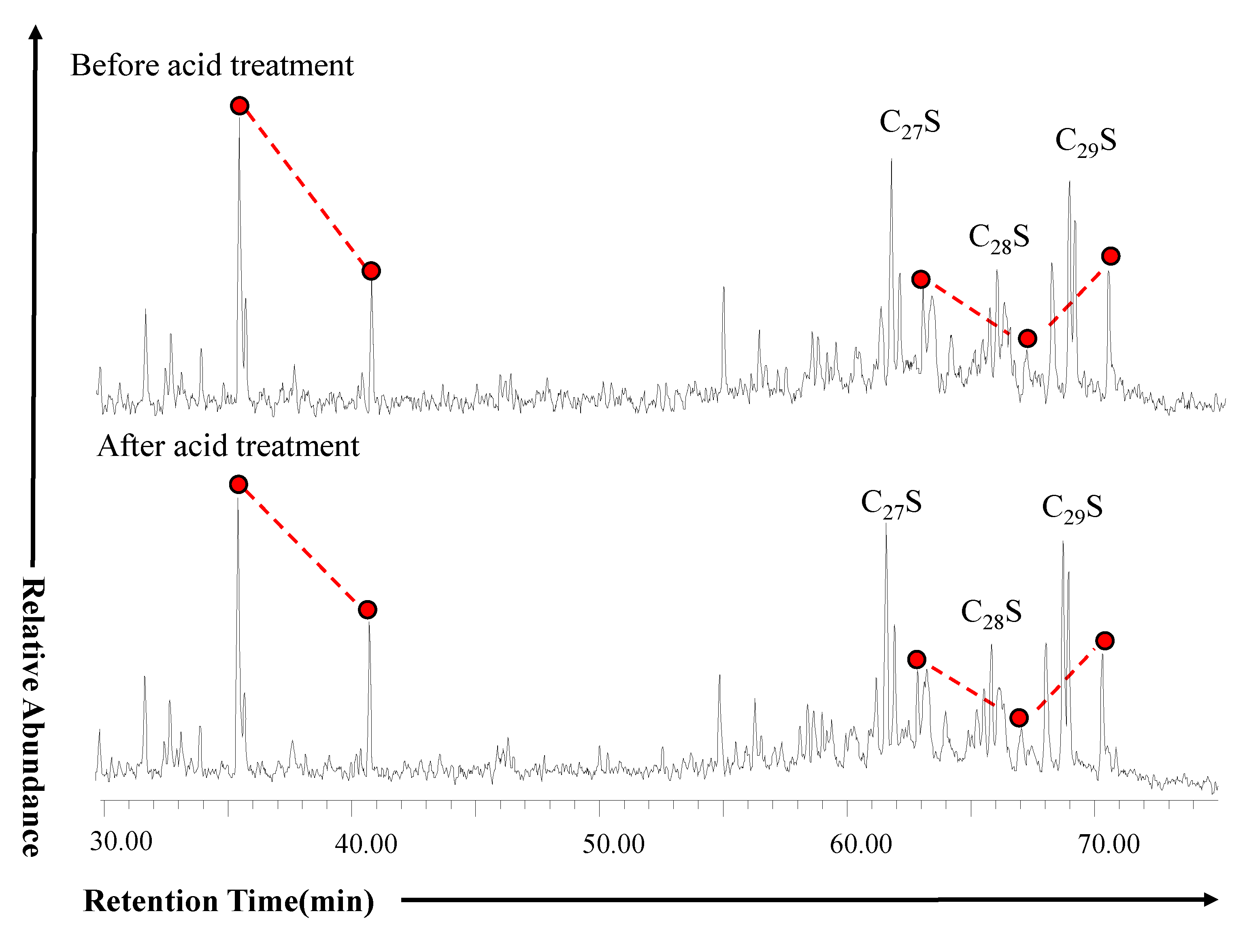

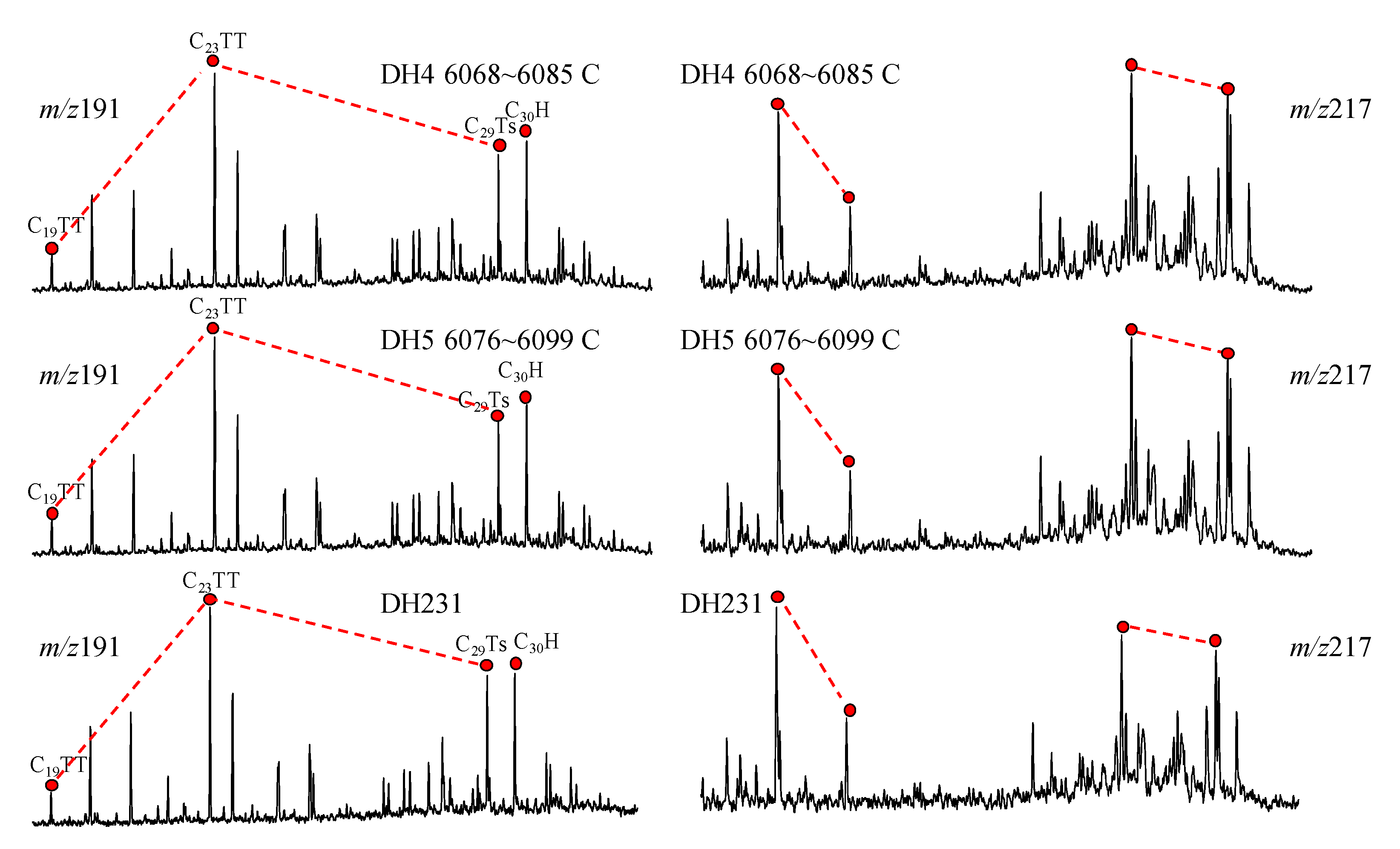

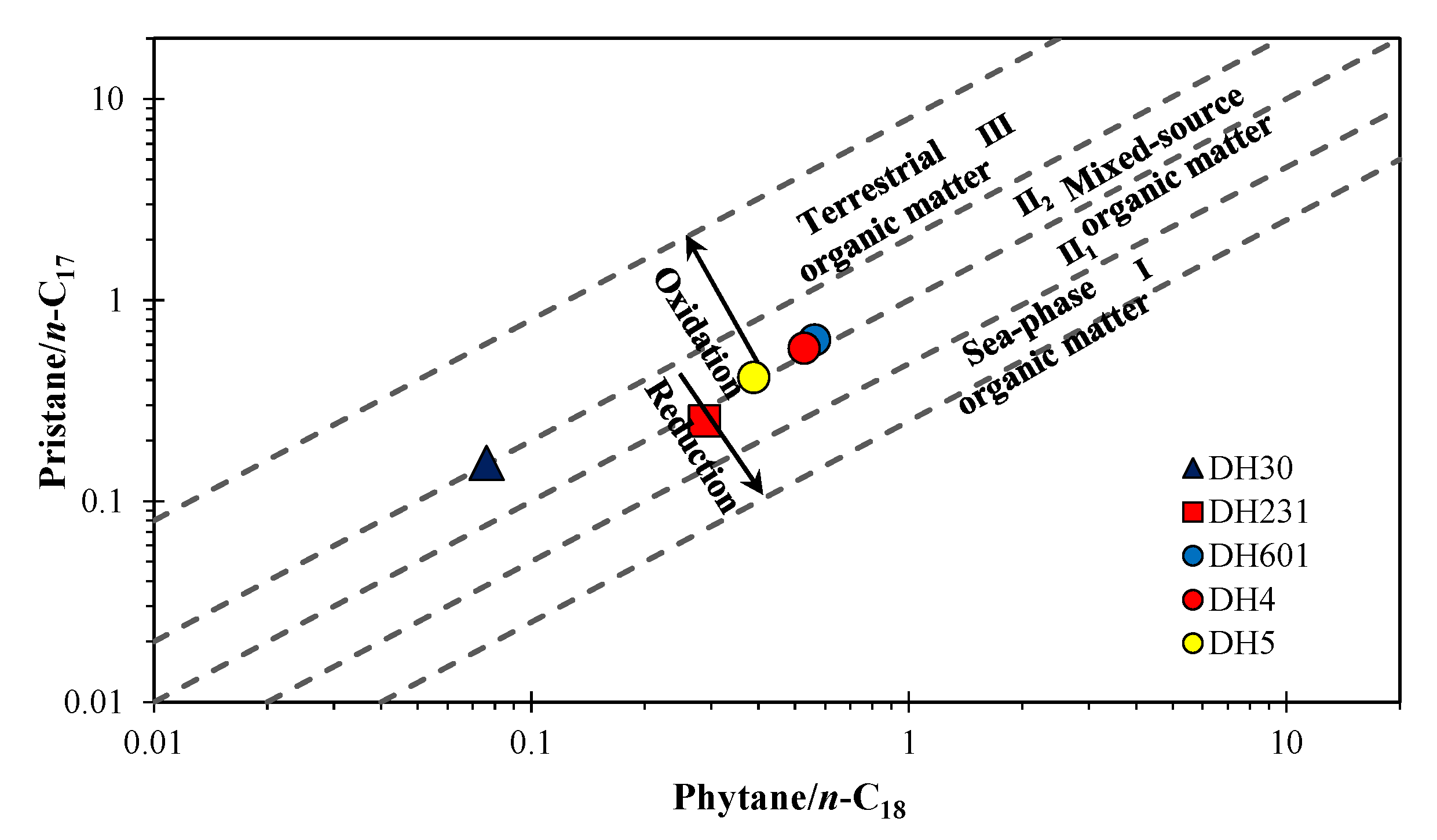

4.2. Composition, Distribution Characteristics, and Significance of Organic Steroid Terpenoids

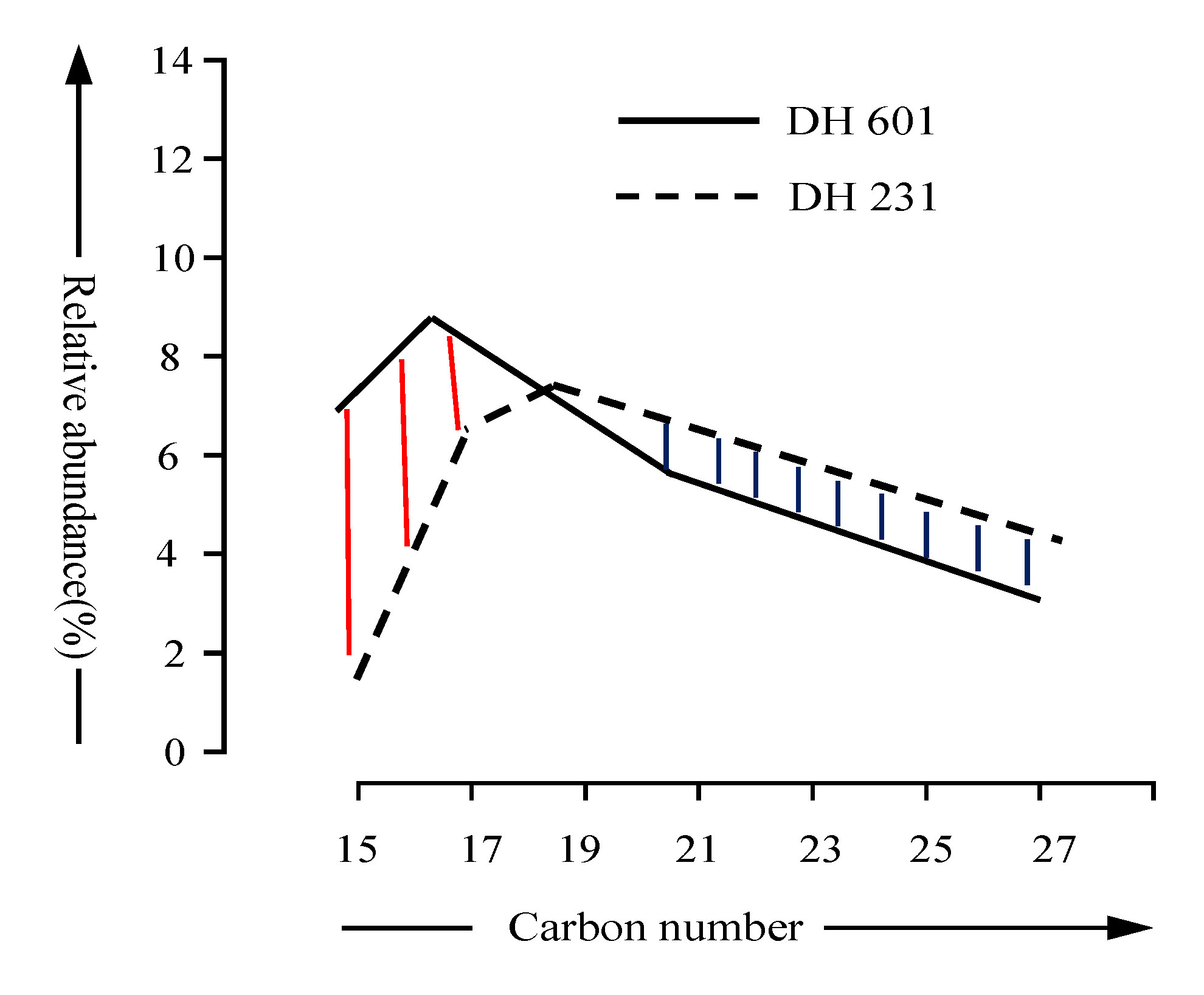

4.3. Comparative Analysis of Wellhead Blockage and Adjacent-Well Crude Oil

5. Conclusions

- (1)

- The inorganic substances in the wellhead blockage of well DH231 are mainly iron oxide, sodium chloride, and dolomite. The high abundance of iron oxide comes from rust on the metal parts of the wellbore liner. Dolomite and other inorganic minerals are rock fragments or cement from the drill