Review of the Main Mechanical Testing Methods for Interlayer Characterization in Laminated Glass

Abstract

1. Introduction

2. Test Methods for LG Interlayers Characterization

- (i)

- Type of specimen: only interlayer or laminated glass;

- (ii)

- Type of load: static or dynamic;

- (iii)

- Type of stress: tension or shear;

- (iv)

- Duration of load: instantaneous or creep behavior;

- (v)

- Temperature effects: test conducted at different temperatures or at ambient temperature.

2.1. Uniaxial Tensile Tests of Interlayers

2.2. Through-Cracked Tensile Tests

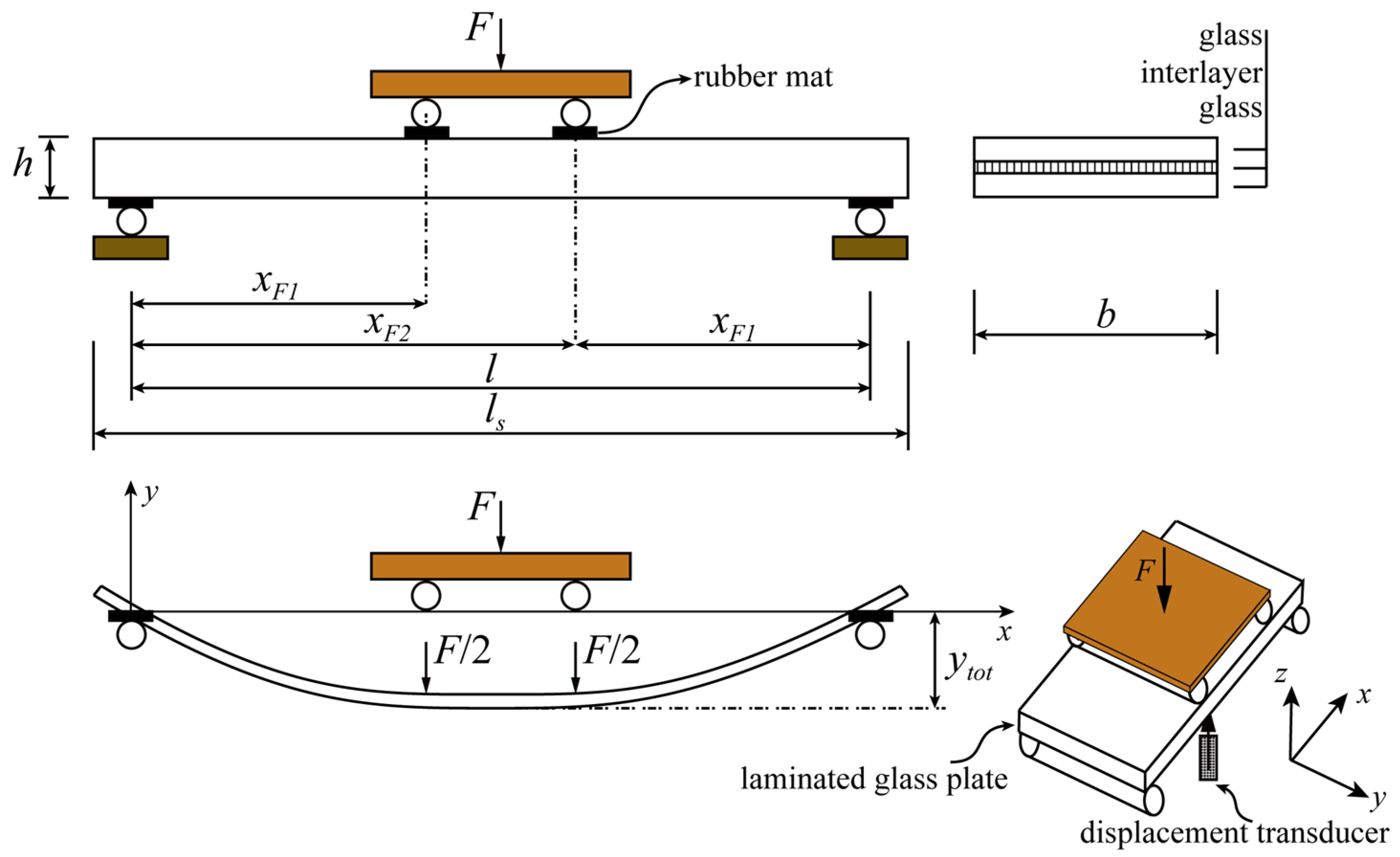

2.3. Four-Point Creep Bending

2.4. Single-Lap Shear Tests

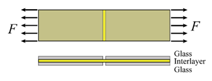

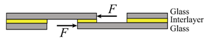

2.5. Double-Lap Shear Test

