Superelastic Shape Memory Alloy Honeycomb Damper

Abstract

:1. Introduction

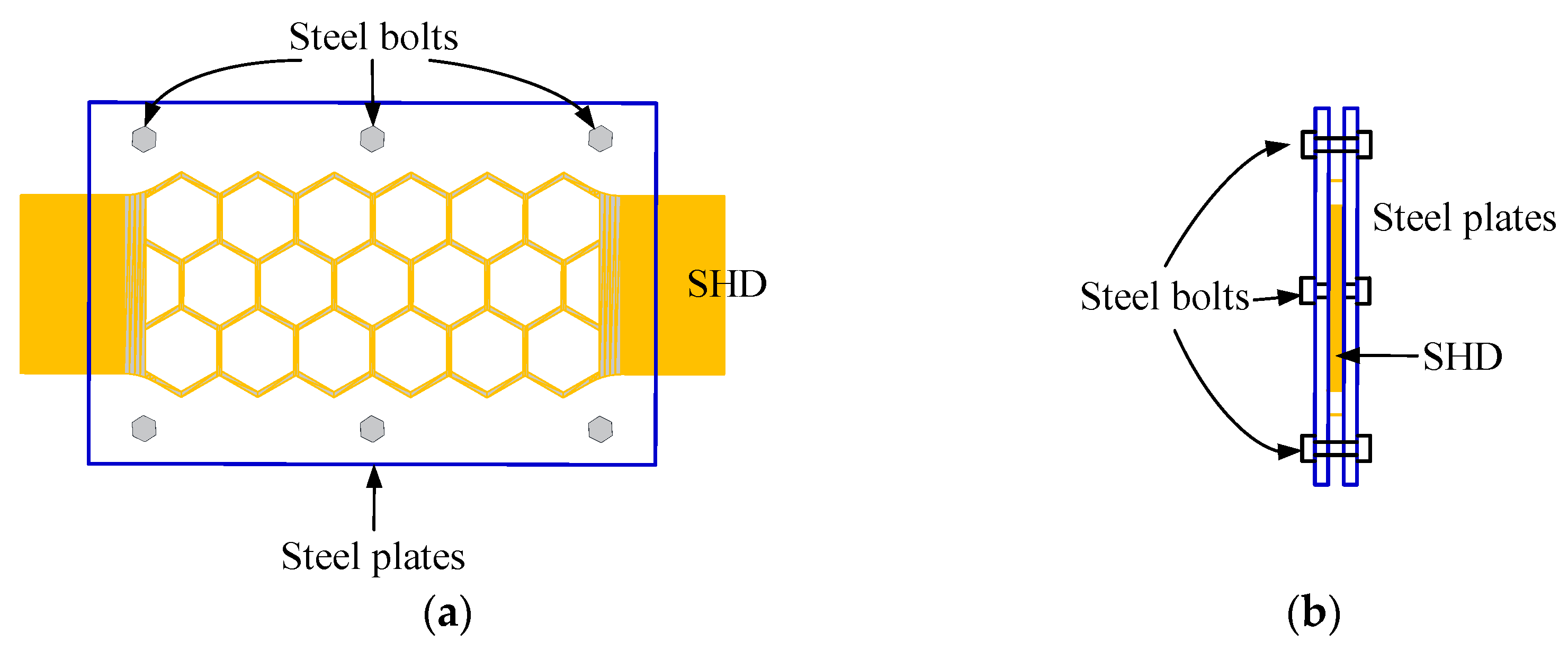

2. Superelastic SMA Honeycomb Damper

2.1. Design Principle and Configuration

2.2. Working Mechanism

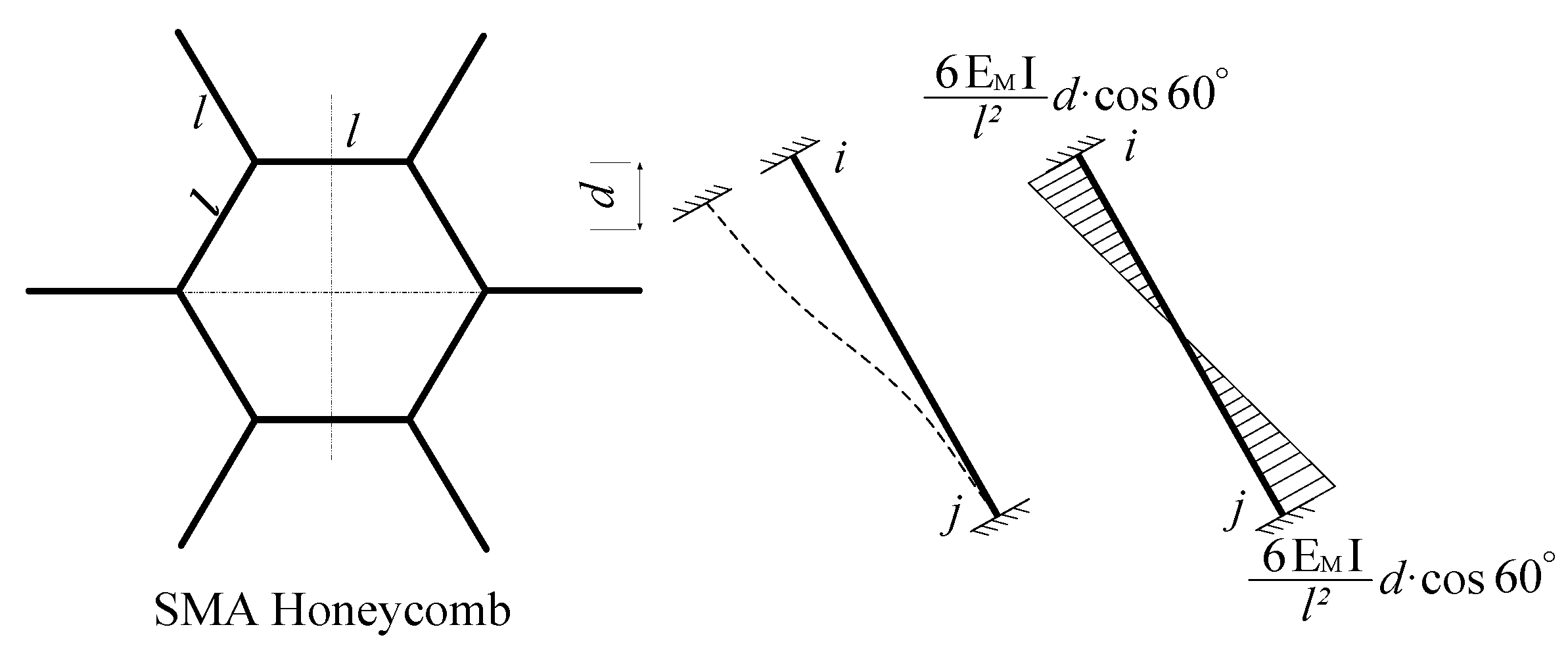

2.3. Theoretical Analysis of a Singular Hexagonal Cell

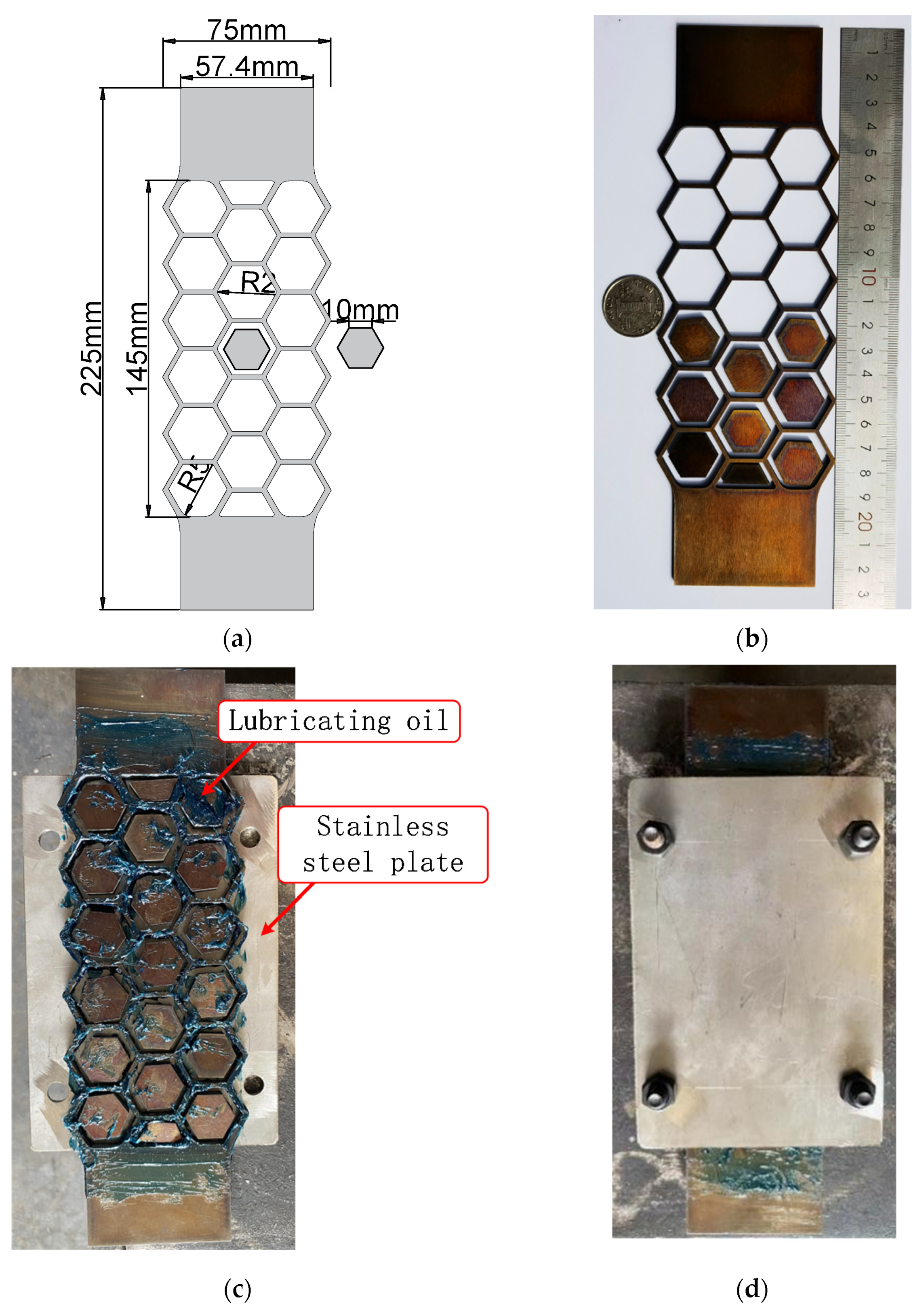

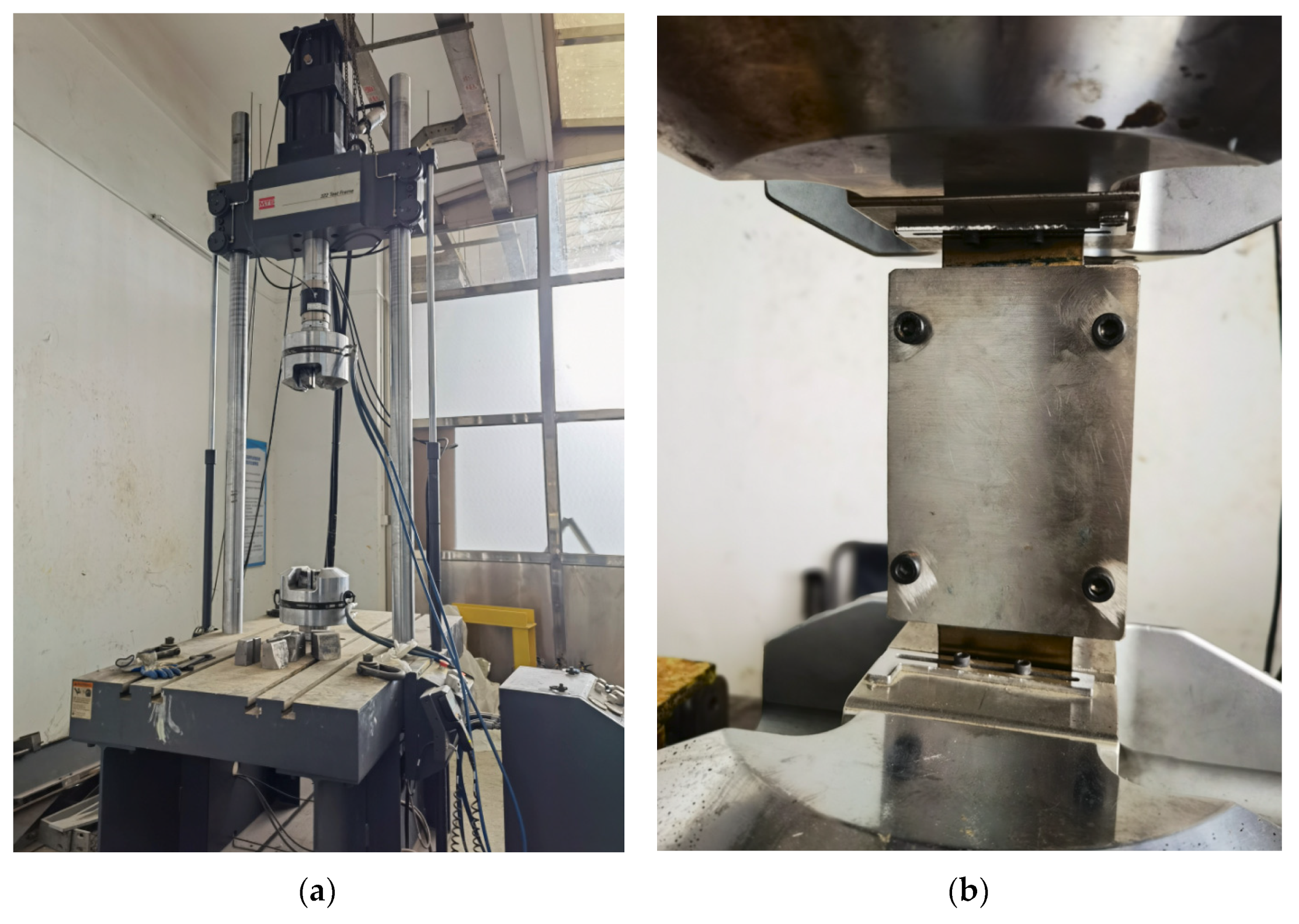

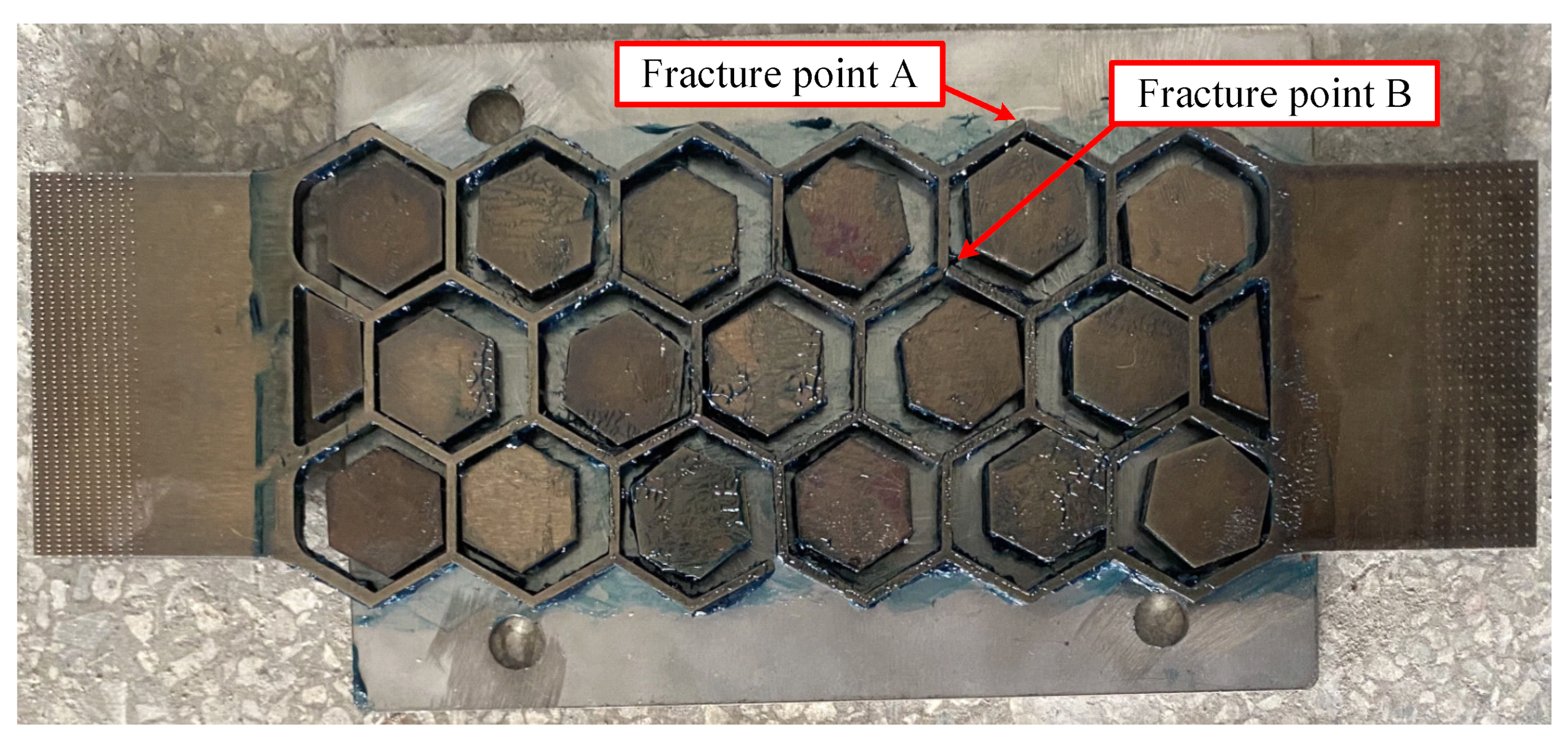

3. Experimental Test

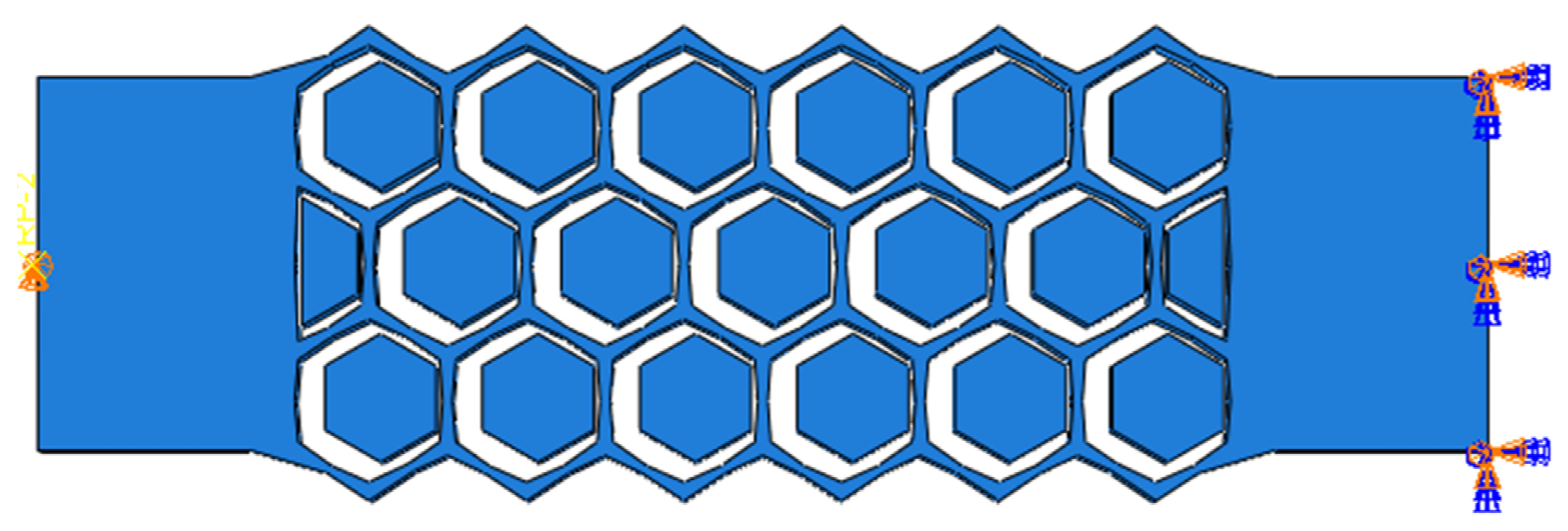

3.1. Specimen

3.2. Test Setup and Loading Procedure

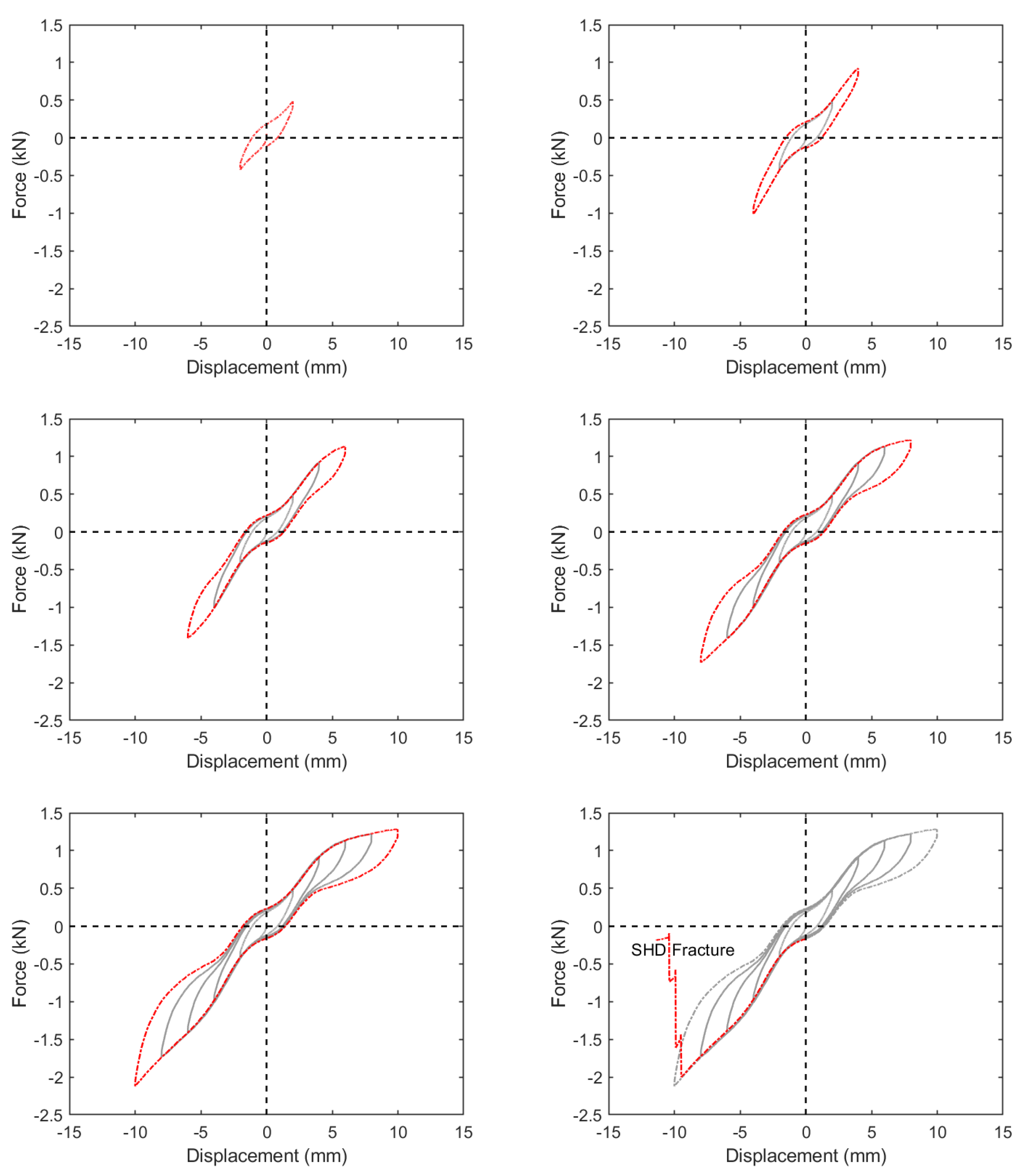

3.3. Experimental Results

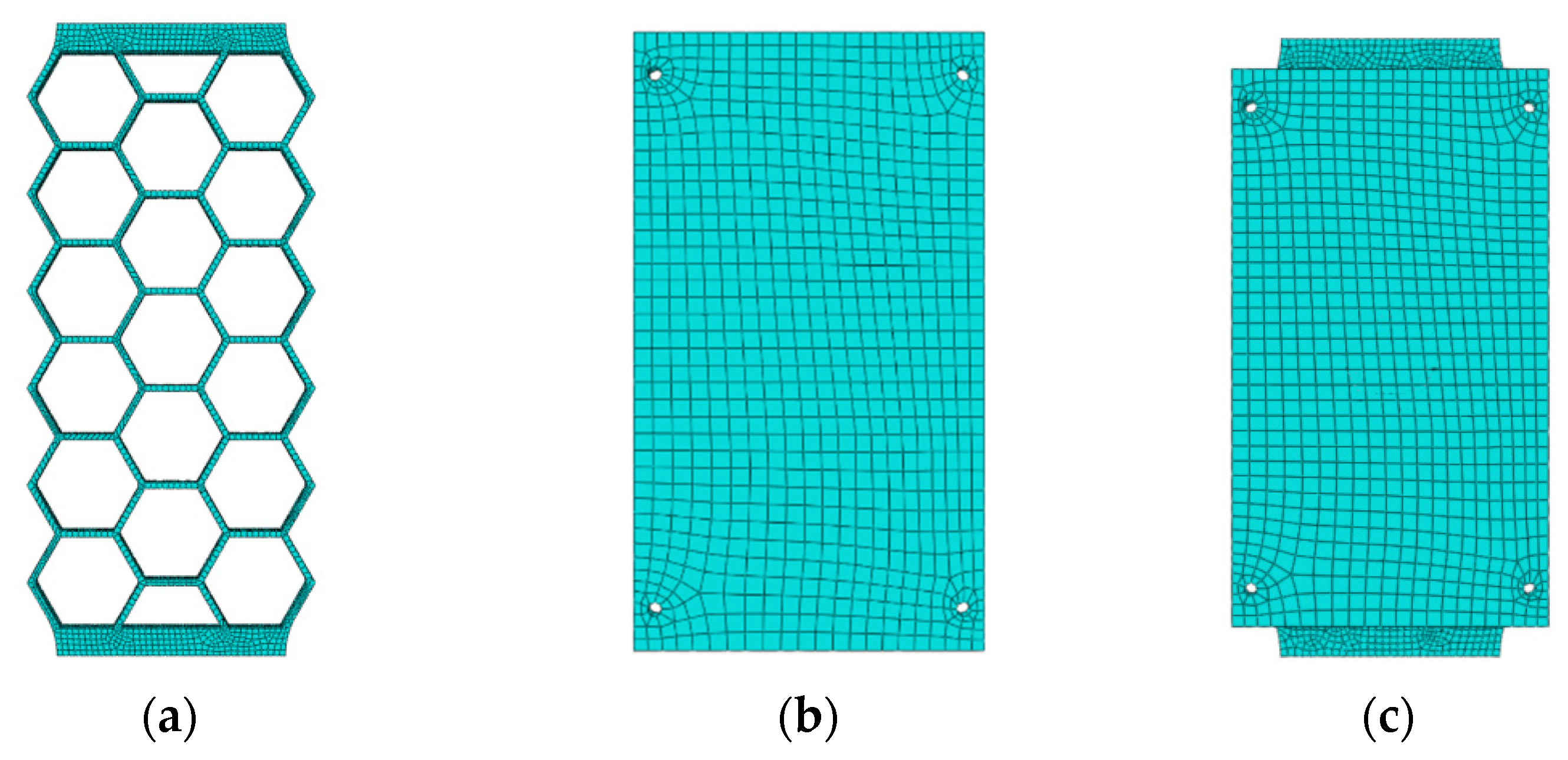

4. Numerical Simulation of SHD

4.1. Finite Element Model

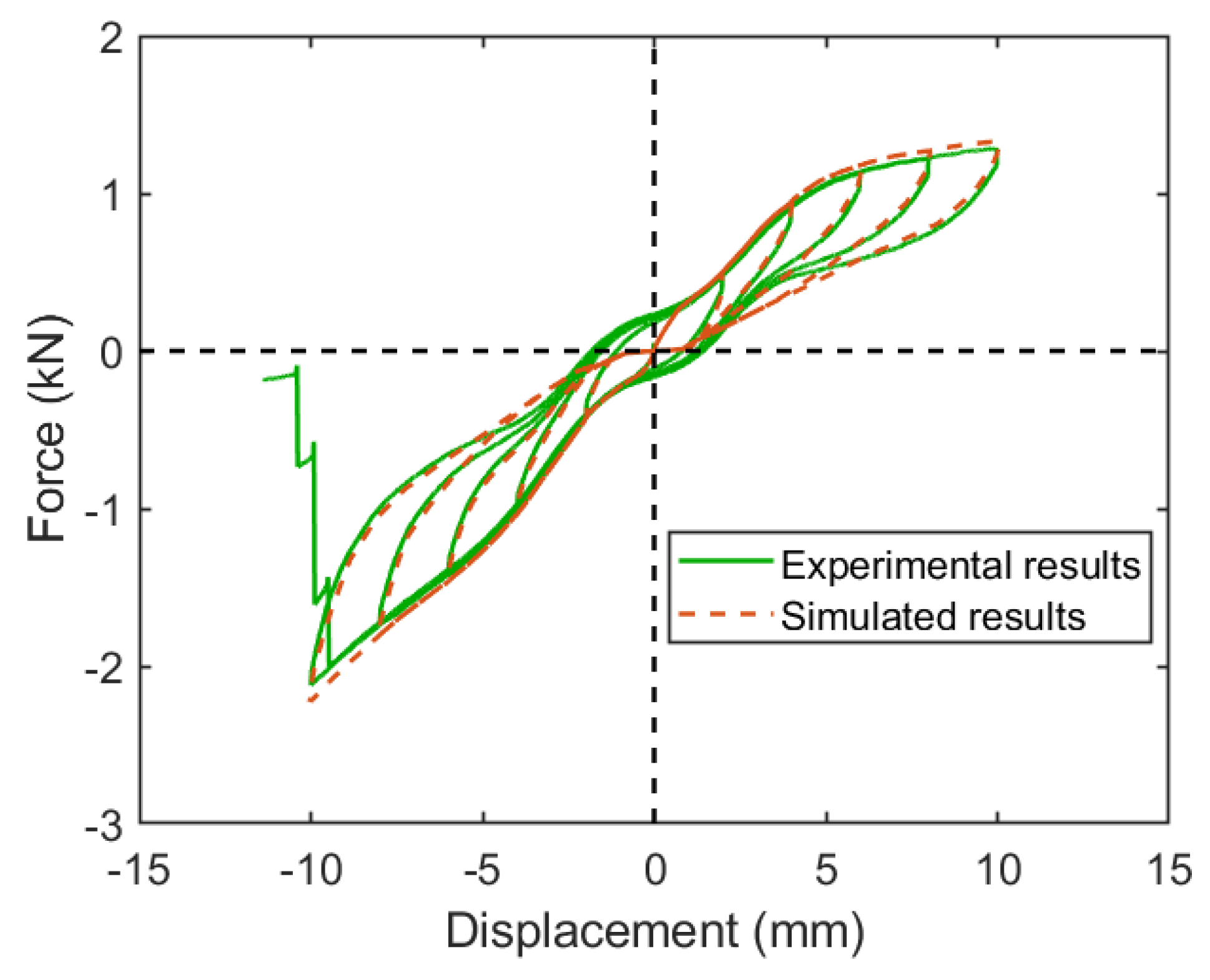

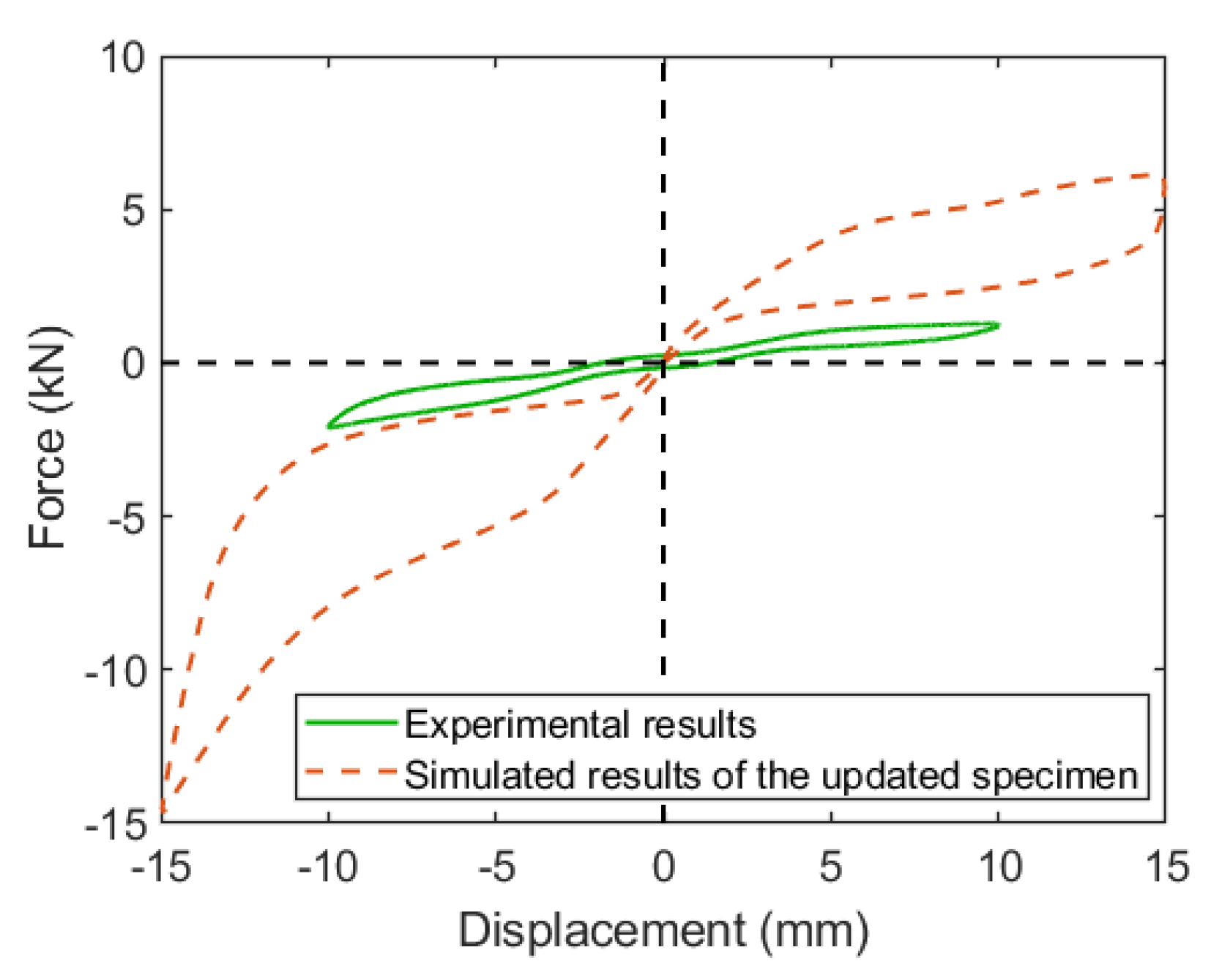

4.2. Experimental and Simulated Results

5. Improvement of SHD

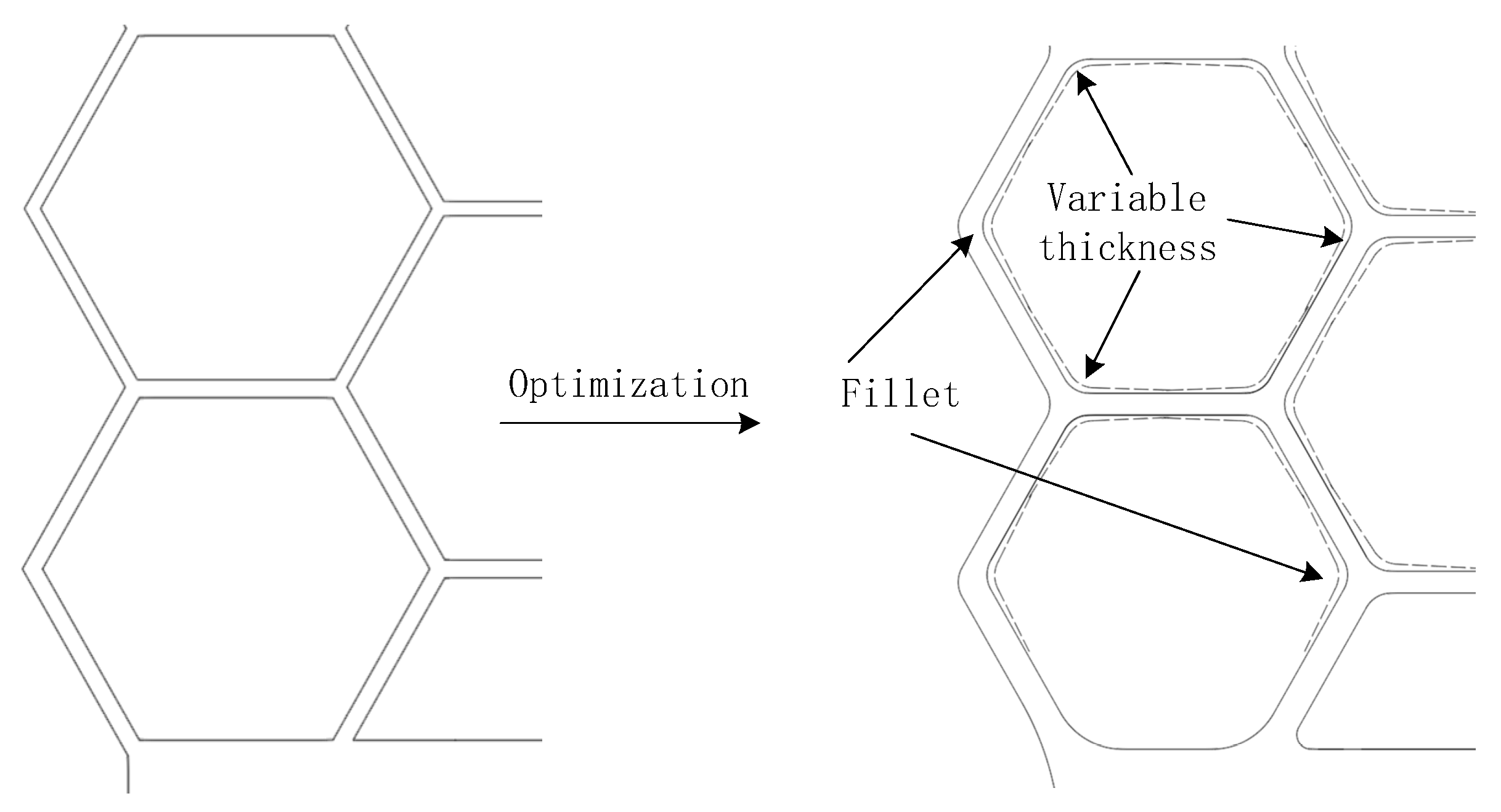

