Environmentally Friendly Smart Construction—Review of Recent Developments and Opportunities

Abstract

1. Introduction

2. Modern Challenges of Construction

- -

- -

- -

- -

- Building sustainability—enhanced resilience and improved structural longevity [9];

- -

3. Current Strategies

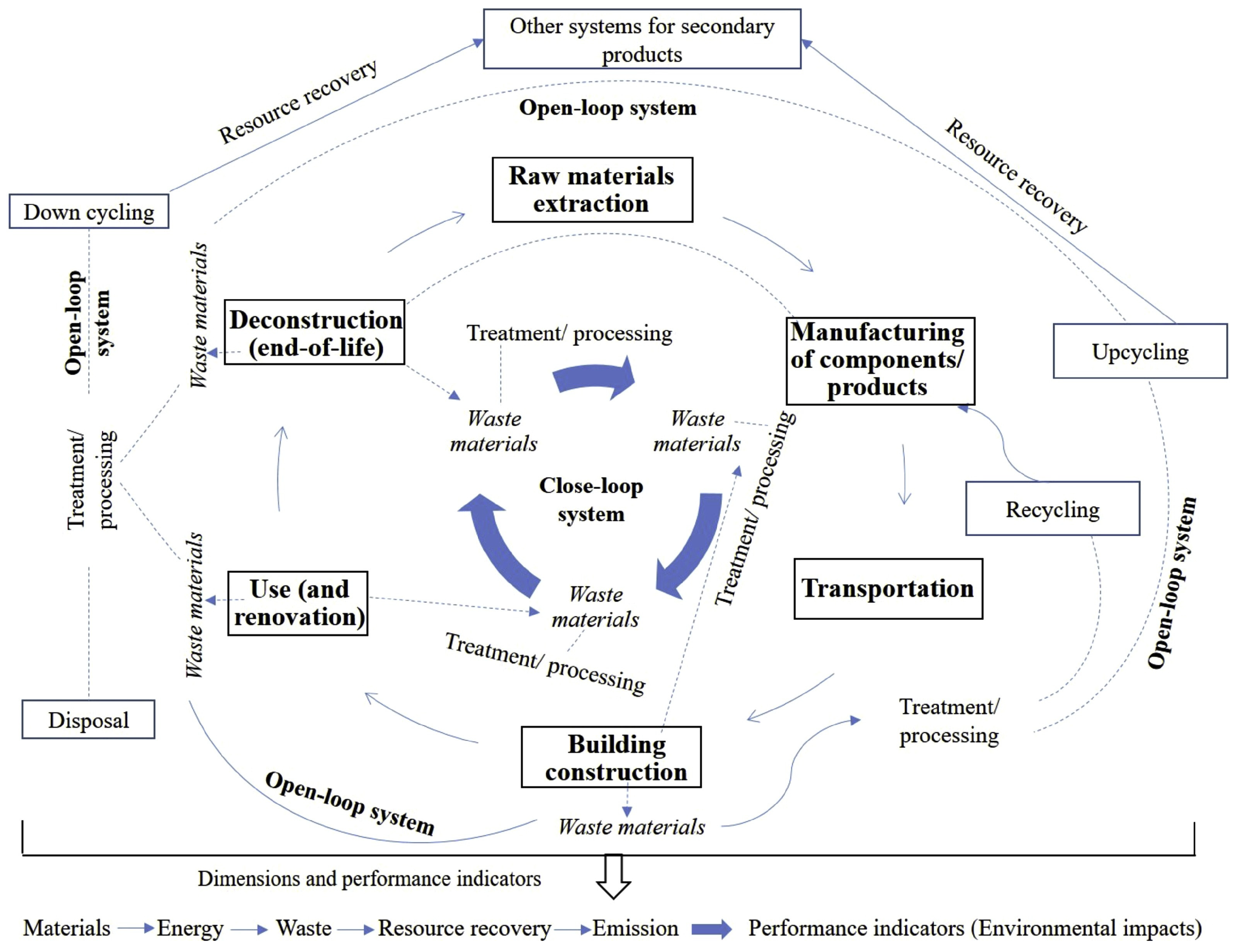

3.1. Targeting the Environmental Impacts

3.1.1. Assessment of the Environmental Impacts

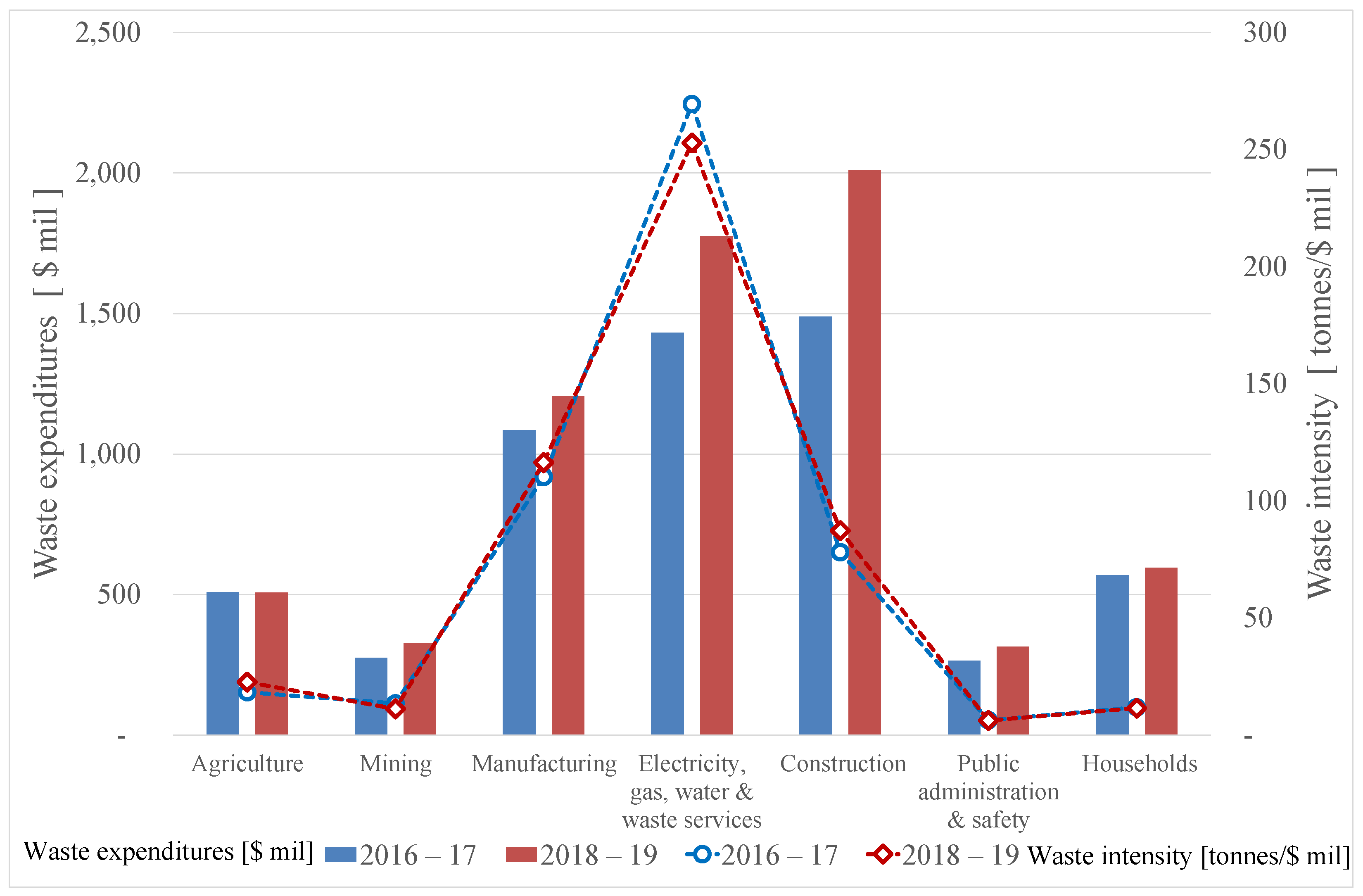

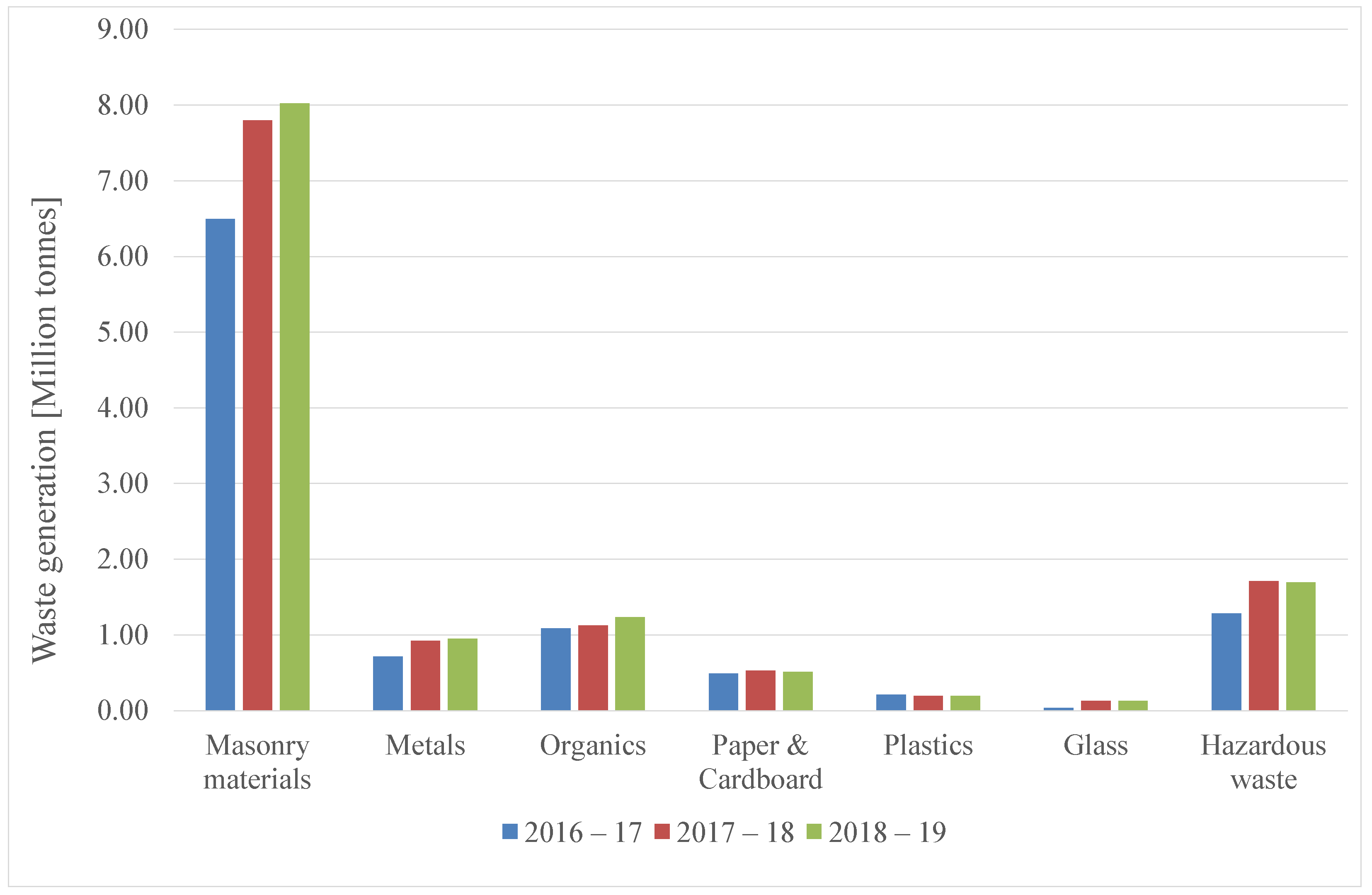

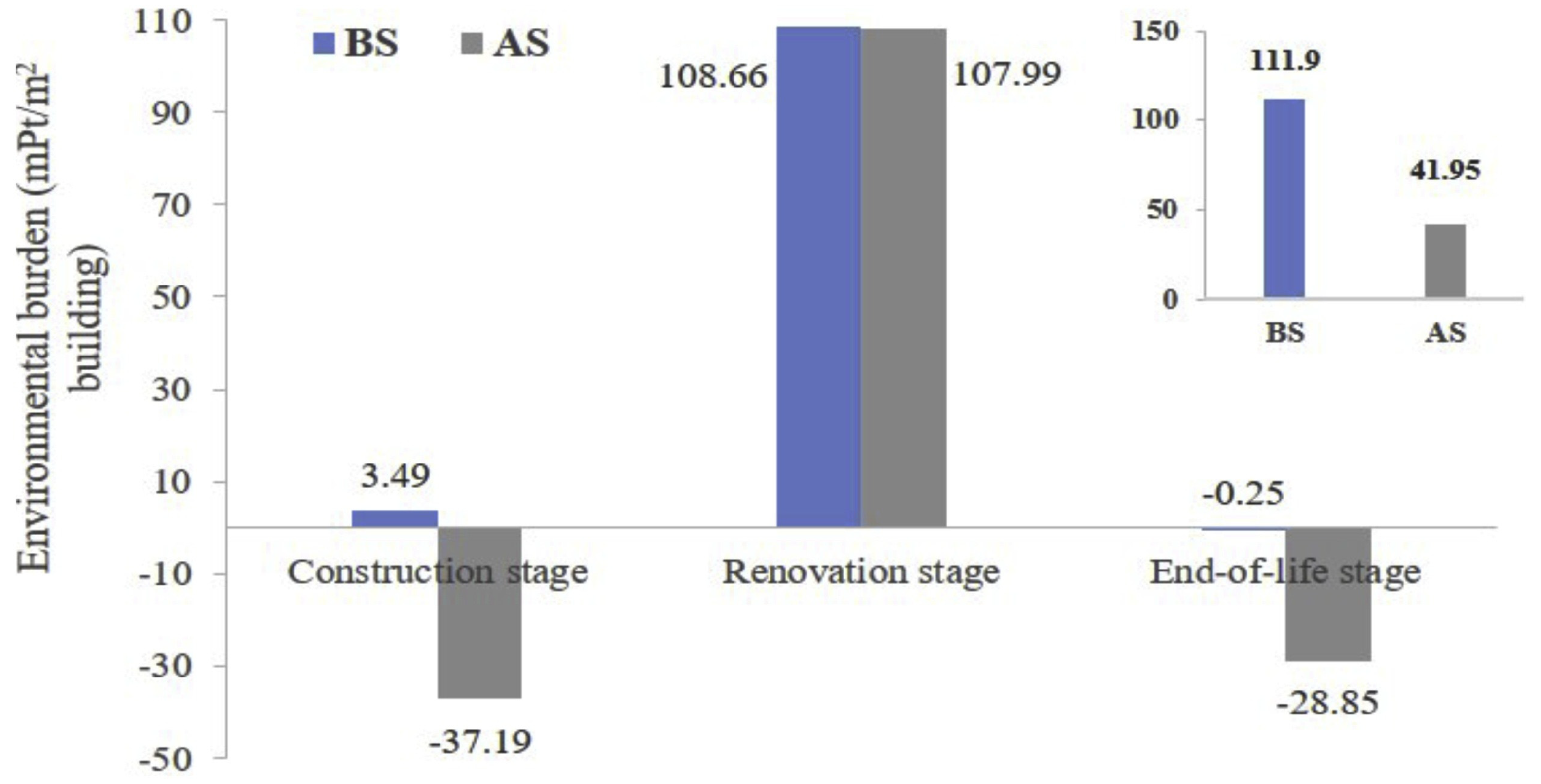

3.1.2. What Are the Greatest Environmental Impacts?

3.1.3. Strategies for Reduction in the Environmental Impacts

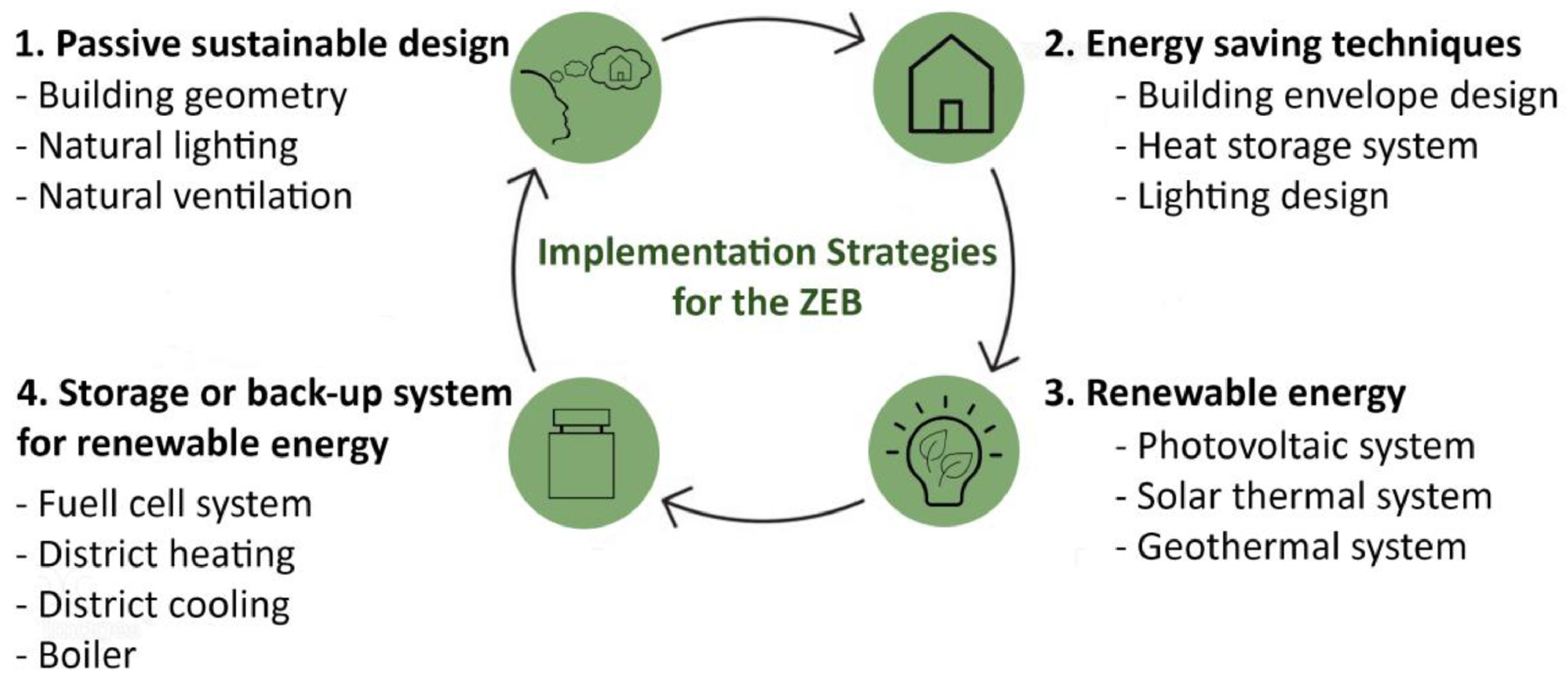

3.2. Improving Energy Efficiency

3.2.1. Energy Consumption at Various Life Cycle Stages and Its Assessment

3.2.2. Existing Approaches for Energy Saving

Building Envelopes

Adaptive Building Insulation

Architectural and Design Solutions

Nature-Based Solutions for Energy Saving

- -

- Green façades demonstrated capacity to reduce the temperature of externals walls by 3.5 °C on average during hot periods and increase the temperature by an average of 2.8 °C during cold periods [99];

- -

- Green façades exhibited ability to reduce an annual HVAC energy use by up to 20% [99];

- -

- Green façades demonstrated stable thermal performance in extreme weather conditions [100];

- -

- Green façades showed better cooling performance on a building façade subjected to the solar radiation at the highest and steepest angles [100].

