1. Introduction

Red clay is a distinctive clay type primarily composed of minerals like kaolinite, illite, and chlorite, displaying characteristics such as swelling-shrinkage behavior, high fissuring propensity, and heightened sensitivity to changes in moisture content [

1,

2]. Red clay is widely distributed in regions of China, including Yunnan, Guizhou, and Guangxi. However, due to its unique properties, it cannot be directly utilized as roadbed material [

3,

4]. Consequently, researchers both domestically and internationally have undertaken extensive investigations into the enhancement of red clay properties. Among the various approaches, the common and effective method involves amending red clay with materials such as lime, cement, and fly ash [

5,

6,

7]. Nevertheless, the production of lime and cement consumes substantial resources, and lime-treated and cement-treated soils often exhibit early-age strength deficiencies and poor moisture stability. Additionally, the escalating problem of environmental pollution has exacerbated the issue of solid waste disposal. In response to these challenges, some researchers have begun to explore the utilization of solid waste materials for the improvement of red clay, with the incorporation of phosphogypsum into red clay being a frequently employed and efficacious technique [

8,

9].

Phosphogypsum is a solid waste generated during the wet-process production of phosphoric acid, containing hazardous components such as diphosphorus pentoxide, fluoride, and free acids. It is worth noting that the production of 1 ton of phosphoric acid yields approximately 4 to 5 tons of phosphogypsum [

10,

11]. Due to the lack of appropriate disposal methods, a significant amount of phosphogypsum in China is currently disposed of through stacking, with only a small fraction being effectively recycled. This not only occupies valuable land resources but also poses potential environmental hazards [

12]. In response to these challenges, both domestic and international researchers have conducted extensive studies on phosphogypsum treatment and have made notable progress in soil improvement. Gu et al. [

13], for instance, employed scanning electron microscopy (SEM) analysis to investigate the influence of cement and phosphogypsum on the microstructure of loess, revealing that those changes in mechanical properties primarily stem from alterations in the internal bonding system. Ebailila et al. [

14] conducted experiments by incorporating phosphogypsum into lime-treated soil, finding a direct proportionality between the strength and swelling rate of the improved soil and the content of lime and gypsum. Peng Bo et al. [

15] utilized phosphogypsum to modify lime-treated and cement-treated soils, conducting a series of laboratory tests to confirm the feasibility of phosphogypsum-modified soil for roadbed construction and providing recommended mix ratios. Chen Kaisheng et al. [

16], through a high phosphogypsum content modification of red clay, observed that the improved soil met road use requirements in terms of 7-day unconfined compressive strength (UCS), albeit with increased swelling deformation. In summary, many scholars at home and abroad have conducted extensive research on the application of phosphogypsum in road engineering, but the research on phosphogypsum-improved diabase-stabilized red clay is still imperfect. The optimal phosphogypsum content ratio remains undefined, and there is a scarcity of studies combining macroscopic and microscopic analyses in this field.

Therefore, in order to solve the problems of low early strength and poor water stability of lime-fly ash-stabilized red clay, the recycling of solid waste phosphogypsum was also considered. The present study conducted a series of indoor experiments by manipulating the dosage of phosphogypsum and the curing age, ultimately culminating in an analysis of the microstructure of the improved lime-ash soil using SEM (Scanning Electron Microscopy) and XRD (X-Ray Diffraction) techniques. These analyses aimed to elucidate the reinforcement mechanism of phosphogypsum on the lime-ash stabilized red clay. The goal is to provide pertinent parameter references for engineering projects and to offer a methodology for the treatment of solid waste phosphogypsum.

2. Experimental Overview

The red clay samples were collected from a construction site in Liuzhou City, Guangxi, displaying a reddish-brown color and relatively high natural moisture content with minimal impurities. The particle size distribution curve is illustrated in

Figure 1. Basic physical properties were determined according to the "Standard for Geotechnical Testing Method" (GB/T 50123-2019) [

17], as presented in

Table 1. Fly ash was procured from a manufacturer in Henan and classified as Class II fly ash, meeting all technical specifications in accordance with regulatory requirements. The testing parameters are detailed in

Table 2. Calcium-based quicklime was selected, comprising predominantly calcium oxide (86.35%) and appearing as a white powder. Phosphogypsum was obtained from a water purification materials plant in Gongyi City, characterized by its grayish-white powdered form. The main parameters of phosphogypsum are outlined in

Table 3.

2.1. Experimental Scheme

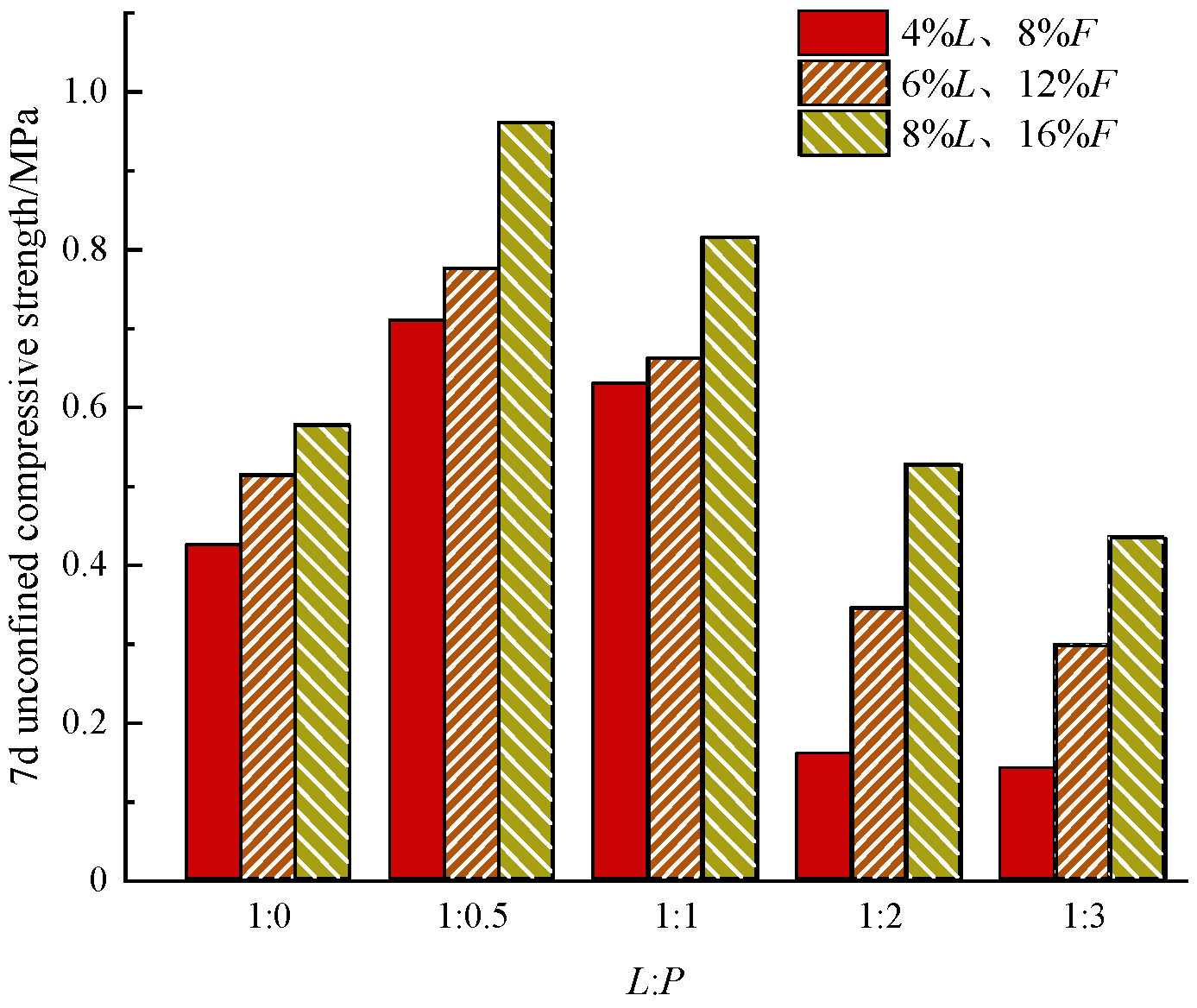

In the previous experimental phase, this study utilized phosphogypsum to enhance the stability of lime-ash stabilized red clay. Samples were prepared with a lime-to-fly ash ratio of L:F = 1:2, along with lime-to-phosphogypsum ratios ranging from L:P = 1:0, 1:0.5, 1:1, 1:2, and 1:3. Compaction tests and UCS tests with a 7-day curing period were conducted, and the results are depicted in

Figure 2 and

Figure 3, respectively.

