3.1. Meta-Aramid

Meta-aramid (m-aramid) fibres are composed of poly(m-phenyleneisophthalamide) and were the first aramid fibres to be released onto the market [

1]. Today, there are two commercial versions of m-aramid fibres: Nomex

® from DuPont and Conex

® from Teijin. Kermel

® fibre, commercialized by Rhodia, is sometimes classified as an m-aramid fibre, but its structure is different, which affects its electrospinning process; therefore, it is covered in a separate section (

Section 3.2). The structure of m-aramid is aromatic, containing a large number of double bonds and high C/H ratios [

1]. This provides the polymer with inherent flame resistance. M-aramid is also highly temperature resistant. The polymer maintains its useful properties up to 370 °C and displays self-extinguishing properties upon ignition. As a result, m-aramid nanofibres are a popular choice in applications where flame resistance is required for a nanofibrous membrane. For example, Merighi et al. [

43] studied the use of m-aramid nanowebs to act as a wood-surface flame retardant. Other applications of m-aramid nanofibres include antimicrobial water filters [

8], lithium-ion batteries [

7], and breathable waterproof membranes [

21].

Multiple studies have confirmed the feasibility of electrospinning m-aramid. M-aramid is readily soluble in many polar aprotic solvents including dimethylacetamide (DMAc), dimethylformamide (DMF), dimethyl sulfoxide (DMSO), and N-methyl-2-pyrroidone (NMP) [

11]. However, due to the highly crystalline structure of the polymer, the use of solvent alone can only swell the polymer. To fully relax and dissolve m-aramid, the solvent is combined with alkaline salts such as lithium chloride and calcium chloride. In this process, the lithium and calcium ions link to the carbonyl group in the solvent, leaving the chloride ions free to interact with the m-aramid polymers. These ionic interactions allow for improved solubility of the polymer in the solvent. DMAc and LiCl is the most common solvent system reported for m-aramid polymers and was found to be the best solvent system for producing m-aramid nanofibrous webs with good mechanical properties (e.g.,

Figure 2) [

11]. NMP is also an effective solvent for dissolving m-aramid with both LiCl and CaCl

2, but the solvent properties made electrospinning difficult. Notably, DMF and DMSO are less effective at dissolving m-aramid. Both solvents require high concentrations of salt to fully dissolve m-aramid at a 10 wt% concentration. The addition of salt changes the viscosity and conductivity of the solution, which impacts the diameter of the resultant nanofibres. With an increase in the concentration of LiCl salts, the average fibre diameter increases [

11]. Generally, optimal concentrations of LiCl range from 0.5 wt% to 4 wt% for solutions containing between 10 wt% and 14 wt% m-aramid [

11,

43]. As a starting point to produce m-aramid polymer solutions, a variety of polymer sources were used. In many cases, m-aramid polymer (presumably in powdered form) was purchased directly for use [

7,

9,

12,

21,

43,

44]. However, there were instances in which m-aramid fibres were used as a polymer source for the solution [

8,

11,

45,

46,

47]. Moreover, some studies chose to synthesize their own m-aramid prior to electrospinning [

48,

49].

