Mechanism and Effect Factor of Toughening of High-Speed Train Wheels

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials

2.2. Experimental Methods

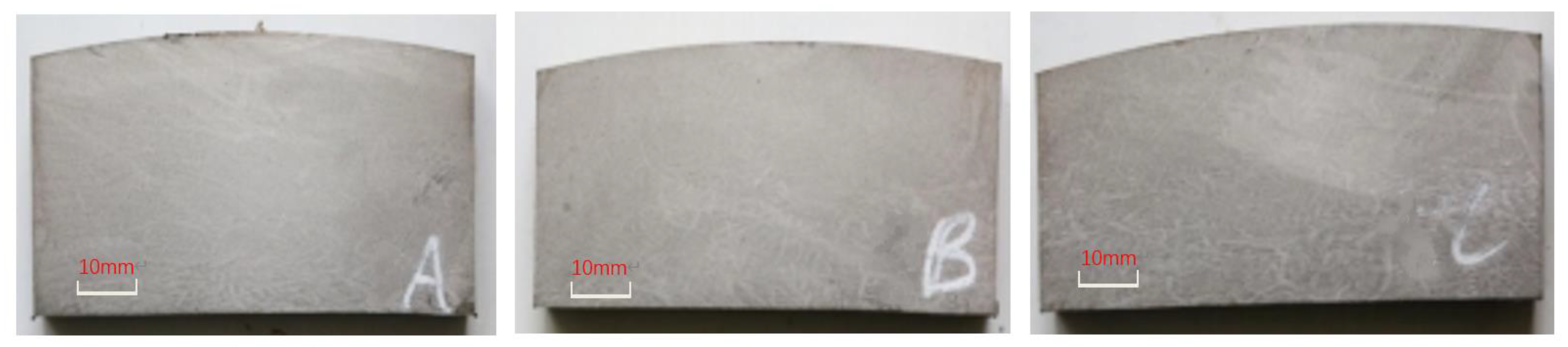

2.2.1. Macroanalysis

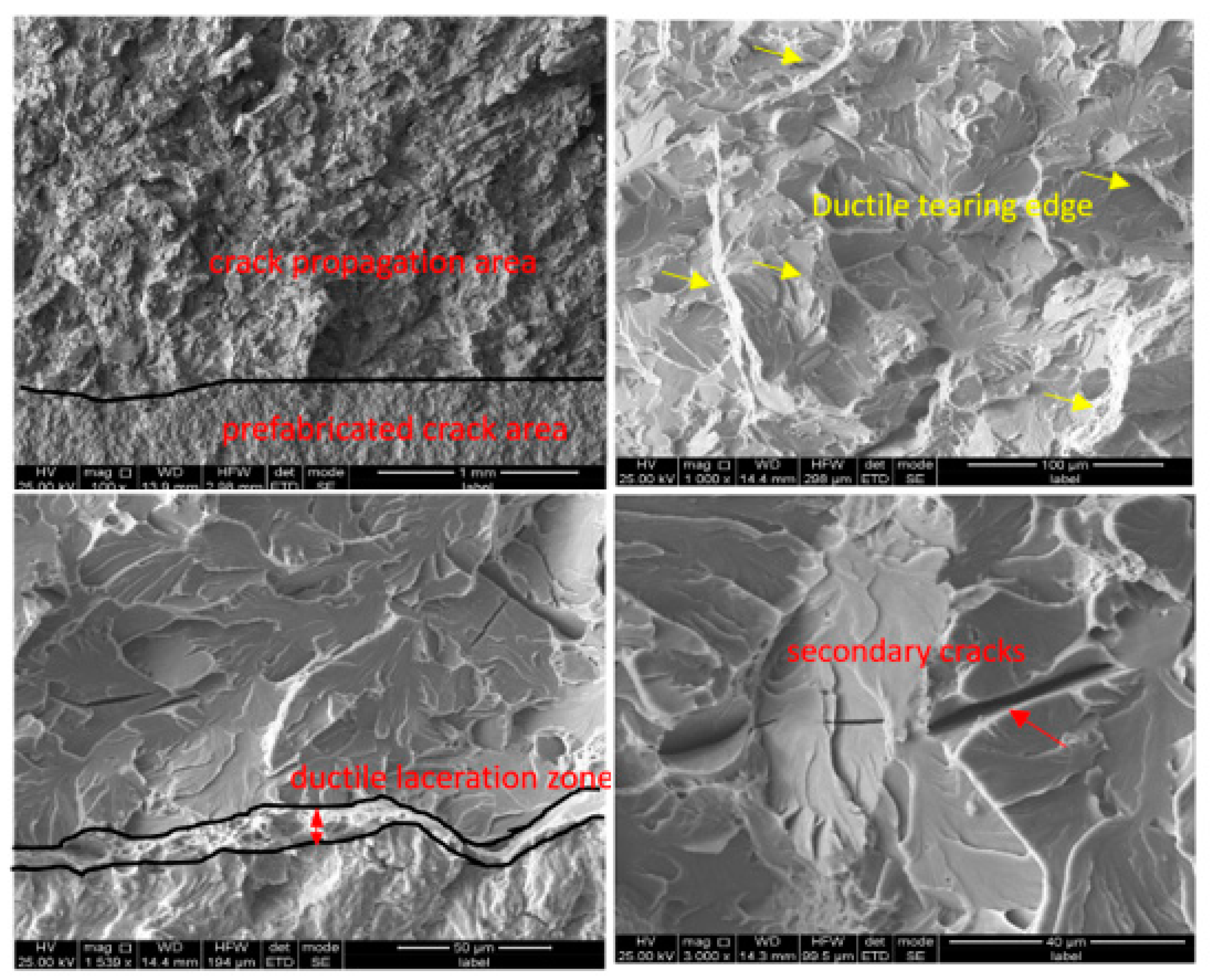

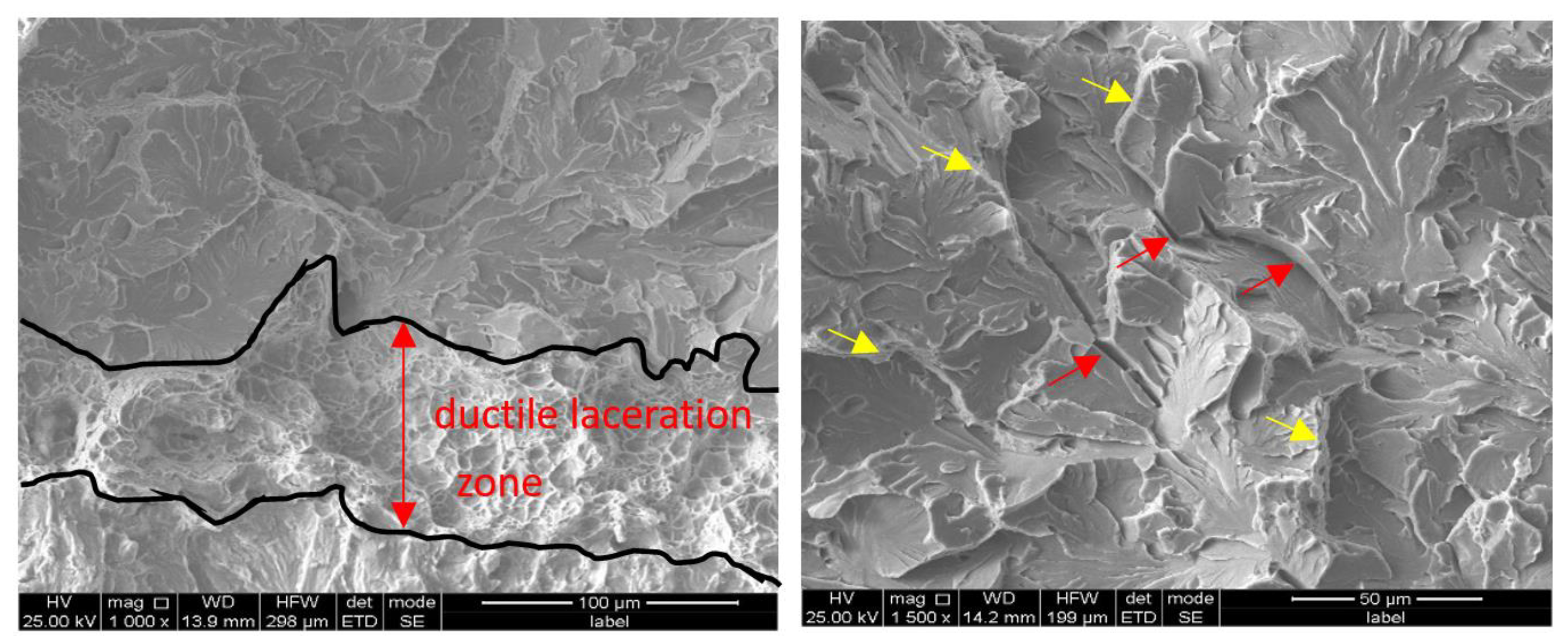

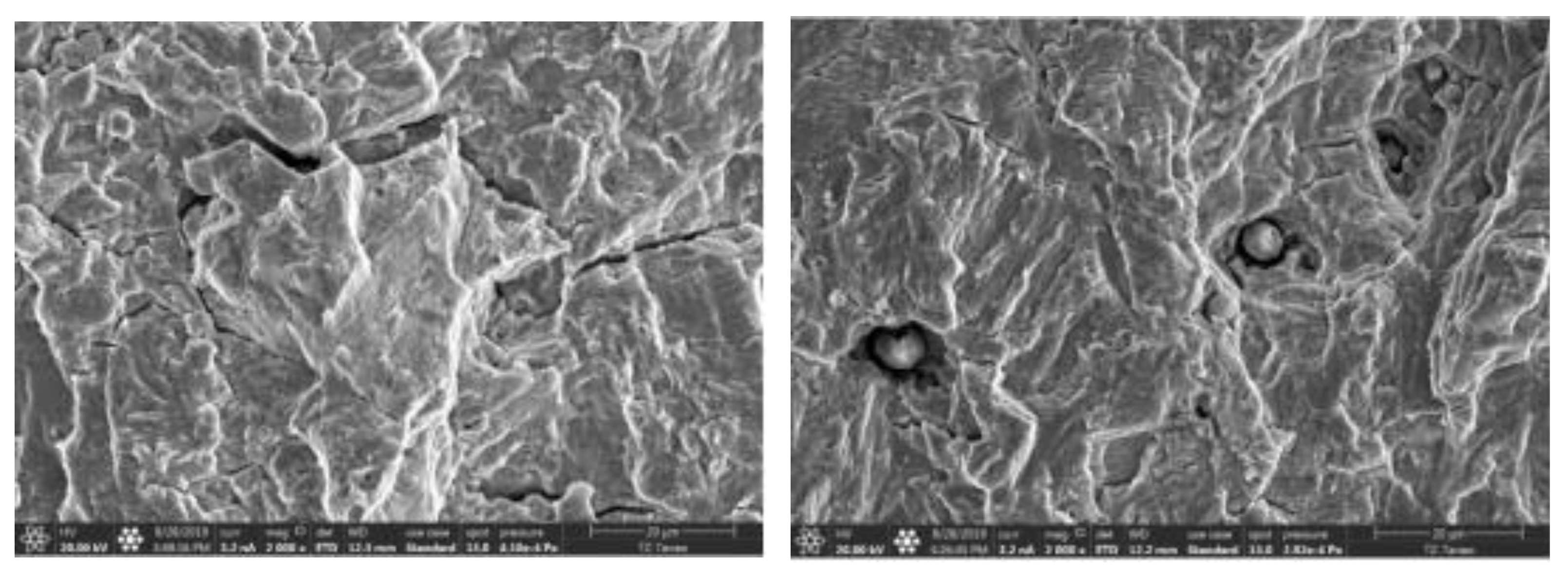

2.2.2. SEM Analysis of Fracture Morphology Analysis