5.1. Optimization of SHD

5.2. Validation of Optimization

6. Conclusions

- The SHD combines the geometrically nonlinear nature of honeycomb structures with the superelastic capabilities of shape memory alloy (SMA) materials. As a result, it has the capability to undergo significant deformation within a limited distance. An SHD of 1700 mm in length possesses a deformation capability of 150 mm, making it suitable for use in typical simply supported bridges.

- The SHD exhibits exceptional self-centering capacity and stable hysteretic responses. The static residual displacement to maximum displacement ratios are less than 0.7%. The incorporation of this technique in the seismic design of structures has the potential to significantly improve their resilience.

- The stress and strain concentration that is present at the sharp edges of the SHD can be effectively mitigated by adjusting the thickness of the non-horizontal cell wall. The SHD is capable of supplying over 10.3% of the overall strain, while the local strain remains below the SMA material’s maximal recoverable strain. The honeycomb structure design method increased the deformation capacity of the SMA damper by 60% in the optimized specimen. This enables SHD to exhibit a comparatively larger stroke in comparison to analogous SMA-based devices.

- A numerical simulation of the application of the SHD in bridges subjected to earthquakes is necessary to verify its effectiveness and applicability in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Xiong, J. Seismic resilient design with base isolation device using friction pendulum bearing and viscous damper. Soil Dyn. Earthq. Eng. 2022, 153, 107073. [Google Scholar] [CrossRef]