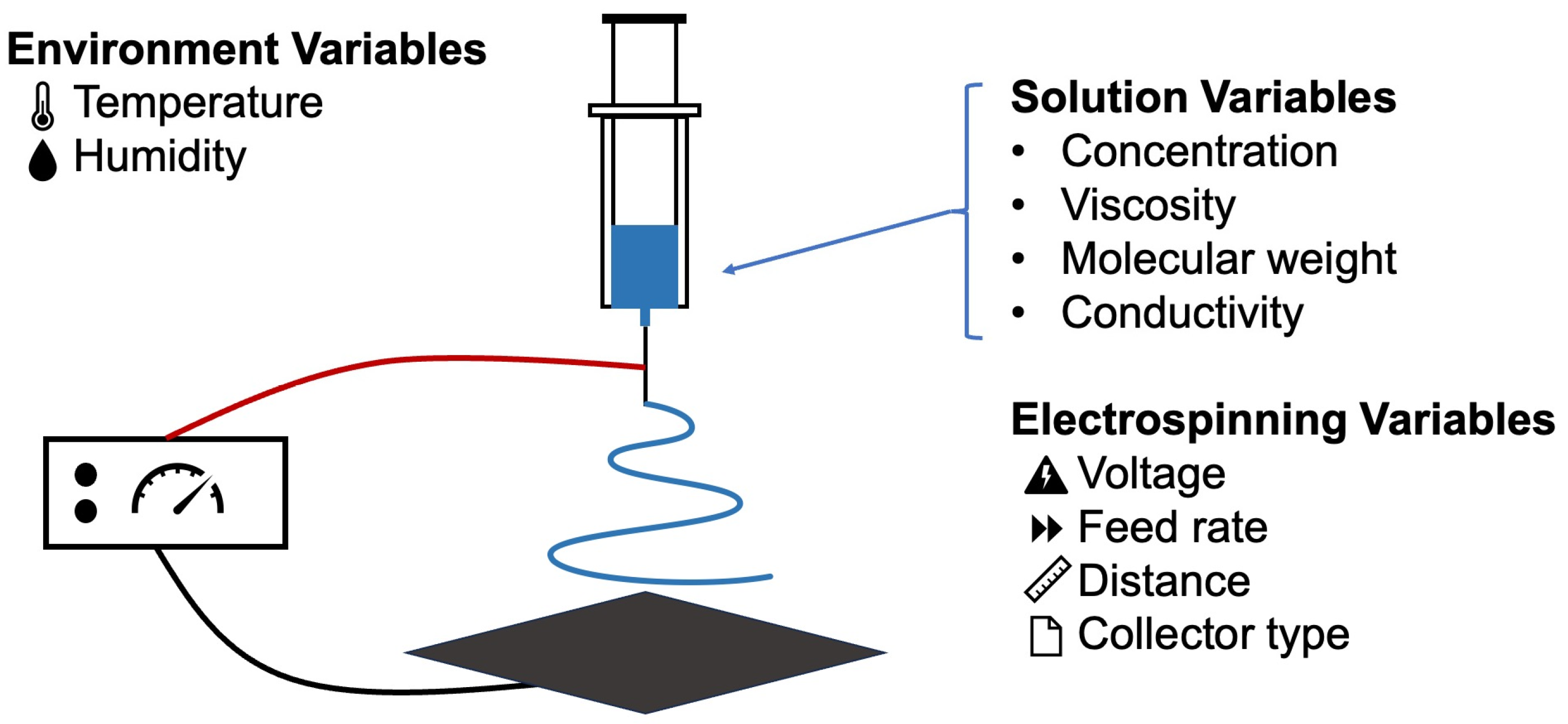

Although m-aramid has been electrospun by many different researchers, the exact parameters for electrospinning have varied widely between individual studies.

Table 1 describes some of the different electrospinning conditions for producing m-aramid nanofibres. Voltage is one parameter that has a significant impact on fibre diameter. The electrospinning of m-aramid fibres using CaCl

2 and DMAc solvent at voltages of 12 kV and 15 kV produced average fibre diameters of 150 nm and 121 nm, respectively [

12]; a difference of only 3 kV created a variation of 20% in the average fibre diameters. Other studies used much higher voltages. Merighi et al. [

44] found that 20–25 kV was optimal to electrospin a similar concentration of m-aramid fibres (14 wt%) with diameters of 175 nm. In most instances, optimal voltages for electrospinning m-aramid polymers were between 15 and 25 kV [

10,

11,

12,

43,

44]. Variations in the polymer concentration, salt type, distance, flow rate, and ambient parameters may explain similar fibre diameters reported at different voltages. Flow rates for the electrospinning of m-aramid fibres are variable, with values between 1.6 and 25 µL/min being used to supply sufficient amounts of polymer solution to the spinneret [

9,

10,

11,

12]. Distance also varied, with a maximum distance of 20 cm being used for a needle-based electrospinning setup [

10].

The mechanical strength of m-aramid nanofibres has been widely investigated in the literature, for both as-spun m-aramid nanofibres and treated electrospun nanofibres. The tensile strength of m-aramid nanofibrous membranes electrospun at three different concentrations (9, 11, and 13 wt%) in a DMAc/LiCl solvent system was compared by Yao et al. [

11]. It was found that the 11 wt% solution produced the nanofibrous membrane with the highest elongation at break and modulus, with a breaking strength of 1.5 mPa. At a higher concentration of 13 wt%, it was theorized that the viscosity of the solution was too high, slowing down the jet, leading to weaker conglutinated interactions among fibres. This resulted in a breaking strength of 0.25 mPa. The orientation of the nanofibres in the membrane was also found to have an effect on the overall strength of the membrane [

43]. Aligning the nanofibres using a rotating collector was found to increase the elastic modulus by five times for the aligned nanofibrous mat compared to the randomly oriented mat (5000 and 1000 mPa, respectively). However, when measuring the oriented membrane in the transverse direction, the mat was so weak that it could not be properly attached to the testing frame.

Compared to conventional m-aramid fibres, initial investigations of the mechanical strength of as-spun m-aramid nanofibres found that nanofibrous membranes displayed reduced elastic modulus and strength [

45]. This was attributed to a more segmented crystalline structure of the spun polymer. This lower mechanical performance limits the practical usage of electrospun m-aramid nanofibres, particularly in applications where high strength is required. One of the reasons identified for the reduced crystallinity of the as-spun nanofibrous mats is that the salts added into the polymer solution to assist with dissolution remain in the nanofibrous mats at high concentrations [

45]. For example, the addition of 2 to 3.5 wt% LiCl in a solution of 14 wt% m-aramid produced a nanofibrous membrane with between 12.5 and 20 wt% LiCl [

9]. The presence of this salt disrupts the formation of crystalline regions within nanofibres [

9,

45]. The hygroscopic nature of LiCl also leads to higher water adsorption, which can cause fibre disentanglement when the material is under tensile deformation [

9]. Depending on the amount of salt, it may also increase the diameter of the nanofibres.

As a result, post-treatments of m-aramid nanofibrous membranes are being investigated to increase the crystallinity of the nanofibers and improve the mechanical properties of m-aramid nanofibrous mats. One study used a washing treatment to remove excess salt from the nanofibrous mats and improve the mechanical properties [

9]. The m-aramid nanofibrous mats were washed in distilled water and dried at 70 °C. The Young’s modulus increased from 170 mPa to 752 mPa after washing, confirming the significant effect of the presence of LiCl on the mechanical properties of the nanofibrous mat and showing the efficiency of the washing treatment at improving the performance of the nanofibrous mats. The annealing of m-aramid nanofibrous mats was also attempted [

47]. However, a heat treatment below 200 °C showed little effect on the mechanical properties of the nanofibres. Above 200 °C, the properties of the membrane decreased. Conversely, microwave irradiation was able to remove excess solvent and salt present in the as-spun nanofibrous membrane, leading to an increase in tensile strength of 2.8 times compared to the untreated membrane [

49]. However, this method was highly energy intensive. A lower-energy, solvent-assisted heat treatment was proposed as an alternative method [

45]. Electrospun membranes were submersed in a solution of DMAc, water, and ethylene glycol before being heat-treated. It was found that a heat treatment of 120 °C was optimal to encourage crystallization within the nanofibres. The resultant membrane showed an increase in tensile strength and modulus compared to the untreated and heat-treated mats. The Young’s modulus was 13.5 times and 1.7 times higher than that of the untreated and heat-treated membranes, respectively. It also showed improved chemical resistance. Due to the interest in m-aramid nanofibres as high-strength scaffolds for nanocomposites [

7,

8] and coaxial nanofibres [

46], finding efficient methods to increase the crystallinity and strength of the membranes is vital in ensuring their relevance to practical applications.