Figure 3 clearly illustrates that with an increase in the phosphogypsum content, the UCS of the lime-ash-stabilized red clay initially rises, then declines, and eventually levels off. According to the ‘Technical Guidelines for Construction of Highway Roadbases’ (JTG/T F20-2015) [

18], the 7-day UCS of lime-fly ash stabilized materials in highway subbases should be greater than or equal to 0.5 MPa. Based on the test results, the 7-day UCS of the lime-ash stabilized red clay with an 8% lime content meets this requirement. In the saturated condition test after 7 days of curing, it was observed that the samples with 8% lime content had fewer attached air bubbles on the surface, no particle detachment, and exhibited superior overall integrity.

In summary, this study utilized an 8% lime content, 16% fly ash content, and lime-to-phosphogypsum ratios of 1:0, 1:0.5, 1:1, 1:2, and 1:3 to prepare samples. Road performance tests and swelling characteristics tests for phosphogypsum-modified lime-ash stabilized red clay (referred to hereafter as ‘lime-ash stabilized soil’) were conducted following the ‘Test Methods of Materials Stabilized with InorganicBinders for Highway Engineering’ (JTG E51-2009) [

19]. Finally, scanning electron microscopy (SEM) tests and X-ray diffraction (XRD) tests were employed for microstructural and quantitative analyses of the optimal lime-ash stabilized soil content, unveiling the micro mechanisms of phosphogypsum-modified lime-ash stabilized red clay.

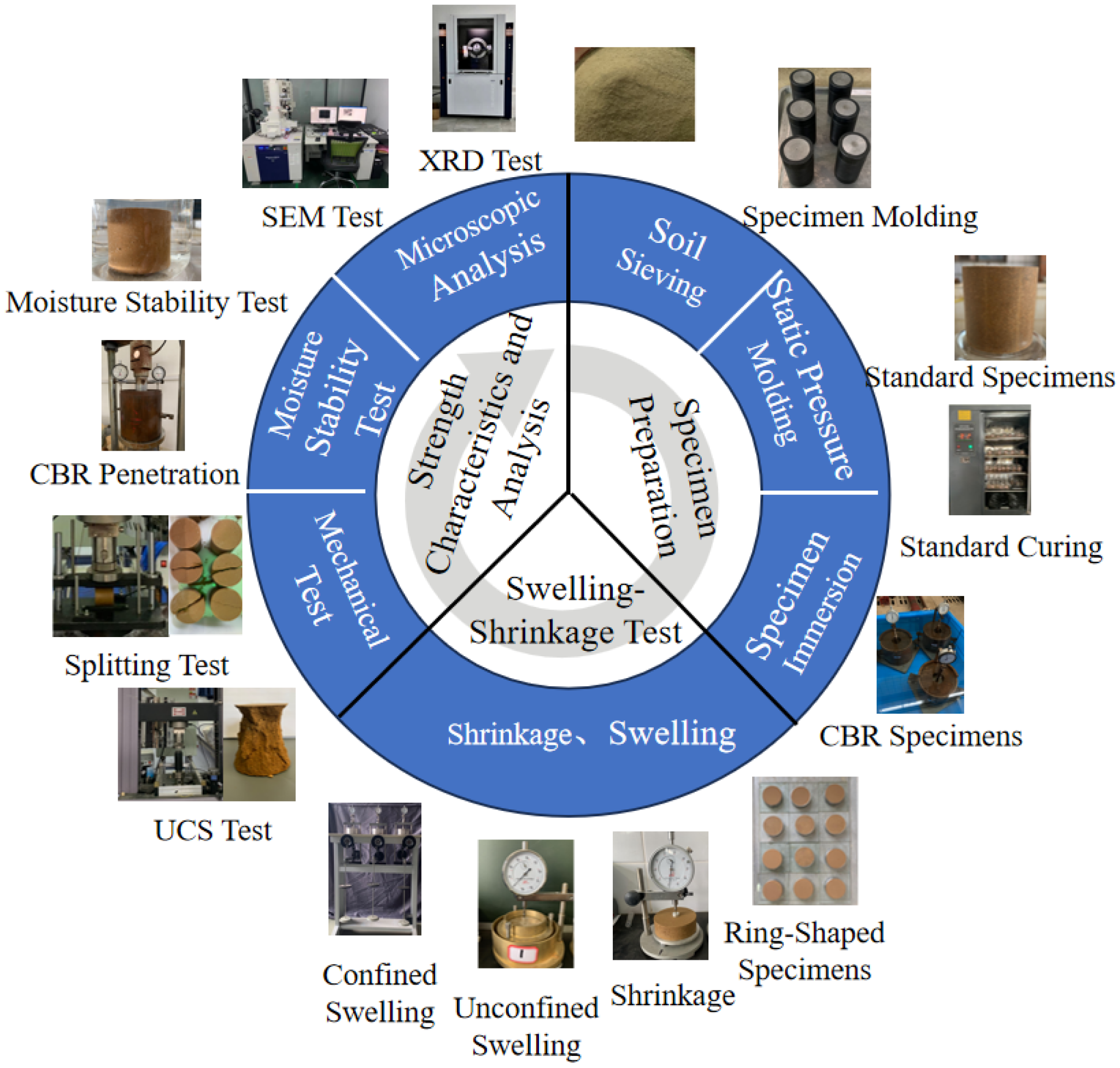

2.2. Testing Procedures

2.2.1. Strength-Characteristic Testing

Mechanical strength indicators are crucial testing criteria for mixed materials used as roadbed fill. This study primarily investigates the mechanical properties of phosphogypsum-modified lime-ash stabilized soil through UCS, splitting tensile strength, and California Bearing Ratio (CBR) tests. Both UCS and splitting tensile strength specimens were cylindrical with dimensions of Φ 50 mm × H 50 mm. The compaction degree was set at 96%, and samples were prepared using a static pressure method with a one-time molding process. After maintaining pressure for 3 h, the specimens were demolded and then transferred to a standard curing chamber (temperature 20 ± 2 °C, relative humidity > 95%) for curing. The curing periods for UCS specimens were 7 days, 14 days, 28 days, 60 days, and 90 days, while those for splitting tensile strength specimens were 28 days, 60 days, and 90 days. Each group included six parallel samples, totaling 840 samples. Prior to testing, the samples were soaked in water for 24 h the day before the end of their respective curing periods. The tests were conducted using a universal testing machine with a strain rate controlled at 1 mm/min, and the maximum pressure at failure was recorded. CBR test specimens measured Φ 152 mm × H 120 mm, with a compaction degree of 96%. Each group included three parallel samples, totaling 15 samples. After soaking in water for 96 h, a penetration rod was used to press into the specimens at a rate of 1 mm/min using a pavement material strength tester. The CBR value was determined as the ratio of the displayed pressure value when the penetration rod penetrated the sample by 2.5 mm to the standard crushed stone pressure.

2.2.2. Moisture Stability Testing

Moisture stability is one of the crucial performance characteristics of road materials, typically defined as the material’s ability to retain its original properties when saturated with water. It is assessed by observing indicators such as cracking and disintegration of the material when subjected to water saturation. However, the moisture stability of the material is typically quantified effectively using the moisture stability coefficient, denoted as ‘

K’. This study explores the moisture stability of improved soils through UCS specimens at different curing periods, with calculations following Equation (1).

where

K represents the moisture stability coefficient;

RC stands for the UCS of the sample soaked in water for 24 h (in MPa); and

R represents the UCS of the sample without water immersion (in MPa).

2.2.3. Expansion and contraction Testing

According to the ‘Test Methods of Soils for Highway Engineering’ (JTG 3430-2020) [

20], shrinkage tests, unconfined swelling tests, and confined swelling tests (with vertical loads of 25 kPa and 50 kPa) were conducted on lime-ash stabilized soils with different phosphogypsum contents. The specimens were ring-shaped with dimensions of Φ 61.8 mm × H 20 mm, compacted to 96% density using a static pressure method for one-time molding. To minimize the impact of errors and ensure the reliability of the test results, each group included three parallel specimens, totaling 60 ring-shaped specimens. The tests were performed using an SS-1 type shrinkage apparatus, a WZ-2 type expansion apparatus, and a WG-1C type triaxial low-pressure consolidation apparatus, as illustrated in

Figure 4.

