1. Introduction

China’s Inner Mongolia region encompasses 1.3 billion mu of natural grassland and 30 million mu of artificial grassland, creating unique advantages for the development of the dairy farming industry. With 66 major cattle and sheep farming counties in the region and approximately 95,000 large-scale cattle and sheep farms, it holds the highest number of cows in the country [

1,

2]. The herd size is steadily increasing year by year, resulting in a large volume of cow manure. Untreated cow manure can lead to massive environmental pollution [

3,

4,

5]. The acceleration of China’s urbanization and the rural population decline has created challenges in agricultural production, most significantly, the decrease in land fertility. Traditional agricultural production relies on the extensive use of chemical fertilizers and pesticides, causing environmental pollution, soil fatigue, and the imbalance of nature. Therefore, it is crucial to identify environmentally friendly and sustainable agricultural production methods.

Aerobic fermentation composting is one of the most effective methods to address environmental pollution and soil fatigue stemming from cow manure [

6,

7,

8]. Composting organically converts waste into high-quality fertilizer through the decomposition of microorganisms. However, traditional composting methods face issues such as insufficient fermentation, long fermentation periods, and odor [

9,

10,

11]. Consequently, more efficient and environmentally friendly composting equipment is necessary.

Cow manure is a prevalent organic waste, and its treatment and utilization play a significant role in environmental protection and agricultural production. Traditional cow manure treatment methodologies, including open-air composting [

10,

12], closed composting, and biogas fermentation, often results in odor interference, harmful gas generation, and low fertilizer efficiency. Recently, due to heightened environmental awareness and technological advancements, ventilation and heating of cow manure composting equipment have gained considerable attention. This equipment facilitates microbial activity in cow manure through heating and ventilation, accelerating compost decomposition and transformation [

13,

14,

15,

16], thereby enhancing fertilizer utilization efficiency and reducing odors and harmful gas emissions. However, current research on ventilated and heated cow manure composting equipment remains limited, necessitating the evaluation and optimization of such equipment, which holds significant theoretical and practical implications. This study aims to investigate the working principles, advantages, disadvantages, and factors affecting the performance of ventilated and heated cow manure composting equipment to provide a scientific basis for its promotion and application.

Conventional cow manure composting equipment design often lacks ventilation, heating, and real-time monitoring and adjustment functions, hindering effective manure maturation, compost utilization, moisture reduction, and providing suitable environmental conditions for microbial activities [

17,

18,

19]. Based on these limitations, traditional composting equipment was optimized. Cow manure composting equipment employing the target composting method was developed, selecting appropriate air pumps and designing a heating box with a ventilation structure. The control system was optimized for real-time monitoring and adjustment capabilities, creating an effective device to promote the composting process. Subsequently, fermented cow dung equipment was evaluated.

Traditional manure composting equipment has long faced several challenges that have hindered optimal composting processes [

20]. Chief among these drawbacks is the lack of ventilation and heating functions and the absence of a system for real-time composting data monitoring [

21,

22]. These limitations hinder the efficient maturation of livestock and poultry manure and obstruct comprehensive compost utilization. Additionally, the operational complexity of traditional composting equipment necessitates considerable manpower and resources, adding another layer of difficulty to the process [

23,

24]. In a bid to overcome these limitations and propel composting practices forward, this paper introduces a composting apparatus that checks all the boxes that traditional composting systems do not. This innovative device comes with integrated ventilation, heating, and real-time composting data monitoring capabilities [

25].

Ventilation is crucial for supplying the necessary oxygen for proper composting [

26]. The heating function maintains the ideal composting temperature, accelerating the breakdown of organic material. Real-time data monitoring allows for prompt adjustments and maintains ideal composting conditions [

27,

28]. Moreover, the apparatus inextricably links the aeration and heating devices. This linkage enhances the control of the entire composting process, optimizing operations and ensuring all components work in harmony. This new, integrated, and optimized equipment is a game-changer. It offers a solution conducive to the effective and efficient conversion of manure to valuable compost, marking a crucial progression in manure composting and organic waste management and, ultimately, more sustainable agriculture.

2. Materials and Methods

2.1. Structural Design of Ventilation and Heating Cow Manure Composting Equipment

2.1.1. Design of Cattle Manure Fermentation Tank Based on Target Compost Amount

In the operation of cow dung composting equipment, the design of inlet and outlet is very important. This paper believes cow dung import and export should be based on the fermentation tank’s structural size and target compost amount. The fermentation tank of cow dung composting equipment is regarded as a cylinder, and the corresponding inner cavity diameter and height [

29,

30,

31] can be further determined after the internal volume is known. The study found that cow dung composting is most effective when the height–diameter ratio of the fermentation tank is greater than 2, which also minimizes heat loss during the process. With this in mind, the authors designed the fermentation tank cavity of the composting equipment to have a height diameter ratio greater than 2, taking into account the equipment’s practical needs. To ensure optimal results, the inner cavity of the fermentation tank should meet the following expression:

Among them,

represents internal height;

refers to inner diameter. The authors designed the fermentation tank cavity of the composting equipment to have a height diameter ratio greater than 2 for optimal cow dung composting. To calculate the volume of the fermentation tank, the following expression should be used:

Among them,

represents the volume;

represents the diameter. Cattle manure composting equipment produces gases such as ammonia, methane, hydrogen sulfide, and carbon dioxide during the composting process. To accommodate these gases, a portion of the internal space in the fermentation tank needs to be reserved. The cow dung is in a loose accumulation state with large internal porosity [

32]. To facilitate feeding and material collection, the fermentation tank is equipped with a feed inlet and a discharge outlet on the side and bottom, respectively. The feed inlet includes open and closed bin doors and a ramp feed channel to avoid mixer impact, achieve synchronous feeding and mixing, and improve mixing efficiency [