Beyond optimizing the mechanical properties of m-aramid nanofibrous membranes, multiple studies have conducted other manipulations in membrane properties to make nanofibrous m-aramid mats more suitable for specific applications. One of the major advantages of working with the m-aramid polymer is its excellent resistance to heat and flame. Therefore, ensuring the heat and flame resistance of nanofibrous mats is important for many applications [

10,

43]. The thermal degradation of m-aramid nanofibrous mats was found to be similar to that of the corresponding staple fibre, with weight loss occurring at 100 °C due to solvent evaporation and again at 430–450 °C due to chain scission [

10]. In contrast, the heat shrinkage behaviour of the m-aramid nanofibrous membranes was much larger compared to microfibrous mats. In 30 min intervals, the membrane was exposed to temperatures between 200 and 350 °C. At 200 °C, the shrinkage was 7.5%, but increasing the temperature to 350 °C resulted in a heat shrinkage of 50.4%. Work was conducted to try reducing the thermal shrinkage of m-aramid nanofibrous membranes. In one study, m-aramid/polysulfone-amide (PSA) membranes with different ratios of the two polymers were electrospun to see if the blending would improve the dimensional stability of the resulting mats after heat exposure [

50]. After 200 h in a 250 °C oven, the 100% m-aramid nanofibrous membranes had shrinkage of 10% and 6% in the warp and weft directions. In contrast, a 7/3 blend of m-aramid/PSA resulted in a 6% shrinkage in both directions, and blends of 5/5 and 3/7 displayed no shrinkage after heat exposure. PSA is a flame-resistant polymer, therefore its addition to the nanofibrous membrane should not affect the flammability of the membrane [

51]. However, the flame resistance of the membrane was not tested in this study [

50]. The addition of SiO

2 nanoparticles also reduced the shrinkage of the m-aramid nanofibrous membrane, providing thermal stability without shrinkage up to 260 °C [

7]. Without the SiO

2, the membrane began shrinking at 260 °C. In addition, the membranes containing SiO

2 showed an increase in tensile strength compared to the pure m-aramid membranes. This is attributed to the van der Waals forces, electrostatic attraction, and polarity of the polymers and SiO

2, which may form a three-dimensional structure allowing for better dispersion of stress in the polymer and nanoparticle network. The pure m-aramid membrane had a tensile strength of 8.75 MPa, whereas the membrane containing 6 wt% SiO

2 had a strength of 18.14 MPa. However, above 6% SiO

2, the membrane strength began to decrease as the nanoparticles agglomerated within the structure.

The flame resistance of m-aramid nanofibres has also been investigated, particularly for applications as a flame-retardant coating on other materials. When m-aramid nanofibrous membranes are used to improve the flame resistance of another material, the fibre alignment and the attachment method to the material both impact the flame resistance of the system [

9,

43,

44]. Attaching an m-aramid nanofibrous membrane to the surface of wood was found to improve its flame resistance compared to untreated wood [

44]. However, it was found that randomly oriented membranes were more effective than aligned nanofibrous membranes at improving flame resistance [

43]. During exposure to flame, a buildup of gases between the wood and nanofibrous membrane led to disruptions in the m-aramid layer, exposing the wood to flame. Since the randomly oriented mat had improved mechanical properties in all directions, it was more resistant to failure, thus providing better flame protection to the wood. In contrast, the aligned membrane had poor mechanical strength in the transverse direction, leading to a faster failure time. Mazzocchetti et al. [

9] studied the flame resistance of m-aramid nanofibrous mats bonded to carbon fibre-reinforced composites. The presence of the nanofibrous mats did not improve the flame resistance of the material, but this behaviour was attributed to an outer layer of epoxy present on the samples, which burned before the flame reached the nanofibrous membrane. The only improvement provided by the m-aramid nanofibrous mat was the time to ignition, which increased by 50 s compared to the original carbon fibre-reinforced composite.

For liquid filtration applications, the pore size and permeability of the membrane are important in ensuring that the membrane can perform effectively. The nanofibre diameter distribution and membrane thickness are the main factors determining pore size and permeability [

8,

10]. In general, m-aramid nanofibrous membranes have a narrow pore size distribution compared to micro-scale fibrous filtration media, with pore sizes between 0 and 2 µm [

8,

10]. Pore size distribution decreases as a smaller distribution of nanofibre diameters is achieved by optimizing the concentration of m-aramid in the spinning solution [

8]. Moreover, as membrane thickness increases, average pore size gradually decreases [

10]. However, in m-aramid nanofibrous membranes, it was observed that pore size only decreased up to a membrane thickness of 8.95 µm, after which the pore size plateaued [

10]. In general, m-aramid nanofibrous membranes perform well compared to conventional liquid filters. Liquid permeability was found to be improved in m-aramid nanofibrous membranes compared to commercial glass fibre water filters [

8]. For applications for air filtration, the water vapour permeability of m-aramid was investigated for a breathable, temperature-resistant membrane [

10]. The water vapour permeability was measured to be 7650 g/m

2, nearly twice the minimum value for a breathable membrane (4000 g/m

2) [

52]. However, the addition of PSA used to improve the dimensional stability led to increased pore sizes and decreased mechanical strength in the nanofibrous membranes.