Energy Retrofit

3.3. Enhancing Resilience

Design Strategies for Resilience

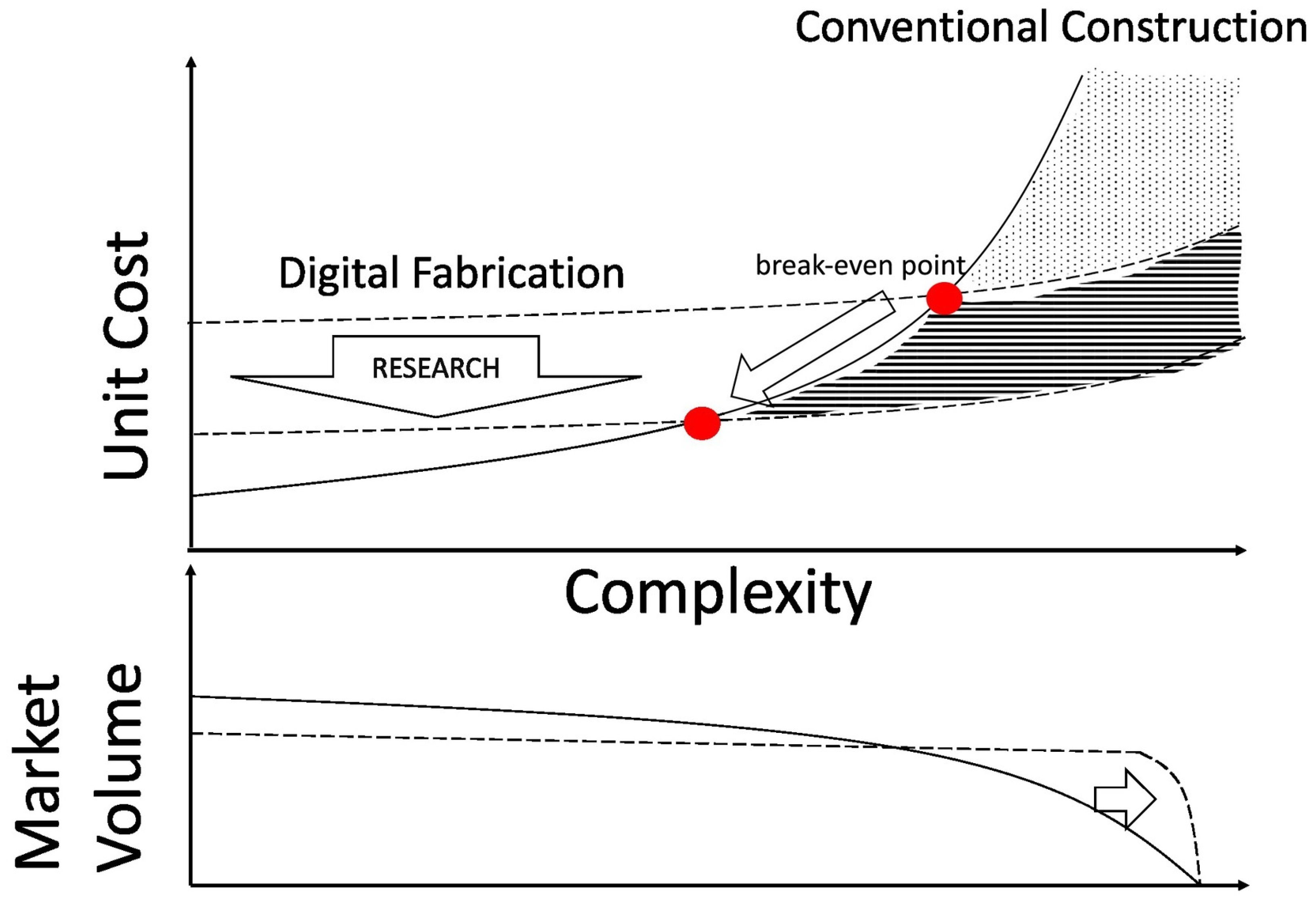

4. Novel Approaches

- -

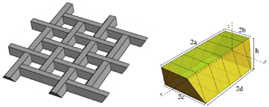

- Digital fabrication or 3D concrete printing—Fully automated process that allows more flexible material selection, flexibility in the achieved geometrical shapes, a higher degree of customisation and optimal design for energy efficiency.

- -

- Off-site prefabrications—Modular construction methods that allow a high level of automation and construction quality. In addition, eliminating the formworks from the construction site will also increase the safety levels.

- -

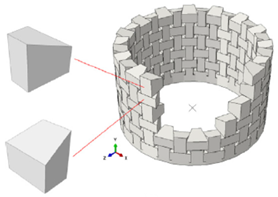

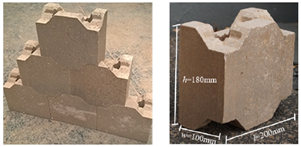

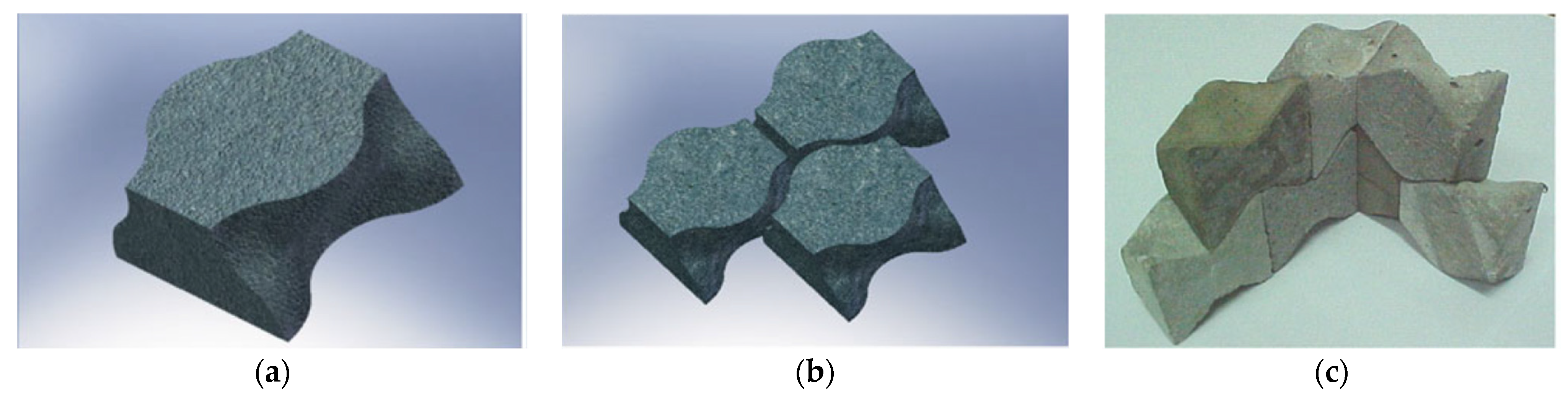

- Mortarless construction—The construction methods based on the principles of interlocking that allow for an increase in structural resilience, erecting demountable structures and hence achieving the reuse of the construction elements and the automation levels and construction quality.

- -

- Application of novel materials—Hybrid and recycled materials and structures that allow for the recovery of the embodied building energy, reduction in the environmental impacts and improving the thermal and acoustic insulation.

4.1. Three-Dimensional Concrete Printing

4.2. Modular Construction

4.3. Mortarless Construction

| Type of Connection | Block/Connection Shape | Materials and Manufacturing |

|---|---|---|

| Lego-type | ||

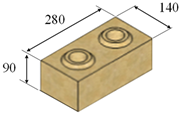

| Mortise and tenon |  | HiLoTec—compressed earth block [190,206,207] |

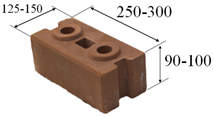

| Mortise and tenon |  | Rhino block [208], Arca Classic Clay block [209], recycled PET [210], rubberized concrete blocks [194] |

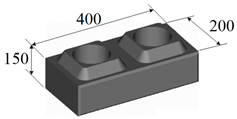

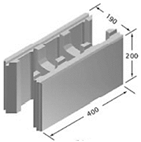

| Mortise and tenon |  | Hollow Concrete Interlocking block [211] |

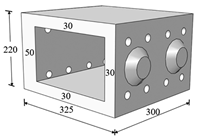

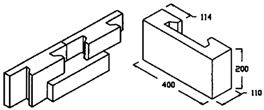

| Mortise and tenon |  | Lego–inspired assemblies [176,212] |

| Key and connectors | ||

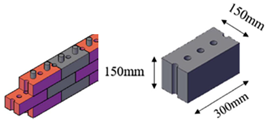

| Shear keys |  | Coconut fibre reinforced concrete blocks [197,213,214] |

| Shear keys |  | Putra Block Concrete [191,215] |

| Tongue and groove |  | Hydraform block: fly ash and cement concrete [184] |

| Tongue and groove |  | Azar concrete hollow block [189,193,195,216] |

| Shear key and Tongue and groove |  | Versaloc concrete block [189] |

| Dovetail joints |  | SILBLOCK: concrete [217] |

| Grouting and rebars |  | ICEB–SJTU blocks [178] |

| Grouting and rebars |  | Fly Ash–Lime–Slag block [179] |

| Topological interlocking (TI) | ||

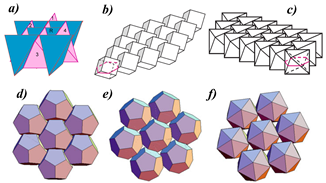

| Planar interfaces |  | Regular assembly of tetrahedra [181,183,218,219,220,221,222,223,224,225,226] |

| Planar interfaces |  | Regular assembly of truncated tetrahedra [227,228] |

| Planar interfaces |  | Assemblies of interlocking cubes [229,230,231] |

| Planar interfaces |  | Regular assemblies of platonic solids: (a) interlocking of tetrahedra, (b) assembly of cubes, (c) assembly of octahedra, (d) interlocking of dodecahedra in the plane normal to 3rd order symmetry axes, (e) interlocking of dodecahedra in the plane normal to 5th order symmetry axes, (f) assembly of interlocked icosahedra [180,224,225,229,230,232,233] |

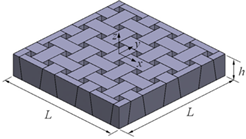

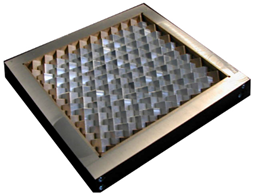

| Planar interfaces |  | Design patterns for TI floors [234] |

| Planar interfaces |  | Stone flats assembled of blocks with isosceles trapezium cross sections in both directions [235,236] |

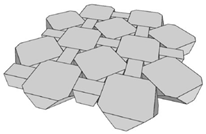

| Planar interfaces |  | Non-planar assemblies of truncated tetrahedra [182] |

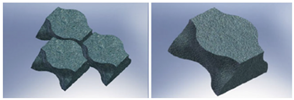

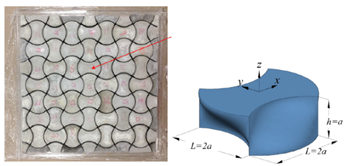

| Non-planar interfaces |  | Osteomorphic blocks [180,181,201] |

| Non-planar interfaces |  | Tetraloc concrete and rammed earth blocks [180,199,202,203,237,238] |

| Non-planar interfaces |  | Osteomorphic blocks with two interlocking directions [239,240] |

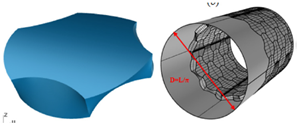

| Non-planar interfaces |  | Non-planar topologically interlocking blocks for tubular structures [241] |

| Partial interlocking | ||

| Semi-interlocked |  | Semi-interlock concrete blocks [184,242,243,244] |

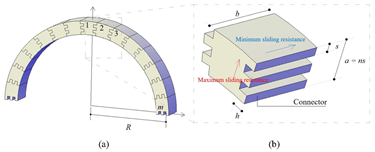

| One-dimensional interlocking structures |  | Semi-circular masonry arches assembled of concrete interlocking blocks [185] |

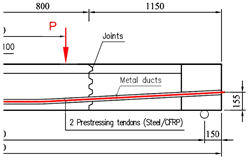

| One-dimensional interlocking structures |  | Precast segmented post-tensioned beams [186,192,245,246] |

| One-dimensional interlocking structures |  | Prestressed segmented columns with 2 types of interlocking elements [187,188] |

4.4. Use of Recycling Materials in Construction

4.4.1. Rubberised Concrete

- The lower thermal conductivity is important for the energy saving in buildings.

- The lower density is advantageous for the weight reduction in high-rise buildings.

- The recycled rubber can be naturally used in asphalt mixes as powder or large particulars (chips).

- Road pavements can benefit from the additional elasticity, which can improve the skid resistance.

- Enhanced impact resistance presents potential for the protective roadside barriers.