33,

34,

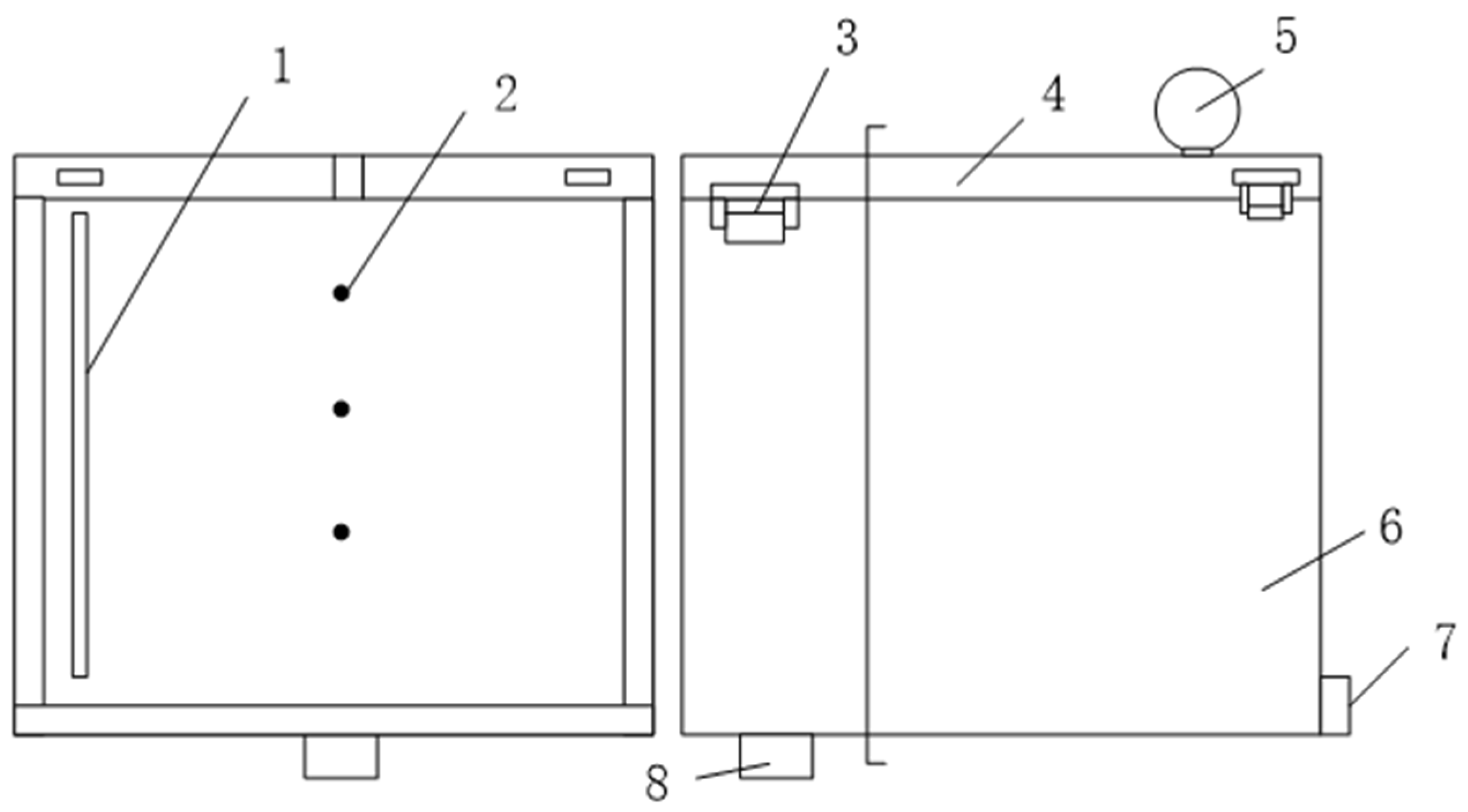

35]. The bottom of the fermentation tank is funnel-shaped to allow for natural material falls, and the outlet is located in the middle. The structure diagram of the fermentation tank of cow dung composting equipment designed in this paper is shown in

Figure 1.

Cow dung composting is a relatively static and oxygen-consuming process. The amount and activity of microorganisms are different due to different fermentation processes of materials in different areas of composting, which affects the overall fermentation rate of materials [

36]. Regular mixing and rotation of the reactor body can make the materials in the reactor body mix evenly and provide enough oxygen for the reactor body, which is conducive to the life activities of aerobic bacteria. During mixing, the temperature of each space area is evenly mixed [

17]. Therefore, in the design of composting equipment fermentation tanks, special attention should be paid to the rationality of its mixing section design.

2.1.2. Reasonability Verification of Mixing Blades Based on ANSYS

The stirring blade design presented in this article comprises three transverse main blades and multiple oblique auxiliary blades. The main blade is welded to the middle support section at a 45° angle to the shaft’s axial direction. The three transverse main blades are spaced 120° apart. Each transverse main blade has three parallel diagonal auxiliary blades fixed to it, with a 60° angle between them. Threaded holes are located on the middle support section’s side, allowing it to be locked onto the shaft using set screws.

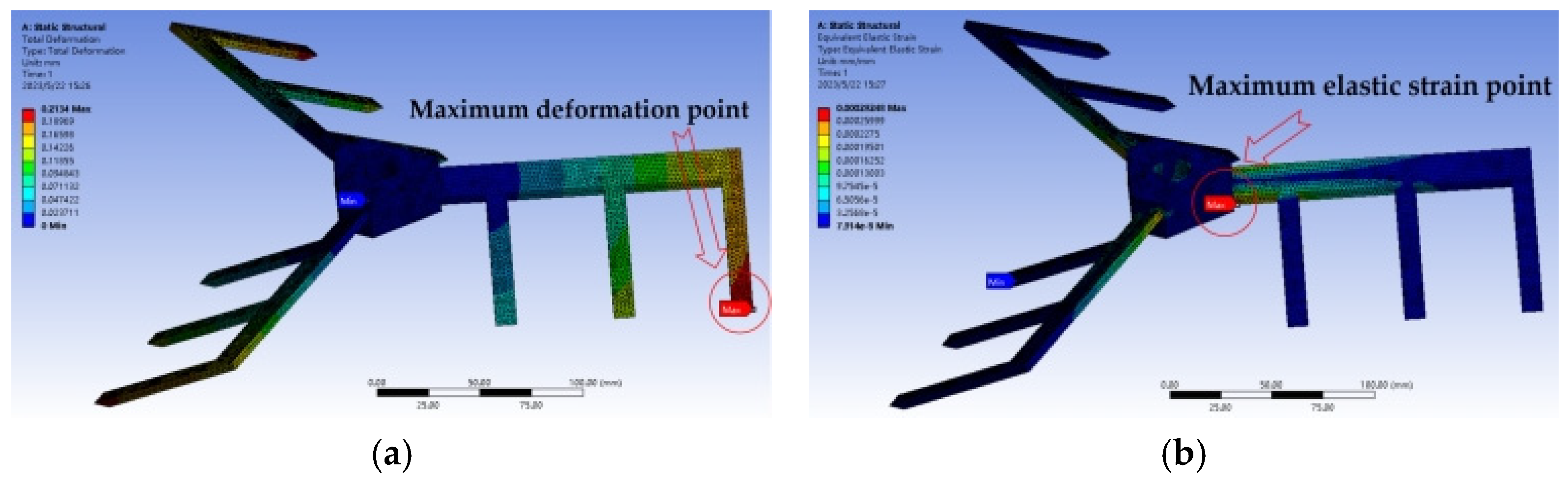

Three-dimensional solid modeling of the mixing blades in the mixing section was completed using SOLIDWORKS 2023, with a physical image displayed in

Figure 2. During finite element analysis, the mixing device was idealized, and a 3D tetrahedral 4-node computational domain grid was generated using Workbench, featuring a mesh size of 2 mm and a total of 167,074 elements. According to material mechanical property estimates, the external load produced by the mixing device is approximately 120 N. Based on literature analysis [

37], the maximum temperature of the aerobic composting pile can reach 70 °C. To better simulate the composting environment, the temperature is set at 70 °C. Analysis results are illustrated in

Figure 3.

As shown in

Figure 3, the maximum deformation of the three-blade E-shaped stirring blade is located at the tip of the E-shaped blade, while the maximum stress and elastic strain are located at the connection part between the blade and the fixed component. The maximum stress is 58.194 Mpa, which meets the standard and has strong firmness. Based on previous research [

38], it can be seen that the stirring blade has stirring function, which is superior to most stirring structures on the market and will greatly improve the degree of fermentation maturity.

2.1.3. Selection of Air Pump for Composting Device

As an important part of the hot air device of the cow dung composting equipment, the air pump can provide the required air volume for the operation of the composting equipment and the working air pressure required by the agitator. The air pump design involves creating two separate ventilation pipelines using a y-shaped three-way interface. One of these pipelines delivers and heats the air, which is then dispersed into the fermentation tank through an aeration pipe. The other pipeline is connected to a pneumatic agitator with a cylinder-driven shaft. The speed of the agitator increases in proportion to the gas flow rate as long as the working pressure remains stable. Based on the above requirements, select the type of air pump commonly used in the market at present, and finally, determine the air pump model and working parameters for this equipment, as shown in

Table 1.

As shown in

Table 1, the model and working parameters of the air pump of the cow dung composting equipment with vent heating designed in this paper, the ventilation volume of its air outlet meets the requirements of the ventilation volume required by the stack, and the exhaust pressure meet the requirements of the working pressure of the pneumatic mixer.

2.1.4. Structural Design of Heating Box with Vent

After completing the air pump selection and working parameter design of the above composting equipment, the next step is to comprehensively design the structure of the heating box with vents of the composting equipment. Before designing the structure of the heating box with vents, it is necessary to calculate the ventilation rate of the cattle manure composting equipment with vents.