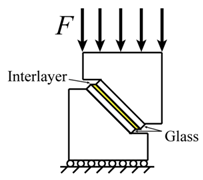

2.6. Compression Shear Tests

2.7. Creep Tests

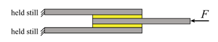

2.8. Stress Relaxation Tests

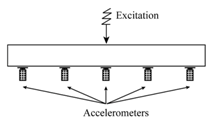

2.9. Modal Tests

2.10. Dynamic Torsion Tests

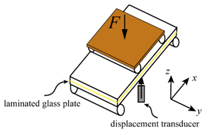

3. Evaluation of Interlayer Properties According to EN 16613:2019

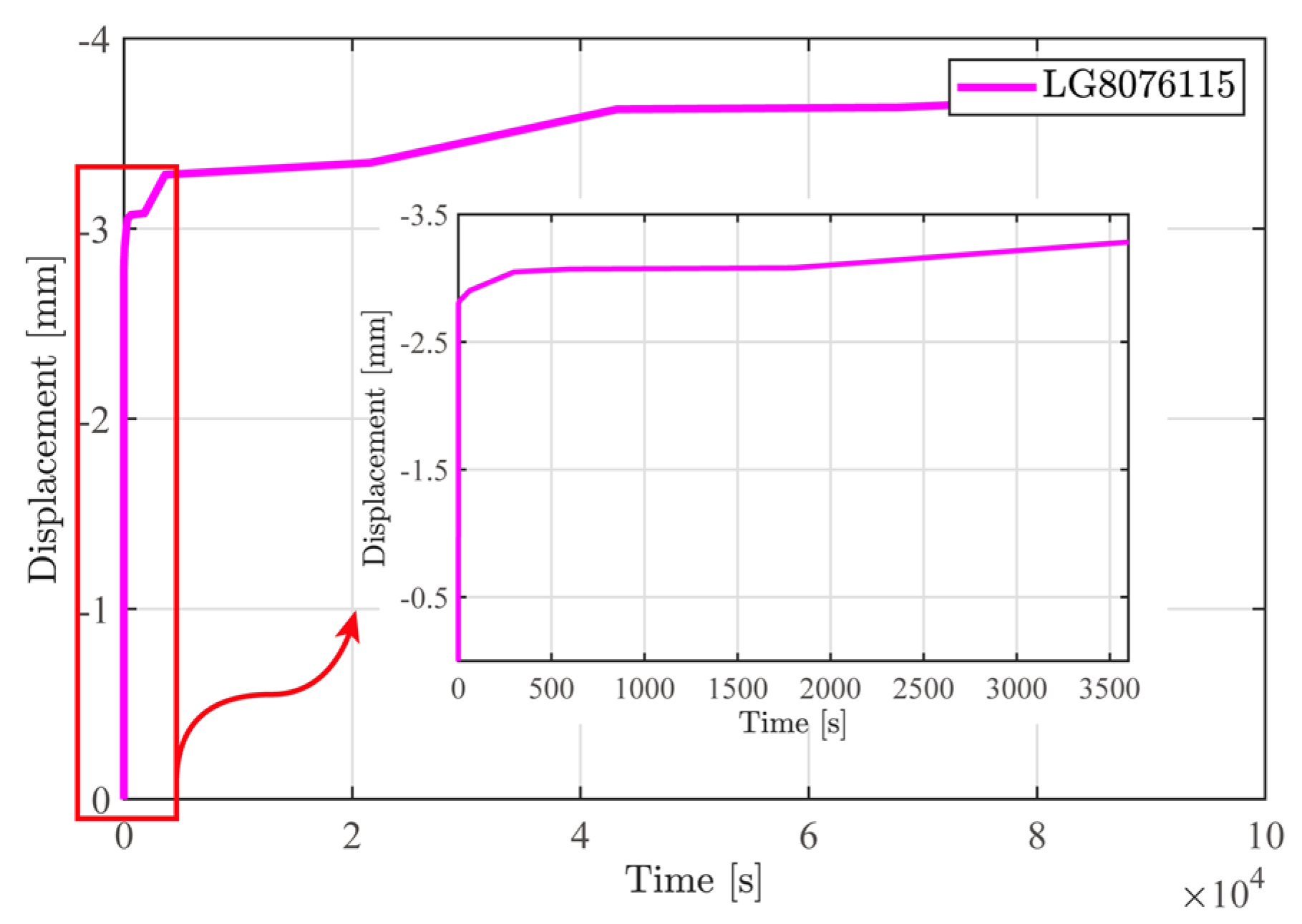

3.1. Experimental Research

3.2. F.E.M. Modeling

- (i)

- Constitutive assumptions of the materials (Section 3.2.1), in particular the viscoelastic behavior of interlayers;

- (ii)

- The numerical model (finite element type, mesh, boundary conditions, and the load application (Section 3.2.2);

- (iii)

- Validation of the finite element model established with the experimental results (Section 3.2.3).