4.4.2. Geopolymer Concrete (GPC)

4.4.3. Recycled Aggregate Concretes

4.5. Resilient Structures Based on Topological Interlocking

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| MFA | Material Flow Analysis |

| GHG | Greenhouse Gas |

| EC | Embodied Carbon |

| CE | Circular Economy |

| IO | Input–Output |

| HVAC | Heating, Ventilation and Air Conditioning |

| PCM | Phase-Change Materials |

| 3DCP | Three-Dimensional Concrete Printing |

| ECC | Engineered Cementitious Composite |

| TI | Topological Interlocking |

| CDW | Construction and Demolition Waste |

| RuC | Rubberised Concrete |

| GPC | Geopolymer Concrete |

| OPCC | Ordinary Portland Cement Concrete |

| UHSC | Ultra-High Strength Concrete |

| UHPC | Ultra-High Performance Concrete |

| RAC | Recycled Aggregate Concrete |

| RCA | Recycled Coarse Aggregate |

| RFA | Recycled Fine Aggregate |

| ITZ | Interfacial Transition Zone |

| UCS | Uniaxial Compressive Strength |

| UTS | Uniaxial Tensile Strength |

References

- Hampson, K.; Bfandon, P. Construction 2020—A Vision for Australia’s Property and Construction Industry; CRC Construction Innovation: Brisbane, Australia, 2004. [Google Scholar]

- Chen, L.; Chan, A.P.C.; Owusu, E.K.; Darko, A.; Gao, X. Critical success factors for green building promotion: A systematic review and meta-analysis. Build. Environ. 2022, 207, 108452. [Google Scholar] [CrossRef]

- Chen, S.; Teng, Y.; Zhang, Y.; Leung, C.K.Y.; Pan, W. Reducing embodied carbon in concrete materials: A state-of-the-art review. Resour. Conserv. Recycl. 2023, 188, 106653. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Satola, D.; Wiberg, A.H.; Singh, M.; Babu, S.; James, B.; Dixit, M.; Sharston, R.; Grynberg, Y.; Gustavsen, A. Comparative review of international approaches to net-zero buildings: Knowledge-sharing initiative to develop design strategies for greenhouse gas emissions reduction. Energy Sustain. Dev. 2022, 71, 291–306. [Google Scholar] [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent advancements of robotics in construction. Autom. Constr. 2022, 144, 104591. [Google Scholar] [CrossRef]

- Xu, M.; Nie, X.; Li, H.; Cheng, J.C.P.; Mei, Z. Smart construction sites: A promising approach to improving on-site HSE management performance. J. Build. Eng. 2022, 49, 104007. [Google Scholar] [CrossRef]

- Zielinski Nguyen Ajslev, J.; Elisabeth Ejstrup Nimb, I. Virtual design and construction for occupational safety and health purposes—A review on current gaps and directions for research and practice. Saf. Sci. 2022, 155, 105876. [Google Scholar] [CrossRef]

- Menna, C.; Felicioni, L.; Negro, P.; Lupíšek, A.; Romano, E.; Prota, A.; Hájek, P. Review of methods for the combined assessment of seismic resilience and energy efficiency towards sustainable retrofitting of existing European buildings. Sustain. Cities Soc. 2022, 77, 103556. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Trewin, D. Construction and the environment. In Year Book Australia; Australian Bureau of Statistics: Canberra, Australia, 2003; Volume 85, p. 640. [Google Scholar]

- Australian Bureau of Statistics (ABS). Production of Selected Construction Material; Australian Bureau of Statistics: Canberra, Australia, 2014.

- Australian Bureau of Statistics (ABS). Engineering Construction Activity, Australia; Australian Bureau of Statistics: Canberra, Australia, 2022.

- Macedo, K.R.M.; Cestari, S.P.; Mendes, L.C.; Albitres, G.A.V.; Rodrigues, D.C. Sustainable hybrid composites of recycled polypropylene and construction debris. J. Compos. Mater. 2018, 52, 2949–2959. [Google Scholar] [CrossRef]

- Australian Bureau of Statistics (ABS). Waste Account, Australia, Experimental Estimates 2018–2019; Australian Bureau of Statistics: Canberra, Australia, 2020.

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Struhala, K.; Ostrý, M. Life-Cycle Assessment of phase-change materials in buildings: A review. J. Clean. Prod. 2022, 336, 130359. [Google Scholar] [CrossRef]

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905. [Google Scholar] [CrossRef]

- Andersen, S.C.; Birgisdottir, H.; Birkved, M. Life Cycle Assessments of Circular Economy in the Built Environment—A Scoping Review. Sustainability 2022, 14, 6887. [Google Scholar] [CrossRef]

- Cheng, B.; Lu, K.; Li, J.; Chen, H.; Luo, X.; Shafique, M. Comprehensive assessment of embodied environmental impacts of buildings using normalized environmental impact factors. J. Clean. Prod. 2022, 334, 130083. [Google Scholar] [CrossRef]

- Zuo, J.; Pullen, S.; Rameezdeen, R.; Bennetts, H.; Wang, Y.; Mao, G.; Zhou, Z.; Du, H.; Duan, H. Green building evaluation from a life-cycle perspective in Australia: A critical review. Renew. Sustain. Energy Rev. 2017, 70, 358–368. [Google Scholar] [CrossRef]

- Kaufman, S.M. 3—Quantifying sustainability: Industrial ecology, materials flow and life cycle analysis. In Metropolitan Sustainability; Zeman, F., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 40–54. [Google Scholar] [CrossRef]

- Augiseau, V.; Barles, S. Studying construction materials flows and stock: A review. Resour. Conserv. Recycl. 2017, 123, 153–164. [Google Scholar] [CrossRef]

- Göswein, V.; Silvestre, J.D.; Habert, G.; Freire, F. Dynamic Assessment of Construction Materials in Urban Building Stocks: A Critical Review. Environ. Sci. Technol. 2019, 53, 9992–10006. [Google Scholar] [CrossRef]

- Lausselet, C.; Urrego, J.P.F.; Resch, E.; Brattebø, H. Temporal analysis of the material flows and embodied greenhouse gas emissions of a neighborhood building stock. J. Ind. Ecol. 2020, 25, 419–434. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-analysis of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- Roh, S.; Tae, S. An integrated assessment system for managing life cycle CO2 emissions of a building. Renew. Sustain. Energy Rev. 2017, 73, 265–275. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23. [Google Scholar] [CrossRef]

- Heeren, N.; Hellweg, S. Tracking Construction Material over Space and Time: Prospective and Geo-referenced Modeling of Building Stocks and Construction Material Flows. J. Ind. Ecol. 2019, 23, 253–267. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 2019, 14, 043004. [Google Scholar] [CrossRef]

- de Oliveira Fernandes, M.A.; Keijzer, E.; van Leeuwen, S.; Kuindersma, P.; Melo, L.; Hinkema, M.; Gonçalves Gutierrez, K. Material-versus energy-related impacts: Analysing environmental trade-offs in building retrofit scenarios in The Netherlands. Energy Build. 2021, 231, 110650. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Inés Fernández, A. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A framework for sustainable and circular system design: Development and application on thermal insulation materials. Resour. Conserv. Recycl. 2020, 154, 104631. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, R. Reducing building embodied emissions in the design phase: A comparative study on structural alternatives. J. Clean. Prod. 2020, 243, 118656. [Google Scholar] [CrossRef]

- Robati, M.; Oldfield, P.; Nezhad, A.A.; Carmichael, D.G.; Kuru, A. Carbon value engineering: A framework for integrating embodied carbon and cost reduction strategies in building design. Build. Environ. 2021, 192, 107620. [Google Scholar] [CrossRef]

- Pan, W.; Teng, Y. A systematic investigation into the methodological variables of embodied carbon assessment of buildings. Renew. Sustain. Energy Rev. 2021, 141, 110840. [Google Scholar] [CrossRef]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular Economy of Construction and Demolition Waste: A Literature Review on Lessons, Challenges, and Benefits. Materials 2021, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Xi, B.; Li, J.; Liu, L.; Song, G. Utilization of CO2 into recycled construction materials: A systematic literature review. J. Mater. Cycles Waste Manag. 2022, 24, 2108–2125. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 18, 93–113. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current state and barriers to the circular economy in the building sector: Towards a mitigation framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Nodehi, M.; Taghvaee, V.M. Applying Circular Economy to Construction Industry through Use of Waste Materials: A Review of Supplementary Cementitious Materials, Plastics, and Ceramics. Circ. Econ. Sustain. 2022, 2, 987–1020. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Eberhardt, L.C.M.; Birgisdóttir, H.; Birkved, M. Life cycle assessment of a Danish office building designed for disassembly. Build. Res. Inf. 2018, 47, 666–680. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Caldera, S.; Ryley, T. Transformation towards a circular economy in the Australian construction and demolition waste management system. Sustain. Prod. Consum. 2022, 30, 89–106. [Google Scholar] [CrossRef]

- Gunawardena, T.; Mendis, P. Prefabricated Building Systems—Design and Construction. Encyclopedia 2022, 2, 70–95. [Google Scholar] [CrossRef]

- Nguyen, T.D.H.N.; Moon, H.; Ahn, Y. Critical Review of Trends in Modular Integrated Construction Research with a Focus on Sustainability. Sustainability 2022, 14, 12282. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S. A Comprehensive Review on Fly Ash-Based Geopolymer. J. Compos. Sci. 2022, 6, 219. [Google Scholar] [CrossRef]

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Yang, J.; Ling, T.-C. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resour. Conserv. Recycl. 2021, 164, 105103. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Cobirzan, N.; Muntean, R.; Thalmaier, G.; Felseghi, R.A. Recycling of Mining Waste in the Production of Masonry Units. Materials 2022, 15, 594. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, X.; Wang, J.; Zhang, T. Workability and Durability of Concrete Incorporating Waste Tire Rubber: A Review. J. Renew. Mater. 2023, 11, 745–776. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Althoey, F.; Zaid, O.; Sor, N.H. Rubberized geopolymer composites: A comprehensive review. Ceram. Int. 2022, 48, 24234–24259. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Xiao, J.; Youssf, O. Dynamic performance of rubberised concrete and its structural applications—An overview. Eng. Struct. 2021, 234, 111990. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Khan, A.M.; Hao, H.; Elchalakani, M.; Tran, T.M. Dynamic compressive properties of lightweight rubberized concrete. Constr. Build. Mater. 2020, 238, 117705. [Google Scholar] [CrossRef]

- Dong, M.; Elchalakani, M.; Karrech, A.; Fawzia, S.; Mohamed Ali, M.S.; Yang, B.; Xu, S.-Q. Circular steel tubes filled with rubberised concrete under combined loading. J. Constr. Steel Res. 2019, 162, 105613. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using bibliometric analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Ilori, O.M. Changing significance of embodied energy: A comparative study of material specifications and building energy sources. J. Build. Eng. 2019, 23, 324–333. [Google Scholar] [CrossRef]

- Crawford, R.H. Validation of a hybrid life-cycle inventory analysis method. J. Environ. Manag. 2008, 88, 496–506. [Google Scholar] [CrossRef]

- Crawford, R.H.; Bontinck, P.-A.; Stephan, A.; Wiedmann, T.; Yu, M. Hybrid life cycle inventory methods—A review. J. Clean. Prod. 2018, 172, 1273–1288. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Basarir, H.; Doherty, J.; Elchalakani, M.; Joldes, G.R.; Karrech, A.; Lehane, B.; Miller, K.; Pasternak, E.; Shufrin, I.; et al. Computational monitoring in real time: Review of methods and applications. Geomech. Geophys. Geo-Energy Geo-Resour. 2018, 4, 235–271. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Chàfer, M. Technological options and strategies towards zero energy buildings contributing to climate change mitigation: A systematic review. Energy Build. 2020, 219, 110009. [Google Scholar] [CrossRef]

