Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method

Abstract

:1. Introduction

2. Materials and Processing Methods

2.1. Raw Materials

2.2. Samples Preparing

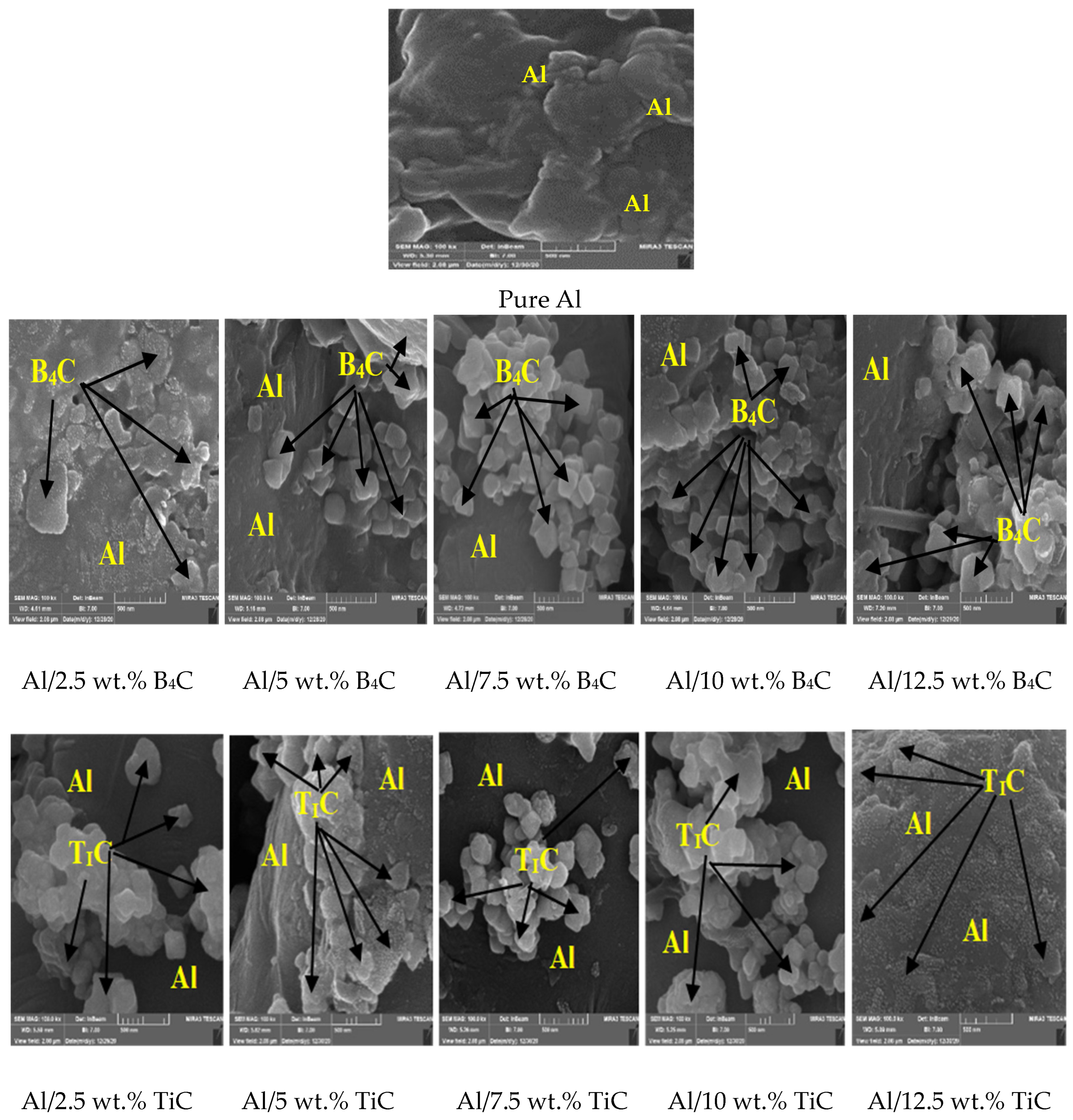

2.3. Examination of the Microstructure

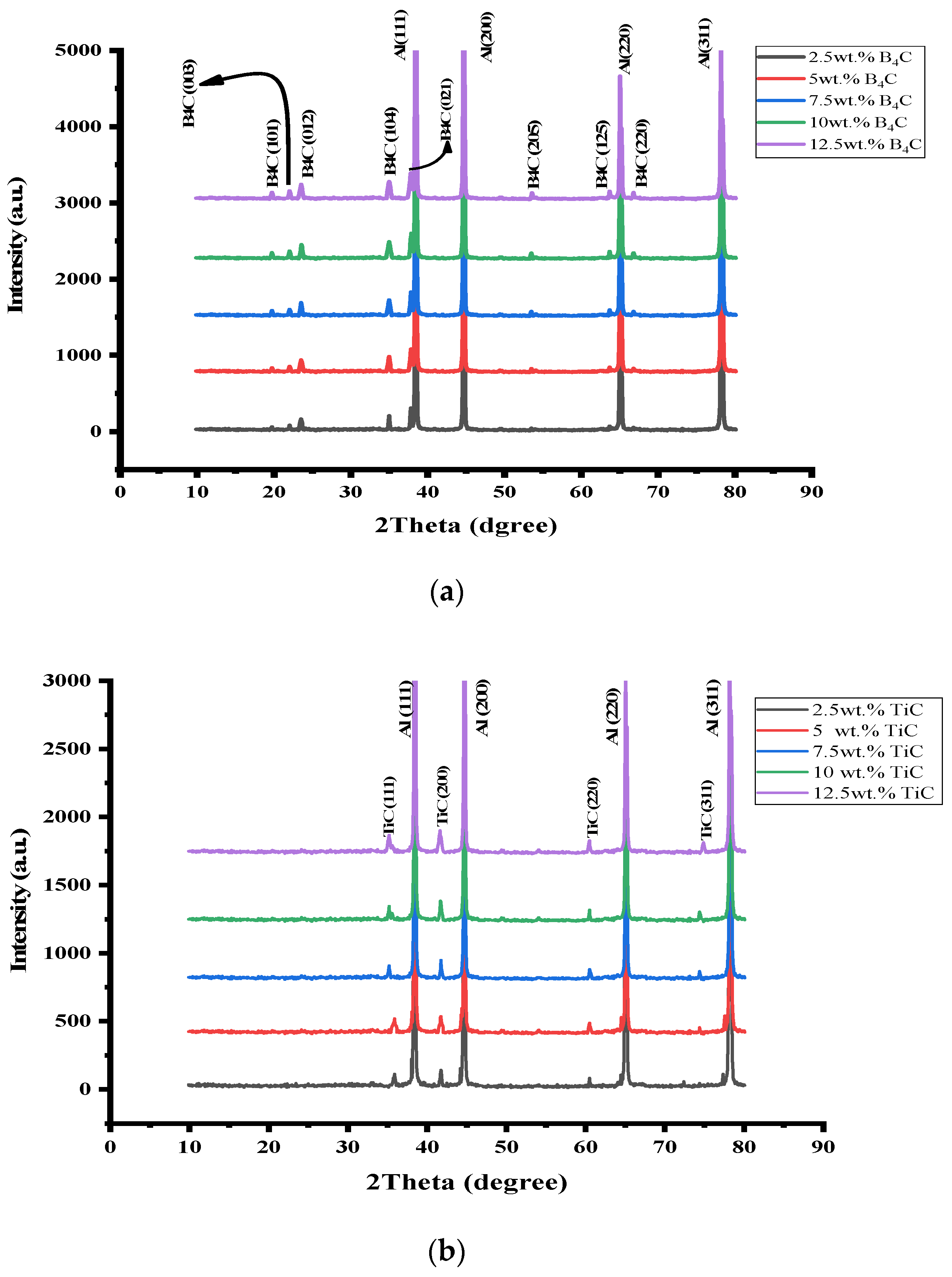

2.4. X-ray Diffraction Analysis

2.5. Micro-Hardness Testing

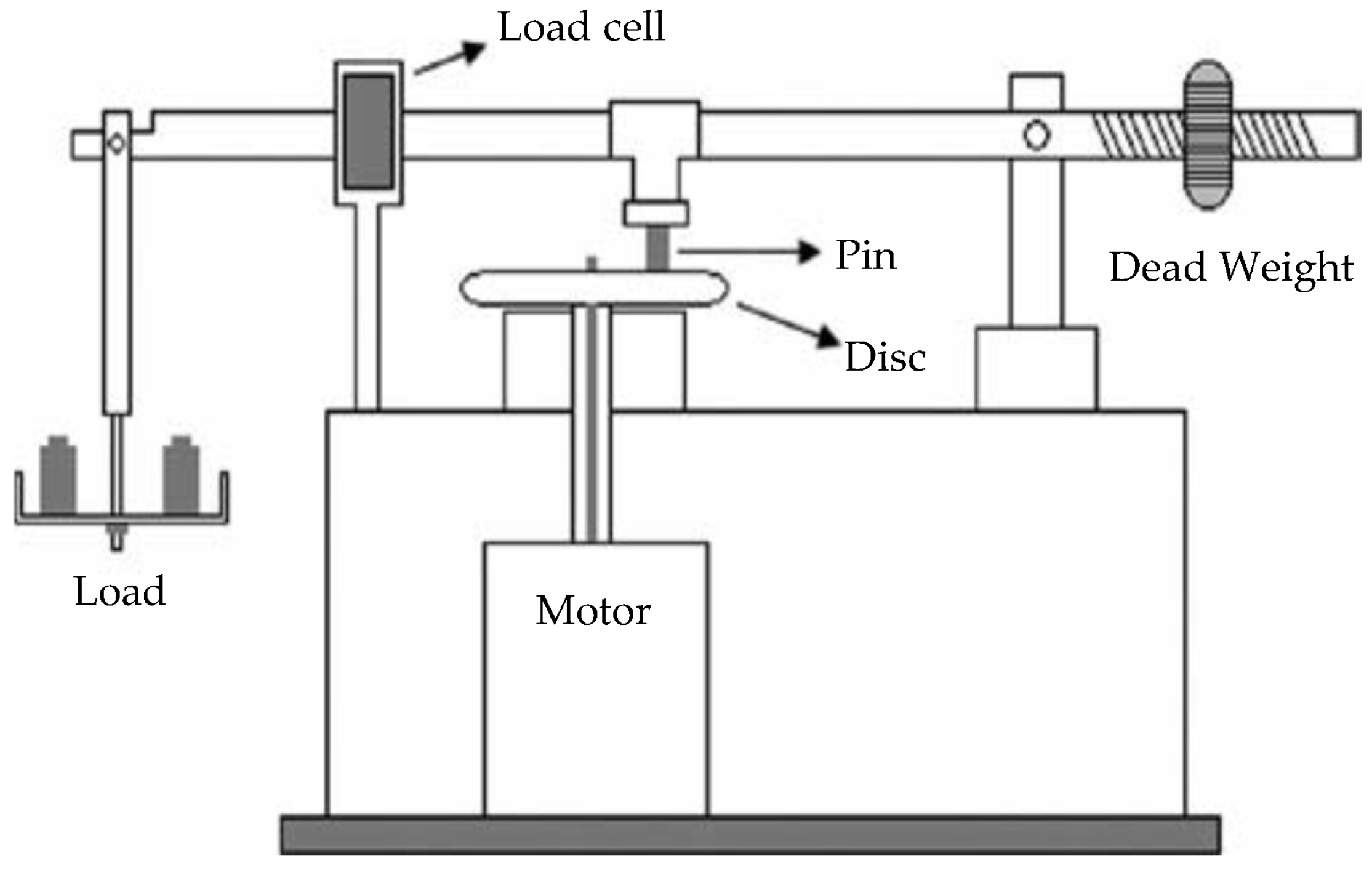

2.6. Wear Testing

3. The Obtained Data and Their Discussion