3.2.1. Materials

3.2.2. Finite Element Type, Mesh, Boundary Conditions, and Load Application

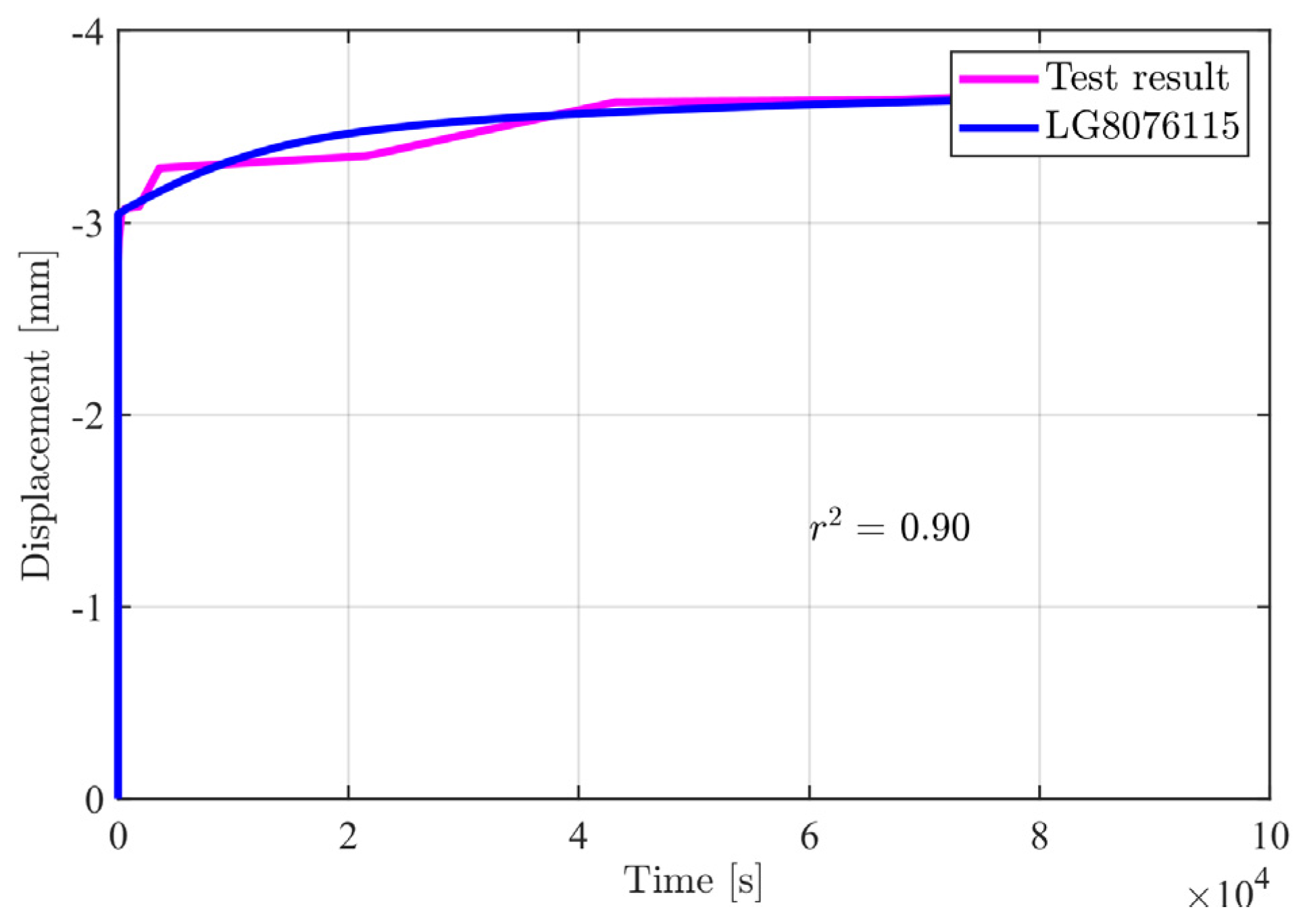

3.2.3. Validation of the Finite Element Model

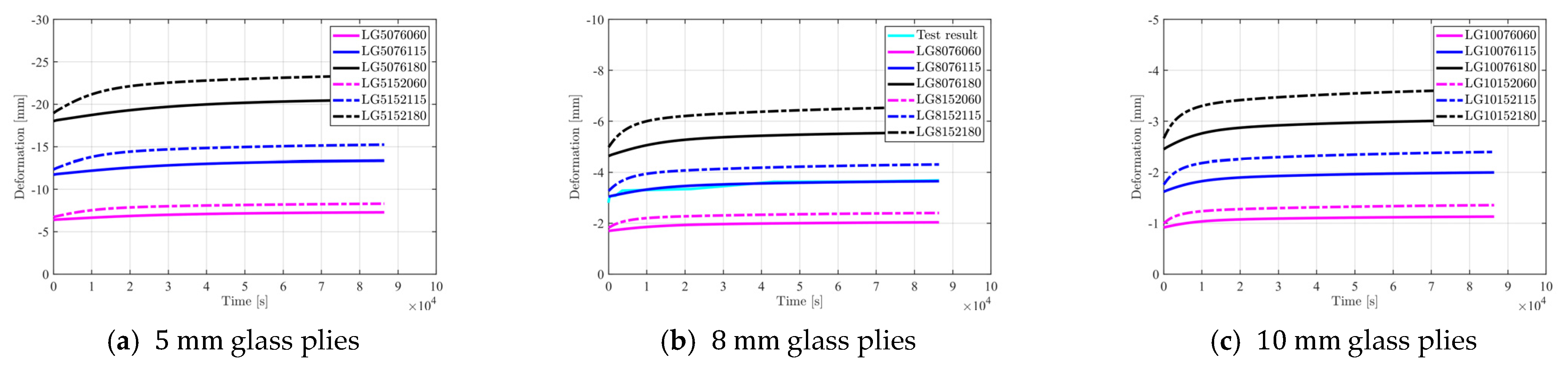

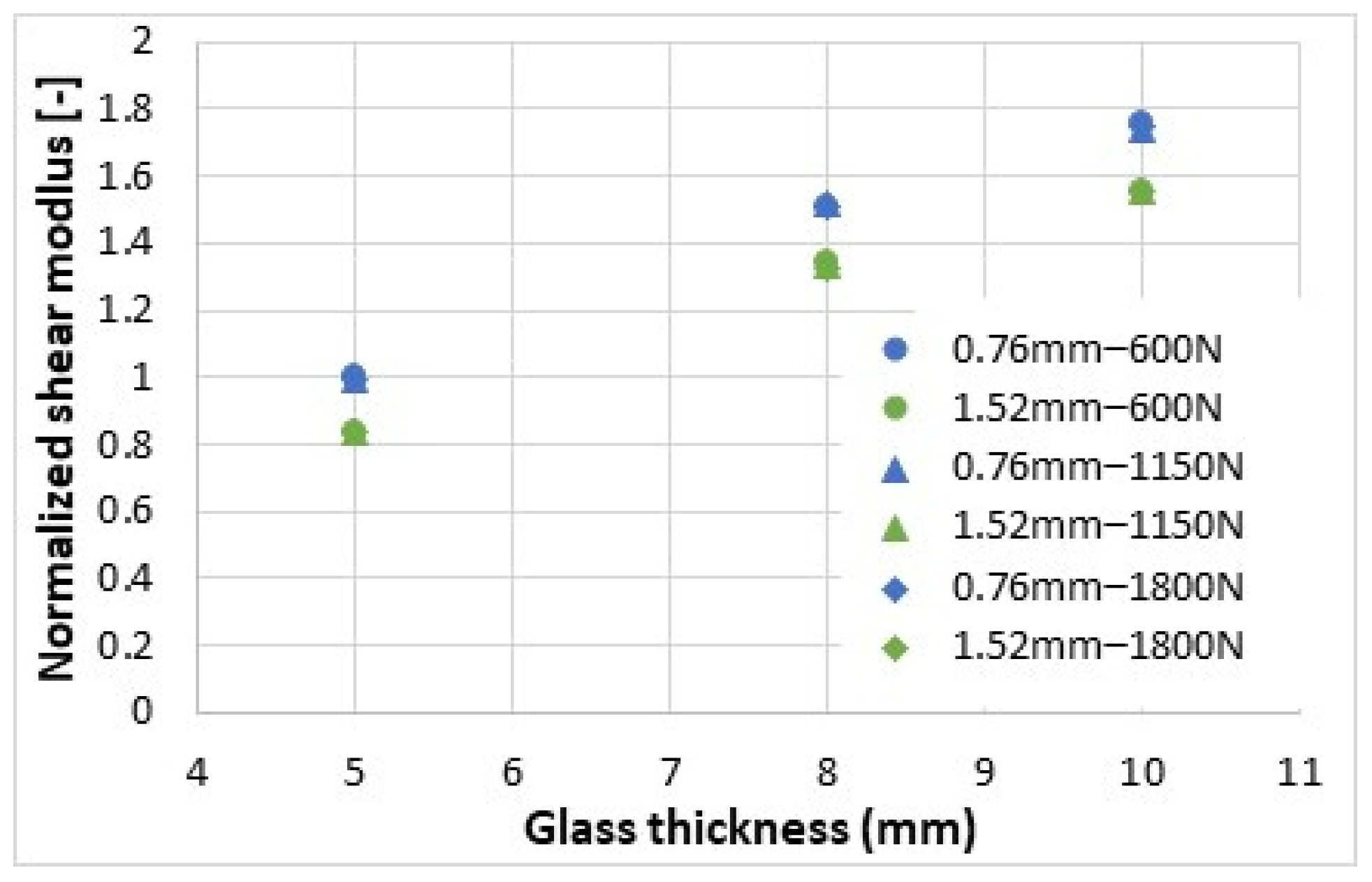

3.3. Parametric Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Piscitelli, L.R. Serviceability and Post-Failure Behaviour of Laminated Glass Structural Elements; Firenze University Press: Florence, Italy, 2019. [Google Scholar]

- CEN/TS 19100-1:2021-11; Design of glass structures: Part 1: Basis of Design and Materials. European Committee for Standardization: Brussels, Belgium, 2021.

- CEN/TS 19100-2:2021-11; Design of glass structures: Part 2: Design of out-of-Plane Loaded Glass Components. European Committee for Standardization: Brussels, Belgium, 2021.

- CEN/TS 19100-3:2021-11; Design of glass structures: Part 3: Design of in-Plane Loaded Glass Components and Their Mechanical Joints. European Committee for Standardization: Brussels, Belgium, 2021.