- Belussi, L.; Barozzi, B.; Bellazzi, A.; Danza, L.; Devitofrancesco, A.; Fanciulli, C.; Ghellere, M.; Guazzi, G.; Meroni, I.; Salamone, F.; et al. A review of performance of zero energy buildings and energy efficiency solutions. J. Build. Eng. 2019, 25, 100772. [Google Scholar] [CrossRef]

- Fu, S.C.; Zhong, X.L.; Zhang, Y.; Lai, T.W.; Chan, K.C.; Lee, K.Y.; Chao, C.Y.H. Bio-inspired cooling technologies and the applications in buildings. Energy Build. 2020, 225, 110313. [Google Scholar] [CrossRef]

- Omrany, H.; Chang, R.; Soebarto, V.; Zhang, Y.; Ghaffarianhoseini, A.; Zuo, J. A bibliometric review of net zero energy building research 1995–2022. Energy Build. 2022, 262, 111996. [Google Scholar] [CrossRef]

- Moran, P.; Goggins, J.; Hajdukiewicz, M. Super-insulate or use renewable technology? Life cycle cost, energy and global warming potential analysis of nearly zero energy buildings (NZEB) in a temperate oceanic climate. Energy Build. 2017, 139, 590–607. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Ambli, K.G.; Dodamani, B.M.; Jagadeesh, A.; Vanarotti, M.B. Heterogeneous composites for low and medium temperature thermal insulation: A review. Energy Build. 2019, 199, 455–460. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Fawaier, M.; Bokor, B. Dynamic insulation systems of building envelopes: A review. Energy Build. 2022, 270, 112268. [Google Scholar] [CrossRef]

- Cui, H.; Overend, M. A review of heat transfer characteristics of switchable insulation technologies for thermally adaptive building envelopes. Energy Build. 2019, 199, 427–444. [Google Scholar] [CrossRef]

- Rupp, S.; Krarti, M. Analysis of multi-step control strategies for dynamic insulation systems. Energy Build. 2019, 204, 109459. [Google Scholar] [CrossRef]

- van Roosmalen, M.; Herrmann, A.; Kumar, A. A review of prefabricated self-sufficient facades with integrated decentralised HVAC and renewable energy generation and storage. Energy Build. 2021, 248, 111107. [Google Scholar] [CrossRef]

- Karanafti, A.; Theodosiou, T.; Tsikaloudaki, K. Assessment of buildings’ dynamic thermal insulation technologies-A review. Appl. Energy 2022, 326, 119985. [Google Scholar] [CrossRef]

- Navarro, L.; de Garcia, A.; Solé, C.; Castell, A.; Cabeza, L.F. Thermal loads inside buildings with phase change materials: Experimental results. Energy Procedia 2012, 30, 342–349. [Google Scholar] [CrossRef]

- Abden, M.J.; Tao, Z.; Alim, M.A.; Pan, Z.; George, L.; Wuhrer, R. Combined use of phase change material and thermal insulation to improve energy efficiency of residential buildings. J. Energy Storage 2022, 56, 105880. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2020, 33, 101913. [Google Scholar] [CrossRef]

- Lamrani, B.; Johannes, K.; Kuznik, F. Phase change materials integrated into building walls: An updated review. Renew. Sustain. Energy Rev. 2021, 140, 110751. [Google Scholar] [CrossRef]

- Bekler, C.; Ayçam, İ.; Gökşen, F. Evaluation of Climate Adaptive Building Skins in the Last Decade. Period. Polytech. Archit. 2022, 53, 82–94. [Google Scholar] [CrossRef]

- Loonen, R.C.G.M.; Trčka, M.; Cóstola, D.; Hensen, J.L.M. Climate adaptive building shells: State-of-the-art and future challenges. Renew. Sustain. Energy Rev. 2013, 25, 483–493. [Google Scholar] [CrossRef]

- Bajcinovci, B.; Jerliu, F. Achieving Energy Efficiency in Accordance with Bioclimatic Architecture Principles. Environ. Clim. Technol. 2016, 18, 54–63. [Google Scholar] [CrossRef][Green Version]

- Nguyen, A.T.; Reiter, S. Bioclimatism in architecture: An evolutionary perspective. Int. J. Des. Nat. Ecodyn. 2017, 12, 16–29. [Google Scholar] [CrossRef]

- Bugenings, L.A.; Kamari, A. Bioclimatic Architecture Strategies in Denmark: A Review of Current and Future Directions. Buildings 2022, 12, 224. [Google Scholar] [CrossRef]

- Zilberberg, E.; Trapper, P.; Meir, I.A.; Isaac, S. The impact of thermal mass and insulation of building structure on energy efficiency. Energy Build. 2021, 241, 110954. [Google Scholar] [CrossRef]

- Saroglou, T.; Meir, I.A.; Theodosiou, T.; Givoni, B. Towards energy efficient skyscrapers. Energy Build. 2017, 149, 437–449. [Google Scholar] [CrossRef]

- Saroglou, T.; Theodosiou, T.; Givoni, B.; Meir, I.A. A study of different envelope scenarios towards low carbon high-rise buildings in the Mediterranean climate—Can DSF be part of the solution? Renew. Sustain. Energy Rev. 2019, 113, 109237. [Google Scholar] [CrossRef]

- Pérez, G.; Rincón, L.; Vila, A.; González, J.M.; Cabeza, L.F. Green vertical systems for buildings as passive systems for energy savings. Appl. Energy 2011, 88, 4854–4859. [Google Scholar] [CrossRef]

- Al-Kodmany, K. Greenery-Covered Tall Buildings: A Review. Buildings 2023, 13, 2362. [Google Scholar] [CrossRef]

- Koch, K.; Ysebaert, T.; Denys, S.; Samson, R. Urban heat stress mitigation potential of green walls: A review. Urban For. Urban Green. 2020, 55, 126843. [Google Scholar] [CrossRef]

- Pérez, G.; Coma, J.; Martorell, I.; Cabeza, L.F. Vertical Greenery Systems (VGS) for energy saving in buildings: A review. Renew. Sustain. Energy Rev. 2014, 39, 139–165. [Google Scholar] [CrossRef]

- Bakhshoodeh, R.; Ocampo, C.; Oldham, C. Thermal performance of green façades: Review and analysis of published data. Renew. Sustain. Energy Rev. 2022, 155, 111744. [Google Scholar] [CrossRef]

- Seyrek Şık, C.I.; Woźniczka, A.; Widera, B. A Conceptual Framework for the Design of Energy-Efficient Vertical Green Façades. Energies 2022, 15, 8069. [Google Scholar] [CrossRef]

- Nagdeve, S.S.; Manchanda, S.; Dewan, A. Thermal performance of indirect green façade in composite climate of India. Build. Environ. 2023, 230, 109998. [Google Scholar] [CrossRef]

- Mastouri, H.; Bahi, H.; Radoine, H.; Benhamou, B. Improving energy efficiency in buildings: Review and compiling. Mater. Today Proc. 2020, 27, 2999–3003. [Google Scholar] [CrossRef]

- Mourão, J.; Gomes, R.; Matias, L.; Niza, S. Combining embodied and operational energy in buildings refurbishment assessment. Energy Build. 2019, 197, 34–46. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C.; Rabe, B.I.B.; Razon, L.F.; Aviso, K.B.; Tan, R.R. A multi-criterion decision analysis framework for sustainable energy retrofit in buildings. Energy 2022, 239, 122315. [Google Scholar] [CrossRef]

- Bruneau, M.; Reinhorn, A.M. Overview of the resilience concept. In Proceedings of the 8th U.S. National Conference on Earthquake Engineering, San Francisco, CA, USA, 18–22 April 2006; Earthquake Engineering Research Institute: Oakland, CA, USA. [Google Scholar]

- Wang, J.; Zhao, H. High Performance Damage-Resistant Seismic Resistant Structural Systems for Sustainable and Resilient City: A Review. Shock. Vib. 2018, 2018, 8703697. [Google Scholar] [CrossRef]

- Hassler, U.; Kohler, N. Resilience in the built environment. Build. Res. Inf. 2014, 42, 119–129. [Google Scholar] [CrossRef]

- Bruneau, M.; Reinhorn, A.M. Exploring the Concept of Seismic Resilience for Acute Care Facilities. Earthq. Spectra 2007, 23, 41–62. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Nagarajaiah, S.; Kunnath, S.K. (Eds.) Computational Methods, Seismic Protection, Hybrid Testing and Resilience in Earthquake Engineering. A Tribute to the Research Contributions of Prof. Andrei Reinhorn; Springler: Cham, Switzerland; Berlin/Heidelberg, Germany, 2015; Volume 33. [Google Scholar]

- De Domenico, D.; Ricciardi, G. Earthquake Protection of Existing Structures with Limited Seismic Joint: Base Isolation with Supplemental Damping versus Rotational Inertia. Adv. Civ. Eng. 2018, 2018, 6019495. [Google Scholar] [CrossRef]

- Nuzzo, I.; Losanno, D.; Caterino, N.; Serino, G.; Bozzo Rotondo, L.M. Experimental and analytical characterization of steel shear links for seismic energy dissipation. Eng. Struct. 2018, 172, 405–418. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the presss five-story precast concrete test building. PCI J. 1999, 44, 42–67. [Google Scholar] [CrossRef]

- Soong, T.T.; Spencer, B.F., Jr. Supplemental energy dissipation: State-of-the-art and state-of-the-practice. Eng. Struct. 2002, 24, 243–259. [Google Scholar] [CrossRef]

- Rodgers, G.W.; Mander, J.B.; Chase, J.G.; Dhakal, R.P. Beyond Ductility: Parametric Testing of a Jointed Rocking Beam-Column Connection Designed for Damage Avoidance. J. Struct. Eng. 2016, 142, C4015006. [Google Scholar] [CrossRef]

- Nuzzo, I.; Losanno, D.; Cilento, F.; Caterino, N. Analytical and numerical modelling of shear-link device for seismic energy dissipation in frame structures. Eng. Struct. 2020, 214, 110630. [Google Scholar] [CrossRef]

- Ji, X.; Wang, Y.; Ma, Q.; Okazaki, T. Cyclic Behavior of Replaceable Steel Coupling Beams. J. Struct. Eng. 2017, 143, 04016169. [Google Scholar] [CrossRef]

- Garlock Maria, M.; Sause, R.; Ricles James, M. Behavior and Design of Posttensioned Steel Frame Systems. J. Struct. Eng. 2007, 133, 389–399. [Google Scholar] [CrossRef]

- Eatherton, M.R.; Hajjar, J.F. Hybrid simulation testing of a self-centering rocking steel braced frame system. Earthq. Eng. Struct. Dyn. 2014, 43, 1725–1742. [Google Scholar] [CrossRef]

- Kim, H.-J.; Christopoulos, C. Seismic design procedure and seismic response of post-tensioned self-centering steel frames. Earthq. Eng. Struct. Dyn. 2009, 38, 355–376. [Google Scholar] [CrossRef]

- Wang, H.; Marino, E.M.; Pan, P.; Liu, H.; Nie, X. Experimental study of a novel precast prestressed reinforced concrete beam-to-column joint. Eng. Struct. 2018, 156, 68–81. [Google Scholar] [CrossRef]

- Krauthammer, T. Modern Protective Structures; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Draganić, H.; Gazić, G.; Varevac, D. Experimental investigation of design and retrofit methods for blast load mitigation—A state-of-the-art review. Eng. Struct. 2019, 190, 189–209. [Google Scholar] [CrossRef]

- UFC 3-340-02; Structures to Resist the Effects of Accidental Explosions. U.S. Department of Defense: Washington, DC, USA, 2014.

