Abstract

This work evaluates the feasibility of utilizing an organic Rankine cycle (ORC) for waste heat recovery in internal combustion engines to meet the stringent regulations for reducing emissions resulting from the combustion of fossil fuels. The turbine is the most crucial component of the ORC cycle since it is responsible for power production. In this study, a variable geometry radial inflow turbine is designed to cope with variable exhaust conditions. A variable geometry turbine is simply a radial turbine with different throat openings: 30, 60, and 100%. The exhaust gases of a heavy-duty diesel engine are utilized as a heat source for the ORC system. Different engine operating points are explored, in which each point has a different exhaust temperature and mass flow rate. The results showed that the maximum improvements in engine power and brake specific fuel consumption (BSFC) were 5.5% and 5.3% when coupled to the ORC system with a variable geometry turbine. Moreover, the variable geometry turbine increased the thermal efficiency of the cycle by at least 20% compared to the system with a fixed geometry turbine. Therefore, variable geometry turbines are considered a promising technology in the field and should be further investigated by scholars.

1. Introduction

Manufacturers are currently under pressure to improve the efficiency of internal combustion engines in terms of fuel consumption and exhaust emissions [1]. In fact, the combustion of fossil fuels is a primary source of harmful gases, such as CO2 and NOx [2]. Diesel engines, in fact, are among the most significant polluters due to their widespread applications. Most of the heat wasted in internal combustion engines comes from exhaust gases [3]. In fact, only 30 to 40% of fuel energy is converted into useful work [4]. To harness this wasted energy, waste heat recovery technologies can be integrated.

Recently, organic Rankine cycle (ORC) as a waste heat recovery technology has received great attention among scholars and in the industry sector due to the availability of components, its simplicity, and reliability [5,6]. Moreover, ORC systems exhibit great thermal efficiency in comparison to other WHR technologies under a variety of operating situations [7]. The organic Rankine cycle is simply a Rankine cycle operating with organic fluids instead of steam. Due to the low boiling point of some organic fluids, they can be utilized in low to medium heat source applications [8,9]. In addition, the densities of organic fluids are relatively high, which results in smaller systems compared to steam; hence, there are lower costs [10]. Typical Rankine cycles consist of four main components, namely, an evaporator, turbine, condenser, and pump. The turbine is one of the most important components in the system since this is the medium where power production takes place [11].

Variable geometry turbines are of valuable interest especially in internal combustion engines in order to cope with the transient operating conditions in the engine. Conventional radial turbines (fixed geometry turbines) suffer from low efficiencies at part-load conditions [12]. A variable geometry radial turbine is simply a radial turbine that has movable stator vanes which provide a quick response to the change in engine load/speed [13]. In addition, by utilizing variable geometry vanes, it is possible to adjust the mass flow rate and to balance the volume of the working fluid [13]. The concept of variable geometry turbines is not new and has been extensively studied for turbocharging. However, applying such a technology in ORC systems is an area in which little available literature exists. Therefore, the investigated literature is limited to applications of the ORC with variable geometry turbines. The application of ORCs in internal combustion engines, covering different types of expansion machines, was extensively reviewed in the authors’ study [14]. The authors also experimentally tested the potential of ORCs for waste heat recovery using fixed geometry turbines in several studies [15].

Thaddaeus et al. [16] simulated a 1.25 L Zetec-SE DOHC engine model coupled with an organic Rankine cycle and a variable geometry turbine. The results showed that the variable geometry turbine can improve the thermal efficiency and net power by 5.59% and 3 kW, respectively. Manente et al. [17] evaluated the performance of an ORC considering geothermal resources as the heat sources. Although a variable geometry turbine was considered, the authors did not point out the potential of the turbine. They concluded that the net power output is higher at low ambient temperatures than at warm ones. Lebedevas and Čepaitis [18] examined the decarbonization of marine transport using an ORC and a variable geometry turbine. The results showed that the highest system efficiency of 15% was achieved by utilizing the variable geometry turbine. Schuster et al. [19] investigated the thermodynamic optimization of organic Rankine cycles considering both fixed and variable geometry radial inflow turbines. The results proved the efficacy of variable geometry turbines when operating at off-design conditions. Other scholars integrated fixed geometry radial inflow turbines or other types of turbines, such as axial ones. Guillaume et al. [20] tested the potential of improving heavy-duty diesel engine performance using an ORC and a fixed geometry radial turbine. The results showed that the radial turbine presented a maximum power of 2.8 kW. Wang et al. [21] investigated the possibility of capturing the wasted heat of engine coolants and exhaust gases using a supercritical ORC. An improvement of 8% in fuel efficiency was obtained. Furukawaet et al. [22] concluded from their experiment that the engine BSFC could be decreased by 7.5% when adapting an ORC to capture the wasted heat in the engine coolant. Recently, Chen et al. [5] analyzed the performance of a preheated ORC as a waste heat recovery system in a ship two-stroke low-speed main engine. The authors utilized the wasted heat in both exhaust gases and coolants. The maximum cycle power and efficiency were 491.3 kW and 12.84%, respectively.