- Xiang, N.; Alam, M.S.; Li, J. Yielding Steel Dampers as Restraining Devices to Control Seismic Sliding of Laminated Rubber Bearings for Highway Bridges: Analytical and Experimental Study. J. Bridge Eng. 2019, 24, 04019103. [Google Scholar] [CrossRef]

- Pang, Y.; He, W.; Zhong, J. Risk-based design and optimization of shape memory alloy restrained sliding bearings for highway bridges under near-fault ground motions. Eng. Struct. 2021, 241, 112421. [Google Scholar] [CrossRef]

- Cao, S.; Ozbulut, O.E.; Dang, X.; Tan, P. Experimental and numerical investigations on adaptive stiffness double friction pendulum systems for seismic protection of bridges. Soil Dyn. Earthq. Eng. 2024, 176, 108302. [Google Scholar] [CrossRef]

- Alam, M.S.; Bhuiyan, M.R.; Billah, A.M. Seismic fragility assessment of SMA-bar restrained multi-span continuous highway bridge isolated by different laminated rubber bearings in medium to strong seismic risk zones. Bull. Earthq. Eng. 2012, 10, 1885–1909. [Google Scholar] [CrossRef]

- Andreacola, F.R.; Brando, G. Optimization methods for the design of advanced 3d-printed metal seismic dissipation devices. ce/papers 2023, 6, 888–892. [Google Scholar] [CrossRef]

- De Domenico, D.; Tubaldi, E.; Takewaki, I.; Karavasilis, T.; Dall’Asta, A.; Lavan, O. Editorial: Recent Advances and Applications of Seismic Isolation and Energy Dissipation Devices. Front. Built Environ. 2020, 6, 126. [Google Scholar] [CrossRef]

- Brando, G.; D’Agostino, F.; De Matteis, G. Seismic performance of MR frames protected by viscous or hysteretic dampers. Struct. Des. Tall Spec. Build. 2015, 24, 653–671. [Google Scholar] [CrossRef]

- De Matteis, G.; D’Agostino, F.; Brando, G. Experimental tests on steel buckling inhibited shear panels. Open Constr. Build. Technol. J. 2014, 8, 279–288. [Google Scholar] [CrossRef]