Ventilation is an important factor affecting the quality of compost products. Part of the total ventilation is used to provide microbial degradation of organics, and part of it is used to remove water in compost [

39]. Therefore, the total ventilation volume is determined by considering the oxygen consumption of physical and chemical reactions and the oxygen required for water removal. There are many organics in the pile, including about 15% nitrogenous organics, about 90% volatile solids, about 60% material moisture, and about 12% biodegradable organics [

40]. The formula for calculating the ventilation rate of composting equipment is

Among them,

represents the ventilation volume of cow dung composting equipment;

represents the total material mass of cow dung composting equipment;

represents the material moisture content of cow dung composting equipment;

represents the amount of volatile solids in cow dung composting equipment;

represents the degradable organic matter of cow dung composting equipment;

represents the oxygen mass fraction in the air during the operation of the cow dung composting equipment; and

refers to the air density under standard atmospheric pressure when the cow dung composting equipment is running. According to the ventilation calculation results of the cow dung composting equipment, the ventilation distribution ring of the equipment vent is designed, and the structure diagram is shown in

Figure 4.

There are two kinds of ventilation pipes used in this composting equipment; one is a PU hose, and the other is a stainless steel pipe. The parameters and function settings of the two ventilation pipes are shown in

Table 2.

As shown in

Table 2, this refers to the parameter and function settings of the vent pipe of composting equipment with vent heating. There are three modes of ventilation and oxygen supply: passive ventilation, natural ventilation, and forced ventilation [

12]. Forced ventilation is to inject sufficient air into the reaction tank regularly and quantitatively through the mechanical agitator. The ventilation hole is arranged on the blade of the mixing shaft to allow air to enter during the mixing operation [

36]. On this basis, the heating box with the vent of the composting equipment is designed as a rectangle, and the size of the heating box refers to the structure of the fermentation tank. This paper describes the design of a heating box made of 304 stainless steel, with dimensions of 500 mm × 350 mm × 300 mm and vents [

41]. The box consists of a top cover and a main structure, with an electric heating pipe installed in the middle of the top cover. Air inlets and outlets are located on both sides of the box, connected to the air inlet and outlet pipes. Air is pumped into the box through the pipe and heated by flowing through the electric heating pipe. Heat balance analysis is necessary to understand the heat transfer during air heating and determine the appropriate power of the electric heating tube. The selection of electric heating tubes is based on commonly used types in the market.

2.2. Control Design of Ventilation and Heating Cow Manure Composting Equipment

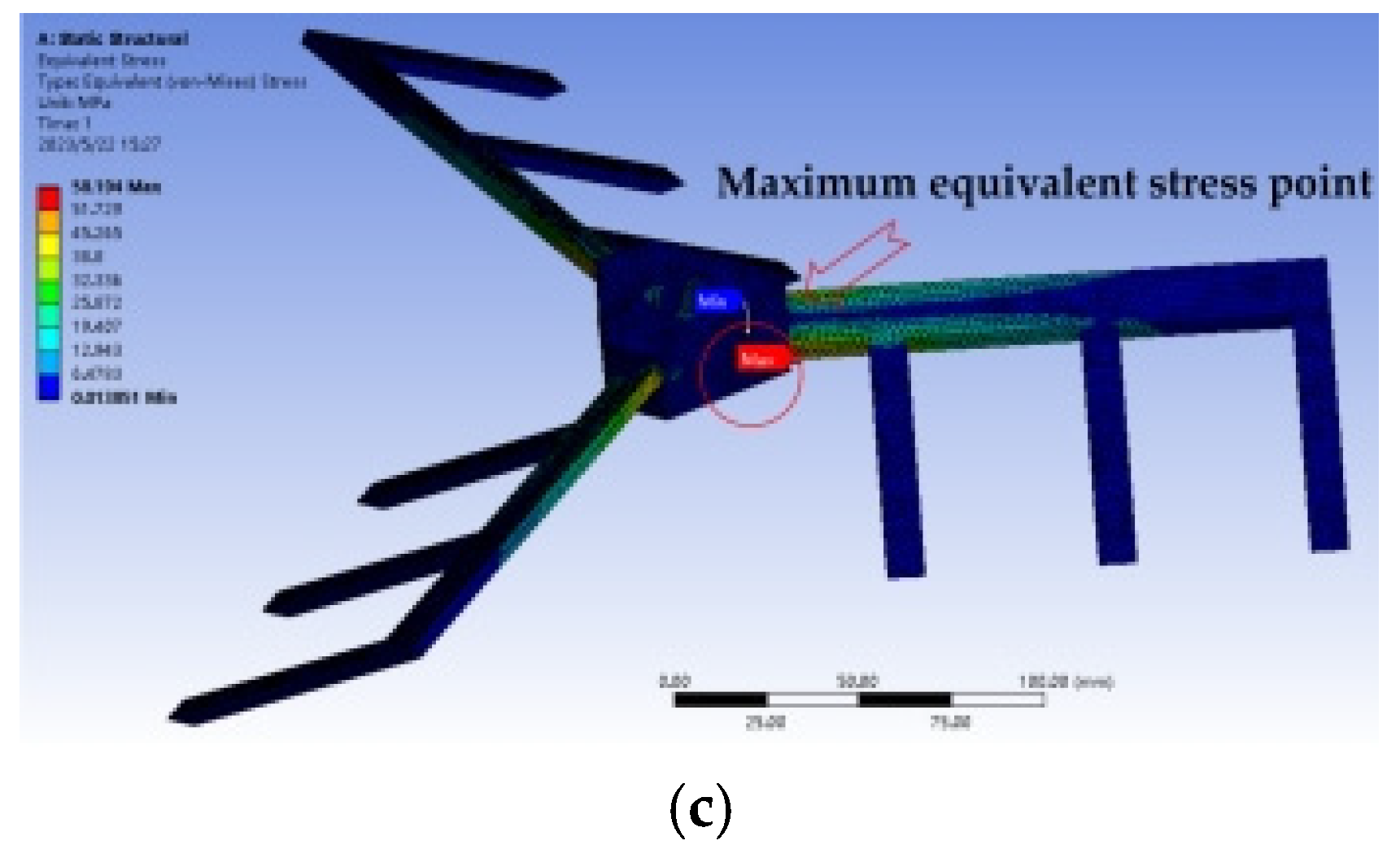

2.2.1. MCGS Touch Screen Design

Touch screens serve as crucial human–computer interaction tools and are vital components of automation control equipment. In the composting control system, the touch screen establishes communication with the PLC and sensors, allowing it to display real-time data collected by the sensors during the pile fermentation process and from the air within the tank. Simultaneously, it provides an operation interface, facilitating start and stop control of the air pump, electric heating tube, and motor. The chosen touch screen model is the Kunlun Tongtai TPC7062Ti, which is primarily designed for constructing the user window section. This section displays real-time data information on the stacking material and allows for automatic or manual operation. The primary monitoring interface of the user window is showcased in

Figure 5.