It is obvious that studies that investigate the potential of variable geometry turbines in engine–ORC systems are extremely limited. In fact, although [16,17,19] evaluated the benefits of variable geometry turbines, they did not cover the design process of the turbine. Moreover, the authors in studies [16,17,18,19] did not study the effects of the variable geometry turbines on the engines’ power and BSFC. Therefore, the aim of this study is to shed more light on the design process of the turbine and explore its efficacy in improving heavy-duty diesel engines in terms of power and BSFC. It is worth mentioning that the authors have published several studies on the design and optimization of fixed geometry radial inflow turbines [23].

2. System Description

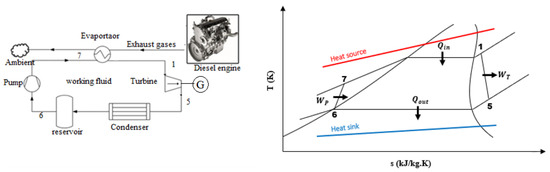

The proposed system consists of a 10.3 L heavy-duty diesel engine and the ORC system as shown in Figure 1. Stages 1 to 5 represent the turbine stage as shown in Figure 2 and Figure 3.

Figure 1.

The proposed system along with T-s diagram of the thermodynamic cycle.

2.1. Engine Modeling

The data of the heavy-duty diesel engines were provided by the Saudi Electricity Company in Hail, Saudi Arabia. To explore the potential of the radial inflow turbine on the engine power and BSFC, three different engine operating points were explored as shown in Table 1.

Table 1.

Engine properties at different engine operating conditions.

The powertrain power (engine + ORC) can be obtained using Equation (1) and the engine BSFC can be calculated using Equation (2).

2.2. Organic Rankine Cycle Modeling

A typical ORC is composed of four components, namely, an evaporator, condenser, turbine, and pump. The liquid organic fluid is firstly heated to a superheated state by absorbing the wasted heat in the exhaust gas of the engine via the evaporator. The superheated fluid then drives the turbine to generate power. For the cycle to repeat, the superheated fluid is condensed to the liquid phase and pumped again to the evaporator. The mathematical model of the ORC system is detailed below.

The energy balance through the evaporator is presented in Equation (3).

Similarly, the energy rejected through the condenser can be obtained using Equation (4).

To ensure a liquid state at the outlet of the condenser (pump inlet), a sub-cooling of 2 °C is assumed. A 65% pump efficiency is assumed. Therefore, the power consumed by the pump can be obtained from Equation (5).

The cycle thermal efficiency can be obtained using the following (6). The numerator of Equation (6) is simply the cycle network.

It is worth mentioning that NOVEC 649 is used as the working fluid in the cycle because it is non-flammable and has a near-zero GWP. Moreover, NOVEC649 produces lower back pressure at the evaporator outlet and lower turbine rotational speed.