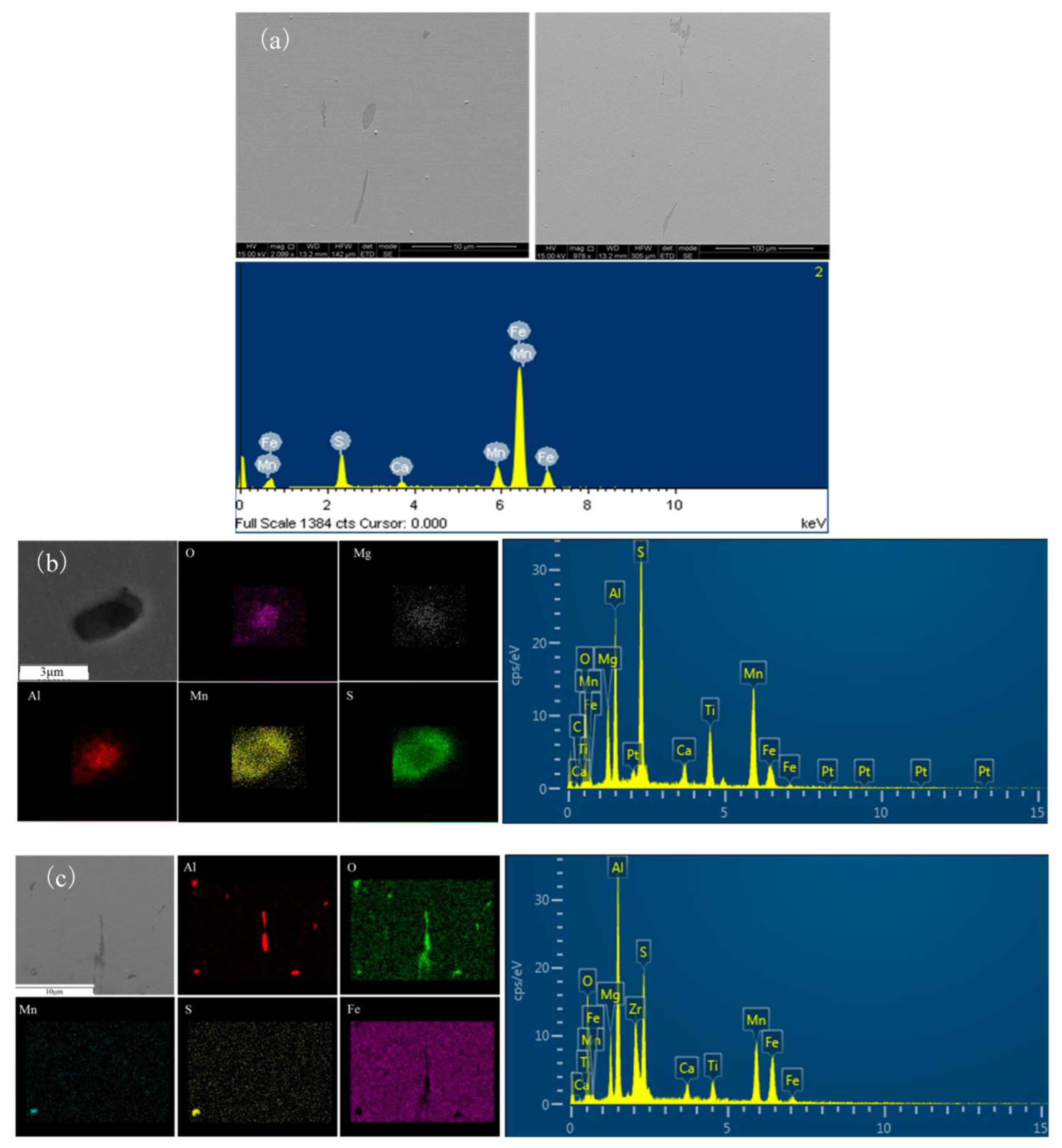

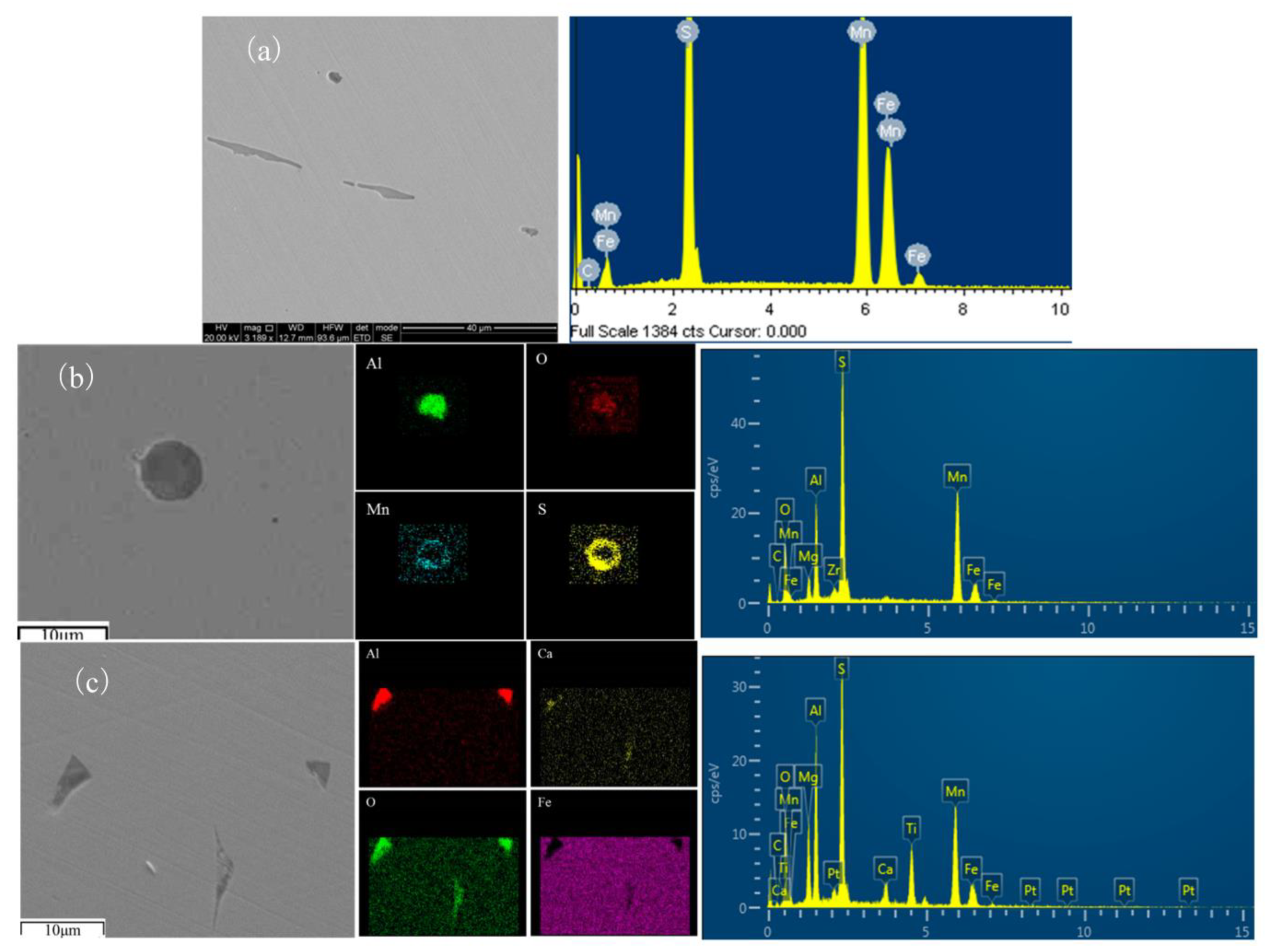

2.2.3. Inclusion Analysis

2.2.4. Analysis of Pearlite Lamellar Spacing

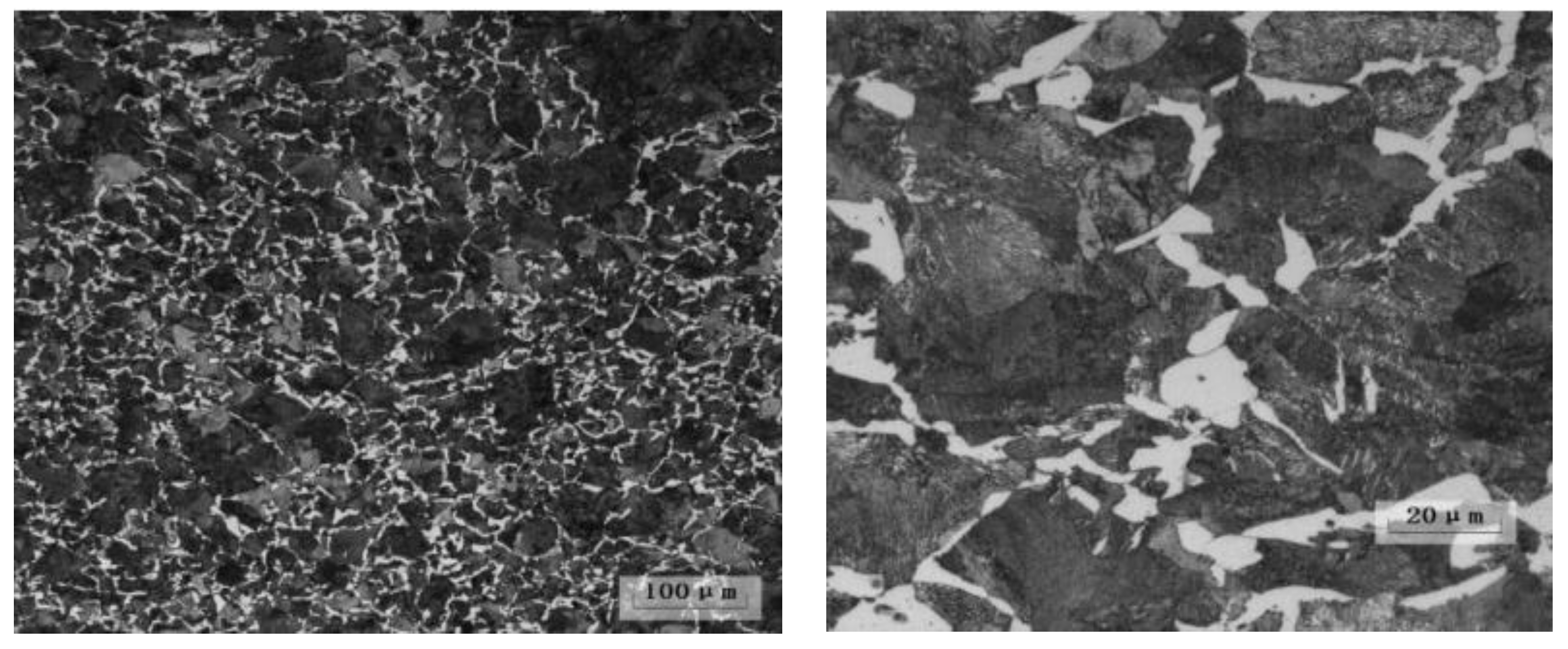

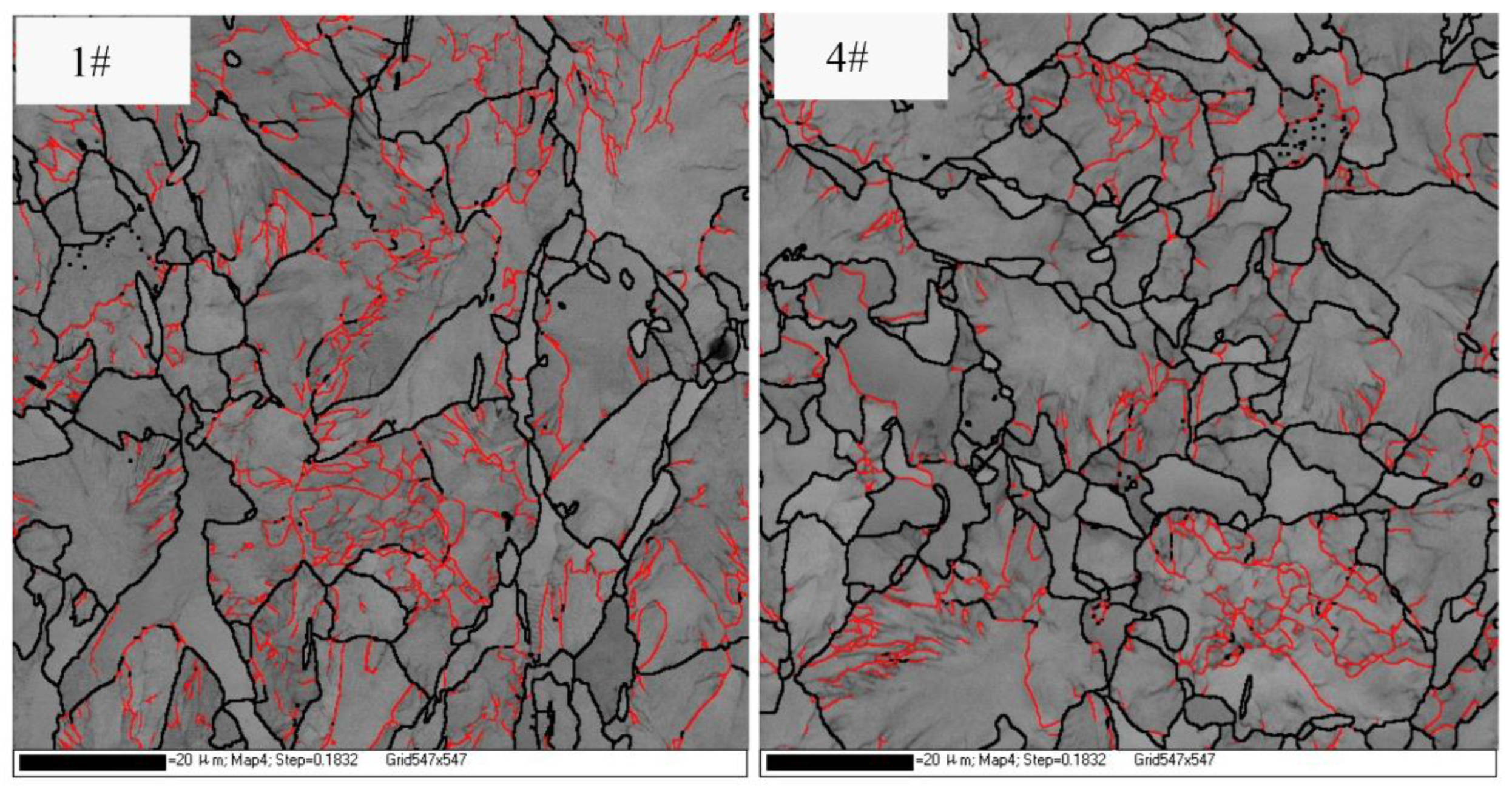

2.2.5. Analysis of EBSD

3. Results and Discussion

3.1. Macroanalysis

3.2. SEM and EBSD Analysis

3.3. Results Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Faccoli, M.; Petrogalli, C.; Ghidini, A. On