3.1. Results of Microstructure Examination

3.2. Analysis of X-ray Diffraction Results

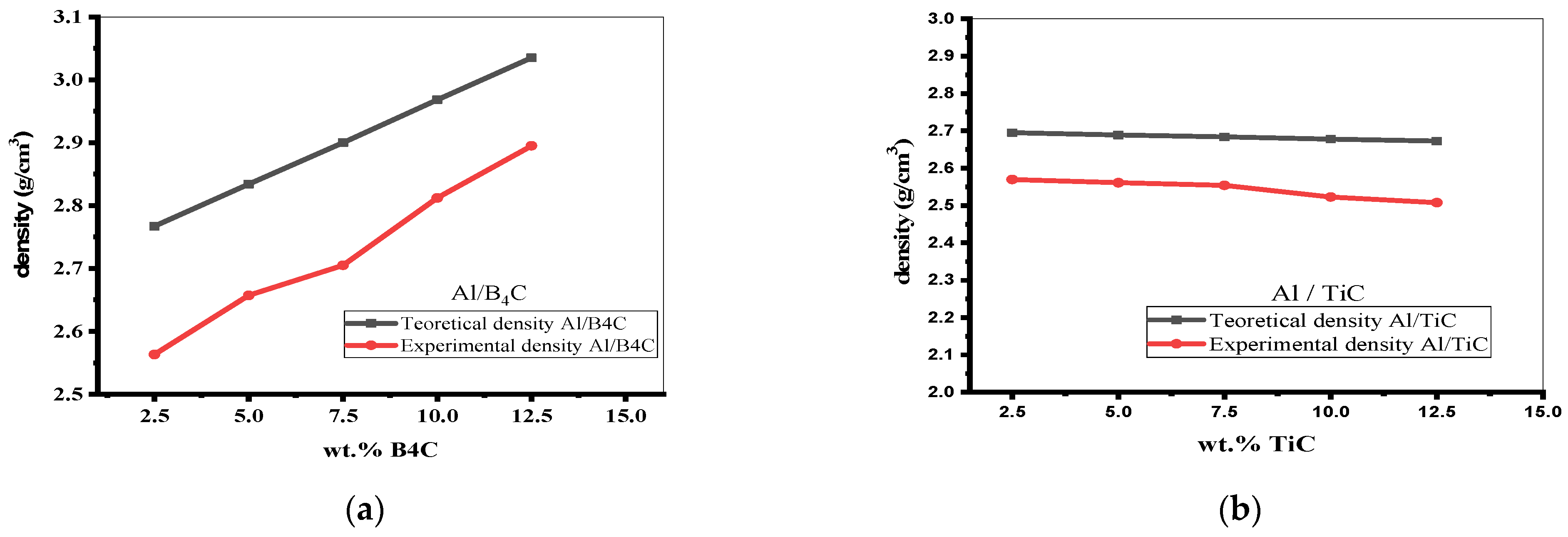

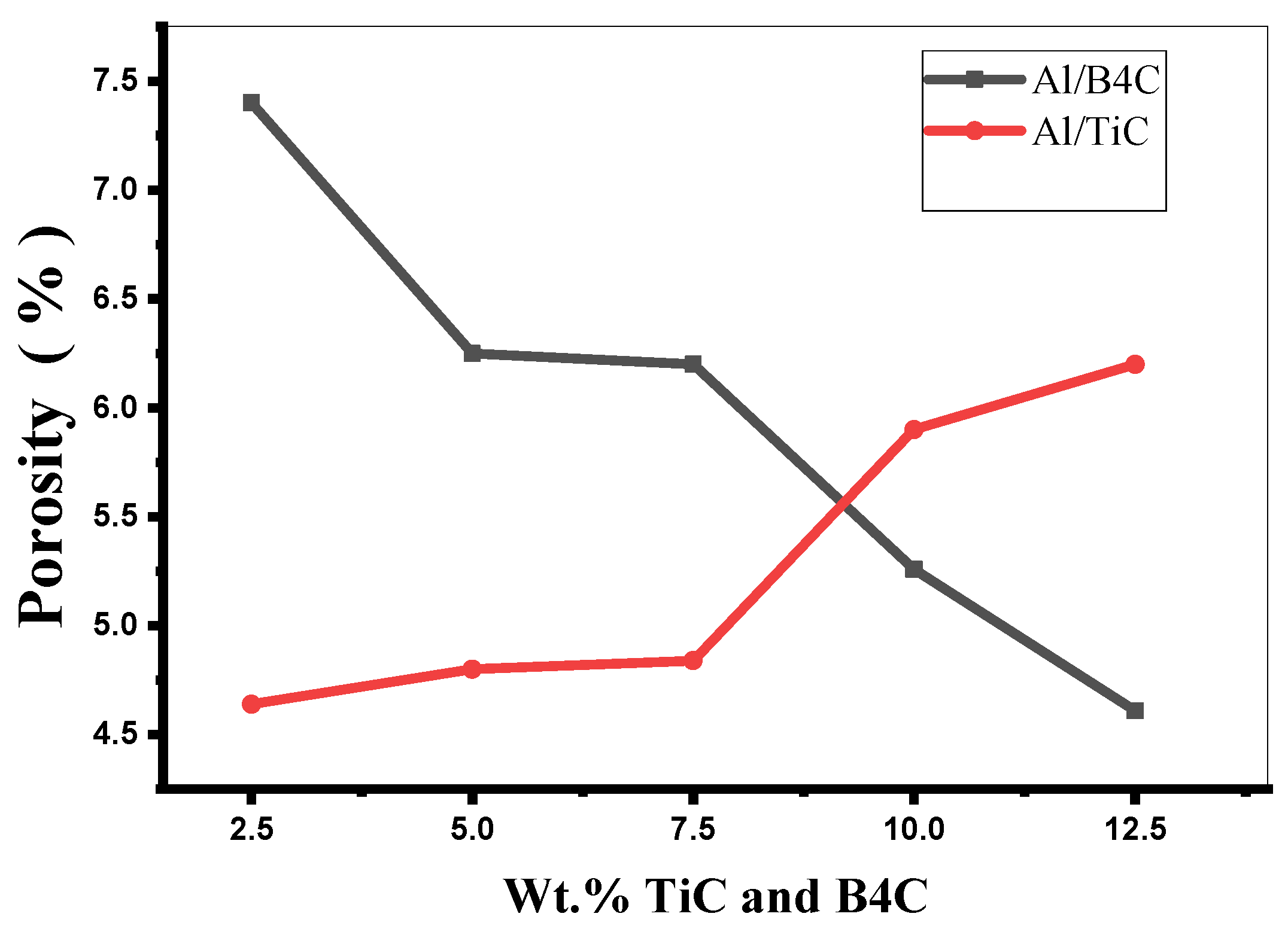

3.3. Mechanisms of Pressing and Sintering Processes

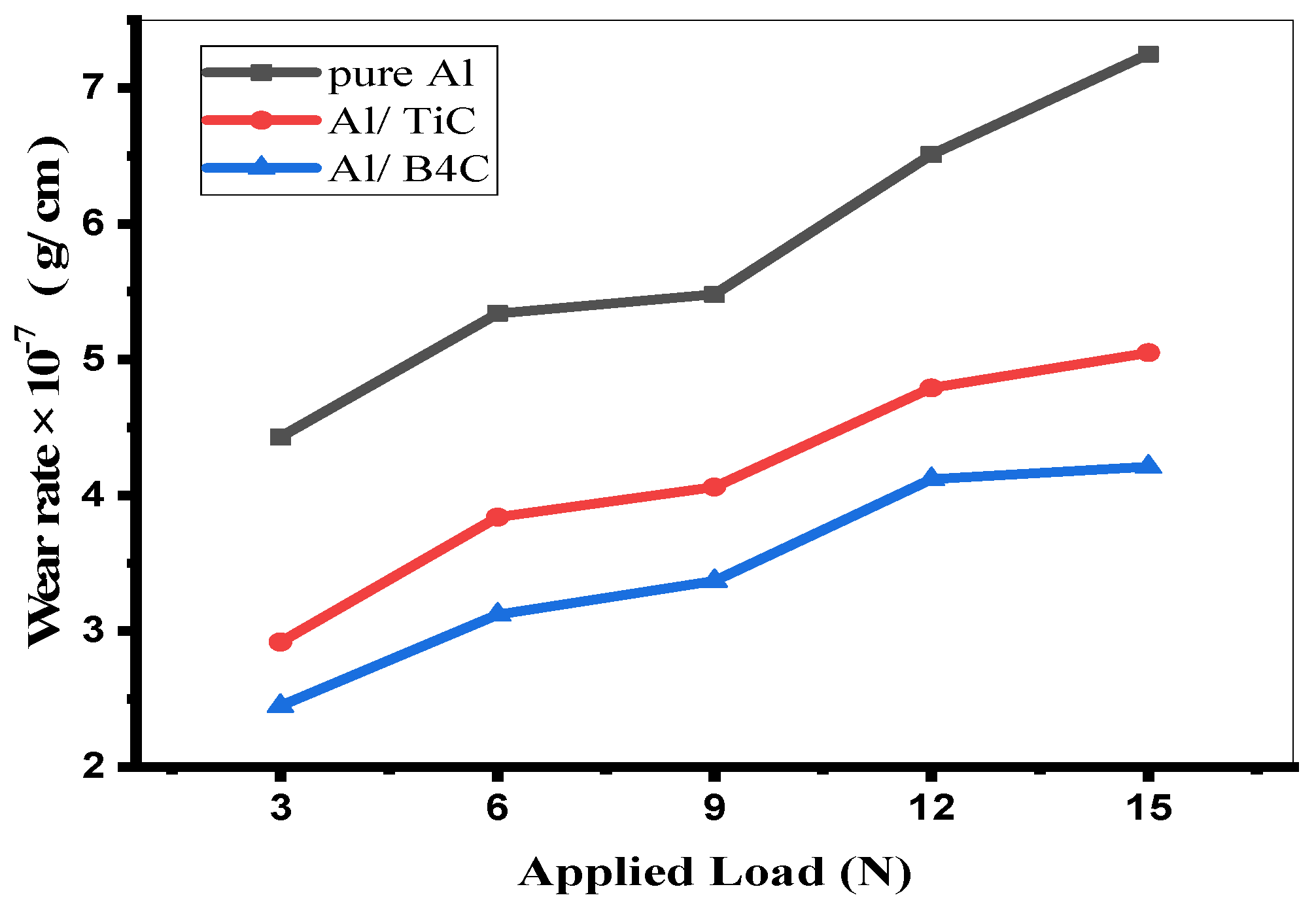

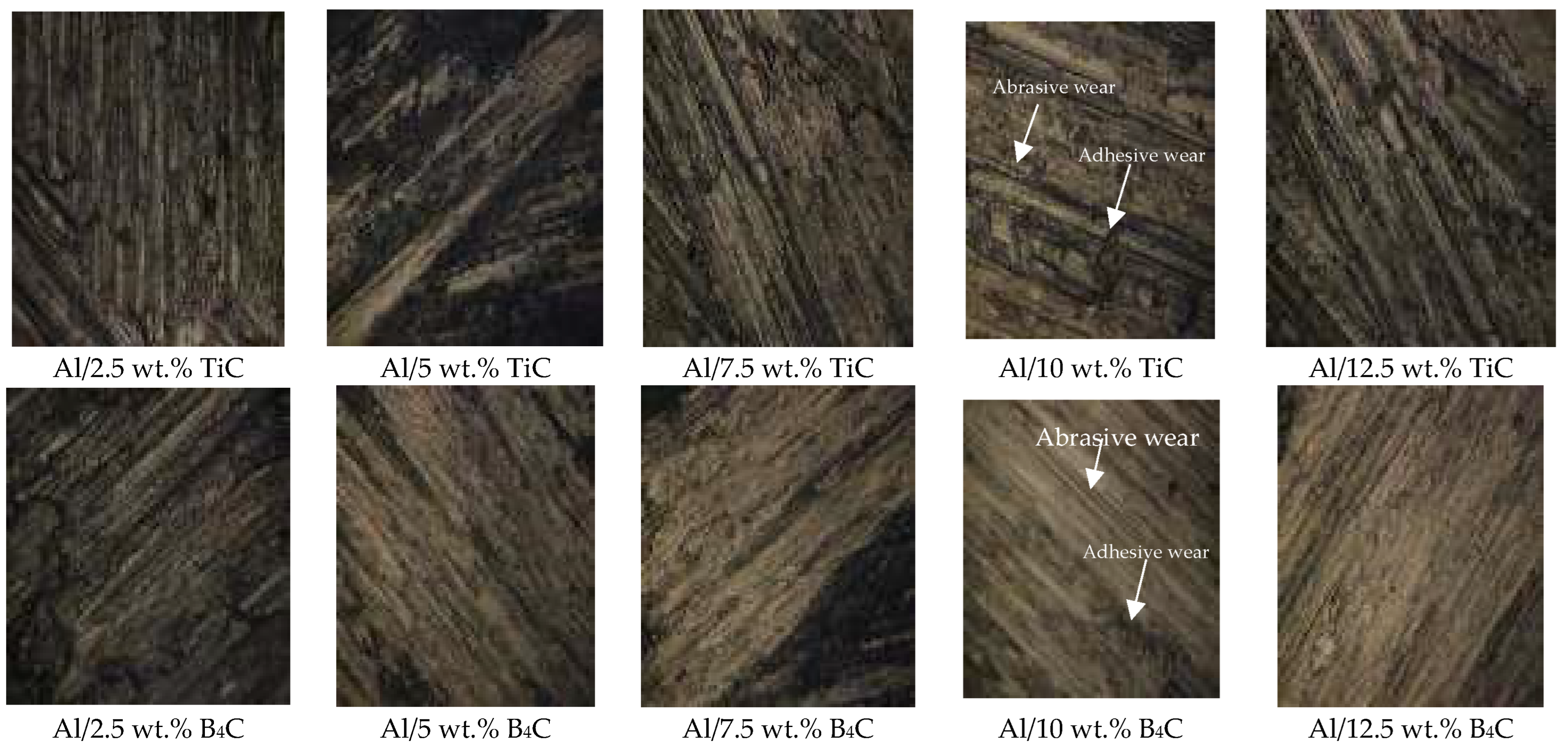

3.4. Wear Testing

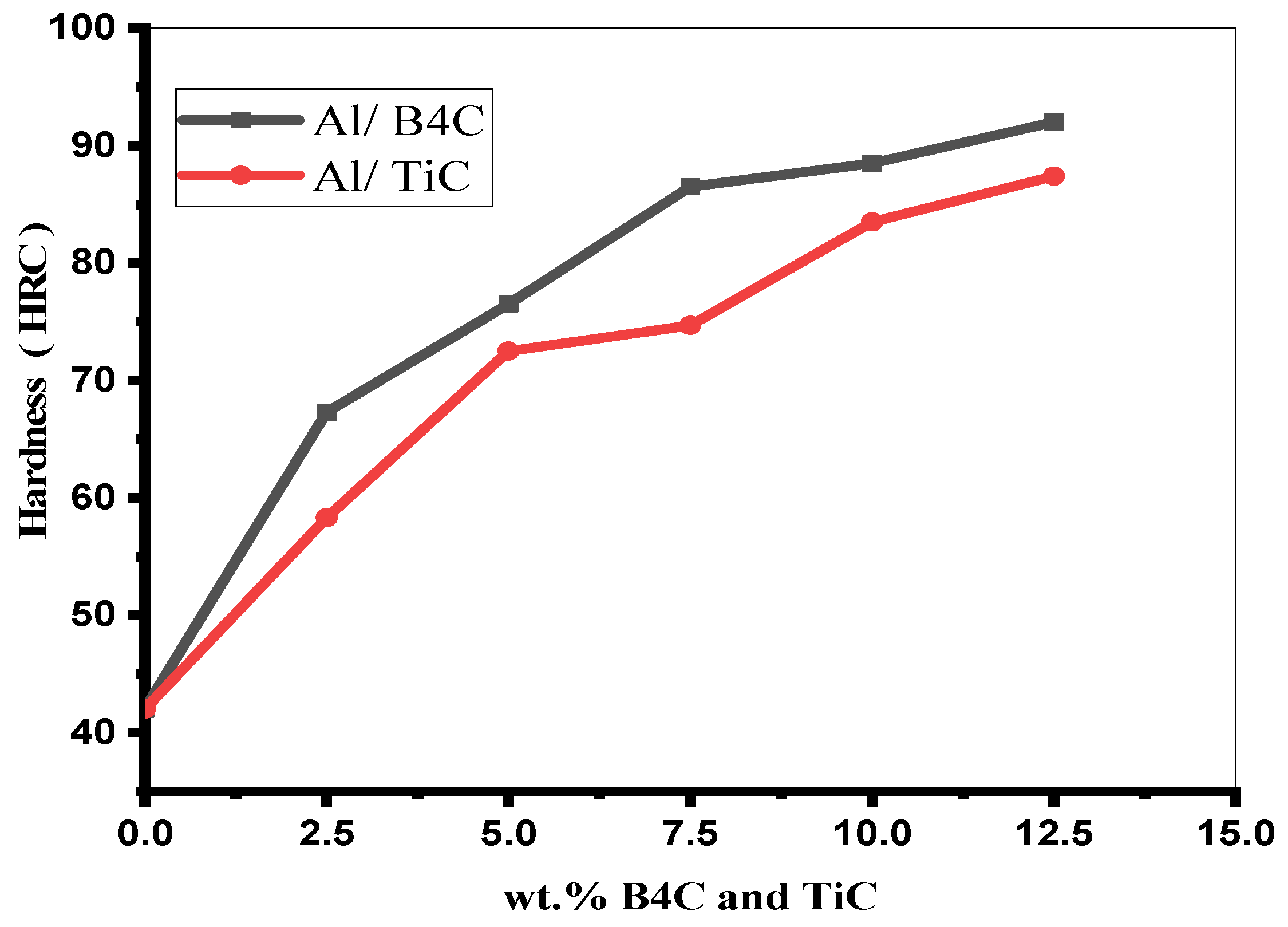

3.5. Micro-Hardness Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khazaal, S.M.; Namer, N.S.M.; Szabolcs, S.; Al