Pile Arrangement for Minimizing Plastic Deformation in Pile-Supported Immersed Tunnel under Seismic Loads

Abstract

:1. Introduction

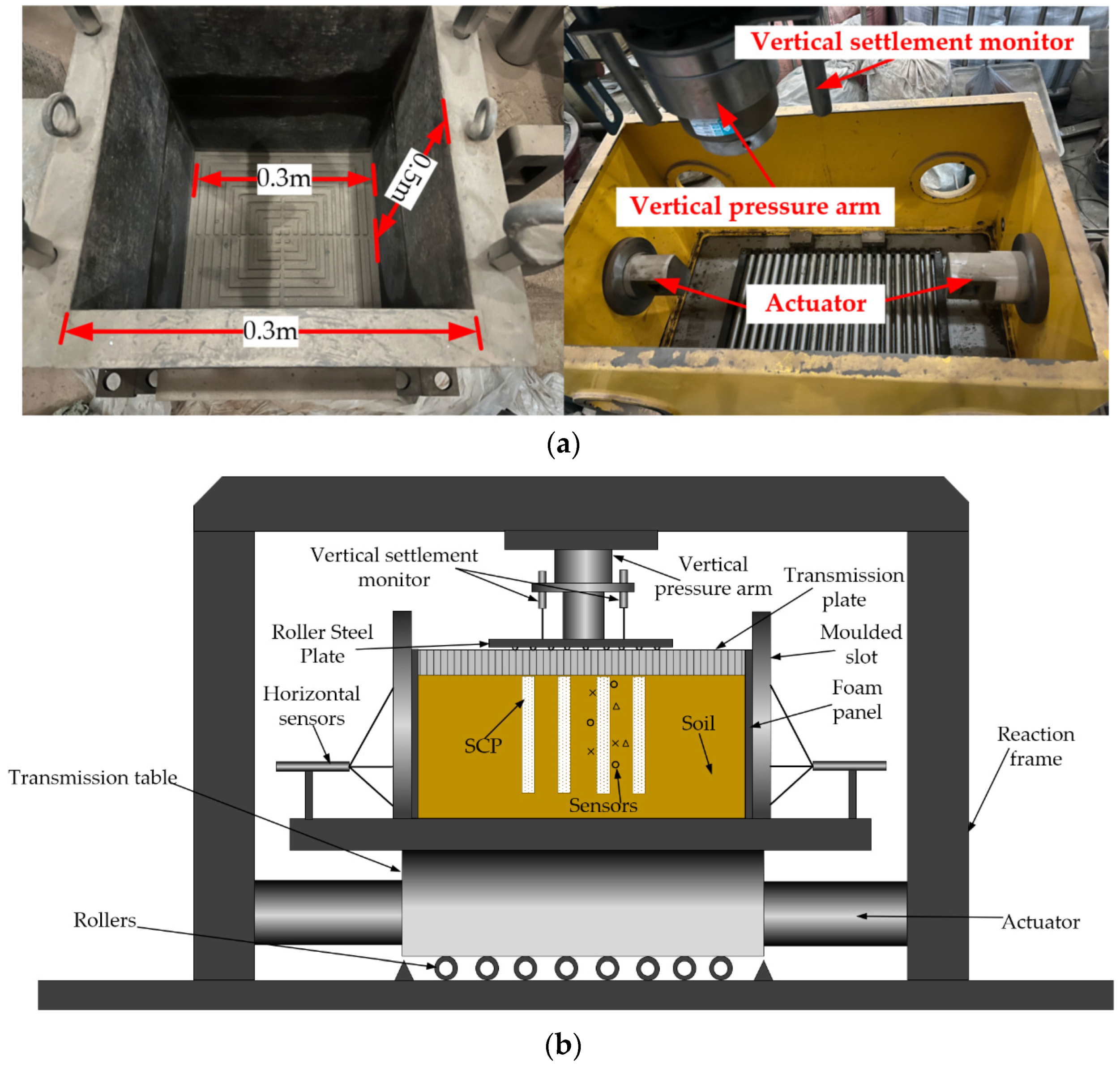

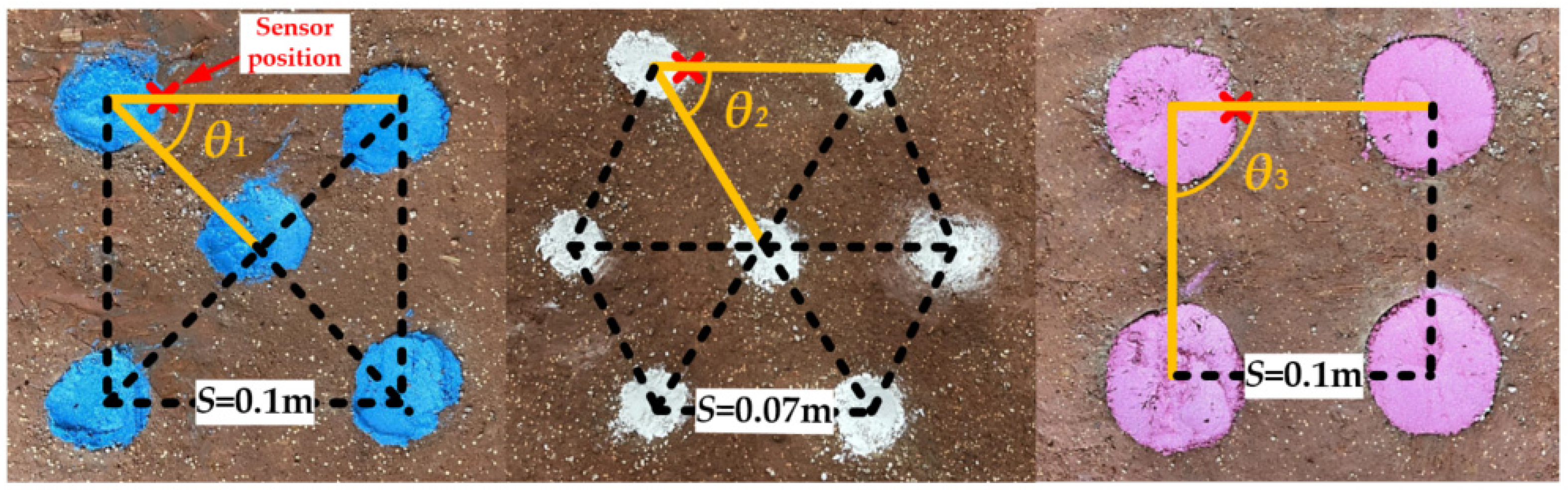

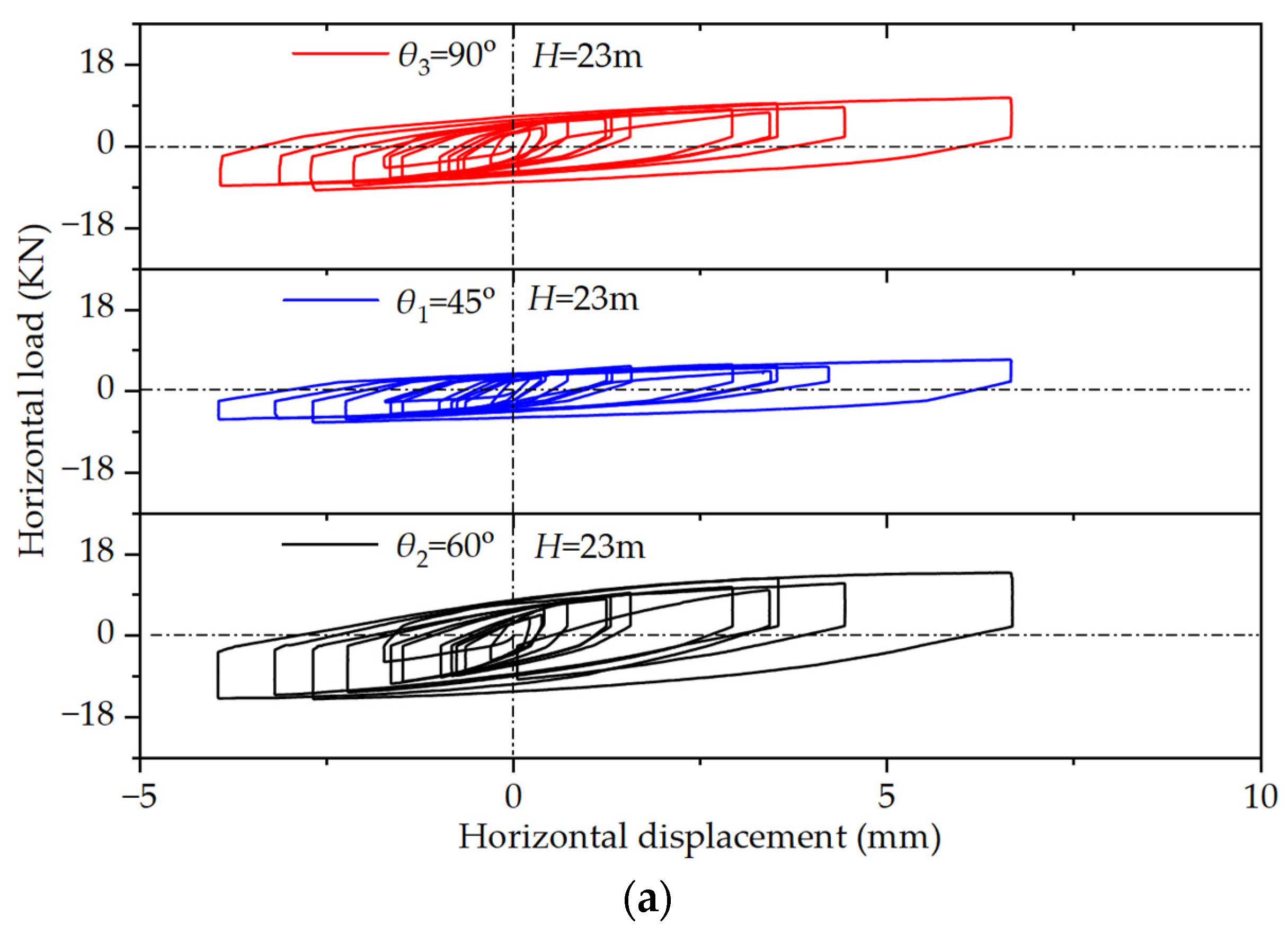

2. Physical Modelling

2.1. Design of Physical Model

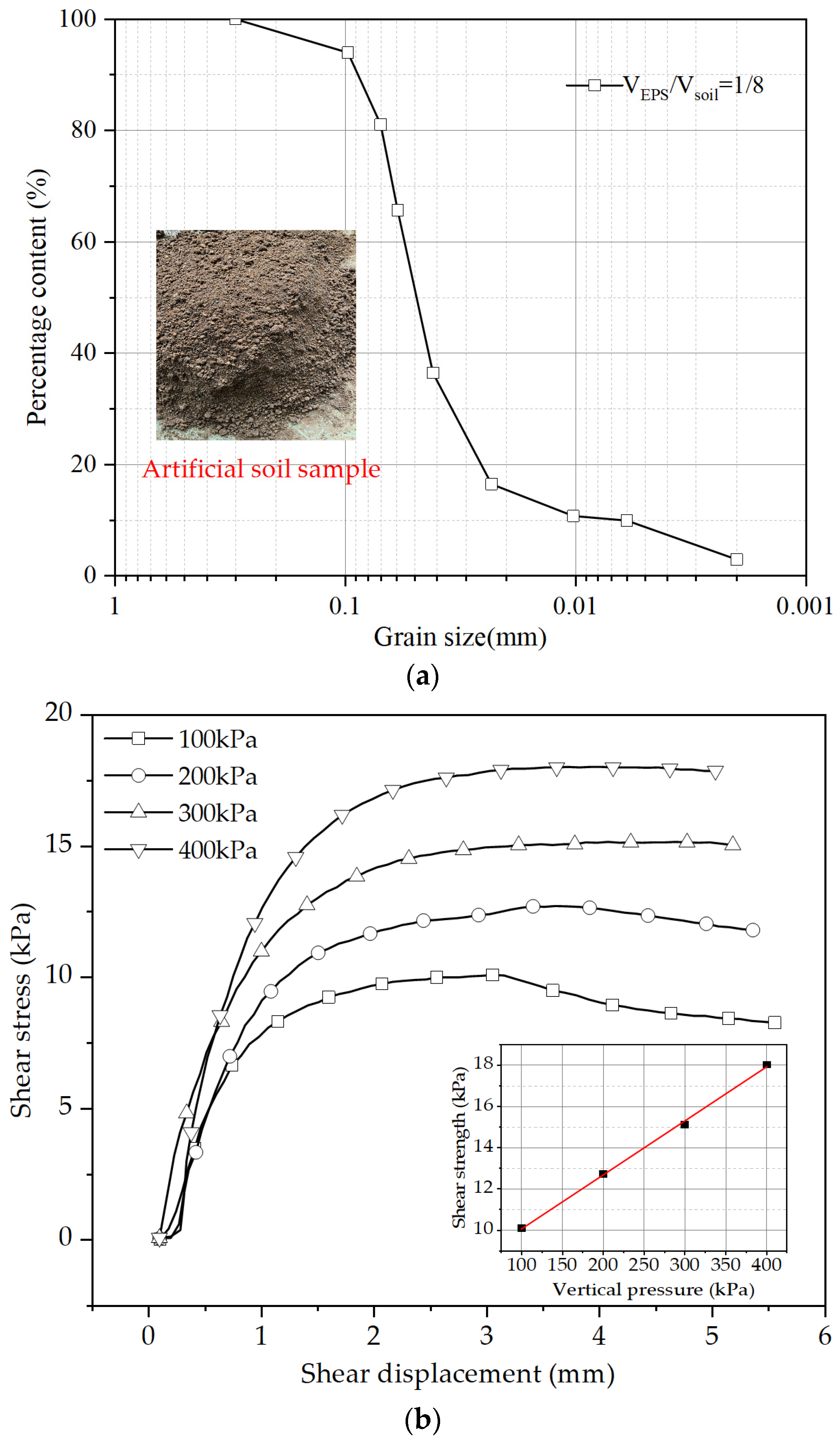

2.2. Research Material

3. Analysis of Experimental Results

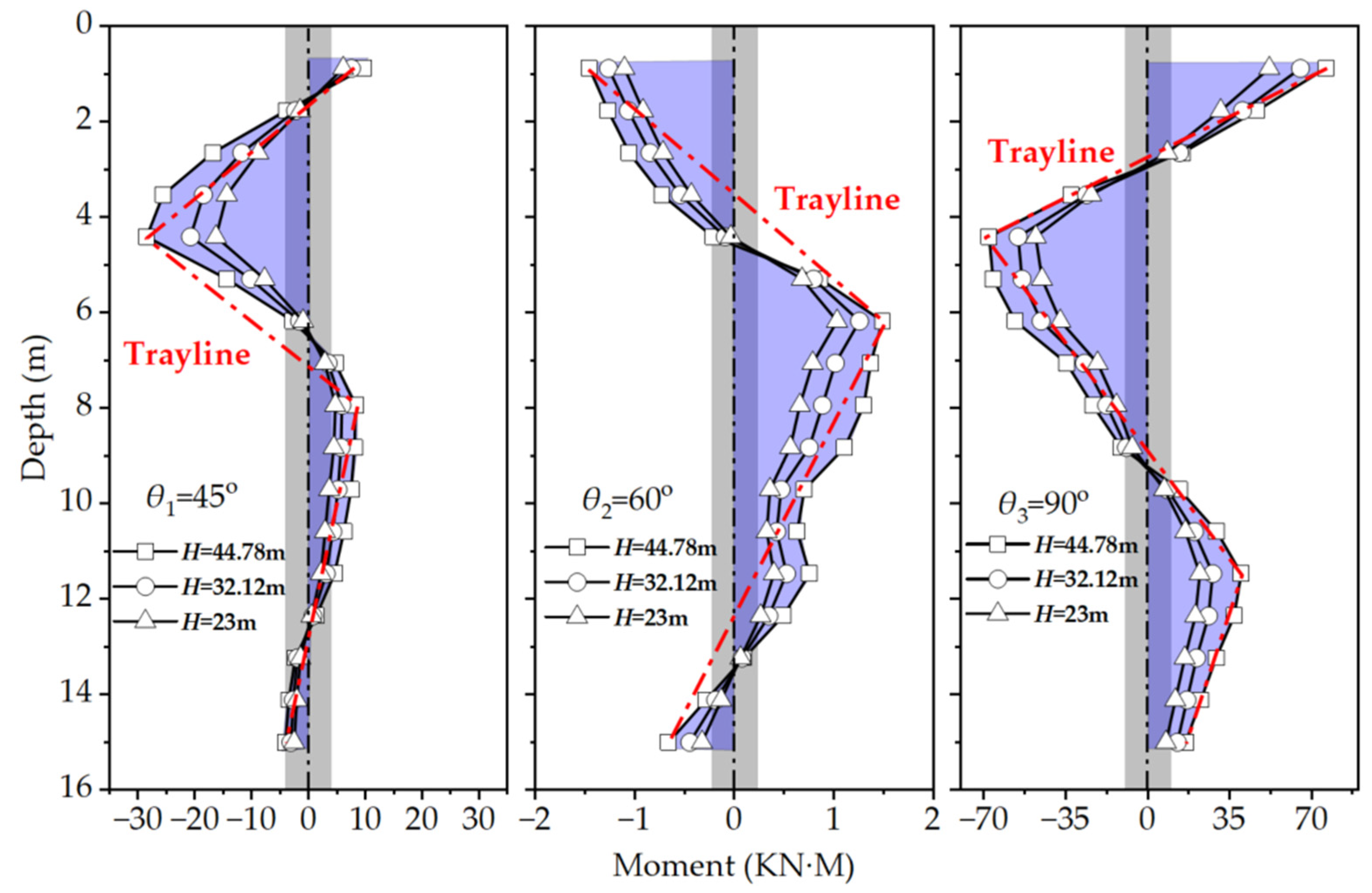

3.1. Bending Moment of the Piles

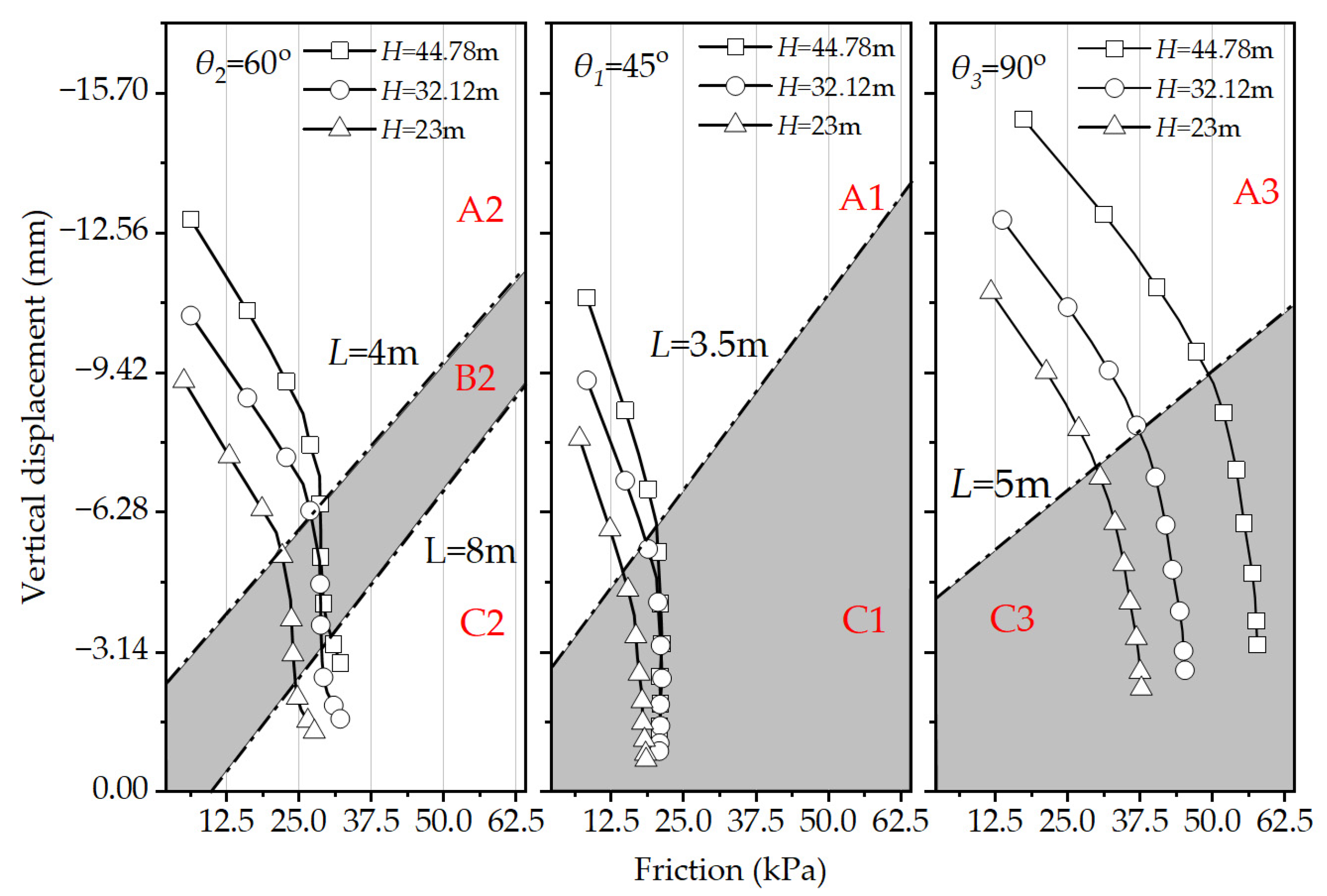

3.2. Friction and Displacement of the Pile–Soil Interface

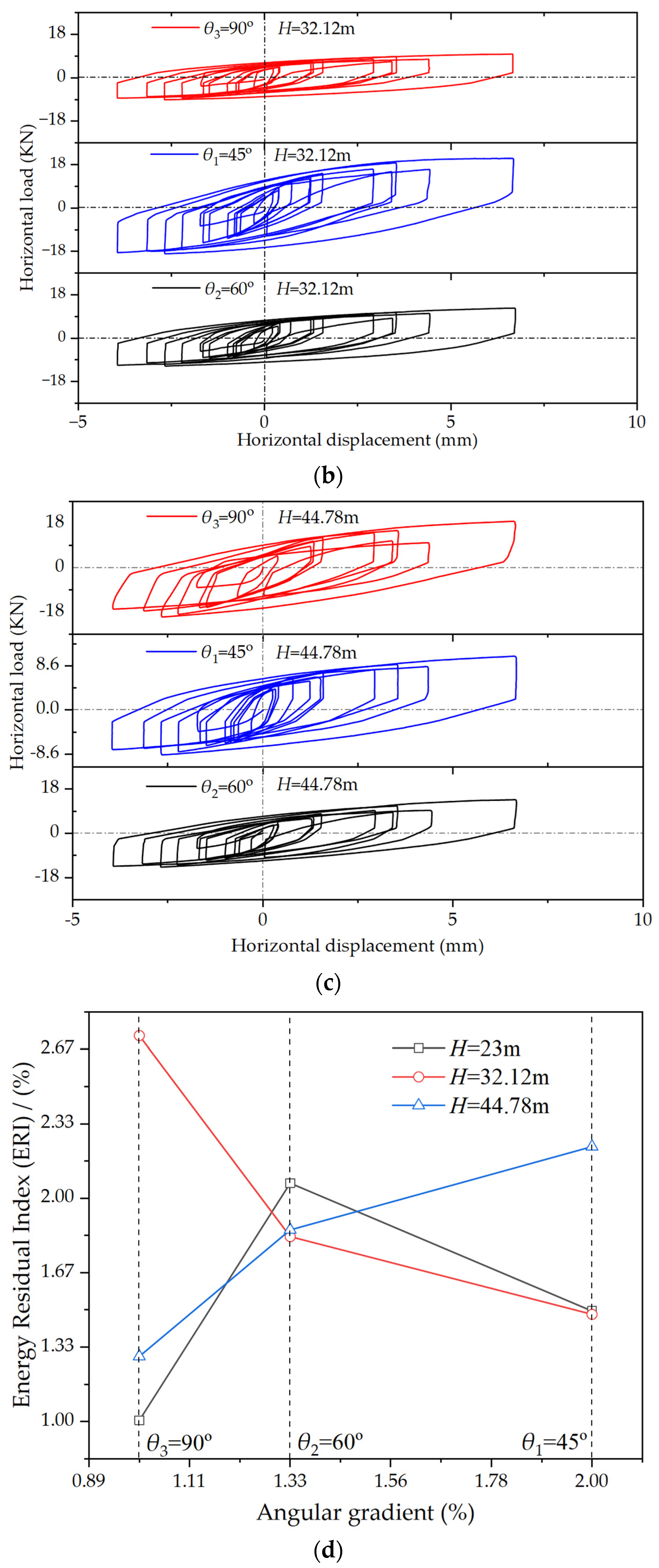

3.3. Piled Foundation Energy Absorption and Dissipation

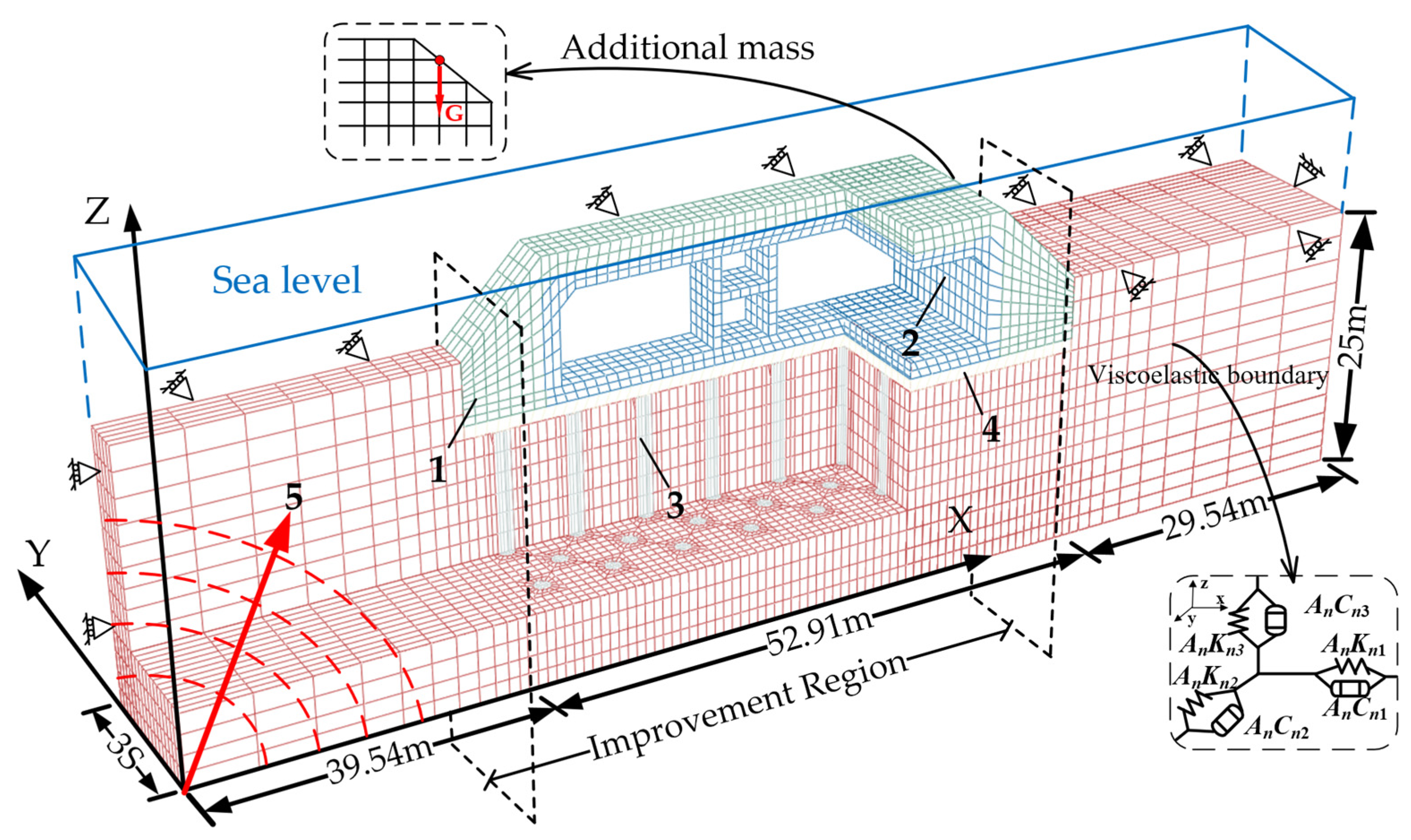