3. Testing Results and Analysis

3.1. Strength Characteristics Testing

3.1.1. Unconfined Compressive Strength Testing

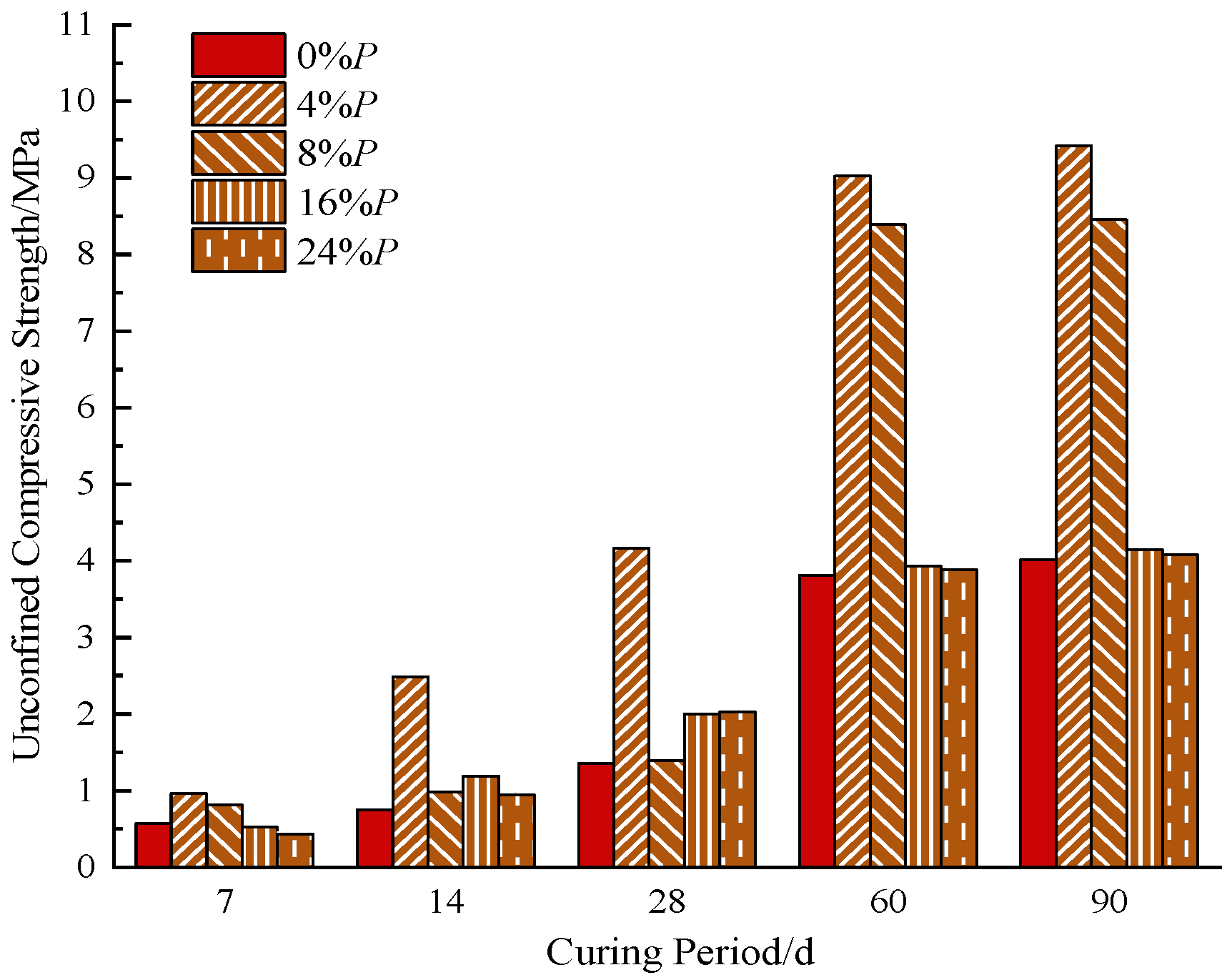

The UCS test results of phosphogypsum-modified lime-ash stabilized soil are presented in

Figure 5. Several observations can be derived from

Figure 5: (1) The addition of phosphogypsum significantly influences the UCS of the lime-ash-stabilized soil. When the phosphogypsum content is 4%, the 7-day UCS of the lime-ash stabilized soil (0.97 MPa) increases by 67.2%, the 14-day UCS (2.49 MPa) increases by 3.3 times, and the 28-day UCS (4.2 MPa) increases by 3.1 times. However, when the phosphogypsum content exceeds 4%, the UCS value begins to decrease. (2) The UCS of the lime-ash stabilized soil gradually increases with an extended curing period. For the lime-ash stabilized soil, its strength exhibits relatively rapid growth in the early curing stages but slower growth in the later stages. Conversely, for the lime-ash stabilized soil with added phosphogypsum, there is a significant acceleration in strength growth during the early curing period, followed by even faster growth during the mid-curing period (from 28 days to 60 days). However, this phenomenon diminishes in the later stages (from 60 days to 90 days) of curing as the strength of the lime-ash stabilized soil gradually stabilizes. Additionally, for the specimens with a phosphogypsum content exceeding 8%, there is no significant increase in UCS values. The reason for these observations is that the addition of phosphogypsum enhances the cohesion and stability of soil particles, allowing their strength to continue increasing over an extended period. However, the change in strength is related to the generation of ettringite. Ettringite can enhance soil strength within a certain range, but an excess of ettringite can cause expansion, disrupt soil stability, and lead to a reduction in soil strength [

21]. Therefore, this study initially determines the optimal phosphogypsum content to be 4%.

3.1.2. Splitting Strength Experiment

The splitting strength test results for phosphogypsum-modified lime-ash stabilized soil are presented in

Figure 6. Several observations can be derived from

Figure 6: (1) The splitting strength of phosphogypsum-modified lime-ash stabilized soil initially increases and then decreases with an increase in phosphogypsum content. When the phosphogypsum content is 4%, the splitting strength of the lime-ash stabilized soil reaches its maximum value (0.73 MPa), which is 4.3 times higher than the strength of the unmodified lime-ash stabilized soil (0.17 MPa). The early splitting strength of the lime-ash-stabilized soil is significantly improved. However, when the phosphogypsum content is 24%, the splitting strength of the lime-ash stabilized soil at different curing periods is lower than that of the unmodified lime-ash stabilized soil. (2) With an increase in the curing period, the splitting strength of phosphogypsum-modified lime-ash stabilized soil gradually increases. In the early curing period, the reaction between soil particles and the cementitious materials has not yet fully occurred, resulting in a slower rate of splitting strength growth. However, as the curing period increases, the soil particles gradually become more stable and firmly bonded together. Additionally, certain active components within the soil gradually become effective during the curing process, accelerating the growth of the splitting strength of the lime-ash stabilized soil [

22]. It is worth noting that, under different phosphogypsum contents and curing periods, the splitting strength of the lime-ash stabilized soil is highest at a phosphogypsum content of 4%. Combining this result with the UCS test results, this study considers a 4% phosphogypsum content as the optimal content.