2.3. Modeling of the Radial Inflow Turbine

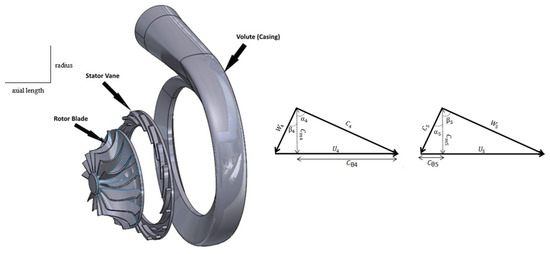

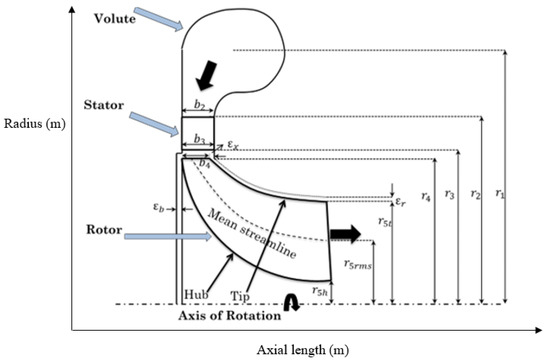

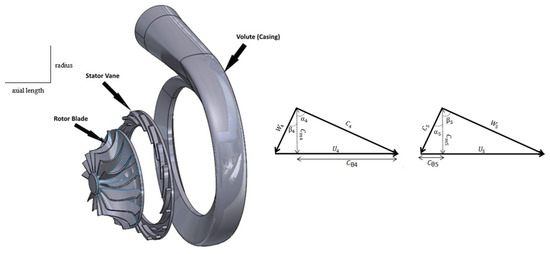

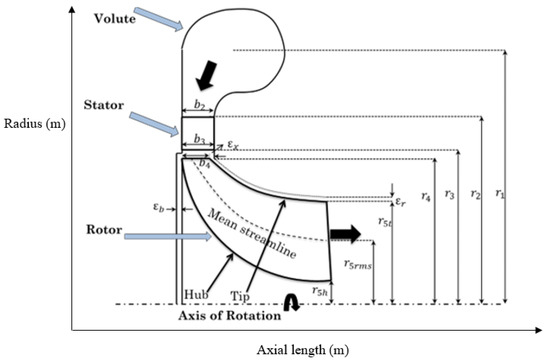

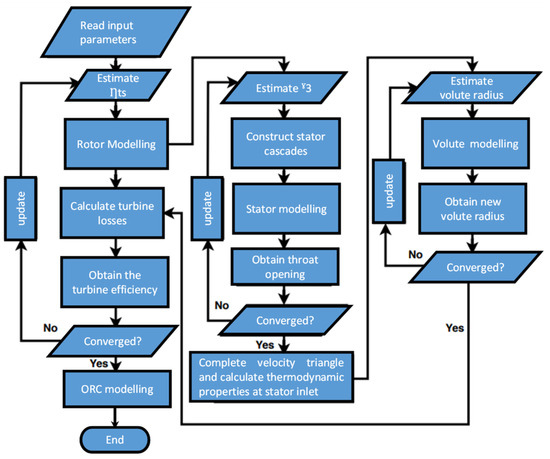

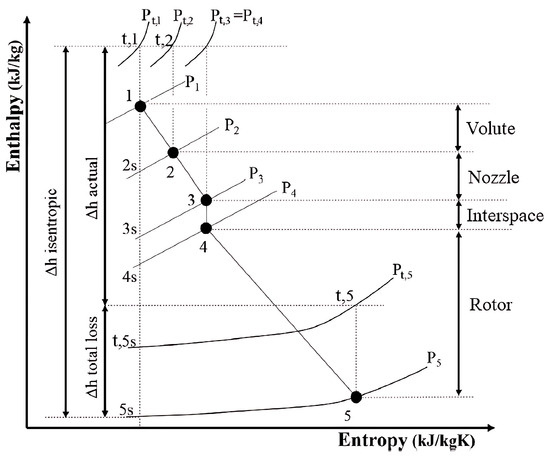

Volute, stator vanes, and rotor blades are the three primary parts of the radial inflow turbine, as depicted in Figure 2. Figure 3 presents a meridional view of the turbine stage. The flow is firstly collected in the volute, accelerated, and further expanded through the stator vanes and directed to the rotor blades at the proper angle. Finally, the fluid rotates the rotor blades, converting the kinetic energy into mechanical power. The turbine is coupled to an electrical generator to convert the mechanical power into electrical power. The design process is depicted in Figure 4 and detailed in the following subsections. Figure 5 presents an enthalpy–entropy diagram of the turbine stage.

Figure 2.

Turbine architecture (left) and velocity triangles of the rotor (right).

Figure 3.

Meridional view of the turbine stage.

Figure 4.

Flow chart of design process of the radial inflow turbine.

Figure 5.

An enthalpy–entropy diagram of the turbine stage.

2.3.1. Rotor Modeling

The rotor is simulated using two common non-dimensional parameters, namely, loading coefficient Ψ and flow coefficient φ. These parameters are shown in Equations (7) and (8) [24].

Knowing that loading and flow coefficients are given, the blade speed U4 and the meridional velocity Cm5 can be obtained as per Equations (7) and (8). The rotor radius and blade height can be obtained utilizing Equations (9) and (10), respectively. After that, the blockage factor KB4 and blade thickness tb4 are calculated using Equations (11) and (12), respectively. The rotor number of blades Zr can be calculated using the Glassman correlation [25], expressed in Equation (13).

The thermodynamic properties of the working fluid can be calculated as per Equations (14)–(17), completing the inlet geometry of the rotor. Refprop, version 9 [26] software was utilized to obtain the thermodynamic properties of the fluid.

Turbine power can be obtained using the Euler equation, Equation (18). As proposed by Aungier [27], the meridional speed Cm5 can be calculated using Equation (19).

The smallest distance between two adjacent blades is the rotor throat o5. It can be obtained considering the behavior of the exit Mach number M5rel, as expressed in Equation (20)