encounter formation. The presence of sodium chloride indicates that geological fluid plays a role in the blockage formation.

- (2)

- The organic matter in the wellhead blockage of Well DH231 is mainly oil stains. The oil stain is a native organic matter in geological bodies, which is a display of oil and gas during the drilling process. It has the same composition as crude oil rather than gasoline, diesel, and additives left over from the drilling process. The percentage of asphaltene in oil stains is as high as 47%. High asphaltene content in oil stains could be a potential reason for generating the wellhead blockage in Well DH231.

- (3)

- The blockage of Well DH231 contains some abundance of 25-norhopanes, but the distribution of n-alkanes is intact. It indicates that secondary charging and multi-period accumulation of crude oil occurred in this well.

- (4)

- The fingerprint characteristics of the steroid terpenoids in the wellhead blockage of Well DH231 are comparable to those of the carboniferous crude oil from Wells DH 4 and DH 5, suggesting some “kinship” between the two.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, D.; Wang, T.-G.; Li, H. Geochemical Characteristics and Origin of the Crude Oils and Condensates from Yakela Faulted-Uplift, Tarim Basin. J. Pet. Sci. Eng. 2015, 133, 602–611. [Google Scholar] [CrossRef]

- Liu, J.; Steel, R.J.; Lin, C.; Yang, H.; Yang, Y.; Peng, L.; Gong, Y.; Chu, C. Geomorphology Control on the Development of Reservoir Depositional Systems, Devonian Donghetang Formation in the Tabei Uplift of the Tarim Basin, China. Mar. Pet. Geol. 2012, 38, 177–194. [Google Scholar] [CrossRef]

- Li, W.; Xu, H.; Gao, S.; Yu, Y.; Ning, C.; Yang, J.; Jiang, T. Inner Architectural Characteristics of Wave-Dominated Shoreface Deposits and Their Geological Implications: A Case Study of Devonian ‘Donghe Sandstones’ in Tarim Basin, China. Mar. Pet. Geol. 2021, 134, 105334. [Google Scholar] [CrossRef]