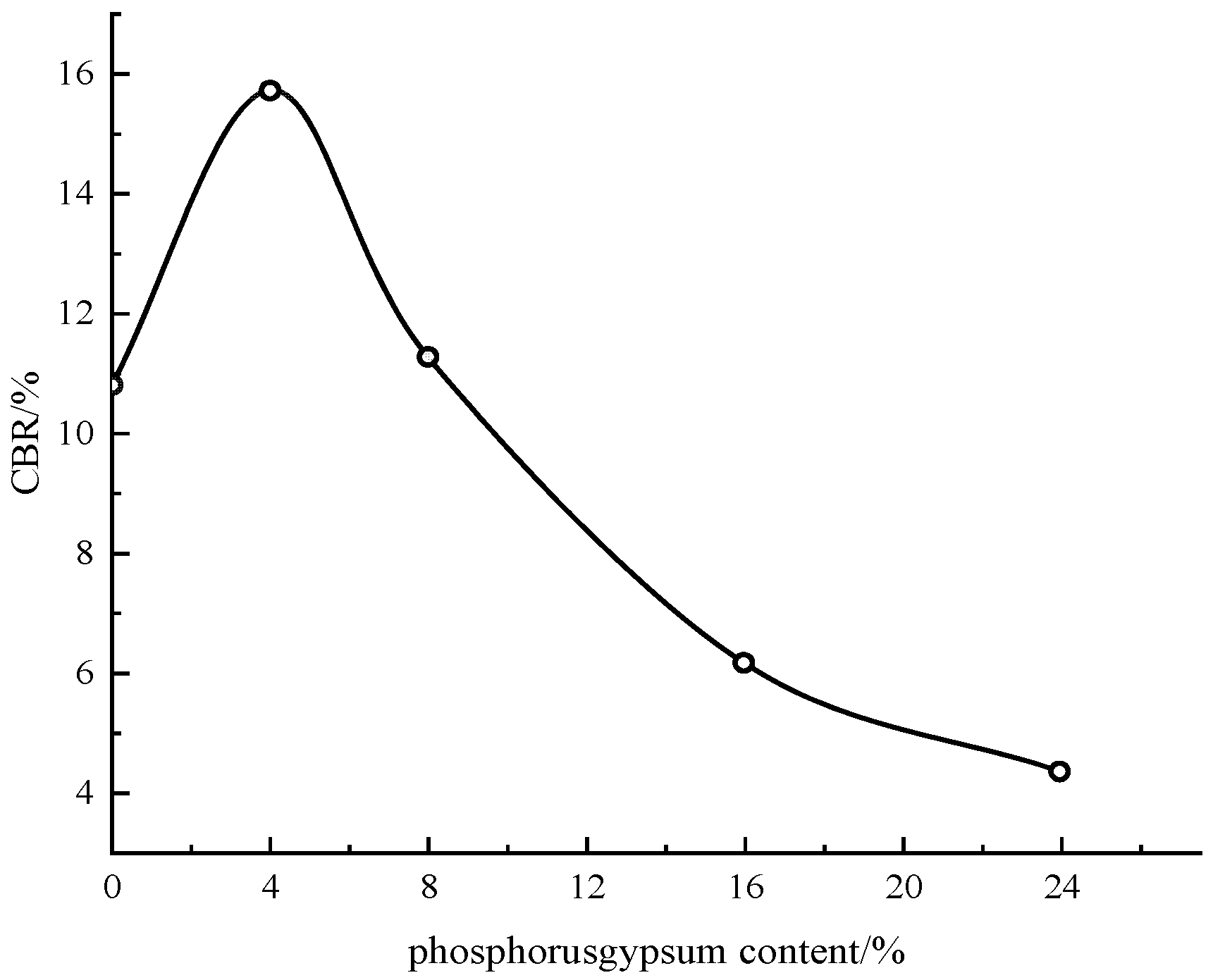

3.1.3. CBR Testing

The CBR strength test results of phosphogypsum-modified lime-ash stabilized soil are presented in

Figure 7. The CBR values of the lime-ash-stabilized soil initially increase and then decrease as the phosphogypsum content increases. When the phosphogypsum content is 4%, the CBR value of the lime-ash stabilized soil reaches its peak (15.73%). This value aligns with the requirements of the ‘Technical Specifications for Construction of Highway Subgrades’ (JTG/T3610—2019) [

23] for the minimum subgrade fill CBR (2–8%). However, when the phosphogypsum content exceeds 8%, the CBR values of the lime-ash stabilized soil are all lower than those of the unmodified lime-ash stabilized soil. Furthermore, during the 96 h soaking process, an increase in phosphogypsum content results in noticeable expansion of the lime-ash-stabilized soil samples. This expansion results in a reduction in their bearing capacity.

3.2. Moisture Stability Test

Due to the susceptibility of the lime-ash stabilized soil to cracking when saturated during the early stages of curing, this study primarily focuses on investigating the moisture stability of specimens after 7 days, 14 days, and 28 days of curing.

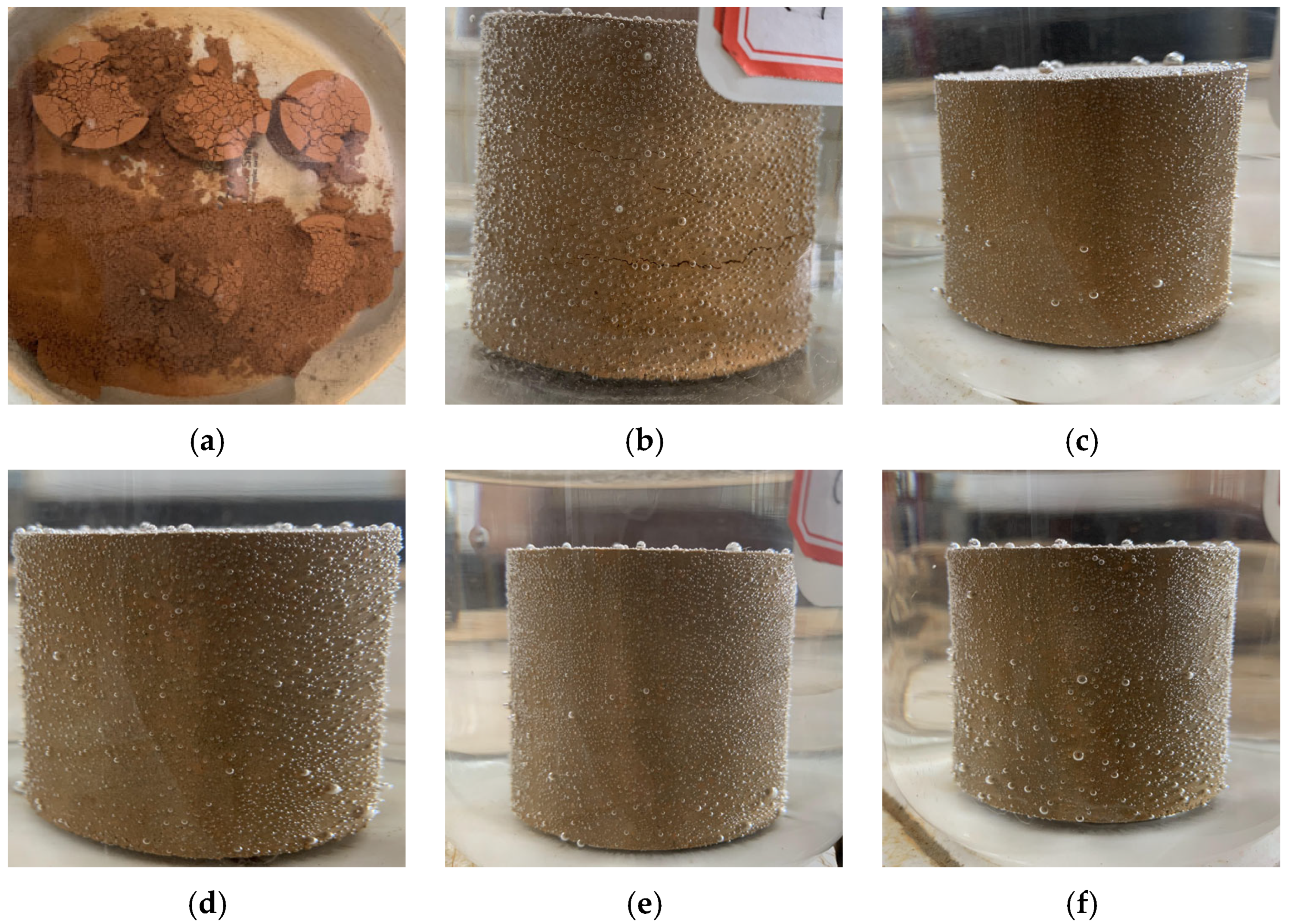

Figure 8 illustrates the saturation conditions of the specimens after 7 days of curing. In

Figure 8a, the original soil sample begins to develop cracks from the edges towards the center after soaking for 3 h. This is accompanied by the continuous emergence of a significant number of bubbles above the soil sample. Subsequently, the soil sample continues to disintegrate and accumulate at the bottom of the container. These outcomes indicate a relatively poor resistance to disintegration of the natural red clay soil. In

Figure 8b, after the addition of lime and fly ash for improvement, the red clay soil’s resistance to disintegration is significantly enhanced. The specimen maintains its structural integrity after 24 h of soaking, with no signs of disintegration. However, the lime-ash stabilized soil specimens still exhibit cracks, resulting in reduced strength. Upon the further addition of phosphogypsum for modification, the appearance of the lime-ash stabilized soil specimens remains entirely intact, with no cracks or particle detachment observed. This result indicates that the addition of phosphogypsum markedly addresses the shortcomings of the soil, enhancing its resistance to disintegration and overall stability.