Ansari, L.S.; Sammad, H.J.A. Study of manufacturing and material properties of the hybrid composites with metal matrix as tool materials. J. Results Eng. 2022, 16, 100647. [Google Scholar] [CrossRef]

- Behera, M.P.; Dougherty, T.; Singamneni, S. Conventional and additive Manufacturing with Metal Matrix Composites: A Perspectivc. Procedia Manuf. 2019, 30, 159–166. [Google Scholar] [CrossRef]

- Jawalkar, C.; Verma, A.S.; Suri, N. Fabrication of aluminum metal matrix composites with particulate reinforcement: A review. Mater. Today Proc. 2017, 4, 2927–2936. [Google Scholar]

- Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Microstructural Analysis and Mechanical Properties of a Hybrid Al/Fe2O3/Ag Nano-Composite. Appl. Sci. 2022, 12, 4730. [Google Scholar] [CrossRef]

- Acikgoz, A.; Aktas, B.; Demircan, G.; Amasyah, F.; Akdemir, F. Characterization of Nano Aluminum Oxide Reinforced Iron Composites Produced by Powder Metallurgy. In Proceedings of the Fourth International Iron & Steel Symposium, Karabük, Turkey, 4–6 April 2019; pp. 351–355. [Google Scholar]

- Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Microstructural Analysis and Mechanical Characterization of Shape Memory Alloy Ni-Ti-Ag Synthesized by Casting Route. Appl. Sci. 2022, 12, 4639. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Rashid, R.A.; Masood, S.H.; Ruan, D.; Palanisamy, S. Mechanical Properties of imprinted aluminum alloys: A review. Materials 2020, 13, 4301. [Google Scholar] [CrossRef]

- Awotuncle, M.A.; Adegbenjo, A.O.; Obaded, B.A.; Okovo, M.; Shongwe, B.M.; Olubambi, P.A. Influence of sintering methods on the mechanical properties of aluminum nanocomposites reinforced with carbonaceous compounds: A review. J. Mater. Res. Technol. 2019, 8, 2432–2449. [Google Scholar] [CrossRef]