Mechanical Properties of New Railway Wheel Steels for Desert Environments and Sand Caused Wheel Damage Mechanisms. J. Mater. Eng. Perform. 2019, 28, 2946–2953. [Google Scholar] [CrossRef]

- Faccoli, M.; Ghidini, A.; Mazzù, A. Changes in the Microstructure and Mechanical Properties of Railway Wheel Steels as a result of the Thermal Load Caused by Shoe Braking. Met. Mater. Trans. A 2019, 50, 1701–1714. [Google Scholar]

- Faccoli, M.; Petrogalli, C.; Lancini, M.; Ghidini, A.; Mazzù, A. Rolling Contact Fatigue and Wear Behavior of High-Performance Railway Wheel Steels under Various Rolling-Sliding Contact Conditions. J. Mater. Eng. Perform. 2017, 26, 3271–3284. [Google Scholar]

- Ostash, O.P.; Anofriev, V.H.; Andreiko, I.M.; Muradyan, L.A.; Kulyk, V.V. On the concept of selection of steels for high-strength railroad wheels. Mater. Sci. 2013, 48, 697–703. [Google Scholar] [CrossRef]

- Cong, T.; Han, J.; Hong, Y.; Domblesky, J.P.; Liu, X. Shattered rim and shelling of high speed railway wheels in the very-high-cycle fatigue regime under rolling contact loading. Eng. Fail. Anal. 2019, 97, 556–567. [Google Scholar]

- Tarafder, S.; Sivaprasad, S.; Ranganath, V.R. Comparative assessment of fatigue and fracture behaviour of cast and forged railway wheels. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 863–876. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Wang, Q. The effect of wheel polygonal wear on temperature and vibration characteristics of a high speed train braking system. Mech. Syst. Signal Process. 2023, 186, 109864. [Google Scholar] [CrossRef]