- Michailidis, P.A.; Triantafyllidis, N.; Shaw, J.A.; Grummon, D.S. Superelasticity and Stability of a Shape Memory Alloy Hexagonal Honeycomb under In-plane Compression. Int. J. Solids Struct. 2009, 46, 2724–2738. [Google Scholar] [CrossRef]

- Galehdari, S.; Khodarahmi, H. Design and analysis of a graded honeycomb shock absorber for a helicopter seat during a crash condition. Int. J. Crashworthiness 2016, 21, 231–241. [Google Scholar] [CrossRef]

- Lee, M.; Lee, J.; Kim, J. Seismic Retrofit of Structures Using Steel Honeycomb Dampers. Int. J. Steel Struct. 2017, 17, 215–229. [Google Scholar] [CrossRef]

- Javanmardi, A.; Ghaedi, K.; Ibrahim, Z.; Huang, F.; Xu, P. Development of a new hexagonal honeycomb steel damper. Arch. Civ. Mech. Eng. 2020, 20, 63. [Google Scholar] [CrossRef]

- Hedayati Dezfuli, F.; Alam, M.S. Smart lead rubber bearings equipped with ferrous shape memory alloy wires for seismically isolating highway bridges. J. Earthq. Eng. 2018, 22, 1042–1067. [Google Scholar] [CrossRef]

- Ozbulut, O.E.; Hurlebaus, S. Seismic assessment of bridge structures isolated by a shape memory alloy/rubber-based isolation system. Smart Mater. Struct. 2010, 20, 015003. [Google Scholar] [CrossRef]

- Shrestha, B.; He, L.-X.; Hao, H.; Bi, K.; Ren, W.-X. Experimental study on relative displacement responses of bridge frames subjected to spatially varying ground motion and its mitigation using superelastic SMA restrainers. Soil Dyn. Earthq. Eng. 2018, 109, 76–88. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, Y. Performance-based assessment of bridges with steel-SMA reinforced piers in a life-cycle context by numerical approach. Bull. Earthq. Eng. 2019, 17, 1667–1688. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, Y.; Li, Y. Resilience and life-cycle performance of smart bridges with shape memory alloy (SMA)-cable-based bearings. Constr. Build. Mater. 2018, 158, 389–400. [Google Scholar] [CrossRef]