M-aramid nanofibrous membranes have also been adapted for specific applications. M-aramid nanofibrous membranes were investigated as a precursor to N-halamine, for the production of an antimicrobial water filter [

8]. Here, m-aramid nanofibres were submerged in a solution of diluted bleach to form an N-halamine structure. The chlorinated membrane was able to be recharged with 98% efficacy. Moreover, the membrane was able to fully remove both

Escherichia coli and

Staphylococcus aureus from water through a non-pressure-driven filtration process without contaminating the water with chlorine. M-aramid nanofibres were also produced with a helical morphology through co-electrospinning with an m-aramid core and thermoplastic polyurethane outer shell [

46]. The production of helical nanofibres can be used in applications where high fibre resiliency is needed. M-aramid was also electrospun as a composite with SiO

2 nanoparticles in order to improve the conductivity and electrolyte uptake of the membrane [

7]. The presence of SiO

2 nanoparticles increased the wettability, porosity, breaking strength, conductivity, and dimensional stability. Silver nanoparticles have also been added to m-aramid nanofibrous membranes in order to produce a high-performance flexible pressure sensor [

53]. The m-aramid membrane contributed excellent mechanical and breathable properties to the sensor, making it suitable for wearable applications.

In summary, M-aramid nanofibrous membranes have been successfully produced via electrospinning using a variety of methods. The optimization of the electrospinning process through solvent, salt content, polymer concentration, and electric field behaviour has been demonstrated [

9,

11,

46]. Moreover, methods to improve the mechanical properties and thermal stability of the nanofibres continue to improve [

7,

45,

49,

50]. M-aramid nanofibres are now being studied for specific applications, and the increasing interest in m-aramid nanofibrous composites is allowing for the enhancement of the nanofibrous membrane properties.

3.2. Polyamide-Imide

Polyamide-imide (PAI) is commercialized under the trade name Kermel

® [

1]. The polymer combines the properties of polyimides and polyamides, providing excellent strength and thermal stability [

17]. As a result, PAI nanofibres are a popular choice in high-temperature filtration applications [

19]. In electrospinning, PAI is also considered a useful alternative to polyimide, as it displays similar properties but has enhanced solubility [

19]. While PI nanofibres cannot be electrospun directly, PAI may be directly dissolved in solvent and electrospun. PAI is soluble in a variety of solvents including DMAc, DMF, DMSO, pyridine, cyclohexanone, and tetrahydrofuran [

54]. The electrospinning of PAI has been performed via dissolution in DMF at 25 wt% [

21], in a 34 wt% NMP/DMF mixture [

19], and in 1,3 dimethyl-2-imidazolidinone [

20]. The use of various solvents to produce PAI solutions allows enhanced customizability of the solutions and resultant nanofibres as well as the potential for polymer blend nanofibres, as other polymers may be soluble in the same solvents.

One advantage of the excellent solubility of PAI in various solvents is that a mixed-solvent system can be used to alter the nanofibre morphology during electrospinning [

19]. A mixed solvent system of NMP and DMF under high humidity produced biomimetic pine needle-like fibres with a grooved surface morphology (

Figure 3). Upon exposure to high humidity, the DMF was replaced by water and formed a porous semi-solid structure. Then, the water gradually replaced the NMP, and the pores on the surface of the jet became stretched by the electrostatic repulsive forces, leading to a grooved fibre structure. The grooved structure increased the specific surface area to allow for greater adsorption and retention of particulate matter during air filtration. Electrospinning within a humid environment also led to the formation of curled fibres, which produced a highly porous membrane. Increased specific surface area and membrane porosity contributed to improved filtration and decreased pressure drop, respectively.

PAI may also be electrospun from a precursor and then converted to PAI via post-treatment [

16]. Traditionally, PAI is difficult to synthesize. However, Duan et al. [

25] considered a simplified method to synthesize PAI nanofibres inspired by the two-step process for polyimide fabrication. Here, an amide-containing diamine was reacted with a dianhydride to produce a precursor solution of amide-containing polyamic acid. The precursor solution was diluted with DMAc and DMSO and electrospun at 20 kV with a distance of 25 cm and a flow rate of 0.70 mL/h. They used a disk-shaped rotating collector and a stationary collector to produce aligned and randomly oriented fibres, respectively. The membrane was then thermally treated under a nitrogen atmosphere to produce PAI. Thermal treatment was successful up to 450 °C. Above this temperature, the fibres displayed poor thermal stability. PAI nanofibres produced via electrospinning showed improved tensile strength and modulus compared to PAI films produced in the same way.

The strength of electrospun PAI nanofibres is significantly higher than that of other polymeric nanofibres including nylon, PBO, and polyimide [

16]. Further improvements in the mechanical properties of PAI nanofibres may be achieved by thermal annealing at high temperatures. Aligned nanofibrous PAI membranes produced from a precursor and annealed at a temperature of 400 °C had a strength of 892 ± 15 MPa. This was a significant improvement compared to the strength of a membrane which was annealed at 350 °C, with a strength of 504 ± 4 MPa. However, further increasing the annealing temperature to 430 °C decreased the tensile strength of the nanofibrous membrane to 702 ± 6 MPa. Fibre alignment also altered the mechanical strength of the fibres, with aligned fibres showing much greater tensile strength and modulus compared to randomly aligned fibres. For example, a mat with randomly aligned nanofibres annealed at 400 °C had a strength of 120 ± 10 MPa, several times lower than the oriented nanofibrous mat.

The high strength of PAI’s nanofibres also makes them an excellent candidate for reinforcement with other nanofibrous materials. PAI nanofibres have been used as a reinforcement in an electrospun polytetrafluoroethylene (PTFE) membrane, where it was found to significantly increase the strength of the nanofibrous membrane at a 3% concentration [

17]. The PAI precursor was blended with PTFE and electrospun at a voltage of 12 kV onto a stationary collector. The membrane was then heat-treated at 380 °C for 10 min to obtain a PTFE/PAI composite. The addition of PAI was found to increase the thermal stability and strength of the nanofibrous membranes. At 20 wt% PAI, the randomly oriented membrane had a strength of 19 MPa, which was a 31% increase compared to the 100% PTFE membrane. However, the PAI led to significant changes in morphology. Where pure PTFE nanofibres showed even diameters, increasing amounts of PAI produced thinner fibres with a wider diameter distribution.