2.3.2. Stator Modeling

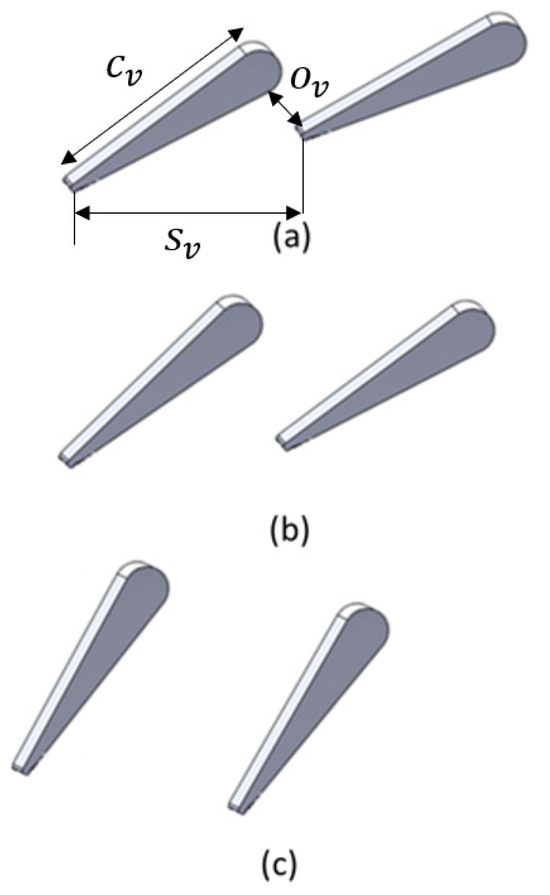

Three different stator openings are investigated, namely, 30%, 60%, and 100%, as shown in Figure 6. The stator opening is controlled by varying the stator width, , as shown in Equation (21). The stator throat width is shown in Figure 6, where sv is the nozzle pitch, as shown in Figure 6. are the sonic condition density and the speed of sound, respectively.

Figure 6.

Different stator openings: (a) 30%, (b) 60%, and (c) 100%.

The design method of the turbine nozzle is conducted in an iterative manner, as depicted in the flowchart in Figure 4. The tangential velocity at the stator outlet Cθ3 is obtained using Equation (22). As shown in the flowchart of the design process, the nozzle exit absolute velocity C3 is found in an iterative manner. The static enthalpy h3 is then found using Equation (23). The remaining thermodynamic properties of the working fluid are calculated, as shown in Equation (24). The mass flow rate is recalculated using Equation (25) until convergence is satisfied.

2.3.3. Volute Modeling

For simplicity, a circular section is assumed and Equations (26)–(29) are solved in an iterative manner. SC is the swirl coefficient, which is given a value of 0.95 as suggested by [24].

2.3.4. Losses Modeling

To verify the original assumption of the total to static efficiency , the rotor losses model is used. The turbine rotor is responsible for the majority of the losses. The most common rotor losses as outlined in [24,28] are incidence loss, passage loss, tip clearance loss, windage loss, and exit energy; these are included in the present model and summarized in Table 2. In a subsequent step, the rotor losses are summed together using Equation (30).

Table 2.

Losses model across the radial turbine stage.

3. Results and Discussions

This section presents the effects of the variable geometry turbine on the overall system performance at different engine operating points. The results are also compared with those obtained using a fixed geometry turbine.

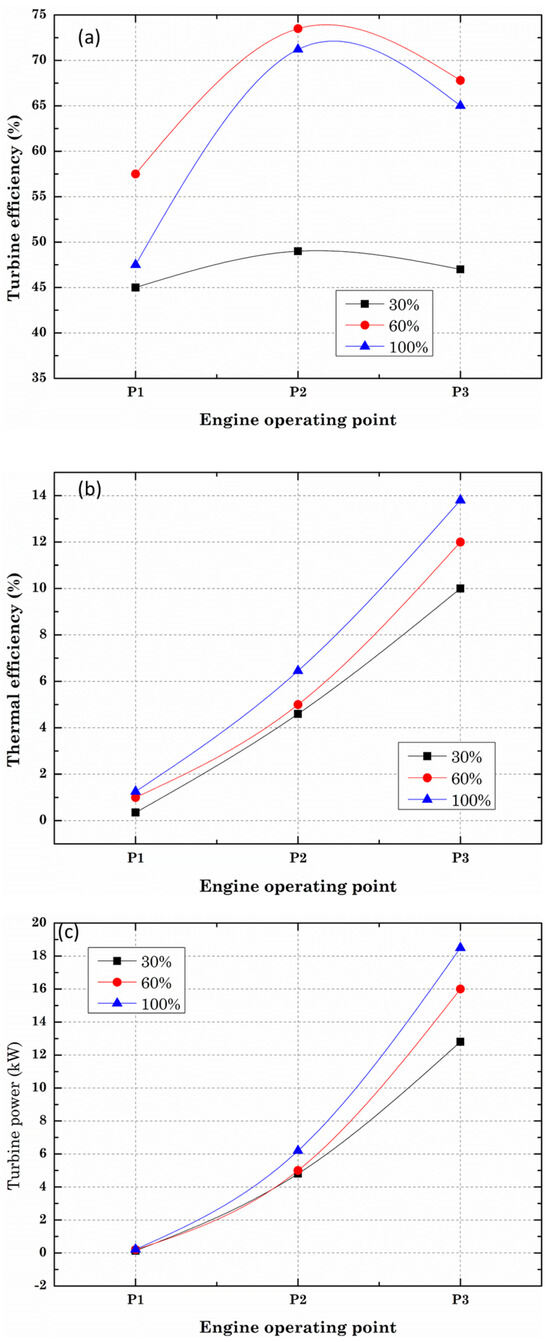

3.1. Effects of Stator Openings on Cycle and Turbine Performances

First, the effects of stator openings on turbine efficiency are investigated as shown in Figure 7. All engine operating points present a similar trend, where turbine efficiency increases, reaching a maximum value at P3, then decreases at P3 as shown in Figure 7a. At P1, the 60% opening presents substantially higher turbine efficiency with 57.5%, while P3 presents the lowest turbine efficiency with a value of 42.4%. The 30% opening presents the lowest turbine efficiency because of the excessive heat for the low mass flow rates of the exhaust gas as shown in Table 1. In other words, the mass flow rate of the working fluid decreases at low openings. Therefore, the excessive heat results in an extremely superheated fluid at the turbine inlet. Moreover, radial turbine losses (tip clearance and incidence, as shown in Table 2) increase at higher turbine inlet temperatures, which deteriorates the turbine efficiency as per Equation (30). Regarding stator openings, the 100% opening is not always favorable due to the increased fluid capacity that requires more heat to be fully vaporized.