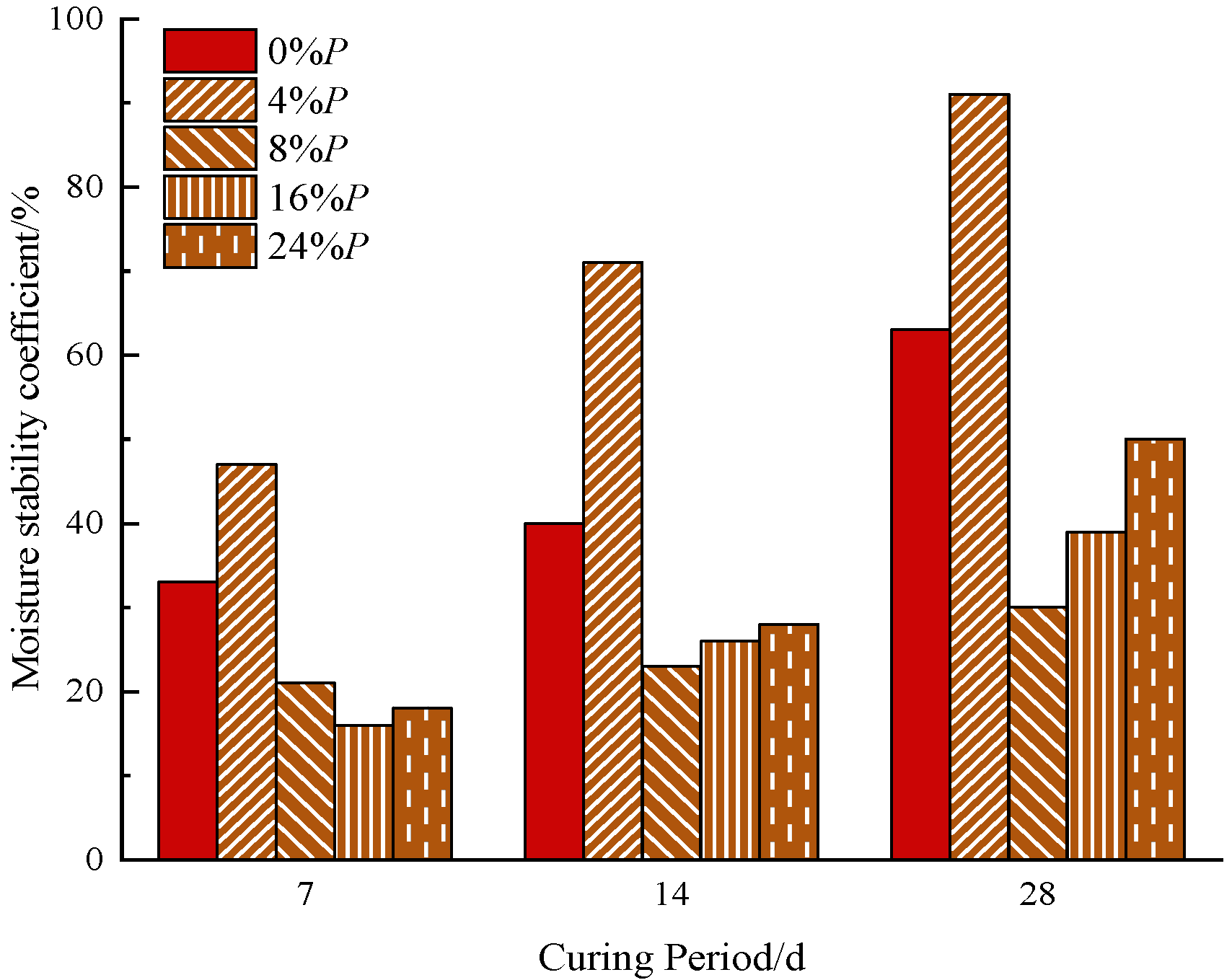

The moisture stability coefficient, denoted as K, is determined by the ratio of the UCS of saturated specimens to the UCS of specimens under standard curing conditions without saturation. The calculated moisture stability coefficients are presented in

Figure 9. It is evident from

Figure 9 that phosphogypsum significantly enhances the moisture stability of the lime-ash-stabilized soil. When the phosphogypsum content is 4%, the specimens exhibit the highest moisture stability coefficient. However, when the phosphogypsum content exceeds 4%, the moisture stability coefficients of the modified lime-ash stabilized soil specimens are all lower than those of the unmodified specimens. Furthermore, with an increase in the curing duration, the moisture stability coefficients of the specimens gradually increase. In the early curing stages, the moisture stability of the specimens is relatively poor, with saturation significantly impacting strength. At 14 days of curing, the moisture stability coefficient of the specimens with 4% phosphogypsum content reaches 71%. By 28 days, it increases significantly to 91%, indicating that saturation has a minimal impact on strength at this point. This suggests that the addition of an appropriate amount of phosphogypsum promotes better consolidation of the lime-ash-stabilized soil over extended curing periods, enhancing its strength.

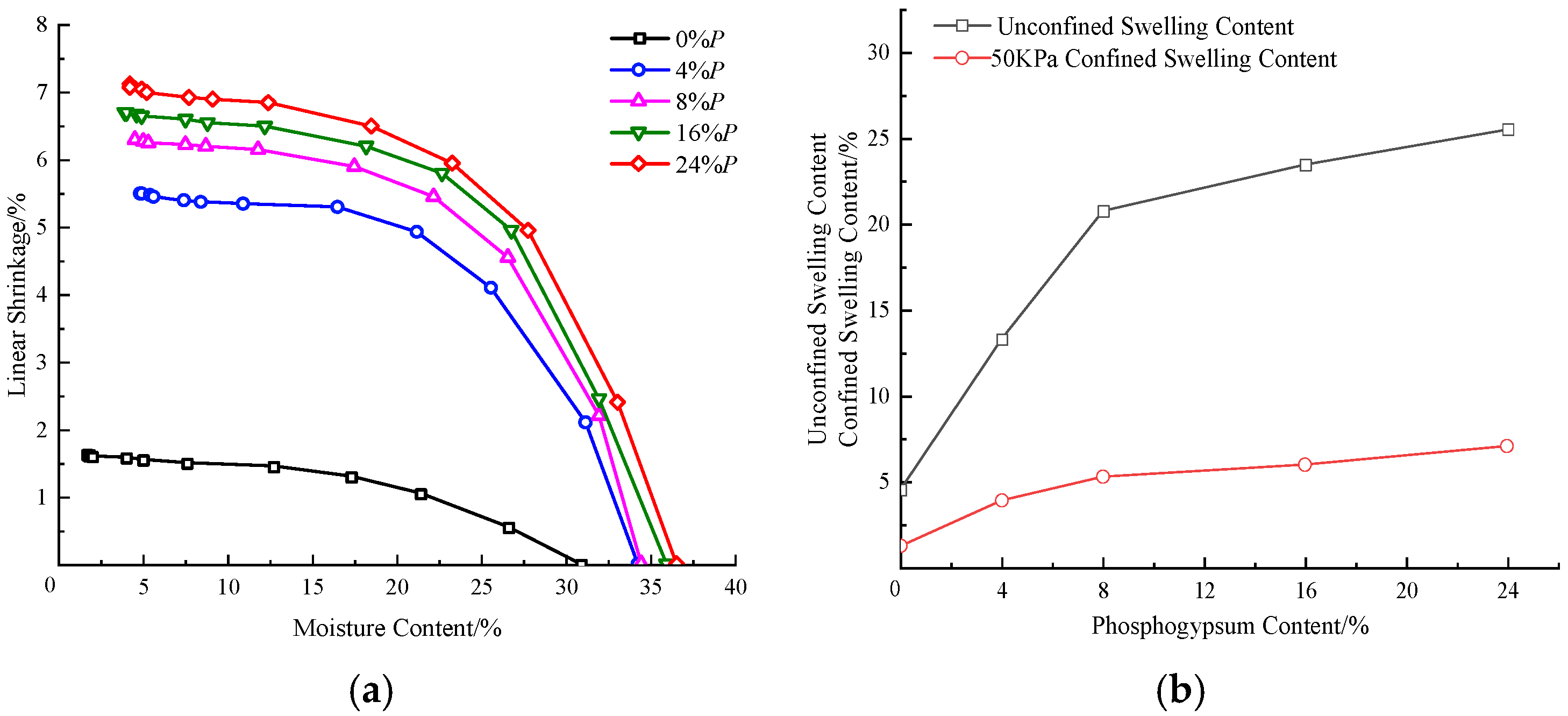

3.3. Swelling-Shrinkage Testing

The swelling-shrinkage curve of phosphogypsum-modified lime-ash-stabilized soil is presented in

Figure 10, and various shrinkage indicators are summarized in

Table 4. The test results reveal that the addition of phosphogypsum to the lime-ash stabilized soil significantly exacerbates its shrinkage and swelling characteristics, which intensify progressively with increasing phosphogypsum content. Specifically, as observed from

Table 4, soils with higher initial moisture content exhibit greater linear shrinkage. In the early stages of the experiment, moisture loss from the specimen’s surface, resulting in the thinning of the water film between the particles, leads to increased matrix suction between the particles, causing specimen shrinkage [

16]. However, specimens with higher initial moisture content experience a more significant reduction in the water film as they lose moisture, leading to greater matrix suction and exacerbating internal pore and crack shrinkage, ultimately resulting in increased specimen shrinkage deformation [

24]. Furthermore, under the alkaline conditions created by lime, the active silicon and aluminum in the soil react chemically with water, generating cementitious substances like hydrated calcium silicate and hydrated calcium aluminate. The addition of phosphogypsum continues these chemical reactions, leading to the formation of ettringite. Although the formation of ettringite enhances the soil’s strength, its multilayered structure and large specific surface area make it highly adsorbent, causing the soil to absorb more water during wetting. Consequently, the soil undergoes significant expansion upon wetting. Additionally, with increasing immersion time, the large volume of ettringite results in more pronounced water absorption and expansion, damaging the specimen’s structure and causing significant expansion. This phenomenon further exacerbates the soil’s shrinkage and swelling characteristics.