- Sun, P.; Fang, H.; Xu, Z.; Wang, C.; Xu, H.; Lu, M. Siliciclastic Depositional Model within a Subsurface Coastal Parasequence Based on Barriers and Baffles—An Application to the Donghe Sandstone Member in the Hudson Oilfield, Tarim Basin, NW China. J. Pet. Sci. Eng. 2020, 195, 107947. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, H.; Hu, J.; Zhu, Y. Exploration Examples of Marine Oil and Gas Fields in China—Exploration and Discovery of Donghetang Marine Sandstone Oilfield in Tarim Basin. Mar. Oil-Gas Geol. 2010, 15, 73–78, (In Chinese with English abstract). [Google Scholar]

- Zhang, J.; Wang, Z.; Sun, B.; Sun, X.; Liao, Y. An Integrated Prediction Model of Hydrate Blockage Formation in Deep-Water Gas Wells. Int. J. Heat Mass Transf. 2019, 140, 187–202. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, S.; Zhou, W.; Liu, H.; Hu, Y.; Guo, P.; Du, J.; Ren, J. Experimental Research of Condensate Blockage and Mitigating Effect of Gas Injection. Petroleum 2018, 4, 292–299. [Google Scholar] [CrossRef]

- Zhang, L.; Geng, S.; Yang, L.; Wen, R.; He, C.; Zhao, Z.; Qin, G. Formation Blockage Risk Analysis of Geothermal Water Reinjection: Rock Property Analysis, Pumping and Reinjection Tests, and Long-Term Reinjection Prediction. Geosci. Front. 2022, 13, 101299. [Google Scholar] [CrossRef]

- Luo, W.; Lin, Y.; Dong, H.; Wu, Q. Wellbore blockage removal technology in Yuanba gas field. Pet. Drill. Technol. 2018, 46, 109–114, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Jiang, T.; Meng, X.; Huang, K.; Zhao, L.; Chen, D.; Wu, H. Wellbore Plugging Mechanism and Plugging Removal Technology in Keshen 2 Gas Field. Oil Drill. Amp 2020, 42, 657–661, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Li, E.; Jin, J.; Chen, L.; Lu, F.; Shi, Q.; Wu, J.; Zhang, Y. Study on Molecular Composition of Asphaltene in Wellbore Blockage in Southern Junggar Basin. Exp. Pet. Geol. 2022, 44, 306–313, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Yang, J.; Feng, Y.; Zhang, B.; Tang, Y.; Jiang, Z. A Blockage Removal Technology for Natural Gas Hydrates in the Wellbore of an Ultra-High Pressure Sour Gas Well. Nat. Gas Ind. B 2021, 8, 188–194. [Google Scholar] [CrossRef]

- Han, R.; Liu, Q.; Jiang, T.; Xu, H.; Xu, Z.; Zhao, L.; Lei, C.; Zhang, P. Feature, Origin and Distribution of Calcareous Interlayers: A Case of Carboniferous Donghe Sandstone in Hade Oil Field, Tarim Basin, NW China. Pet. Explor. Dev. 2014, 41, 475–484. [Google Scholar] [CrossRef]

- Fang, H.; Xu, H.; Wang, Z.; Jiang, T.; Zhao, Y.; Li, J. Formation Mechanism of the Donghe Sandstone Residual Oil Zone in the Tarim Basin, NW China. J. Pet. Sci. Eng. 2018, 171, 1023–1032. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, G.; Su, J.; Lu, Y. Oil and Gas Source and Distribution of Donghetang in West of Tabei Uplift. Earth Sci. Front. 2012, 19, 276–283. [Google Scholar]

- Hiyoshi, N.; Ikeda, T.; Hasegawa, Y.; Sato, K. Observation of La-Exchanged NaY Zeolite Using Aberration-Corrected Scanning Transmission Electron Microscopy. Microporous Mesoporous Mater. 2021, 311, 110711. [Google Scholar] [CrossRef]

- Kishida, K.; Okutani, M.; Inui, H. Direct Observation of Zonal Dislocation in Complex Materials by Atomic-Resolution Scanning Transmission Electron Microscopy. Acta Mater. 2022, 228, 117756. [Google Scholar] [CrossRef]