Figure 7.

Effects of stator opening on (a) turbine efficiency, (b) turbine power, and (c) cycle thermal efficiency at different engine operating points.

Figure 7c depicts the behavior of turbine power with different stator openings and various engine operating points. It is clear that the 100% opening is superior for all the investigated engine points. This is expected, since turbine power is directly related to the mass flow rate and the enthalpy drop through the turbine. P3 with a 100% stator opening presents the highest turbine power with 18.5 kW. The 30% and 60% stator openings present maximum values of 12.60 and 16 kW, respectively. Again, as the mass flow rate decreases, the turbine power decreases according to Equation (18). Figure 7c shows that the 30 and 60% throat openings present comparable turbine power at engine point P2. This is due to the comparable exhaust temperatures as per Table 1.

The effects of stator openings on the thermal efficiency are depicted in Figure 7b. The cycle thermal efficiency is directly related to turbine power and the absorbed heat in the evaporator. Thermal efficiency follows the trend of turbine power qualitatively. As per Equation (6), the cycle thermal efficiency is a function of turbine power. As the turbine power increases, the cycle thermal efficiency increases. As already depicted in Figure 7c, the turbine power increases and, hence, the cycle efficiency increases. The 100% opening presents the highest thermal efficiency for all the engine operating points, followed by the 60% opening. The maximum thermal efficiency of the system is 13.8% and obtained at P3, with a 100% opening. The lowest thermal efficiency is 0.4% and presented by engine operating point P1 with a 30% stator opening.

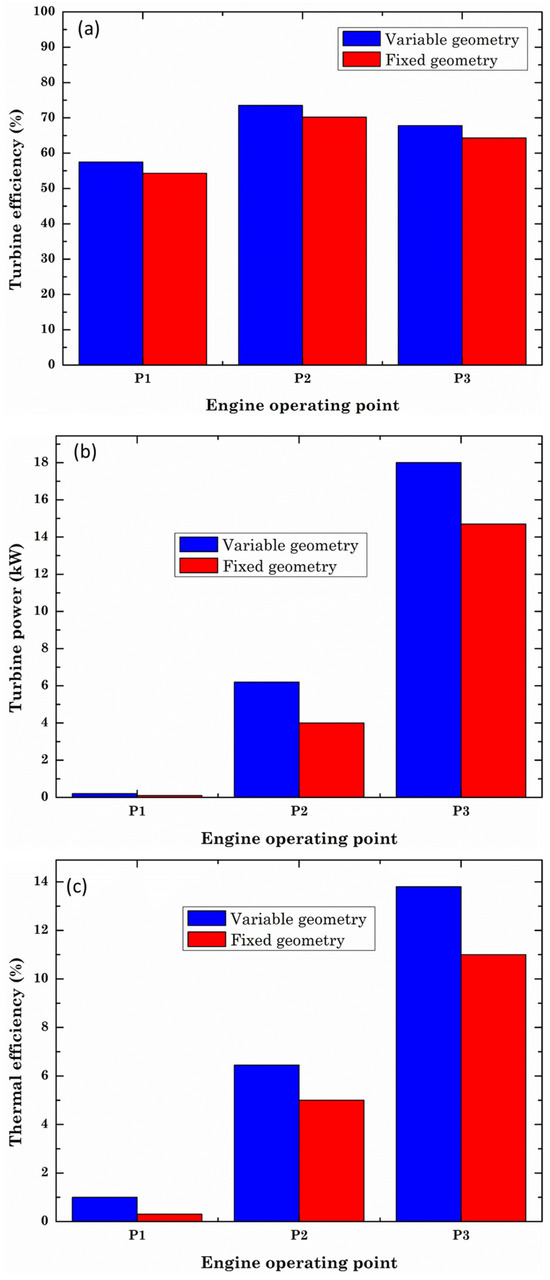

3.2. Comparison between Fixed and Variable Geometry Turbines

The potential of utilizing a variable geometry turbine instead of a fixed one is clearly depicted in Figure 8. It can be seen from Figure 8a that turbine efficiency for variable geometry is always higher than with a fixed geometry turbine for the various engine operating points. For a fixed geometry turbine, the mass flow rate is fixed. Therefore, and as explained earlier, the evaporator produces excessive heat which results in extremely superheated fluid. A variable geometry turbine, on the other hand, has the ability to adapt the wasted heat in the engine, which substantially improves the turbine performance. The minimum and maximum improvements in the turbine efficiency with variable geometry in comparison to that with fixed geometry are 20% and 70%, respectively. Similarly, turbine power is significantly higher when integrated with a variable geometry turbine, as shown in Figure 8b. This is because of the variable mass flow rate that directly influences the turbine power as per Equation (18). At P3, for instance, the variable geometry turbine presents 18 kW turbine power, while the fixed geometry turbine presents 14.7 kW. At P1, in fact, the turbine power could be doubled when utilizing a variable geometry turbine compared to a fixed one.