4. Numerical Modelling

4.1. Seismic Loads Input

4.2. Model Parameters

4.3. Finite Element Mesh and Boundary Condition

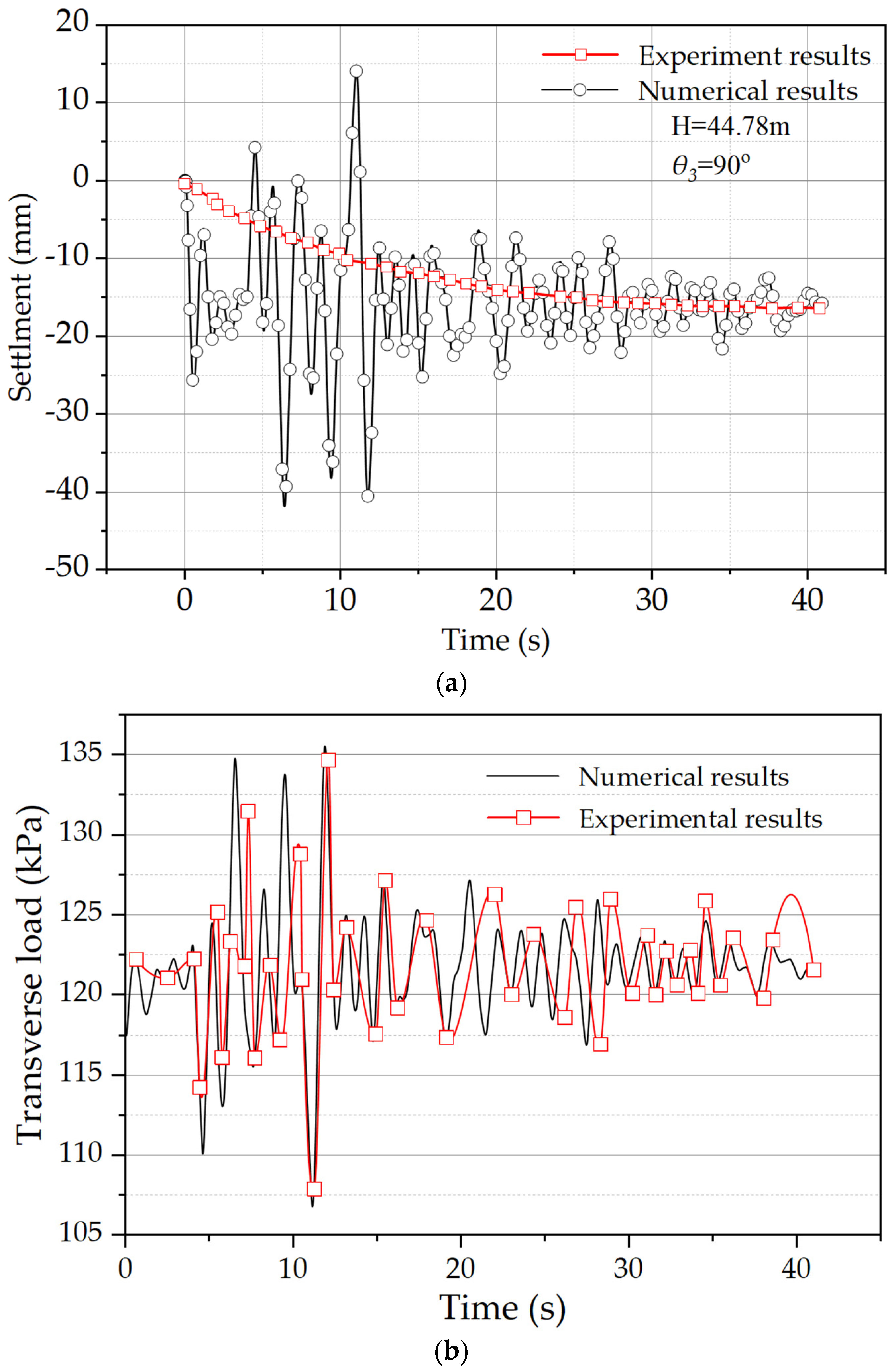

4.4. Verification of Numerical Results

5. Energy Absorption and Dissipation of the SCP and Soil

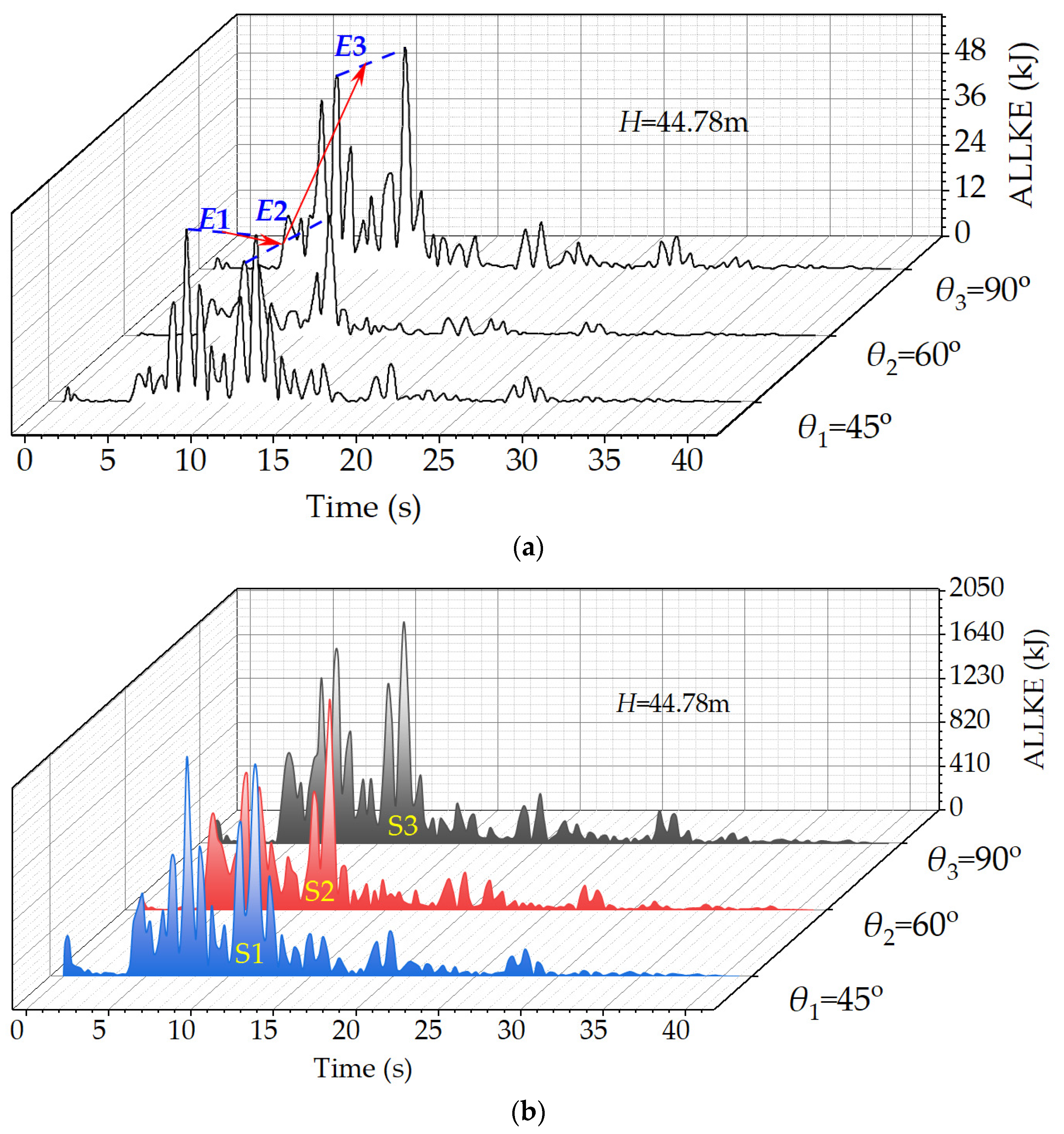

5.1. Total Kinetic Energy (ALLKE) of the Piles and Foundation

5.2. Total Strain Energy (ALLSE) of the Pile

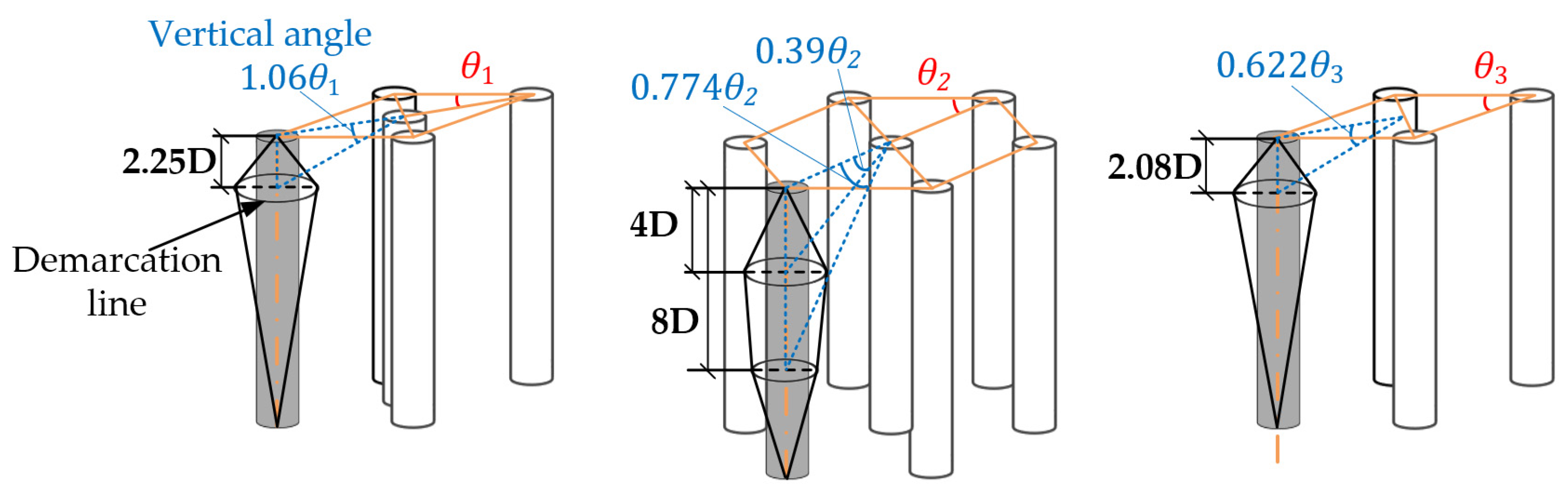

6. Location of the Boundaries of the Damaged Region

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oka, F.; Tsai, P.; Kimoto, S.; Kato, R. Damage patterns of river embankments due to the 2011 off the Pacific Coast of Tohoku Earthquake and a numerical modeling of the deformation of river embankments with a clayey subsoil layer. Soils Found. 