- Khan, M.R.; Dasaka, S.M. Wheel-rail interactions in high speed railway networks during rapid train transit. Mater. Today Proc. 2018, 5, 25450–25457. [Google Scholar] [CrossRef]

- Ma, Y. Study on Toughening Mechanism and Production Process Optimization of Wheel Steel for High Speed Train. Ph.D. Thesis, Central Iron & Steel Research Institute, Beijing, China, 2012. [Google Scholar]

- Zhu, K.; Xu, Y.J.; Jing, T.; Hou, H.L. Fracture behavior of a composite composed by Ti-aluminide multi-layered and continuous-SiCf-reinforced Ti-matrix. Rare Met. 2017, 36, 925–933. [Google Scholar] [CrossRef]

- Huang, Y.L.; Jia, L.N.; Kong, B. Microstructure and room temperature fracture toughness of Nb–Si-based alloys with Sr addition. Rare Met. 2018. [Google Scholar] [CrossRef]

- Kumar, A.S.; Kumar, B.R.; Datta, G.; Ranganath, V. Effect of microstructure and grain size on the fracture toughness of a micro-alloyed steel. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2010, 527, 954–960. [Google Scholar] [CrossRef]

- Sakamoto, H.; Toyama, K.; Hirakawa, K. Fracture toughness of medium-high carbon steel for railroad wheel. Mater. Sci. Eng. 2000, 285, 288–292. [Google Scholar] [CrossRef]

- Wang, P.; Li, Z.; Lin, G.; Zhou, S.; Yang, C.; Yong, Q. Influence of vanadium on the microstructure and mechanical properties of medium-carbon steels for wheels. Metals 2018, 8, 978. [Google Scholar] [CrossRef]

- Li, D.; Hui, S.X.; Ye, W.J.; Li, C.L. Microstructure and mechanical properties of a new high-strength and high-toughness titanium alloy. Rare Met. 2016. [Google Scholar] [CrossRef]

- Ostash, O.P.; Kulyk, V.V.; Lenkovskiy, T.M. Relationships between the fatigue crack growth resistance characteristics of a steel and the tread surface damage of railway wheel. Arch. Mater. Sci. Eng. 2018, 90, 49–55. [Google Scholar] [CrossRef]

- Ekberg, A.; Kabo, E. Fatigue of railway wheels and rails under rolling contact and thermal loading-an overview. Wear 2005, 258, 1288–1300. [Google Scholar] [CrossRef]

- Beretta, S. Application of multiaxial fatigue criteria to materials containing defects. Fatigue Fract. Eng. Mater. Struct. 2010, 26, 551–559. [Google Scholar] [CrossRef]

- Sevillano, J.G.; Ibabe, J.M.R.; Meizoso, A.M. Analysis of brittle fracture toughness of UIC R7 steel. In Proceedings of the 8th International Wheelset Congress, Madrid, Spain; 1985. [Google Scholar]

- Bower, A.F.; Johnson, K.L. The influence of strain Harding on cumulative plastic deformation in rolling and sliding line contact. J. Mech. Phys. Solids 1989, 37, 471–493. [Google Scholar] [CrossRef]

- Fan, J. A micro/macroscopic analysis for cyclic plasticity of dual-phase materials. J. Appl. Mech. 1999, 66, 124–136. [Google Scholar] [CrossRef]

- Peng, X.; Ponter, A.R.S. A constitutive law for a class of two-phase with experimental verification. Int. J. Solid Struct. 1994, 31, 1099–1111. [Google Scholar] [CrossRef]

- Zhang, X.; Jia, Y.; Sheng, L.; Yuan, L.; Li, J. Characterization of segregation degree for large size metal component and application on high speed train wheel. Anal. Chim. Acta 2022, 1203, 339719. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Kobayashi, Y.; Nagai, K.; Yang, J.; Kuwabara, M. Morphology control of copper sulfide in strip casting of low carbon steel. ISIJ Int. 2006, 46, 744–753. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, T.; Jiang, B.; Cui, Y.; Su, H.; Peng, Y. Study of the effect of sulfur contents on fracture toughness of railway wheel steels for high speed train. Acta Metall. Sin. 2011, 47, 978–983. [Google Scholar]

- Mizoguchi, S.; Takamura, J. Control of oxides as inoculants metallurgy of oxides in steel process. In Proceedings of the Sixth International Iron and Steel Congress 1990, Nagoya, Japan, 21–26 October 1990; pp. 2331–2342. [Google Scholar]

- Krajnc, L.; Mrvar, P.; Medved, J. Thermodynamic characterization of multiphase non-metallic inclusions in re-sulphurised steel grades. Mater. Technol. 2014, 48, 923–929. [Google Scholar]

- Wu, S.; Li, X.-C.; Zhang, J.; Shang, C.-J.; Misra, R.D.K. Microstructural refinement and mechanical properties of high speed niobium-microalloyed railway wheel steel. Steel Res. Int. 2015, 86, 775–784. [Google Scholar] [CrossRef]