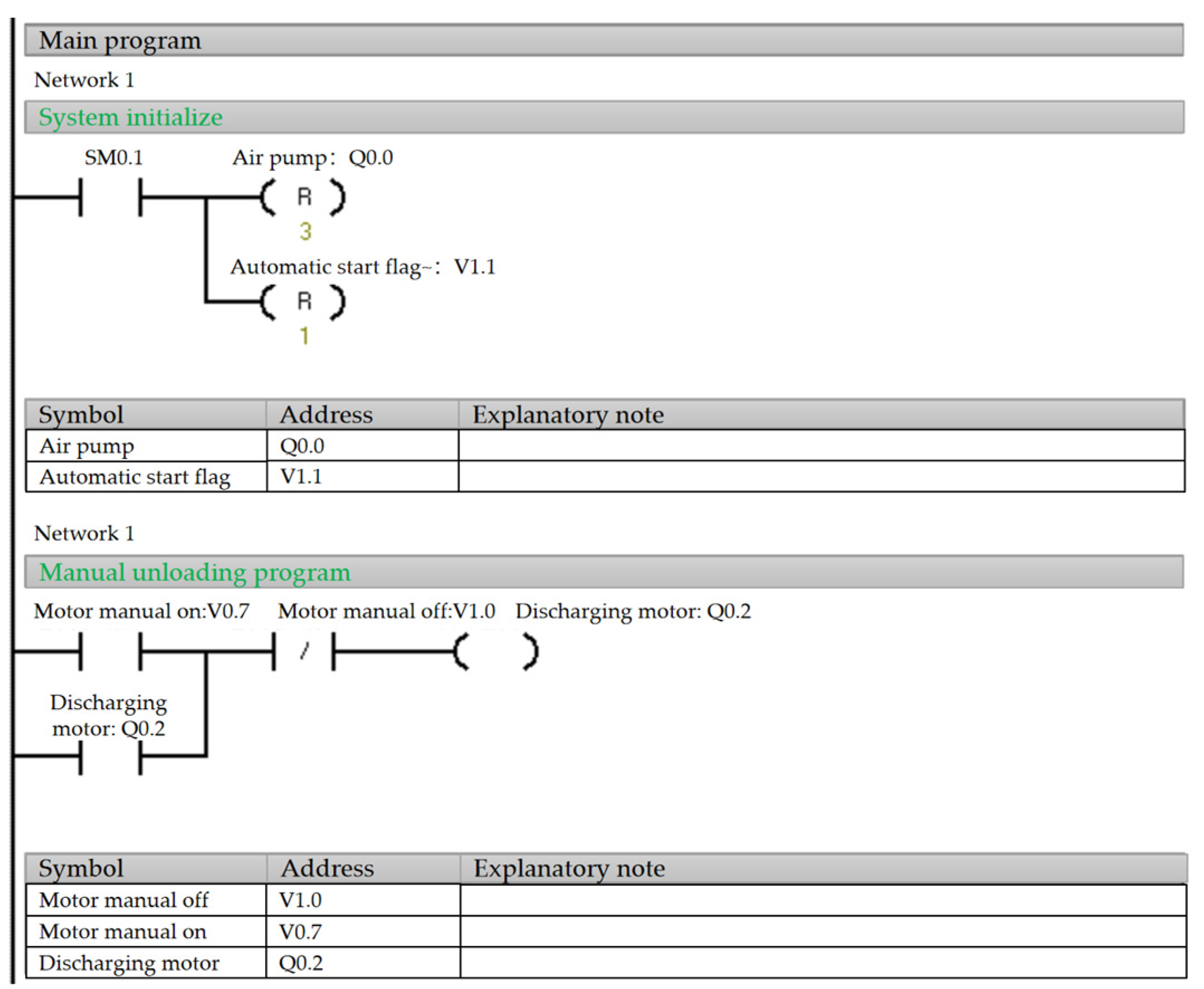

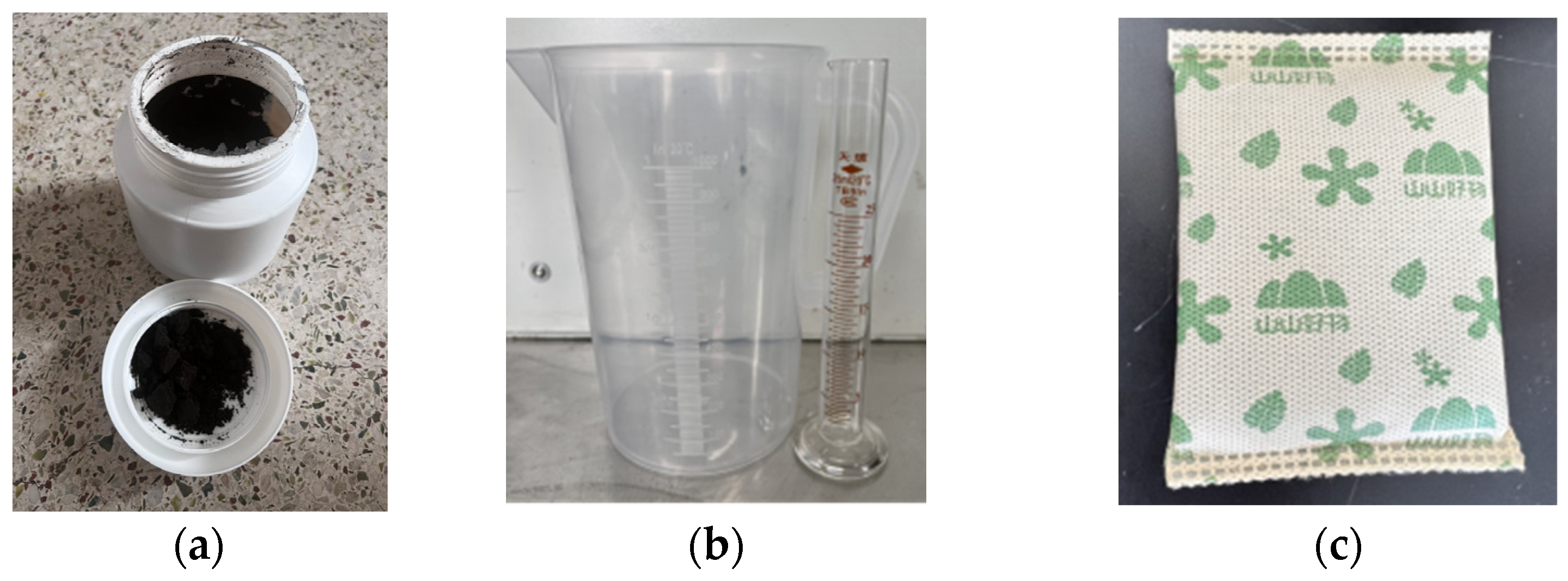

2.2.2. PLC Programming

To achieve the high-temperature stage of composting, it is essential to maintain the compost material’s temperature between 55 °C and 65 °C for as long as possible, promoting organic matter decomposition and enhancing the fermentation rate. If the stacking temperature falls below 55 °C, the control system activates the electric heating tube for preheating. Upon reaching the preheating time, the air pump is started for ventilation, and both the air pump and electric heating tube are turned off once the stacking temperature reaches 65 °C or above. Simultaneously, microorganisms decomposing organic matter will continuously consume oxygen, reducing the oxygen concentration in the fermentation tank. If the oxygen concentration drops below 15%, the control system starts the air pump to introduce room temperature air until the tank’s oxygen concentration rises above 19% before turning off the air pump.

The Siemens S7-200/200 CN series PLC is programmable using V4.0 STEP7 MicroWIN SP9 software, which supports three programming methods: ladder diagram, function block diagram, and instruction table. Considering the control principles and conditions of this composting control system, using a ladder diagram for control program writing is more convenient and intuitive. The main program section is illustrated in

Figure 6.

2.2.3. Touch Screen and PLC Communication Settings

The touch screen connects to the PLC via an RS485 serial port. During communication, it not only receives data information transmitted by sensors through the PLC but also sends control commands for the PLC to execute related operations. By utilizing configuration design software, data channels and connection variables are set within the window of the central and western gate PLC equipment, which allows for a one-to-one correspondence between data and instruction transmission. In the device editing window, corresponding data channels are added, and channel types, data types, channel addresses, and read/write methods are configured. Subsequently, variable objects and their connections from the database are specified, establishing a link between the touch screen and the PLC.