2012, 52, 890–909. [Google Scholar] [CrossRef]

- Tani, S. Consideration of Earthquake Damage to Earth Dam for Irrigation in Japan. In Proceedings of the International Conferences on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics, St. Louis, MO, USA, 11–15 March 1991. [Google Scholar]

- Kawakami, F.; Asada, A. Damage to the Ground and Earth Structures by the Niigata Earthquake of June 16, 1964. Soils Found. 1966, 6, 14–30. [Google Scholar] [CrossRef]

- Tani, S. Damage to Earth Dams. Soils Found. 1996, 36, 263–272. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, Y.; Towhata, I.; Tokida, K.-I.; Yamada, K.; Matsumoto, H.; Tamari, Y.; Saya, S. Mechanism of Permanent Displacement of Ground Caused by Seismic Liquefaction. Soils Found. 1992, 32, 79–96. [Google Scholar] [CrossRef] [PubMed]

- Koga, Y.; Matsuo, O. Shaking Table Tests of Embankments Resting on Liquefiable Sandy Ground. Soils Found. 1990, 30, 162–174. [Google Scholar] [CrossRef] [PubMed]

- Matsuo, O. Damage to River Dikes. Soils Found. 1996, 36, 235–240. [Google Scholar] [CrossRef]

- Anas, S.M.; Alam, M.; Umair, M. Experimental and numerical investigations on performance of reinforced concrete slabs under explosive-induced air-blast loading: A state-of-the-art review. Structures 2021, 31, 428–461. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Wu, W.; Wang, L.; Jiang, G. A 3D analytical model for distributed low strain test and parallel seismic test of pipe piles. Ocean. Eng. 2021, 225, 108828. [Google Scholar] [CrossRef]

- Zheng, C.; Kouretzis, G.; Ding, X.; Luan, L. Vertical vibration of end-bearing single piles in poroelastic soil considering three-dimensional soil and pile wave effects. Comput. Geotech. 2022, 146, 104740. [Google Scholar] [CrossRef]

- Zheng, C.; Gan, S.; Luan, L.; Ding, X. Vertical dynamic response of a pile embedded in a poroelastic soil layer overlying rigid base. Acta Geotech. 2020, 16, 977–983. [Google Scholar] [CrossRef]

- Li, L.; Liu, H.; Wu, W.; Wen, M.; El Naggar, M.H.; Yang, Y. Investigation on the behavior of hybrid pile foundation and its surrounding soil during cyclic lateral loading. Ocean. Eng. 2021, 240, 110006. [Google Scholar] [CrossRef]

- Wu, W.; Yang, Z.; Liu, X.; Zhang, Y.; Liu, H.; El Naggar, M.H.; Xu, M.; Mei, G. Horizontal dynamic response of pile in unsaturated soil considering its construction disturbance effect. Ocean. Eng. 2022, 245, 110483. [Google Scholar] [CrossRef]

- Faghihnia Torshizi, M.; Saitoh, M.; Álamo, G.M.; Goit, C.S.; Padrón, L.A. Influence of pile radius on the pile head kinematic bending strains of end-bearing pile groups. Soil Dyn. Earthq. Eng. 2018, 105, 184–203. [Google Scholar] [CrossRef]

- Anand, V.; Satish Kumar, S.R. Seismic Soil-structure Interaction: A State-of-the-Art Review. Structures 2018, 16, 317–326. [Google Scholar] [CrossRef]