The feasibility of industrial scale-up for PAI fibres has also been examined by electrospinning PAI nanofibres on a wire-based electrospinning setup [

20]. A solution of PAI was electrospun on an Elmarco Nanospider

TM to determine the viability of the industrial scale-up of aramid nanofibres. While needle-based electrospinning is suitable for preliminary studies on nanofibre production, the throughput is extremely small and thus unsuitable for industrial applications. Needleless electrospinning allows for the free formation of jets across the surface of a polymer solution [

55]. This allows jets to be configured optimally, leading to the most efficient spacing of jets for multi-jet electrospinning. Wire-based electrospinning is a technique patented by Elmarco; it involves a stationary wire electrode that is coated in polymer solution via a moving carriage [

56]. Jets form across the surface of the wire and are distributed on a collector, which is positioned above the wire. Oertel et al. [

20] used the enhanced productivity of the wire-based electrospinning setup to determine the feasibility of electrospinning PAI nanofibres at an industrial scale. A solution of PAI in 1,3-dimethyl-2-imidazolidinone is prepared with a viscosity of 60 Pa.s. Voltage, airflow, distance, relative humidity, and temperature were manipulated in order to determine the best processing parameters for PAI. It was found that relative humidity, voltage, and distance had the greatest effect on the mean fibre diameter. Relative humidity and distance were observed to have a positive effect on the mean fibre diameter. In contrast, an increase in voltage was found to slightly decrease the mean fibre diameter. Within the set parameters, increasing airflow and temperature showed no effect on the mean fibre diameter.

Finally, post-treatment of PAI has been used to increase the hydrophilicity of PAI nanofibrous mats [

21]. PAI nanofibres were electrospun from a solution of PAI and DMF using a needle-based electrospinning setup. Nanofibrous membranes then underwent atmospheric-pressure plasma treatment at various times (60, 120, 180, and 240 s). Longer atmospheric-pressure plasma treatments were found to alter the chemical structure of the fibres, as well as the surface morphology. From these observations, it was found that a treatment time of 120 s was optimal to improve hydrophilicity whilst minimizing etching and oxidative reactions. Increasing the time of the atmospheric-pressure plasma treatment was found to decrease the water contact angle, but it increased again above 120 s. Therefore, it was concluded that 120 s of plasma treatment time was optimal to improve the hydrophilicity of the nanofibres.

In summary, the electrospinning of PAI has progressed into many specific applications. The ease of solubility of the polymer allows it to be readily electrospun from solution [

54]. Furthermore, the cost-effective alternative to electrospinning from a precursor has also been performed for PAI [

16]. A major advantage of electrospun PAI nanofibres is their high strength relative to nanofibres spun from other polymers. This makes them an excellent candidate for applications requiring high strength, as well as for reinforcement in nanofibrous membranes made from other polymers. The scale-up of PAI polymers has also been studied, with effective parameters found to produce PAI nanofibrous membranes using needleless electrospinning [

20]. However, the performance characterization of membranes electrospun on the needleless setup has not been performed. Moving forward, it will be important to understand whether PAI nanofibrous membranes electrospun on a needleless setup can exhibit the same mechanical and thermal characteristics as those electrospun using a needle-based setup.

3.3. Para-Aramid

Para-aramid (p-aramid) is a class of highly crystalline high-performance fibres with superior mechanical properties and excellent chemical resistance [

1]. The most popular p-aramid is poly-paraphenylene terephthalamide (PPTA), which has been commercialized by DuPont as Kevlar

® and by Teijin as Twaron

®. Due to its high crystallinity, the fibre is especially useful for applications requiring ballistic resistance [

3]. P-aramid has high thermal resistance, with a continuous operating temperature of 190 °C and a melting temperature of 400 °C [

1]. It is also inherently flame-resistant. Unfortunately, the high crystallinity and lack of sidechain groups in the p-aramid polymer make it very difficult to dissolve [

3]. As a result, electrospinning from solution is very difficult to achieve. The earliest record of electrospinning p-aramid involved dissolution in a concentrated solution of sulphuric acid at a high temperature and with a grounded water bath as a collector [

57]. However, this method was unable to allow a continuous electrospinning process. Moreover, the use of concentrated sulphuric acid as a solvent for p-aramid makes industrial scale-up difficult, as the solvent is corrosive.

Methods to produce p-aramid nanofibres without the use of sulphuric acid have also been explored. For the most part, p-aramid nanofibres are synthesized using alternative methods such as top-down dispersal [

58], polymerization-induced self-assembly [

14], and centrifugal spinning [

13]. While bottom-up methods showed some promise, they still resulted in nanofibres with large diameters and low tensile strength [

14]. Likewise, centrifugal spinning suffers from high energy consumption and faces the issue of equipment corrosion. Therefore, investigation into the electrospinning process is still useful. Within electrospinning, two major discoveries have encouraged the use of this method to produce p-aramid nanofibres.