- Italian National Council—CNR DT 210 Guide for the Design, Construction and Control of Buildings with Structural Glass Elements. 2013. Available online: https://www.cnr.it/en/node/3843 (accessed on 21 June 2023).

- Biolzi, L.; Cattaneo, S.; Orlando, M.; Spinelli, P. Post-failure behavior of laminated glass beams using different interlayers. Compos. Struct. 2018, 202, 578–589. [Google Scholar] [CrossRef]

- Foraboschi, P. Optimal design of glass plates loaded transversally. Mater. Des. (1980–2015) 2014, 62, 443–458. [Google Scholar] [CrossRef]

- Jóźwik, A. Introduction to structural design of glass according to current European standards. Arch. Civ. Eng. 2022, LXVIII-2, 147–170. [Google Scholar]

- Kuntsche, J.; Schuster, M.; Schneider, J. Engineering design of laminated safety glass considering the shear coupling: A review. Glass Struct. Eng. 2019, 4, 209–228. [Google Scholar] [CrossRef]

- Viviani, L.; Di Paola, M.; Royer-Carfagni, G. Fractional viscoelastic modeling of laminated glass beams in pre-crack state under explosive loads. Int. J. Solids Struct. 2022, 248, 111617. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley & Son: New York, NY, USA, 1980. [Google Scholar]

- Centelles, X.; Ramon Castro, J.; Cabeza, L.F. Experimental results of mechanical, adhesive and laminated connections for laminated glass elements—A review. Eng. Struct. 2019, 180, 192–204. [Google Scholar] [CrossRef]

- Bez, A.; Bedon, C.; Manara, G.; Amadio, C.; Lori, G. Calibrated numerical approach for the dynamic analysis of glass curtain walls under spheroconical bag impact. Buildings 2021, 11, 154. [Google Scholar] [CrossRef]

- Yin, F.; Liu, M.; Bai, Y.; Zhang, Y.; Yang, L. Experimental study on failure mechanism of point-supported tempered glass panels under fire conditions. Structures 2021, 30, 495–502. [Google Scholar] [CrossRef]

- Bedon, C.; Fasan, M. Reliability of field experiments, analytical methods and pedestrian’s perception scales for the vibration serviceability assessment of an in-service glass walkway. Appl. Sci. 2019, 9, 1936. [Google Scholar] [CrossRef]

- Biolzi, L.; Bonati, A.; Cattaneo, S. Laminated Glass Cantilevered Plates under Static and Impact Loading. Adv. Civ. Eng. 2018, 2018, 7874618. [Google Scholar] [CrossRef]