- Aatthisugan, I.; Muralidharan, S.; Majumdar, S.; Rose, A.R.; Jebadurai, D.S. Wear and mechanical properties of Al-6% Cu-X% Mg alloy fabricated by powder metallurgy. IOP Conf. Ser. Mater. Sci. Eng. 2018, 402, 012106. [Google Scholar] [CrossRef]

- Manikanden, R.; Arjunan, T. Studies on microstructural characteristics, mechanical and tribological behaviors of boron carbide and cow dung ash reinforced aluminum (Al 7075) hybrid metal matrix composite. Compos. Part B Eng. 2020, 183, 107668. [Google Scholar] [CrossRef]

- Chintada, S.; Dora, S.P.; Kare, D.; Pujari, S.R. Powder metallurgy versus casting: Damping behavior of pure aluminum. J. Mater. Eng. Perform 2022, 31, 9122–9128. [Google Scholar] [CrossRef]

- Kumar, D.; Angra, S.; Singh, S. Mechanical Properties and Wear Behavior of Stir Cast Aluminum Metal Matrix Composite: A Review. Int. J. Eng. Trans. A Basics 2022, 35, 794–801. [Google Scholar]

- Salman, K.D. Synthesis and Characterization Unsaturated Polyester Resin Nanocomposites Reinforced by Fe2O3+ Ni Nanoparticles: Influence on Mechanical and Magnetic Properties. Int. J. Eng. Trans. A Basics 2022, 35, 21–28. [Google Scholar]

- Aswad, M.A.; Awad, S.H.; Kayyem, A.H. Study on Iraqi Bauxite Ceramic Reinforced Aluminum Metal Matrix Composite Synthesized by Stir Casting. Int. J. Eng. Trans. A Basics 2020, 33, 1331–1339. [Google Scholar]

- Selvan, J.D.R.; Dinaharan, I.; Mashinini, P.M. High temperature sliding wear behavior of AA6061/fly ash aluminum matrix composites prepared using compo casting process. Tribol. Mater. Surf. Interfaces 2017, 11, 39–46. [Google Scholar]

- Golestanipour, M.; Aysak, H.K.; Sasani, N.; Sadeghian, M.H. A Novel, Simple and Cost-Effective Al A356/ Al2O3 Nano-composite Manufacturing Rout with Uniform Distribution of Nanocomparticles. Int. J. Eng. Trans. A Basics 2015, 28, 1320–1327. [Google Scholar]

- Kaushik, N.; Singhal, S. Experimental Investigations on Microstructural and Mechanical Behavior of Friction Stir Welded Aluminum Matrix Composite. Int. J. Eng. Trans. A Basics 2019, 32, 162–170. [Google Scholar]

- Wu, Y.; Zhan, K.; Yang, Z.; Sun, W.; Zhao, B.; Yan, Y.; Yang, J. Graphene oxide/Al composites with enhanced mechanical properties fabricated by simple electrostatic interaction and powder metallurgy. J. Alloys Compd. 2019, 775, 233–240. [Google Scholar] [CrossRef]

- Tian, W.; Qin, G.Q.; Liang, Q.C. Effects of sintering temperature on microstructure and wear properties of Al2O3 particle reinforced Al composites. Adv. Mater. Res. 2015, 1095, 16–19. [Google Scholar]

- Venkatesh, B.; Harish, B. Mechanical Properties of Metal Matrix Composites (Al SiCp) Particles Produced by Powder Metallurgy. Int. J. Eng. Res. Gen. Sci. 2015, 3, 1277–1284. [Google Scholar]

- Thangarasu, A.; Murugan, N.; Dinaharan, I.; Vijay, S.J. Synthesis and Characterization of titanium carbide particulate reinforced AA 6082 aluminum alloy composites via friction stir processing. Arch Civ. Mech. Eng. 2015, 15, 324–334. [Google Scholar] [CrossRef]

- Manohar, G.; Maity, S.R.; Pandey, K.M. Microstructural and mechanical properties of microwave sintered AA7075/ graphite/ SiC hybrid composite fabricated by powder metallurgy techniques. Silicon 2022, 14, 5179–5189. [Google Scholar] [CrossRef]

- Negin, A.; Hanim, A.; Sarraf, M.; Sulaiman, S.; Hong, T.S. Microstructural, Tribology and Corrosion Properties of Optimized Fe3O4-SiC Reinforced Aluminum Matrix Hybrid Nano Filler Composite Fabricated through Powder Metallurgy Method. Materials 2020, 13, 4090. [Google Scholar]

- Li, G.; Xiong, B. Effects of graphene content on microstructures and tensile property of graphene-nanosheets/ aluminum composites. J. Alloys Compd. 2017, 697, 31–36. [Google Scholar] [CrossRef]

- Maleki, A.; Taherizadeh, A.R.; Issa, H.K.; Niroumand, B.; Allafchian, A.R.; Ghaei, A. Development of a new magnetic aluminum matrix nanocomposite. Ceram. Int. 2018, 44, 15079–15085. [Google Scholar] [CrossRef]

- Soy, U.; Demir, A.; Findik, F. Friction and wear behaviors of Al-SiC-B4C composites produced by pressure infiltration method. Ind. Lubr. Tribol. 2011, 63, 387–393. [Google Scholar] [CrossRef]