- Cui, C.; Meng, K.; Xu, C.; Liang, Z.; Li, H.; Pei, H. Analytical solution for longitudinal vibration of a floating pile in saturated porous media based on a fictitious saturated soil pile model. Comput. Geotech. 2021, 131, 103942. [Google Scholar] [CrossRef]

- Naggar, M.H.E.; Shayanfar, M.A.; Kimiaei, M.; Aghakouchak, A.A. Simplified BNWF model for nonlinear seismic response analysis of offshore piles with nonlinear input ground motion analysis. Can. Geotech. J. 2005, 42, 365–380. [Google Scholar] [CrossRef]

- Li, Y.; Kitazume, M.; Takahashi, A.; Harada, K.; Ohbayashi, J. Centrifuge study on the effect of the SCP improvement geometry on the mitigation of liquefaction-induced embankment settlement. Soil Dyn. Earthq. Eng. 2021, 148, 106852. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Liu, H.; Fan, X.; Jiang, G.; El Naggar, M.H.; Wu, W.; Liu, X. Analytical solution for lateral dynamic response of pile foundation embedded in unsaturated soil. Ocean. Eng. 2022, 265, 112518. [Google Scholar] [CrossRef]

- Chen, L.; Wu, W.; Liu, H.; Li, J.; Newson, T.; El Naggar, M.H. Analytical solution for kinematic response of offshore piles under vertically propagating S-waves. Ocean. Eng. 2022, 262, 112018. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, P.; Zhao, M.; Zhang, C.; Du, X. Dynamic responses of an end-bearing pile subjected to horizontal earthquakes considering water-pile-soil interactions. Ocean. Eng. 2021, 238, 109726. [Google Scholar] [CrossRef]

- Wang, C.; Ding, X.; Cao, G.; Jiang, C.; Fang, H.; Wang, C. Numerical investigation of the effect of particle gradation on the lateral response of pile in coral sand. Comput. Geotech. 2022, 152, 105012. [Google Scholar] [CrossRef]

- Su, D.; Wu, Z.; Lei, G.; Zhu, M. Numerical study on the installation effect of a jacked pile in sands on the pile vertical bearing capacities. Comput. Geotech. 2022, 145, 104690. [Google Scholar] [CrossRef]

- Zhao, M.-H.; Heng, S.; Zheng, Y. Numerical simulation on behavior of pile foundations under cyclic axial loads. J. Cent. South Univ. 2017, 24, 2906–2913. [Google Scholar] [CrossRef]

- Yadav, S.K.; Ye, G.-L.; Khalid, U.; Fukuda, M. Numerical and centrifugal physical modelling on soft clay improved with floating and fixed sand compaction piles. Comput. Geotech. 2019, 115, 103160. [Google Scholar] [CrossRef]

- Rouholamin, M.; Lombardi, D.; Bhattacharya, S. Experimental investigation of transient bending moment of piles during seismic liquefaction. Soil Dyn. Earthq. Eng. 2022, 157, 107251. [Google Scholar] [CrossRef]

- Hong, Y.; He, B.; Wang, L.Z.; Wang, Z.; Ng, C.W.W.; Mašín, D. Cyclic lateral response and failure mechanisms of semi-rigid pile in soft clay: Centrifuge tests and numerical modelling. Can. Geotech. J. 2017, 54, 806–824. [Google Scholar] [CrossRef]

- Kim, B.I.; Lee, S.H. Comparison of bearing capacity characteristics of sand and gravel compaction pile treated ground.pdf. KSCE J. Civ. Eng. 2005, 9, 197–203. [Google Scholar] [CrossRef]

- Solymar, Z.V.; Samsudin; Osellame, J.; Purnomo, B.J. Ground Improvement by Compaction Piling. J. Geotech. Eng. 1986, 112, 1069–1083. [Google Scholar] [CrossRef]

- Yi, J.T.; Goh, S.H.; Lee, F.H. Effect of sand compaction pile installation on strength of soft clay. Géotechnique 2013, 63, 1029–1041. [Google Scholar] [CrossRef]

- Jung, J.-B.; Lee, K.-I.; Lee, J.-S. Consolidation behavior of clay ground improved by sand compaction piles. KSCE J. Civ. Eng. 1999, 3, 205–212. [Google Scholar] [CrossRef]

- Murali Krishna, A.; Madhav, M. Treatment of loose to medium dense sands by granular piles: Improved SPT’ N 1′Values. Geotech. Geol. Eng. 2009, 27, 455–459. [Google Scholar] [CrossRef]

- Aarthi, N.; Dodagoudar, G.R. Three-Dimensional Finite-Element Analysis of Pressure–Settlement Response of Sand Compaction Pile-Treated Cohesionless Deposits. Int. J. Geomech. 2021, 21, 04021019. [Google Scholar] [CrossRef]

- Padmanabhan, G.; Shanmugam, G.K. Liquefaction and reliquefaction resistance of saturated sand deposits treated with sand compaction piles. Bull. Earthq. Eng. 2021, 19, 4235–4259. [Google Scholar] [CrossRef]

- He, H.; Lin, Y.; Li, J.; Zhang, N. Immersed tunnel foundation on marine clay improved by sand compaction piles. Mar. Georesour. Geotechnol. 2017, 36, 218–226. [Google Scholar] [CrossRef]

- Saha, R.; Haldar, S.; Dutta, S.C. Influence of dynamic soil-pile raft-structure interaction: An experimental approach. Earthq. Eng. Eng. Vib. 2015, 14, 625–645. [Google Scholar] [CrossRef]

- Deb Roy, S.; Pandey, A.; Saha, R. Shake table study on seismic soil-pile foundation-structure interaction in soft clay. Structures 2021, 29, 1229–1241. [Google Scholar] [CrossRef]

- Yang, J.; Yang, M.; Chen, H. Influence of pile spacing on seismic response of piled raft in soft clay: Centrifuge modeling. Earthq. Eng. Eng. Vib. 2019, 18, 719–733. [Google Scholar] [CrossRef]

- Jian, Z.; Yurun, L.; Zhixiao, Y.; Da, H.; Xian, R.; Yan, L. Experimental study of vertical and batter pile groups in saturated sand using a centrifuge shaking table. Earthq. Eng. Eng. Vib. 2021, 21, 23–36. [Google Scholar] [CrossRef]

- Zhang, L.; Goh, S.H.; Liu, H. Seismic response of pile-raft-clay system subjected to a long-duration earthquake: Centrifuge test and finite element analysis. Soil Dyn. Earthq. Eng. 2017, 92, 488–502. [Google Scholar] [CrossRef]

- Dehghanpoor, A.; Thambiratnam, D.; Taciroglu, E.; Chan, T. Soil-pile-superstructure interaction effects in seismically isolated bridges under combined vertical and horizontal strong ground motions. Soil Dyn. Earthq. Eng. 2019, 126, 105753. [Google Scholar] [CrossRef]

- Azizkandi, A.S.; Baziar, M.H.; Yeznabad, A.F. 3D Dynamic Finite Element Analyses and 1 g Shaking Table Tests on Seismic Performance of Connected and Nonconnected Piled Raft Foundations. KSCE J. Civ. Eng. 2017, 22, 1750–1762. [Google Scholar] [CrossRef]