- Duser, A.V.; Jagota, A.; Bennison, S.J. Analysis of glass/polyvinyl butyral laminates subjected to uniform pressure. J. Eng. Mech. 1999, 125, 435–442. [Google Scholar] [CrossRef]

- Hooper, P.A.; Blackman, B.R.K.; Dear, J.P. The mechanical behaviour of poly (vinyl butyral) at different strain magnitudes and strain rates. J. Mater. Sci. 2012, 47, 3564–3576. [Google Scholar] [CrossRef]

- Stevels, W.; D’Haene, P.; Zhang, P.; Haldeman, S. A comparison of different methodologies for PVB interlayer modulus characterization. Challenging Glass Conf. Proc. 2016, 5, 399–410. [Google Scholar]

- Centelles, X.; Martín, M.; Solé, A.; Ramon Castro, J.; Cabeza, L.F. Tensile test on interlayer materials for laminated glass under diverse ageing conditions and strain rates. Constr. Build. Mater. 2020, 243, 118230. [Google Scholar] [CrossRef]

- Ranocchiai, G.; Zulli, F.; Andreozzi, L.; Fagone, M. Test methods for the determination of interlayer properties in laminated glass. J. Mater. Civ. Eng. 2017, 29, 04016268. [Google Scholar]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2002.

- EN. 6721-1:2019; Plastics—Determination of Dynamic Mechanical Properties—Part 1: General Principles. International Organization of Standardization: Geneva, Switzerland, 2019.

- EN 16613:2019; Glass in Building-Laminated Glass and Laminated Safety Glass-Determination of Interlayer Mechanical Properties. European Standard: Brussels, Belgium, 2019.

- Centelles, X.; Pelayo, F.; Lamela-Rey, M.J.; Cabeza, L.F. Viscoelastic characterization of seven laminated glass interlayer materials from static tests. Constr. Build. Mater. 2021, 279, 122503. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S.; Rosati, G. Progressive damage and fracture of laminated glass beams. Constr. Build. Mater. 2010, 24, 577–584. [Google Scholar] [CrossRef]

- Biolzi, L.; Cagnacci, E.; Orlando, M.; Piscitelli, L.; Rosati, G. Long term response of glass–PVB double-lap joints. Compos. Part B Eng. 2014, 63, 41–49. [Google Scholar] [CrossRef]

- Nawar, M.; Salim, H.; Lafta, M.; Elshihy, A. Quasi-static performance of interlayer systems for laminated glass. J. Mater. Civ. Eng. 2016, 28, 04015084. [Google Scholar] [CrossRef]

- Chen, S.; Chen, Z.; Chen, X.; Schneider, J. Evaluation of the delamination performance of polyvinyl-butyral laminated glass by through-cracked tensile tests. Constr. Build. Mater. 2022, 341, 127914. [Google Scholar] [CrossRef]

- Serafinavičius, T.; Lebet, J.P.; Louter, C.; Lenkimas, T.; Kuranovas, A. Long-term laminated glass four point bending test with PVB, EVA and SG interlayers at different temperatures. Procedia Eng. 2013, 57, 996–1004. [Google Scholar] [CrossRef]

- Valarinho, L.; Correia, J.R.; Garrido, M.; Sá, M.; Branco, F.A. Flexural creep behavior of full-scale laminated glass panels. J. Struct. Eng. 2017, 143, 04017139. [Google Scholar] [CrossRef]

- Hána, T.; Eliášová, M.; Machalická, K.; Vokáč, M. Determination of PVB Interlayer’s Shear Modulus and Its Effect on Normal Stress Distribution in Laminated Glass Panels. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012076. [Google Scholar] [CrossRef]

- Hána, T.; Vokáč, M.; Eliášová, M.; Machalická, K.V. Experimental investigation of temperature and loading rate effects on the initial shear stiffness of polymeric interlayers. Eng. Struct. 2020, 223, 110728. [Google Scholar] [CrossRef]

- Valarinho, L.; Correia, J.R.; Branco, F.A. Experimental study on the flexural behaviour of multi-span transparent glass–GFRP composite beams. Constr. Build. Mater. 2013, 49, 1041–1053. [Google Scholar] [CrossRef]

- Centelles, X.; Castro, J.R.; Cabeza, L.F. Double-lap shear test on laminated glass specimens under diverse ageing conditions. Constr. Build. Mater. 2020, 249, 118784. [Google Scholar] [CrossRef]

- Froli, M.; Lani, L. The Influence of Parameter Setting on the Mechanical Properties of PVB in Lamination Process. In Challenging Glass 3; IOS Press: Amsterdam, The Netherlands, 2012; pp. 669–678. [Google Scholar]