- Tollefson, A.D.; Smith, C.M.; Carpenter, M.H.; Croce, M.P.; Fassbender, M.E.; Koehler, K.E.; Lilley, L.M.; O’Brien, E.M.; Schmidt, D.R.; Stein, B.W.; et al. Measurement of 227Ac impurity in 225Ac using decay energy spectroscopy. Appl. Radiat. Isot. 2021, 172, 109693. [Google Scholar] [CrossRef]

- Guilbaud, R.; White, M.L.; Poulton, S.W. Surface Charge and Growth of Sulphate and Carbonate Green Rust in Aqueous Media. Geochim. Et Cosmochim. Acta 2013, 108, 141–153. [Google Scholar] [CrossRef]

- Li, Z.; Li, B.; Du, L.; Wang, W.; Liao, X.; Yu, H.; Yu, C.; Wang, H.; Li, Q. Three-Dimensional Oxygen-Doped Porous Graphene: Sodium Chloride-Template Preparation, Structural Characterization and Supercapacitor Performances. Chin. J. Chem. Eng. 2021, 40, 304–314. [Google Scholar] [CrossRef]

- Hanor, J.S.; Wendeborn, F.C. Origin of Sodium Bicarbonate Groundwaters, Southern Hills Aquifer System, USA by Silicate Hydrolysis. Appl. Geochem. 2022, 148, 105512. [Google Scholar] [CrossRef]

- Zhang, X.; Li, W.; Wang, F.; Wang, N.; Xu, Y.; Liu, Y.; Cheng, R.; Liu, H. Biomarker Characteristics of Paleogene Source Rocks in Liaodong Bay Area and Its Geological Significance. Lithol. Hydrocarb. Reserv. 2021, 34, 73–85, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Alfken, S.; Wörmer, L.; Lipp, J.S.; Wendt, J.; Taubner, H.; Schimmelmann, A.; Hinrichs, K.-U. Micrometer Scale Imaging of Sedimentary Climate Archives—Sample Preparation for Combined Elemental and Lipid Biomarker Analysis. Org. Geochem. 2019, 127, 81–91. [Google Scholar] [CrossRef]

- Graham, S.A.; Brassell, S.; Carroll, A.R.; Xiao, X.; Demaison, G.; McKnight, C.L.; Liang, Y.; Chu, J.; Hendrix, M.S. Characteristics of Selected Petroleum Source Rocks, Xianjiang Uygur Autonomous Region, Northwest China. AAPG Bull. 1990, 74, 493–512. [Google Scholar] [CrossRef]

- Wu, W.; Hou, J. Analysis of the composition and causes of oil well plugging in an oilfield in Xinjiang. Oilfield Chem. 2022, 39, 349–354, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- da Silva Brito, A.; Rodrigues Nogueira, A.C.; Gomes de Almeida, L.T.; Gonçalo de Lima, S. Orbital-Scale Cyclicity and Organic Matter Production in a Permian Shallow Mixed Carbonate-Siliciclastic System: Paraná Basin, Brazil. Mar. Pet. Geol. 2023, 147, 105987. [Google Scholar] [CrossRef]

- Lima, B.L.B.; Marques, N.N.; Souza, E.A.; Balaban, R.C. Polysaccharide Derivative as an Additive in Olefin-Based Drilling Fluid. J. Mol. Liq. 2022, 364, 120023. [Google Scholar] [CrossRef]

- Bagum, M.; Ahammad, J.M.; Husain, T.; Hossain, M.E. An Experimental Study to Develop an Environmental Friendly Mud Additive of Drilling Fluid Using Aloe Vera. J. Pet. Sci. Eng. 2022, 211, 110135. [Google Scholar] [CrossRef]

- Han, H.; Feng, Y.; Chen, J.; Xie, Q.; Chen, S.; Sheng, M.; Zhong, S.; Wei, W.; Su, S.; Fu, P. Acidification Impacts on the Molecular Composition of Dissolved Organic Matter Revealed by FT-ICR MS. Sci. Total Environ. 2022, 805, 150284. [Google Scholar] [CrossRef]

- Li, S.; Cao, J.; Hu, S.; Luo, G. Characterization of Compounds in Unresolved Complex Mixtures (UCM) of a Mesoproterzoic Shale by Using GC×GC-TOFMS. Mar. Pet. Geol. 2015, 66, 791–800. [Google Scholar] [CrossRef]

- Meyers, P.; Ishiwatari, R. Lacustrine Organic Geochemistry—An Overview of Indicators of Organic Matter Sources and Diagenesis in Lake Sediments. Org. Geochem. 1993, 20, 867–900. [Google Scholar] [CrossRef]