- Elsayed, M.; El-Dakhakhni, W.; Tait, M. Resilience Evaluation of Seismically Detailed Reinforced Concrete-Block Shear Walls for Blast-Risk Assessment. J. Perform. Constr. Facil. 2016, 30, 04015087. [Google Scholar] [CrossRef]

- Li, B.; Pan, T.C.; Nair, A. A case study of the structural responses of a tall building in Singapore subjected to close-in detonations. Struct. Des. Tall Spec. Build. 2011, 20, 223–246. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Russell, R.; Hongkyu, K.; Bukkapatnam, S. Crafting large prototypes. IEEE Robot. Autom. Mag. 2001, 8, 33–42. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Duballet, R.; Baverel, O.; Dirrenberger, J. Classification of building systems for concrete 3D printing. Autom. Constr. 2017, 83, 247–258. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Ali, M.H.; Issayev, G.; Shehab, E.; Sarfraz, S. A critical review of 3D printing and digital manufacturing in construction engineering. Rapid Prototyp. J. 2022, 28, 1312–1324. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Muthukrishnan, S.; Sanjayan, J.; Pasupathy, K. Concrete 3D printing of lightweight elements using hollow-core extrusion of filaments. Cem. Concr. Compos. 2021, 123, 104220. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar] [CrossRef]

- Lloret, E.; Shahab, A.R.; Linus, M.; Flatt, R.J.; Gramazio, F.; Kohler, M.; Langenberg, S. Complex concrete structures. Comput.-Aided Des. 2015, 60, 40–49. [Google Scholar] [CrossRef]

- Shakor, P.; Chu, S.H.; Puzatova, A.; Dini, E. Review of binder jetting 3D printing in the construction industry. Prog. Addit. Manuf. 2022, 7, 643–669. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nazari, A.; Nematollahi, B. (Eds.) 3D Concrete Printing Technology—Construction and Building Applications; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Pasco, J.; Lei, Z.; Aranas, C., Jr. Additive Manufacturing in Off-Site Construction: Review and Future Directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef]

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Li, W.; Lin, X.; Bao, D.W.; Min Xie, Y. A review of formwork systems for modern concrete construction. Structures 2022, 38, 52–63. [Google Scholar] [CrossRef]

- Menna, C.; Mata-Falcón, J.; Bos, F.P.; Vantyghem, G.; Ferrara, L.; Asprone, D.; Salet, T.; Kaufmann, W. Opportunities and challenges for structural engineering of digitally fabricated concrete. Cem. Concr. Res. 2020, 133, 106079. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Hamidi, F.; Aslani, F. Additive manufacturing of cementitious composites: Materials, methods, potentials, and challenges. Constr. Build. Mater. 2019, 218, 582–609. [Google Scholar] [CrossRef]

- Sheeja, T.V.; Jebadurai, S.V.S.; Tensing, D. Additive manufacturing techniques in construction. Res. Eng. Struct. Mater. 2022, 8, 535–551. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Development of alternative cementitious binders for 3D printing applications: A critical review of progress, advantages and challenges. Compos. Part B Eng. 2023, 252, 110492. [Google Scholar] [CrossRef]

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J.; et al. On the emergence of 3D printable Engineered, Strain Hardening Cementitious Composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Panda, B.; Chandra Paul, S.; Jen Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing. Ceram. Int. 2021, 47, 27107–27121. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiang, D.; Sharma, R.; Xie, Y.M.; Singh, A. Enhancement of 3D printed cementitious composite by short fibers: A review. Constr. Build. Mater. 2023, 362, 129763. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Baz, B.; Aouad, G.; Leblond, P.; Al-Mansouri, O.; D’Hondt, M.; Remond, S. Mechanical assessment of concrete—Steel bonding in 3D printed elements. Constr. Build. Mater. 2020, 256, 119457. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schmeier, T. Extrusion-Based Additive Manufacturing with Carbon Reinforced Concrete: Concept and Feasibility Study. Materials 2020, 13, 2568. [Google Scholar] [CrossRef]

- Wang, Y.; Aslani, F.; Dyskin, A.; Pasternak, E. Digital Twin Applications in 3D Concrete Printing. Sustainability 2023, 15, 2124. [Google Scholar] [CrossRef]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef]

- Thai, H.-T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the impact of prefabrication on construction waste reduction: An empirical study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Navaratnam, S. Selecting a Suitable Sustainable Construction Method for Australian High-Rise Building: A Multi-Criteria Analysis. Sustainability 2022, 14, 7435. [Google Scholar] [CrossRef]

- Malaia, K. A Unit of Homemaking: The Prefabricated Panel and Domestic Architecture in the Late Soviet Union. Archit. Hist. 2020, 8, 12. [Google Scholar] [CrossRef]

- Chourasia, A.; Singhal, S.; Manivannan. Prefabricated Volumetric Modular Construction: A Review on Current Systems, Challenges, and Future Prospects. Pract. Period. Struct. Des. Constr. 2023, 28, 03122009. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings—An overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Bhandari, S.; Riggio, M.; Jahedi, S.; Fischer, E.C.; Muszynski, L.; Luo, Z. A review of modular cross laminated timber construction: Implications for temporary housing in seismic areas. J. Build. Eng. 2023, 63, 105485. [Google Scholar] [CrossRef]

- Liew, J.Y.R.; Chua, Y.S.; Dai, Z. Steel concrete composite systems for modular construction of high-rise buildings. Structures 2019, 21, 135–149. [Google Scholar] [CrossRef]

- Deng, E.-F.; Zong, L.; Ding, Y.; Zhang, Z.; Zhang, J.-F.; Shi, F.-W.; Cai, L.-M.; Gao, S.-C. Seismic performance of mid-to-high rise modular steel construction—A critical review. Thin-Walled Struct. 2020, 155, 106924. [Google Scholar] [CrossRef]

- Khan, K.; Chen, Z.; Liu, J.; Javed, K. State-of-the-Art on Technological Developments and Adaptability of Prefabricated Industrial Steel Buildings. Appl. Sci. 2023, 13, 685. [Google Scholar] [CrossRef]

- Shi, F.-W.; Li, Y.-M. Innovative inner sleeve composite bolted connections for modular steel constructions: Experimental and numerical studies. J. Build. Eng. 2023, 64, 105624. [Google Scholar] [CrossRef]

- Dai, X.-M.; Zong, L.; Ding, Y.; Li, Z.-X. Experimental study on seismic behavior of a novel plug-in self-lock joint for modular steel construction. Eng. Struct. 2019, 181, 143–164. [Google Scholar] [CrossRef]

- Nadeem, G.; Safiee, N.A.; Bakar, N.A.; Karim, I.A.; Mohd Nasir, N.A. Experimental and numerical study of self-locking adaptable inter connection for modular steel structures. J. Build. Eng. 2023, 65, 105723. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Simplified structural behaviours of post-tensioned inter-module connection for modular buildings. J. Constr. Steel Res. 2020, 175, 106347. [Google Scholar] [CrossRef]

- Dhanapal, J.; Ghaednia, H.; Das, S.; Velocci, J. Structural performance of state-of-the-art VectorBloc modular connector under axial loads. Eng. Struct. 2019, 183, 496–509. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Y.; Shi, L.; Hou, L.; Zhang, G. Current State of Using Prefabricated Construction in Australia. Buildings 2022, 12, 1355. [Google Scholar] [CrossRef]

- Bao, Y.; Li, V.C. Feasibility study of lego-inspired construction with bendable concrete. Autom. Constr. 2020, 113, 103161. [Google Scholar] [CrossRef]

- Stiros, S.C. Monumental articulated ancient Greek and Roman columns and temples and earthquakes: Archaeological, historical, and engineering approaches. J. Seismol. 2020, 24, 853–881. [Google Scholar] [CrossRef]

- Ma, H.; Ma, Q.; Gaire, P. Development and mechanical evaluation of a new interlocking earth masonry block. Adv. Struct. Eng. 2019, 23, 234–247. [Google Scholar] [CrossRef]

- Kasiviswanathan, M.; Varatharajapuram Govindarajulu, K. Experimental Study on Mechanical and Durability Properties of Fly Ash-Lime-Slag Block for Dry Stack Masonry Construction. J. Mater. Civ. Eng. 2023, 35, 04022479. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Estrin, Y.; Pasternak, E. Topological Interlocking Materials. In Architectured Materials in Nature and Engineering: Archimats; Estrin, Y., Bréchet, Y., Dunlop, J., Fratzl, P., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 23–49. [Google Scholar]

- Dyskin, A.V.; Pasternak, E.; Estrin, Y. Mortarless structures based on topological interlocking. Front. Struct. Civ. Eng. 2012, 6, 188–197. [Google Scholar] [CrossRef]

- Mahoney, K.; Siegmund, T. Mechanics of tubes composed of interlocking building blocks. Int. J. Eng. Sci. 2022, 174, 103654. [Google Scholar] [CrossRef]

- Weizmann, M.; Amir, O.; Grobman, Y.J. The effect of block geometry on structural behavior of topological interlocking assemblies. Autom. Constr. 2021, 128, 103717. [Google Scholar] [CrossRef]

- Jeba Jeslin, A.; Padmanaban, I. Experimental studies on interlocking block as wall panels. Mater. Today Proc. 2020, 21, 1–6. [Google Scholar] [CrossRef]

- Casapulla, C.; Mousavian, E.; Zarghani, M. A digital tool to design structurally feasible semi-circular masonry arches composed of interlocking blocks. Comput. Struct. 2019, 221, 111–126. [Google Scholar] [CrossRef]

- Le, T.D.; Pham, T.M.; Hao, H.; Hao, Y. Flexural behaviour of precast segmental concrete beams internally prestressed with unbonded CFRP tendons under four-point loading. Eng. Struct. 2018, 168, 371–383. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Li, C. Multi-hazard resistance capacity of precast segmental columns under impact and cyclic loading. Int. J. Prot. Struct. 2018, 9, 24–43. [Google Scholar] [CrossRef]

- Li, J.; Hao, H.; Wu, C. Numerical study of precast segmental column under blast loads. Eng. Struct. 2017, 134, 125–137. [Google Scholar] [CrossRef]

- Dorji, S.; Derakhshan, H.; Thambiratnam, D.P. Experimental investigation of semi-interlocking mortarless masonry-infilled frames. Structures 2022, 43, 1913–1931. [Google Scholar] [CrossRef]

- Lan, G.; Wang, T.; Wang, Y.; Zhang, K. Seismic performance of interlocking compressed-earth block composite walls. Compos. Struct. 2023, 308, 116704. [Google Scholar] [CrossRef]

- Safiee, N.A.; Mohd Nasir, N.A.; Ashour, A.F.; Abu Bakar, N. Behaviour of interlocking mortarless hollow block walls under in-plane loading. Aust. J. Struct. Eng. 2018, 19, 87–95. [Google Scholar] [CrossRef]

- Le, T.D.; Pham, T.M.; Hao, H. Numerical study on the flexural performance of precast segmental concrete beams with unbonded internal steel tendons. Constr. Build. Mater. 2020, 248, 118362. [Google Scholar] [CrossRef]