2.3. Experimental Verification of the Composting Effect of Cow Manure

2.3.1. Test Materials

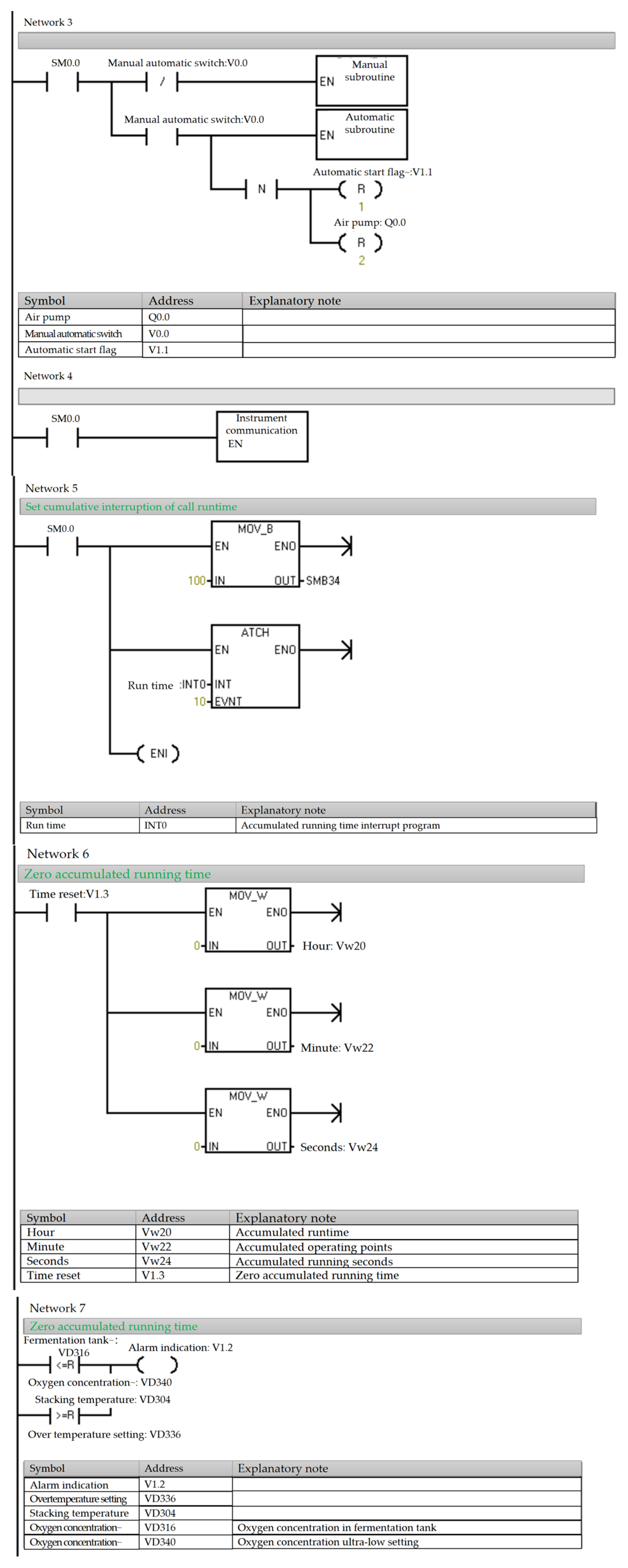

The cow manure used in the composting experiment was taken from the modern dairy farming pasture in Inner Mongolia, China, as shown in

Figure 7a; corn stalks are taken from the Agricultural Machinery Laboratory of the College of Inner Mongolia Agricultural University, which are crushed into 2–3 mm stalks, as shown in

Figure 7b.

2.3.2. Test Equipment

When carrying out composting experiments, besides the necessary composting materials, additional experimental materials, supplies, and relevant testing instruments or equipment are required, as shown in

Figure 8 and

Figure 9 The test materials and supplies primarily entail fermentation starter, activated carbon, mung bean seeds, farmland soil, seedling basins, glass measuring cylinders, and watering cans. The testing instruments mainly comprise electronic scales and small soil testers.

Before composting, it is necessary to add an appropriate amount of fermentation starter to the heap to increase the content of microbial flora and improve. The decomposition effect of organic matter promotes the composting of the heap. The additional amount of the fermentation starter is related to the actual composting amount, and they are added at the ratio of 1 kg: 1 mL (stack: fermentation starter). Activated carbon is placed in the deodorization device of the composting equipment to adsorb and filter the odor discharged from the fermentation tank; seedling pots, farmland soil, mung bean seeds, spray pots, etc., are used for determining the seed germination index of the compost samples taken during subsequent composting experiments, which is one of the evaluation indicators of the compost maturity.

The electronic scale is mainly used for weighing the quality of composting raw materials, such as cow manure and corn straw, and plays an accurate role in controlling the mixing ratio of materials in pre-composting experiments and actual composting experiments. The soil multi-element tester can detect indicators such as pH value, temperature and humidity, electrical conductivity EC, and nitrogen, phosphorus, and potassium content of the compost material. In subsequent composting experiments, this data can be used as one of the evaluation indicators for whether the compost material has completed its maturity.

2.3.3. Test Method

The most suitable initial moisture content for composting is 50% to 60%, while the original moisture content of cow manure raw materials cannot meet this requirement. Therefore, pretreatment is needed to improve the moisture content. At the same time, the relevant research results of livestock manure composting show that [

42,

43,

44] adding crop straw can effectively improve the organic matter content of the compost and the levels of nitrogen, phosphorus, potassium, and other elements in the final manure are significantly increased. Referring to the research content of the previous literature and the production status of manure, the mixed stack of cow dung and corn straw was mixed at a mass ratio of 20:1, and then appropriate water was added to adjust the initial moisture content of the mixed stack to reach 50~60%.

During the actual composting experiment, the temperature, humidity, and oxygen concentration within the composting material’s tank are recorded at 12 h intervals. This data collection continues until the end of the composting cycle. Based on previous research, it is determined that compost can decompose within a few days after three ventilation–heating cycles. Therefore, the experiments designed in this article all feature three ventilation–heating treatments. When placing the processed pile material into the fermentation tank, daily unloading and sampling of the pile material are performed.

A portion of the stacked samples is combined with a specific amount of farmland soil, and 36 mung bean seeds are spread across the mixture. Regular watering simulates the actual planting effect, allowing the observation of seed germination. Another portion of the sample is poured into a bucket, and a soil comprehensive sensor is used to detect the pile material and collect data. By utilizing the MCGS data report function and experimental test data, graphs illustrating fermentation temperature changes, seed germination index, oxygen concentration changes within the tank, and stack humidity changes can be generated. The acquired graphs can be further discussed and analyzed.

3. Results and Analysis

3.1. Temperature Changes in Composting

Figure 10 illustrates the temperature changes during the composting process of cow manure composting equipment. According to the composting material’s temperature change chart, the total duration of this composting experiment is 13 days, with the high-temperature stage lasting about 8 days under ventilated heating conditions. The composting material’s maximum temperature can reach 69.9 °C. The time interval between two adjacent ventilation and heating operations in this experiment is approximately 48 h, indicating that the insulation time of the fermentation tank designed in this article is around 48 h.

The national standard document “Technical Specification for Harmless Treatment of Livestock and Poultry Manure” specifies requirements for solid livestock and poultry manure treatment: the pile temperature must be maintained above 50 °C for no less than 7 days or above 45 °C for no less than 14 days. With a high-temperature stage duration of 8 days, this experiment satisfies the national standard requirements.

3.2. Humidity Changes in Composting

Figure 11 displays the changes in humidity during the composting process. As composting progresses, the humidity of the compost continuously decreases, with the rate of decrease being faster during the high-temperature stage. During the cooling stage, the rate of decrease gradually slows down and ultimately stabilizes at around 9%.

The industry standard document organic fertilizer stipulates that the moisture content of composted organic fertilizer shall be less than 30%. After 13 days of composting, the moisture content decreased from 58.3% to 9.3%, meeting national requirements.