- Didyk, B.M.; Simoneit, B.R.T.; Brassell, S.C.; Eglinton, G. Organic Geochemical Indicators of Palaeoenvironmental Conditions of Sedimentation. Nature 1978, 272, 216–222. [Google Scholar] [CrossRef]

- Peters, K.E.; Walters, C.C.; Moldowan, J.M. Biomarkers: Assessment of Petroleum SourceRock Age and Depositional Environment; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–11. [Google Scholar]

- Seifert, W.K.; Michael Moldowan, J. Applications of Steranes, Terpanes and Monoaromatics to the Maturation, Migration and Source of Crude Oils. Geochim. Et Cosmochim. Acta 1978, 42, 77–95. [Google Scholar] [CrossRef]

- McArthur, J.M. Early Toarcian Black Shales: A Response to an Oceanic Anoxic Event or Anoxia in Marginal Basins? Chem. Geol. 2019, 522, 71–83. [Google Scholar] [CrossRef]

- Li, N.; Huang, H.; Jiang, W.; Wu, T.; Sun, J. Biodegradation of 25-Norhopanes in a Liaohe Basin (NE China) Oil Reservoir. Org. Geochem. 2015, 78, 33–43. [Google Scholar] [CrossRef]

- Yin, F.; He, Z.; Song, Z.; Su, P.; Zhang, L.; Feng, D.; Yang, T. The Fingerprint Stability of the Biomarker Hopanes and Steranes in Soot Emissions from In-Situ Burning of Oil. Sci. Total Environ. 2022, 839, 156273. [Google Scholar] [CrossRef]

- Holba, A.; Dzou, L.; Masterson, W.; Hughes, W.; Huizinga, B.; Singletary, M.; Moldowan, J.; Mello, M.; Tegelaar, E. Application of 24-Norcholestanes for Constraining Source Age of Petroleum. Org. Geochem. 1998, 29, 1269–1283. [Google Scholar] [CrossRef]

- Barbanti, S.; Moldowan, J.; Watt, D.; Kołaczkowska, E. New Triaromatic Steroids Distinguish Paleozoic from Mesozoic Oil. Org. Geochem. 2011, 42, 409–424. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, H.; Yin, M.; Han, D. Molecular Composition Characterization of Oilsand Heating Experiments to Investigate Steam-Solvent Effects and Chemical Reactions during Thermal Recovery. Energy Fuels 2021, 35, 9917–9929. [Google Scholar] [CrossRef]

- Wu, L.; Jin, Z.; Liu, K.; Chu, Z.; Yang, P. Evolution of a Deeply-Buried Oil Reservoir in the North Shuntuoguole Low Uplift, Tarim Basin, Western China: Insights from Molecular Geochemistry and Re–Os Geochronology. Mar. Pet. Geol. 2021, 134, 105365. [Google Scholar] [CrossRef]

- Curiale, J.A.; Harrison, W.E.; Smith, G. Sterane Distribution of Solid Bitumen Pyrolyzates. Changes with Biodegradation of Crude Oil in the Ouachita Mountains, Oklahoma. Geochim. Et Cosmochim. Acta 1983, 47, 517–523. [Google Scholar] [CrossRef]

- Hong, W.; Qinglai, F.; Jianxin, Y.; Shan, C. Characteristics and Sources of Organic Matter from the Early Cambrian Niutitang Formtion and Its Preservation Environment in Guizhou. J. Earth Sci. 2022, 33, 933–944. [Google Scholar] [CrossRef]

- Wu, X.; Guo, Q.; Zhang, W.; He, D.; Qi, X.; Li, D. Characteristics of Volcanic Reservoirs and Hydrocarbon Accumulation of Carboniferous System in Junggar Basin, China. J. Earth Sci. 2021, 32, 972–985. [Google Scholar] [CrossRef]

- Chengpeng, S.; Shu, J.; Zhixin, W.; Zhaomin, W. Comparison of the Petroleum Geology in the Deep-Water Basins between the Passive Margin of Morocco and Its Conjugate Margin of Canada. J. Earth Sci. 2020, 31, 919–929. [Google Scholar] [CrossRef]