In summary, the addition of phosphogypsum does impact the swelling and shrinkage properties of lime-ash-stabilized soil. However, in moderate amounts, it significantly enhances the soil’s performance and durability. When phosphogypsum is added to lime-stabilized soil and subsequently subjected to prolonged curing and saturation, its expansion can be significantly reduced or even eliminated [

25]. Furthermore, although the inclusion of 4% phosphogypsum does lead to increased expansion and shrinkage deformation, the magnitude of this change is not substantial. In contrast, the improved engineering properties of the soil after the addition of phosphogypsum are more significant. Therefore, it is possible to further control these adverse effects by incorporating other additives and extending the curing duration.

4. Microanalysis

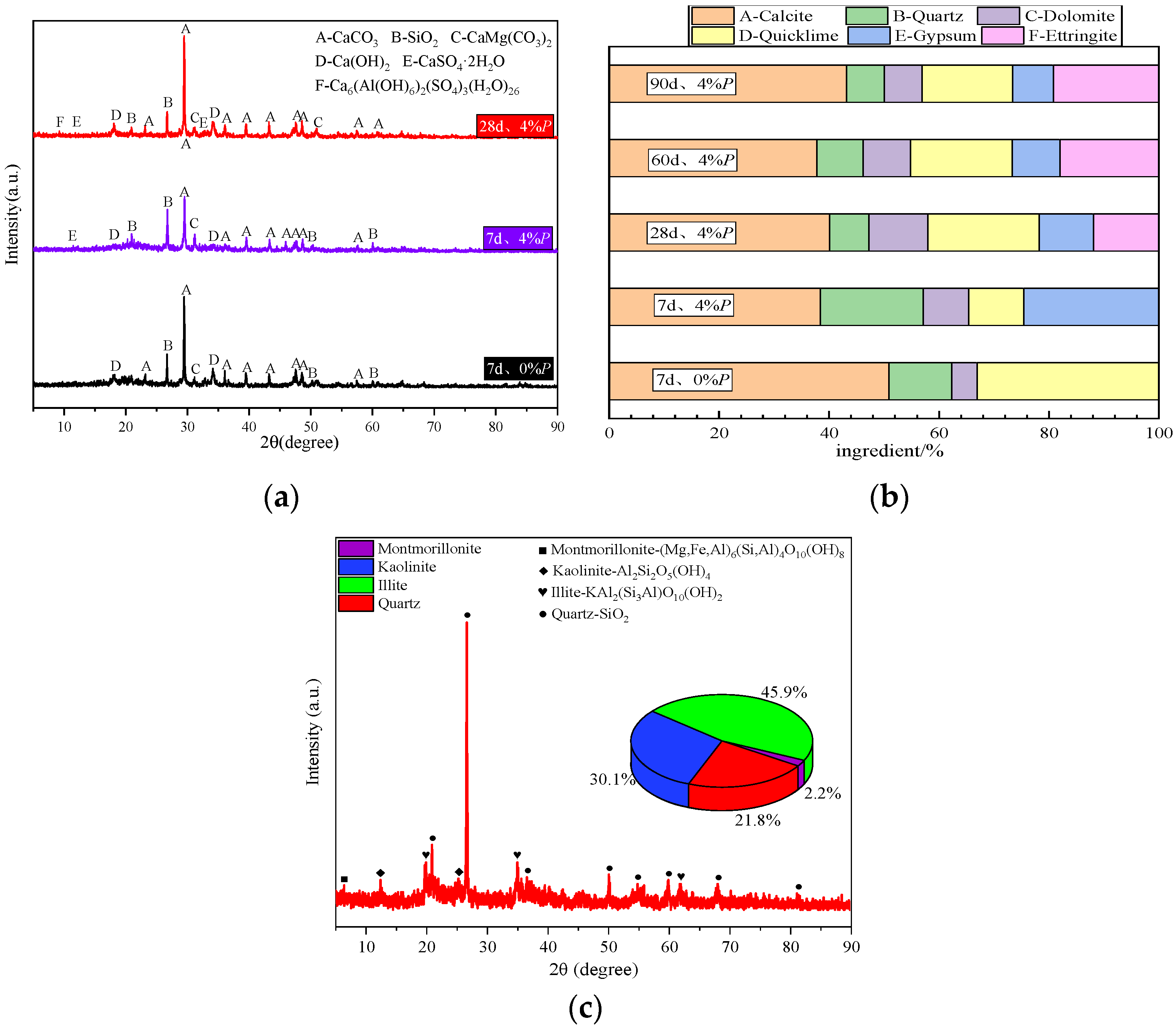

4.1. X-Ray Diffraction Quantitative Analysis

Figure 11 displays XRD patterns and component ratios of red clay and lime-ash-stabilized soil at different curing durations. As depicted in

Figure 8c, the predominant constituents of red clay encompass minerals like quartz, kaolinite, and illite. Following the introduction of lime and fly ash, a notable alteration in its mineral composition is discernible. The emergence of calcium carbonate and calcium hydroxide signifies that the incorporation of lime-ash has induced structural modifications in the red clay.

Figure 8a reveals that there are negligible alterations in XRD diffraction angles and components for both lime-ash-stabilized soils at different curing periods. This implies that the integration of phosphogypsum into the clay has engendered a relatively stable soil structure. Upon introducing phosphogypsum into the lime-ash-stabilized soil, the formation of gypsum dihydrate and the reduction in the proportion of calcium hydroxide indicate additional reactions between phosphogypsum, lime, and fly ash, culminating in the generation of a small quantity of ettringite. Nonetheless, XRD patterns failed to manifest characteristic peaks of ettringite after 7 days of curing due to the brief reaction duration and the minimal amount produced. After 28 days of curing, the proportion of ettringite increased, and the volumetric expansion resulting from ettringite formation further occupied some pores, thereby diminishing soil porosity, bolstering pore structures, and significantly augmenting the strength of the stabilized soil. As curing time progresses, reactions between internal materials in the samples become more extensive, and the proportion of ettringite gradually escalates. Nevertheless, the rise in ettringite content between the 60- and 90-day curing durations is insignificant. To summarize, the generation of ettringite consequent to the judicious addition of phosphogypsum to lime-ash-stabilized soil constitutes the primary impetus for enhancing soil strength, and protracted curing periods yield heightened strength.

4.2. Scanning Electron Microanalysis

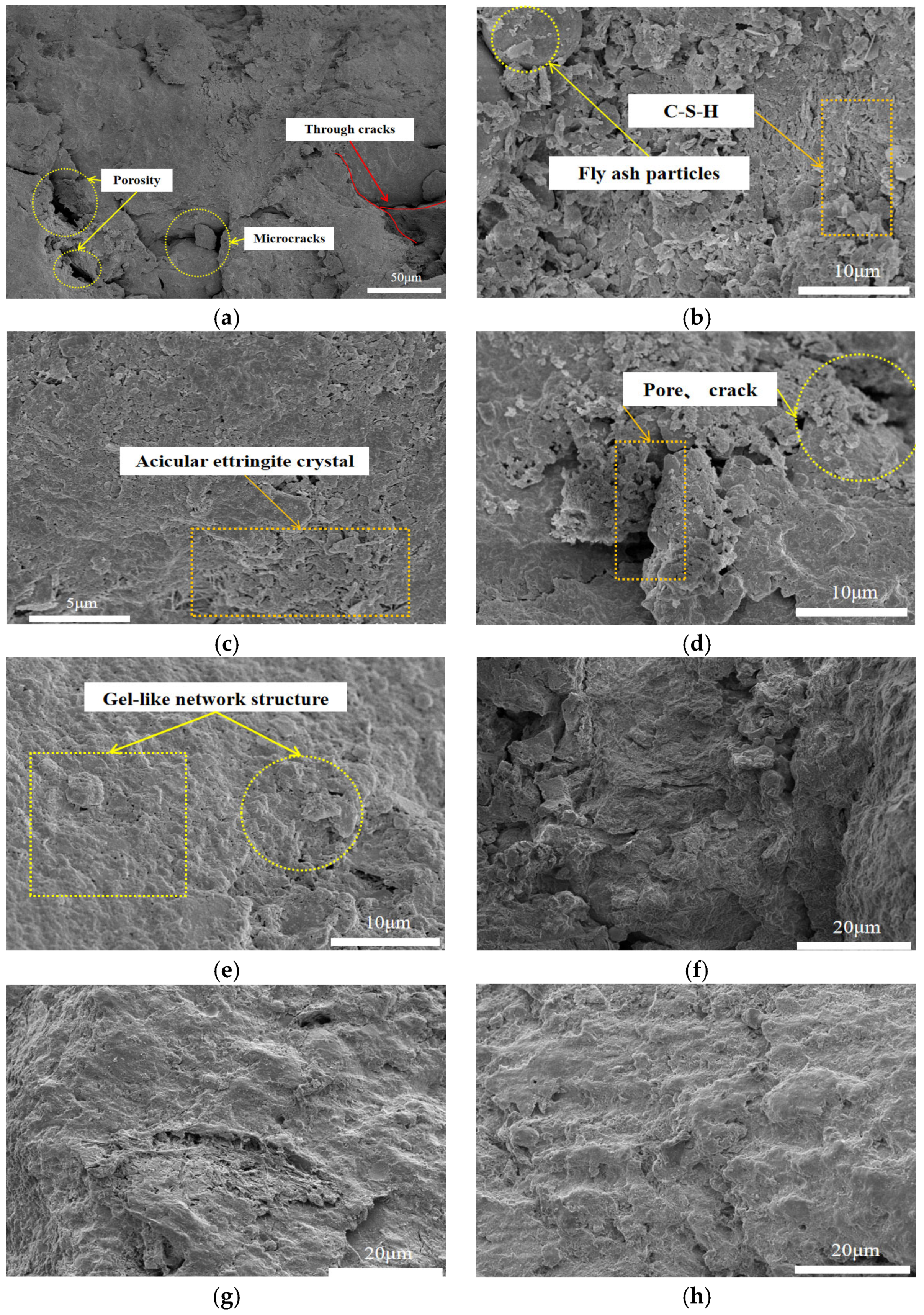

Figure 12 depicts the SEM images of the red clay and lime-ash stabilized soil at different curing durations. As illustrated in