Figure 8.

Comparison between fixed and variable geometry turbines for (a) turbine efficiency, (b) turbine power, and (c) cycle thermal efficiency at different engine operating points.

Since cycle thermal efficiency is directly related to turbine performance, it presents similar trends, as shown in Figure 8c. A minimum improvement of 4.48% can be achieved when a variable geometry turbine is utilized. At P3, the advantage of utilizing a variable geometry turbine over a fixed one is clear. The cycle efficiency of the variable geometry turbine is 25.45% higher than that of the fixed geometry turbine.

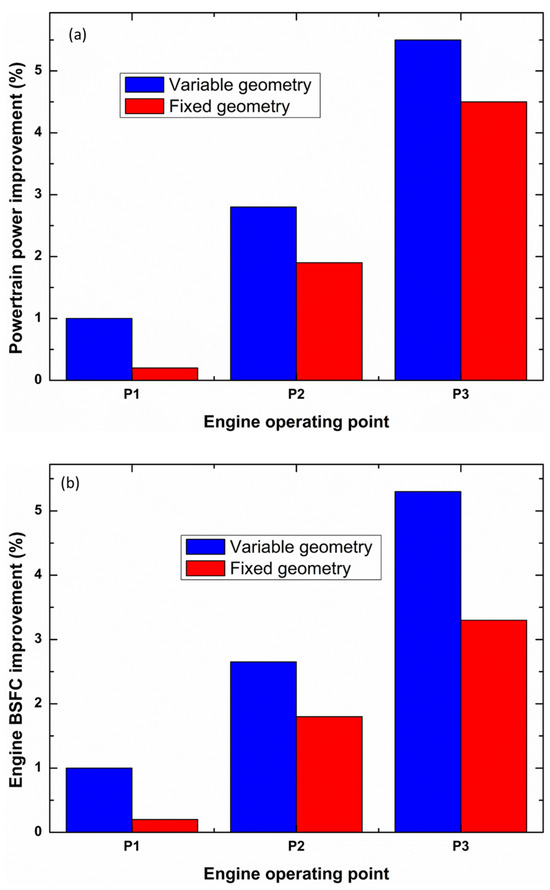

The main aim of coupling the ORC system to the engine was to explore the feasibility of such a system in improving engine performance. Figure 9 shows that the engine performance is enhanced in terms of power and BSFC after utilizing the ORC system. This enhancement is expected since the ORC power output is added to the engine power as per Equation (1). Similarly, and as per Equation (2), the engine BSFC improves by improving the engine power. As presented in Figure 9a, the engine power could improve by at least 1% when integrated with an ORC system with a variable geometry turbine. At P3, in fact, the engine power may increase by 5.5% when bottomed with an ORC system. Engine BSFC presents a similar trend, as shown in Figure 9b. Figure 9 also depicts the benefits of utilizing a variable geometry turbine instead of a fixed geometry turbine. It is clear that, a variable geometry turbine is favorable over different engine operating points.

Figure 9.

Comparison between fixed and variable geometry turbines for (a) powertrain power and (b) engine BSFC.

4. Conclusions

The current study explored the potential of integrating a variable geometry radial turbine instead of a fixed geometry turbine for an engine–ORC system. The study was carried out using different engine operating conditions, where different exhaust temperatures and mass flow rates were investigated. Moreover, different stator openings were explored: 30, 60, and 100%. The results confirmed the potential of utilizing variable geometry turbines in improving the overall system performance. This is because variable geometry turbines can adapt to the different operating conditions of the exhaust gases by changing the stator opening accordingly. The conclusions can be summarized as follows:

- The total to static efficiency of a variable geometry turbine is 25.45% higher than that of a fixed geometry turbine.

- Due to the increased mass capacity with a variable geometry radial turbine, the powertrain power increased substantially when integrated with an ORC as a bottom cycle. This increase could be as high as 5.5%.

- The ORC performance benefited significantly from the utilization of the variable geometry turbine. The ORC efficiency could be improved by at least 20%.

- The results also showed that even at low engine torque and power, P1, the overall system performance improved substantially by integrating an ORC system with a variable geometry turbine. However, this improvement is trivial (1%) and cannot justify the added complexity and cost.

- It is worth noting that the ORC system has a large weight, which will significantly affect its benefits. In the future, this phenomenon will be investigated in addition to cost analysis.