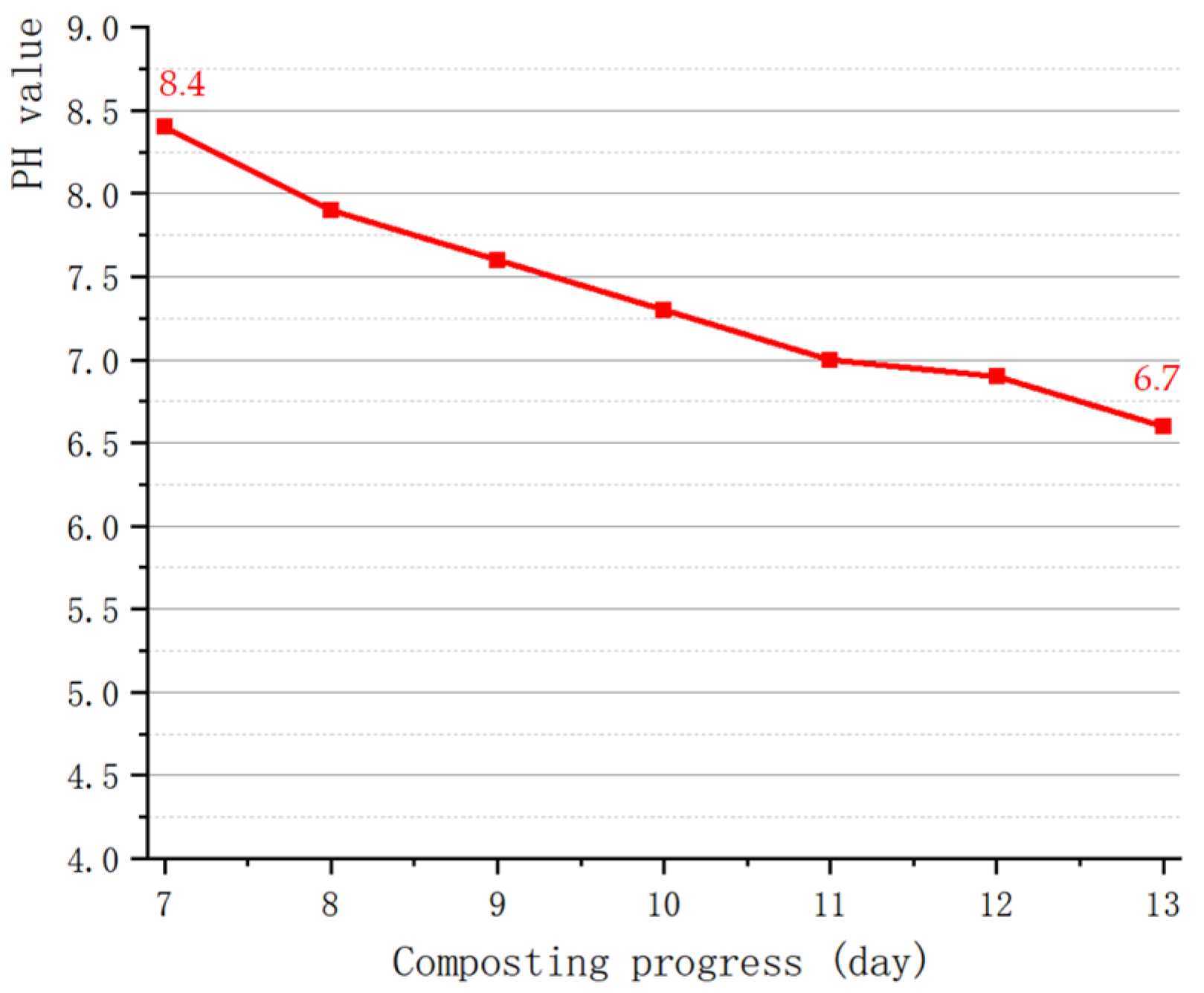

3.3. PH Value Changes in Composting

Once the artificial heating phase starting on the 8th day of the composting process is completed, the pH value of the composting material is sampled and tested.

Figure 12 shows the changes in pH value during the composting process. From the graph, it can be seen that the pH value of compost changes from weakly alkaline to weakly acidic in the middle and later stages of composting, both before and after improvement. This observation is consistent with the results of the natural fermentation composting experiment.

The industry standard document organic fertilizer (NY 525-2012) stipulates that the pH of composted organic fertilizer should be between 5.5 and 8.5. The pH value after composting is 6.7, which meets the requirements of national standards.

The composting process often witnesses a decrease in pH value during the mature or stable stage, primarily due to the interplay between the production and consumption of organic acids. Initially, microorganisms decompose organic matter, generating a significant volume of organic acids and, consequently, lowering the pH value. As the process progresses, these microorganisms further break down these acids while converting ammonia nitrogen—a major component of compost—into nitrate. Both these processes consume hydrogen ions within the compost heap, facilitating an increase in pH value. However, during the compost’s mature stage, the generation of organic acids declines as most materials have been decomposed. Consequently, hydrogen ion concentrations rise within the compost heap, causing the pH value to decrease once more. This pH transition not only signifies compost maturity but also aids in suppressing the proliferation of harmful microorganisms, thereby enhancing the compost’s safety and stability.

3.4. Seed Germination Index Changes in Composting

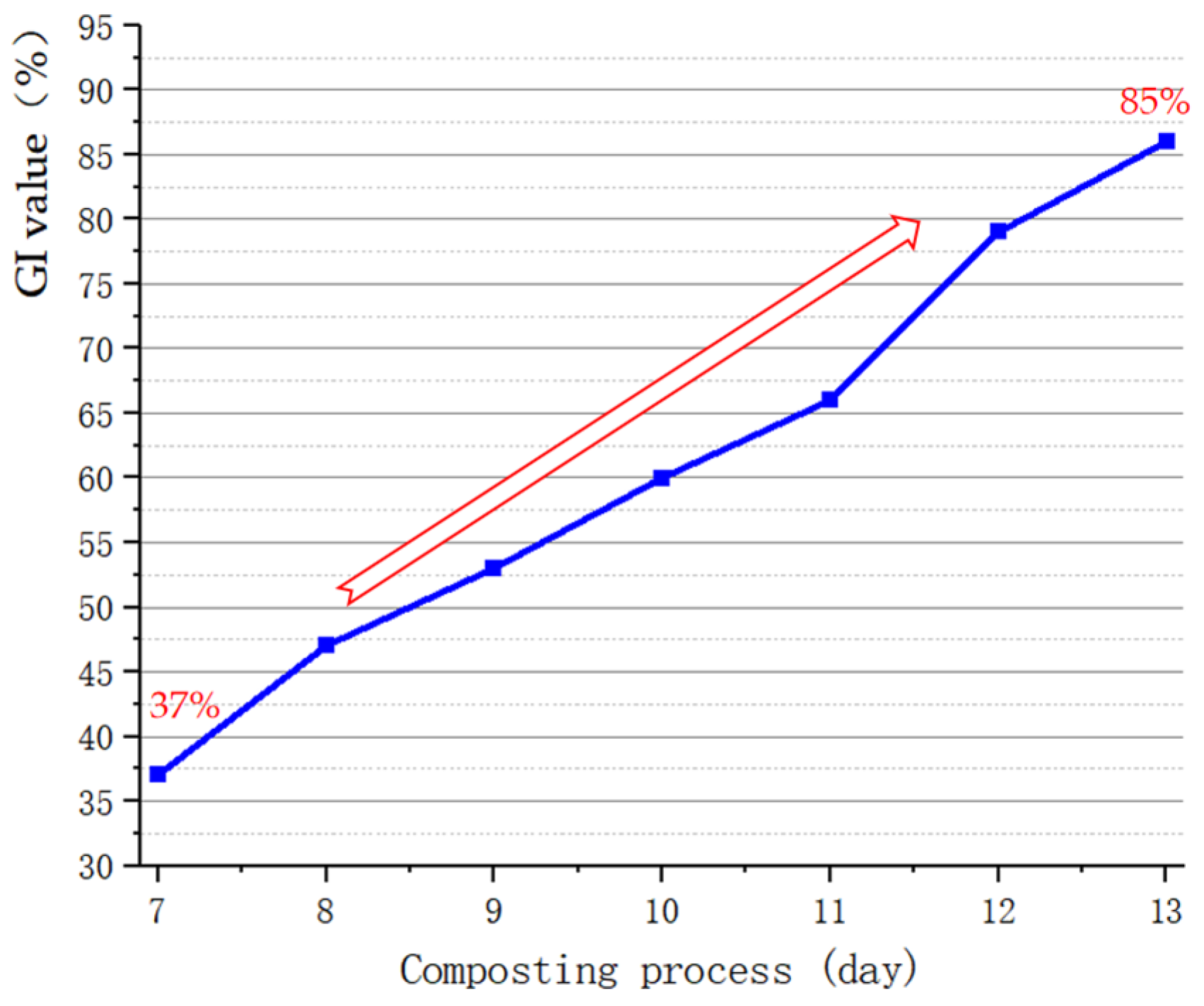

The Germination Index (GI) is an indicator used to evaluate the degree of harmless and stable composting by assessing the compost’s inhibitory effect on plant germination. This index can detect the level of plant toxicity in compost samples and predict changes in plant toxicity within the compost.

The changes in seed germination rate during the composting process are shown in

Figure 13. After the heating stage, the seed germination index (GI) of the pile material was sampled and tested in this experiment.