Figure 12a, the particles in red clay are loosely arranged, presenting a laminar structure, resulting in numerous small to medium-sized pores and cracks. Consequently, the interparticle connections are weakened, affecting the overall integrity and strength of the soil. In

Figure 12b, after the addition of lime and fly ash, there is a significant alteration in the pore structure of red clay. The exchange of clay minerals and the formation of binders through reactions with volcanic ash lead to particle flocculation. Consequently, red clay transitions from granular and laminar structures to block-like structures, thereby enhancing the soil’s strength [

26]. Additionally, spherical particles within the sample can be observed in (b), which are unreacted fly ash.

Figure 12c reveals that after the introduction of phosphogypsum, evident needle-like and filamentous binders fill the gaps between pores. These materials are calcium ettringite, generated through further reactions between calcium aluminate hydrates and phosphogypsum. This process contributes to the increased strength of the lime-ash stabilized soil [

27].

Figure 12d shows that at a curing age of 28 days, the untreated lime-ash stabilized soil still exhibits noticeable internal pores and cracks. However, with prolonged curing, the reaction between lime and fly ash becomes more comprehensive, resulting in a flocculated structure within the sample’s interior. Furthermore,

Figure 12e demonstrates that at a curing age of 28 days, fly ash particles disappear and a significant amount of binder adheres to the soil particle surfaces. The proportion of the gel network structure is relatively large, which enhances the overall structural integrity of the soil and further enhances its strength. Microscopic morphology differences between lime-ash stabilized soil samples with 4% phosphogypsum at 60 days and 90 days of curing are minimal, resembling the 28-day curing period, with extensive coverage of the gel network structure within the sample’s interior.

In summary, the addition of phosphogypsum to binary lime-phosphogypsum soil activates the reactivity of fly ash. The generated calcium aluminate fills the pores and cracks within the soil aggregates. With an extended curing period, the proportion of this binding material area increases, leading to higher soil strength. The microscopic results corroborate the increase in soil strength with an extended curing period.

5. Conclusions

In this paper, through a series of indoor experiments, the effects of phosphogypsum on the strength, water stability, expansion, and contraction of diash-stabilized red clay were discussed, and the microscopic mechanism of phosphogypsum-improved diash-stabilized red clay was analyzed. The conclusions of this study are as follows:

(1) Phosphogypsum can significantly enhance the early strength of lime-stabilized red clay. With an increasing phosphogypsum content, the UCS of lime-stabilized clay first increases and then decreases. When the phosphogypsum content is 4%, the strength reaches its maximum. The 7-day UCS increases by 67.2%, and the 28-day UCS is enhanced by a factor of 3. Notably, the lime-stabilized clay shows a substantial increase in UCS during the 7-day to 28-day curing period, while the rate of increase slows down after 60 days of curing. Similarly, the splitting strength follows a similar trend of initially increasing and then decreasing with phosphogypsum content. The maximum splitting strength is achieved at 4% phosphogypsum content, resulting in a 4.3-fold increase at 28 days. With an increase in curing age, the splitting strength of lime-stabilized clay gradually increases without a significant decrease in the rate of improvement. Furthermore, the CBR value of lime-stabilized clay at 4% phosphogypsum content increases by 46%, meeting the road performance requirements.

(2) Phosphogypsum significantly enhances the moisture stability of lime-stabilized red clay. The 7-day moisture stability coefficient of samples with 4% phosphogypsum increases by 43%, reaching 0.91 at 28 days. Across various curing durations, lime-stabilized clay samples with phosphogypsum show good overall integrity after 24 h of soaking. However, when the phosphogypsum content exceeds 4%, the moisture stability of lime-stabilized clay gradually diminishes.

(3) High phosphogypsum content leads to increased expansion and shrinkage deformations in lime-stabilized clay. The shrinkage and expansion deformations of lime-stabilized clay are relatively small when the phosphogypsum content is below 4%. However, when the phosphogypsum content exceeds 4%, the deformation amplitude increases significantly. In addition, the higher the initial moisture content of lime-stabilized clay, the greater the shrinkage and expansion deformations.

(4) Microscopic analysis reveals that the calcium aluminate produced by adding phosphogypsum to lime-stabilized clay can effectively fill the internal pores and cracks of lime-stabilized clay, bonding the laminar and granular soil particles together and forming an overall gel-like network structure adhered to the surface of the soil particles. This significantly enhances the overall integrity and strength of lime-stabilized clay. However, excessive phosphogypsum can lead to the overaccumulation of calcium aluminate within the soil, causing increased expansion deformation, which disrupts the overall integrity of lime-stabilized clay and leads to reduced strength and moisture stability.

Experimental results indicate that the addition of phosphogypsum effectively enhances the early strength and moisture stability of lime-stabilized red clay. Lime-stabilized clay modified with 4% phosphogypsum (8% lime and 16% fly ash) can be used as a road subbase material. This not only offers an environmentally friendly solution for addressing phosphogypsum waste but also contributes to improved engineering performance. However, this study focused on phosphogypsum content greater than 4%, and future research could consider reducing the content for further investigation.

Author Contributions

Conceptualization, S.H.; methodology, S.H., Y.M. and T.C.; software, Y.M.; validation, S.H.; formal analysis, Y.M.; writing—original draft preparation, S.H.; writing—review and editing, S.H., J.W. and Z.L.; supervision, Z.L.; project administration, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, No. 41962017; the Key Project of the Guangxi Natural Science Foundation, No. 2022GXNSFDA035081; the High-Level Innovation Team and Outstanding Scholars Program of Guangxi Higher Education Institutions (No. 6 of Guangxi Education Talent [2020]); and the Graduate Education Innovation Program of Guangxi University of Science and Technology (GKYC202328).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to Differences in testing conditions and geographical differences in raw materials can lead to different test results. In addition, due to privacy constraints, these data are not available to the public.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jiang, W.Y. Study on the Soil Characteristics and Filling Performance of Guangxi Red Clay. Ph.D. Thesis, Guangxi University, Nanning, China, 2015. [Google Scholar]

- Kong, L.W.; Chen, Z.H. Advancement in the techniques for special soils and slopes. J. Civ. Eng. 2012, 45, 141–161. [Google Scholar]

- Zhao, Y.W.; Kong, L.W.; Guo, A.G.; Tuo, Y.F. Mechanical behaviors and water-sensitive properties of intact Guangxi laterite. Rock Soil Mech. 2003, 24, 568–572. [Google Scholar]

- Tan, Y.Z.; Kong, L.W.; Guo, A.G.; Feng, X.; Wan, Z. Discussion on compaction degree index of subgrade filled with laterite. Rock Soil Mech. 2010, 31, 851–855. [Google Scholar]

- Al-Mukhtar, M.; Khattab, S.; Alcover, J.-F. Microstructure and geotechnical properties of lime-treated expansive clayey soil. Eng. Geol. 2012, 139–140, 17–27. [Google Scholar] [CrossRef]

- Tan, Y.Z.; Hu, Y.; Cao, L.; Deng, Y.F.; Ming, H.J. Mechanism of metakaolin and lime modification of water sensitivity for compacted laterite. Rock Soil Mech. 2020, 41, 2207–2214, 2282. [Google Scholar]

- Tan, Y.Z.; Hu, Y.; Deng, Y.F.; Cao, L.; Zuo, Q.J. Behavior and mechanism of laterite shrinkage inhibition with lime and meta-kaolin mixture. Rock Soil Mech. 2019, 40, 4213–4219. [Google Scholar]

- Qi, J.; Zhu, H.; Zhou, P.; Wang, X.; Wang, Z.; Yang, S.; Yang, D.; Li, B. Application of phosphogypsum in soilization: A review. Int. J. Environ. Sci. Technol. 2023, 20, 10449–10464. [Google Scholar] [CrossRef]