Author Contributions

Conceptualization, F.A. and I.A.; Data curation, F.A., A.A. (Abdullah Alghafis), I.A., A.A. (Ahmed Alzamil) and A.A. (Abdullah Alrashidi); Formal analysis, F.A. and A.A. (Abdullah Alghafis); Funding acquisition, F.A.; Investigation, F.A., A.S.A. and A.A. (Abdullah Alrashidi); Methodology, F.A., I.A., A.S.A. and A.A. (Ahmed Alzamil); Project administration, F.A.; Resources, A.S.A.; Software, F.A. and A.A. (Abdullah Alrashidi); Supervision, F.A.; Validation, F.A., I.A., A.S.A. and A.A. (Ahmed Alzamil); Visualization, F.A.; Writing—original draft, F.A.; Writing—review and editing, A.A. (Abdullah Alghafis), I.A., A.S.A., A.A. (Ahmed Alzamil) and A.A. (Abdullah Alrashidi). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Scientific Research Deanship at the University of Ha’il—Saudi Arabia through project number “RD-21 003”.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| 1–5 | Stations through turbine | Subscript | |

| a | Speed of sound [m/s] | h | Hub, hydraulic |

| A | Area | r | Radial, rotor |

| b | Blade height [m] | s | Insentropic, stator |

| K | Blockage factor [-] | t | Tip, total |

| C | Absolute velocity [m/s] | Greek Symbols | |

| Cm | Meridional velocity [m/s] | Efficiency [-] | |

| Cθ | Tangential velocity [m/s] | β | Relative angle [deg] |

| Ca | Axial coefficient [-] | ε | Clearance [m] |

| Cr | Radial coefficient [-] | Density [kg/m3] | |

| d | Diameter [m] | Absolute flow angle [deg] | |

| h | Enthalpy [kJ/kg] | ˠ | Stator setting angle [deg] |

| Ka | Discharge coefficient of the axial component [-] | Abbreviations | |

| Kr | Discharge coefficient of the radial component [-] | BSFC | Brake specific fuel consumption |

| Ka,r | Cross coupling coefficient of the axial and radial components [-] | CFD | Computational fluid dynamics |

| M | Mach number [-] | GWP | Global warming potential |

| Mass flow rate [kg/s] | ICE | Internal combustion engine | |

| o | Throat opening [m] | NOx | Nitrogen oxide |

| P | Pressure [kPa] | ORC | Organic Ranke cycle |

| s | Entropy [kJ/kg.k] | WHR | Waste heat recovery |

| T | Temperature [K] | ||

| U | Tip speed [m/s] | ||

| w | Relative velocity [m/s] | ||

| W | Work [kW] | ||

| z | Axial length [m] |

References

- Seher, D.; Lengenfelder, T.; Gerhardt, J.; Eisenmenger, N.; Hackner, M.; Krinn, I. Waste Heat Recovery for Commercial Vehicles with a Rankine Process. In Proceedings of the 21st Aachen Colloquium Automobile and Engine Technology, Aachen, Germany, 8–10 October 2012. [Google Scholar]

- Liu, L.; Wang, K.; Wang, S.; Zhang, R.; Tang, X. Assessing energy consumption, CO2 and pollutant emissions and health benefits from China’s transport sector through 2050. Energy Policy 2018, 116, 382–396. [Google Scholar] [CrossRef]

- Galindo, J.; Ruiz, S.; Dolz, V.; Royo-Pascual, L.; Haller, R.; Nicolas, B.; Glavatskaya, Y. Experimental and thermodynamic analysis of a bottoming Organic Rankine Cycle (ORC) of gasoline engine using swash-plate expander. Energy Convers. Manag. 2015, 103, 519–532. [Google Scholar] [CrossRef]

- Zhao, R.; Li, W.; Zhuge, W.; Zhang, Y.; Yin, Y. Numerical study on steam injection in a turbocompound diesel engine for waste heat recovery. Appl. Energy 2017, 185, 506–518. [Google Scholar] [CrossRef]

- Chen, W.; Fu, B.; Zeng, J.; Luo, W. Research on the Operational Performance of Organic Rankine Cycle System for Waste Heat Recovery from Large Ship Main Engine. Appl. Sci. 2023, 13, 8543. [Google Scholar] [CrossRef]

- Badescu, V.; Aboaltabooq, M.H.K.; Pop, H.; Apostol, V.; Prisecaru, M.; Prisecaru, T. Avoiding malfunction of ORC-based systems for heat recovery from internal combustion engines under multiple operation conditions. Appl. Therm. Eng. 2019, 150, 977–986. [Google Scholar] [CrossRef]

- Berchiche, A.; Guenoune, M.; Belaadi, S.; Léonard, G. Optimal Energy Integration and Off-Design Analysis of an Amine-Based Natural Gas Sweetening Unit. Appl. Sci. 2023, 13, 6559. [Google Scholar] [CrossRef]

- Liu, P.; Shu, G.; Tian, H.; Feng, W.; Shi, L.; Xu, Z. Preliminary experimental comparison and feasibility analysis of CO2/R134a mixture in Organic Rankine Cycle for waste heat recovery from diesel engines. Energy Convers. Manag. 2019, 198, 111776. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y.; Wang, L.; Yuan, Y.; Liu, Z.; Roskilly, A.P. Experimental Investigation of a Scroll Expander for Power Generation Part of a Resorption Cogeneration. Energy Procedia 2015, 75, 1027–1032. [Google Scholar] [CrossRef][Green Version]