- Kohail, M.; Elshafie, H.; Rashad, A.; Okail, H. Behavior of post-tensioned dry-stack interlocking masonry shear walls under cyclic in-plane loading. Constr. Build. Mater. 2019, 196, 539–554. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Wahab, M.M.A.; Liew, M.S.; Mugahed Amran, Y.H. Flexural behavior of rubberized concrete interlocking masonry walls under out-of-plane load. Constr. Build. Mater. 2020, 263, 120661. [Google Scholar] [CrossRef]

- Sokairge, H.; Rashad, A.; Elshafie, H. Behavior of post-tensioned dry-stack interlocking masonry walls under out of plane loading. Constr. Build. Mater. 2017, 133, 348–357. [Google Scholar] [CrossRef]

- Odessa, I.; Shufrin, I. Nonlinear mechanics of fragmented beams. Eur. J. Mech.-A/Solids 2022, 93, 104488. [Google Scholar] [CrossRef]

- Ali, M.; Briet, R.; Chouw, N. Dynamic response of mortar-free interlocking structures. Constr. Build. Mater. 2013, 42, 168–189. [Google Scholar] [CrossRef]

- Schapira, Y.; Chernin, L.; Shufrin, I. Blast energy absorption in topological interlocking elastic columns. Mech. Adv. Mater. Struct. 2022, 1–13. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, X.; Hao, H.; Bi, K.; Lin, Y. Response of reinforced mortar-less interlocking brick wall under seismic loading. Bull. Earthq. Eng. 2022, 20, 6129–6165. [Google Scholar] [CrossRef]

- Autruffe, A.; Pelloux, F.; Brugger, C.; Duval, P.; Bréchet, Y.; Fivel, M. Indentation behaviour of interlocked structures made of ice: Influence of the friction coefficient. Adv. Eng. Mater. 2007, 9, 664–666. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Estrin, Y.; Pasternak, E.; Khor, H.C.; Kanel-Belov, A.J. Fracture Resistant Structures Based on Topological Interlocking with Non-planer contacts. Adv. Eng. Mater. 2003, 5, 116–119. [Google Scholar] [CrossRef]

- Shi, T.; Zhang, X.; Hao, H.; Xie, G. Experimental and numerical studies of the shear resistance capacities of interlocking blocks. J. Build. Eng. 2021, 44, 103230. [Google Scholar] [CrossRef]

- Zhang, X.; Biswas, W.K. Development of eco-efficient bricks—A life cycle assessment approach. J. Build. Eng. 2021, 42, 102429. [Google Scholar] [CrossRef]

- Thamboo, J.A.; Zahra, T.; Dhanasekar, R. Development of design methodology for mortarless masonry system: Case study—A resettlement housing colony. J. Build. Eng. 2020, 27, 100973. [Google Scholar] [CrossRef]

- Bosro, M.Z.M.; Samad, A.A.A.; Mohamad, N.; Goh, W.I.; Tambichik, M.A.; Iman, M.A. A review on past and present development on the interlocking loadbearing hollow block (ILHB) system. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012135. [Google Scholar] [CrossRef]

- Sturm, T.; Ramos, L.F.; Lourenço, P.B. Characterization of dry-stack interlocking compressed earth blocks. Mater. Struct. 2014, 48, 3059–3074. [Google Scholar] [CrossRef]

- Silva, R.A.; Soares, E.; Oliveira, D.V.; Miranda, T.; Cristelo, N.M.; Leitão, D. Mechanical characterisation of dry-stack masonry made of CEBs stabilised with alkaline activation. Constr. Build. Mater. 2015, 75, 349–358. [Google Scholar] [CrossRef]

- Castro, I.G.; Laursen, P.T.; Jansen, D.C.; Qu, B. Performance of interlocking compressed earth block infill in confined masonry construction. In Proceedings of the 10th U.S. National Conference on Earthquake Engineering Frontiers of Earthquake Engineering, Anchorage, AK, USA, 21–25 July 2014. [Google Scholar]

- Lee, Y.H.; Shek, P.N.; Mohammad, S. Structural performance of reinforced interlocking blocks column. Constr. Build. Mater. 2017, 142, 469–481. [Google Scholar] [CrossRef]

- Alaloul, W.S.; John, V.O.; Musarat, M.A. Mechanical and Thermal Properties of Interlocking Bricks Utilizing Wasted Polyethylene Terephthalate. Int. J. Concr. Struct. Mater. 2020, 14, 1–11. [Google Scholar] [CrossRef]

- Fay, L.; Cooper, P.; de Morais, H.F. Innovative interlocked soil–cement block for the construction of masonry to eliminate the settling mortar. Constr. Build. Mater. 2014, 52, 391–395. [Google Scholar] [CrossRef]

- Barhemat, R.; Mahjoubi, S.; Li, V.C.; Bao, Y. Lego-inspired reconfigurable modular blocks for automated construction of engineering structures. Autom. Constr. 2022, 139, 104323. [Google Scholar] [CrossRef]

- Tang, Z.; Ali, M.; Chouw, N. Residual compressive and shear strengths of novel coconut-fibre-reinforced- concrete interlocking blocks. Constr. Build. Mater. 2014, 66, 533–540. [Google Scholar] [CrossRef]

- Ali, M.; Gultom, R.J.; Chouw, N. Capacity of innovative interlocking blocks under monotonic loading. Constr. Build. Mater. 2012, 37, 812–821. [Google Scholar] [CrossRef]

- Safiee, N.A.; Jaafar, M.S.; Alwathaf, A.H.; Noorzaei, J.; Abdulkadir, M.R. Structural Behavior of Mortarless Interlocking Load Bearing Hollow Block Wall Panel under Out-of-Plane Loading. Adv. Struct. Eng. 2011, 14, 1185–1196. [Google Scholar] [CrossRef]

- Zahra, T.; Dhanasekar, M. Characterisation and strategies for mitigation of the contact surface unevenness in dry-stack masonry. Constr. Build. Mater. 2018, 169, 612–628. [Google Scholar] [CrossRef]

- Anand, K.B.; Ramamurthy, K. Development and Performance Evaluation of Interlocking-Block Masonry. J. Archit. Eng. 2000, 6, 45–51. [Google Scholar] [CrossRef]

- Feng, Y.; Siegmund, T.; Habtour, E.; Riddick, J. Impact mechanics of topologically interlocked material assemblies. Int. J. Impact Eng. 2015, 75, 140–149. [Google Scholar] [CrossRef]

- Khandelwal, S.; Siegmund, T.; Cipra, R.J.; Bolton, J.S. Transverse loading of cellular topologically interlocked materials. Int. J. Solids Struct. 2012, 49, 2394–2403. [Google Scholar] [CrossRef]

- Khandelwal, S.; Siegmund, T.; Cipra, R.J.; Bolton, J.S. Scaling of the elastic behavior of two-dimensional topologically interlocked materials under transverse loading. J. Appl. Mech. Trans. ASME 2014, 81, 031011. [Google Scholar] [CrossRef]

- Khandelwal, S.; Siegmund, T.; Cipra, R.J.; Bolton, J.S. Adaptive mechanical properties of topologically interlocking material systems. Smart Mater. Struct. 2015, 24, 045037. [Google Scholar] [CrossRef]

- Mather, A.; Cipra, R.; Siegmund, T. Structural integrity during remanufacture of a topologically interlocked material. Int. J. Struct. Integr. 2012, 3, 61–78. [Google Scholar] [CrossRef]

- Siegmund, T.; Barthelat, F.; Cipra, R.; Habtour, E.; Riddick, J. Manufacture and Mechanics of Topologically Interlocked Material Assemblies. Appl. Mech. Rev. 2016, 68, 040803. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Estrin, Y.; Kanel-Belov, A.J.; Pasternak, E. A new concept in design of materials and structures: Assemblies of interlocked tetrahedron-shaped elements. Scr. Mater. 2001, 44, 2689–2694. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Estrin, Y.; Kanel-Belov, A.J.; Pasternak, E. A new principle in design of composite materials: Reinforcement by interlocked elements. Compos. Sci. Technol. 2003, 63, 483–491. [Google Scholar] [CrossRef]

- Weizmann, M.; Amir, O.; Grobman, Y.J. Structural Performance of Semi-regular Topological Interlocking Assemblies. In Proceedings of the SimAUD 2019, Atlanta, GA, USA, 7–9 April 2019; International Society for Modeling & Simulation: Vista, CA, USA; pp. 217–223. [Google Scholar]

- Mirkhalaf, M.; Sunesara, A.; Ashrafi, B.; Barthelat, F. Toughness by segmentation: Fabrication, testing and micromechanics of architectured ceramic panels for impact applications. Int. J. Solids Struct. 2019, 158, 52–65. [Google Scholar] [CrossRef]

- Mirkhalaf, M.; Tanguay, J.; Barthelat, F. Carving 3D architectures within glass: Exploring new strategies to transform the mechanics and performance of materials. Extrem. Mech. Lett. 2016, 7, 104–113. [Google Scholar] [CrossRef]

- Schaare, S.; Dyskin, A.V.; Estrin, Y.; Arndt, S.; Pasternak, E.; Kanel-Belov, A. Point loading of assemblies of interlocked cube-shaped elements. Int. J. Eng. Sci. 2008, 46, 1228–1238. [Google Scholar] [CrossRef]

- Estrin, Y.; Dyskin, A.V.; Pasternak, E.; Schaare, S.; Stanchits, S.; Kanel-Belov, A.J. Negative stiffness of a layer with topologically interlocked elements. Scr. Mater. 2004, 50, 291–294. [Google Scholar] [CrossRef]

- Lecci, F.; Mazzoli, C.; Bartolomei, C.; Gulli, R. Design of Flat Vaults with Topological Interlocking Solids. Nexus Netw. J. 2020, 23, 607–627. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Estrin, Y.; Kanel-Belov, A.J.; Pasternak, E. Toughening by fragmentation-how topology helps. Adv. Eng. Mater. 2001, 3, 885–888. [Google Scholar] [CrossRef]

- Dyskin, A.V.; Estrin, Y.; Kanel-Belov, A.J.; Pasternak, E. Topological interlocking of platonic solids: A way to new materials and structures. Philos. Mag. Lett. 2003, 83, 197–203. [Google Scholar] [CrossRef]

- Weizmann, M.; Amir, O.; Grobman, Y.J. Topological interlocking in architecture: A new design method and computational tool for designing building floors. Int. J. Archit. Comput. 2017, 15, 107–118. [Google Scholar] [CrossRef]

- Brocato, M.; Deleporte, W.; Mondardini, L.; Tanguy, J.E. A proposal for a new type of prefabricated stone wall. Int. J. Space Struct. 2014, 29, 97–112. [Google Scholar] [CrossRef]

- Brocato, M.; Mondardini, L. Parametric analysis of structures from flat vaults to reciprocal grids. Int. J. Solids Struct. 2015, 54, 50–65. [Google Scholar] [CrossRef]

- Tetraloc. Tetraloc. 2023. Available online: https://tetraloc.com/ (accessed on 22 February 2023).