- Biolzi, L.; Cattaneo, S.; Orlando, M.; Spinelli, P. Constitutive relationships of different interlayer materials for laminated glass. Compos. Struct. 2020, 244, 112221. [Google Scholar] [CrossRef]

- López-Aenlle, M.; Noriega, A.; Pelayo, F. Mechanical characterization of polyvinil butyral from static and modal tests on laminated glass beams. Compos. Part B Eng. 2019, 169, 9–18. [Google Scholar] [CrossRef]

- Andreozzi, L.; Bati, S.B.; Fagone, M.; Ranocchiai, G.; Zulli, F. Dynamic torsion tests to characterize the thermo-viscoelastic properties of polymeric interlayers for laminated glass. Constr. Build. Mater. 2014, 65, 1–13. [Google Scholar] [CrossRef]

- Hána, T.; Janda, T.; Schmidt, J.; Zemanová, A.; Šejnoha, M.; Eliášová, M.; Vokáč, M. Experimental and numerical study of viscoelastic properties of polymeric interlayers used for laminated glass: Determination of material parameters. Materials 2019, 12, 2241. [Google Scholar] [CrossRef]

- Weller, B.; Wünsch, J.; Härth, K. Experimental Study on Different Interlayer Materials for Laminated Glass. In Proceedings of the Glass Processing Days, Tampere, Finland, 17–20 January 2005; pp. 120–123. [Google Scholar]

- Weller, I.B.; Kothe, D.L.C.C.; Kothe, D.C.M.; Wünsch, D.I.J. Thermo Mechanical Behaviour of Polymeric Interlayer Materials. In Proceedings of the Glass Performance Days 2009, Tampere, Finland, 12–15 June 2009; pp. 734–737. [Google Scholar]

- Pelayo, F.; Lamela-Rey, M.J.; Muniz-Calvente, M.; López-Aenlle, M.; Vázquez, A.; Fernández-Canteli, A. Study of the time-temperature-dependent behaviour of PVB: Application to laminated glass elements. Thin-Walled Struct. 2017, 119, 324–331. [Google Scholar] [CrossRef]

- Chen, S.; Lu, Y.; Zhang, Y.; Shao, X. Experimental and analytical study on uniaxial tensile property of ionomer interlayer at different temperatures and strain rates. Constr. Build. Mater. 2020, 262, 120058. [Google Scholar] [CrossRef]

- Huntsberger, J.R. Adhesion of plasticized polyvinyl butyral) to glass. J. Adhes. 1981, 13, 107–129. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, S.; Shao, X. Shear modulus of ionomer interlayer: Effects of time, temperature and strain rate. Constr. Build. Mater. 2021, 302, 124224. [Google Scholar] [CrossRef]

- Sobek, W.; Kutterer, M.; Messmer, R. Shear Stiffness of the Interlayer in Laminated Glass. In Proceedings of the Glass Processing Days, Tampere, Finland, 13–16 June 1999; pp. 360–365. [Google Scholar]

- Hartwell, R.; Overend, M. Effects of Humidity and the Presence of Moisture at the Bond-line on the Interfacial Separation of Laminated Glass for Flat Glass Re-use. Challenging Glass Conf. Proc. 2020, 7. [Google Scholar] [CrossRef]

- Gant, F.S.; Bower, M.V. Domain of influence method: A new method for approximating Prony series coefficients and exponents for viscoelastic materials. J. Polym. Eng. 1997, 17, 1–22. [Google Scholar] [CrossRef]

- Wölfel, E. Nachgiebiger, Verbund Eine Näherungslösung und deren Anwendungsmöglichkeiten. Stahlbau 1987, 6, 173–180. [Google Scholar]

- Bennison, S.J.; Stelzer, I. Structural Properties of Laminated Glass. In Short Course; Glass Perfomance Days: Tampere, Finland, 2009. [Google Scholar]

| Test | Specimen (I/LG) | Load (S/D) | Stress (T/S) | Duration (I/C) | Temperature (A or M) |

|---|---|---|---|---|---|

Uniaxial tensile test [20,28] | I | S | T | I | A |

Through-cracked tensile test [29] | LG | S | T | I | A |

Four-point creep bending test [30,31] | LG | S | S | C | M |

Single-lap shear test [32,33] | LG | S | S | I | M |

Double-lap shear test [34,35] | LG | S | S | I | M |

Compression shear test [36] | LG | S | S | I | A |

Creep test [27] | LG | S | S | C | M |

Stress relaxation test [37] | LG | S | S | C | M |

Modal test [38] | LG | D | S | I | M |

Dynamic torsion test [39,40] | LG | D | S | I | M |

| Dynamic mechanical thermal analysis [25,39,41,42,43] | LG | D | T | I | M |

| Test | Advantage | Disadvantage |

|---|---|---|

| Uniaxial tensile test | Standard test Low cost Uniform stress distribution | Not laminated glass No long-term behavior |