- Clayton, P. The relations between wear behavior and basic material properties for pearlitic steels. Wear 1980, 60, 75–93. [Google Scholar] [CrossRef]

- Heller, W.; Schweitaer, R. Hardness microstructure and wear behaviors of rail steels. In Proceedings of the Second International Heavy Haul Railway Conference, Colorado Springs, CO, USA, 25–30 September 1982; pp. 282–286. [Google Scholar]

- Hodson, W.H.; Preston, R.R. Production processes to yield superior rail steel. Transp. Rec. 1988, 1774, 150–162. [Google Scholar]

- Sugino, K.K.; Ageyama, K.; Masumoto, H. Development of weldable high strength steel. In Proceedings of the International Heavy Haul Conference, Colorado Springs, CO, USA; 1982; pp. 113–121. [Google Scholar]

- Mishra, K.; Singh, A. Effect of interlamellar spacing on fracture toughness of nano-structured pearlite. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 706, 22–26. [Google Scholar] [CrossRef]

- Modi, O.P.; Desmukh, N.; Mondal, D.P. Effect of interlamellar spacing on the mechanical properties of 0.65 percent C steel. Mater. Charact. 2001, 46, 347–352. [Google Scholar] [CrossRef]

- Ray, K.K.; Mondal, D. The effect of interlamellar spacing on strength of pearlite in annealed eutectoid and hypoeutectoid plain carbon steels. Acta Metall. Mater. 1991, 39, 2201–2208. [Google Scholar] [CrossRef]

- Park, Y.J.; Bernstein, I.M. The process of crack initiation and effective grain size for cleavage fracture in pearlitic eutectoid steel. Metall. Trans. A 1979, 10, 1653–1664. [Google Scholar] [CrossRef]

- Hyzak, J.M.; Bernstein, I.M. The role of microstructure on the strength and toughness of fully pearlitic steels. Metall. Trans. 1976, 7, 1217–1224. [Google Scholar] [CrossRef]

- Q’Donnelly, B.E.; Reuben, R.L.; Baker, T.N. Quantitative assessment of strengthening parameters in ferrite-pearlite steels from microstructural measurements. Metall. Sci. J. 2013, 11, 45–51. [Google Scholar] [CrossRef]

| Grade | C [%] | S [%] | P [%] | Mn [%] | Si [%] | Cu [%] | Cr [%] | Ni [%] | Mo [%] | V [%] |

|---|---|---|---|---|---|---|---|---|---|---|

| ER7 | ≤0.52 | ≤0.015 | ≤0.020 | ≤0.80 | ≤0.40 | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.08 | ≤0.06 |

| Sample 1 [MPa·m1/2] | Sample 2 [MPa·m1/2] | Sample 3 [MPa·m1/2] | Sample 4 [MPa·m1/2] | Sample 5 [MPa·m1/2] | Sample 6 [MPa·m1/2] | Average [MPa·m1/2] | |

|---|---|---|---|---|---|---|---|

| Test result | 63.9 | 93.6 | 94.2 | 101 | 74.4 | 97.7 | 87.5 |

| KQ [MPa·m1/2] | Upper Surface Hardness [HB] | Lower Surface Hardness [HB] | Hardness Difference [HB] | |

|---|---|---|---|---|

| Sample 1 | 63.9 | 253 | 234 | 19 |

| Sample 4 | 101 | 260 | 235 | 25 |

| Sample 5 | 74.4 | 254 | 234 | 20 |

| A [class] | B [class] | C [class] | D [class] | DS [class] | Microstructure | Grain Size | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thick | Thin | Thick | Thin | Thick | Thin | Thick | Thin | ||||

| Sample 1 | 0.5 | 1.0 | 0 | 0 | 0.5 | 0 | 0 | 0.5 | 0 | P + F | 7.5 |

| Sample 4 | 0.5 | 1.0 | 0 | 0 | 0.5 | 0 | 0 | 0.5 | 0 | P + F | 7.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, T.; Liu, C.; Shen, Z.; Wu, Z. Mechanism and Effect Factor of Toughening of High-Speed Train Wheels. Appl. Sci. 2023, 13, 8300. https://doi.org/10.3390/app13148300

Jia T, Liu C, Shen Z, Wu Z. Mechanism and Effect Factor of Toughening of High-Speed Train Wheels. Applied Sciences. 2023; 13(14):8300. https://doi.org/10.3390/app13148300

Chicago/Turabian StyleJia, Tuosheng, Cuirong Liu, Zhigang Shen, and Zhisheng Wu. 2023. "Mechanism and Effect Factor of Toughening of High-Speed Train Wheels" Applied Sciences 13, no. 14: 8300. https://doi.org/10.3390/app13148300

APA StyleJia, T., Liu, C., Shen, Z., & Wu, Z. (2023). Mechanism and Effect Factor of Toughening of High-Speed Train Wheels. Applied Sciences, 13(14), 8300. https://doi.org/10.3390/app13148300