Yao et al. [

15] determined that anisotropic solutions of p-aramid could be more readily electrospun at higher concentrations compared to the traditional isotropic solutions (

Figure 4). The p-aramid polymer was dissolved in sulphuric acid to form both isotropic p-aramid solutions at 2, 5, and 7 wt% of solid content and anisotropic solutions at 15, 17, and 19 wt%. The solution was electrospun using a needle-based electrospinning setup. Fibres were collected into a water bath for coagulation, which was necessary due to the non-volatility of sulphuric acid. A heating band was also used to maintain an electrospinning solution temperature between 80 and 90 °C. Below 80 °C, anisotropic solutions of p-aramid would begin to solidify, and above 90 °C, the solution would begin to degrade. After electrospinning, fibres had to go through an additional drying step. It was observed that the jet had minimal whipping due to high voltage and low distances (2–8 cm), which formed a very strong electric field. At lower concentrations of isotropic p-aramid solutions, only droplets were observed. At 7 wt%, some very short fibres were seen, but breakages of the solution jet prevented continuous spinning. The entanglement of the polymer at higher p-aramid concentrations in anisotropic solutions allowed for the formation of continuous fibres. However, these fibres showed large distributions in diameters, between 16 and 300 µm, which was attributed to branching during the electrospinning process. Although some nanoscale p-aramid fibres were observed, the large diameter distribution, high voltages, use of corrosive solvent, and jet breakage inhibited the continuous production of large amounts of nanofibres. Therefore, although using higher polymer concentrations in anisotropic solutions was successful in the formation of fibres via electrospinning, a continuous and scalable process could not be achieved.

Another innovation in the electrospinning of p-aramid involved the use of side-chain substitutions to improve the solubility of the polymer [

3]. Through N-substitutions, the solubility of p-aramid was improved. Side-chain substitutions were performed on conventional Kevlar

® (p-aramid) fibres. The side-group substitutions were confirmed with NMR. The allyl-, propyl-, and pentenyl-functionalized fibres obtained were soluble in DMAc, DMF, and NMP. Benzyl-functionalized p-aramid showed solubility in DMAc and NMP. Finally, methyl-functionalized polymers were soluble only in NMP at high temperatures. The solution was then electrospun via needle-based electrospinning onto a stationary aluminum collector at a concentration of 20 to 50 wt%, a voltage of 20 kV, a flow rate of 0.1 mL/h, and a distance of 10 cm. In this instance, a coagulating water bath was not needed, as volatile solvents were used. Electrospinning at high voltage and low flow rate was generally successful, and fibres with an average diameter of 68 nm were produced using the propyl-functionalized p-aramid DMF at a concentration of 20 wt%. Fibre diameter was found to increase with polymer concentration, with a concentration of 50 wt% creating fibres with a diameter of 1.75 µm. This study provided a first step in the scalable and continuous electrospinning of p-aramid polymers. However, it did not fully explore the impact of the side-group substitutions on the mechanical strength of the resultant nanofibres. Since the addition of side groups can increase amorphous regions of the fibre, it is likely that this method would have a negative impact on the strength of the nanofibres.

In summary, compared to the electrospinning of other high-performance nanofibres, p-aramid nanofibres show considerable challenges due to the high crystallinity and low solubility of the polymer. The use of anisotropic solutions may improve the electrospinnability of the polymer but still requires the use of a highly corrosive solvent [

15]. In contrast, side-chain substitutions provide a promising method to improve the electrospinning of p-aramids, as the functionalized fibres can be dissolved in common solvents [

3]. Further investigation into the impacts of side-chain substitutions on the properties of the resulting nanofibrous mats will be important in determining the best applications for these. The use of post-treatments to improve the mat performance will also be a vital step to further optimize the p-aramid nanofibres.

3.4. PBO

Poly(p-phenylene-2,6-benzobisoxazole) (PBO) is a rigid-rod polymer with excellent chemical, thermal, and mechanical properties [

1,

59]. The conventional fibre is commercially produced by Toyobo under the trade name Zylon

®. The polymer has very high thermal resistance and will not degrade in air until 600 °C [

1]. PBO is also flame-resistant and has self-extinguishing properties. Although the rigid rod structure imparts many desirable characteristics to the polymer, such as excellent mechanical properties, it also makes the processing of PBO very difficult. PBO is only soluble in strong acids, making it difficult to electrospin directly [

37,

59]. Instead, PBO nanofibres can be electrospun indirectly either from poly(o-hydroxy-amide)s (OH-PA) or poly(o-hydroxy-amic acid)s (OH-PAA) [

25]. These precursors are soluble in organic solvents and can be transformed into PBO nanofibres via heat treatment processing after electrospinning [

25,

59].

The most common method of electrospinning PBO from precursors involves the electrospinning of an o-hydroxy aromatic monomer, such as poly(o-hydroxy-amide) (OH-PA) or poly(o-hydroxy-amic acid) (OH-PAA), which can be dissolved in common organic solvents, electrospun, and then thermally converted to PBO nanofibres [

25]. However, using the OH-PA precursor can be problematic due to its low molecular weight, leading to poor mechanical properties of the resultant nanofibres. However, the lower molecular weight of the precursor can also lead to thinner nanofibres, which should be kept in mind while optimizing nanofibre diameters [

23]. OH-PAA, having a higher molecular weight, can be used to electrospin PBO nanofibres with higher thermal resistance and improved mechanical properties. Zhang et al. [

25] used a solution of 6 wt% OH-PAA in DMAc with cetyltrimethylammonium bromide (CTAB) to electrospin PBO precursor nanofibres. The solution was electrospun at 20 kV with a distance of 20 cm and collected on a rotating disc to form a nanofibre belt. The nanofibres were then heated under a nitrogen atmosphere and annealed at various temperatures to form PBO nanofibres. To assess the mechanical and thermal properties, a thermal–mechanical analyzer was used. The tensile testing of the aligned nanofibre belts was performed at various temperatures. It was observed that the modulus was well retained as the heat increased, with an 86% modulus retention at 350 °C. The test was performed up to 500 °C, where the modulus retention was still over 50%. The use of a high-molecular-weight precursor allowed for the formation of heat-resistant and high-strength PBO nanofibres with stability up to 643 °C.