According to

Figure 13, the germination index (GI) significantly increased during the composting process. From 37% at the beginning to 85% at the end of composting. According to the standard, when the GI is greater than 80%, it indicates that the pile material has completed decomposition and is basically free from plant toxicity. After composting, the GI value of cow dung manure is increased to about 85%, which meets the requirement of low plant toxicity for organic fertilizer.

4. Discussion

Cow dung, an abundant byproduct of dairy farming, carries a dichotomous potentiality—it can manifest as a source of pollution or serve as organic fertilizer. Its transformation hangs in the balance, subject to the effectiveness of composting management. Ineffective composting management or insufficient utilization of cow dung often culminates in dung accumulation, leading to environmental pollution. Hence, devising an efficient cow manure composting system is critical to optimizing its use as organic fertilizer and minimizing its environmental impact.

Traditional cow manure composting methods, while practical, often grapple with operational inefficiencies and practical application issues. These issues undermine the effectiveness of composting and, consequently, the quality of the resulting product. Recognizing these challenges, this article introduces an innovative cow manure composting device designed to improve traditional composting equipment.

The new composting device posits enhancements that address the deficiencies of traditional equipment. Notably, it incorporates ventilation, heating, and real-time monitoring and adjustment capabilities—functions untypically seen in traditional composting methods. Ventilation ensures optimal aeration, which is crucial to accelerating microbial activity and, consequently, the composting process. Simultaneously, integrated heating expedites the composting process by providing an environment conducive to microbial degradation of organic matter. Real-time monitoring and adjustment mechanisms imbue users with the capability to monitor key composting parameters such as temperature and moisture and make real-time adjustments in response to disturbances. Such improvements hold immense potential to boost the efficiency of the composting process and enhance the quality of the resulting compost.

The research conducted and presented in this article has precipitated the development of this cow manure composting system—a system that synergizes ventilation, heating, and real-time monitoring. The implementation of these features has resulted in significant improvement in the efficiency and fermentation quality of cow manure composting.

The resulting compost, following the improved composting process, meets and often exceeds the requisites of pertinent composting standards. These standards include parameters such as high-temperature duration, water content, pH, and a seed germination indicator referred to as the GI value. The composted cow manure complies with high-temperature duration norms, signifying that it has undergone sufficient processing to eliminate disease-causing pathogens. The compost also maintains appropriate water content, which is necessary for controlling moisture-dependent processes such as microbial activity and nutrient availability. Moreover, the compost registers acceptable pH and GI values, indicating its neutrality and non-phytotoxicity, respectively.

More importantly, the quality of the resulting compost provides conducive conditions for the survival and catabolism of microorganisms and aerobic organisms—an often overlooked yet crucial aspect of composting. The presence of these organisms ensures the continuous breakdown of organic matter within the compost even after its application to the soil. This ensures that nutrients are made available at a rate conducive to plant uptake, further enhancing the value of the compost as an organic fertilizer.

In conclusion, efficient management and utilization of cow manure through composting are essential to harnessing its potential as a valuable organic fertilizer while simultaneously averting its potential as an environmental pollutant. The introduction of the enhanced cow manure composting system, as presented in this study, marks significant advances in composting technology. It signifies a move towards enhancing composting efficiency, improving compost quality, and ultimately moving towards more sustainable and environmentally friendly agricultural practices.

5. Conclusions

This study provides compelling evidence that the cow manure composting equipment proposed herein significantly enhances the efficiency of livestock manure composting while yielding high-quality organic fertilizer. Through our thorough analysis, we derive two key conclusions:

The incorporation of efficient ventilation and heating systems, complemented by increased automation, augments the overall composting process efficiency. This advancement harbors the potential to be transformative in the realm of agricultural sustainability and offers solutions to the longstanding challenges faced in livestock manure management;

Compiled data confirms that the newly developed cow dung composting equipment successfully upholds the high-temperature duration of composting materials, aligning with industry-established norms. Moreover, the technology consistently produces organic fertilizer presenting desirable parameters: satisfactory water content, optimal acidity levels, and favourable seed germination rates.

In summary, the research findings underscore the feasibility and potential benefits of the proposed composting equipment, pointing towards a promising future for improved livestock manure management and sustainable agricultural practices.

Author Contributions

Conceptualization, methodology, writing—original draft preparation, and investigation, K.R. and L.S.; validation, formal analysis, and writing—review and editing, X.H. and H.W.; writing—review and editing and supervision, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Innovation Team of Higher Education Institutions in Inner Mongolia Autonomous Region, grant number NMGIRT2312 and Modern Agriculture and Inner Mongolia Grassland Talent Innovation Team, grant number No. [2018] 19.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| MCGS | Monitor and Control Generated System |

| PLC | Programmable logic Controller |

| °C | Anders Celsius |

| GI | Germination index |

| PH | Potential of hydrogen |

References

- Li, S.; Dang, Y.Q.; Tang, F.B.; Meng, Y.J. Optimization research on evaluation index of aerobic compost based on ventilation frequency control. Soil Fertil. Sci. China 2020, 3, 182–188. [Google Scholar]

- Zhang, Z.H.; Zhang, D.H.; Liu, H. Overview of International Dairy Industry Development in 2020 and Analysis and Prospect of China’s Dairy Industry Situation. Chin. Cows 2021, 5, 51–54. [Google Scholar]

- Lu, Y.; Chadwick, D.; Norse, D.; Powlson, D.; Shi, W. Sustainable intensification of China’s agriculture: The key role of nutrient management and climate change mitigation and adaptation. Agric. Ecosyst. Environ. 2015, 209, 1–4. [Google Scholar] [CrossRef]

- Antonious, G.F.; Turley, E.T.; Gyawali, B.R.; Freeman, A.C. Influence of Biochar and Animal Manures Application on Ammonia and Nitrate Concentrations in the Root and Shoot of Three Varieties of Turnips. Agriculture 2023, 13, 137. [Google Scholar] [CrossRef]

- Shuang, Q.; Wang, Y.L.; Zhong, J.W. The Development History and Current Situation of Inner Mongolia Dairy Industry. China Dairy Ind. 2018, 46, 32–35+60. [Google Scholar]

- Soliman, Y.M.; Soliman, W.S.; Abbas, A.M. Alley Cropping and Organic Compost: An Efficient and Sustainable Agro-Ecological Strategy for Improving Turmeric (Curcuma longa L.) Growth and Attributes. Agriculture 2023, 13, 149. [Google Scholar] [CrossRef]

- Rehman, S.U.; De Castro, F.; Marini, P. Vermibiochar: A Novel Approach for Reducing the Environmental Impact of Heavy Metals Contamination in Agricultural Land. Sustainability 2023, 15, 9380. [Google Scholar] [CrossRef]

- Więckol-Ryk, A.; Pierzchała, Ł.; Bauerek, A. Minimising Coal Mining’s Impact on Biodiversity: Artificial Soils for Post-Mining Land Reclamation. Sustainability 2023, 15, 9707. [Google Scholar] [CrossRef]

- Lambu, Z.N.; Shamsuddeen, U.; Yahaya, S. Production of Bio-Fertilizer through Composting of Tannery Wastes with Cow Dung and Rice Bran. UMYU J. Microbiol. Res. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Malewski, T.; Borowik, P.; Olejarski, I.; Rutkiewicz, A.; Okorski, A.; Oszako, T. Addition of Organic Matter to Pine Plantations on Agricultural Land Positively Alters the Mycobiome of Agricultural Soils. Appl. Sci. 2023, 13, 5800. [Google Scholar] [CrossRef]

- Patricia, W.; Kerstin, B.; Yin, T. Microscopic differential cell count and specific mastitis pathogens in cow milk from compost-bedded pack barns and cubicle barns. J. Dairy Res. 2021, 88, 413–419. [Google Scholar]

- Siswati, L.; Nizar, R.; Ariyanto, A. Manfaatkan Kotoran Sapi Menjadi Kompos Untuk Tanaman Masa Pandemi Di Kelurahan Umbansari Kota Pekanbaru. Din. J. Pengabdi. Kpd. Masy. 2021, 5, 531–537. [Google Scholar] [CrossRef]