- Fowler, M.G.; Brooks, P.W. Organic Geochemistry as an Aid in the Interpretation of the History of Oil Migration into Different Reservoirs at the Hibernia K-18 and Ben Nevis I-45 Wells, Jeanne d’Arc Basin, Offshore Eastern Canada. Org. Geochem. 1990, 16, 461–475. [Google Scholar] [CrossRef]

| (a) Soxhlet Extraction Workflow | (b) Components Separation Workflow |

|---|---|

| Put the blockage into an oven and dry at 40 °C for 12 h ↓ | Take 50 mg chloroform bitumen “A” in a triangular flask ↓ |

| Pulverize the dried blockage to 100–120 mesh ↓ | Add 1 mL of dichloromethane and 20 mL of petroleum ether in the triangular flask and leave for 12 h to precipitate out the bitumen ↓ |

| The powder of blockage is subjected to 72 h Soxhlet extraction with chloroform ↓ | After filtration of asphaltene, the filtrate is concentrated to 1 mL ↓ |

| Chloroform bitumen “A” is air-dried at room temperature ↓ | The filtrate is transferred into a chromatographic column filled with 2.5 g 100–200 mesh neutral alumina ↓ |

| The air-dried chloroform bitumen “A” is weighed | The saturated hydrocarbon is eluted with 10 mL of n-hexane |

| No. | Type | Components | Weight, mg |

|---|---|---|---|

| DH 231H (before acid treatment) | Mineral | Iron oxide, dolomite | 2.2 |

| Organics | Sat | 11.2 | |

| Aro | 5.1 | ||

| Res | 1.2 | ||

| Asp | 17.6 | ||

| DH 231H (after acid treatment) | Mineral | Iron oxide, dolomite | 1.27 |

| Organics | Sat | 12.6 | |

| Aro | 6.9 | ||

| Res | 2.8 | ||

| Asp | 16.3 |

| No. | Well | Depth (m) | Type | Strata | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | B1 | B2 | B3 | B4 | B5 | B6 | B7 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | DH30 | 6043–6078 | Oil | C | / | 1.08 | 1.05 | 1.92 | 0.15 | 0.07 | / | / | 1.92 | 7.34 | 0.20 | 0.06 | 0.60 | 0.67 | 0.47 |

| 2 | DH4 | 6068–6085 | Oil | C | nC10 | 1.07 | 0.99 | 1.20 | 0.58 | 0.53 | 5.68 | 3.30 | 1.89 | 11.70 | 0.26 | 0.05 | 0.92 | 0.65 | 0.50 |

| 3 | DH5 | 6076–6099 | Oil | C | nC10 | 1.11 | 1.02 | 1.23 | 0.41 | 0.39 | 5.27 | 2.53 | 2.04 | 10.91 | 0.26 | 0.06 | 0.91 | 0.65 | 0.48 |

| 4 | DH601 | 6063–6089 | Oil | C | nC11 | 1.04 | 1.02 | 1.22 | 0.63 | 0.56 | 4.38 | 1.67 | 1.05 | 2.18 | 0.28 | 0.05 | 0.98 | 0.66 | 0.49 |

| 5 | DH231(B) | / | / | / | / | 1.07 | 1.02 | 0.94 | 0.25 | 0.29 | 0.8 | 3.11 | 0.71 | 10.05 | 0.25 | 0.07 | 0.80 | 0.60 | 0.48 |

| 6 | DH231(A) | / | / | / | / | 1.06 | 1.02 | 0.90 | 0.30 | 0.34 | 0.81 | 3.85 | 0.97 | 11.05 | 0.23 | 0.06 | 0.71 | 0.61 | 0.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Chen, Z.; Xie, W. A Study on the Material Composition and Traceability of the Wellhead Blockage in the Process of Oil and Gas Exploitation—A Case of the DH231 Well in the Tarim Basin, China. Appl. Sci. 2023, 13, 1504. https://doi.org/10.3390/app13031504

Lu Z, Chen Z, Xie W. A Study on the Material Composition and Traceability of the Wellhead Blockage in the Process of Oil and Gas Exploitation—A Case of the DH231 Well in the Tarim Basin, China. Applied Sciences. 2023; 13(3):1504. https://doi.org/10.3390/app13031504

Chicago/Turabian StyleLu, Zhongdeng, Zulin Chen, and Wei Xie. 2023. "A Study on the Material Composition and Traceability of the Wellhead Blockage in the Process of Oil and Gas Exploitation—A Case of the DH231 Well in the Tarim Basin, China" Applied Sciences 13, no. 3: 1504. https://doi.org/10.3390/app13031504

APA StyleLu, Z., Chen, Z., & Xie, W. (2023). A Study on the Material Composition and Traceability of the Wellhead Blockage in the Process of Oil and Gas Exploitation—A Case of the DH231 Well in the Tarim Basin, China. Applied Sciences, 13(3), 1504. https://doi.org/10.3390/app13031504