| Through-cracked tensile test | Laminated glass | No long-term behavior Boundary conditions affect the stress distribution |

| Four-point creep bending test | Standard test Long-term behavior Laminated glass | Non-homogeneous stress distribution Affected by geometrical features |

| Single-lap shear test | Laminated glass | No long-term behavior Normal and shear stresses in the interlayer |

| Double-lap shear test | Laminated glass Uniform shear stress distribution | No long-term behavior Non-standard setup |

| Compression shear test | Standard setup Laminated glass Low cost | Normal and shear stresses in the interlayer |

| Creep test | Laminated glass Uniform shear stress Long-term behavior | Non-standard setup and specimen |

| Stress relaxation test | Laminated glass Uniform shear stress Long-term behavior | Non-standard setup |

| Modal test | Laminated glass Dynamic response | No long-term behavior Non-homogeneous stress distribution Non-standard test |

| Dynamic torsion test | Laminated glass Dynamic response | Non-standard test Non-homogeneous stress distribution |

| Dynamic mechanical thermal analysis | Laminated glass | Non-standard test |

| [s] | 123.6 | 3142.5 | 37,234.9 |

| [MPa] | 0.47 | 0.18 | 0.11 |

| Specimen | Glass Thickness [mm] | Interlayer Thickness [mm] | Load Level [N] | [mm] | [mm] | [–] | [MPa] |

|---|---|---|---|---|---|---|---|

| LG5076060 | 5 | 0.76 | 600 | 7.28 | 9.5 | 0.60 | 1.93 |

| LG5076115 | 1150 | 13.36 | 9.5 | 0.60 | 1.92 | ||

| LG5076180 | 1800 | 20.54 | 9.5 | 0.60 | 1.92 | ||

| LG5152060 | 1.52 | 600 | 8.30 | 9.1 | 0.39 | 1.62 | |

| LG5152115 | 1150 | 15.23 | 9.1 | 0.39 | 1.61 | ||

| LG5152180 | 1800 | 23.40 | 9.1 | 0.39 | 1.62 | ||

| LG8076060 | 8 | 0.76 | 600 | 2.04 | 14.7 | 0.59 | 2.92 |

| LG8076115 | 1150 | 3.65 | 14.7 | 0.59 | 2.93 | ||

| LG8076180 | 1800 | 5.56 | 14.7 | 0.59 | 2.92 | ||

| LG8152060 | 1.52 | 600 | 2.40 | 13.9 | 0.39 | 2.59 | |

| LG8152115 | 1150 | 4.31 | 13.9 | 0.39 | 2.58 | ||

| LG8152180 | 1800 | 6.57 | 13.9 | 0.39 | 2.56 | ||

| LG10076060 | 10 | 0.76 | 600 | 1.13 | 18.1 | 0.57 | 3.39 |

| LG10076115 | 1150 | 2.00 | 18.1 | 0.57 | 3.35 | ||

| LG10076180 | 1800 | 3.02 | 18.1 | 0.57 | 3.37 | ||

| LG10152060 | 1.52 | 600 | 1.36 | 17.0 | 0.37 | 3.01 | |

| LG10152115 | 1150 | 2.40 | 17.0 | 0.37 | 3.01 | ||

| LG10152180 | 1800 | 3.63 | 17.0 | 0.37 | 3.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Cattaneo, S.; Biolzi, L. Review of the Main Mechanical Testing Methods for Interlayer Characterization in Laminated Glass. Appl. Sci. 2023, 13, 8733. https://doi.org/10.3390/app13158733

Zhou S, Cattaneo S, Biolzi L. Review of the Main Mechanical Testing Methods for Interlayer Characterization in Laminated Glass. Applied Sciences. 2023; 13(15):8733. https://doi.org/10.3390/app13158733

Chicago/Turabian StyleZhou, Sicheng, Sara Cattaneo, and Luigi Biolzi. 2023. "Review of the Main Mechanical Testing Methods for Interlayer Characterization in Laminated Glass" Applied Sciences 13, no. 15: 8733. https://doi.org/10.3390/app13158733

APA StyleZhou, S., Cattaneo, S., & Biolzi, L. (2023). Review of the Main Mechanical Testing Methods for Interlayer Characterization in Laminated Glass. Applied Sciences, 13(15), 8733. https://doi.org/10.3390/app13158733