- Patra, R.K.; Behera, D.; Mohapatra, K.K. Juxtaposing the quality of compost and vermicompost produced from organic wastes amended with cow dung. Environ. Res. 2022, 214 Pt 4, 114119. [Google Scholar] [CrossRef] [PubMed]

- Magotra, V.K.; Kang, T.W.; Kim, D.Y. Urea fuel cell using cow dung compost soil as a novel biocatalyst for power generation applications. Energy 2022, 239, 122357.1–122357.12. [Google Scholar] [CrossRef]

- Gorasiya, T.; Faldu, N. Exploring floral waste into bio-compost using microbial consortium from cow dung: A review. J. Food Agric. Environ. 2021, 19, 71–74. [Google Scholar]

- Zailani, S.N.; Shaheen, A.; Noor, A.Z. Compost Bed Size Influences the Co-Composting of Cow Dung and Spent Mushroom at Mesophilic Stage. IOP Conf. Ser. Earth Environ. Sci. 2021, 765, 012074. [Google Scholar] [CrossRef]

- Utami, A.; Hidayat, B. Mukhlis Study of some chemical properties of ultisol soil applied by biochar and compos from some biomasses and incubation time. IOP Conf. Ser. Earth Environ. Sci. 2021, 782, 042040. [Google Scholar] [CrossRef]

- Kakihara, H.; Ogura, S. Effect of soil acidification on regrowth of orchardgrass (Dactylis glomerata) under application of grazing cattle dung, cattle manure compost, and chemical fertilizer. Grassl. Sci. 2022, 68, 255–262. [Google Scholar] [CrossRef]

- Nurmas, A.; Rakian, T.C.; Asdari, N. Evaluation of plant distance and composition of goat manure in okra (Abelmoschus esculentus l.) plant in supporting food security. IOP Conf. Ser. Earth Environ. Sci. 2021, 681, 012026. [Google Scholar] [CrossRef]

- Chi, W.H.; Ren, Y.X.; Chen, W.; Chen, R.; Liu, Y.Z.; Wang, X.C. Development and application of a pyriform rotating drum reactor for aerobic composting. Chin. J. Environ. Eng. 2013, 7, 3561–3566. [Google Scholar]

- Makan, A.; Fadili, A.; Oubenali, M. Interaction of physicochemical parameters during pressurized in-vessel composting of food waste. Bioresour. Technol. Rep. 2020, 10, 100350. [Google Scholar] [CrossRef]

- Xiong, J.; Ma, S.; He, X.; Han, L.; Huang, G. Nitrogen transformation and dynamic changes in related functional genes during functional-membrane covered aerobic composting. Bioresour. Technol. 2021, 332, 125087. [Google Scholar] [CrossRef] [PubMed]

- Schneider, J.; Burg, J.M.; Theilen, U. Towards optimized drum composting: Evaluation of the radial mixing performance of a model substrate on the laboratory scale. Environ. Technol. 2020, 41, 1606–1613. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Liang, W.; Hu, K. Simulated Ammonia Nitrogen Wastewater Treated with Spent Mushroom Compost in a Laboratory Bioreactor. Pol. J. Environ. Stud. 2016, 25, 2197–2203. [Google Scholar] [CrossRef] [PubMed]

- Jain, M.; Paul, S.; Kalamdhad, A.S. Kinetics and physics during composting of various organic wastes: Statistical approach to interpret compost application feasibility. J. Clean. Prod. 2020, 255, 120324. [Google Scholar] [CrossRef]

- Yu, P.; Chen, J. Performance test on the composting process of food wastes in a small composting reactor. J. Hunan Agric. Univ. Nat. Sci. 2021, 47, 351–355. [Google Scholar]

- Sobieraj, K.; Stegenta-Dąbrowska, S.; Luo, G.; Koziel, J.A.; Białowiec, A. Biological treatment of biowaste as an innovative source of CO—The role of composting process. Front. Bioeng. Biotechnol. 2023, 11, 1126737. [Google Scholar] [CrossRef]

- Yan, C.; Cao, L.P.; Liu, Y.H. Effect of new high temperature aerobic composting device on maturation of chicken manure and rice chaff. Chin. J. Environ. Eng. 2021, 15, 1103–1111. [Google Scholar]

- Malik, K.; Rani, S.; Ahlawat, S. Bioconversion process for compost production from agricultural residue. Int. J. Chem. Eng. 2021, 9, 827–830. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Ying, Y. Effects of different additives on the chemical composition and microbial diversity during composting of Camelliaoleiferashell. Bioresour. Technol. 2021, 330, 124990. [Google Scholar] [CrossRef] [PubMed]

- Kuddus, M.A.; Alam, M.J.; Datta, G.C. Climate resilience technology for year round vegetable production in northeastern Bangladesh. Int. J. Agric. Res. Innov. Technol. 2021, 11, 29–36. [Google Scholar] [CrossRef]

- Sukariawan, A.; Febrianto, E.B. Sakiah Ganoderma boninense control in palm oil plantations using Trichoderma harzianum in various Media. IOP Conf. Ser. Earth Environ. Sci. 2021, 819, 012001. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, A.; Chava, V. A Review on Vermicomposting: By-Products and Its Importance. Plant Cell Biotechnol. Mol. Biol. 2021, 22, 156–164. [Google Scholar]

- Sultana, M.; Jahiruddin, M.; Islam, M.R. Nutrient Enriched Municipal Solid Waste Compost Increases Yield, Nutrient Content and Balance in Rice. Sustainability 2021, 13, 1047. [Google Scholar] [CrossRef]

- Huang, S.; Ma, Q.; Hou, Q. Identification and quantitative chemical analysis of betaines in different organic wastes and their bioconversion composts. Bioresour. Technol. 2021, 328, 124857. [Google Scholar] [CrossRef]

- Komolafe, A.F.; Adejuyigbe, C.O.; Babalola, O.A. Fertilizer values of composts as affected by plant materials and composting duration on maize (Zea mays) performance. Agro-Science 2021, 20, 87–94. [Google Scholar] [CrossRef]

- Wang, Y.; Pang, L.; Liu, X. Using thermal balance model to determine optimal reactor volume and insulation material needed in a laboratory-scale composting reactor. Bioresour. Technol. 2016, 206, 164–172. [Google Scholar] [CrossRef]

- Wang, F. Design and Experiment of Small Composting Equipment for Fecal Matter of Livestock and Poultry Based on Heating by Aeration. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2021. [Google Scholar]

- Yusnaini, S.; Niswati, A.; Aini, S.N. Changes in soil respiration after application of in situ soil amendment and phosphate fertilizer under soybean cultivation at Ultisol South Lampung, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2021, 724, 012002. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M.K.; Zhao, J.; Ren, X.; Li, R.; Wang, Z.; Wang, M.; Zhang, Z. Improvement of pig manure compost lignocellulose degradation, organic matter humification and compost quality with medical stone. Bioresour. Technol. 2017, 243, 771–777. [Google Scholar] [CrossRef]

- Sobieraj, K.; Stegenta-Dąbrowska, S.; Zafiu, C.; Binner, E.; Białowiec, A. Carbon Monoxide Production during Bio-Waste Composting under Different Temperature and Aeration Regimes. Materials 2023, 16, 4551. [Google Scholar] [CrossRef]

- Petric, I.; Selimbašić, V. Composting of poultry manure and wheat straw in a closed reactor: Optimum mixture ratio and evolution of parameters. Biodegradation 2008, 19, 53–63. [Google Scholar] [CrossRef] [PubMed]

- Strenner, M.; Chmelíková, L.; Hülsbergen, K.J. Compost Fertilization in Organic Agriculture—A Comparison of the Impact on Corn Plants Using Field Spectroscopy. Appl. Sci. 2023, 13, 3676. [Google Scholar] [CrossRef]

- Kujawa, S.; Niedbała, G.; Czekała, W.; Pentoś, K. Neural Image Analysis for the Determination of Total and Volatile Solids in a Composted Sewage Sludge and Maize Straw Mixture. Appl. Sci. 2023, 13, 3363. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).