- Altınkok, N.; Özsert, I.; Fındık, F. Dry Sliding Wear Behavior of Al2O3/SiC Particle Reinforced Aluminium Based MMCs Fabricated by Stir Casting Method. Acta Phys. Pol. A 2013, 124, 11–19. [Google Scholar] [CrossRef]

- Salman, S.; Köse, R.; Urtekin, L.; Findik, F. An investigation of different ceramic coating thermal properties. J. Mater. Des. 2006, 27, 585–590. [Google Scholar] [CrossRef]

- Abbasi, M.; Givi, M.; Ramazani, A. Friction stir vibration processing: A new method to improve the microstructure and mechanical properties of Al5052/SiC surface nanocomposite layer. Int. J. Adv. Manuf. Technol. 2019, 100, 1463–1473. [Google Scholar] [CrossRef]

- Abbasi, M.; Abdollahzadeh, A.; Bagheri, B.; Omidvar, H. The effect of SiC particle addition during FSW on microstructure and mechanical properties of AZ31 magnesium alloy. J. Mater. Eng. Perform. 2015, 24, 5037–5045. [Google Scholar] [CrossRef]

- Dadaei, M.; Omidvar, H.; Bagheri, B.; Jahazi, M.; Abbasi, M. The effect of SiC/Al2O3 particles used during FSP on mechanical properties of AZ91 magnesium alloy. Int. J. Mater. Res. 2014, 105, 369–374. [Google Scholar] [CrossRef]

- Amin, A.; Bagheri, B.; Shamsipur, A. Development of Al/Cu/SiC bimetallic nano-composite by friction stir spot welding. Mater. Manuf. Process. 2023, 38, 1416–1425. [Google Scholar]

- Balaji, P.; Arun, R.; JegathPriyan, D.; Ram, I.M.; Manikandan, E. Comparative study of Al 6061 alloy with Al 6061-magnesium oxide (MgO) composite. Int. J. Sci. Eng. Res. 2015, 6, 408. [Google Scholar]

- AZOM. AZO Materials. Available online: https://www.azom.com/ (accessed on 2 May 2023).

- ASTM-D 618; Standard Practice for Conditioning Plastics for Testing. ASTM International: West Conshehoken, PA, USA, 2021.

- Zaid, H.M.; Abed, A.R.; Hasan, H.S. Improvement of Mechanical properties of Magnesium (Mg) Matrix Composites Reinforced with Nano Alumina (Al2O3) Particles. In Proceedings of the IOP Conference Series: Material Science and Engineering, Chennai, India, 16–17 September 2020; IOP Publishing: Bristol, UK; Volume 67, p. 012162. [Google Scholar]

- Bayraktar, E.; Katundi, D.; Ferreira, L.M.; Robert, M.H. Design and microstructural evolution, mechanical and physical properties of fine particles reinforced aluminum matrix composites. Adv. Mater. Process. Technol. 2016, 2, 566–577. [Google Scholar]

- Krishna, S.M.; Shridhar, T.N.; Krishnamurthy, I. Evaluation and examination of volume fraction, porosity, microstructure and computational modeling of hybrid metal matrix composites to reveal the heat flow distribution characteristics. Int. J. Mater. Sci. Eng. 2015, 3, 231–243. [Google Scholar]

- Alaneme, K.K.; Fajemisin, A.V.; Maledi, N.B. Development of aluminum-based composites reinforced with steel and graphite particles: Structural, mechanical and wear characterization. J. Mater. Res. Technol. 2019, 8, 670–682. [Google Scholar] [CrossRef]

| Mg | Si | Fe | Cr | Cu | Zn | Ti | Mn | Al |

|---|---|---|---|---|---|---|---|---|

| 0.81 | 0.59 | 0.21 | 0.19 | 0.19 | 0.08 | 0.08 | 0.018 | Rem. |

| Tensile Strength

(MPa) | Micro-Hardness (HB-500) | Modulus of Elasticity

(GPa) | Density (gm/cm3) | Poisson’s Ratio |

|---|---|---|---|---|

| 115 | 30 | 70–80 | 2.7 | 0.33 |

| Substance | Tensile Strength

(MPa) | Micro-Hardness

(MPa) | Poisson’s Ratio | Modulus of Elasticity

(GPa) | Melting Point (°C) | Density (g/m3) |

|---|---|---|---|---|---|---|

| B4C | 261–569 | 3810 | 0.18–0.21 | 362–472 | 2350 | 2.5 |

| TiC | 258 | 3200 | 0.18–0.19 | 448–451 | 3160 | 4.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, L.K.; Jiaad, S.M.; Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method. Appl. Sci. 2023, 13, 12939. https://doi.org/10.3390/app132312939

Hasan LK, Jiaad SM, Salman KD, Al-Maliki WAK, Alobaid F, Epple B. Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method. Applied Sciences. 2023; 13(23):12939. https://doi.org/10.3390/app132312939

Chicago/Turabian StyleHasan, Lamyaa Khaleel, Suaad Makki Jiaad, Khansaa Dawood Salman, Wisam Abed Kattea Al-Maliki, Falah Alobaid, and Bernd Epple. 2023. "Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method" Applied Sciences 13, no. 23: 12939. https://doi.org/10.3390/app132312939

APA StyleHasan, L. K., Jiaad, S. M., Salman, K. D., Al-Maliki, W. A. K., Alobaid, F., & Epple, B. (2023). Wear Characteristics of (Al/B4C and Al/TiC) Nanocomposites Synthesized via Powder Metallurgy Method. Applied Sciences, 13(23), 12939. https://doi.org/10.3390/app132312939