However, the use of the o-hydroxy monomer as a precursor to PBO can be problematic as it is difficult to synthesize, leading to high costs that limit the scalability of the process [

29,

60,

61]. Duan et al. [

59] attempted to create PBO nanofibres using inexpensive precursor materials. Monomers of 4, 4′-diamino-3, 3′-dimethoxydiphenyl (DMOBPA), and isophthaloyl dichloride (IPC) were used in combination with DMAc, pyridinium, and LiCl to prepare a solution of methoxy-containing polyaramide (MeO-PA). The solution was electrospun on a needle-based electrospinning setup at a voltage of 30 kV, a flow rate of 0.8 mL/h, and a distance of 30 cm. The mat was then post-treated to remove LiCl and pyridinium and heat-treated under a nitrogen atmosphere. FTIR analysis indicated that a temperature of 350 °C was sufficient to transform the precursor to PBO. This method provides an inexpensive way to produce PBO nanofibres from an electrospun precursor. However, the low molecular weight of the precursor compromised the mechanical strength of the resultant nanofibres [

24].

Combinations of both the high molecular weight OH-PAA and the inexpensive DMOBPA were also used to produce an affordable PBO nanofibre without compromising the mechanical strength [

24]. The synthesized precursor, methoxy-containing polyamic acid (MeO-PAA), had a higher intrinsic viscosity than OH-PAA or MeO-PA and thus an increased molecular weight. MeO-PAA was electrospun onto a rotating disk collector and then heat-treated to form the ring structure of PBO. However, a direct transformation to PBO was not observed. The MeO-PAA was converted to methoxy-containing polyimide (MeO-PI) at 350 °C and to poly(imide-

co-benzoxazole) (PI-

co-PBO) at 450 °C and 500 °C. It is suspected that more energy is required to fully convert MeO-PI into PBO, but this was not investigated in the study. The PI-

co-PBO nanofibres were tested for tensile strength and thermal resistance. The nanofibres demonstrated thermal resistance above 500 °C, but the thermal decomposition temperature was approximately 50 °C lower than that of PBO nanofibres directly spun from the OH-PAA precursor. The tensile strength of the PI-

co-PBO nanofibrous belts was the highest after a heat treatment at 450 °C, which resulted in a strength of 559 MPa. Compared to the tensile strength of other high-performance films and fibres, including m-aramid, pure PBO, and multiwalled carbon nanotubes, the tensile strength of PI-

co-PBO was the highest that had been observed. The thermomechanical properties of the PI-

co-PBO were slightly lower than that of the pure PBO nanofibres, with only a 76% modulus retention at 300 °C. However, the nanofibres were still sufficiently heat resistant and better maintained their strength and modulus at high temperatures when compared with other nanofibres.

In summary, the literature reflects a variety of methods to electrospin PBO from precursors, with good consideration of how each precursor type affects both the performance and scalability of the process [

24,

25,

59]. Given the high temperature resistance and excellent mechanical properties that have been displayed by PBO nanofibres, this type of nanofibre would be suitable for several applications where high heat and durability are primary concerns. Investigations into the porosity and filtration performance of PBO, as well as the potential for composite PBO nanofibre materials, will be interesting paths forward to progress the research on PBO and determine suitable applications.

3.5. PBI

Polybenzimidazole (PBI) was developed in the 1960s; it has excellent mechanical, chemical, and thermal properties [

62]. The polymer has a high glass transition temperature of 450 °C and a degradation temperature of 580 °C [

1]. Due to its high thermal resistance, PBI lends itself to many applications for nanofibrous membranes. PBI nanofibrous membranes have been studied for applications including lithium-ion battery separators, fuel cells, water electrolyzers, respiratory masks, and carbon nanofibre precursors [

26,

28,

30,

31,

32]. PBI is readily dissolved in DMAc alone and in the presence of aprotic salts such as LiCl and LiBr [

26,

63,

64]. The earliest reported method for electrospinning PBI fibres involved a solution of 20 wt% PBI dissolved in DMAc and 4 wt% LiCl in a nitrogen atmosphere under high temperature [

63]. A top-down electrospinning setup was used, where the polymer solution was contained in a glass pipette with a small opening, and the positive charge was supplied by a wire immersed directly in the polymer solution. A grounded rotating drum was used as a collector. After collection, nanofibrous mats were washed in methanol to remove excess salt and solvent, then washed again with 50% sulphuric acid to improve the thermal shrinkage resistance. Finally, the membranes were heat-treated above the glass transition temperature of PBI. This method was able to produce randomly oriented nanofibres with diameters around 260 nm. More recently, electrospun nanofibrous mats using an altered form of PBI (m-es-PBI

net) have been produced using needleless electrospinning on the Elmarco Nanospider [

65]. The m-es-PBI

net was dissolved at 15 wt% in a solution of DMAc and ethanol and electrospun at a voltage of 70 kV and a distance of 180 mm. This produced nanofibres with diameters between 520 and 250 nm.

Optimizations of electrospinning processes and solution properties have been conducted for PBI nanofibres. However, there is a major focus on the application of PBI; therefore, studies looking at the effect of electrospinning parameters alone are not found in the literature. Instead, studies that examined PBI nanofibres for a specific application also performed optimization processes for the electrospinning process. Jung et al. [

28] observed the impact of the PBI concentration in the polymer solution on the nanofibre diameter. PBI was dissolved in DMAc at concentrations between 14 and 18 wt% and electrospun to determine the optimal polymer concentration. At PBI concentrations of 14 and 15 wt%, highly beaded nanofibres were observed [

28]. Between 16 and 18 wt%, smooth and even fibres were formed via electrospinning. It was found that 16 wt% was the optimal concentration for achieving even fibres with small diameters (90–150 nm). Higher concentrations of PBI (up to 35 wt%) have also been electrospun successfully; however, the diameter of these nanofibres was significantly higher, with a mean diameter of 729.9 nm [

26]. Jahangiri et al. [

27] used various solution concentrations, voltages, distances, and feed rates to optimize the electrospinning process for PBI nanofibres (

Figure 5). The relationship between feed rate and polymer concentration was examined; it was determined that 15 wt% PBI and 100 µL/h was the most effective combination for stable electrospinning and bead-free fibres with an average diameter of 170 nm. The effects of voltage were also characterized using voltages of 12, 15, and 18 kV. It was found that the combination of 15 wt% PBI, 15 kV, and 100 µL/h was the most effective for a reproducible electrospinning process with smaller fibre diameters.