- Shi, T.; Zhang, X.; Hao, H.; Chen, C. Experimental and numerical investigation on the compressive properties of interlocking blocks. Eng. Struct. 2021, 228, 111561. [Google Scholar] [CrossRef]

- Rezaee Javan, A.; Seifi, H.; Lin, X.; Xie, Y.M. Mechanical behaviour of composite structures made of topologically interlocking concrete bricks with soft interfaces. Mater. Des. 2020, 186, 108347. [Google Scholar] [CrossRef]

- Rezaee Javan, A.; Seifi, H.; Xu, S.; Lin, X.; Xie, Y.M. Impact behaviour of plate-like assemblies made of new and existing interlocking bricks: A comparative study. Int. J. Impact Eng. 2018, 116, 79–93. [Google Scholar] [CrossRef]

- Xu, W.; Lin, X.; Xie, Y.M. A novel non-planar interlocking element for tubular structures. Tunn. Undergr. Space Technol. 2020, 103, 103503. [Google Scholar] [CrossRef]

- Lin, K.; Totoev, Y.Z.; Liu, H.; Guo, T. In-plane behaviour of a reinforcement concrete frame with a dry stack masonry panel. Materials 2016, 9, 108. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.A.; Totoev, Y.Z.; Masia, M.J. Experimental Investigation of Frictional Behavior of Mortarless Surface in Semi-Interlocking Masonry under Cyclic Displacement. J. Mater. Civ. Eng. 2020, 32, 04020259. [Google Scholar] [CrossRef]

- Forghani, R.; Totoev, Y.; Kanjanabootra, S.; Davison, A. Experimental Investigation of Water Penetration through Semi-Interlocking Masonry Walls. J. Archit. Eng. 2017, 23, 04016017. [Google Scholar] [CrossRef]

- Jiang, H.; Cao, Q.; Liu, A.; Wang, T.; Qiu, Y. Flexural behavior of precast concrete segmental beams with hybrid tendons and dry joints. Constr. Build. Mater. 2016, 110, 1–7. [Google Scholar] [CrossRef]

- Jiang, H.; Li, Y.; Liu, A.; Ma, Z.J.; Chen, L.; Chen, Y. Shear Behavior of Precast Concrete Segmental Beams with External Tendons. J. Bridge Eng. 2018, 23, 04018049. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Quattrone, M.; Ambros, W.M.; Grigore Cazacliu, B.; Hoffmann Sampaio, C. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef] [PubMed]

- Bao, Z.; Lu, W. A decision-support framework for planning construction waste recycling: A case study of Shenzhen, China. J. Clean. Prod. 2021, 309, 127449. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.Y.; Xue, C. Advanced progress in recycling municipal and construction solid wastes for manufacturing sustainable construction materials. Resour. Conserv. Recycl. X 2020, 6, 100036. [Google Scholar] [CrossRef]

- Ul Islam, M.M.; Li, J.; Roychand, R.; Saberian, M.; Chen, F. A comprehensive review on the application of renewable waste tire rubbers and fibers in sustainable concrete. J. Clean. Prod. 2022, 374, 133998. [Google Scholar] [CrossRef]

- Xue, J.; Shinozuka, M. Rubberized concrete: A green structural material with enhanced energy-dissipation capability. Constr. Build. Mater. 2013, 42, 196–204. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential use of waste tire rubber as aggregate in cement concrete—A comprehensive review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- Marie, I. Thermal conductivity of hybrid recycled aggregate—Rubberized concrete. Constr. Build. Mater. 2017, 133, 516–524. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlík, Z.; Čítek, D.; Jankovský, O.; Pavlíková, M. Eco-friendly concrete with scrap-tyre-rubber-based aggregate—Properties and thermal stability. Constr. Build. Mater. 2019, 225, 709–722. [Google Scholar] [CrossRef]

- Elchalakani, M. High strength rubberized concrete containing silica fume for the construction of sustainable road side barriers. Structures 2015, 1, 20–38. [Google Scholar] [CrossRef]

- Liu, B.; Yang, S.; Li, W.; Zhang, M. Damping dissipation properties of rubberized concrete and its application in anti-collision of bridge piers. Constr. Build. Mater. 2020, 236, 117286. [Google Scholar] [CrossRef]

- Duarte, A.P.C.; Silva, B.A.; Silvestre, N.; de Brito, J.; Júlio, E.; Castro, J.M. Tests and design of short steel tubes filled with rubberised concrete. Eng. Struct. 2016, 112, 274–286. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Abu Bakar, B.H.; Ismail, H.; Akil, H.M. Effect of partial replacement of sand by recycled fine crumb rubber on the performance of hybrid rubberized-normal concrete under impact load: Experiment and simulation. J. Clean. Prod. 2013, 59, 284–289. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Experimental investigations of reinforced rubberized concrete structural members. J. Build. Eng. 2017, 10, 149–165. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008; Volume 171. [Google Scholar]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction—Recent developments. Constr. Build. Mater. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Asghar, R.; Khan, M.A.; Alyousef, R.; Javed, M.F.; Ali, M. Promoting the green Construction: Scientometric review on the mechanical and structural performance of geopolymer concrete. Constr. Build. Mater. 2023, 368, 130502. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A state-of-the-art review on the durability of geopolymer concrete for sustainable structures and infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Pradhan, P.; Dwibedy, S.; Pradhan, M.; Panda, S.; Panigrahi, S.K. Durability characteristics of geopolymer concrete—Progress and perspectives. J. Build. Eng. 2022, 59, 105100. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. A review of engineering properties of ultra-high-performance geopolymer concrete. Dev. Built Environ. 2023, 14, 100126. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Sulaiman Atrushi, D.; Mohammed, A.S.; Unis Ahmed, H.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Mohammed Najm, H. Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 2022, 346, 128495. [Google Scholar] [CrossRef]

- Ambily, P.S.; Ravisankar, K.; Umarani, C.; Dattatreya, J.K.; Iyer, N.R. Development of ultra-high-performance geopolymer concrete. Mag. Concr. Res. 2014, 66, 82–89. [Google Scholar] [CrossRef]

- Marinković, S.; Josa, I.; Braymand, S.; Tošić, N. Sustainability assessment of recycled aggregate concrete structures: A critical view on the current state-of-knowledge and practice. Struct. Concr. 2023, 24, 1956–1979. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Wang, R.; Yu, N.; Li, Y. Methods for improving the microstructure of recycled concrete aggregate: A review. Constr. Build. Mater. 2020, 242, 118164. [Google Scholar] [CrossRef]

- Upshaw, M.; Cai, C.S. Critical Review of Recycled Aggregate Concrete Properties, Improvements, and Numerical Models. J. Mater. Civ. Eng. 2020, 32, 03120005. [Google Scholar] [CrossRef]

- Mohanta, N.R.; Murmu, M. Alternative coarse aggregate for sustainable and eco-friendly concrete—A review. J. Build. Eng. 2022, 59, 105079. [Google Scholar] [CrossRef]

- Gholampour, A.; Zheng, J.; Ozbakkaloglu, T. Development of waste-based concretes containing foundry sand, recycled fine aggregate, ground granulated blast furnace slag and fly ash. Constr. Build. Mater. 2021, 267, 121004. [Google Scholar] [CrossRef]

- Marvila, M.; de Matos, P.; Rodriguez, E.; Monteiro, S.N.; de Azevedo, A.R.G. Recycled Aggregate: A Viable Solution for Sustainable Concrete Production. Materials 2022, 15, 5276. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. Expanded glass as light-weight aggregate in concrete—A review. J. Clean. Prod. 2021, 313, 127848. [Google Scholar] [CrossRef]

- Wu, K.; Zheng, Z.; Zhang, S.; He, L.; Yao, H.; Gong, X.; Ni, Y. Interfacial strength-controlled energy dissipation mechanism and optimization in impact-resistant nacreous structure. Mater. Des. 2019, 163, 107532. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, H.; Liu, Y.; Zhang, Z.; Yuan, Y. Nacre-inspired topological design tuning the impact resistant behaviors of composite plates. Compos. Struct. 2022, 299, 116077. [Google Scholar] [CrossRef]

- Molotnikov, A.; Estrin, Y.; Dyskin, A.V.; Pasternak, E.; Kanel-Belov, A.J. Percolation mechanism of failure of a planar assembly of interlocked osteomorphic elements. Eng. Fract. Mech. 2007, 74, 1222–1232. [Google Scholar] [CrossRef]

- Molotnikov, A.; Gerbrand, R.; Qi, Y.; Simon, G.P.; Estrin, Y. Design of responsive materials using topologically interlocked elements. Smart Mater. Struct. 2015, 24, 025034. [Google Scholar] [CrossRef]

- Williams, A.; Siegmund, T. Mechanics of topologically interlocked material systems under point load: Archimedean and Laves tiling. Int. J. Mech. Sci. 2021, 190, 106016. [Google Scholar] [CrossRef]

- Estrin, Y.; Dyskin, A.V.; Pasternak, E. Topological interlocking as a material design concept. Mater. Sci. Eng. C 2011, 31, 1189–1194. [Google Scholar] [CrossRef]

| Method | Procedure | Applicability | |

|---|---|---|---|

| Removal of attached mortar from recycled aggregates | Ultrasonic cleaning | Weakly attached mortar is removed in an ultrasonic bath and subsequently washed out with water | RCA and RFA; however, more efficient for RCA |

| Heat treatment | Thermal stress differences generated by heating remove the attached mortar | RCA and RFA; however, more efficient for RCA | |

| Pre-soaking in acid solutions | Old mortar is removed by pre-soaking the aggregates in acid solution | RCA and RFA | |

| Surface coating of recycled aggregates | Pozzolanic materials | A coat of pozzolanic materials forms a new hydration product and reduces the porosity of the aggregate | RCA and RFA |

| Polymer emulsion | The polymer emulsion fills the pores and coats the old mortar | RCA | |

| Different mixing methods of RAC | Two-stage mixing | A portion of water–cement mixed applied first to form a coat over the aggregate | RCA and RFA |

| Optimised stage mixing | Pozzolanic coats and\or RCA-RFA premixes made before the final mix is made | RCA and RFA | |

| Biodeposition of calcium carbonate | Bacteria precipitates on recycled aggregate surface decrease porosity and improve water absorption | RCA | |

| Carbonation | CO2 is inserted in RAC pores to form CaCO3 and silica gel | RCA Not applicable for steel reinforced concrete | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shufrin, I.; Pasternak, E.; Dyskin, A. Environmentally Friendly Smart Construction—Review of Recent Developments and Opportunities. Appl. Sci. 2023, 13, 12891. https://doi.org/10.3390/app132312891

Shufrin I, Pasternak E, Dyskin A. Environmentally Friendly Smart Construction—Review of Recent Developments and Opportunities. Applied Sciences. 2023; 13(23):12891. https://doi.org/10.3390/app132312891

Chicago/Turabian StyleShufrin, Igor, Elena Pasternak, and Arcady Dyskin. 2023. "Environmentally Friendly Smart Construction—Review of Recent Developments and Opportunities" Applied Sciences 13, no. 23: 12891. https://doi.org/10.3390/app132312891

APA StyleShufrin, I., Pasternak, E., & Dyskin, A. (2023). Environmentally Friendly Smart Construction—Review of Recent Developments and Opportunities. Applied Sciences, 13(23), 12891. https://doi.org/10.3390/app132312891