- Yang, J.; Li, Y.; Tan, H. Integrated hydrogen liquefaction process with a dual-pressure organic Rankine cycle-assisted LNG regasification system: Design, comparison, and analysis. Appl. Energy 2023, 347, 121372. [Google Scholar] [CrossRef]

- He, Y.; Wu, H.; Zhang, Y.; Jin, T.; Xing, Z. Experimental Research on the Effects of Suction Ports on Twin Screw Expander Performance. Appl. Sci. 2022, 12, 3979. [Google Scholar] [CrossRef]

- Rijpkema, J.; Andersson, S.B.; Munch, K. Experimental study of an organic Rankine cycle with R1233zd(E) for waste heat recovery from the coolant of a heavy-duty truck engine. Energy Convers. Manag. 2021, 244, 114500. [Google Scholar] [CrossRef]

- Saidur, R.; Rezaei, M.; Muzammil, W.K.; Hassan, M.H.; Paria, S.; Hasanuzzaman, M. Technologies to recover exhaust heat from internal combustion engines. Renew. Sustain. Energy Rev. 2012, 16, 5649–5659. [Google Scholar] [CrossRef]

- Alshammari, F.; Karvountzis-Kontakiotis, A.; Pesyridis, A.; Usman, M. Expander Technologies for Automotive Engine Organic Rankine Cycle Applications. Energies 2018, 11, 1905. [Google Scholar] [CrossRef]

- Alshammari, F.; Pesyridis, A.; Alshammari, A.S.; Alghafis, A.; Alatawi, I.; Alzamil, A. Potential of capturing transportation wasted heat for better fuel economy and electricity generation: Comprehensive testing. Energy Convers. Manag. 2022, 267, 115939. [Google Scholar] [CrossRef]

- Thaddaeus, J.; Pesiridis, A.; Karvountzis-kontakiotis, A. Design of Variable Geometry Waste Heat Recovery Turbine for High Efficiency Internal Combustion Engine. Int. J. Sci. Eng. Res. 2016, 7, 1001–1017. [Google Scholar]

- Manente, G.; Toffolo, A.; Lazzaretto, A.; Paci, M. An Organic Rankine Cycle off-design model for the search of the optimal control strategy. Energy 2013, 58, 97–106. [Google Scholar] [CrossRef]

- Lebedevas, S.; Čepaitis, T. Research of organic rankine cycle energy characteristics at operating modes of marine diesel engine. J. Mar. Sci. Eng. 2021, 9, 1049. [Google Scholar] [CrossRef]

- Schuster, S.; Markides, C.N.; White, A.J. Design and off-design optimisation of an organic Rankine cycle (ORC) system with an integrated radial turbine model. Appl. Therm. Eng. 2020, 174, 115192. [Google Scholar] [CrossRef]

- Guillaume, L.; Legros, A.; Desideri, A.; Lemort, V. Performance of a Radial-Inflow Turbine Integrated in an ORC System and Designed for a WHR on Truck Application: An Experimental Comparison between R245fa and R1233zd. Appl. Energy 2017, 186, 408–422. [Google Scholar] [CrossRef]

- Wang, E.; Yu, Z.; Zhang, H.; Yang, F. A regenerative supercritical-subcritical dual-loop organic Rankine cycle system for energy recovery from the waste heat of internal combustion engines. Appl. Energy 2017, 190, 574–590. [Google Scholar] [CrossRef]

- Furukawa, T.; Nakamura, M.; Machida, K.; Shimokawa, K. A Study of the Rankine Cycle Generating System for Heavy Duty HV Trucks. SAE Tech. Pap. 2014, 1, 7. [Google Scholar] [CrossRef]

- Alshammari, F.; Ben Khedher, N.; Ben Said, L. Development of an automated design and off-design radial turbine model for solar organic Rankine cycle coupled to a parabolic trough solar collector. Appl. Therm. Eng. 2023, 230, 120677. [Google Scholar] [CrossRef]

- Moustapha, H.; Zelesky, M.F.; Baines, N.C.; Japikse, D. Axial and Radial Turbines, 1st ed.; Concepts NREC: White River Junction, VT, USA, 2003. [Google Scholar]

- Glassman, A. Computer Program for Design Analysis of Radial-Inflow Turbines; NASA: Washington, DC, USA, 1976. [Google Scholar]

- Lemmon, E.; Huber, M.; McLinden, M. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.0; National Institute of Standards and Technology, Standard Reference Data Program: Gaithersburg, MD, USA, 2010. [Google Scholar]

- Aungier, R.H. Turbine Aerodynamics: Axial-Flow and Radial-Inflow Turbine Design and Analysis, 1st ed.; American Society of Mechanical Engineers: New York, NY, USA, 2006. [Google Scholar]

- Rahbar, K.; Mahmoud, S.; Al-Dadah, R.K.; Moazami, N. Modelling and optimization of organic Rankine cycle based on a small-scale radial inflow turbine. Energy Convers. Manag. 2015, 91, 186–198. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).