A variety of post-treatments have been examined to enhance the mechanical properties of the PBI nanofibrous membrane [

26,

28,

32]. Chemical treatments are a common way to encourage the crosslinking of polymers after electrospinning. Yu et al. [

32] immersed an electrospun PBI mat into a solution of glutaraldehyde to encourage crosslinking and observed how the properties of the nanofibrous mat changed over time. The initial PBI nanofibrous membranes showed smooth and even fibres, free of beading. However, these membranes displayed low mechanical properties (7 MPa of tensile stress at break). The use of glutaraldehyde caused the swelling of the fibre; the diameter increased until 12 h of treatment. After 12 h, the diameter began to decrease again, indicating the occurrence of the crosslinking reactions. The tensile strength of the nanofibrous membranes increased after crosslinking, with significant increases seen up until 24 h of glutaraldehyde treatment (37 MPa of tensile stress at break). However, after this point, the glutaraldehyde bonded to PBI and acted as side-chain plasticizers for the polymer, causing a slight decrease in tensile strength for membranes that had been treated beyond 24 h.

A crosslinking treatment using α,α′-dibromo-m-xylene (DBX) was also performed to improve the chemical and thermal stability of PBI nanofibrous mats for application as a battery separator [

28]. In addition, the mats were treated using 4 (chloromethyl) benzoic acid (CMBA) to improve electrolyte wettability. The DBX and CMBA treatments resulted in the formation of rough and curvy nanofibres. In terms of thermal resistance, TGA found weight loss starting as low as 200 °C, but this was likely due to the loss of residual solvent in the fibre. Polymeric weight loss began at around 450 °C. Thermal shrinkage was also measured at 150 °C for 30 min. The membranes displayed excellent thermal resistance at this temperature: no changes in the colour or size of the membrane were observed. The porosity of the PBI membrane was 87% before crosslinking but decreased to 70% following crosslinking with DBX. However, after CMBA treatment, the porosity increased again to 78%. The mechanical properties of the PBI membrane were also tested, and it was found that after crosslinking, the strength of the membrane increased, but it decreased after the CMBA treatment due to the increase in porosity. At its strongest, the crosslinked membrane had an average tensile strength of 11 mPa. Therefore, this membrane was almost three times weaker than the conventional polyethylene (PE) battery separator, indicating that additional research is needed before the PBI electrospun nanofibrous membrane has the strength to rival the conventional PE membrane.

Physical post-treatments to improve the mechanical properties of PBI nanofibrous membranes have also been tested. Cho et al. [

26] used a thermal calendering process and temperatures between 30 and 180 °C to encourage bonding between fibres and increase the strength of the membrane for battery application. As the temperature increased, interbonding between fibres increased, which led to an improvement in the mechanical properties of the nanofibrous membranes. However, this interbonding also led to a decrease in porosity, pore size, and electrolyte uptake as the three-dimensional pore structure was significantly reduced. Moreover, the durability and reusability of PBI membranes for filtration applications were enhanced by laminating the PBI membrane between two layers of polyethylene mesh at 140 °C [

30]. This improved the durability by immobilizing the nanofibres and allowing for bend and flex abrasion without significant damage. The membrane was able to be cleaned in acetic acid and deionized water to remove both organic and inorganic compounds, then reused for several cycles.

Other applications of electrospun PBI nanofibres involved post-treatments to improve the specific adsorption or absorption properties of the membrane. One study used molecular imprinting to make the nanofibres selective for the adsorption of sulfonic compounds for application in the oil and gas industry [

64]. To obtain the molecular imprint, a small amount of acrylonitrile solution containing sulfone and a dispersant was added to the polymer solution of PBI and lithium bromide salt (LiBr) in DMAc before electrospinning. The adsorption of sulfone was found to be significantly improved after performing the molecular imprinting on the nanofibres. Another study used phosphoric acid (PA)-doped PBI nanofibrous membranes to improve proton conductivity for application as a high-temperature proton exchange membrane [

27]. Electrospun PBI membranes were doped in PA for durations of 24, 48, 72, and 96 h, then their conductivity was measured. It was found that a 72 h PA immersion period led to the highest conductivity; at 96 h, free PA in the membrane led to acid leaking. PBI nanofibres have also been used as a substrate for the growth of carbon nanotubes via chemical vapour deposition [

66]. The high surface area, porosity, and temperature resistance of the PBI nanofibrous membrane provided an excellent substrate for the carbon nanotubes, producing a nanocomposite suitable for lithium-sulphur batteries and laminated composites.

In summary, PBI nanofibres have been successfully electrospun by a variety of researchers. Currently, there is a major focus on improving the mechanical properties of the membrane using post-treatments such as crosslinking, thermal calendering, and laminating with support materials [

26,

28,

30,

32]. Moreover, treatments to improve the thermal properties of the membrane have also been explored to overcome the high thermal shrinkage that is experienced by PBI nanofibrous membranes [

28]. Specialized treatments of the PBI nanofibrous membrane have also been used to make the membrane more suitable for specific applications [

27,

64]. Despite the focus on applications of the studies on PBI nanofibrous membranes, it remains to be determined whether the electrospinning process for PBI can be effectively scaled up. In addition, it will be especially important to consider which post-treatments are most scalable to improve the mechanical and thermal performance of the PBI nanofibrous membranes.