- Wang, Z.; Yi, J.T.; Kang, C.Y.; Xu, S.J.; Yin, S.; Pan, Y.T. A novel numerical strategy to analyse the installation and set-up effects of sand compaction piling. Ocean. Eng. 2023, 285, 115331. [Google Scholar] [CrossRef]

- Su, C.; Wang, P.; Zhao, M.; Zhang, G.; Bao, X. Dynamic interaction analysis of structure-water-soil-rock systems under obliquely incident seismic waves for layered soils. Ocean. Eng. 2022, 244, 110256. [Google Scholar] [CrossRef]

- Niu, Y.; Xie, Y.; Zhang, H.; Yue, X.; Han, Y.; Hu, Z. Study on bearing characteristics of marine subsoil for semi-rigid immersed tunnel. Mar. Georesour. Geotechnol. 2021, 40, 1171–1183. [Google Scholar] [CrossRef]

- Wen, K.; Wu, X.; Zhu, B. Numerical investigation on the lateral loading behaviour of tetrapod piled jacket foundations in medium dense sand. Appl. Ocean. Res. 2020, 100, 102193. [Google Scholar] [CrossRef]

- González, F.; Padrón, L.A.; Aznárez, J.J.; Maeso, O. Equivalent linear model for the lateral dynamic analysis of pile foundations considering pile-soil interface degradation. Eng. Anal. Bound. Elem. 2020, 119, 59–73. [Google Scholar] [CrossRef]

- Jones, K.; Sun, M.; Lin, C. Numerical analysis of group effects of a large pile group under lateral loading. Comput. Geotech. 2022, 144, 104660. [Google Scholar] [CrossRef]

- Gholami, N.; Garivani, S.; Askariani, S.S. State-of-the-Art Review of Energy-Based Seismic Design Methods. Arch. Comput. Methods Eng. 2021, 29, 1965–1996. [Google Scholar] [CrossRef]

- Saleh Asheghabadi, M.; Rahgozar, M.A. Finite Element Seismic Analysis of Soil–Tunnel Interactions in Clay Soils. Iran. J. Sci. Technol. Trans. Civ. Eng. 2018, 43, 835–849. [Google Scholar] [CrossRef]

- Aknouche, H.; Airouche, A.; Bechtoula, H. Influence of Earthquake Frequency Nonstationarity on Seismic Structural Response. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 603–614. [Google Scholar] [CrossRef]

- Balaam, N.P.; Booker, J.R. Effect of stone column yield on settlement of rigid foundations in stabilized clay. Num. Anal. Meth Geomech. 1985, 9, 331–351. [Google Scholar] [CrossRef]

- Aboshi, H.; Mizuno, Y.; Kuwabara, M. Present State of Sand Compaction Pile in Japan. In Deep Foundation Improvements: Design, Construction, and Testing; ASTM International: West Conshohocken, PA, USA, 1991; pp. 32–35. [Google Scholar]

- Liu, J.; Du, Y.; Du, X.; Wang, Z.; Wu, J. 3D viscous-spring artificial boundary in time domain. Earthq. Eng. Eng. Vib. 2006, 5, 93–102. [Google Scholar] [CrossRef]

- Ye, J.; He, K.; Zhou, L. Subsidence prediction of a rubble mound breakwater at Yantai port: A application of FSSI-CAS 2D. Ocean Eng. 2021, 219, 108349. [Google Scholar] [CrossRef]

- Savvides, A.A.; Papadrakakis, M. A computational study on the uncertainty quantification of failure of clays with a modified Cam-Clay yield criterion. SN Appl. Sci. 2021, 3, 659. [Google Scholar] [CrossRef]

- Kavvadas, M.; Amorosi, A. A constitutive model for structured soils. Géotechnique 2000, 50, 263–273. [Google Scholar] [CrossRef]

- Miyamoto, J.; Sassa, S.; Sekiguchi, H. Progressive solidification of a liquefied sand layer during continued wave loading. Géotechnique 2004, 54, 617–629. [Google Scholar] [CrossRef]

- Huang, J.; Han, J. Two-dimensional parametric study of geosynthetic-reinforced column-supported embankments by coupled hydraulic and mechanical modeling. Comput. Geotech. 2010, 37, 638–648. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, P.; Zhao, M.; Du, X.; Zhao, X. Seismic structure-water-sediment-rock interaction model and its application to immersed tunnel analysis under obliquely incident earthquake. Tunn. Undergr. Space Technol. 2021, 109, 103758. [Google Scholar] [CrossRef]

| Foundation | Sand | ||

|---|---|---|---|

| Properties | Value | Property | Value |

| Particle size dEPS (mm) | 0.3 | γ1 (d > 0.25 mm) | 0.23 |

| Volume ratio Vsoil:VEPS | 8/1 | γ2 (d = 0.18–0.25 mm) | 0.7 |

| Permeability (m/d) | 0.0016 | γ3 (d < 0.18 mm) | 0.07 |

| Void ratio e | 1.07 | Permeability (m/d) | 2.592 |

| Moisture content Ws | 0.216 | Pile depth L (m) | 0.2 |

| Parameters | Marine Clay | SCP | Immersed | Gravel Cushion | Backfill |

|---|---|---|---|---|---|

| Consolidation index, λ | 0.113 | 0.023 | |||

| Swelling index, Kr | 0.05058 | 0.0103 | |||

| Critical state parameter, M | 0.668 | 1.2 | |||

| Poisson’s ratio, ν | 0.36 | 0.3 | 0.17 | 0.45 | 0.37 |

| Density, ρ (g/m3) | 1.851 | 1.765 | 2.45 | 0.9 | 2 |

| Buoyant density, ρw (g/m3) | 0.801 | 0.715 | 1.4 | 0.85 | 0.95 |

| Cohesion, C (kPa) | 7.4 | 0.5 | |||

| Friction angle φ (o) | 15 | 30 | |||

| Young’s modulus, E (kPa) | 2821.83 | E* | 30,000 | 20,000 | 150,000 |

| Permeability, κ (m/s) | 1.8 × 10−8 | 3 × 10−5 | |||

| Coefficient of lateral pressure | 0.577 | 0.5 | |||

| Initial void ratio, e0 | 1.059 | 0.72 | |||

| Degree of saturation | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, H.; Zhuang, Y.; Li, J.; Chen, Z. Pile Arrangement for Minimizing Plastic Deformation in Pile-Supported Immersed Tunnel under Seismic Loads. Appl. Sci. 2023, 13, 12331. https://doi.org/10.3390/app132212331

Fan H, Zhuang Y, Li J, Chen Z. Pile Arrangement for Minimizing Plastic Deformation in Pile-Supported Immersed Tunnel under Seismic Loads. Applied Sciences. 2023; 13(22):12331. https://doi.org/10.3390/app132212331

Chicago/Turabian StyleFan, Hu, Yan Zhuang, Jinxin Li, and Zhi Chen. 2023. "Pile Arrangement for Minimizing Plastic Deformation in Pile-Supported Immersed Tunnel under Seismic Loads" Applied Sciences 13, no. 22: 12331. https://doi.org/10.3390/app132212331

APA StyleFan, H., Zhuang, Y., Li, J., & Chen, Z. (2023). Pile Arrangement for Minimizing Plastic Deformation in Pile-Supported Immersed Tunnel under Seismic Loads. Applied Sciences, 13(22), 12331. https://doi.org/10.3390/app132212331