- Pu, S.Y.; Zhu, Z.D.; Huo, W.W. Evaluation of engineering properties and environmental effect of recycled gypsum stabilized soil in geotechnical engineering: A comprehensive review. Resour. Conserv. Recycl. 2021, 174, 105780. [Google Scholar] [CrossRef]

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Liu, S.; Wu, F.H.; Qu, G.F.; Zhao, C.Y.; Chen, B.J. Migration and transformation of heavy metals in phosphogypsum storage process and their ecological effect. Asian J. Ecotoxicol. 2022, 17, 302–314. [Google Scholar]

- Murali, G.; Azab, M. Recent research in utilization of phosphogypsum as building materials: Review. J. Mater. Res. Technol. 2023, 25, 960–987. [Google Scholar] [CrossRef]

- Gu, J.X.; Lyu, H.B.; Fan, L.Y. Influence of structural strength on geotechnical properties of intact red clay. Arab. J. Geosci. 2021, 14, 1921. [Google Scholar] [CrossRef]

- Ebailila, M.; Kinuthia, J.; Oti, J. Role of Gypsum Content on the Long-Term Performance of Lime-Stabilised Soil. Materials 2022, 15, 5099. [Google Scholar] [CrossRef]

- Peng, B.; Shang, W.Y.; Zhao, H.W.; Song, Y.F.; Zhang, X.C. Study on mechanical properties and rational addition of phosphogypsum comprehensive stabilized soil. New Build Mater. 2020, 47, 86–90, 127. [Google Scholar]

- Chen, K.S.; Luo, D.P.; Hu, X. Swelling and shrinkage characteristics of high content phosphogypsum stabilized red clay. J. Archit. Civ. Eng. 2023, 40, 150–159. [Google Scholar]

- GB/T 50123-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- JTG/T F20-2015; Ministry of Transport of the People’s Republic of China. Technical Guidelines for Construction of Highway Roadbases. People’s Communications Press: Beijing, China, 2015.

- JTG E51-2009; Ministry of Transport of the People’s Republic of China. Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. People’s Communications Press: Beijing, China, 2009.

- JTG 3430-2020; Ministry of Transport of the People’s Republic of China. Test Methods of Soils for Highway Engineering. People’s Communications Press: Beijing, China, 2020.

- Zhao, Z.; Yang, X.J.; Shi, Q.H.; Fan, H.H.; Liu, J.F. Unconfined compressive strength of phosphogypsum/lignin solidified lead contaminated soil. J. Civ. Environ. Eng. 2022, 1–12, (In Chinese and English). [Google Scholar]

- Li, W.T.; Yi, Y.L.; Puppala, A.J. Effects of curing environment and period on performance of lime-GGBS-treated gypseous soil. Transp. Geotech. 2022, 37, 100848. [Google Scholar] [CrossRef]

- JTG 3610-2009; Ministry of Transport of the People’s Republic of China. Technical Specifications for Construction of Highway Subgrades. People’s Communications Press: Beijing, China, 2009.

- Zhou, B. Study on Road Performance and Microstructure of Lime Phosphogypsum Stabilized Red Clay. Master’s Thesis, Guizhou University, Guizhou, China, 2022. [Google Scholar]

- Jha, A.K.; Sivapullaiah, P.V. Volume change behavior of lime treated gypseous soil—Influence of mineralogy and microstructure. Appl. Clay Sci. 2016, 119, 202–212. [Google Scholar] [CrossRef]

- Chen, L.J.; Chen, X.J.; Wang, H.; Huang, X.; Song, Y. Mechanical Properties and Microstructure of Lime-Treated Red Clay. KSCE J. Civ. Eng. 2021, 25, 70–77. [Google Scholar] [CrossRef]

- Jha, A.K.; Sivapullaiah, P.V. Physical and strength development in lime treated gypseous soil with fly ash—Micro-analyses. Appl. Clay Sci. 2017, 145, 17–27. [Google Scholar] [CrossRef]

Figure 1.

Particle size grading curve of red clay.

Figure 1.

Particle size grading curve of red clay.

Figure 2.

Improve the compaction curve of lime-fly ash soil.

Figure 2.

Improve the compaction curve of lime-fly ash soil.

Figure 3.

Relationship between UCS and phosphoric gypsum dosage.

Figure 3.

Relationship between UCS and phosphoric gypsum dosage.

Figure 4.

Testing procedures and testing equipment.

Figure 4.

Testing procedures and testing equipment.

Figure 5.

Variation Trend of Improved Soil UCS with Different Phosphategypsum Contents.

Figure 5.

Variation Trend of Improved Soil UCS with Different Phosphategypsum Contents.

Figure 6.

Variation trend of improved soil splitting strength under different phosphogypsum content.

Figure 6.

Variation trend of improved soil splitting strength under different phosphogypsum content.

Figure 7.

Variation trend of improved soil CBR under different phosphorusgypsum contents.

Figure 7.

Variation trend of improved soil CBR under different phosphorusgypsum contents.

Figure 8.

Moisture stability test: (a) Natural red clay soil; (b) 0% P (lime-ash stabilized soil); (c) 4% P; (d) 8% P; (e) 16% P; (f) 24% P.

Figure 8.

Moisture stability test: (a) Natural red clay soil; (b) 0% P (lime-ash stabilized soil); (c) 4% P; (d) 8% P; (e) 16% P; (f) 24% P.

Figure 9.

Relationships between moisture stability coefficient and phosphogypsum content.

Figure 9.

Relationships between moisture stability coefficient and phosphogypsum content.

Figure 10.

Improve the swelling and shrinking characteristics of soil: (a) The relationship between phosphogypsum content and shrinkage of soil; (b) The relationship between phosphogypsum content and swelling of soil.

Figure 10.

Improve the swelling and shrinking characteristics of soil: (a) The relationship between phosphogypsum content and shrinkage of soil; (b) The relationship between phosphogypsum content and swelling of soil.

Figure 11.

XRD test analysis of improved soil: (a) XRD patterns; (b) Component proportions; (c) XRD patterns and component proportions of soil.

Figure 11.

XRD test analysis of improved soil: (a) XRD patterns; (b) Component proportions; (c) XRD patterns and component proportions of soil.

Figure 12.

SEM images: (a) Natural red clay soil; (b) 7 d, 0% P; (c) 7 d, 4% P; (d) 28 d, 0% P; (e) 28 d, 4% P; (f) 60 d, 0% P; (g) 60 d, 4% P; (h) 90 d, 4% P.

Figure 12.

SEM images: (a) Natural red clay soil; (b) 7 d, 0% P; (c) 7 d, 4% P; (d) 28 d, 0% P; (e) 28 d, 4% P; (f) 60 d, 0% P; (g) 60 d, 4% P; (h) 90 d, 4% P.

Table 1.

Basic physical indicators of red clay.

Table 1.

Basic physical indicators of red clay.

| Natural Moisture Content/% | Optimal Moisture Content/% | Maximum Dry Density/(g·cm−3) | Liquid Limit/% | Plastic Limit/% | Plasticity Index | CBR/% |

|---|

| 29.78 | 26.7 | 1.518 | 66.87 | 33.96 | 32.91 | 8.3 |

Table 2.

Fly ash performance indicators.

Table 2.

Fly ash performance indicators.

| Experimental Indicators | Experimental Basis | Specification Standard | Result |

|---|

| SiO2 (54.23), Al2O3 (13.45), Fe2O3 (4.47)Total content/% | T0816 | >70 | 72.15 |

| Firing loss/% | T0817 | ≤20 | 4.8 |

| Moisture content/% | T0801 | ≤1.0 | 0.17 |

| 0.3 mm Sieve pass rate/% | T0818 | ≥90 | 100 |

| 0.075 mm Sieve pass rate/% | T0818 | ≥70 | 89.6 |

Table 3.

Main chemical composition and basic physical indexes of phosphogypsum.

Table 3.

Main chemical composition and basic physical indexes of phosphogypsum.

| CaO | P2O5 | SO3 | MgO | Na2O | pH | Radioactivity |

|---|

| 38.74% | 0.57% | 52.46% | 0.18% | 0.31% | 3.6 | None |

Table 4.

Shrinkage index of improved soil.

Table 4.

Shrinkage index of improved soil.

| Phosphogypsum Content/% | Initial Moisture Content/% | Linear Shrinkage/% | Shrinkage Limit/% | Shrinkage Coefficient |

|---|

| 0 | 31.9 | 2.63 | 20.55 | 0.154 |

| 4 | 34.3 | 5.50 | 20.06 | 0.368 |

| 8 | 35.1 | 6.30 | 18.83 | 0.421 |

| 16 | 36.0 | 6.70 | 18.79 | 0.486 |

| 24 | 36.6 | 7.08 | 18.33 | 0.487 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).