- Cao, S.; Ozbulut, O.E. Long-stroke shape memory alloy restrainers for seismic protection of bridges. Smart Mater. Struct. 2020, 29, 115005. [Google Scholar] [CrossRef]

- Li, S.; Hedayati Dezfuli, F.; Wang, J.-Q.; Shahria Alam, M. Seismic vulnerability and loss assessment of an isolated simply-supported highway bridge retrofitted with optimized superelastic shape memory alloy cable restrainers. Bull. Earthq. Eng. 2020, 18, 3285–3316. [Google Scholar] [CrossRef]

- Cardone, D.; Sofia, S. Numerical and Experimental Studies on the Seismic Retrofit of Simply Supported Bridges Using Superelastic Restrainers. Adv. Mater. Res. 2012, 446–449, 3291–3294. [Google Scholar] [CrossRef]

- Guo, A.; Zhao, Q.; Li, H. Experimental study of a highway bridge with shape memory alloy restrainers focusing on the mitigation of unseating and pounding. Earthq. Eng. Eng. Vib. 2012, 11, 195–204. [Google Scholar] [CrossRef]

- Fang, C.; Zheng, Y.; Chen, J.; Yam, M.C.; Wang, W. Superelastic NiTi SMA cables: Thermal-mechanical behavior, hysteretic modelling and seismic application. Eng. Struct. 2019, 183, 533–549. [Google Scholar] [CrossRef]

- Qiu, C.; Fang, C.; Liang, D.; Du, X.; Yam, M.C. Behavior and application of self-centering dampers equipped with buckling-restrained SMA bars. Smart Mater. Struct. 2020, 29, 035009. [Google Scholar] [CrossRef]

- Fang, C.; Qiu, C.X.; Wang, W.; Alam, M.S. Self-Centering Structures Against Earthquakes: A Critical Review. J. Earthq. Eng. 2023, 27, 4354–4389. [Google Scholar] [CrossRef]

- Ge, J.; Saiidi, M.S.; Varela, S. Computational studies on the seismic response of the State Route 99 bridge in Seattle with SMA/ECC plastic hinges. Front. Struct. Civ. Eng. 2019, 13, 149–164. [Google Scholar] [CrossRef]

- Wang, J.-Q.; Li, S.; Dezfuli, F.H.; Alam, M.S. Sensitivity analysis and multi-criteria optimization of SMA cable restrainers for longitudinal seismic protection of isolated simply supported highway bridges. Eng. Struct. 2019, 189, 509–522. [Google Scholar] [CrossRef]

- Zheng, W.-Z.; Wang, H.; Li, J.; Shen, H.-J. Parametric study of SMA-based friction pendulum system for response control of bridges under near-fault ground motions. J. Earthq. Eng. 2021, 25, 1494–1512. [Google Scholar] [CrossRef]

- Deng, J.D.; Hu, F.L.; Ozbulut, O.E.; Cao, S.S. Verification of multi-level SMA/lead rubber bearing isolation system for seismic protection of bridges. Soil Dyn. Earthq. Eng. 2022, 161, 107380. [Google Scholar] [CrossRef]

- Zheng, W.; Tan, P.; Li, J.; Wang, H.; Tan, J.; Sun, Z. Sliding-LRB incorporating superelastic SMA for seismic protection of bridges under near-fault earthquakes: A comparative study. Soil Dyn. Earthq. Eng. 2022, 155, 107161. [Google Scholar] [CrossRef]

- Vaiana, N.; Capuano, R.; Rosati, L. Evaluation of path-dependent work and internal energy change for hysteretic mechanical systems. Mech. Syst. Signal Process. 2023, 186, 109862. [Google Scholar] [CrossRef]

- Cao, S.; Ozbulut, O.E.; Wu, S.; Sun, Z.; Deng, J. Multi-level SMA/lead rubber bearing isolation system for seismic protection of bridges. Smart Mater. Struct. 2020, 29, 055045. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Li, J.; Shen, H. Performance evaluation of bridges isolated with SMA-based friction pendulum system at low temperatures. Soil Dyn. Earthq. Eng. 2019, 125, 105734. [Google Scholar] [CrossRef]

- Li, S.; Wang, J.; Alam, M.S. Seismic performance assessment of a multispan continuous isolated highway bridge with superelastic shape memory alloy reinforced piers and restraining devices. Earthq. Eng. Struct. Dyn. 2021, 50, 673–691. [Google Scholar] [CrossRef]

- Yang, T.; Li, T.; Tobber, L.; Pan, X. Experimental and numerical study of honeycomb structural fuses. Eng. Struct. 2020, 204, 109814. [Google Scholar] [CrossRef]

- Zhakatayev, A.; Kappassov, Z. Analytical modeling and design of negative stiffness honeycombs. Smart Mater. Struct. 2020, 29, 045024. [Google Scholar] [CrossRef]

- Marmo, F.; Sessa, S.; Vaiana, N.; De Gregorio, D.; Rosati, L. Complete solutions of three-dimensional problems in transversely isotropic media. Contin. Mech. Thermodyn. 2020, 32, 775–802. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001. [Google Scholar] [CrossRef]

- Dassault Systemes. ABAQUS 2017 Documentation. English Version. 2018. Available online: http://130.149.89.49:2080/v6.14/ (accessed on 7 November 2023).

- Vaiana, N.; Rosati, L. Analytical and differential reformulations of the Vaiana–Rosati model for complex rate-independent mechanical hysteresis phenomena. Mech. Syst. Sig. Process. 2023, 199, 110448. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, S.; Hu, F.; Zhang, G. Superelastic Shape Memory Alloy Honeycomb Damper. Appl. Sci. 2023, 13, 13154. https://doi.org/10.3390/app132413154

Cao S, Hu F, Zhang G. Superelastic Shape Memory Alloy Honeycomb Damper. Applied Sciences. 2023; 13(24):13154. https://doi.org/10.3390/app132413154

Chicago/Turabian StyleCao, Sasa, Fulong Hu, and Guixin Zhang. 2023. "Superelastic Shape Memory Alloy Honeycomb Damper" Applied Sciences 13, no. 24: 13154. https://doi.org/10.3390/app132413154

APA StyleCao, S., Hu, F., & Zhang, G. (2023). Superelastic Shape Memory Alloy Honeycomb Damper. Applied Sciences, 13(24), 13154. https://doi.org/10.3390/app132413154